Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Less disturbed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

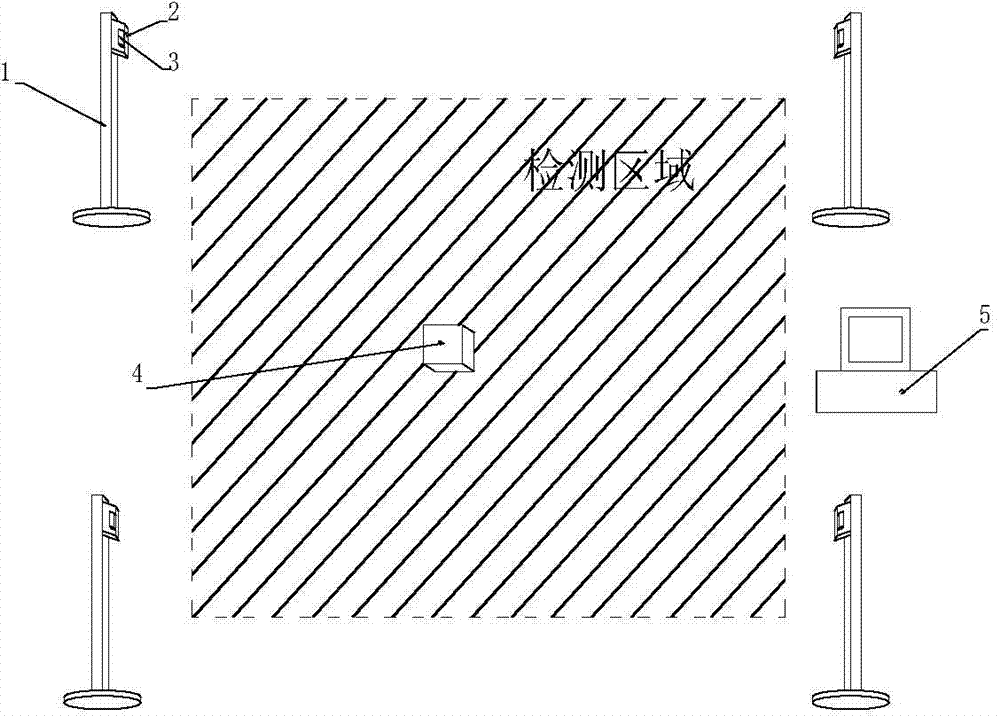

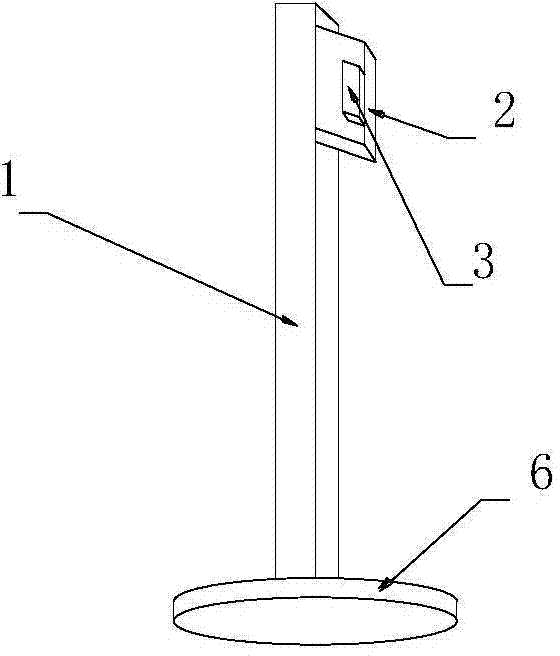

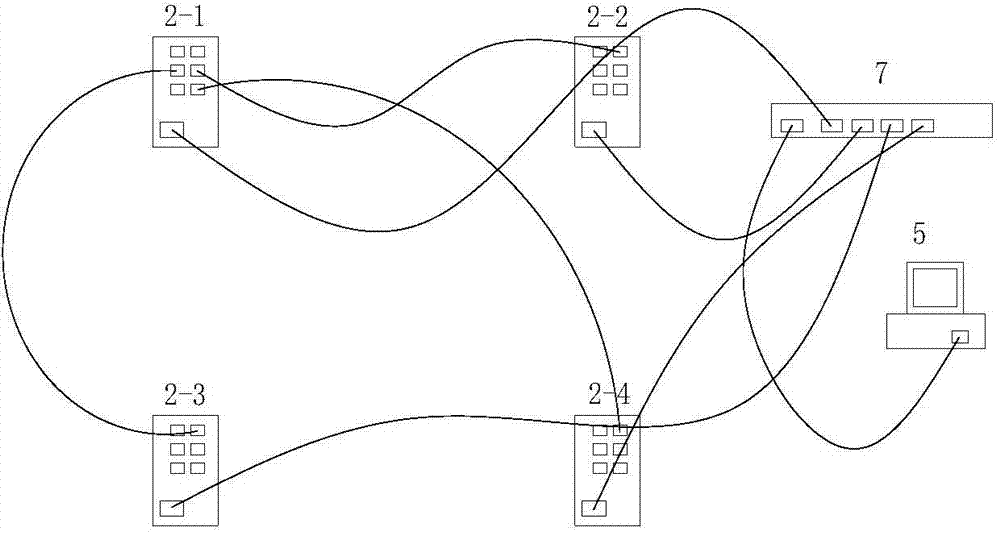

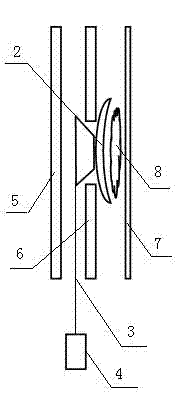

Dynamic positioning method and device based on UWB and laser ranging combination

InactiveCN104714209AAccurate distance measurementImprove anti-interference abilityPosition fixationLaser rangingEngineering

The invention discloses a dynamic positioning method and device based on UWB and laser ranging combination and belongs to dynamic positioning methods and devices. The dynamic positioning device comprises an ultra-wide band (UWB) wireless communication sensors, a UWB positioning label, laser ranging sensors, an upper computer and a POE interchanger. An ultra-wide band (UWB) wireless communication sensor station is arranged in an area to be detected, the laser ranging sensors are installed on and fixed to the ultra-wide band (UWB) wireless communication sensors, the UWB positioning label is fixed to a target to be detected, and the ultra-wide band (UWB) wireless communication sensors and the laser ranging sensors are connected with the upper computer through the POE interchanger. According to the dynamic positioning method and device based on the UWB and laser ranging combination, the laser ranging sensors are arranged on the ultra-wide band (UWB) wireless communication sensors respectively, so that the relative distance between every two adjacent ultra-wide band (UWB) wireless communication sensors is obtained, in this way, the coordinates of the ultra-wide band (UWB) wireless communication sensors can be re-determined or corrected after the ultra-wide band (UWB) wireless communication sensors are moved, and thus the requirement for dynamic positioning is met. The dynamic positioning method and device based on the UWB and laser ranging combination have the advantages that the dynamic positioning method based on the UWB and laser ranging combination is adopted, positioning is accurate, safety and reliability are guaranteed, installation is easy, and operation is convenient.

Owner:CHINA UNIV OF MINING & TECH

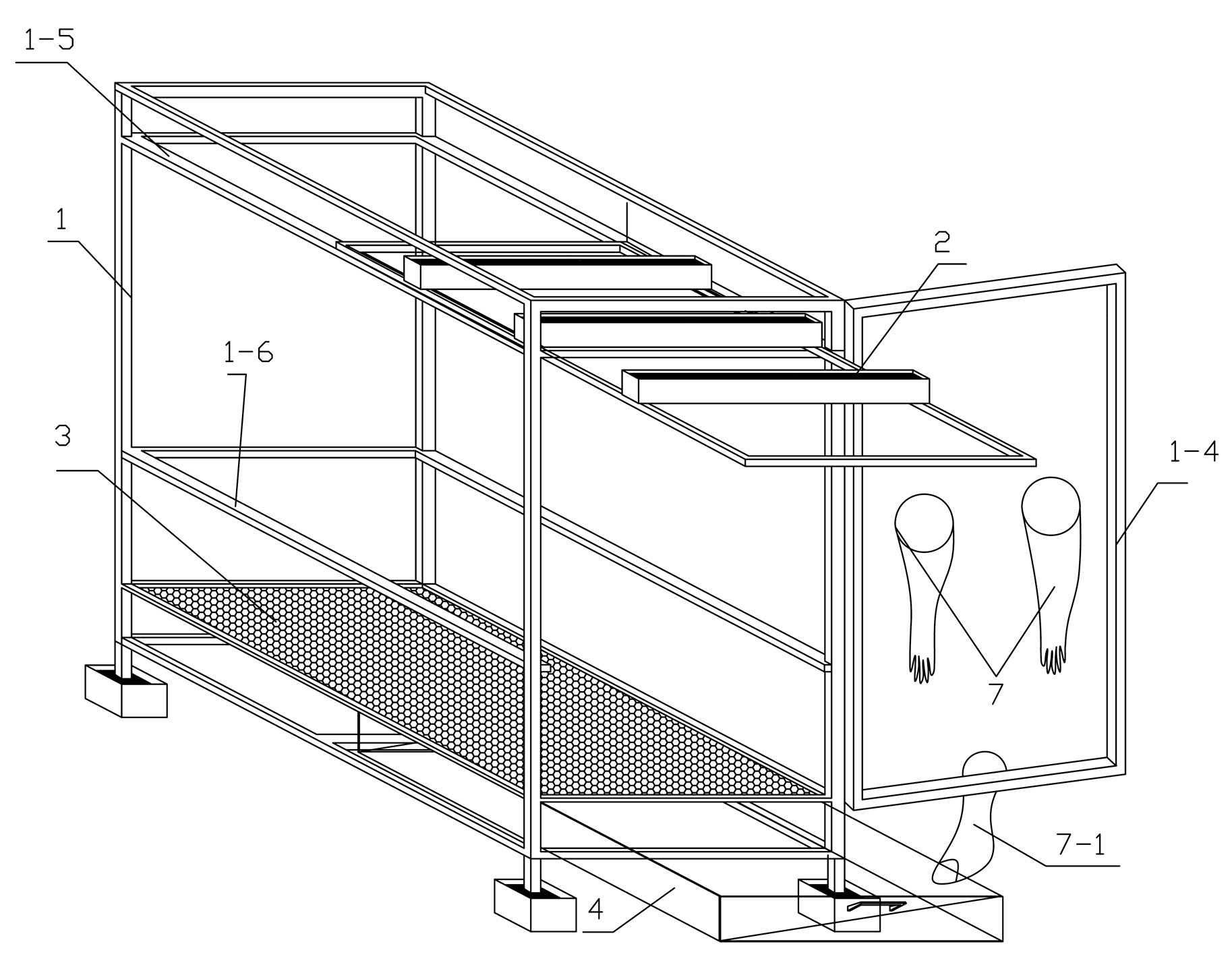

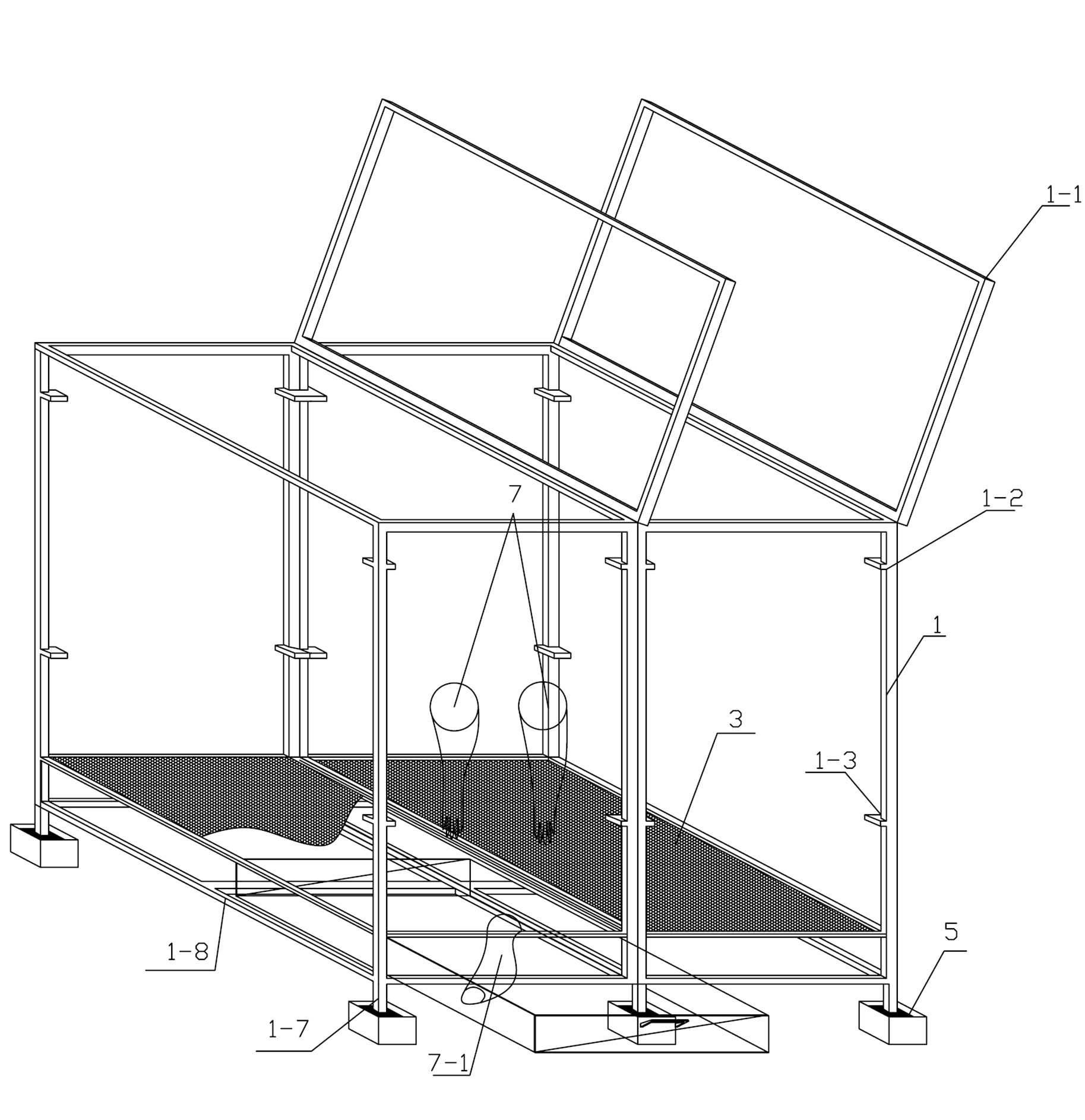

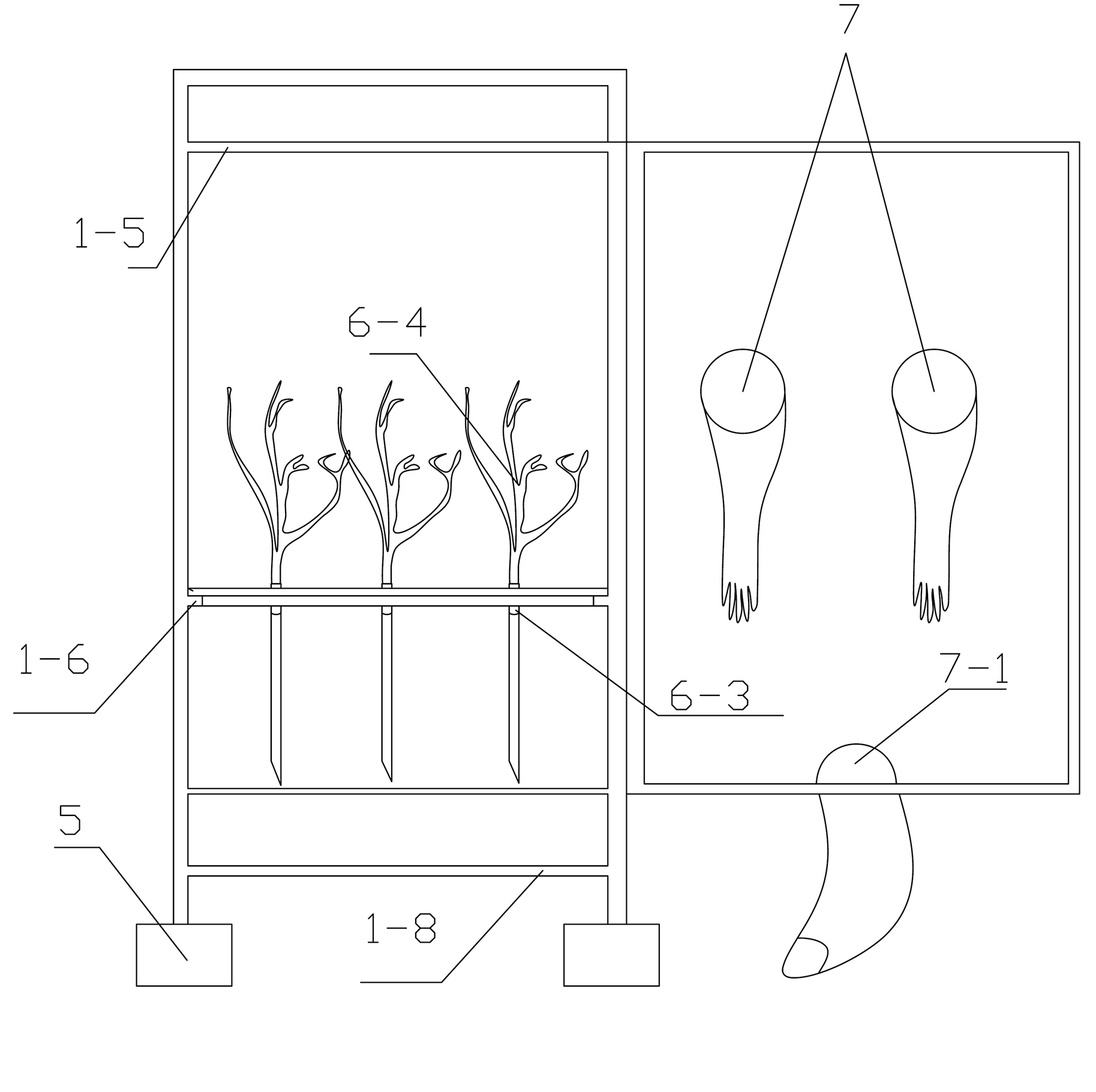

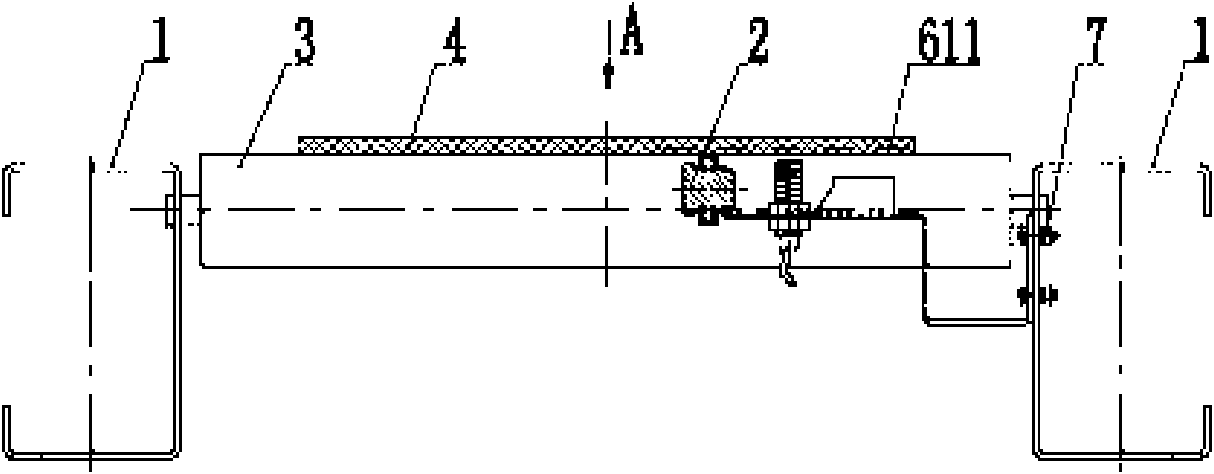

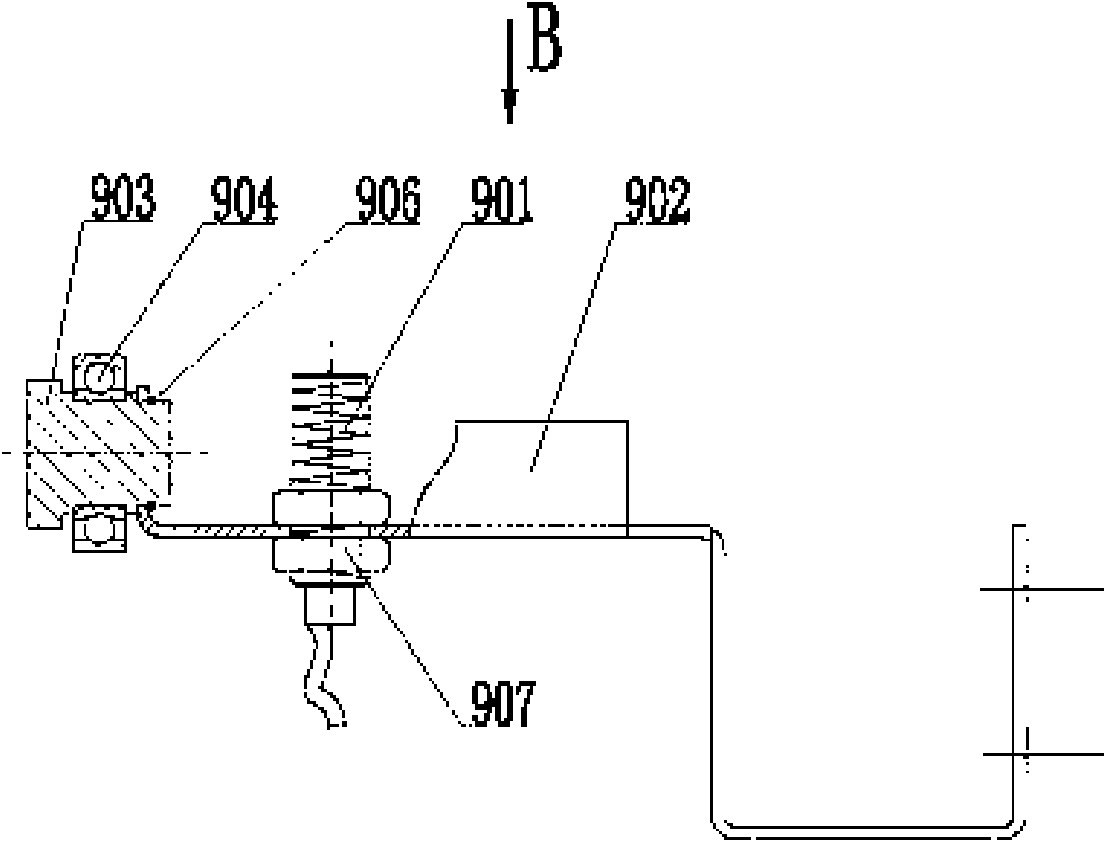

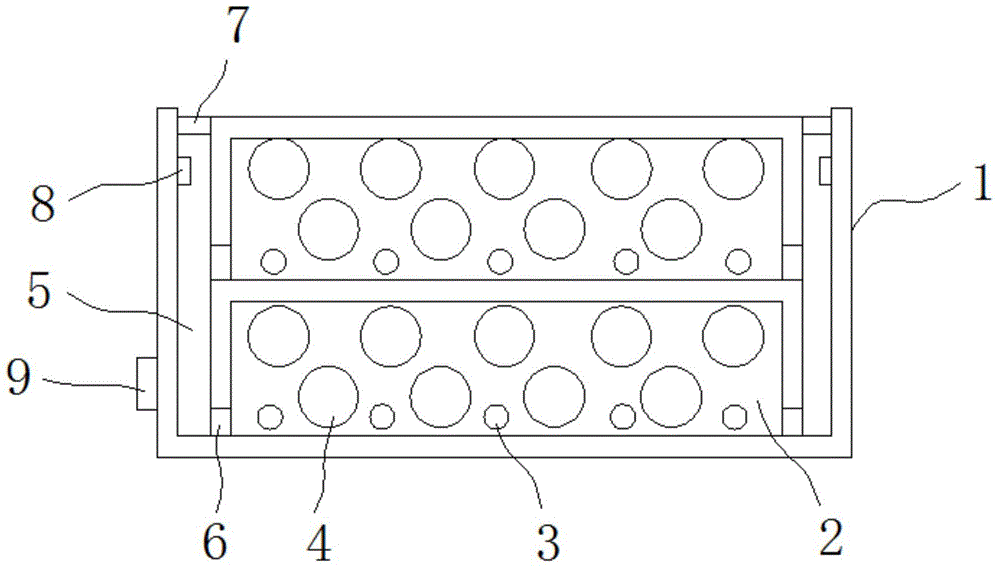

Swiftmoth insect integrated management device and management method thereof

InactiveCN101940192AReduce operating linksReduce labor intensityAnimal husbandryAnimal scienceWater tanks

The invention discloses a swiftmoth insect integrated management device comprising an enclosed box body, a pupa eclosion table, an ovum filtering net, an adult laying table, an ovum receiver and an isolated water tank. The pupa eclosion table is arranged on the upper part inside the enclosed box body; the middle part inside the enclosed box body is provided with the adult laying table; the ovum receiver is arranged under the ovum filtering net; supporting legs under the ovum receiver are arranged in the isolated water tank; and the whole device integrates management of pupa period, eclosion, mating and collection of ovum of the swiftmoth, so as to reduce the operation steps and greatly lighten the labor intensity of work staffs; and because the adults are subjected to little interference, the collection ratio of the ovum is higher; a sealing structure avoids the escape of the swiftmoth, and the isolated water tank prevents ovums from damaging by mice and ants; and the device is adopted under the condition of same radixes of pupas to obtain more and better ovum.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Artificial aphid propagation method

The invention discloses an artificial aphid propagation method. Peas are utilized as a host plant to culture aphids and collect, select and store the propagated aphids. The artificial aphid propagation method realizes the large-scale, low-cost and standardized production of the aphids, makes the annual production of the aphids be possible and provides sufficient fodder or adding ingredients of artificial fodder for the growth and the propagation of natural enemy insects.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

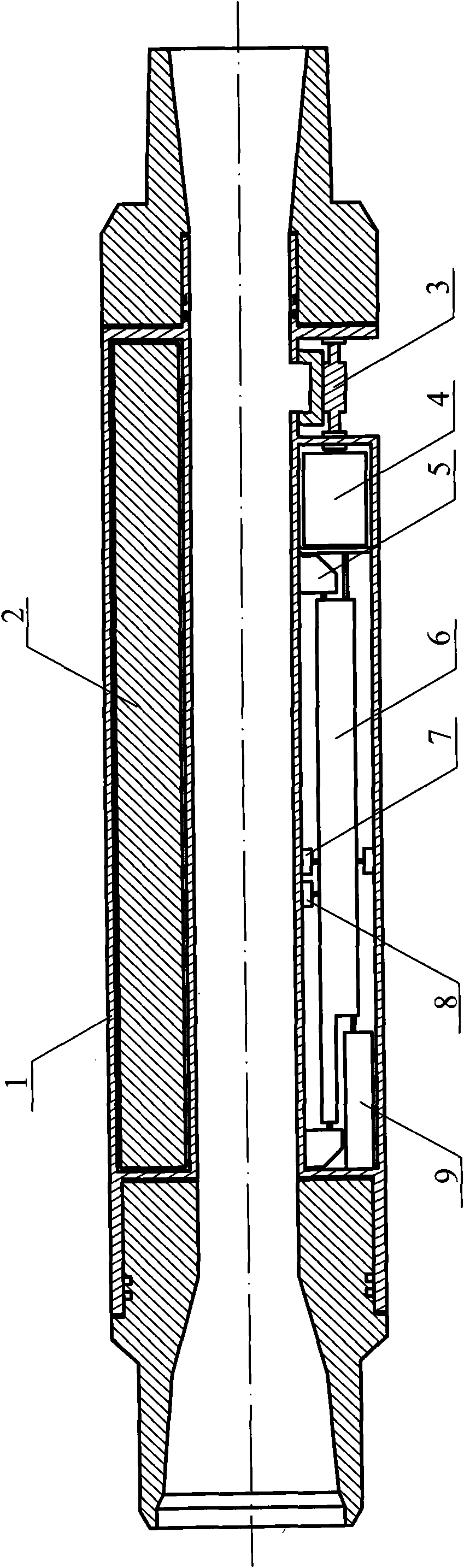

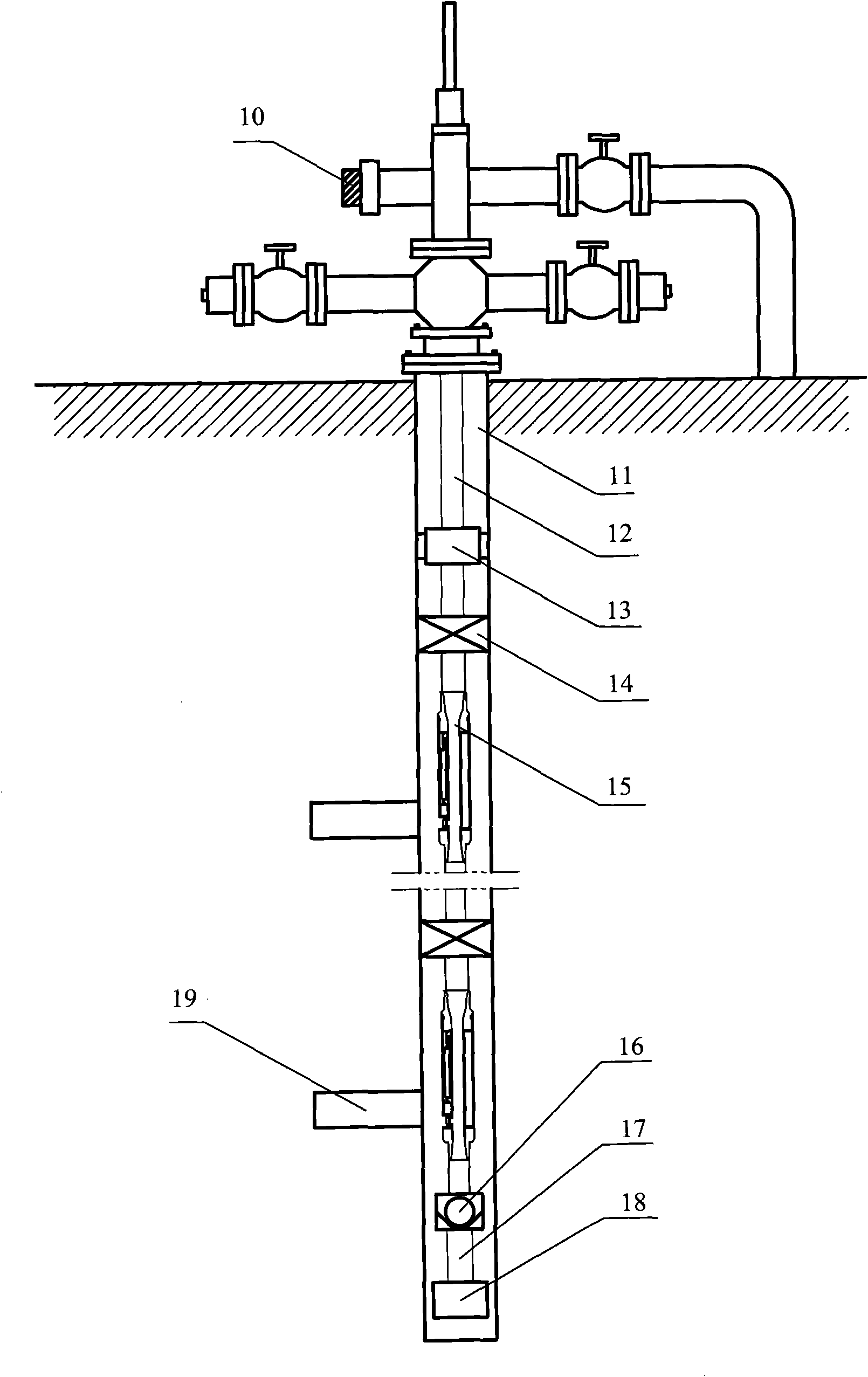

Ultrasonic measured and controlled water distributing device

InactiveCN101871340ASolve efficiency problemsSolve the repeatabilitySurveyFluid removalWireless controlData information

The invention relates to an ultrasonic measured and controlled water distributing device which solves the difficult problems of complicated allocation operation, low efficiency, limited application and the like existing in the prior art. The ultrasonic measured and controlled water distributing device comprises a sleeve pipe, a centralizer, a water-plugging packer, an ultrasonic measured and adjusted water distributor, a ball seat, a screen pipe and a screwed plug and is technically characterized in that underground ultrasonic communication units which are connected with a measurement and adjustment control unit are arranged in the ultrasonic measured and adjusted water distributor in the sleeve pipe, the measurement and adjustment control unit is respectively connected with an ultrasonic flow sensor, a pressure sensor, a temperature sensor and a regulating water nozzle driven by a micromotor, and each underground ultrasonic communication unit is respectively communicated with a ground ultrasonic communication unit by adopting ultrasonic encoding to realize data information transmission between the underground and the ground ultrasonic communication units and automatically finish the regulation on the water injection quantity of each water injection layer. The ultrasonic measured and controlled water distributing device has reasonable structural design, accurate water distribution quantity, no influence from the increase of the water injection layers and widened application range, and realizes that the distributed water flow is directly measured through wireless control by utilizing an ultrasonic communication technology.

Owner:杨忠芳

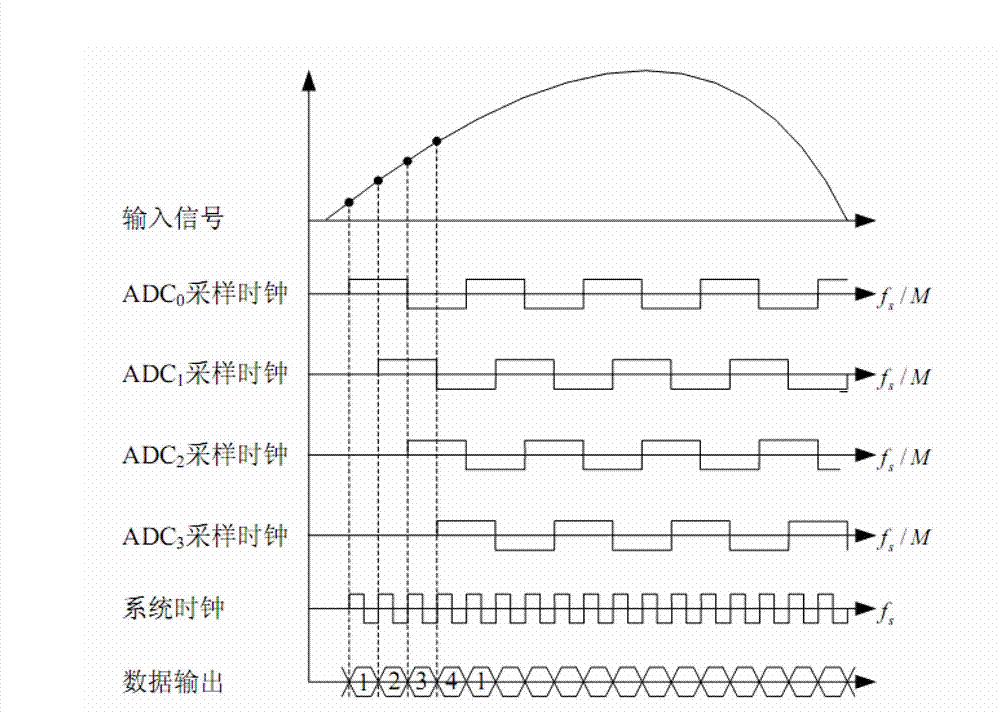

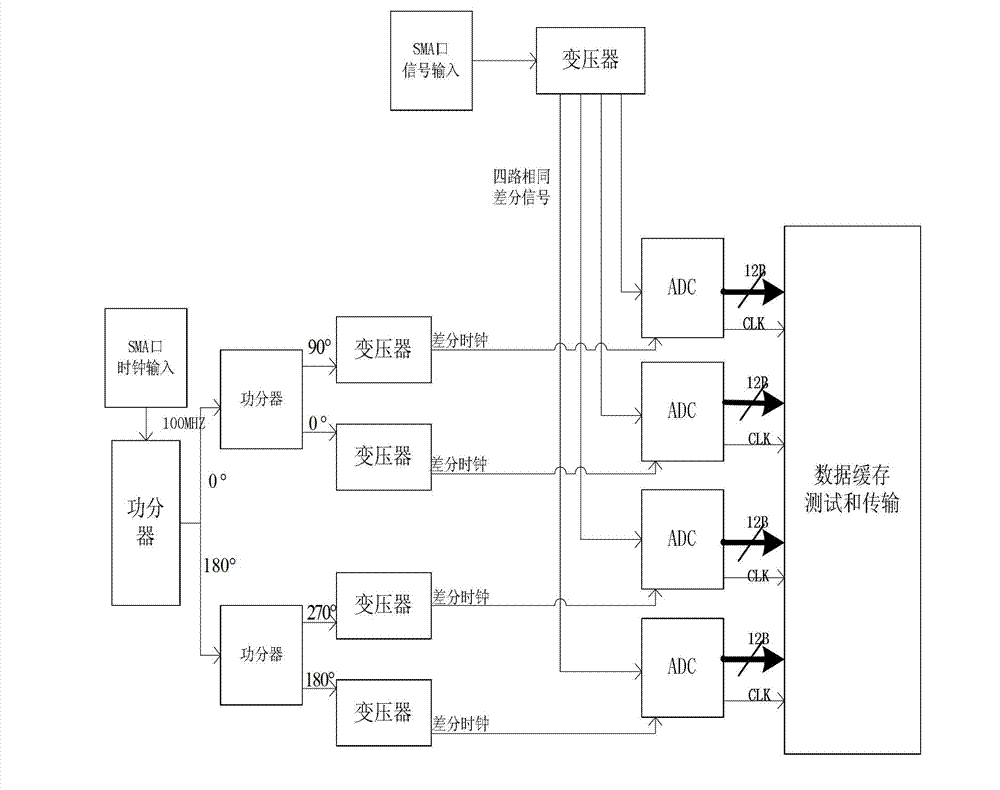

Multichannel high-speed parallel alternate ADC (Analog to Digital Converter) sampling circuit

InactiveCN102868406AHigh precisionLess disturbedAnalogue/digital conversionElectric signal transmission systemsPhase splittingClock phase

The invention provides a multichannel high-speed parallel alternate ADC (Analog to Digital Converter) sampling circuit, which comprises an analog differential signal input module, a clock generating and phase-splitting module, a parallel ADC module and a data transmission module, wherein each data output end of the analog differential signal input module is connected with each corresponding data input end in the parallel ADC module; each clock output end of the clock generating and phase-splitting module is connected with each corresponding clock input end in the parallel ADC module, and each data output end of the parallel ADC module is connected with the data transmission module; and a phase splitting unit consists of passive power divider, wherein each passive power divider is used for equally dividing an input clock phase and then outputting the input clock phase. The multichannel high-speed parallel alternate ADC sampling circuit finishes the phase splitting on a clock signal by using the passive power dividers, is little interfered because no power supply is needed for supplying power, and has high phase-splitting precision on the clock signal and small clock jitter.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

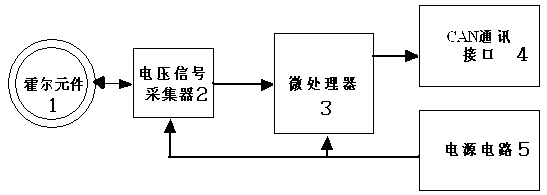

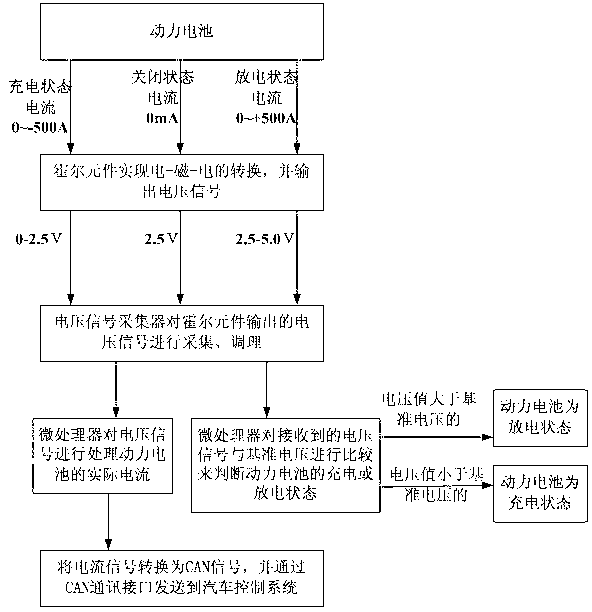

Current sensor for electric vehicle and detecting method by means of same

ActiveCN103323646ASimple structureLess disturbedCurrent/voltage measurementElectrical testingElectrical conductorElectrical battery

The invention provides a current sensor for an electric vehicle. The current sensor comprises a Hall element. The Hall element is electrically connected with a voltage signal collector in an interactive mode, the output end of the voltage signal collector is connected with the input end of a microprocessor, and the working power of the microprocessor and the working power of the voltage signal collector are both provided by a power circuit. The invention further provides a method for detecting currents of a power battery by means of the current sensor. According to the current sensor and the detecting by means of the current sensor, the Hall element is adopted to produce a magnetic field around an energized conductor, wherein the magnetic field is in direct proportion to the currents of the power battery, the currents of the current-carrying conductor are indirectly measured through the method of measuring Hall potentials, and therefore the purposes of detecting the total currents of the power battery and charging and discharging states of the power battery are achieved. The processing amount of the microprocessor is reduced, the circuit structure is simple, interference to voltage signals is small, and a detected value is relatively precise.

Owner:ANHUI ANKAI AUTOMOBILE

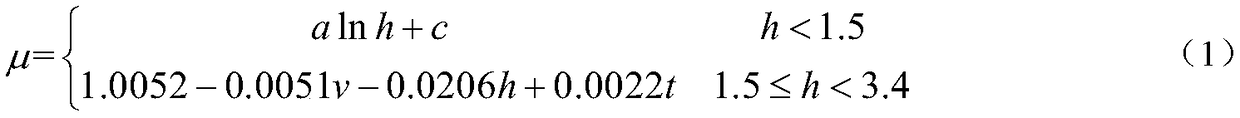

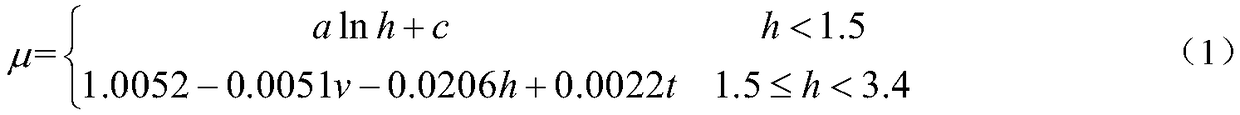

Mountain highway icing environment early warning system and method

ActiveCN109035681AReal-time acquisitionSafe and efficient operationArrangements for variable traffic instructionsAlarmsInformation processingRoad surface

The invention discloses a mountain highway icing environment early warning system. The system is composed of the following functional systems connected to a communication system, namely an informationmonitoring and acquisition system, an information processing system, a decision support system, an information release system and an evaluation system. A meteorological information monitoring and acquisition sensor, a pavement condition information monitoring and acquisition sensor and a traffic flow detection sensor are integrated together, and are arranged in the most unfavorable low temperature environment sections of a mountain highway, so that the defects that an existing highway meteorological monitoring station is not adapted to the road region environment difference, emergency and regionality. Meteorological information, pavement condition information, and traffic flow information data are acquired in real time to provide a data support for the information processing system. The decision support system comprehensively determines a relatively optimal safety management countermeasure by giving consideration to safety, traffic level and economic indicators based on an analysis result of the information processing system, the safety management countermeasure is transmitted to the site for release through the information release system, and finally the safe and efficient operation of icy roads is realized.

Owner:郭忠印 +2

Belt deviation detecting device for weighing and feeding machine

ActiveCN101634582AImprove work efficiencyIncrease profitWeighing apparatus for continuous material flowWeighing auxillary devicesMechanical engineeringUtilization rate

The invention discloses a belt deviation detecting device for a weighing and feeding machine, comprising a belt position detecting device and a belt position inductive element, wherein the belt position inductive element is arranged on a transporting belt of the weighing and feeding machine, and the belt position detecting device is arranged under the transporting belt and used for detecting a position signal of the belt position inductive element in real time and judging the position of the transporting belt. The belt deviation detecting device for the weighing and feeding machine has simple and compact structure and convenient installation, can continuously detect the operation position of the transporting belt on line and is beneficial to increasing the work efficiency of personnel and the utilization rate of devices.

Owner:HUNAN CHANGTIAN AUTOMATION ENG CO LTD

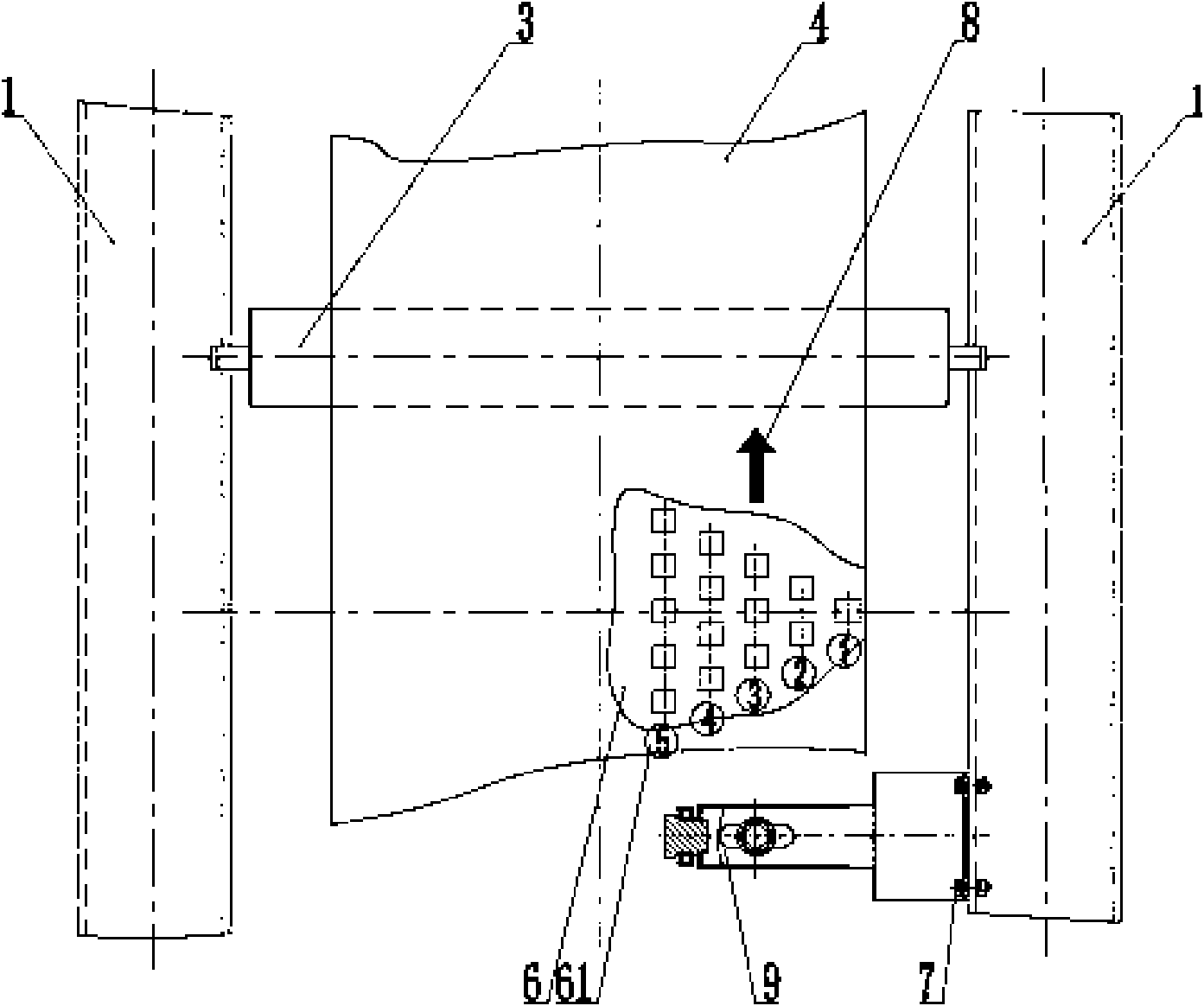

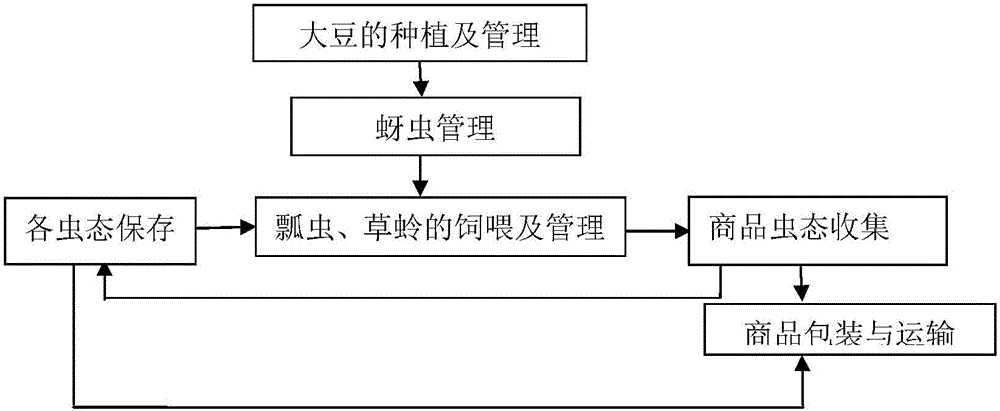

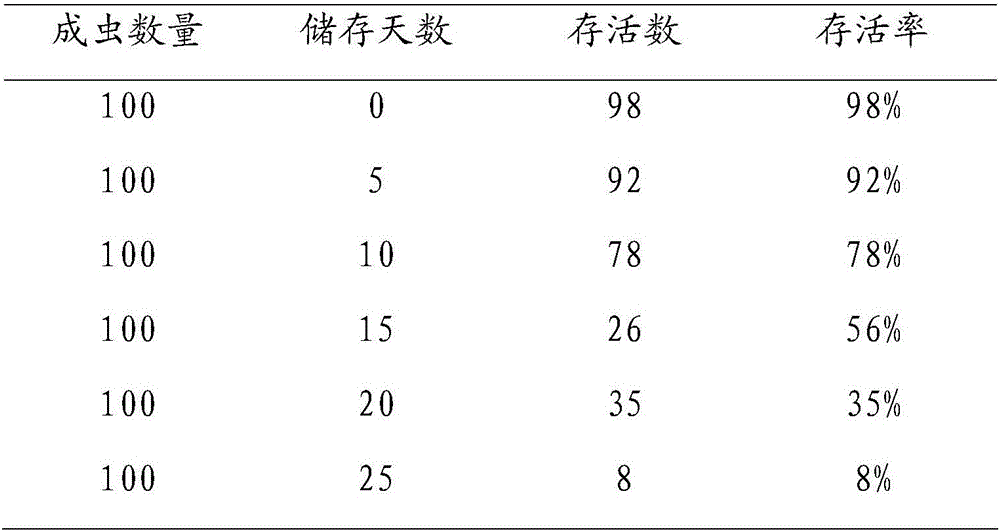

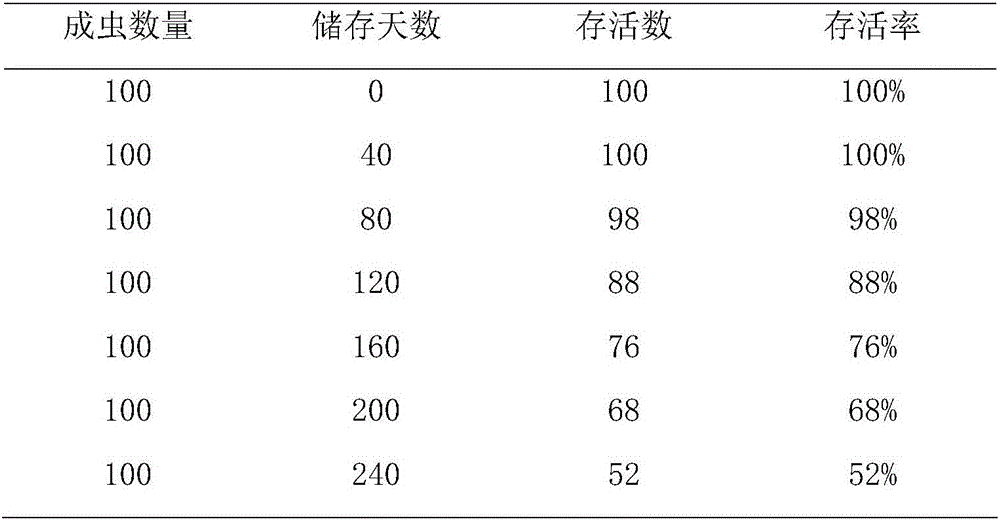

Large-scale feeding and storage method of aphids and predators of aphids

The invention provides a large-scale feeding and storage method of aphids and predators of the aphids. The method comprises the following steps: Step 1, feeding soybean aphids by taking soybeans as host plants, wherein the soybean aphids are used for feeding ladybirds; Step 2, incubating ova of the ladybirds into larvas in concentration manner and feeding the soybean aphids with the larvas so that the soybean aphids pupate; Step 3, performing eclosion on pupas formed in Step 2, so as to obtain adults; Step 4, feeding the adults in Step 3 in pairs, so as to obtain ova of the ladybirds, and placing the ova of the ladybirds into a cold cupboard for dark treatment; and Step 5, storing the adults in Step 3 with the soybean aphids. The method has the beneficial effects that large-scale, low-cost and standardized production of the aphids and the predators of the aphids, so that the large-scale production of high-quality coccinelidae and lacewing comes true, and the commercialization of the ladybirds and the lacewing is promoted.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

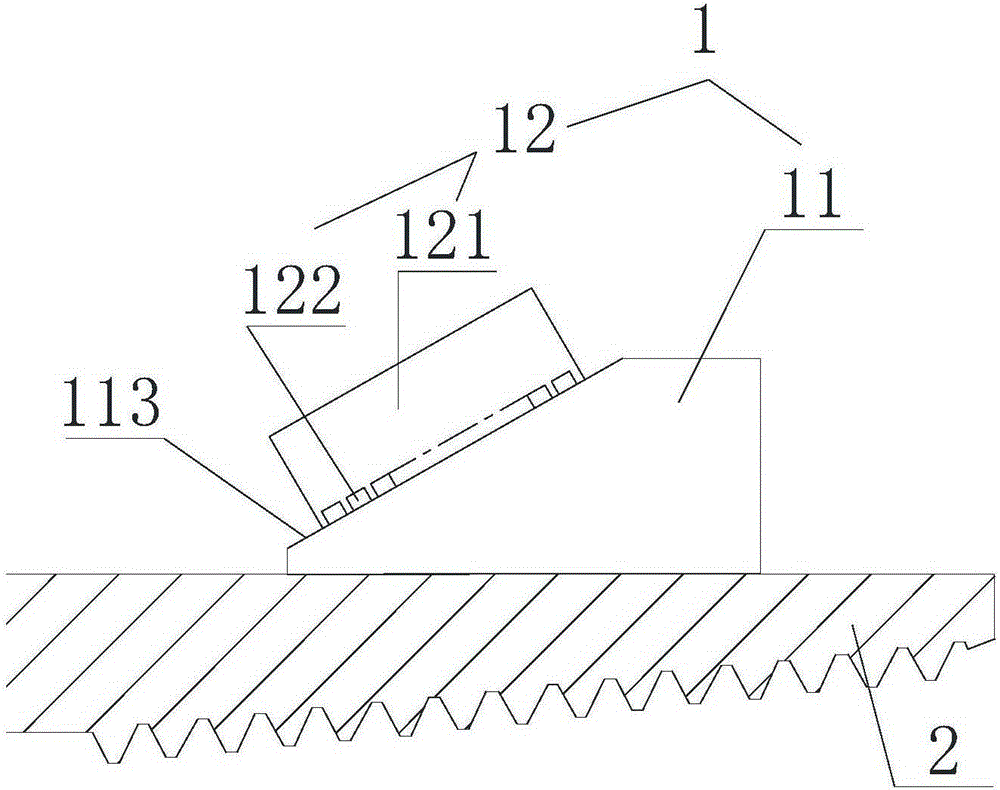

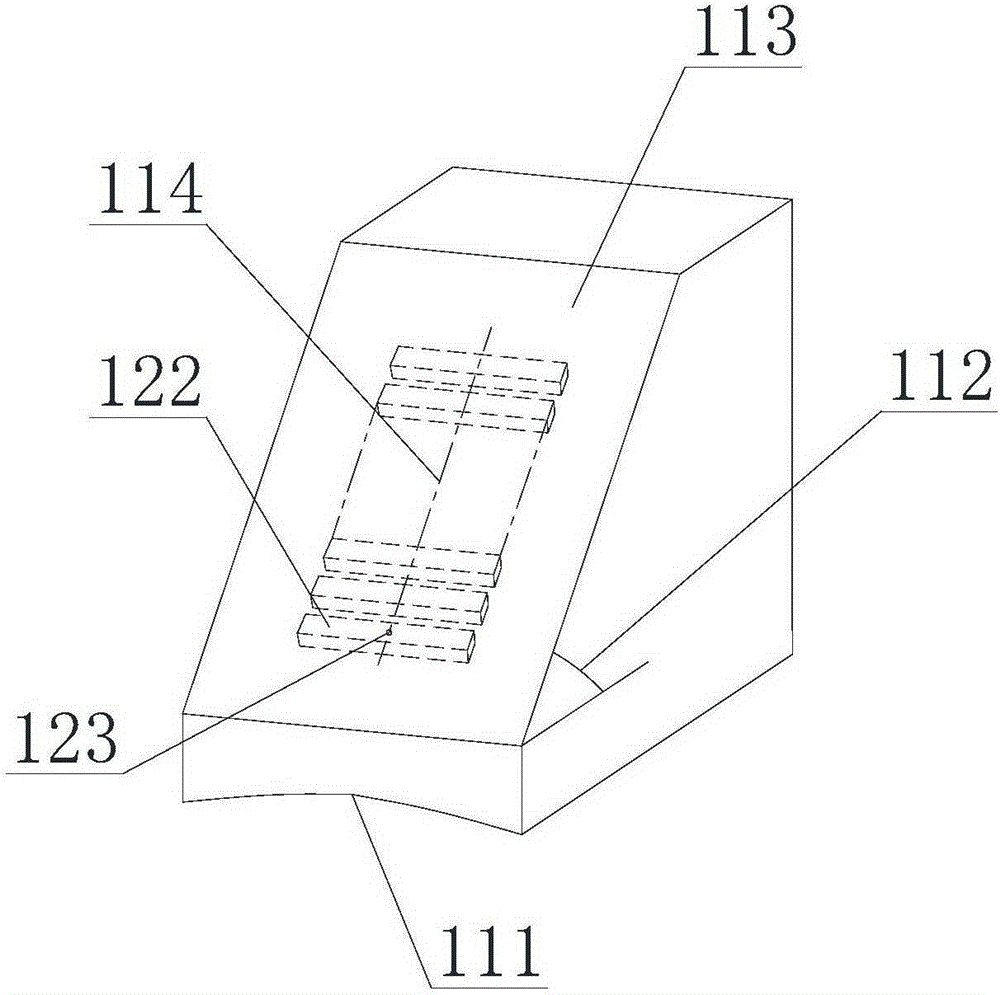

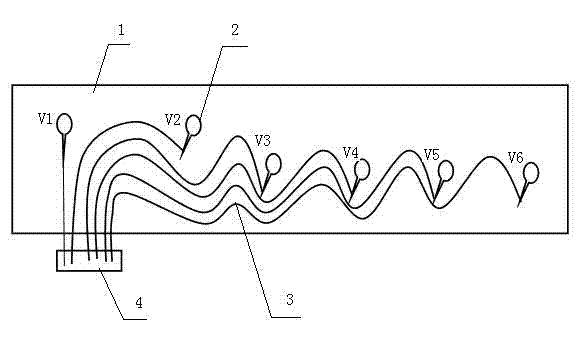

Phased array probe and phased array instrument

InactiveCN105241962AEfficient detectionRealize non-destructive testingMaterial analysis using sonic/ultrasonic/infrasonic wavesCouplingTransducer

The invention provides a phased array probe and a phased array instrument, and relates to the technical field of checkout equipment. No matter whether a thread is machined in an oil casing coupling or not, the oil casing coupling can be effectively detected; the process is simple, time is saved, and work efficiency is improved. The phased array probe is used for conducting flaw detection on the oil casing coupling, and comprises a wedge block and an energy transducer, wherein the wedge block comprises a concave arc-shaped bottom face and an inclined face opposite to the concave arc-shaped bottom face, a preset included angle is formed by the central axes of the inclined face and the concave arc-shaped bottom face, the energy transducer comprises a body and a plurality of wafers, the body comprises a connecting face, the wafers are embedded in the connecting face, the connecting face is opposite to the inclined face, and the wafers are attached to the inclined face and distributed in arrays at intervals along the first straight line in the inclination direction of the inclined face. The phased array probe is mainly used for conducting flaw detection on the oil casing coupling.

Owner:安东检测有限公司

Method for testing sealing performance of shield pipe sheet waterproof gasket

InactiveCN109297658ACredibleImprove reliabilityFluid-tightness measurement using electric meansElectricityContact pressure

The invention relates to a method for testing the sealing performance of a shield pipe sheet waterproof gasket. The method comprises: Step 1: using a jack to calibrate the stress and voltage relationship of the piezoelectric film sensor; Step 2: pasting the calibrated piezoelectric film sensor on the waterproof gasket of the specified measuring point; Step 3: maintaining the position of the contact port of the calibrated piezoelectric film sensor and assemble the shield machine pipe sheet; Step 4: connecting the contact port to external devices and collecting and recording electrical signals;Step 5: inverting the collected electrical signals into the corresponding contact pressure according to the relationship between stress and voltage and compare it with the contact pressure specified by the waterproof failure index. Compared with the prior art, the method for testing sealing performance of shield pipe sheet waterproof gasket has the advantages of high reliability, strong adaptability, comprehensive functions and strong expandability, can realize the recognition of the contact pressure of the shield pipe sheet waterproof gasket, and the recognition precision is high.

Owner:TONGJI UNIV +1

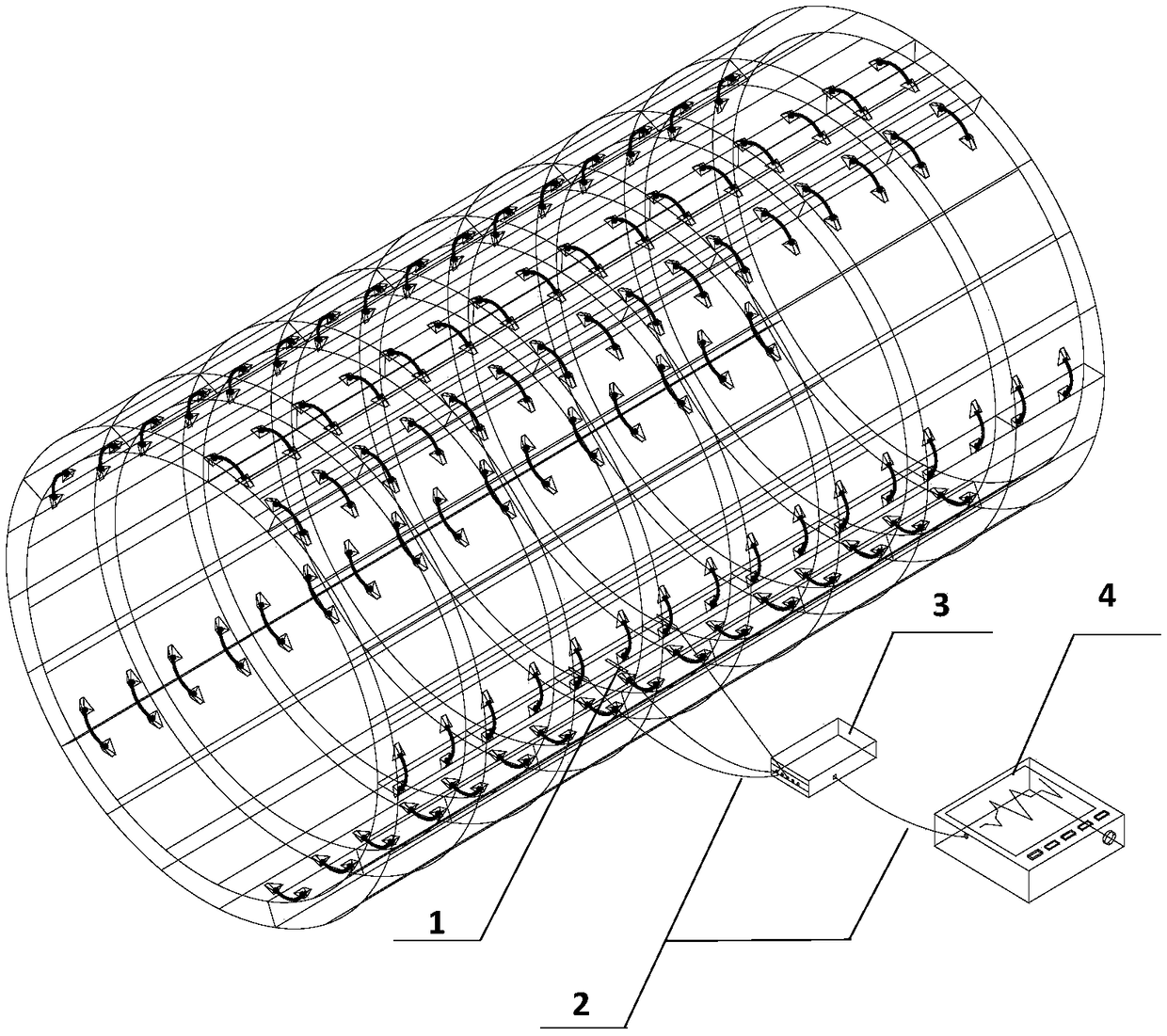

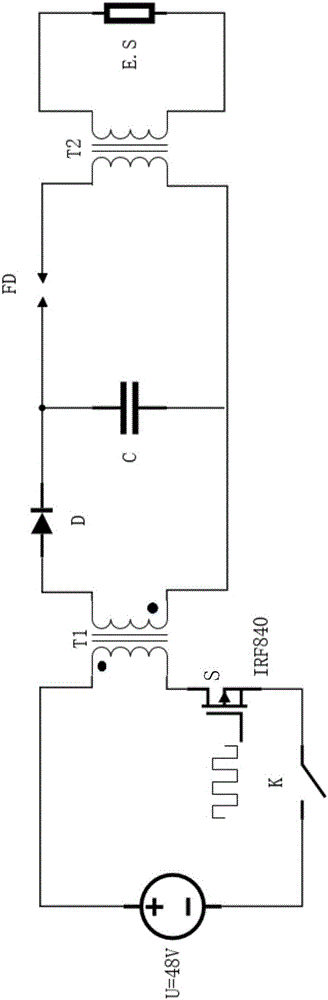

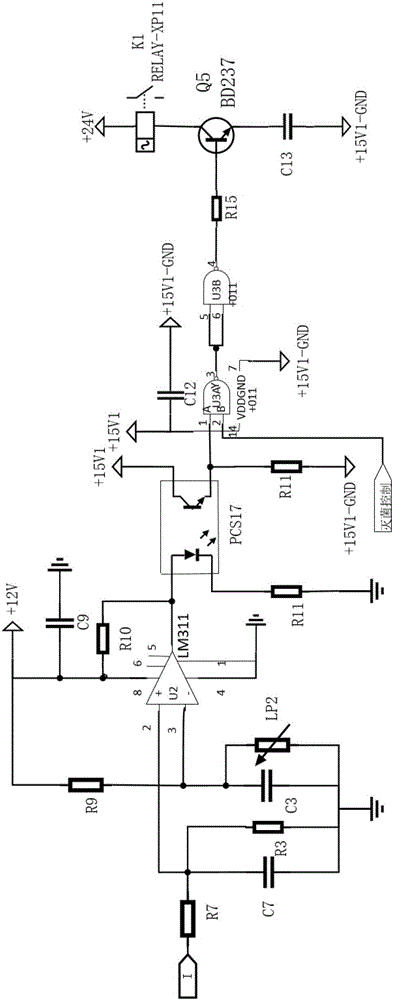

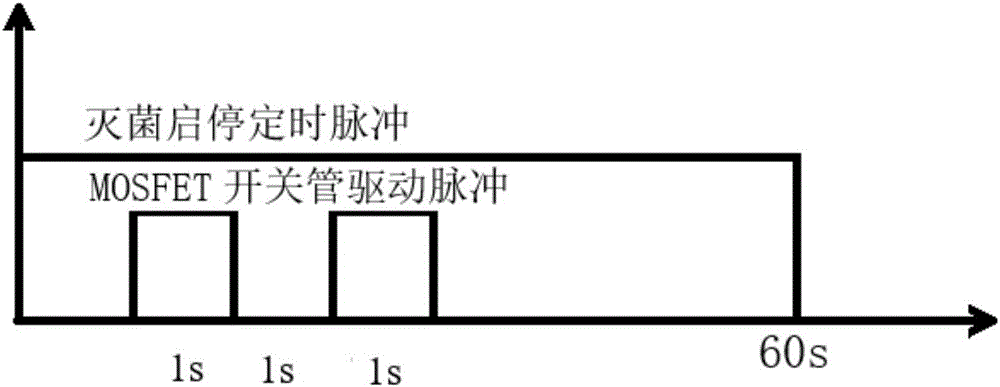

High-frequency and high-voltage pulse generator for sterilizing

InactiveCN105703659AControl energyWon't changeFood preservationPower conversion systemsCapacitanceMOSFET

A high-frequency and high-voltage pulse generator for sterilization relates to a pulse generator. A control circuit and a pulse generating circuit are provided; the control circuit is provided with a voltage comparator, a triode, a first NAND gate, a second NAND gate, a coupler, and a relay; the pulse generating circuit is provided with a relay normally open switch, MOSFET switching tube, first transformer, second transformer, diode, capacitor, spark arrestor. Based on the traditional high-frequency pulse device, a timer based on NE555 is designed, and DSP is used to digitally process the sterilization signal, so that the interference of the sterilization circuit is greatly reduced. Capacitor charging and discharging is used to obtain high-voltage pulses, so that the output pulse can reach 12-100kV / cm, and the width is controlled at the microsecond level, and the pulse front is controlled at the nanosecond level, which can effectively sterilize and will not change the food composition. ; It can be turned on and off in an instant and has a large flow capacity and reliable operation.

Owner:XIAMEN UNIV

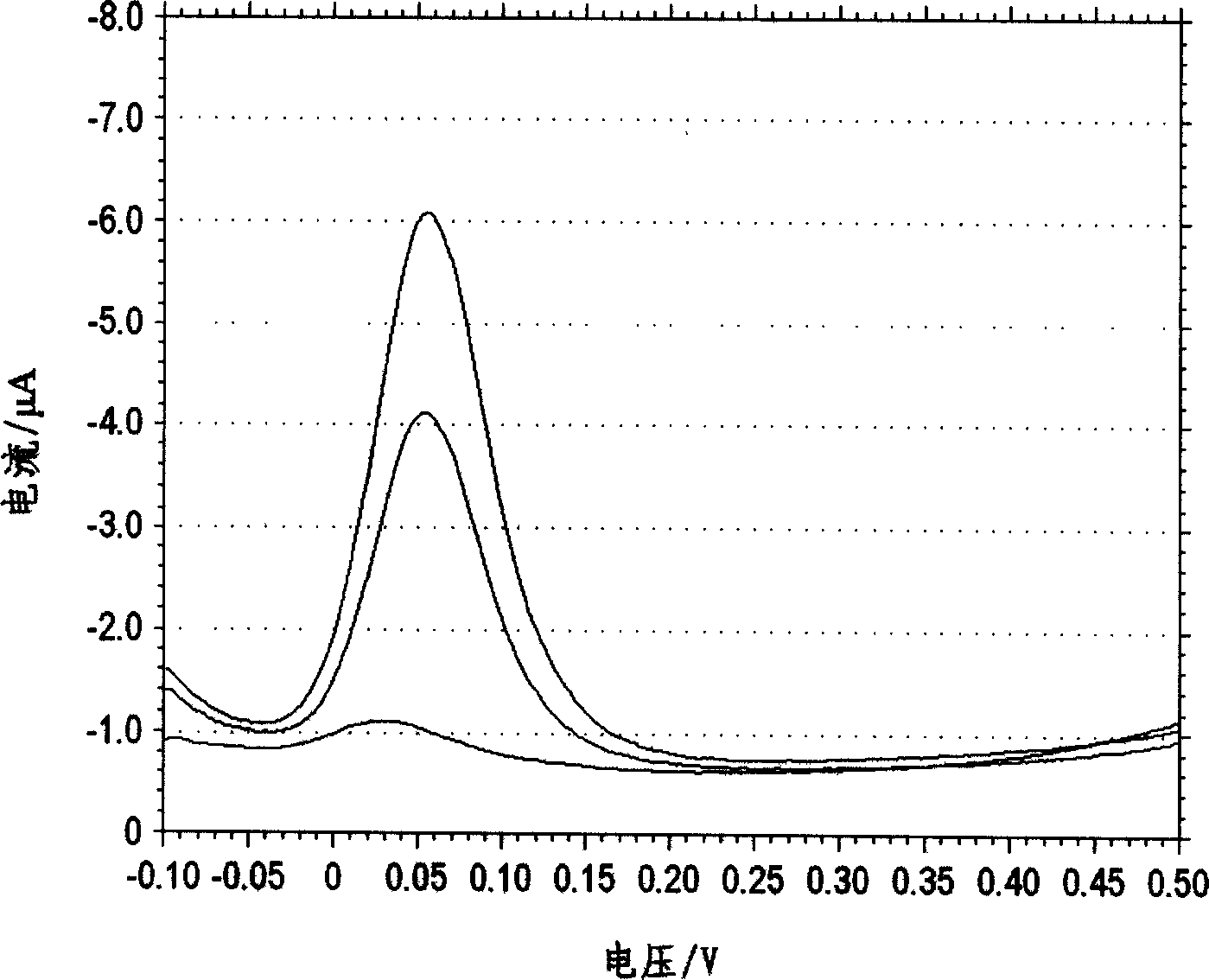

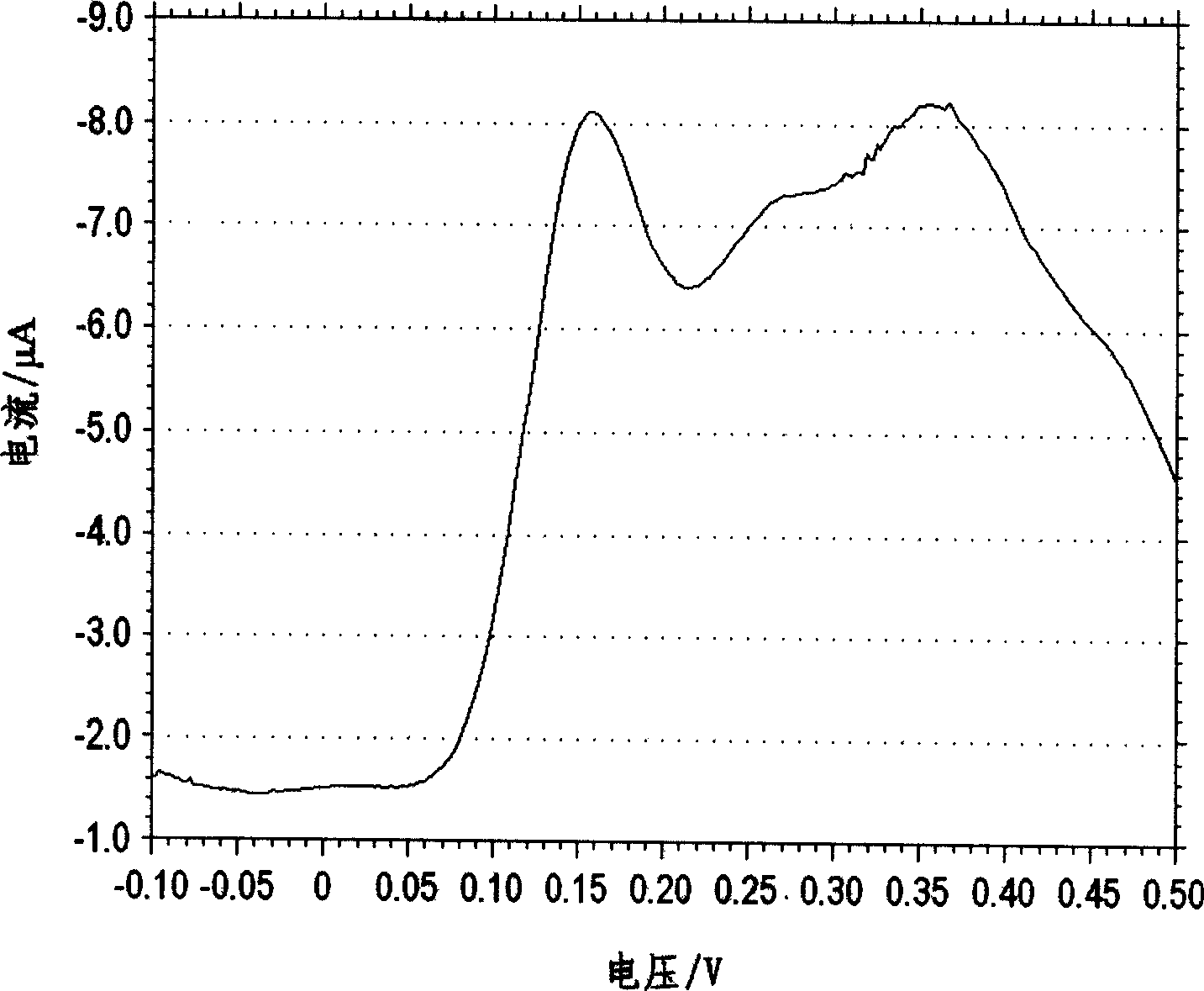

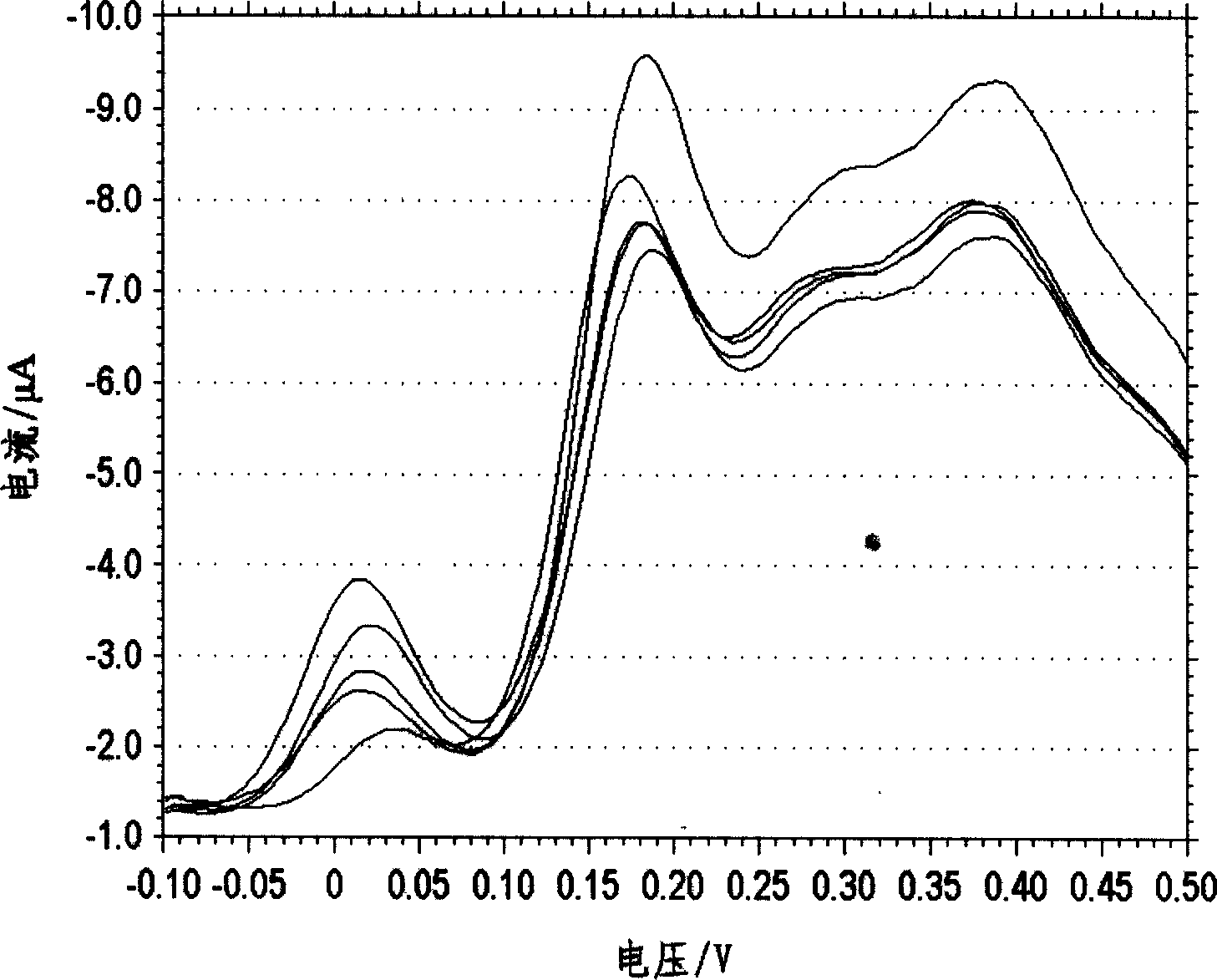

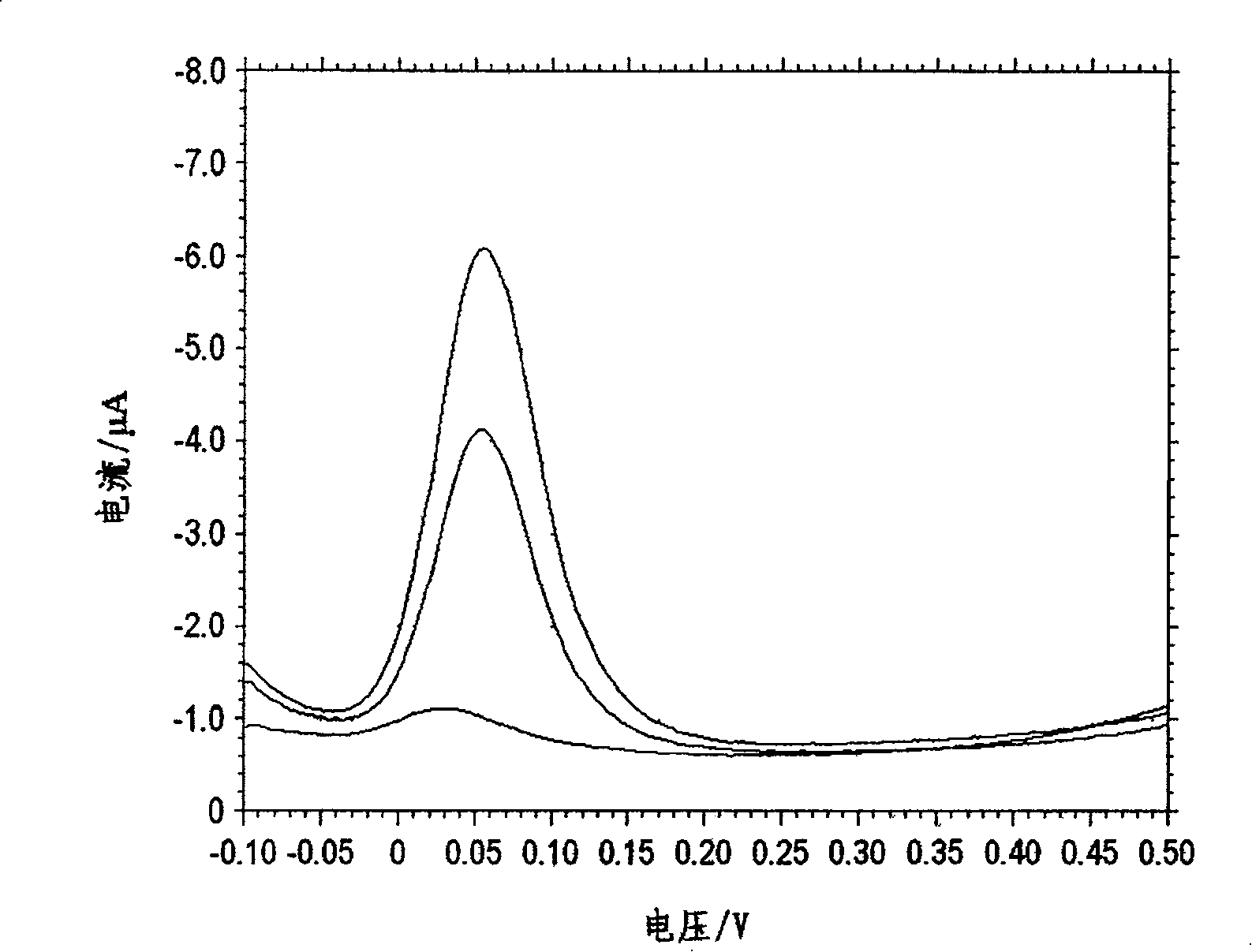

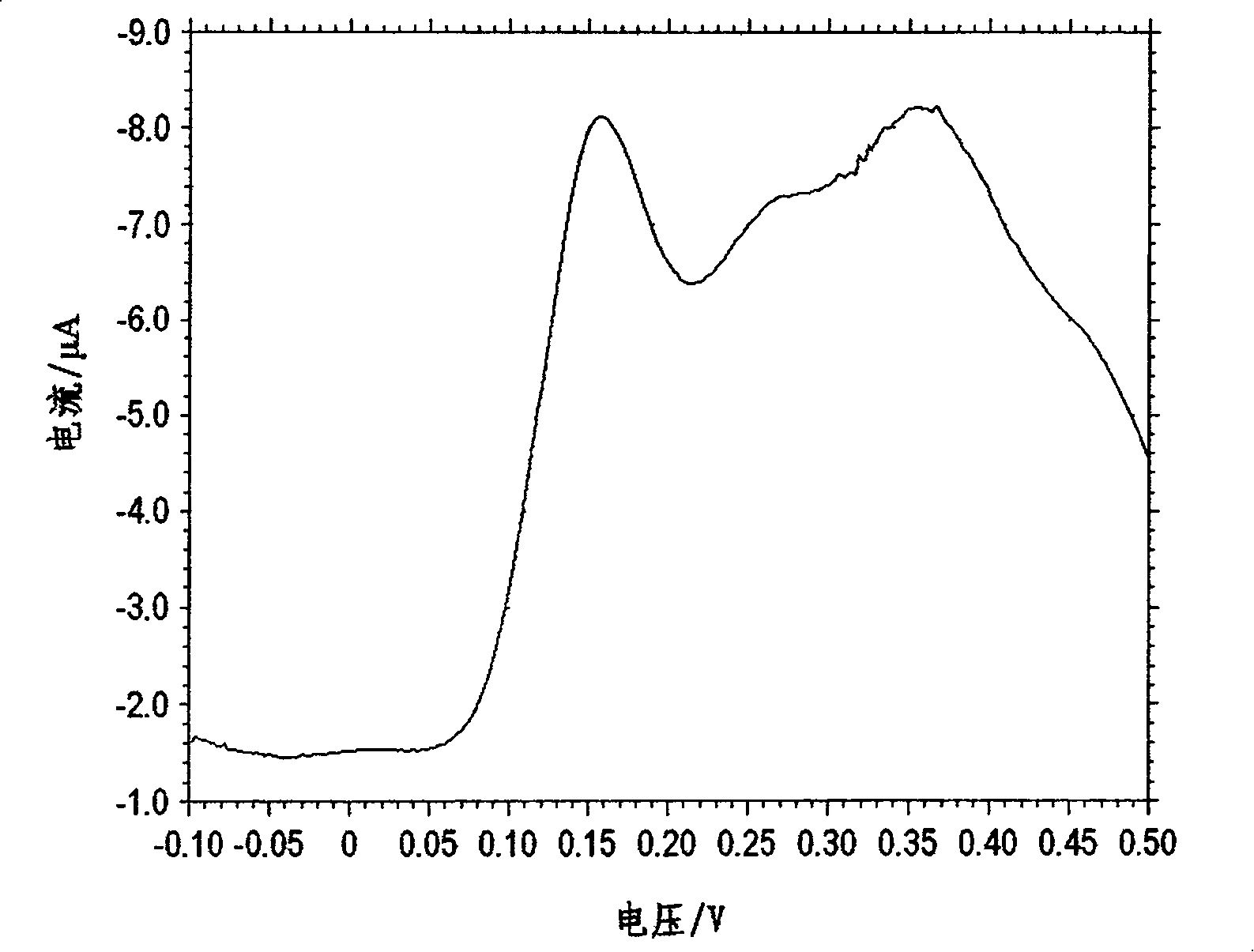

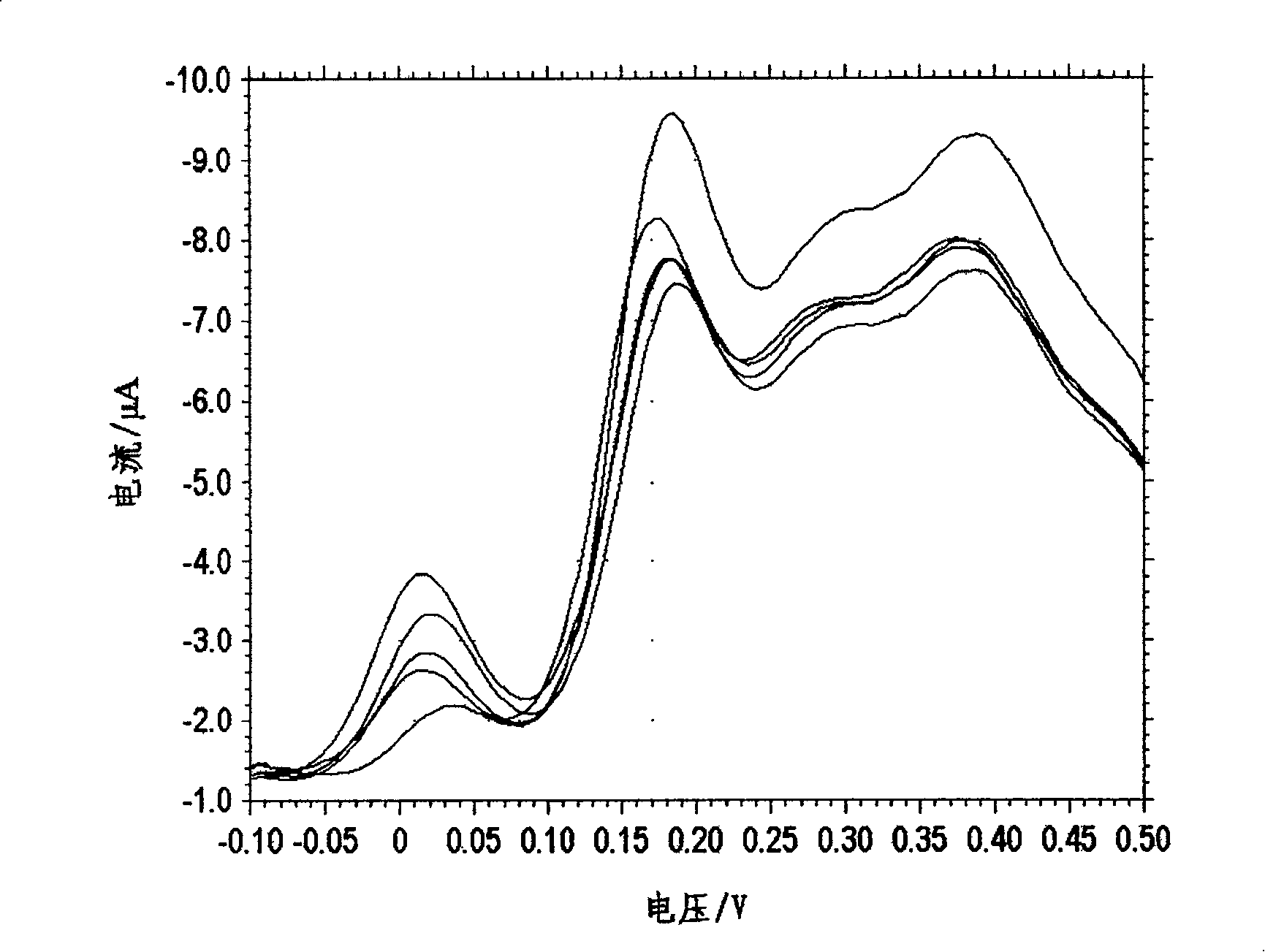

Method for detecting oxidation preventive content in jet fuel

InactiveCN1749747ARealize on-site analysisSimple and fast operationPreparing sample for investigationMaterial electrochemical variablesAlcoholInterference factor

The method of detecting antioxidant content in jet fuel features that the antioxidant in jet fuel is extracted with alcohol solution of alkali metal hydroxide and measured in electrochemical analyzer and by means of differential pulse volt-ampere process. This method has the features of fast detection speed, simple operation, high accuracy and less interference factors. The electrochemical analyzer is portable for in-situ analysis. The present invention is especially suitable for conventional analysis.

Owner:史永刚

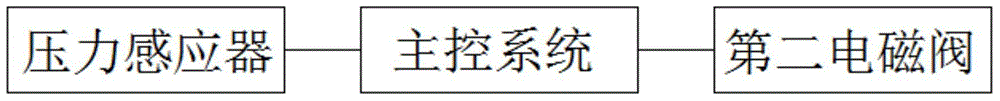

Safe spelter smelting furnace

The invention relates to a safe spelter smelting furnace. The safe spelter smelting furnace comprises a vertical furnace body. Multiple layers of combustion chambers are arranged in the vertical furnace body. The combustion chamber on each layer is provided with nozzles used for injecting gas or air. A plurality of smelting tanks are arranged in the combustion chamber on each layer. The openings of the smelting tanks are all formed in the outer wall of the vertical furnace body. Two flues are further arranged in the vertical furnace body and located at the two ends of each combustion chamber respectively. The two flues are communicated with the two ends of each combustion chamber respectively. A first electromagnetic valve is arranged at the communication position of each flue and each combustion chamber. Two second electromagnetic valves are arranged at smoke outlets of the two flues respectively. Pressure sensors are arranged in the two flues respectively. A main control system is arranged on the outer wall of the vertical furnace body. The two pressure sensors are connected with the main control system through lines. The main control system is connected with the two second electromagnetic valves through lines. Air pressure can be adjusted automatically, in this way, damage to the smelting furnace is avoided, the service life is prolonged, and the safety is improved.

Owner:龙桂山

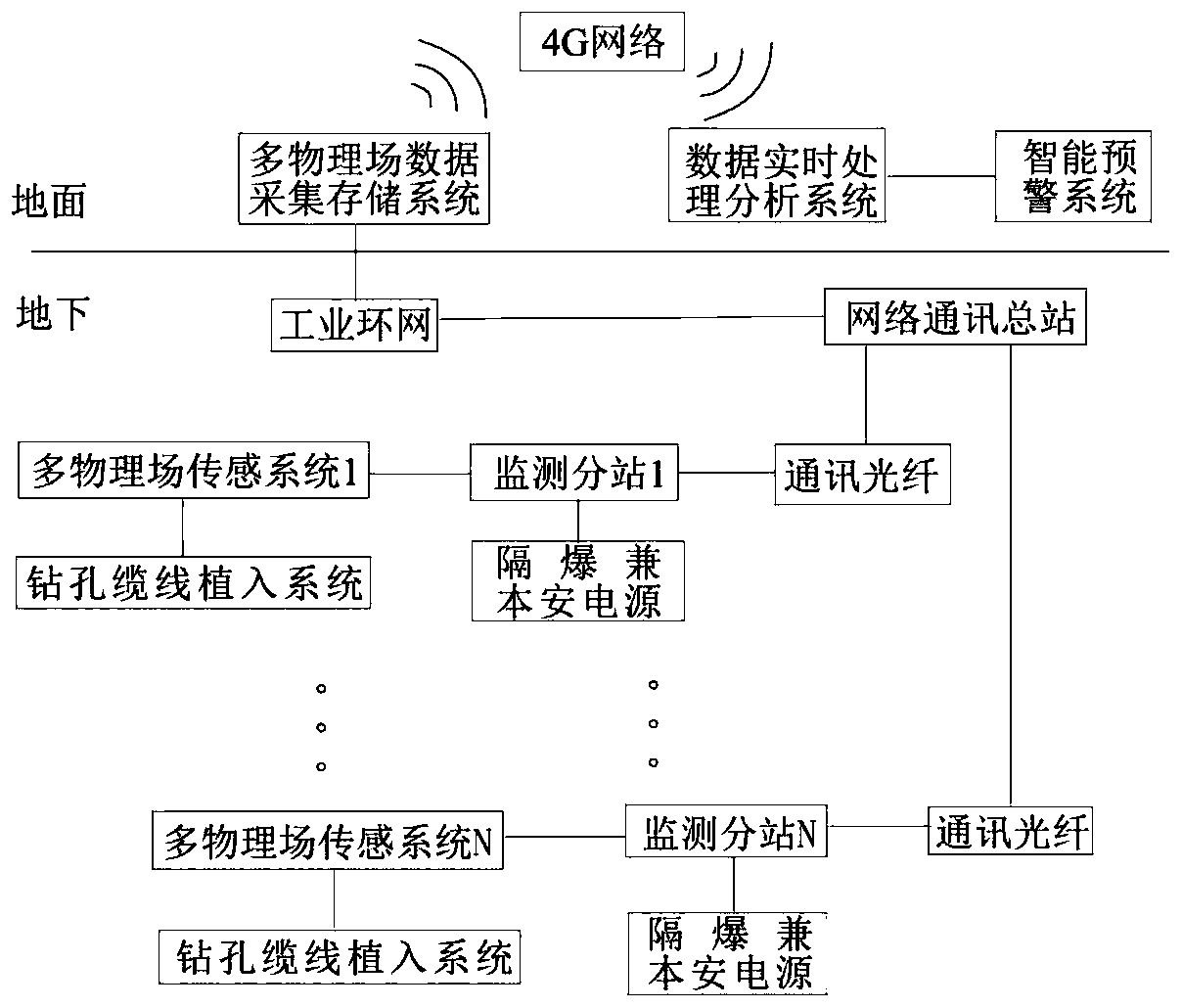

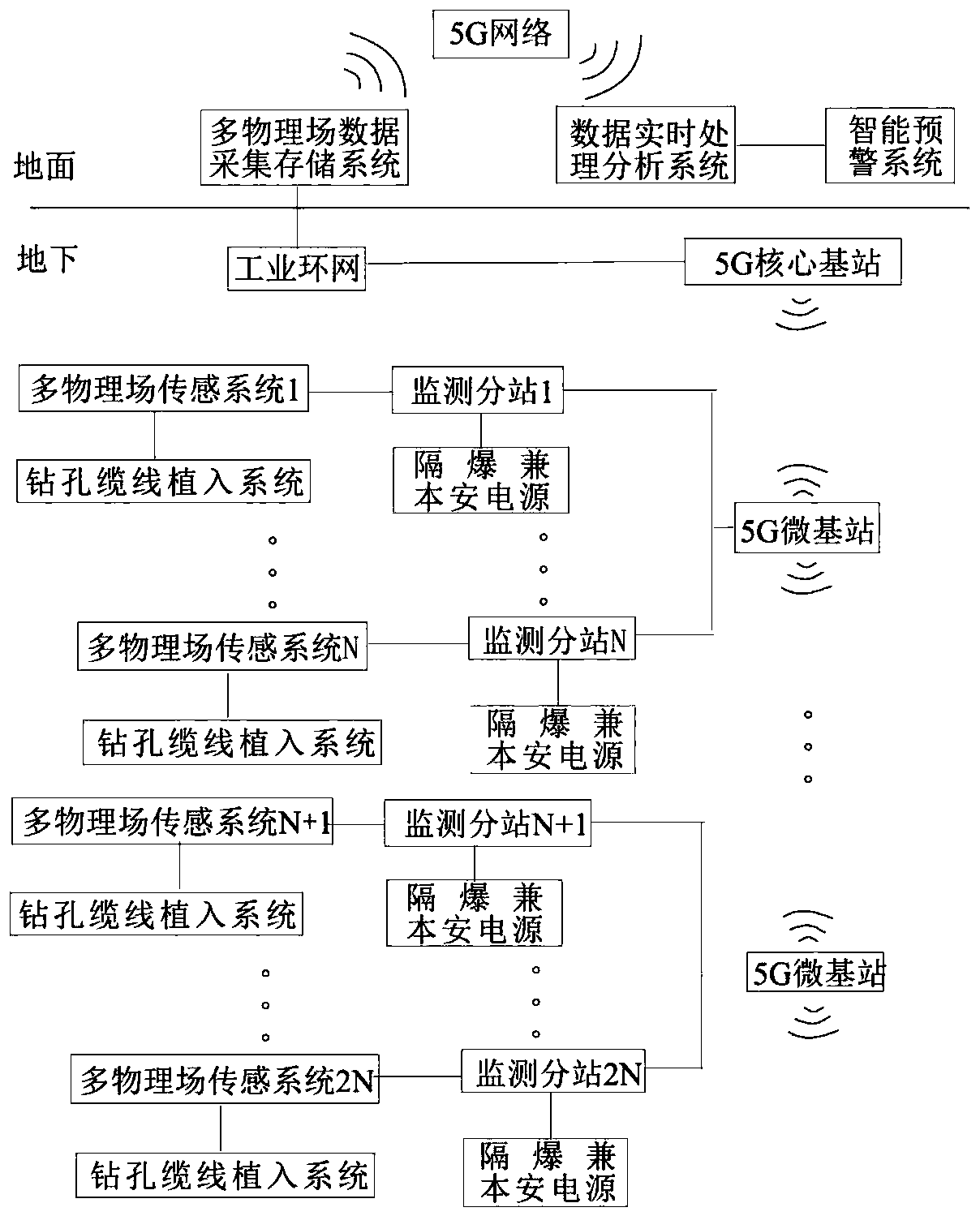

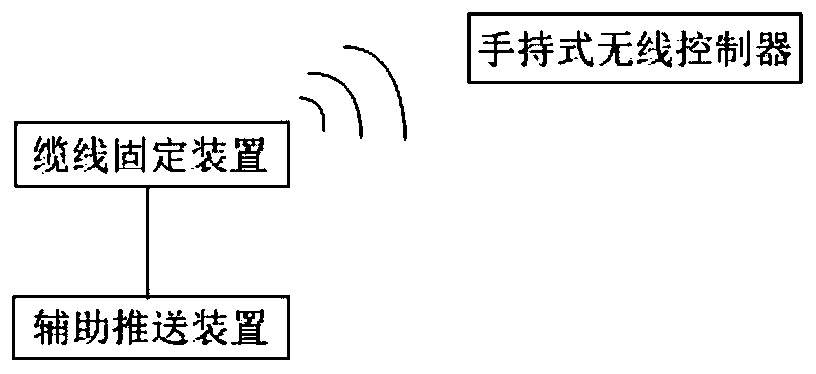

Underground engineering surrounding rock stability multi-physical-field monitoring and early warning system and method

ActiveCN111599137AImprove anti-interference abilityProlong survival timeMining devicesAlarmsData acquisitionNetwork communication

The invention discloses an underground engineering surrounding rock stability multi-physical-field monitoring and early warning system and method. The system comprises an underground monitoring subsystem and a ground monitoring and early warning subsystem. The underground monitoring subsystem comprises a multi-physical-field sensing system, a monitoring substation and an industrial looped network.The ground monitoring and early warning subsystem comprises a multi-physical-field data acquisition and storage system, a remote data real-time processing and analysis system and an intelligent earlywarning system; the multi-physical-field sensing system is connected with the monitoring substation, and the monitoring substation is connected with the industrial looped network through a communication optical fiber and a network communication master station, or the monitoring substation is connected with the industrial looped network through a 5G micro base station and a 5G core base station insequence; the industrial looped network is connected with the multi-physical-field data acquisition and storage system, the multi-physical-field data acquisition and storage system is connected withthe remote data real-time processing and analysis system in a wireless mode, the remote data real-time processing and analysis system is connected with the intelligent early warning system, the manualworkload is effectively reduced, the intelligent degree is high, and the real-time performance is high.

Owner:ANHUI UNIV OF SCI & TECH

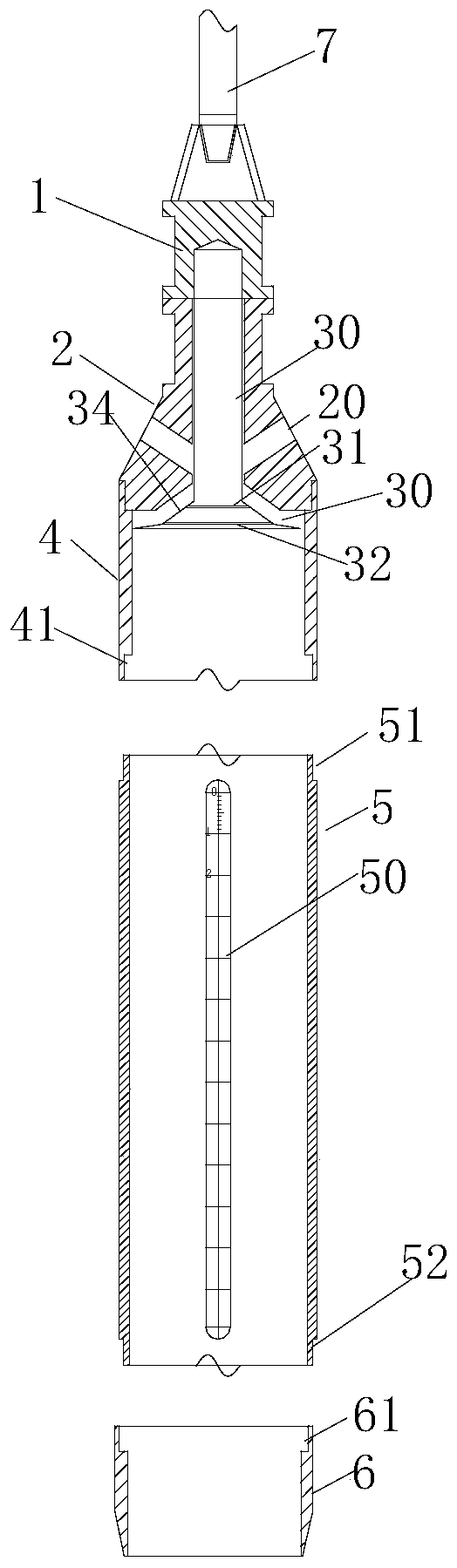

Sludge and sludge soil sample collecting and sampling device

PendingCN110296858AReduce Secondary DisturbancePromote formationWithdrawing sample devicesElectrical/magnetic solid deformation measurementCouplingSludge

The invention discloses a sludge and sludge soil sample collecting and sampling device. The device comprises a sampling cylinder formed by fastening two semicircles; the lower end of the sampling cylinder is provided with a lower external thread to be connected with an annular sampler bottom edge or to be in threaded connection with the annular sampler bottom edge through a strain gauge mounting cylinder in threaded connection; the upper end of the sampling cylinder is provided with an upper external thread to be in threaded connection with a connecting cylinder; the upper end of the connecting cylinder is in threaded connection with an exhaust device internally provided with a piston rod and provided with an exhaust hole in a side wall; a coupling for connecting a driving device is arranged at the upper end of the exhaust device; a conical piston body at the lower end of the piston rod is located at an opening in the bottom of the exhaust device; and a matched conical surface is formed at the opening in the bottom of the exhaust device. According to the device, a commonly used small drilling machine can be used as a driving force, and sampling can be carried out in a relatively shallow sludge area by manual driving; and an original sampling mode is changed into a pure static pressure mode from a rotary static pressure mode, so that primary disturbance is reduced.

Owner:天津市水务规划勘测设计有限公司

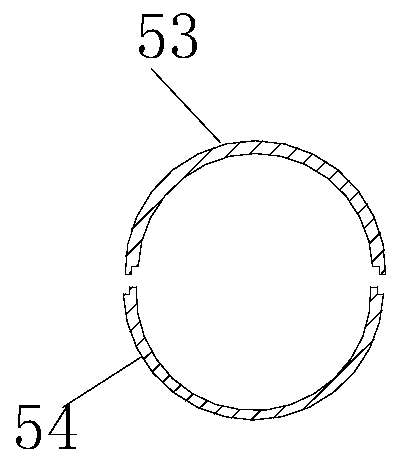

Electrocardiogram precordial lead electrode plate set and preparation method thereof

InactiveCN103784136AIncrease contactAvoid damageDiagnostic recording/measuringSensorsEngineeringElastic bandage

The invention discloses an electrocardiogram precordial lead electrode plate set and a preparation method of the electrocardiogram precordial lead electrode plate set. The electrocardiogram precordial lead electrode plate set comprises an elastic bandage, membrane electrodes, wires and a wire bundling interface. The elastic bandage comprises a protection elastic bandage body, a support elastic bandage body and a protection sticker, wherein the protection elastic bandage body is located on the outer side, the support elastic bandage body is provided with the membrane electrodes, and the protection sticker is located on the inner side. The six membrane electrodes are respectively connected to the wire bundling interface through the wavy wires. The electrocardiogram precordial lead electrode plate set is convenient to use, only the protection sticker needs to be uncovered and the bandage is pasted to the skin, the preparation method is easy and convenient to use, and the electrocardiogram precordial lead electrode plate set is safe and reliable due to the fact that the electrocardiogram precordial lead electrode plate set is disposable.

Owner:薛运章

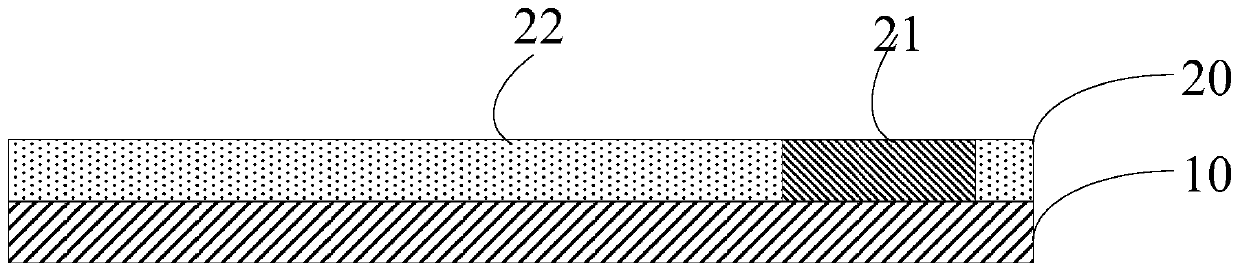

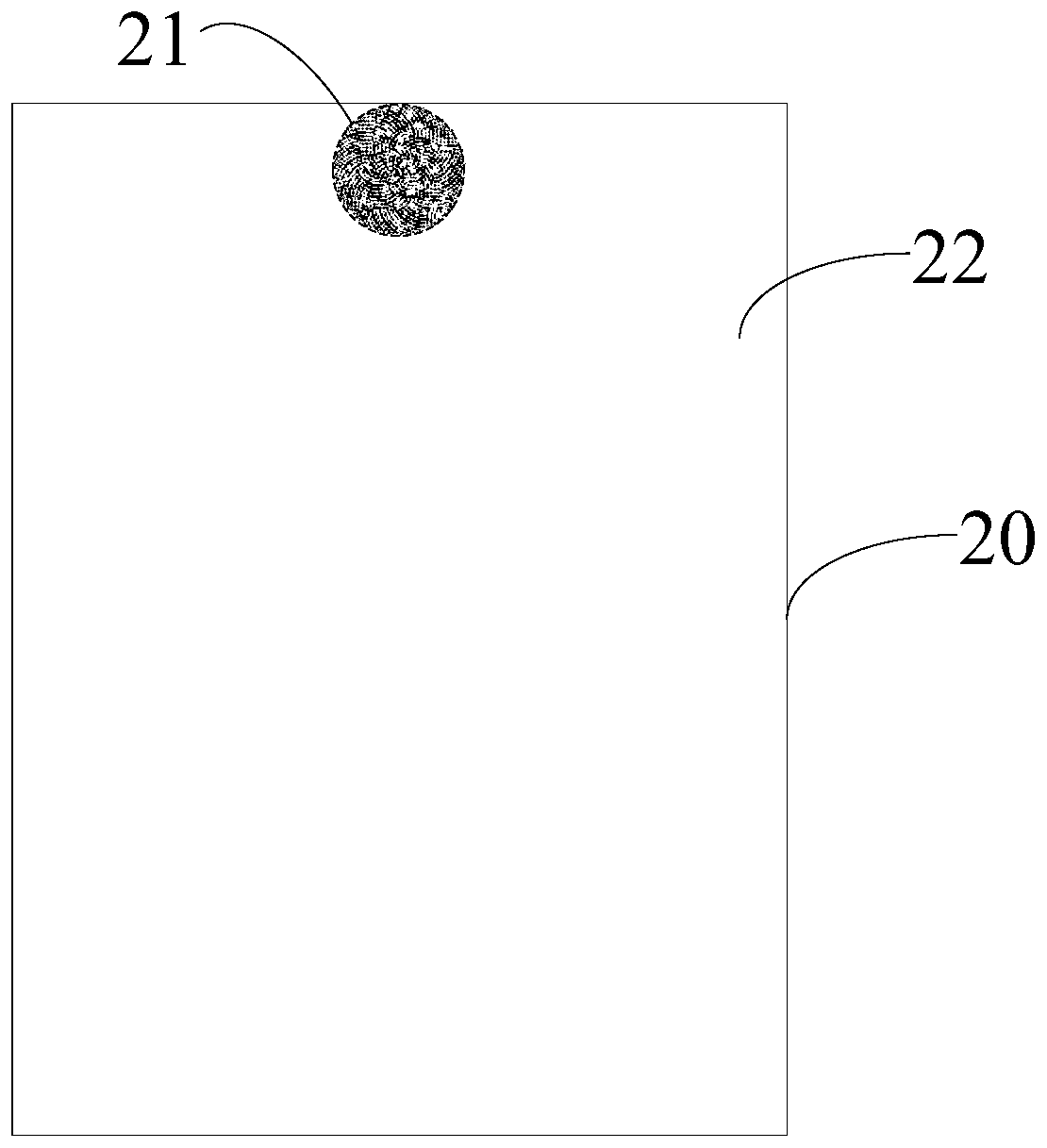

Display panel and electronic equipment

ActiveCN111599840AIncrease the screen ratioEnhance signal passing abilitySolid-state devicesSemiconductor devicesMultiplexingPoint light

The invention provides a display panel and electronic equipment. The display panel comprises: a substrate; a light-emitting function layer arranged on the substrate, wherein the light-emitting function layer comprises a multiplexing function area, the multiplexing function area comprises at least one multiplexing function sub-area, the multiplexing function sub-area is provided with a plurality offirst light-emitting sub-pixels, and part or all of the plurality of first light-emitting sub-pixels are arranged along a plurality of spiral curves and are arranged in a grid shape. According to thedisplay panel provided by the embodiment of the invention, a plurality of first light-emitting sub-pixels of a multiplexing function sub-region are arranged along a plurality of spiral curves and arearranged in a grid shape, so that the number of diffraction fringe rings formed after a point light source penetrates through a screen can be reduced, the signal passing capacity of the multiplexingfunction area can be enhanced, and the interference degree of signals received or sent by the optical device can be reduced.

Owner:MEGVII BEIJINGTECH CO LTD

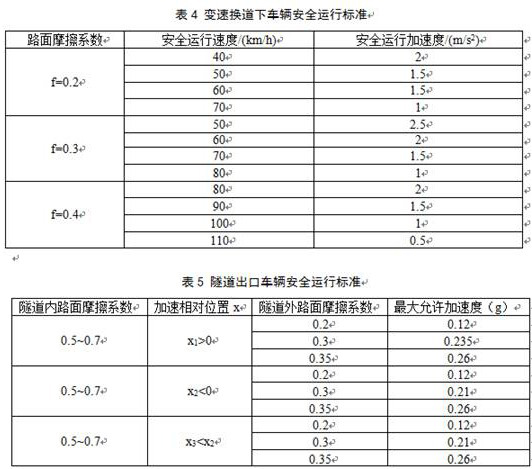

Mountain highway rainfall environment early warning system and method

PendingCN109147358ASafe and efficient operationOptimal Safety Management CountermeasuresArrangements for variable traffic instructionsInformation processingRoad surface

The invention discloses a mountain highway rainfall environment early warning system. The system is formed by an information monitoring and acquisition system, an information processing system, a decision support system, an information release system and an evaluation system which are connected to a communication system. In the invention, a meteorological information monitoring and acquisition sensor, a road condition information monitoring and acquisition sensor, and a traffic flow detection sensor are integrated into one body and are arranged in the typical section position of a highway in amountain area. The defects of current highway meteorological monitoring station and road domain environment differences, burstiness and area disharmony are effectively overcome. Meteorological information, road surface condition information, and traffic flow information data are collected in real time and data support is provided for an information processing system. According to the analysis result of the information processing system, the decision support system considers safety, a traffic level and an economic index, comprehensively determines a relatively optimal safety management countermeasure, and transmits to the site for releasing through the information release system. The safe and high-efficient operation of a pavement under a rainfall environment is finally realized.

Owner:郭忠印 +2

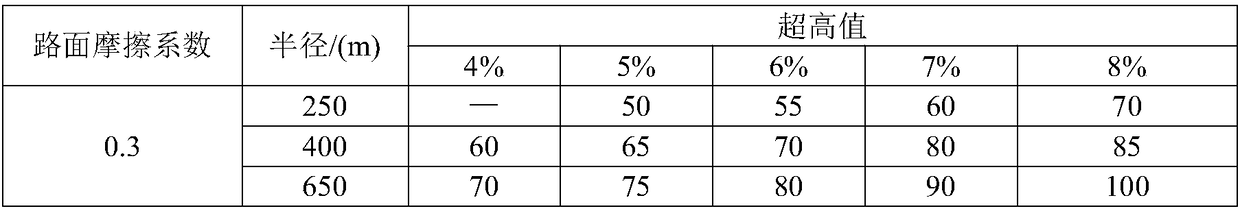

Free triiodothyronine measurement kit and fabrication method thereof

InactiveCN109239371AHigh affinityStrong specificityChemiluminescene/bioluminescenceBiological testingMicrosphereHook effect

The invention discloses a free triiodothyronine measurement kit and a fabrication method thereof, and belongs to the technical field of vitro inspection. By the free triiodothyronine measurement kit,the technical problems of long reaction time, slow measurement speed, narrow of linear range and hook effect easy to generate of the prior art when a tested substance is high in concentration are solved. The kit comprises the following reagents of a solid-phase reagent 1 and a liquid-phase reagent, wherein the solid-phase reagent R1 is a suspension liquid including a T3 analogue-coated paramagnetism microsphere, the liquid-phase reagent R2 is a suspension liquid including an acridinium ester labeled T3 antibody, the paramagnetism microsphere in the R1 is Fe3O4 with a surface wrapped by a carboxyl active group, and the particle size of the paramagnetism microsphere is 0.1-5 micrometers. With the free triiodothyronine measurement kit and the fabrication method thereof, provided by the invention, free triiodothyronine in blood / plasma is quantitatively detected by a chemiluminescence immunity analysis method, the kit has the advantages of high sensitivity, rapid detection, wide linear range, low cost and the like and is simple and convenient to operate, and automation is facilitated.

Owner:DIRUI MEDICAL TECH CO LTD

Circuit board and communication equipment

PendingCN112566353AReduce the impact of interferenceReduce crosstalkCross-talk/noise/interference reductionPrinted circuit aspectsGround planeMechanical engineering

The embodiment of the invention relates to the technical field of communication equipment, and discloses a circuit board, which comprises a first signal line and a second signal line which are arranged adjacently, and further comprises a grounding plane and a conductive layer connected with the grounding plane, and the conductive layer is arranged between the first signal line and the second signal line. The embodiment of the invention also provides communication equipment. According to the circuit board and the communication equipment provided by the invention, the crosstalk problem of a communication line can be effectively reduced.

Owner:ZTE CORP

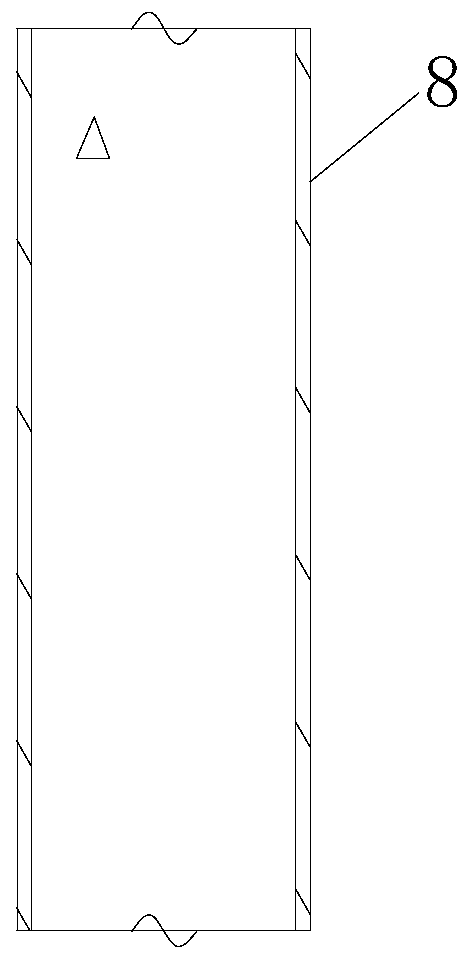

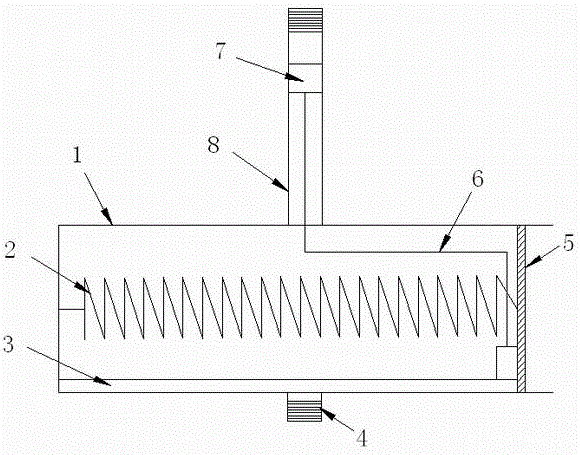

Portable spring flowmeter

PendingCN106768092AAccurate measurementLess disturbedVolume/mass flow by dynamic fluid flow effectPistonEngineering

The invention discloses a portable spring flowmeter and belongs to the technical field of sewage flow measurement in sewage treatment. The portable spring flowmeter comprises a cylindrical casing, a handle with external threads, a spring, a grating ruler displacement sensor, a sealing piston and an electronic display screen, wherein the spring is arranged in the cylindrical casing, one end of the spring is connected with the cylindrical casing, the other end is connected to the sealing piston located in the cylindrical casing, and the grating ruler displacement sensor is arranged at the bottom of the cylindrical casing and connected with the electronic display screen located on the handle with the external threads through signal wires. By use of the principle that elastic deformation of the spring and impulsive force generated by water flow speeds are directly proportional, the flowmeter converts elastic deformation, caused by the impulsive force of water flow, of the spring into the flow speeds and calculates the flow by multiplying the flow speed and the sectional area of a pipeline, defects of a conventional flowmeter are overcome, and the purposes of accurate and timely measurement, little interference and portability are achieved.

Owner:DALIAN DAKAI SEWAGE TREATMENT

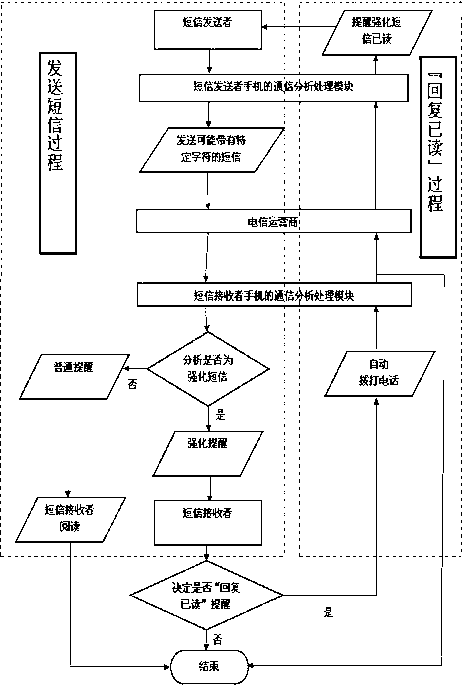

Short message processing method

InactiveCN103237297ALess disturbedReduce the likelihood of being disturbedSubstation equipmentMessaging/mailboxes/announcementsText messagingShort Message Service

The invention discloses a short message processing method and relates to the field of communication, in particular to the short message processing method in mobile phone business. A communication analyzing and processing module for analyzing and processing communication contents is required to be added onto an existing mobile phone in the method. The communication analyzing and processing module is a program. The communication analyzing and processing module can recognize specific characters in short messages and can automatically classify the short messages by distinguishing the specific characters in the short messages. Different processing methods are adopted for different types of short messages. The invention additionally provides a simple and convenient method for sending 'reply read' to a short message sender. The communication analyzing and processing module also can analyze and process a conversation. The short message processing method has the advantages that the short message function can be enabled to be more powerful, many weak points in the existing short message function can be made up and no mobile phone fee or a very small amount of fee is added.

Owner:王亮

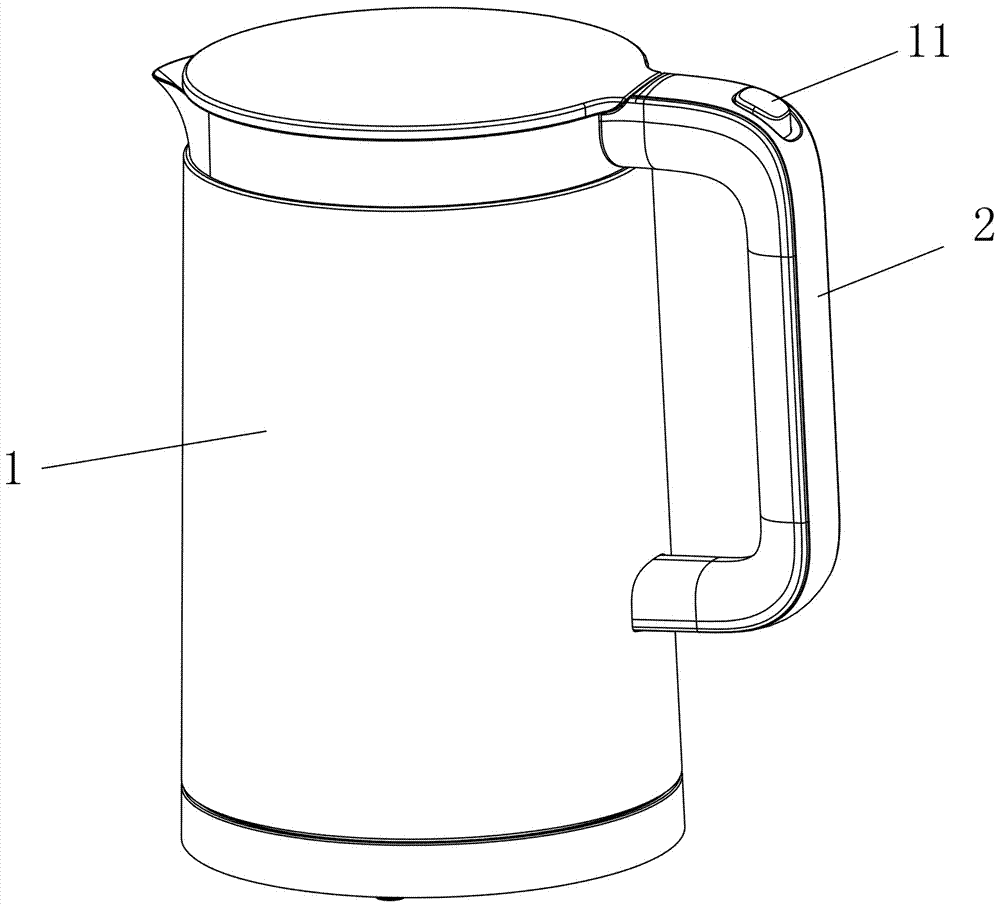

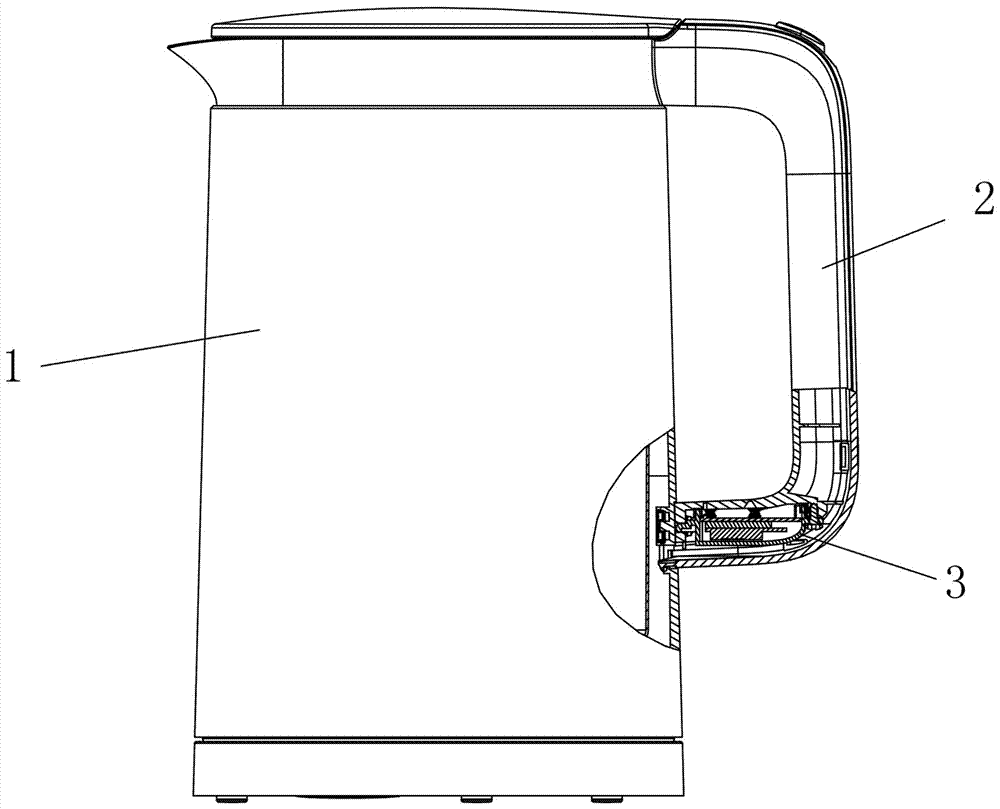

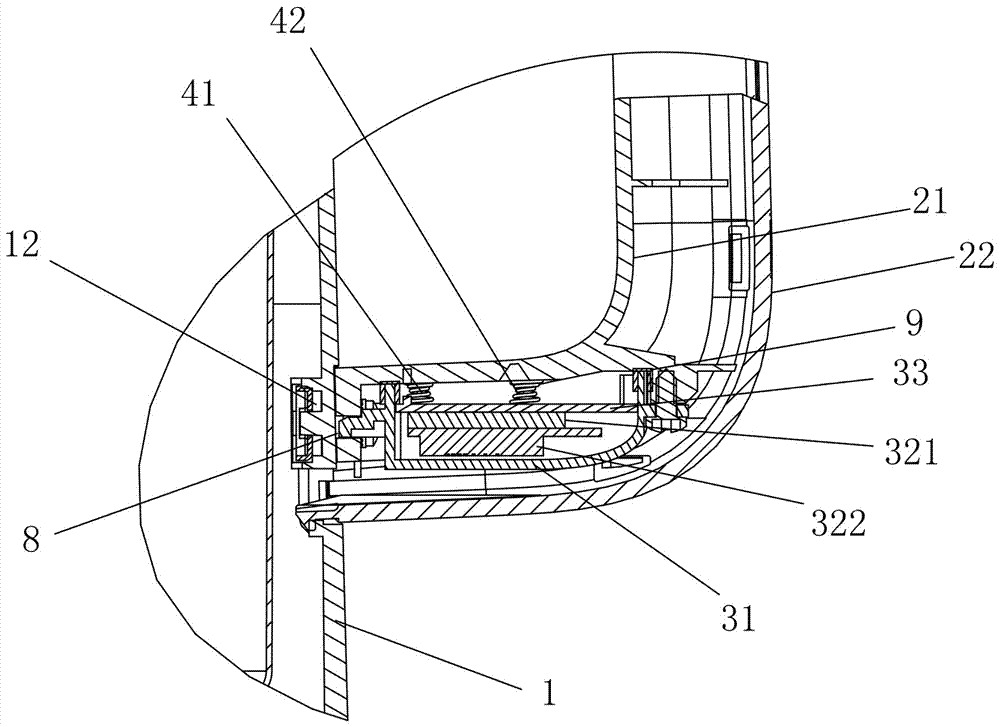

Kettle with WIFI function

The invention relates to a kettle with a WIFI function. The kettle comprises a kettle body and a handle, wherein the handle is detachably connected with the kettle body; the kettle is characterized by further comprising a WIFI module control box which includes a bottom box, a WIFI component and a PCB, the WIFI component and the PCB are connected with each other through signals and installed in the bottom box together, and the bottom box is fixed on the handle. By arranging the WIFI component in the bottom box to protect the WIFI component, the kettle has waterproof and heat insulation functions; moreover, the WIFI component is arranged on the handle which is far from a heat source (a heating element), the interference is small, and the WIFI component works stably and has a long service life; in addition, the WIFI component is arranged on the handle which can be disassembled, so that the assembly, disassembly and maintenance of the WIFI component are more convenient, and the structure is simple and reasonable.

Owner:FOSHAN VIOMI ELECTRICAL TECH +2

Low-power-consumption wireless smoke alarm device

PendingCN110363953AHigh sensitivityWide measurement rangeFire alarm smoke/gas actuationIonData acquisition module

The present invention discloses a low-power-consumption wireless smoke alarm device and belongs to the sensing, detection and safety alarm technical field. The low-power-consumption wireless smoke alarm device comprises a micro control unit, a smoke sensor, a data acquisition module, an alarm circuit, a switching quantity control circuit, a micro power wireless module and a power source module; the micro control unit is connected with the data acquisition module, the power source module, the switching quantity control circuit, the alarm circuit and the micro power wireless module; and the dataacquisition module is connected with the smoke sensor. According to the low-power-consumption wireless smoke alarm device, the micro control unit which adopts a Cortex M3 architecture is used to perform control, and therefore, a low power consumption mode and an A / D conversion function can be realized; an ion type MQ-2 smoke sensor module is adopted as the smoke sensor, and therefore, high sensitivity is realized, and early warning can be realized more quickly; and the wireless analysis and warning of the device are realized through the micro power wireless module, and therefore, data are more sensitive than data obtained through a manual mode, and reaction time is decreased, and the debugging efficiency of the warning is improved, and safety is enhanced.

Owner:南京市嘉隆电气科技股份有限公司

Method for detecting oxidation preventive content in jet fuel

InactiveCN100405055CRealize on-site analysisSimple and fast operationPreparing sample for investigationMaterial electrochemical variablesAlcoholInterference factor

The method of detecting antioxidant content in jet fuel features that the antioxidant in jet fuel is extracted with alcohol solution of alkali metal hydroxide and measured in electrochemical analyzer and by means of differential pulse volt-ampere process. This method has the features of fast detection speed, simple operation, high accuracy and less interference factors. The electrochemical analyzer is portable for in-situ analysis. The present invention is especially suitable for conventional analysis.

Owner:史永刚

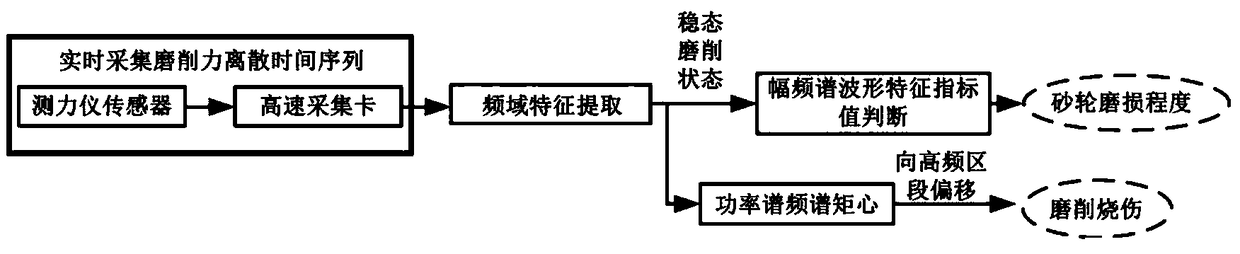

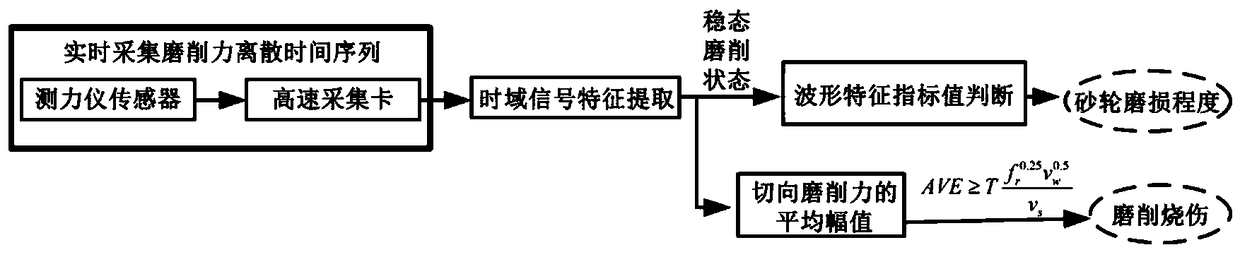

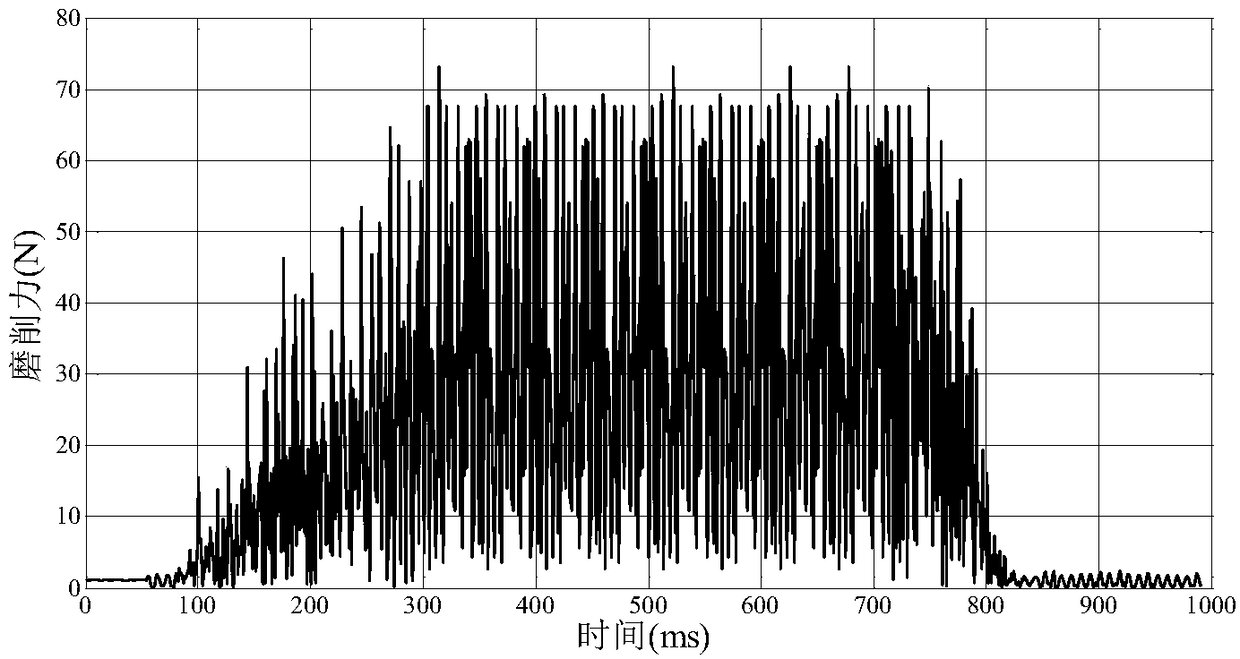

A method of monitoring grinding wheel wear and grinding burn by using grinding force

InactiveCN106826565BRepair in timeControl Grinding BurnGrinding feed controlGrinding/polishing safety devicesTime domainFrequency spectrum

The invention discloses a method for monitoring grinding wheel wear and grinding burn by using a grinding force, and belongs to the technical field of monitor and control of machining processes. The method comprises the following steps of acquiring discrete-time series of a grinding force signal in real time, extracting important characteristic parameters, such as kurtosis, waveform index, pulse index, amplitude-frequency spectrum kurtosis, amplitude-frequency spectrum pulse index, and amplitude-frequency spectrum cumulative probability, of the grinding force signal through time-domain or frequency-domain analysis, identifying different wear degrees of a grinding wheel, and overhauling the blunt grinding wheel in time; during a steady-state grinding stage, extracting an average amplitude of a tangential grinding force or a frequency spectrum centroid of a power spectrum in real time, and controlling the grinding burn. According to the method provided by the invention, the grinding force online monitoring and real-time signal processing are combined, so that the intelligent monitoring and controlling on grinding wheel-workpiece grinding contact status, grinding wheel wear condition, grinding burn and the like in a whole grinding processing process can be realized; the method for monitoring the grinding wheel wear and grinding burn by using the grinding force has various advantages that the antijamming capability is high, the operation is simple, the programming realization is convenient, the intellectualization is realized and the like.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

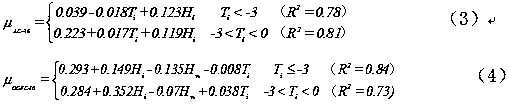

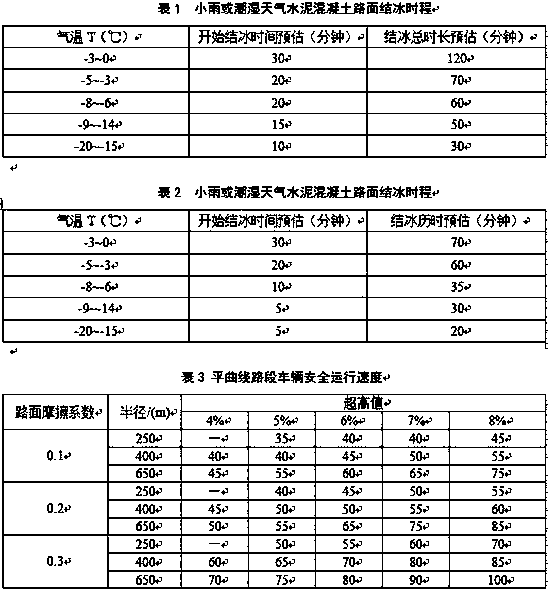

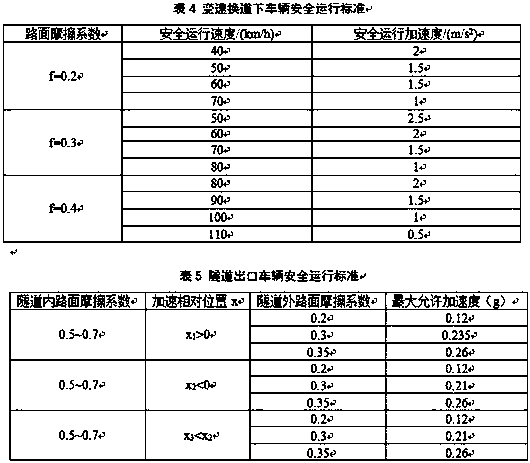

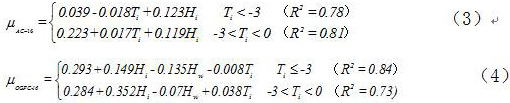

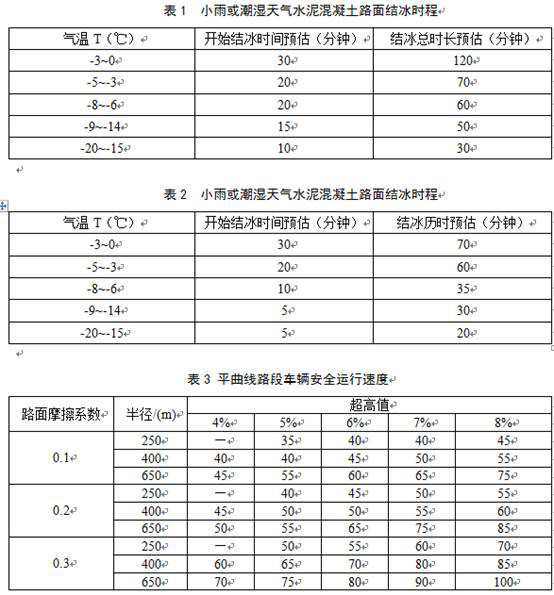

A kind of early warning system and method for icing environment of mountain expressway

ActiveCN109035681BReal-time acquisitionSafe and efficient operationArrangements for variable traffic instructionsAlarmsInformation processingEnvironmental resource management

The invention discloses an early warning system for icing environment on a mountainous expressway, which is composed of the following functional systems connected by a communication system, an information monitoring and acquisition system, an information processing system, a decision support system, an information release system and an evaluation system. Meteorological information monitoring and acquisition sensors, road surface condition information monitoring and acquisition sensors, and traffic flow detection sensors are integrated and arranged in the most unfavorable low-temperature environment section of mountainous expressways, which effectively overcomes the differences, suddenness and Regional incompatibility defects. Collect meteorological information, road condition information and traffic flow information data in real time to provide data support for the information processing system. Based on the analysis results of the information processing system, the decision support system comprehensively determines the relatively optimal safety management countermeasures based on the analysis results of the information processing system, taking into account safety, traffic level and economic indicators, and transmits them to the site through the information release system for release, finally realizing safe and efficient operation on icy roads .

Owner:郭忠印 +2

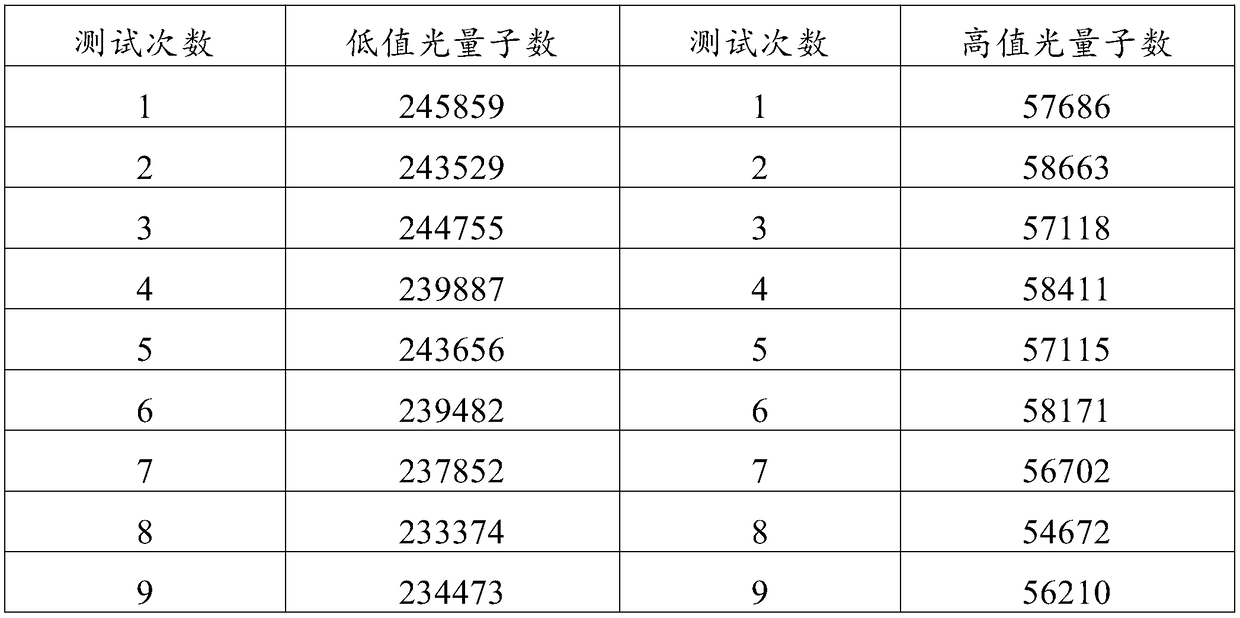

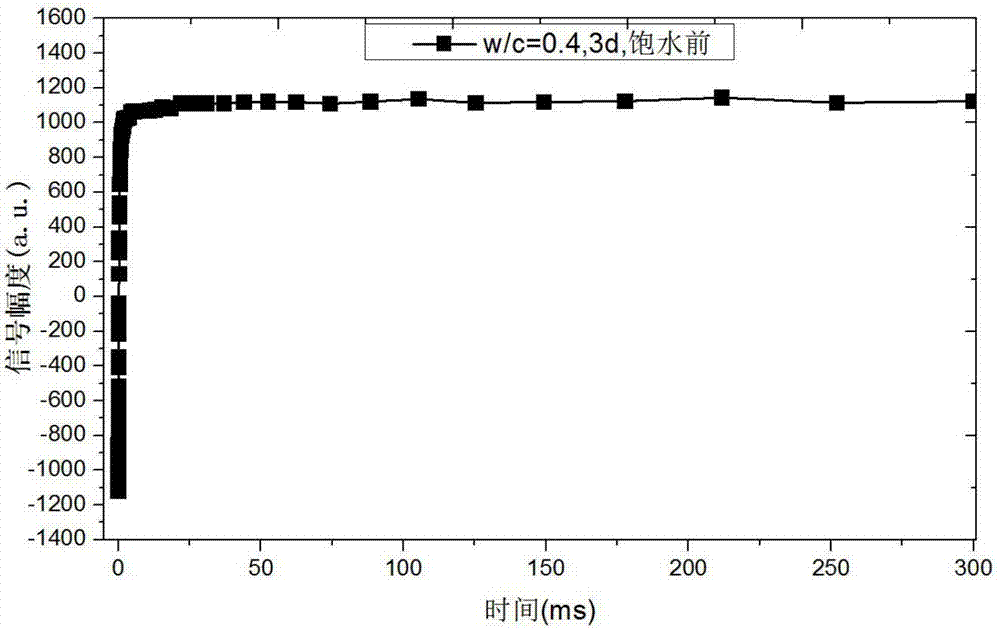

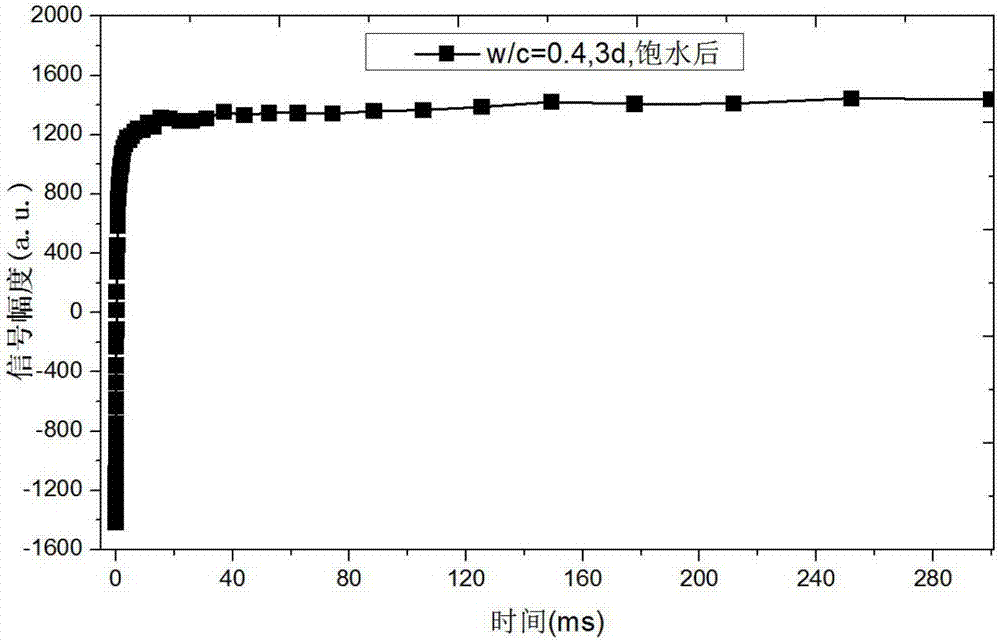

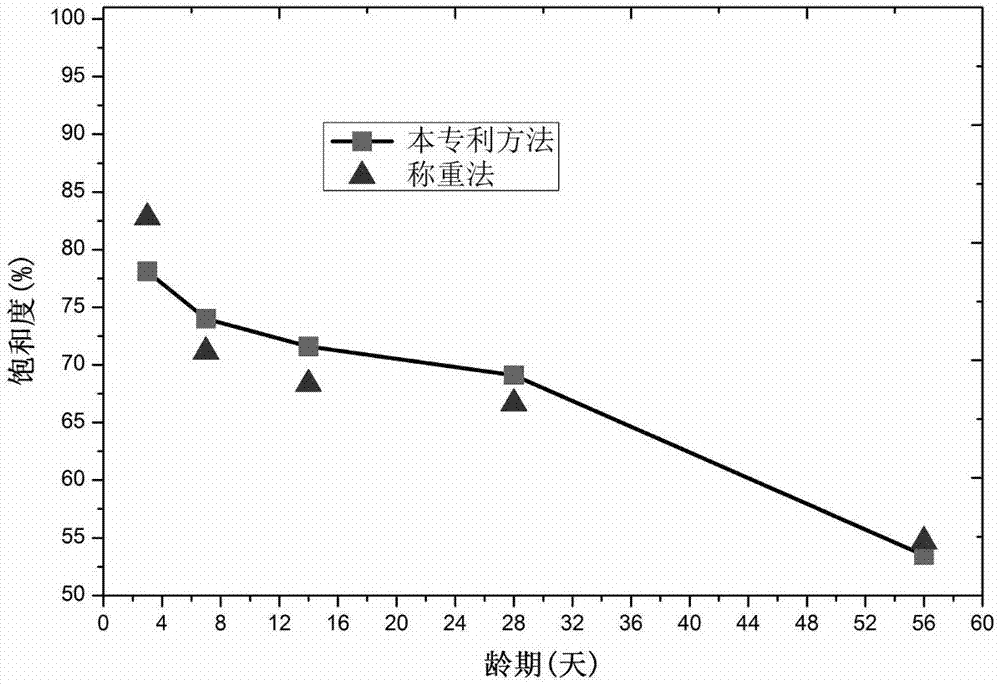

A method for detecting saturation of cement-based materials based on low-field nuclear magnetic resonance technology

ActiveCN106053512BReduce dosageEasy to testAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceLow field nuclear magnetic resonance

The invention relates to a cement-based material saturation degree detection method based on a low field nuclear magnetic resonance technology. The saturation degree detection can be accurately realized by using a fire-new design concept is used and combining the cement-based sample nuclear magnetic resonance longitudinal relaxation restoration signal detection; the test process is convenient and fast; the sample consumption is low; in addition, the nuclear magnetic resonance longitudinal relaxation restoration signal detection process is convenient and fast; the interference is small; the back calculation is not needed; the data processing quantity is small.

Owner:HOHAI UNIV

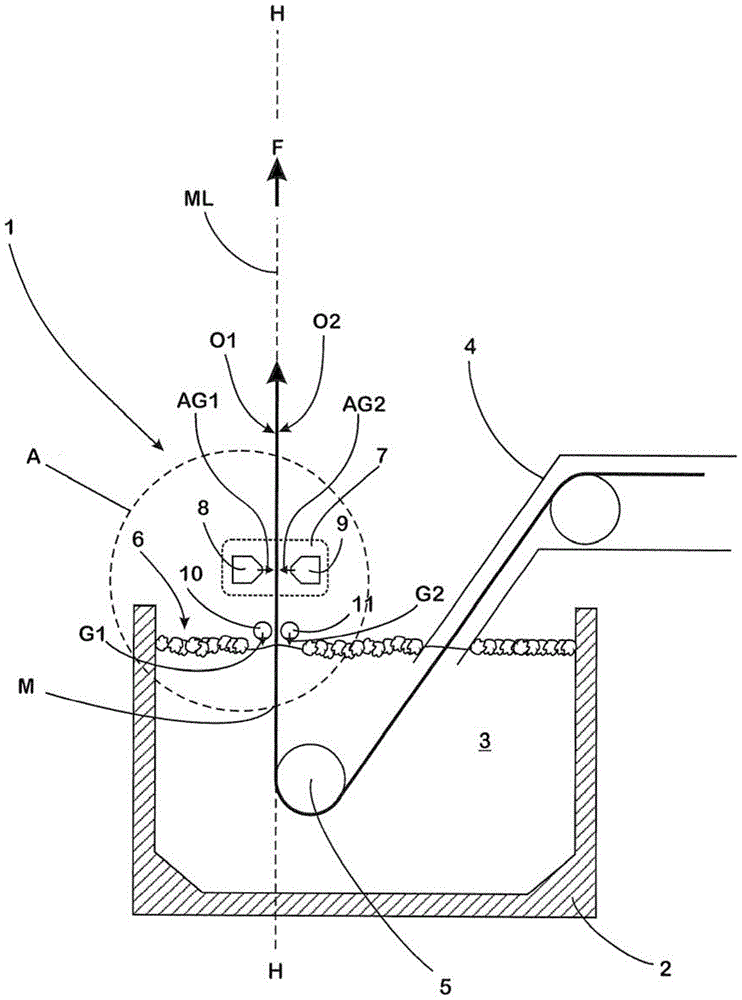

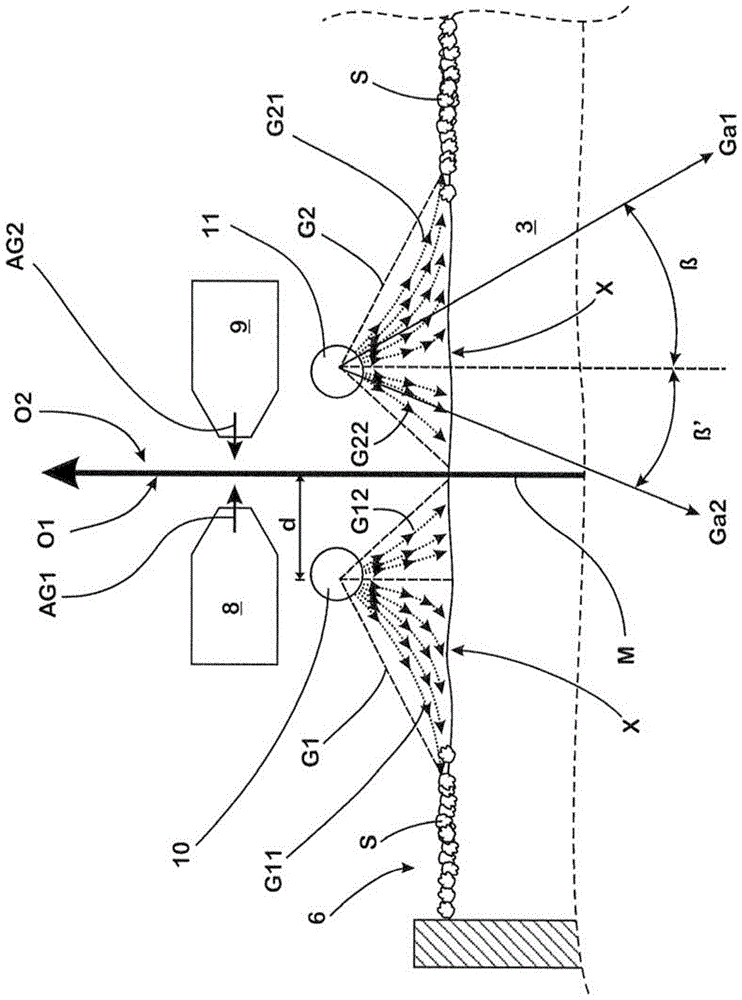

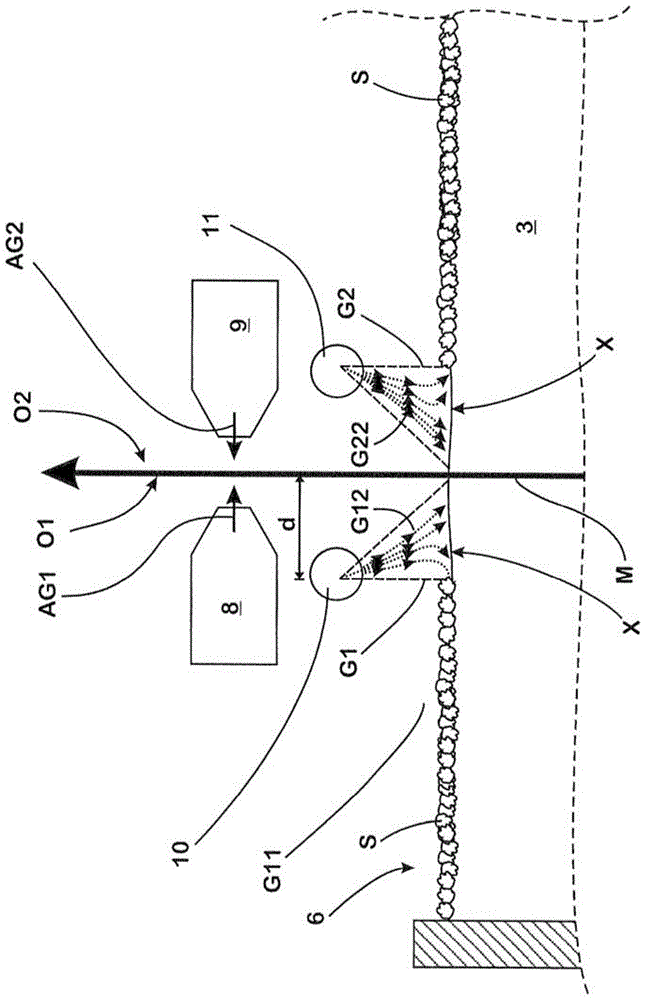

Method and apparatus for hot-dip metal coating of metal strip

InactiveCN103998641BLow risk of surface defectsEasy to useHot-dipping/immersion processesLiquid surface applicatorsMetal coatingMolten slag

The invention relates to a device and a method for hot-dipping a metal strip (M) with a metal coating, in the method: the metal strip (M) passes through the molten pool (3) continuously; (3) Thickness of the metal coating on the metal strip (M) at the exit; the slag (S) on the molten pool (3) is removed from the metal strip (M) leaving the molten pool (3) by means of the gas flow (G1, G2) remove. In order to prevent the molten slag from touching the metal strip leaving the bath in a simple and cost-effective manner in this method and thus ensure an optimum surface quality, the invention proposes that by means of at least one nozzle (10, 11) Directing the gas flow (G1, G2) extending over the width (B) of the metal strip (M) to the surface (6) of the molten pool (3) to remove the slag (S) from the metal strip (M).

Owner:THYSSENKRUPP STEEL EURO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com