Method for testing sealing performance of shield pipe sheet waterproof gasket

A waterproof gasket and sealing performance technology, applied in the field of transportation, can solve the problems of no effective method for visually testing the contact pressure, affecting the performance and operation safety of the tunnel, and no joint safety, etc., achieving small errors, good equipment durability, Effects with little interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

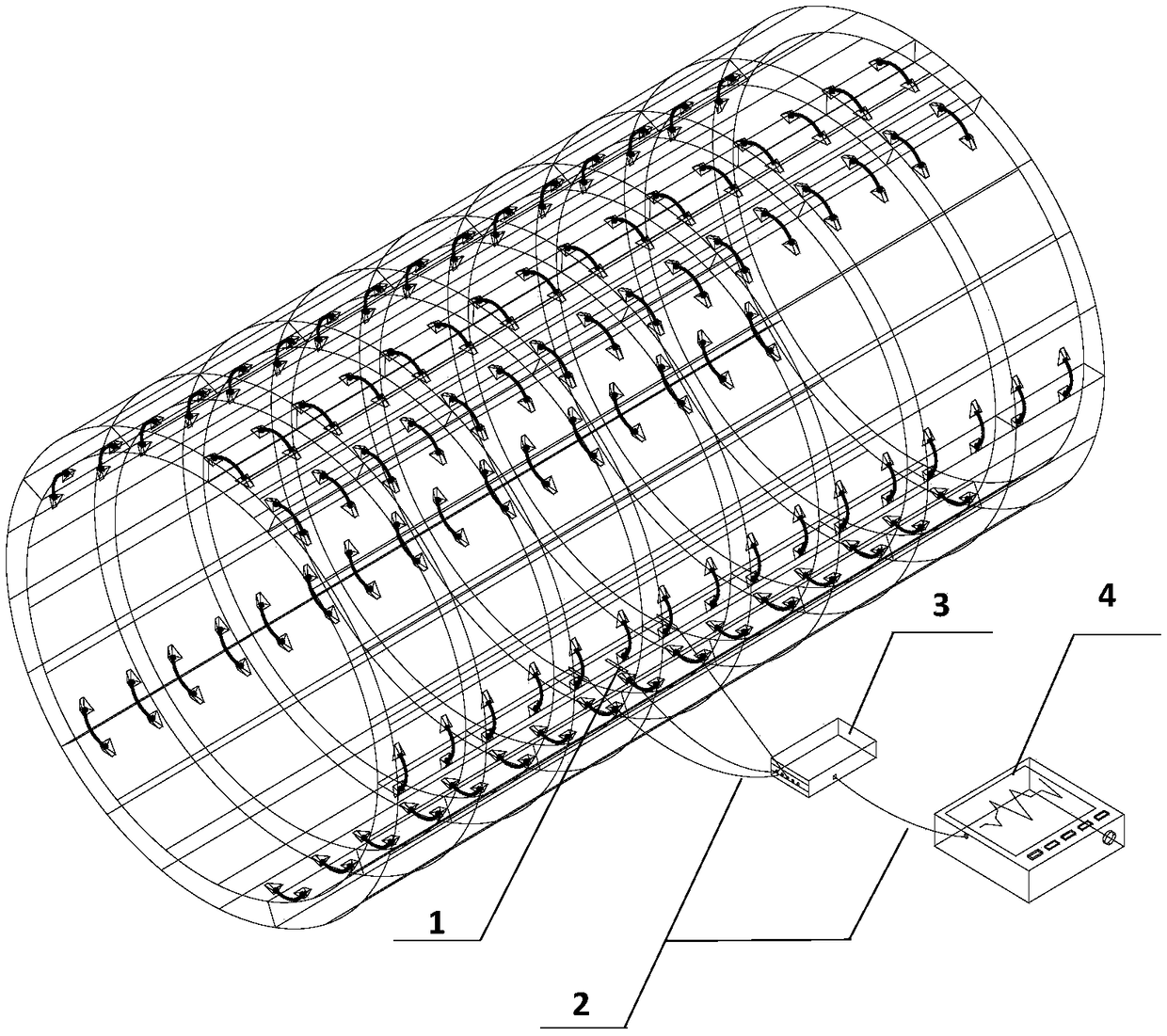

[0036] Such as Figure 5 Shown is a method for testing the sealing performance of the shield segment waterproof gasket of the present invention, comprising the following steps:

[0037] Step S1: use a jack to calibrate the relationship between stress and voltage of the piezoelectric film sensor 1;

[0038] Step S2: Paste the calibrated piezoelectric film sensor 1 on the waterproof gasket 6 at the designated measuring point;

[0039] Step S3: Keep the calibrated contact port position of the piezoelectric film sensor 1 and assemble the segment 5 of the shield machine;

[0040] Step S4: Connect the contact port with various external devices and collect and record electrical signals;

[0041] Step S5: Invert the corresponding contact pressure from the collected electrical signal according to the relationship between stress and voltage, and compare it with the contact pressure specified by the waterproof failure index.

[0042] Such as figure 1 and figure 2 Shown is the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com