Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "Instructive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

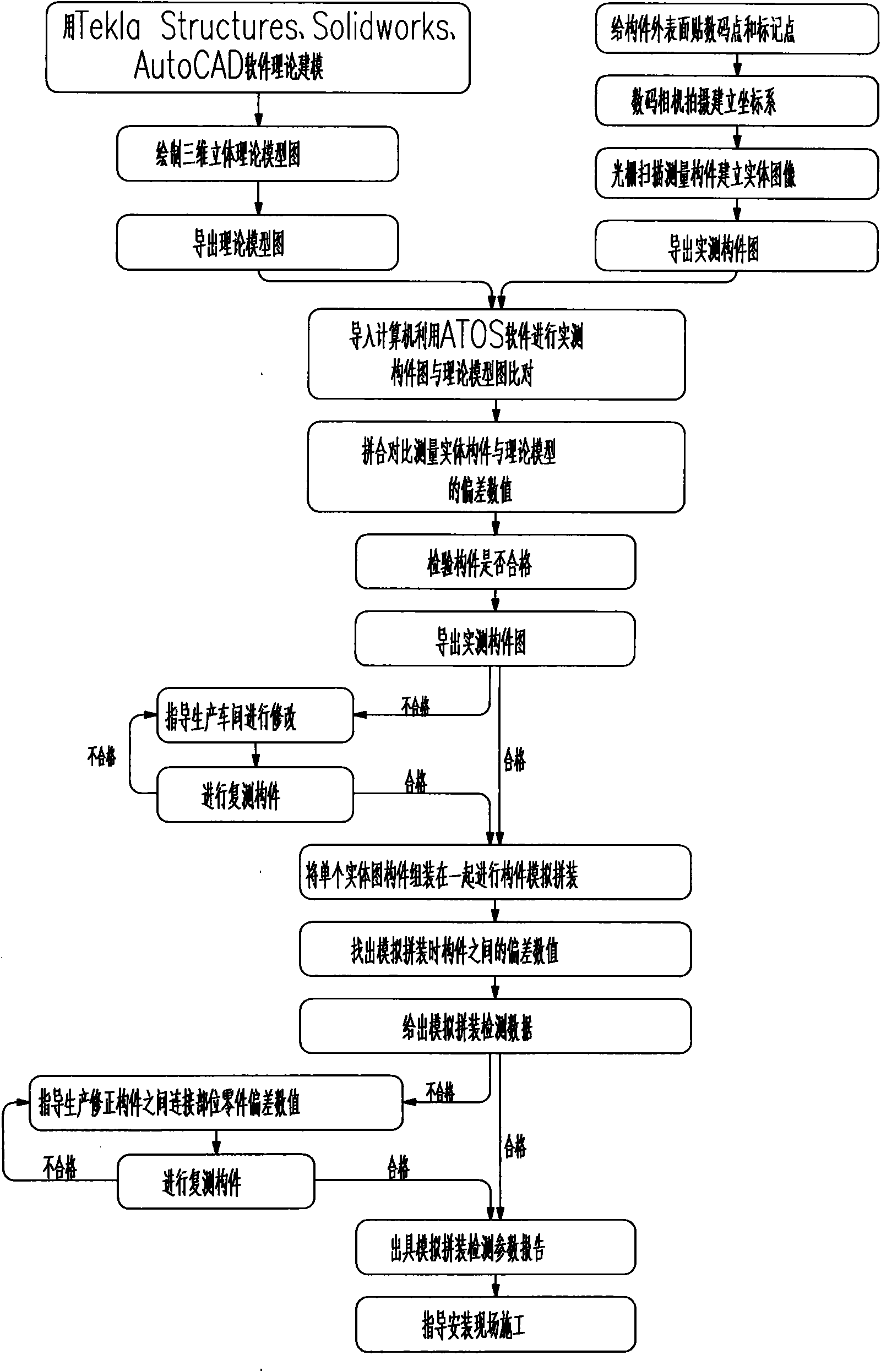

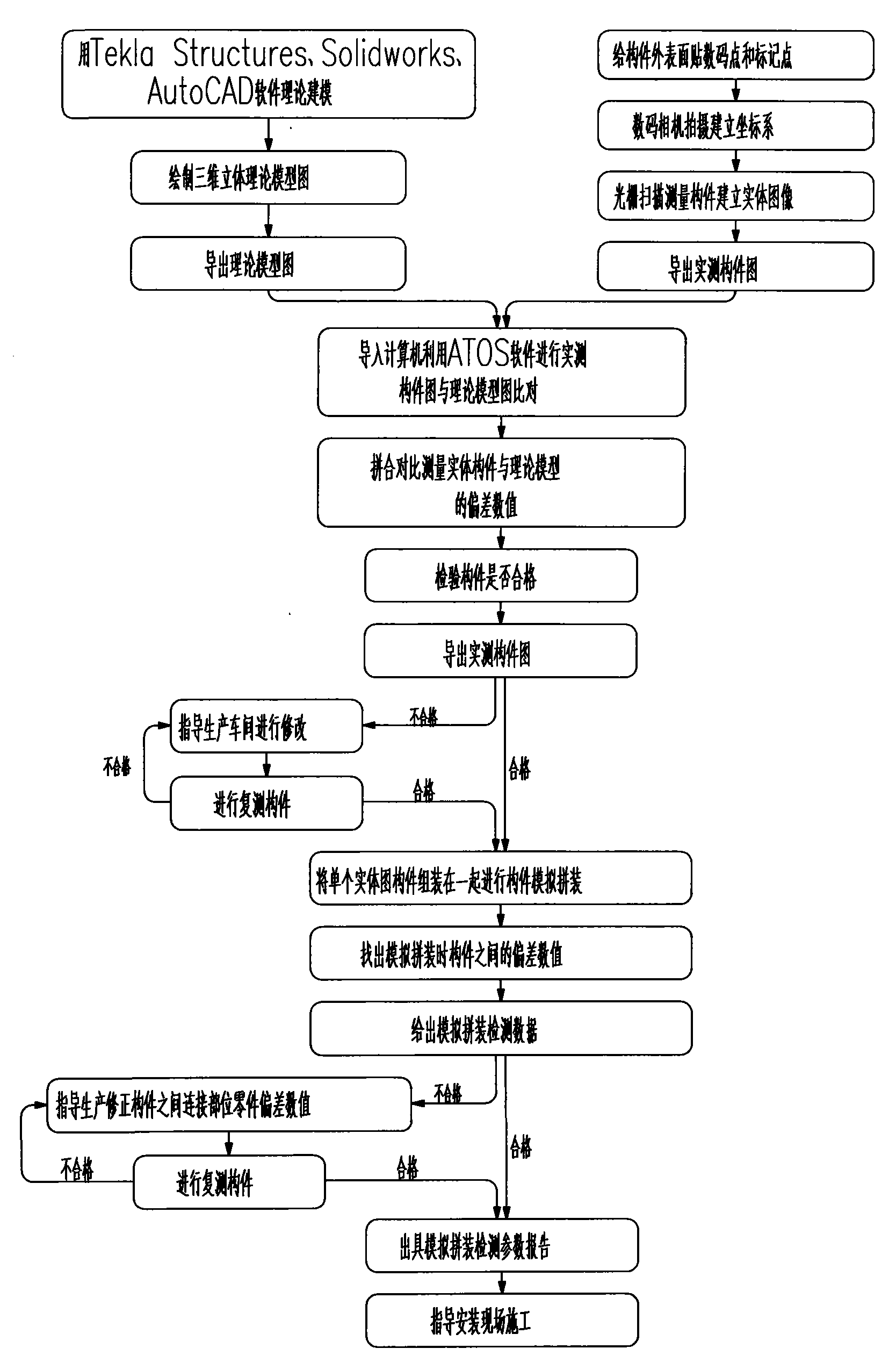

Computer simulation pre-assembly method of construction steel structure

InactiveCN101882180AEasy to operateShort timeSpecial data processing applications3D modellingGratingComputer software

The invention relates to a pre-assembly method of a construction steel structure, in particular to a computer simulation pre-assembly method of the construction steel structure. The method comprises the following steps: drawing out a three-dimensional standard map of all members of a construction structure according to a design drawing through computer software and establishing a three-dimensional model drawing and a standard map library; using a 3D optical scanning measuring system to carry out three-dimensional raster scanning on the members, measuring the entity members, and introducing into a computer for obtaining a three-dimensional stereo image; using the computer software to process the measured entity members, and being compared with the three-dimensional model drawing for inspecting whether the members are qualified or not; using the actually measured members to carry out simulation assembly on the whole construction structure; finding out amount of deflection of connecting parts between the actually measured members and the simulation assembly members; and providing a member simulation assembly detection parameter report after the simulation assembly of the actually measured members is qualified, and guiding the installation and the field construction. The method has simple operation, can cover the full process of the member overall part of the construction steel structure, and has representativeness and guidance; and one-time development can be utilized repeatedly, and the waste of resources can be further avoided.

Owner:CHINA 22MCC GROUP CORP

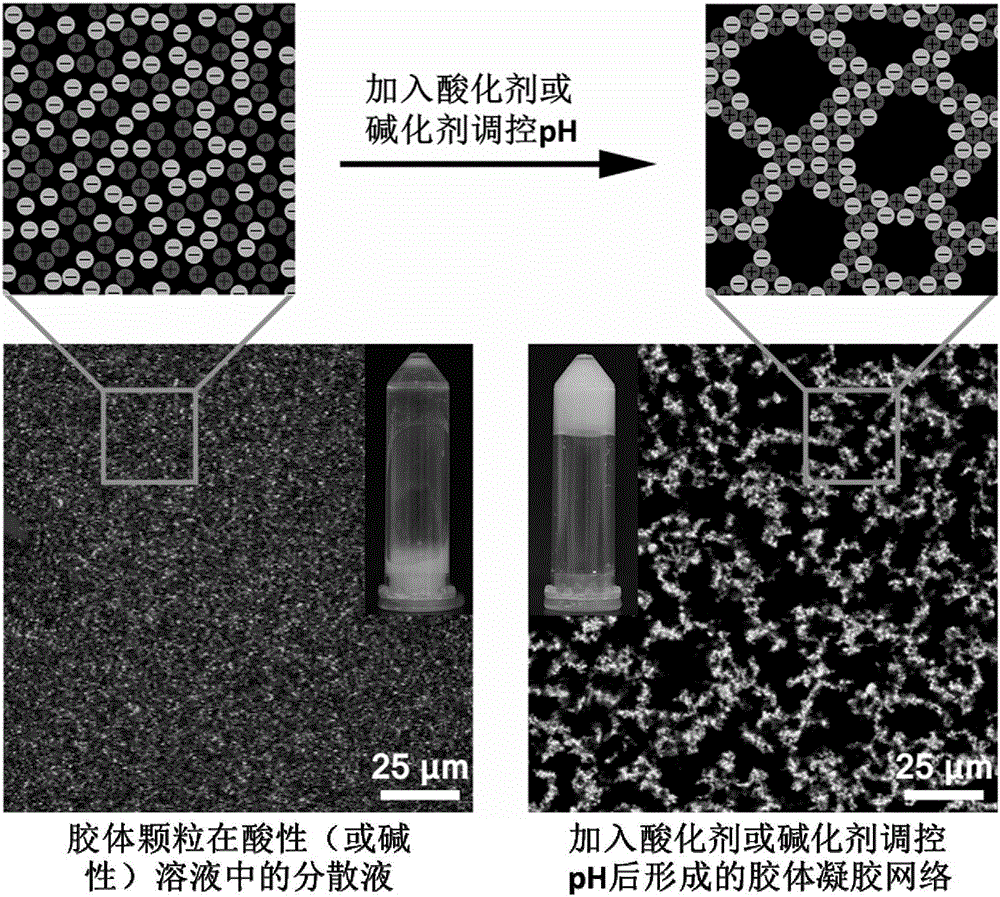

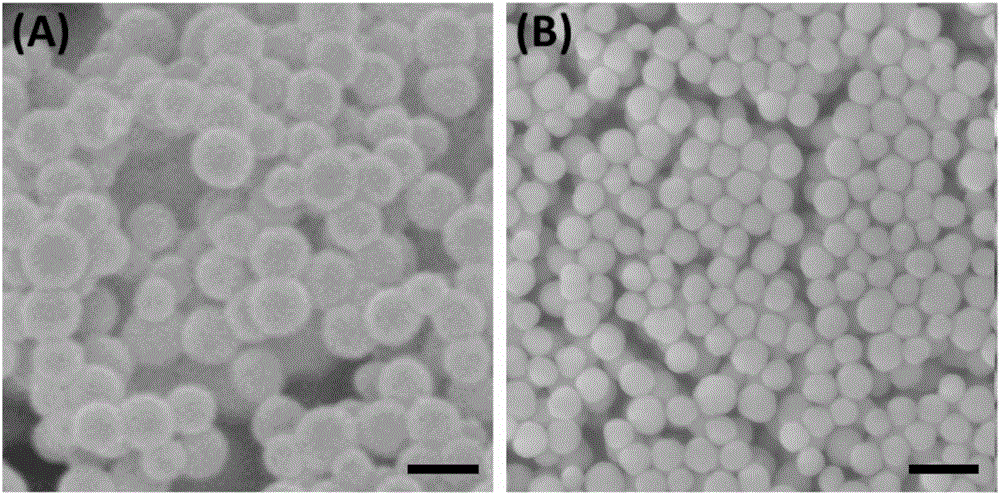

Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

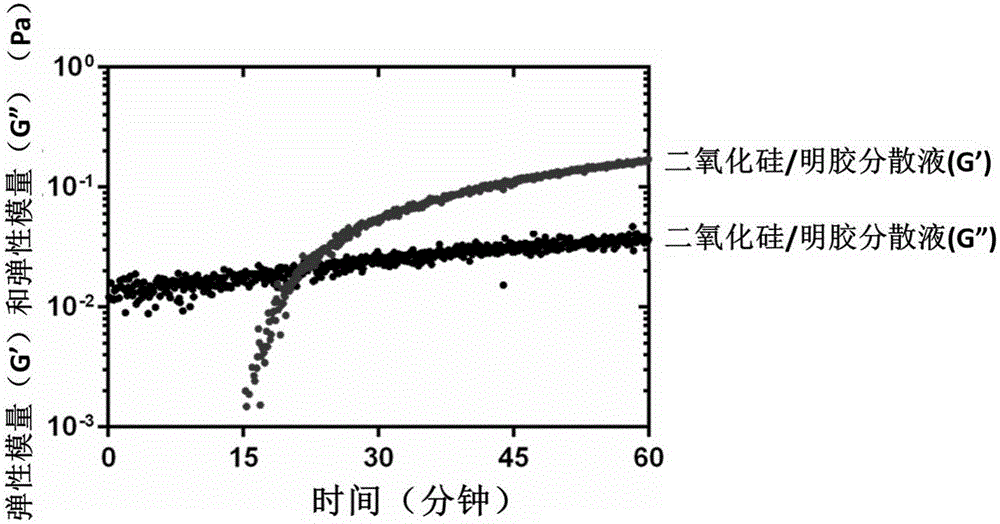

InactiveCN105796478AHigh strengthImprove self-healing abilityAerosol deliveryInorganic non-active ingredientsBiological materialsSilicon dioxide

The invention discloses a nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and a preparation method and application thereof. According to the preparation method, two-phase colloid particles with opposite electric charges are uniformly blended in an alkaline or acidic environment, an acidifying agent or alkalizing agent is added to induce the pH of the solution to recover the neutrality, electrostatic self-assembly among the two-phase colloid particles is initiated, and a uniformly-dispersed composite gel network is formed, wherein the gel is high in mechanical strength and wide in regulation and control range, the elasticity modulus of the gel can be regulated and controlled within the range of 10 Pa-100 kPa, and the self-repairing efficiency of the gel is higher than or equal to 100%. The silicon dioxide-gelatin composite colloid gel which has both the high mechanical strength and the self-repairing performance is finally and successfully prepared, and it is verified that the composite gel still can quickly recover the mechanical strength after being broken by shear force many times; in addition, the composite gel has the excellent injectable property and plasticity and can be used for an in-vitro cell culture matrix material by serving as an injectable biological material.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

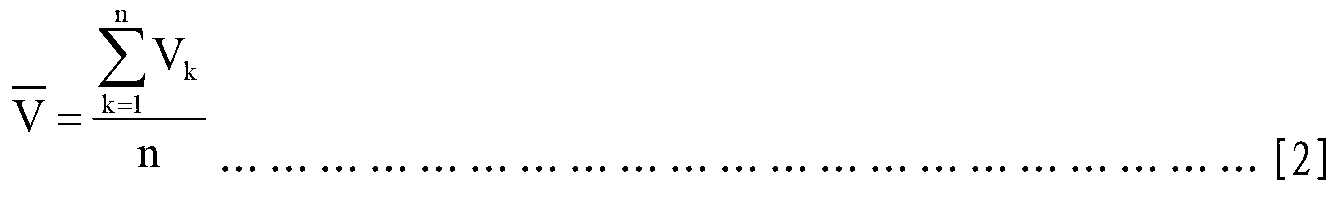

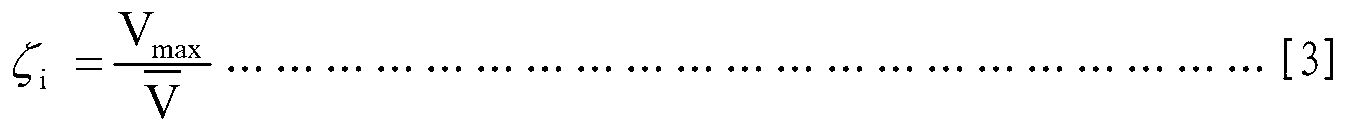

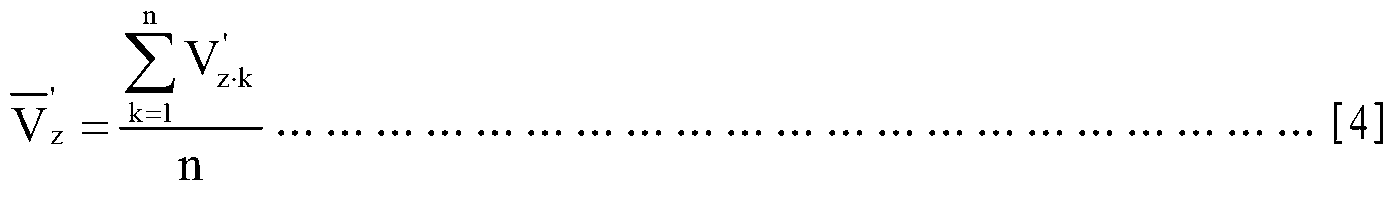

Ground load determination method of multi-fulcrum airplane

InactiveCN103324778AReduce the number of research trialsSimple structural designSpecial data processing applicationsAviationJet aeroplane

The invention belongs to the field of aviation undercarriages and particularly relates to a ground load determination method of a multi-fulcrum airplane. According to the ground load determination method of the multi-fulcrum airplane, by means of equivalent conversion, a static indeterminacy calculation of the multi-fulcrum airplane is converted into a static determinacy calculation, further uneven distribution coefficients of multi-strut loads are introduced, load boundary values in every structural design of undercarriages can be effectively guaranteed, therefore, certain guiding functions are provided for optimizing the structural designs of the multi-strut undercarriages and improving the accuracy of the design of the multi-strut undercarriages. Besides, the calculation idea of the ground load determination method of the multi-fulcrum airplane is clear and rigorous, the calculation method is reliable and easy to comprehend and master, so that the ground load determination method of the multi-fulcrum airplane has a broad application prospect in engineering design of the multi-strut undercarriages. During the actual usage, the quantity of the research trials of the loads of the multi-strut undercarriages can be reduced by applying the ground load determination method of the multi-fulcrum airplane, so that obvious advantages of saving the design cost and shortening the design cycle of the multi-strut undercarriages can be achieved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

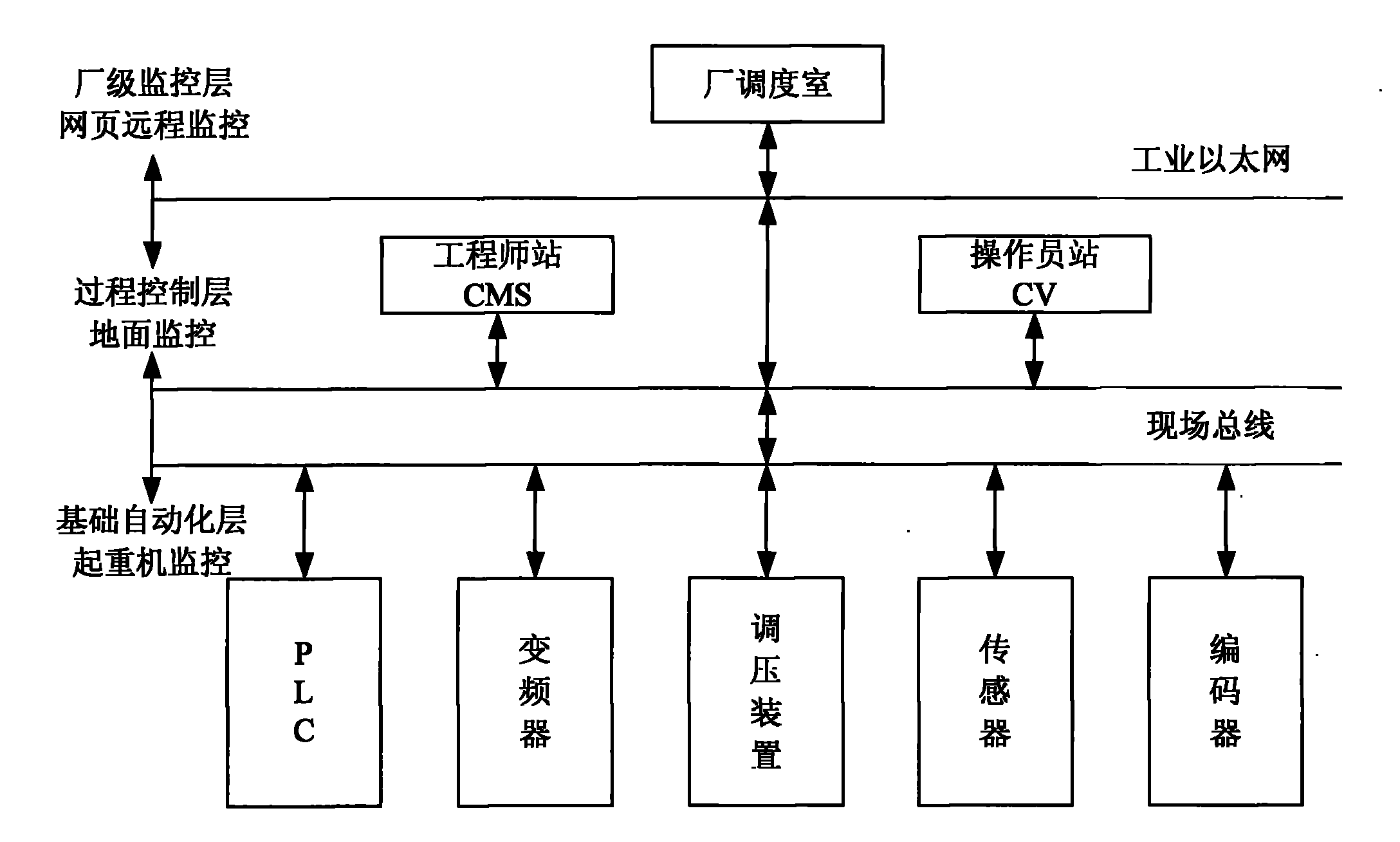

Information management system of crane

InactiveCN101850934AImprove versatilityImprove maintenance efficiencySafety gearExpert opinionOperational system

The invention discloses an information management system of a crane. The information management system of the crane comprises a crane operating system, a data recording system, a fault monitoring system, an equipment management system, a component life monitoring system and a fault diagnosing and analyzing system, wherein the component life monitoring system records the operating time of the important components of the crane in real time, monitors the relevant environments in which the components are positioned and the operating situations of the components by means of a sensing element, i.e. monitoring the operating time, the relevant environments and the operating situations of a contactor, a brake, a motor, a frequency converter and a voltage regulator in the crane, and acquires the residual service life of the components by carrying out difference value computing on the known service life of the components and the monitoring results; and the fault diagnosing and analyzing system is used for calling expert opinions corresponding to an event input by field staff from a database and displaying the expert opinions for the field staff through a display device. The system of the invention has strong logic control performance, high reliability and favorable compatibility and generality, and is suitable for being widely popularized in hoisting equipment.

Owner:大连美恒时代科技有限公司

Method for constructing multi-level three-dimensional terrain model through multi-source data fusion

PendingCN111724477AGood data interactionImprove interactivityImage enhancementImage analysisComputational scienceTerrain

The invention provides a method for constructing a multi-level three-dimensional terrain model through multi-source data fusion. The method sequentially comprises the steps of image control point measurement and setting, unmanned aerial vehicle flight and data processing, three-dimensional laser scanning data acquisition and processing, terrain design and satellite terrain processing, multi-sourceimage data fusion, multi-source point cloud data fusion and multi-source DEM fusion. Finally, a three-dimensional terrain model is constructed, a single-source DOM + single-source DEM fusion mode, amulti-DOM + single-source DEM fusion mode and a multi-DOM + multi-DEM fusion mode are established, and a multi-level and multi-precision three-dimensional real terrain model is constructed. The problems that an existing three-dimensional terrain model is low in precision, single in obtaining mode, poor in expression effect, poor in construction guidance and the like are solved. The invention belongs to the field of constructional engineering.

Owner:CHINA RAILWAY ERJU 1ST ENG

Infrared heating testing device and testing method for bituminous pavement

InactiveCN105319238AImprove heating efficiencyMeet the requirements of hot-in-place regenerationMaterial heat developmentInfraredData acquisition

The invention discloses an infrared heating testing device and testing method for bituminous pavement, and aims to enable the measured test data conclusion to play a theoretical guiding function on practice, and further enable the accuracy to be high, the simulation performance to be high and operation to be simple; the infrared heating testing device comprises a test bed framework, wherein an infrared ray generation device is arranged on the test bed framework; the infrared ray generation device is connected with an infrared ray generation controller, a liquefied petroleum gas inlet control valve and a variable-frequency air blower; the liquefied petroleum gas inlet control valve is connected to a liquefied petroleum gas source; the variable-frequency air blower is connected with an air source; a test block tray used for placement of a pitch test block is arranged at the lower end of the infrared ray generation device; an infrared radiation flow sensor capable of collecting the infrared ray radiation quantity of the infrared ray generation device is arranged on the test block tray; a plurality of temperature sensors are arranged in the pitch test block during testing; the infrared radiation flow sensor and the temperature sensors are all connected to a data acquisition instrument; the data acquisition instrument is connected to a computer capable of displaying test data.

Owner:CHANGAN UNIV

35kV heat shrink power cable intermediate connector manufacturing technology method

InactiveCN105281260AImprove pass rateAvoid excessive wasteApparatus for joining/termination cablesEngineeringPhase splitting

The invention discloses a 35kV heat shrink power cable intermediate connector manufacturing technology method comprising the following steps that an external sheath, an armor and an internal sheath are cut; cable phase splitting is performed, and excessive cable wire cables are sawed; a copper shielding layer and an external semi-conductive layer are cut; wrapping of stress control glue is performed, and heat shrinkage of a semi-conductive stress control tube is performed; wire core tail end insulation is stripped, a "pencil stump" is cut and sharpened, and an internal semi-conductive layer is reserved; tube material and a copper shielding mesh sleeve are sleeved in turn; crimping of a connecting tube, wrapping of a shielding layer and additional wrapping of an insulating tape are performed; heat shrinkage of internal and external insulating tubes and a shielding / insulating composite tube is performed; wrapping of a waterproof adhesive tape and a semi-conductive tape is performed; the copper shielding mesh sleeve is fixed, and the copper shielding layers of the two ends are connected; three phases are tightened, heat shrinkage of the internal sheath is performed and the armor layers of the two ends are connected; and a metal sheath and an external sheath tube are fixed. The technology method has instructiveness and can give clear processing steps to work personnel so that the manufactured intermediate connector is enabled to be high in percent of pass, excessive waste can be avoided and cost can be saved.

Owner:STATE GRID CORP OF CHINA +1

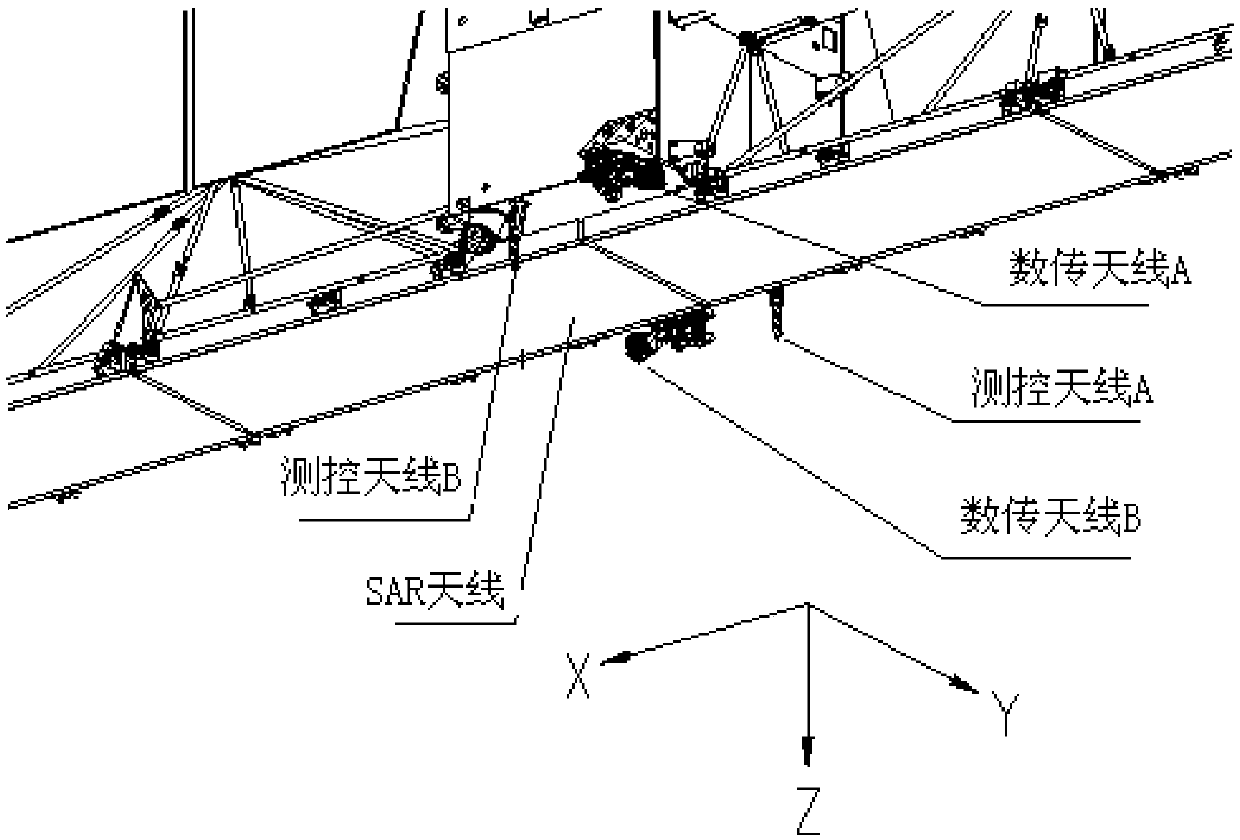

Satellite communication link analysis method under on-orbit complex environment

ActiveCN107733515AEfficient analysisSingle adaptabilityRadio transmissionAntenna designTelecommunications link

The invention discloses a satellite communication link analysis method under an on-orbit complex environment. By comprehensively considering a satellite attitude and orbit, a structure layout configuration and component rotating mechanism, load antenna shielding, data transmission antenna shielding, EMC design, satellite-earth communication link parameter, measurement-control antenna design and model selection, a precise satellite model is constructed, and a method for analyzing a satellite communication link under the on-orbit complex environment is designed; the quantified and refined measurement-control segmental arc coverage feature is obtained by simulating through the above-mentioned method by using the actually measured measurement-control antenna directional pattern information under the astral environment, the satellite configuration layout, the measurement-control data transmission system performance improvement, the user on-orbit working mode and the use strategy design canbe optimized, the measurement-control segmental arc is maximally utilized to perform the unlink emergency control or the downlink telemetering monitoring, and the method is especially important for the security of the whole satellite.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Multifunctional electronic magic cube

InactiveCN104857702AEfficient Prompt Recovery StepsRemove obstaclesIndoor gamesDisplay deviceEngineering

The invention discloses a multifunctional electronic magic cube which comprises a magic cube main body, a solar panel, a mini-type chip and a display, wherein the magic cube main body comprises N cubic blocks; the mini-type chip is connected with the solar panel and the display; the display further comprises a display screen arranged on the corresponding cubic block; the solar panel is used for supplying power to the mini-type chip and the display; the mini-type chip is used for detecting the positions of the cubic blocks in the magic cube main body, controlling the next trend of the magic cube main body according to the current positions of the cubic blocks, and displaying the trend of the magic cube main body on the display screen; the display screen is used for showing the next trend of M cubic blocks on the same edge of the magic cube main body. The multifunctional electronic magic cube has the advantages that rotation can be carried out according to prompt information on the display screen, so that the recovery work can be guided better, the recovery steps of the magic cube can be prompted effectively, a beginner can be helped during the recovery of the magic cube, the barrier of the beginner is eliminated, and the learning interest is improved.

Owner:GUANGXI ZHITONG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Concrete faced rockfill dam construction progress simulation method based on parameter analysis and real time monitoring

ActiveCN104143023ASolve the dynamic determination problemHigh precisionSpecial data processing applicationsParameter analysisTime dynamics

The invention belongs to the technical field of concrete faced rockfill dam construction, and discloses a concrete faced rockfill dam construction progress simulation method based on parameter analysis and real time monitoring. In order to achieve construction parameter real-time dynamic obtaining during simulation, improve simulation precision, enhance simulation real-time performance and enable simulation results to be used for guiding actual construction, according to the technical scheme, the concrete faced rockfill dam construction progress simulation method based on parameter analysis and real time monitoring comprises the steps that (1) a concrete faced rockfill dam construction progress simulation program is built, (2) construction parameters are analyzed, (3) statistical analysis is carried out on key construction parameter monitoring data, (4) the construction progress is simulated and calculated, and (5) key construction links are analyzed. The concrete faced rockfill dam construction progress simulation method based on parameter analysis and real time monitoring is mainly applied to concrete faced rockfill dam construction.

Owner:TIANJIN UNIV

Method for detecting high temperature performance of iron ore powder

The invention relates to a method for detecting high temperature performance of iron ore powder. The method comprises the steps of drying the iron ore powder, grading the size of the iron ore powder into a grade more than 3mm, a grade in the range of 1 to 3mm and a grade of less than 1mm; adding pure calcium oxide or calcium hydroxide for regulating alkalinity to 0, 1.0, 2.0, 3.0 according to SiO2 amount in the iron ore powder; adding an organic adhesive and water, stirring the organic adhesive, water and the iron ore powder to obtain a mixture, and pressing the mixture into cakes; heating the cakes in different temperature sections, and judging the difficulty in generating a liquid phase; calculating a fluidity index of the liquid phase, and judging the high temperature performance. Since the high temperature performance of the iron ore powder is determined under the condition of original particles of iron ore, the detection data is instructive and high in applicability; moreover, since the data in a series of alkalinity range is detected, the reflected performance is more comprehensive.

Owner:武汉钢铁有限公司

Mechanical rotary component and household electrical appliance

ActiveCN104916478AAchieve normal workAvoid safety hazardsElectric switchesHome applianceMechanical engineering

The invention provides a mechanical rotary component and a household electrical appliance. The mechanical rotary component comprises an internal rotary knob and an external rotary knob. A rotating shaft hole is formed in the inner end surface of the internal rotary knob; and the external rotary knob sleeves the internal rotary knob. The axes of the rotation centers of the internal rotary knob and the external rotary knob are superposed. A lock hole is formed in one of the internal rotary knob and the external rotary knob and a slide lock unit corresponding to the lock hole is arranged at the other one; the slide lock unit can be inserted into or move out of the lock hole, thereby realizing connection or disconnection of the internal rotary knob with the external rotary knob. According to the mechanical rotary component, when the appliance needs to be started, the slide lock unit is inserted into the lock hole and the internal rotary knob and the external rotary knob are connected; and the internal rotary knob and the external rotary knob can rotate coaxially, thereby realizing normal starting of the appliance. When the appliance is not in use, the slide lock unit moves out of the lock hole and the internal rotary knob with the external rotary knob are separated; and the internal rotary knob dose not rotate with the external rotary knob, so that the appliance can not be started. Therefore, a risk that the children are burned and the appliance works in a no-load state because of starting of the appliance due to misoperation by the children can be eliminated.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

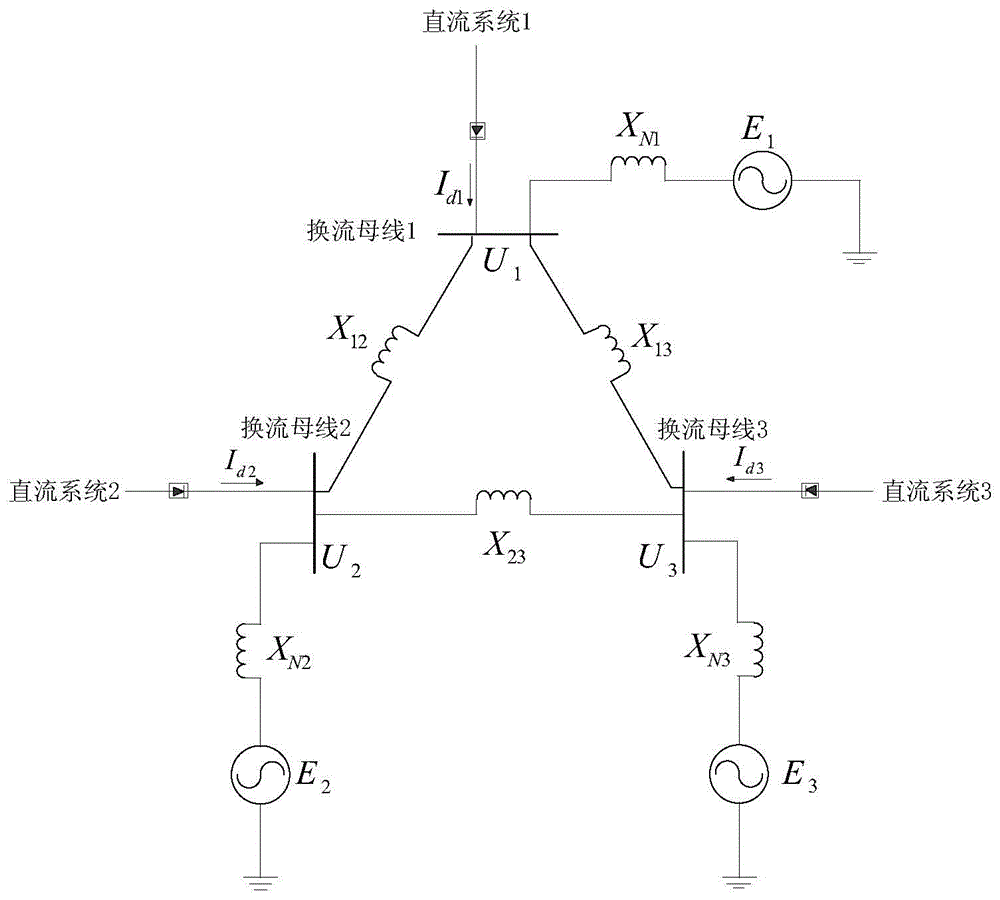

Method for determining risk degrees of mutual influence of multi-infeed alternating current-direct current system inversion stations

The invention discloses a method for determining the risk degrees of mutual influence of multi-infeed alternating current-direct current system inversion stations. The method comprises the following steps that 1, a model corresponding to a multi-infeed alternating current-direct current system is established; 2, disturbance is exerted on a certain inversion station i in the model, so that the voltage Ui of a converter bus i of the inversion station i is reduced by 1%; 3, based on voltage variations delta Uj of other inversion stations j in the multi-infeed alternating current-direct current system, three-phase multi-infeed interaction factors MIIFij of the inversion station i and inversion stations j are calculated; 4, based on the scores of the three-phase multi-infeed interaction factors, the first risk degree Ra and / or the second risk degree Rb of a certain inversion station k are calculated; 5, the first risk degree Ra and / or the second risk degree Rb are compared with reference values (or standard values) so as to determine the risk degrees of one or more inversion stations in the multi-infeed alternating current-direct current system. The method has the guiding effect on finding of potential risks of direct-current station commutation failure and formulation of corresponding prevention measures and can also provide reference indexes for direct-current station address selection.

Owner:STATE GRID CORP OF CHINA +3

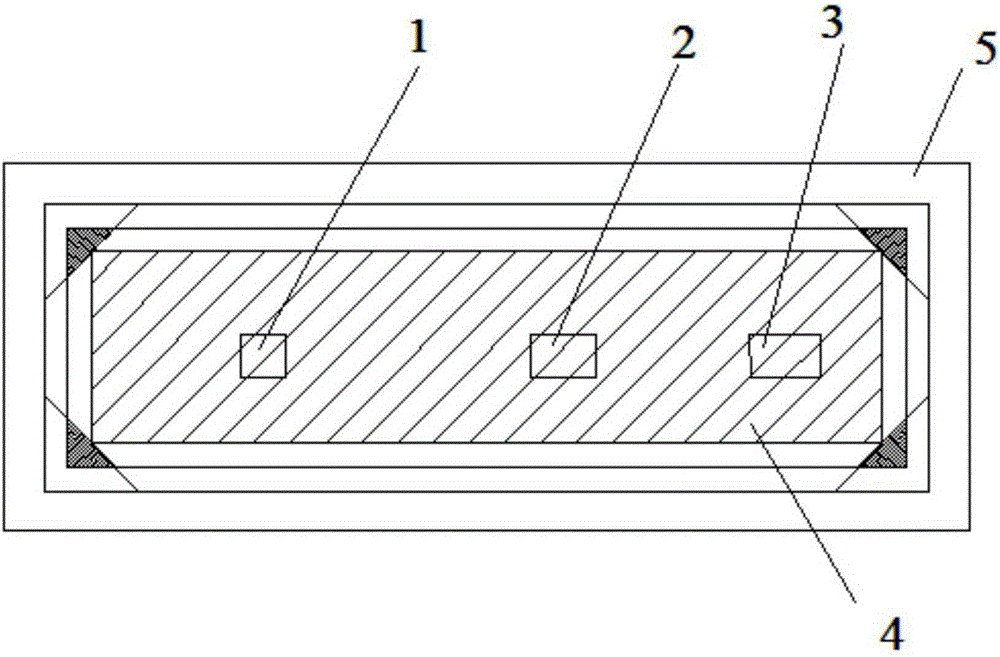

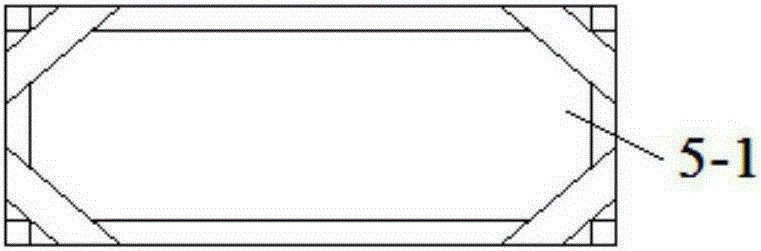

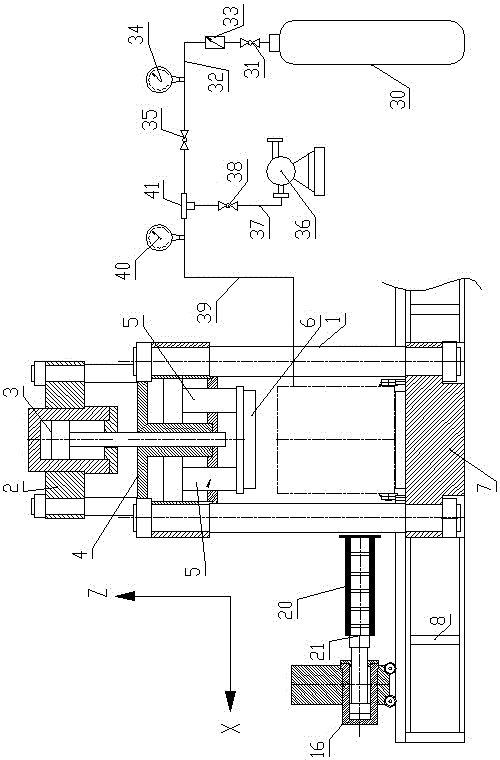

Simulation experiment device and experiment method for coal mine gas dynamic disaster under simulation environment

The invention discloses a simulation experiment device for coal mine gas dynamic disaster under a simulation environment. The device comprises a loading frame, wherein a pneumatic hammer and two Z direction loading hydraulic cylinders are mounted on the loading frame, and a Z direction loading plate is connected between the bottom ends of piston rods of the two Z direction loading hydraulic cylinders; a Y direction guide rail and an X direction guide rail are connected to the bottom of the loading frame; a protruding cylinder body and a Y direction loading hydraulic cylinder are arranged on the Y direction guide rail, and an X direction loading hydraulic cylinder is arranged on an X direction motor trolley; a Z direction loading port is formed in the top of the protruding cylinder body, a Y direction cylinder and an X direction cylinder are connected to the side wall of the protruding cylinder body, and a protruding port is formed in the upper surface of the X direction cylinder; a fourth pipeline with an opened tail end is connected to the X direction cylinder; a vacuum-pumping system and a gas loading system are connected to the protruding cylinder body. The invention further discloses an experiment method using the device, coal mine rock burst, gas flow field, overlaying strata stress and horizontal tectonic stress can be simulated, the experiment simulation degree is improved, and the experiment success rate and the accurate degree are improved.

Owner:HENAN POLYTECHNIC UNIV

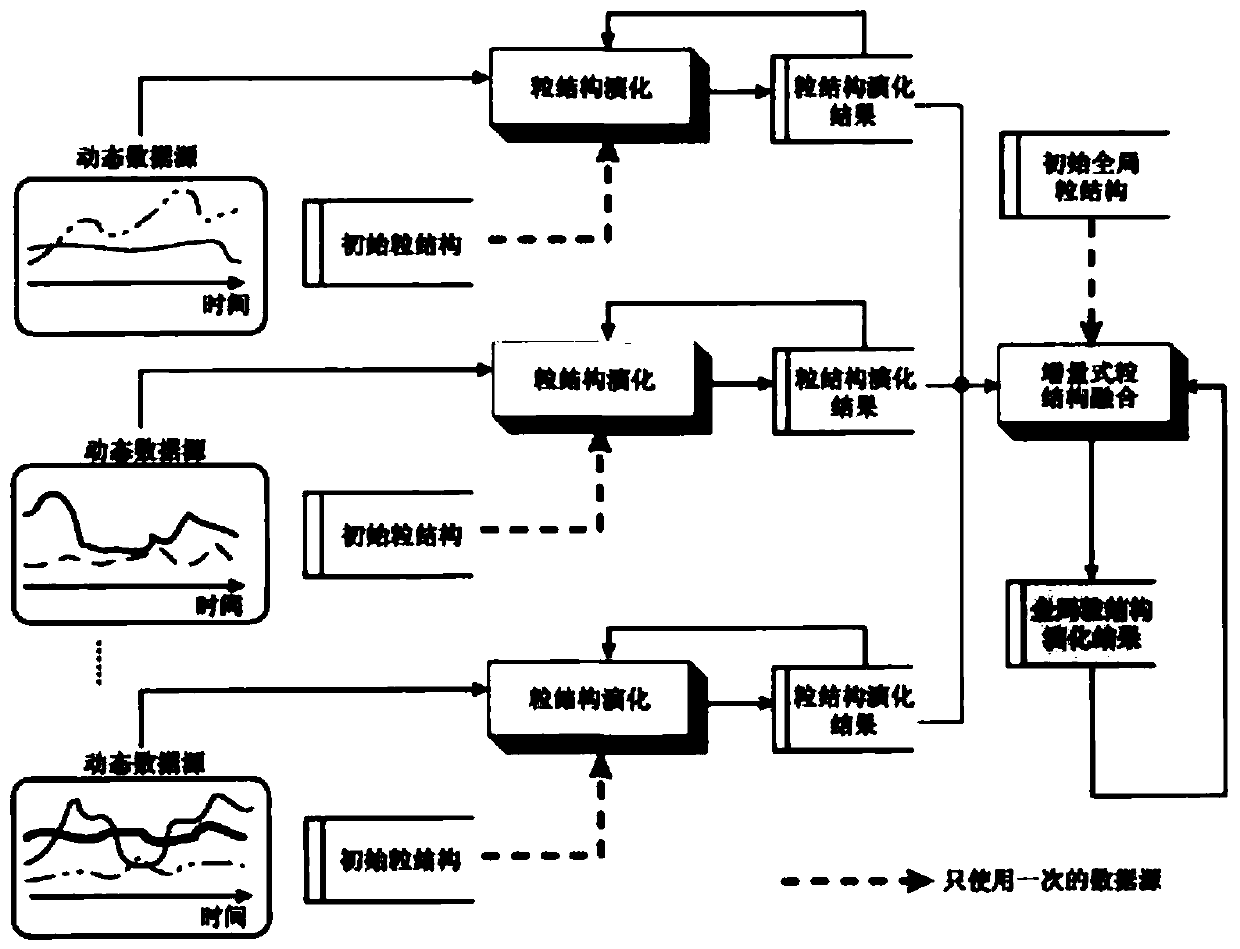

Machine learning hyper-parameter importance assessment method and system, and storage medium

ActiveCN108446741ASave resourcesShorten the timeCharacter and pattern recognitionAssessment methodsAlgorithm

The present invention discloses a machine learning hyper-parameter importance assessment method and system, and a storage medium. The method comprises the steps of: obtaining different data sets in anOpenML, extracting meta features to show each data set, and collecting data of performances of a classification algorithm to be assessed in different hyper-parameter configurations; extracting meta features to show a used target data set, calculating distances between the meta features to obtain an increasing sequence of the distance between the target data set and a historical data set; using the data of the performances of the classification algorithm to be assessed in different hyper-parameter configurations to assess the hyper-parameter importance, executing a provided Relied and a clustering algorithm for former m historical data sets in order being close to the target data set according to an ordered sequence of distance increasing between the historical data set and the target dataset, and finally obtaining the hyper-parameter importance sequence of the classification algorithm to be assessed and a guided automatic parameter regulation process. The machine learning hyper-parameter importance assessment method and system give a certain guide for the hyper-parameter regulation of a classification algorithm black box so as to save the time and improve the purpose of efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

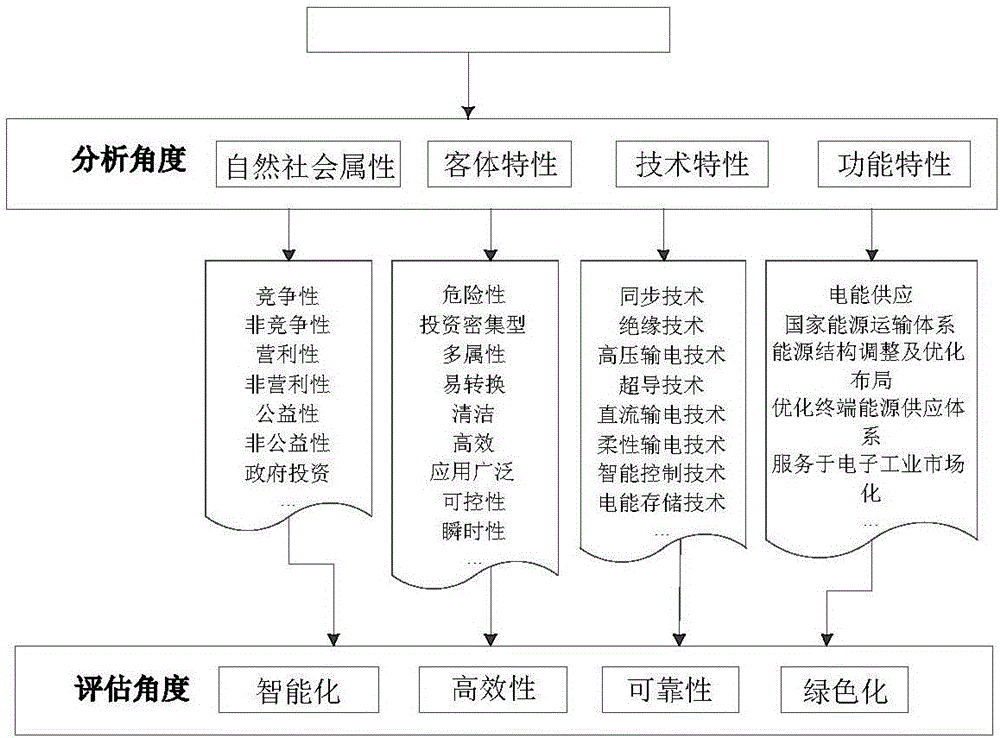

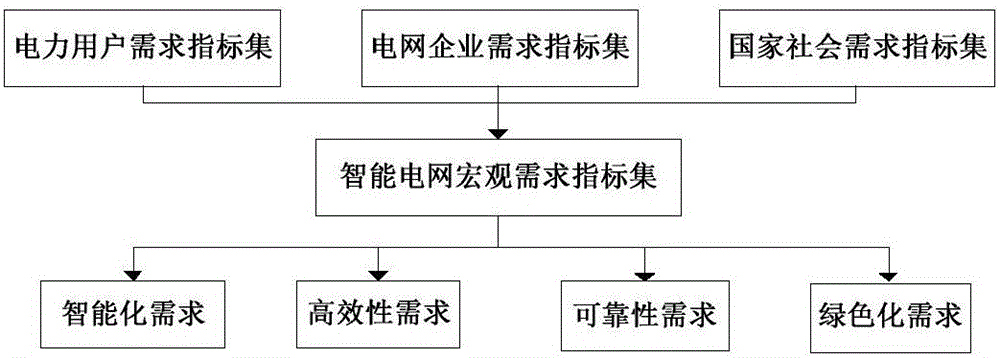

Method and system for comprehensively evaluating smart power grid demonstration project

The invention relates to a method and system for comprehensively evaluating a smart power grid demonstration project. The method comprises the following steps of: receiving a microscopic evaluation index data set of a smart power grid, and calculating weights of various data in the microscopic evaluation index data set by utilizing a combination weighting method based on a torque estimation theory; obtaining a macroscopic demand index value by calculation according to the microscopic evaluation index data set and the weights of the corresponding data; and, calculating weights of various macroscopic demand indexes by utilizing a DEMATEL-ANP anti-entropy weight method, and obtaining and outputting a comprehensive evaluation result according to the macroscopic demand index value and the weight corresponding to the macroscopic demand index. The weights of the data in the microscopic evaluation index data set are calculated by utilizing the combination weighting method based on the torque estimation theory; the problem that a weighting result is bias due to the fact that determination of the weight through the single weighting method can be easily influenced by the weighting method can be avoided; the macroscopic index weight is determined through the DEMATEL-ANP anti-entropy weight method; the microscopic index weight is determined through the combination weighting method based on the torque estimation theory; therefore, the comprehensive benefit can be evaluated scientifically; the evaluation reliability is high; and a guiding role can be played.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

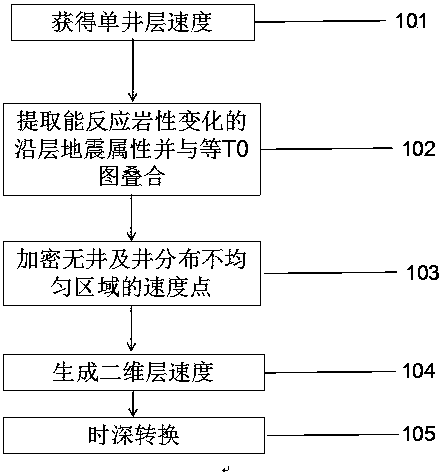

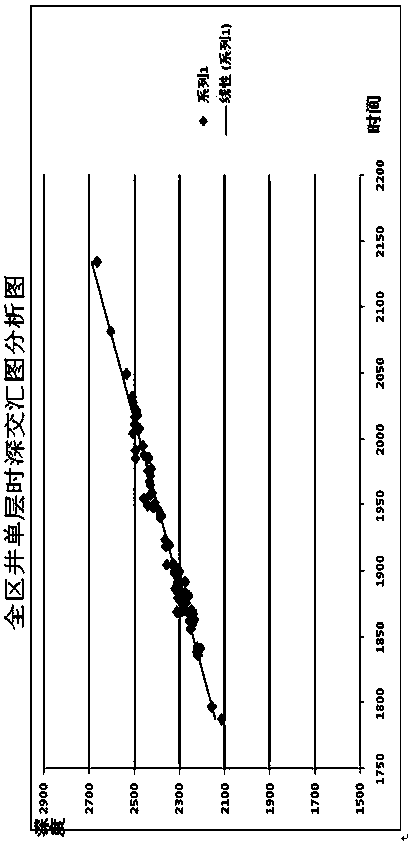

Complex fault block velocity-varied structure mapping method in late development

ActiveCN108121009AHigh precisionInstructiveSeismic signal processingDepth conversionInterval velocity

The invention provides a complex fault block velocity-varied structure mapping method in late development. The method comprises steps: 1, the interval velocity of a single well is acquired through a seismic interpretation horizon and a geological stratification; 2, horizon-oriented seismic attributes which can reflect lithological changes are extracted, and an attribute image and an equal T0 imageare superposed; 3, based on the principle of a consistent formation velocity at the same lithology and at the same time, velocity points of areas with no wells or with nonuniformly-distributed wellsare encrypted; 4, with the seismic interpretation horizon as a trend surface and with a fault boundary as an interpolation boundary, interpolation is carried out on the interval velocity of the singlewell, and a two-dimensional interval velocity field is built; and 5, the generated two-dimensional interval velocity grid and the equal T0 grid are multiplied for time-depth conversion, and a final structure map is obtained. The method provides accurate basic guidance for the study of a remaining oil distribution law and the development of well pattern reorganization in complex fault block fine reservoir description, a guidance role is played in late development of the reservoir of the kind, the prospect of popularization and application is broad, and economic and social benefits are remarkable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for establishing an asphalt pavement asphalt layer on-site modulus main curve

PendingCN109918849AGuaranteed accuracyInstructiveSpecial data processing applicationsGeotechnical engineeringStructural engineering

The embodiment of the invention discloses a method for establishing an asphalt pavement asphalt layer on-site modulus main curve. The establishment method comprises the following steps of: establishing a database, embedding a transverse strain sensor and a longitudinal strain sensor at the bottom of the asphalt layer of the asphalt pavement; detecting transverse strain and longitudinal strain of the bottom of the asphalt layer of the asphalt pavement under different loading conditions; calculating equivalent loading frequencies of the road surfaces corresponding to different loading speeds according to the measured transverse strain and longitudinal strain; acquiring on-site modulus of each asphalt layer under different loading conditions i through back calculation by using abaqus finite element software, establishing an on-site modulus main curve according to a back calculation result, verifying the on-site modulus main curve by using verification data, wherein the deviation is less than 20%, so that the established on-site modulus main curve is proved to be effective data. The method solves the problem that the asphalt pavement design has no guidance data due to unclear stress relation of the asphalt layer of the existing asphalt pavement.

Owner:TONGJI UNIV

Plate type heat exchanger liquid phase medium pressure drop testing system and testing method thereof

ActiveCN106482973ASimple structureLess investmentStructural/machines measurementEngineeringPlate fin heat exchanger

The invention relates to a plate type heat exchanger liquid phase medium pressure drop testing system. The testing system comprises a tank and a plate type heat exchanger. A first circulating loop and a second circulating loop which are communicated with each other are arranged between the tank and the plate type heat exchanger. The first circulating loop is composed of a first circulating inlet liquid testing pipe segment and a first circulating outlet liquid testing pipe segment. The second circulating loop is composed of a second circulating inlet liquid testing pipe segment and a second circulating outlet liquid testing pipe segment. Each of the first circulating inlet liquid testing pipe segment and the second circulating inlet liquid testing pipe segment is provided with a working medium conveying module and a flow adjusting module. Four interfaces of the plate type heat exchanger and the circulating path are respectively provided with a pressure measuring module. The first circulating loop and the second circulating loop are respectively provided with an air exhausting module. The invention further provides three testing methods which match the testing system. The plate type heat exchanger liquid phase medium pressure drop testing system has advantages of simple structure, quick and convenient adjustment, and wide coverage testing range. The plate type heat exchanger liquid phase medium pressure drop testing system can effectively reduce effects of plate sheet deformation factors to a measurement result under a precondition that a pressure drop testing process requirement is satisfied.

Owner:HEFEI GENERAL MACHINERY RES INST +1

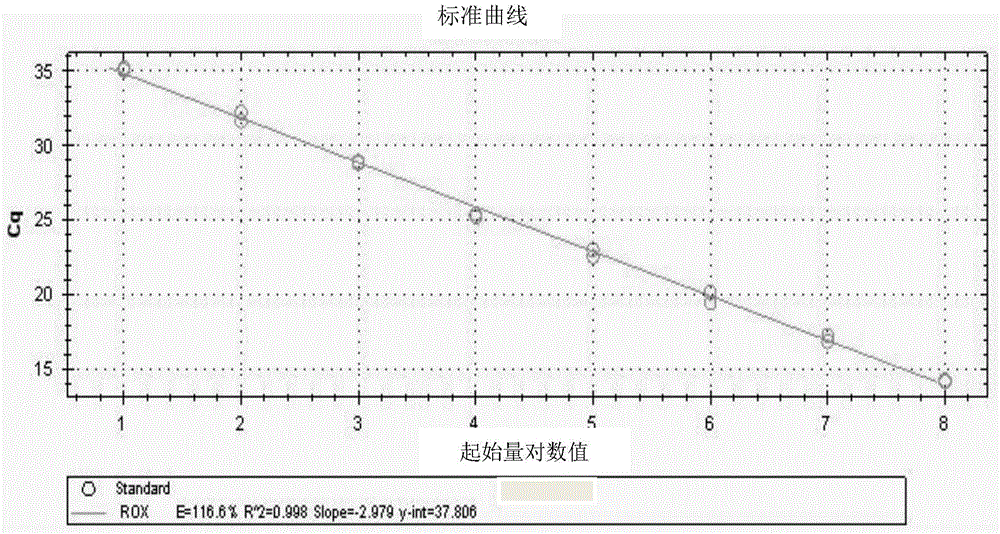

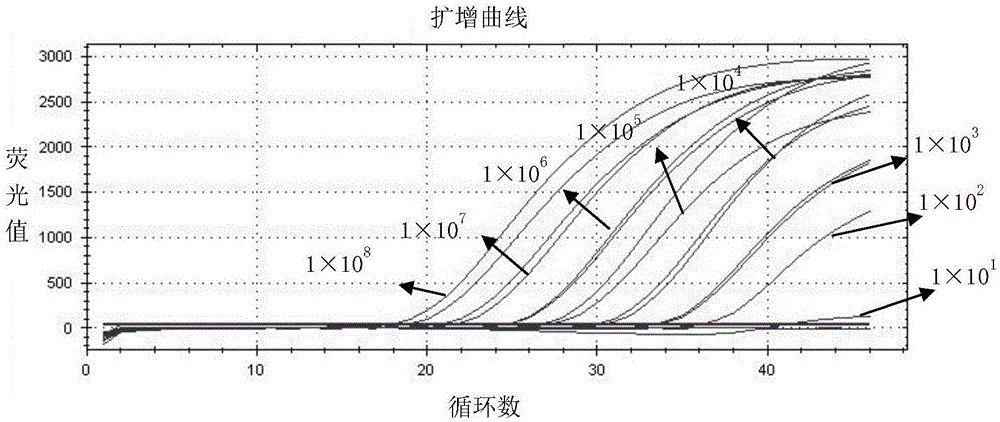

Wild porcine pseudorabies strain and gene-deleted strain dual real-time fluorescence quantification PCR detection kit, primers and probe

ActiveCN106048094ASimple and fast operationEnsure safetyMicrobiological testing/measurementMicroorganism based processesFluorescenceVaccine Production

The invention discloses a dual real-time fluorescence quantification PCR detection kit, specific primers and TagMan probe for detecting a gB gene and a gE gene of a wild porcine pseudorabies strain and a gene-deleted strain. The method builds a gB gene and gE gene dual real-time fluorescence quantification PCR detection method. The method can fast identify a wild porcine pseudorabies strain (simultaneously containing a gB gene and a gE gene) and a gene-deleted strain (only containing the gB gene) and can realize accurate quantification of virus copy number. The kit and detection method can be operated simply, have good specificity and high sensitivity and produce effects in porcine pseudorabies detection, strain identification and vaccine production.

Owner:内蒙古金迈诗生物科技有限公司 +1

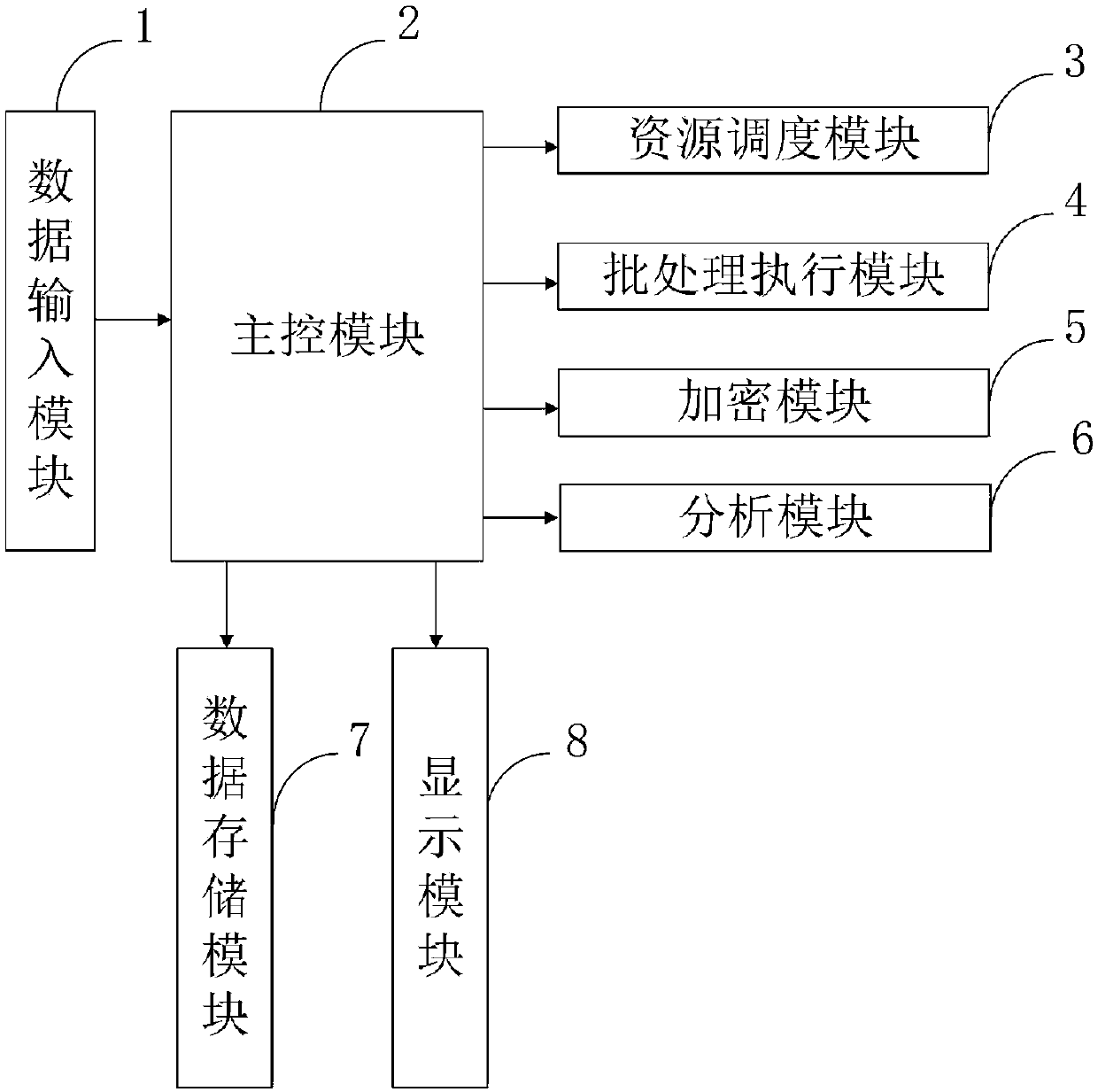

A batch processing method for large computer data

PendingCN109522742APrevent leakageShort timeDatabase management systemsResource allocationBatch processingData information

The invention belongs to the technical field of big data batch processing and discloses a batch processing method for large computer data, which inputs customer data through a data input module by using a data input device. The main control module utilizes the scheduling algorithm to schedule the data resources to be processed through the resource scheduling module, and the resource scheduling module adopts the Min-Min scheduling algorithm, which utilizes batch processing program to schedule processor to batch process the job to be processed by batch processing execution module; Encryption module is used to encrypt the large data by the encryption program. The analysis module analyzes the big data by using the analysis program, and the data storage module stores the big data resources by using the memory. large data information content is displayed by a display module using that display. The invention does not need to obtain large data from a large amount of large data in a distributeddatabase, so the invention is short in time and easy to realize.

Owner:贵州斯曼特信息技术开发有限责任公司

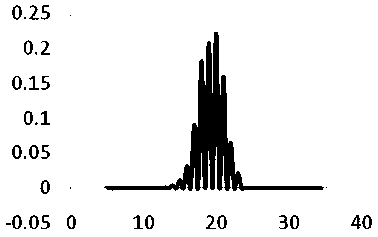

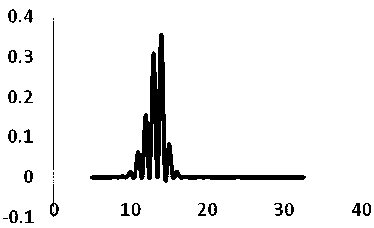

Next generation sequencing primer probe set and detection method of microsatellite instability state

PendingCN109082470AInstructiveIncrease profitMicrobiological testing/measurementDNA fragmentationTissue sample

The invention relates to a next generation sequencing detection method of a microsatellite instability state. The method includes: performing DNA fragmentation on the cancer tissue sample and normal tissue reference substance of a tumor patient, polishing and adding tail A to tail ends, and performing joint connection; designing primers and probes for target area capturing and primers for amplification, the probes are one-way DNA extension probes aiming at five microsatellite loci, and using the probes and the primers to perform target area capturing and then performing amplification to obtaina library; sequencing to obtain the repeated sequence length distribution data of the five microsatellite loci of the cancer tissue sample and the normal tissue reference substance, and comparing thedata of the five microsatellite loci of the cancer tissue sample and the normal tissue reference substance to judge the stability of the microsatellite loci. The invention further relates to a next generation sequencing primer probe set of the microsatellite instability state. The next generation sequencing detection method can reduce influence of sequencing depth on result judgement and is simple, practicable, high in accuracy, high in sensitivity and low in cost.

Owner:上海赛安生物医药科技股份有限公司

Method for controlling coordinated operation of multiple DFACTS devices in urban regional power distribution network

ActiveCN104184142ARealize coordinated controlEasy to implementReactive power adjustment/elimination/compensationAc network voltage adjustmentVoltage dropEngineering

The invention relates to a method for controlling coordinated operation of multiple DFACTS devices in an urban regional power distribution network canonical topology. The method comprises the steps of (1) conducting coordination control on a DVR and an SSTS aiming at system voltage drop, (2) conducting coordination control on a DSTATCOM and multiple sets of TSCs aiming at system voltage flicker and reactive compensation, and (3) obtaining four coordination control methods for the DFACTS devices through the combination of the step (1) and the step (2). By the adoption of the method, coordination control of the multiple DFACTS devices in the urban regional power distribution network is achieved. The method is easy to implement and capable of guiding future engineering practice of the urban regional power distribution network.

Owner:STATE GRID CORP OF CHINA +5

Noise reduction performance evaluation method and system

The invention provides a noise reduction system performance evaluation method and system. The method includes determining the noise reduction depth d on the basis of the noise reduction curve; calculating the comfort level C1 of ambient sound before noise reduction and the comfort level C2 of ambient sound after noise reduction, and obtaining the comfort level change amount delta C; based on the noise reduction depth d and the comfort level change amount delta C, evaluating the noise reduction performance. A novel multi-dimensional evaluation method is formed by increasing comfort level evaluation items in an existing noise reduction system evaluation method, so that the objective noise reduction effect after noise reduction can be achieved, the degree of improvement of the subjective feeling of people can be reflected, and the method is a scientific and comprehensive evaluation method, meanwhile, the design of the noise reduction system has a guiding function, and the evaluation method is simple and easy to implement.

Owner:HUITING ACOUSTICS TECH BEIJING CO LTD

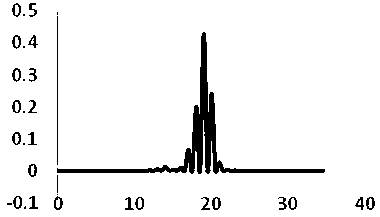

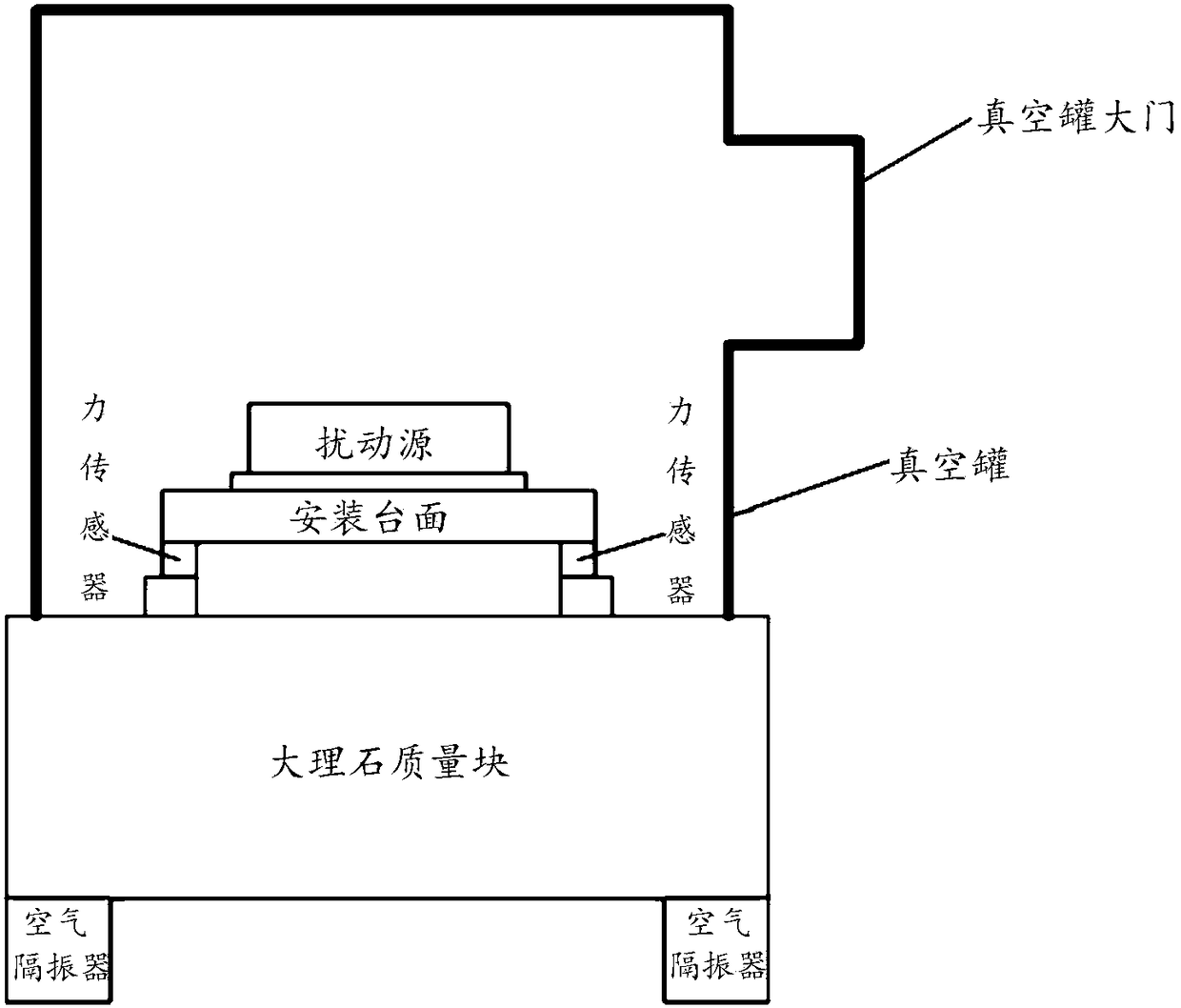

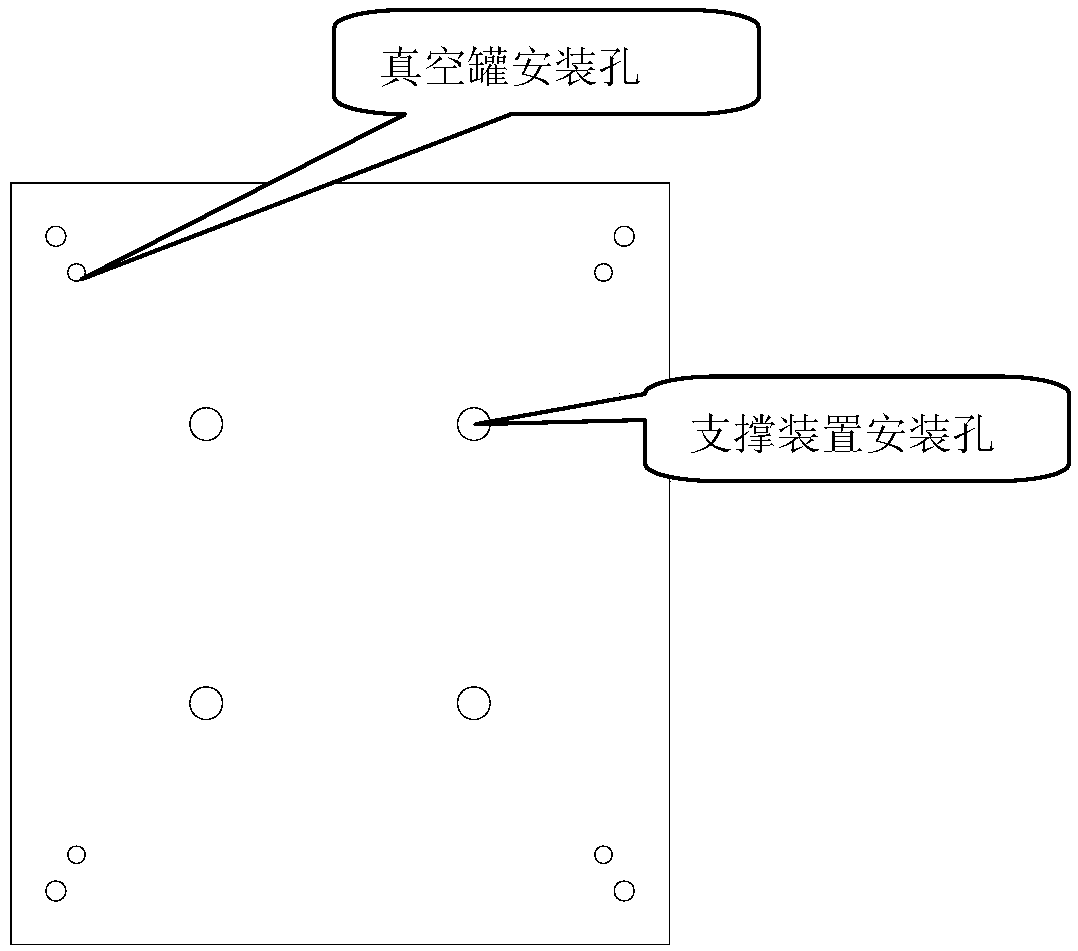

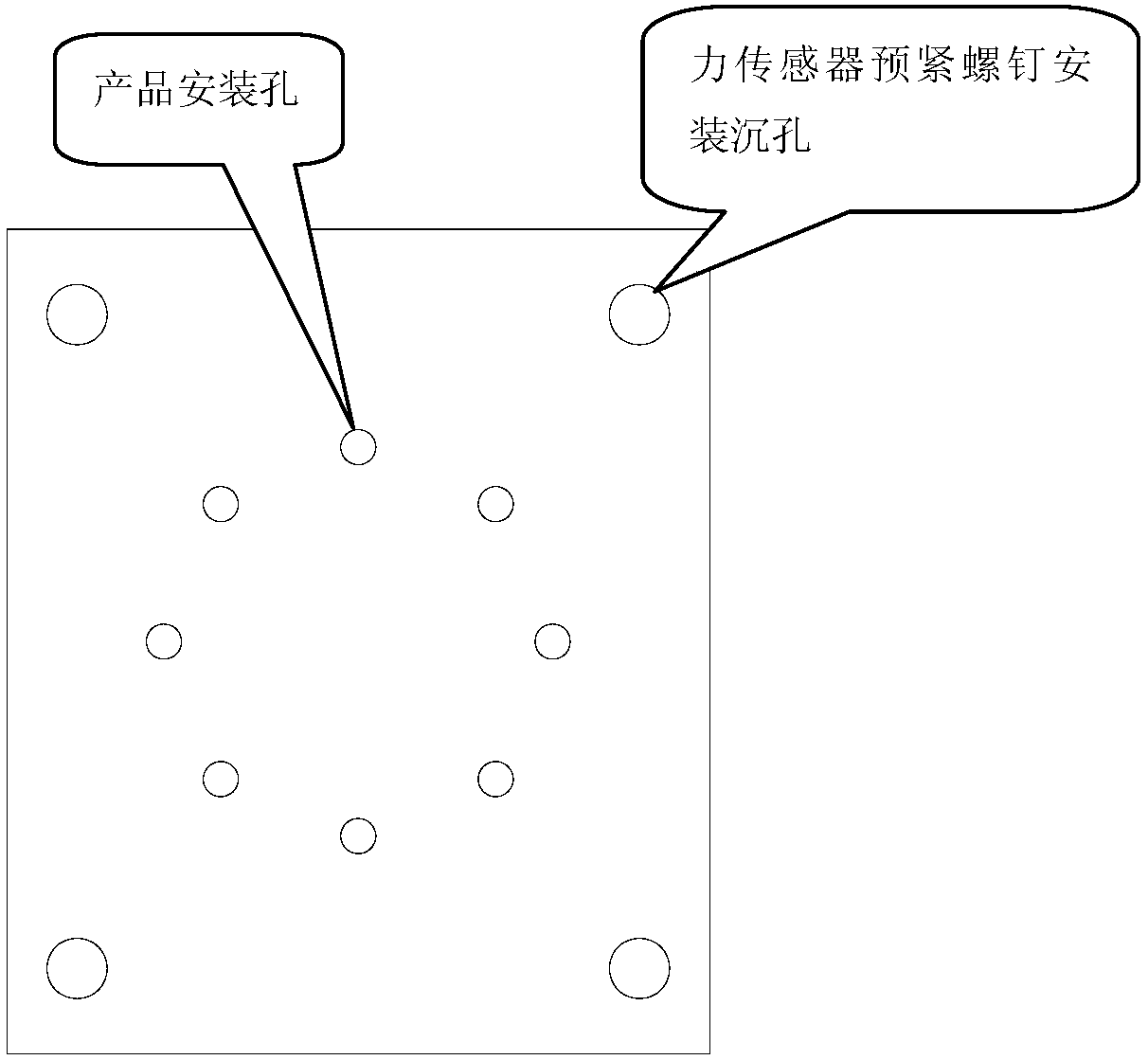

Test device of satellite-borne flywheel disturbance vibration force test in vacuum environment

ActiveCN108287049AIsolation impactInstructiveApparatus for force/torque/work measurementVibration testingSatelliteData collector

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Exhaust valve performance test system and test method

The invention relates to an exhaust valve performance test system and a test method. The test system comprises a compressor, a gas storage section pipeline, a flow measurement section pipeline and a test container, wherein the compressor, the gas storage section pipeline, the flow measurement section pipeline and the test container are successively connected in the gas flow direction. A first total valve is arranged between the compressor and the gas storage section pipeline. A number of parallel gas storage tanks are connected with the gas storage section pipeline. A first switching valve is arranged between the gas storage tanks and the gas storage section pipeline. The flow measurement section pipeline comprises a number of branch pipelines with different calibers, wherein the branch pipelines are arranged in parallel. A second switching valve is arranged in the inlet of each branch pipeline. A third switching valve is arranged in the outlet of each branch pipeline. Each branch pipeline is provided with a pressure regulating valve and a flowmeter. The test container is connected with a mounting pipe used for mounting a tested valve. A first pressure sensor is arranged in the inlet of the tested valve. The exhaust valve performance test system provided by the invention is extensible, and can support subsequent tests of larger exhaust valves by increasing the number of gas storage tanks or the number of branch pipelines.

Owner:HEFEI GENERAL MACHINERY RES INST

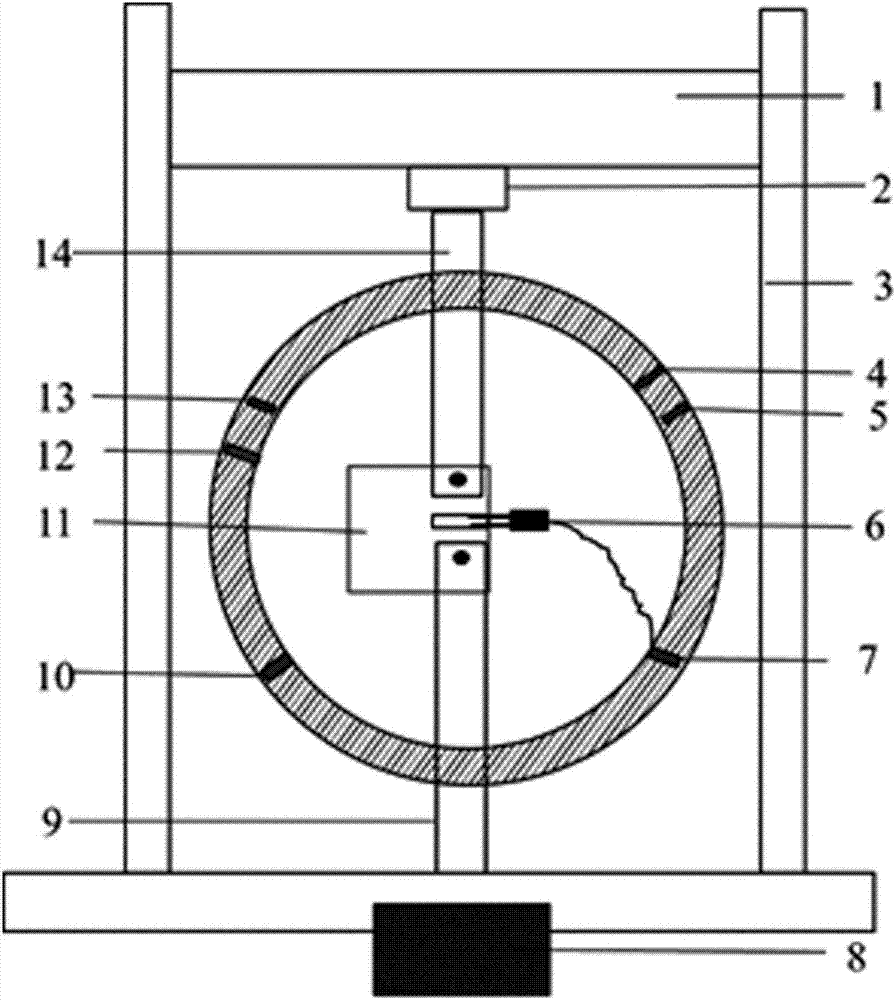

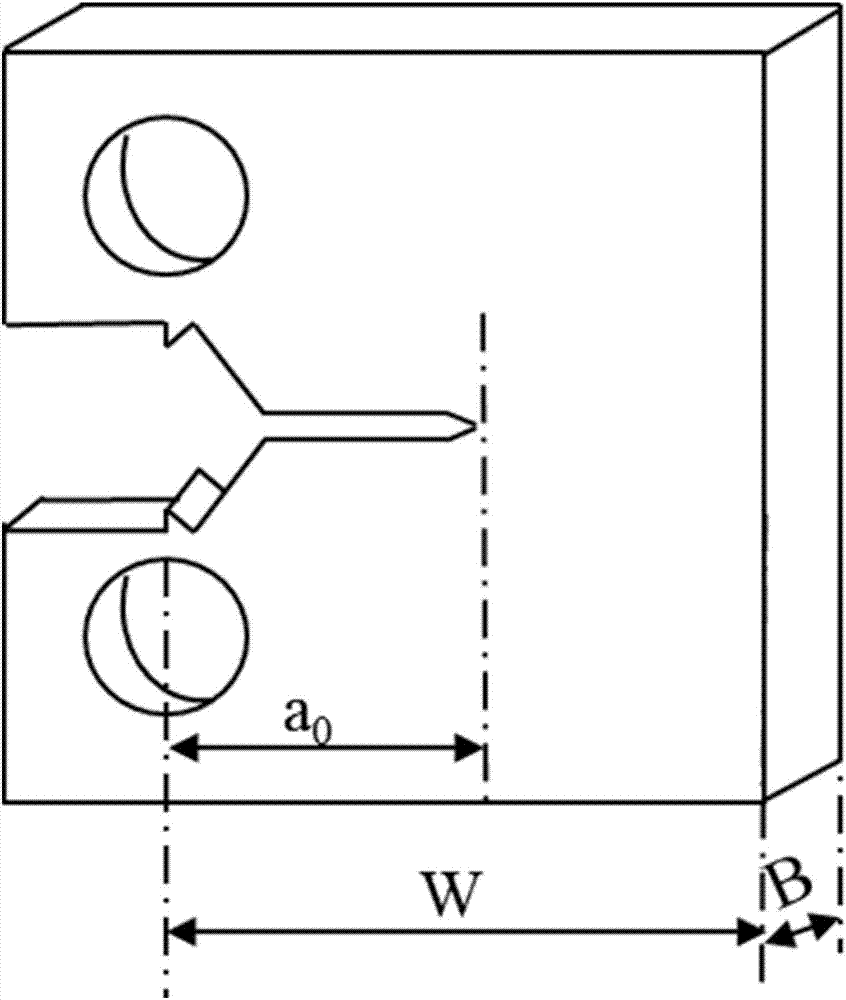

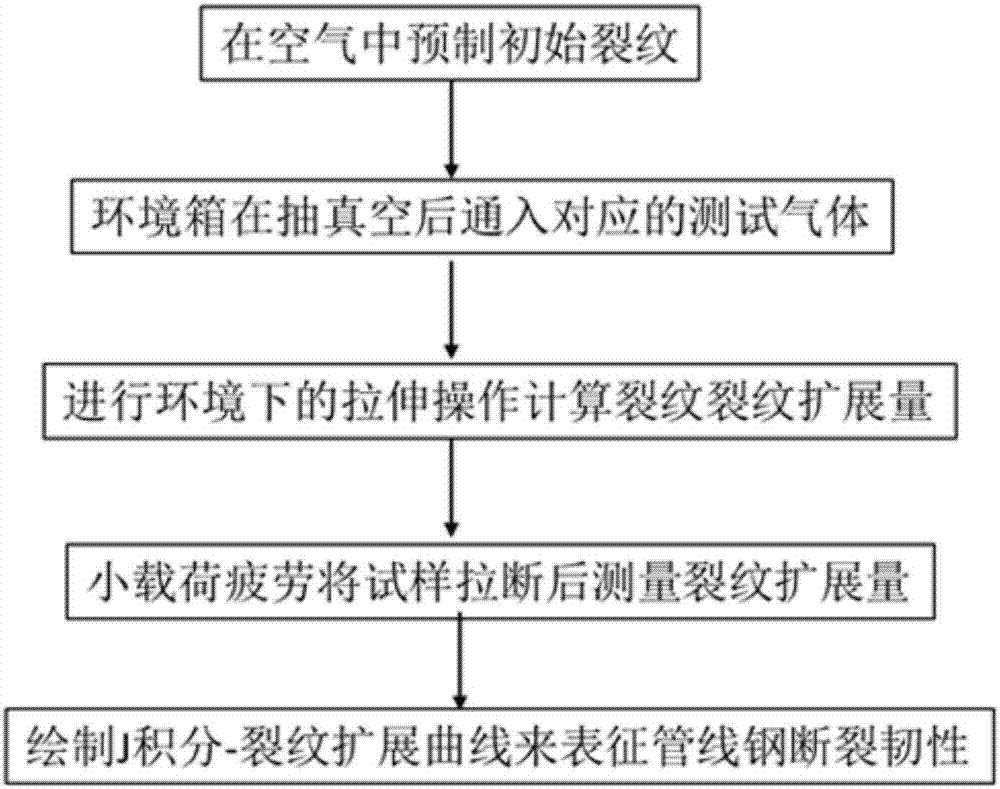

Method and apparatus for testing fracture toughness of pipeline steel in hydrogen-containing synthetic natural gas environment

InactiveCN107966368ATruly reflect the actual service performanceEasy to operateMaterial strength using tensile/compressive forcesLine tubingHydrogen

The invention provides a method and an apparatus for testing fracture toughness of pipeline steel in a hydrogen-containing synthetic natural gas environment. The testing method comprises the followingsteps: initial cracks are prefabricated in air; under a condition environment, a stretching test is carried out, in order to obtain a test crack expansion amount; a curve of J-integration-test crackpropagation amount is drafted, in order to complete test of the fracture toughness of pipeline steel in the hydrogen-containing synthetic natural gas environment. The invention also provides the testing apparatus of the testing method. The testing apparatus and the testing method can be used for practically reflecting practical service performance of the pipeline steel, and the apparatus and the method have the advantages of simple and easy operation, accurate result, and reliability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Sensor molding plastic extruder hopper for observing material conveying condition

The invention discloses a sensor molding plastic extruder hopper for observing a material conveying condition. The hopper comprises a hopper body, wherein the hopper body comprises a cylindrical storing barrel; a funnel-shaped discharging structure is connected with the bottom of the storing barrel. The hopper further comprises a sliding chute fixedly formed in a plastic extruder, wherein the inner width of the sliding chute is greater than the width of an opening of the sliding chute; a feeding inlet communicated with the plastic extruder is formed in the bottom of the sliding chute. An upper sliding block and a lower sliding block are mounted below the hopper body, are respectively positioned inside and outside the sliding chute, and are connected by a pipeline; the pipeline is used for communicating an inner cavity of the hopper body with the feeding inlet; a transparent observation window and a vibration motor are arranged on the discharging structure. The material condition in the hopper body can be observed at any time by arranging the transparent observation window and the vibration motor on the discharging structure, so that the stress among materials can be effectively eliminated, so that the materials can fall. As a result, the normal production is ensured.

Owner:成都长迪传感技术有限公司

Compound essential oil for refreshing and restoring consciousness as well as preparation method and application thereof

InactiveCN111195330AInstructiveSignificant osmotic absorption capacityNervous disorderPharmaceutical delivery mechanismBiotechnologyEngineering

The invention relates to a compound essential oil is prepared from the following components in parts by mass: 5 to 20 parts of lemon essential oil, 5 to 20 parts of lemongrass essential oil, 3 to 20 parts of eucalyptol rosemary essential oil, 20 to 70 parts of herba menthae essential oil, 5 to 20 parts of lemon eucalyptus essential oil, 3 to 20 parts of cypress essential oil and 5 to 20 parts of bergamot essential oil. The invention also discloses a preparation method and an application of the compound essential oil. The compound essential oil provided by the invention can quickly and effectively eliminate fatigue, restore spirit and calm mood, enables people to be refreshing, is suitable for long-term use, can also improve the autoimmunity, and is simple in preparation process and relatively low in cost.

Owner:上海茗想健康科技有限公司

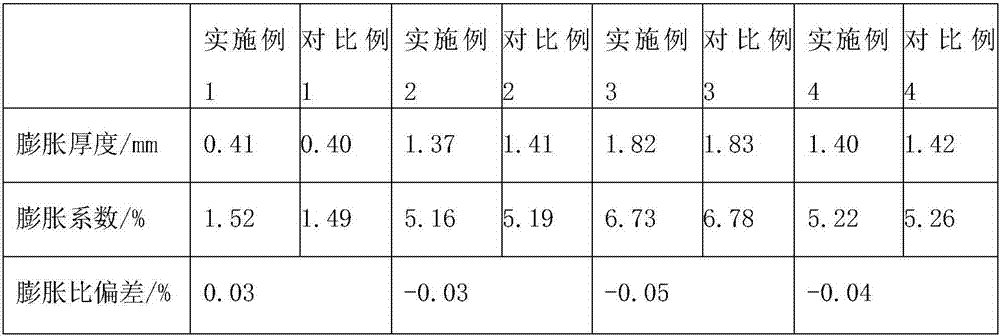

Method for quickly evaluating expansion of aluminum-housing high-nickel ternary battery

InactiveCN107390135ASimulated thicknessJudging safetyElectrical testingFloating chargeFast evaluation

The invention discloses a method for quickly evaluating expansion of an aluminum-housing high-nickel ternary battery. The method is characterized by taking a sealed aluminum-housing high-nickel ternary battery, charging the battery to 4.2 V under constant current and constant voltage, and measuring and recording initial thickness d0 of the battery; and carrying out floating charge on the battery for n days under constant voltage, n=1-100, and measuring and recording the thickness d1 of the battery, battery expansion coefficient being eta=(d1-d0) / d0. The method simulates expansion thicknesses of the battery in different service life through a floating charge mode, is high in test precision, short in period and safe and reliable in detection process, and has a great guidance meaning for battery thickness exploration in normal use process.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com