Phased array probe and phased array instrument

A phased array probe and transducer technology, applied in instruments, scientific instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of time-consuming, numerous processes, low work efficiency, etc. The effect of solving ineffective and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

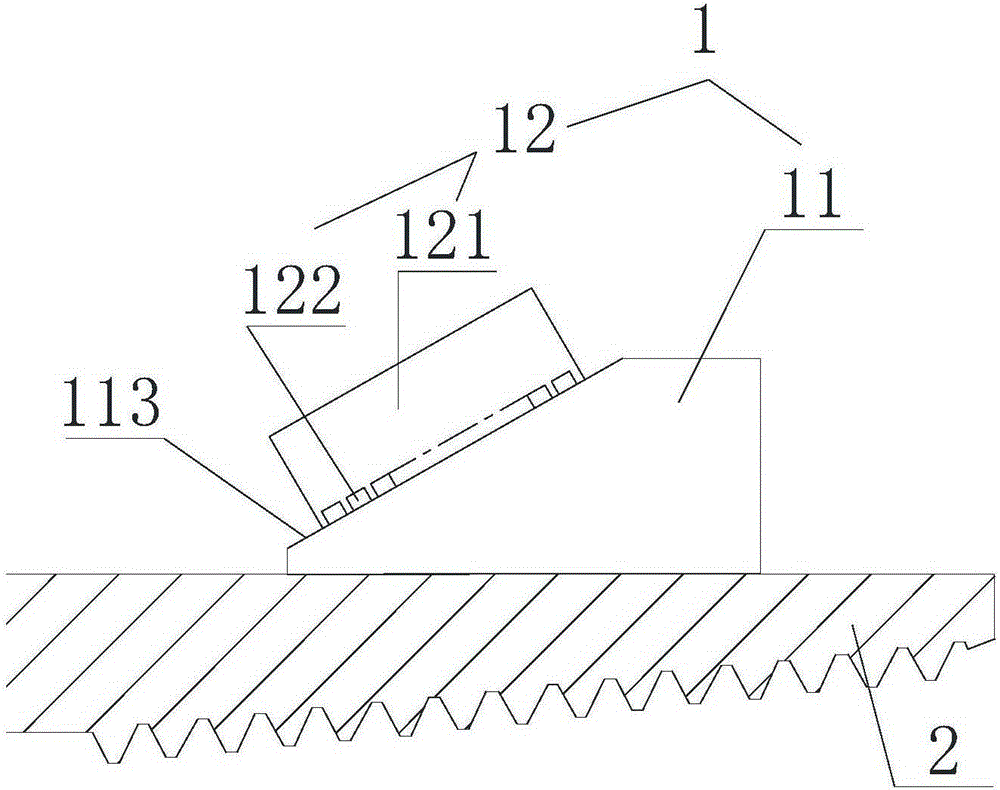

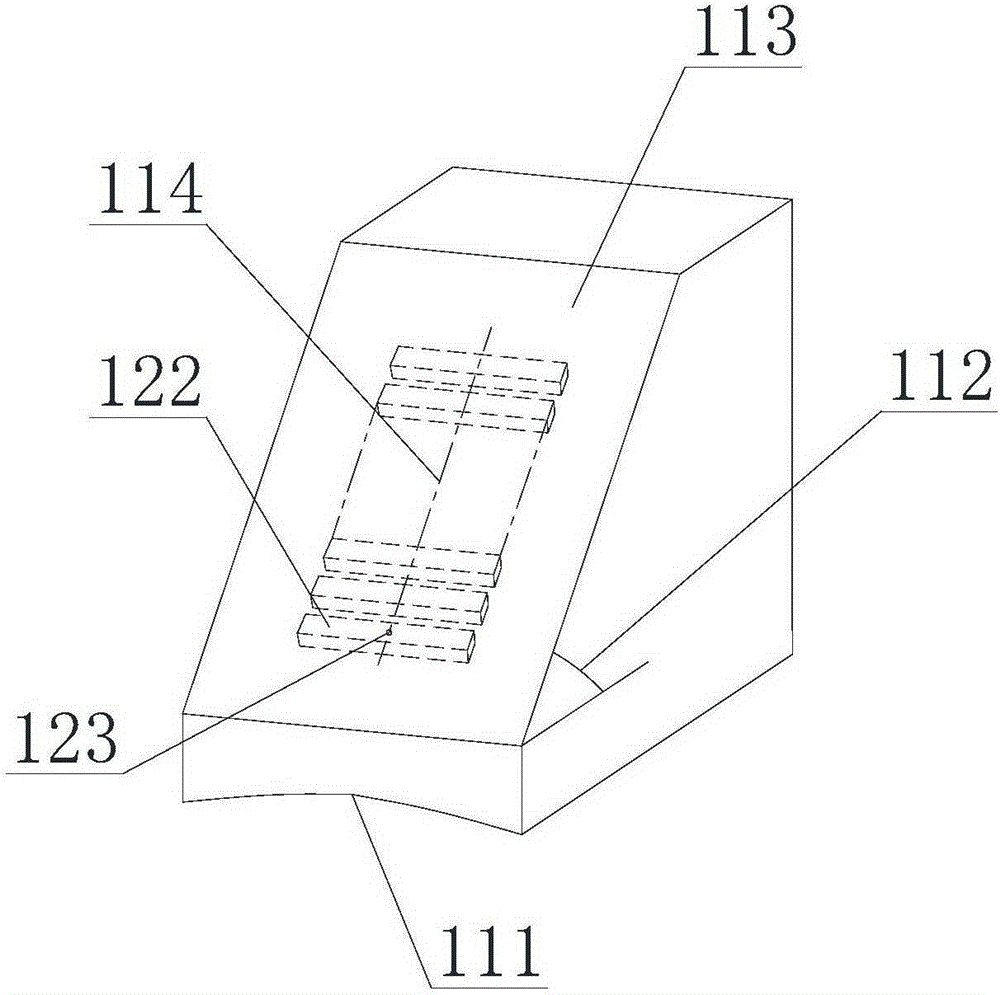

[0025] like figure 1 and figure 2 As shown, the embodiment of the present invention provides a phased array probe 1 for flaw detection of the oil casing collar 2, including: a wedge 11, the wedge 11 includes a concave arc-shaped bottom surface 111 and a concave arc-shaped bottom surface 111 is opposite to the slope 113, the slope 113 forms a preset angle 112 with the central axis of the concave arc bottom surface 111; the transducer 12 arranged on the slope 113, the transducer 12 includes a body 121 and a wafer 122, and the body 121 includes a connection surface, the chip 122 is embedded in the connection surface, the connection surface is opposite to the slope 113, the chip 122 is attached on the slope 113, the number of chips 122 is multiple, and the plurality of chips 122 are along the first straight line in the direction of inclination o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com