Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve the success rate of arc striking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

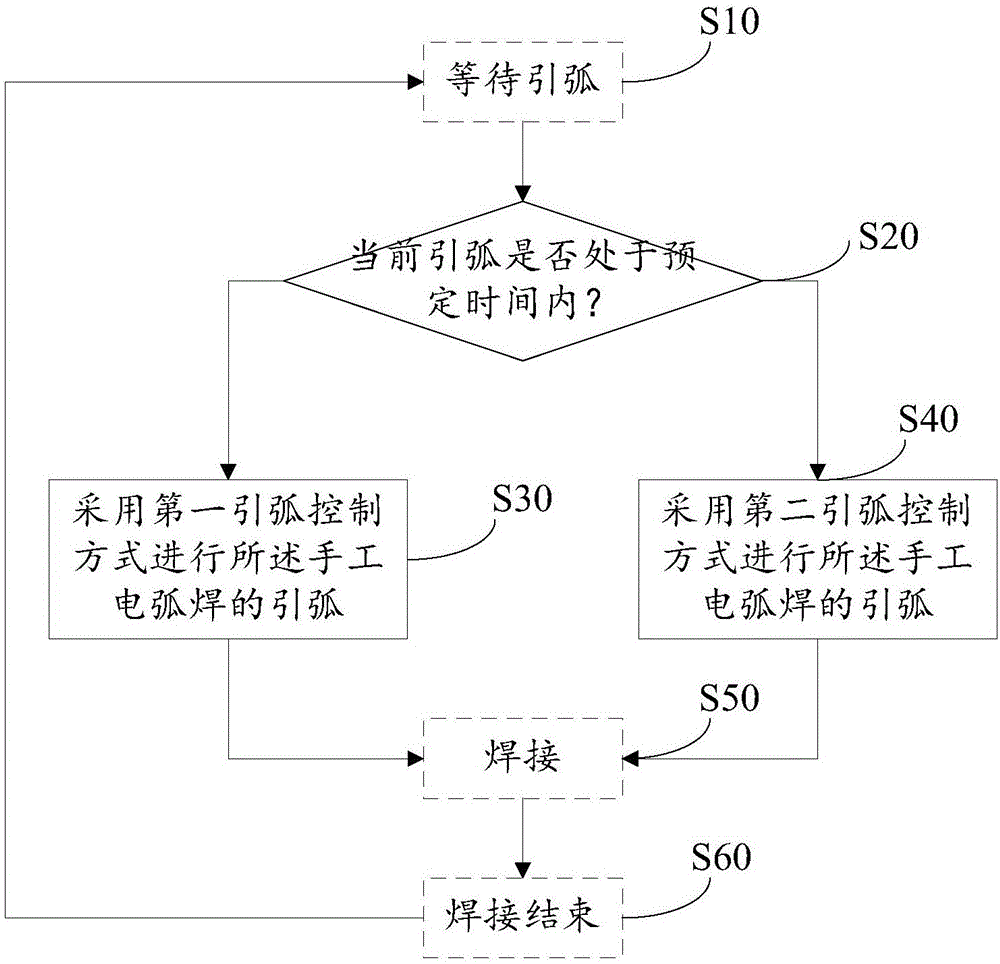

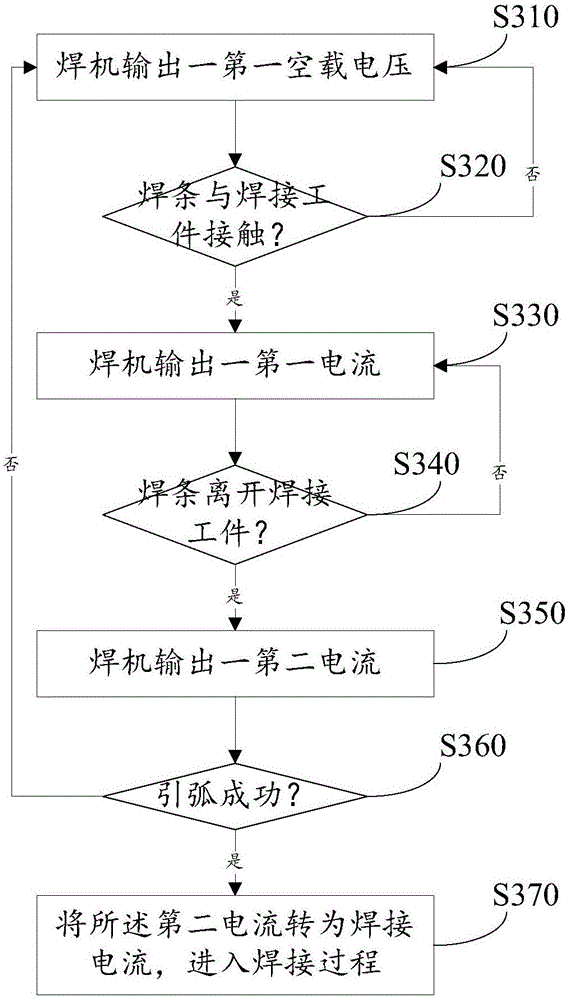

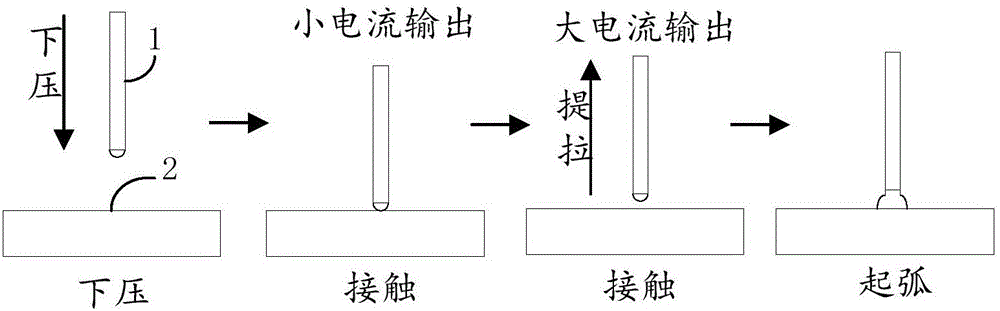

Arc striking control method and device

ActiveCN106695071AImprove the success rate of arc strikingNot easy to extinguishArc welding apparatusShielded metal arc weldingControl mode

The invention provides an arc striking control method and device. The arc striking control method is used for manual arc welding and comprises the steps of judging whether the current arc striking of manual arc welding is within the preset time or not; if not, carrying out arc striking of manual arc welding by the adoption of a first arc striking control mode; and if yes, carrying out arc striking of manual arc welding by the adoption of a second arc striking control mode. The arc striking control scheme disclosed by the invention can improve the arc striking success rate.

Owner:PANASONIC WELDING SYST TANGSHAN

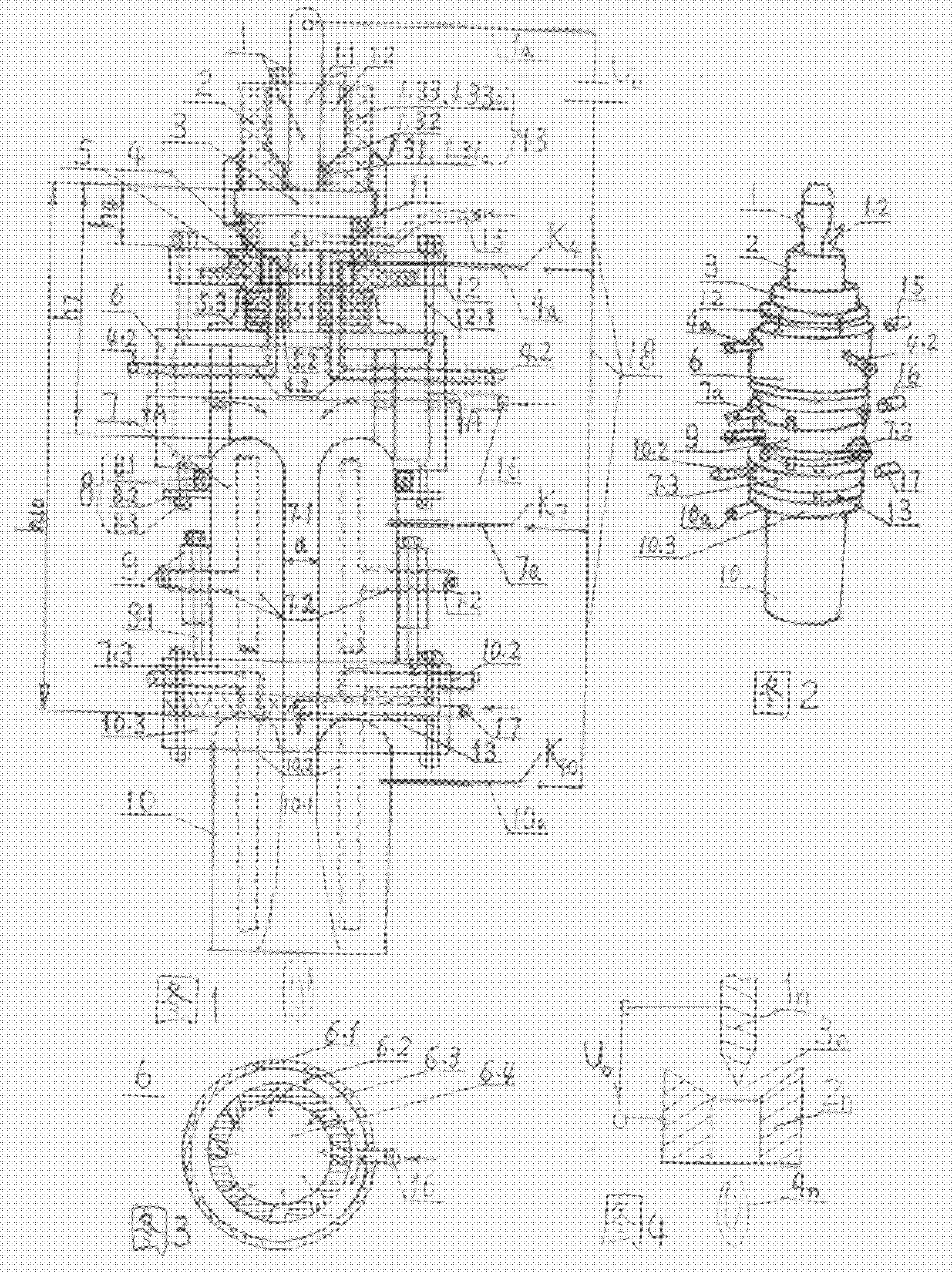

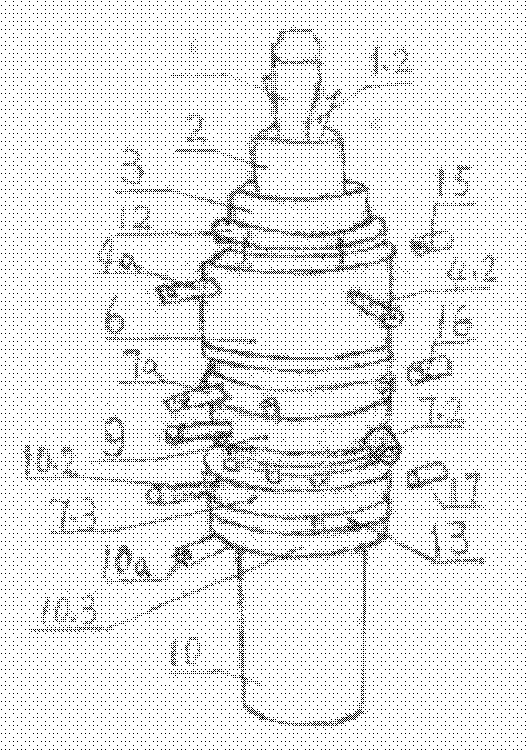

200KW non-transferred arc plasma generator and arc-striking method

ActiveCN102625561AIncrease distanceIncrease arc voltagePlasma techniquePlasma generatorRadioactive waste

Disclosed are a 200KW non-transferred arc plasma generator and an arc-striking method. A negative pole and an insulating sleeve, a clearance, a small positive pole and an adjustable insulating seat, a main gas ring, a second positive pole, an outside seal, an adjusting nut and a big positive pole are arranged sequentially along the injecting direction. The negative pole is of solid red copper, an outer ring of the negative pole is a stainless steel sleeve, and a cooling waterway is formed between the negative pole and the stainless steel sleeve. Each positive pole is of red copper with a center hole and a cooling waterway, a threaded junk ring and a special-shaped flange which can be adjustably connected at an axial direction are arranged outside each positive pole. Inert gases serving as assistant gases are ventilated to the top of the small positive pole; and main gases and protection gases are screwed in the second positive pole and the top of the big positive. The negative pole of the direct current power is connected with the negative pole of the plasma generator; the positive pole of the direct current power is connected with three positive poles of the plasma generator, and each positive pole is provided with an arc-transferring switch. Multiple positive poles are used for increasing the arc pressure, so that the power can be reached to 200KW. The main gases and protection gases are screwed in to produce stable and uniform arcs. Water-cooling is used for meeting the cooling requirements for high powers. The negative poles are arranged at the rearmost end to guarantee convenient installation and replacement. Control parameters can be altered by distance adjustment, so that the service life is prolonged. The 200KW non-transferred arc plasma generator and the arc-striking method can be used for waste detoxifying treatment, fire-resistant heat-insulating material melting production for ore smelting, radioactive waste treatment and funeral-interment and cremation industry.

Owner:CHENGDU JINCHUANGLI SCI & TECH

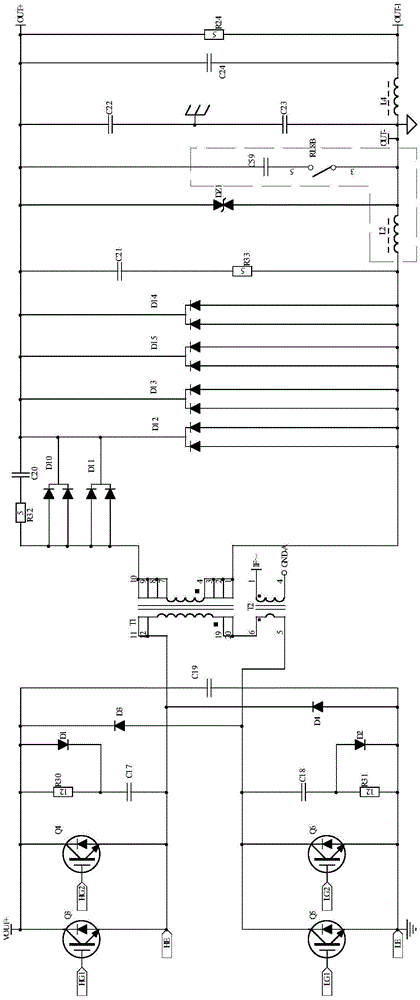

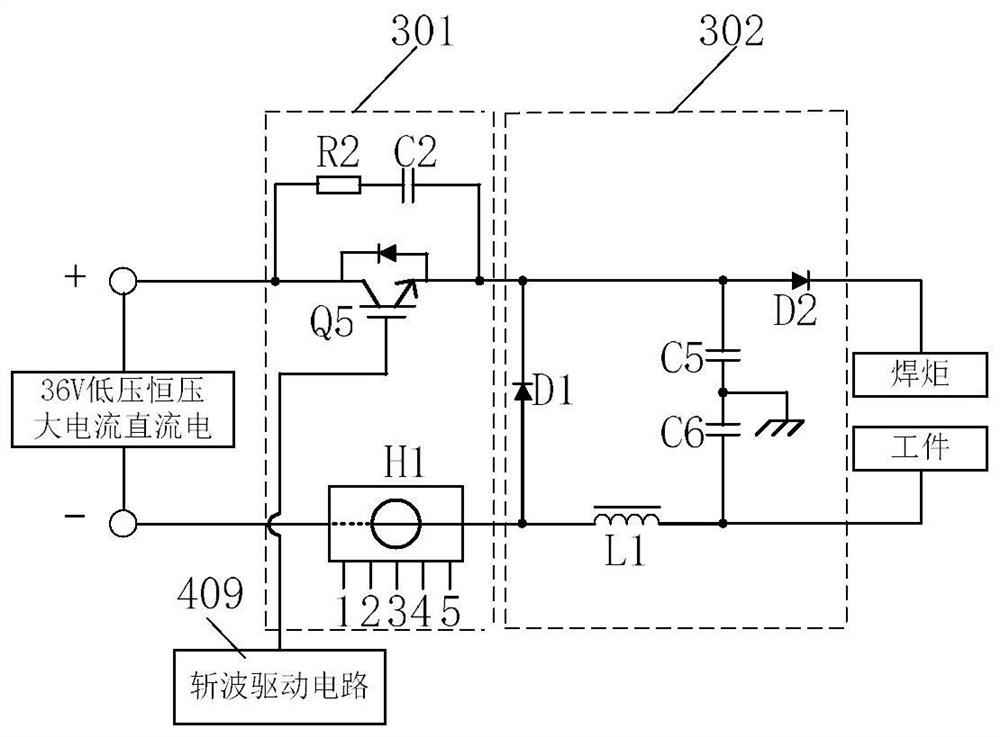

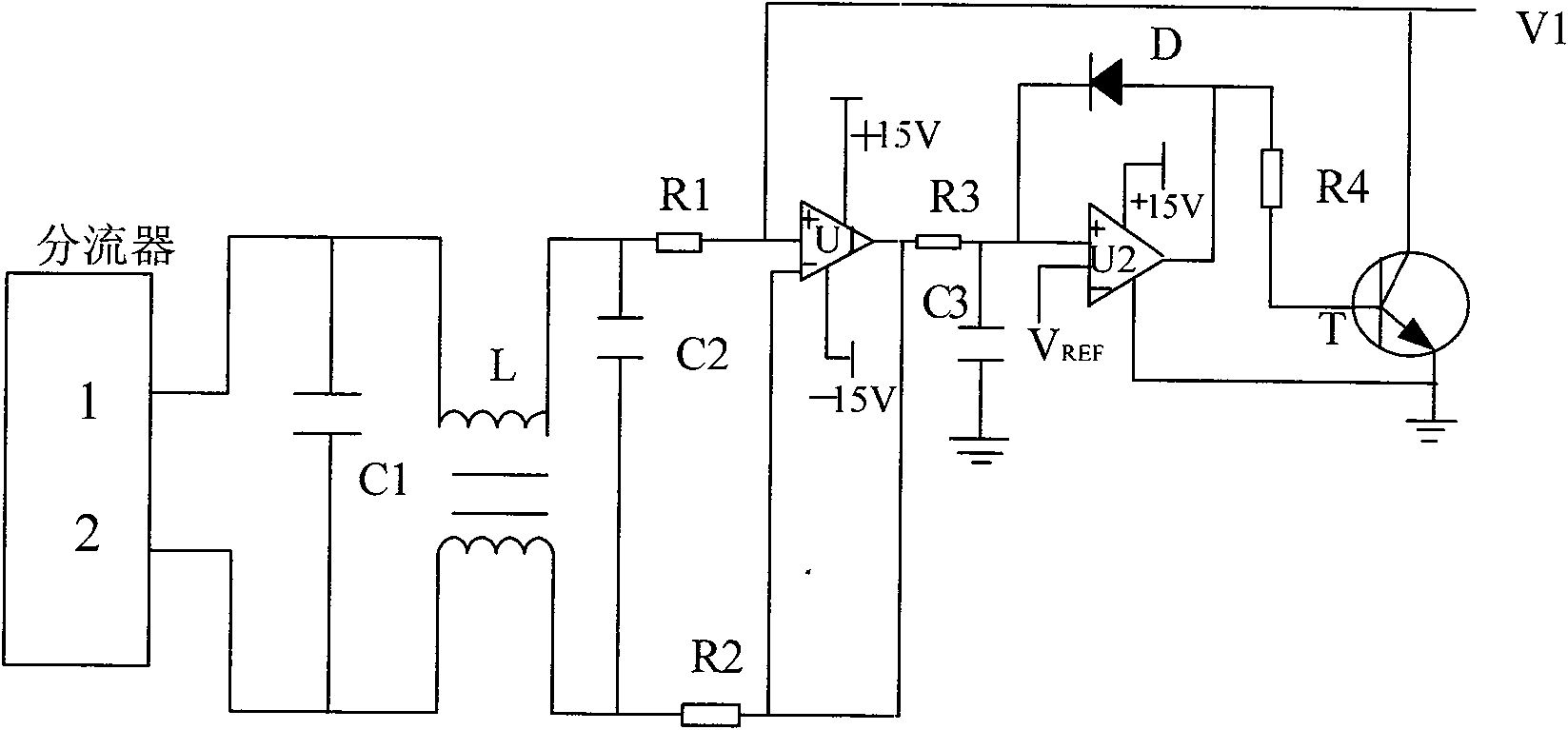

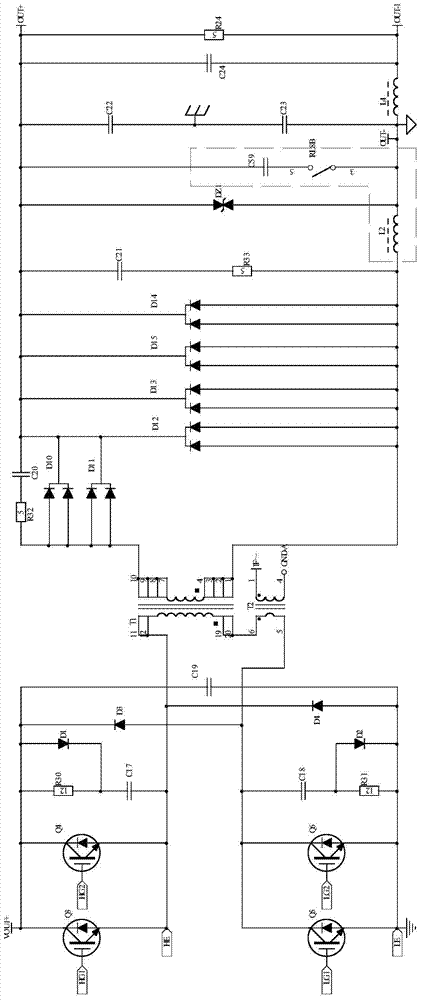

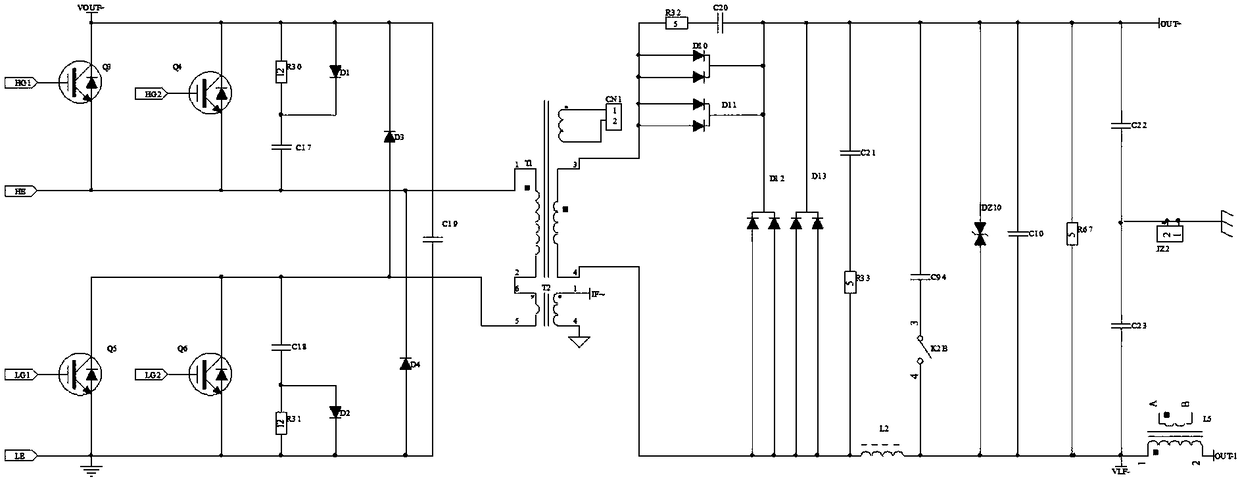

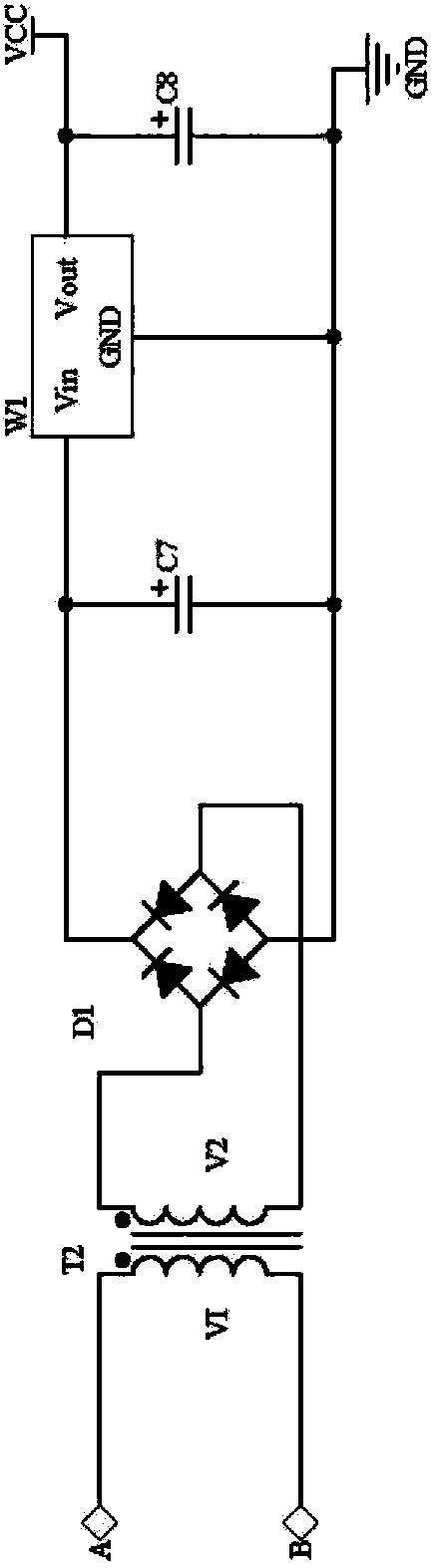

Circuit for increasing small current arc striking successful rate and stability of inverter argon arc welding machine

The invention provides a circuit for increasing the small current arc striking successful rate and stability of an inverter argon arc welding machine. The circuit comprises an inverter welding machine main loop circuit and an output loop arc stabilizing circuit, wherein a double-tube and single-end forward topology circuit is adopted as the inverter welding machine main loop circuit which inverts direct current obtained after input alternating current is rectified into high-frequency square wave current and then rectifies the square wave current into low-voltage direct current needed by the inverter argon arc welding machine to output the low-voltage direct current; and the output loop arc stabilizing circuit is connected into the inverter welding machine main loop circuit in series and used for controlling the working state of the inverter argon arc welding machine. According to the circuit for increasing the small current arc striking successful rate and the stability of the inverter argon arc welding machine, due to the fact that the measures that the arc stabilizing circuit works during arc striking with small current and arc striking with large current and the arc stabilizing circuit only works with small current in the welding process are taken, the size of the arc stabilizing circuit is greatly reduced, cost is saved, the effect of increasing the small current arc striking successful rate and stability can be achieved, and the circuit is economical and applicable.

Owner:SHANGHAI GREATWAY WELDING EQUIP

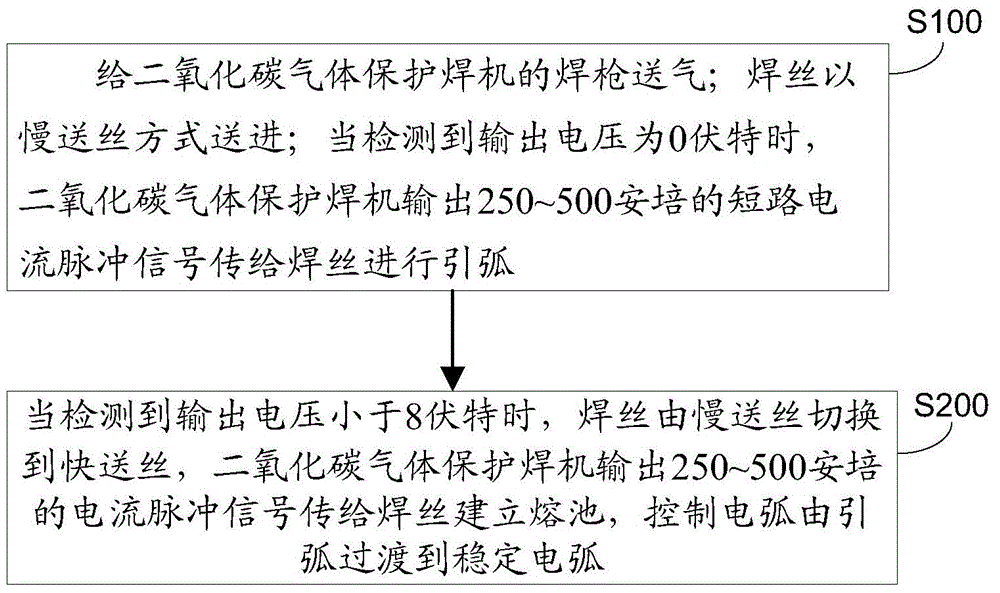

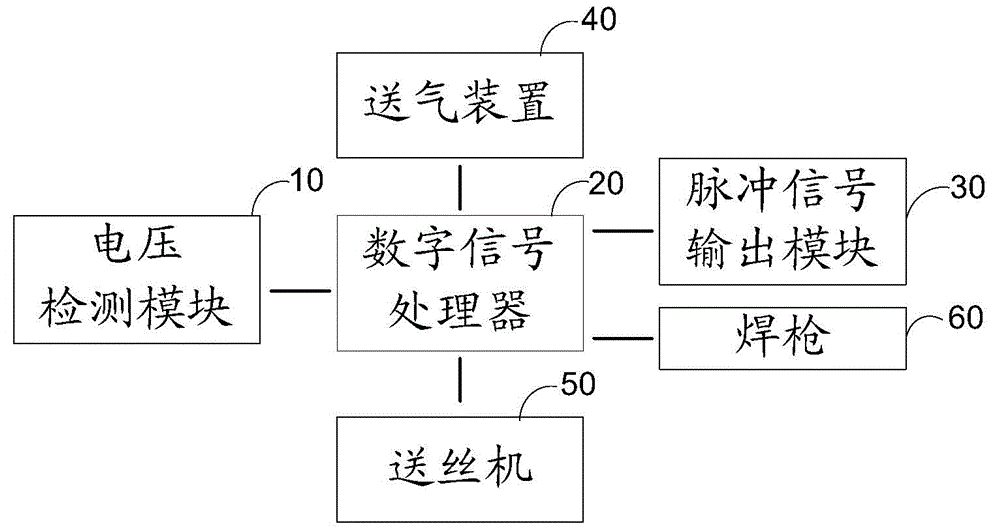

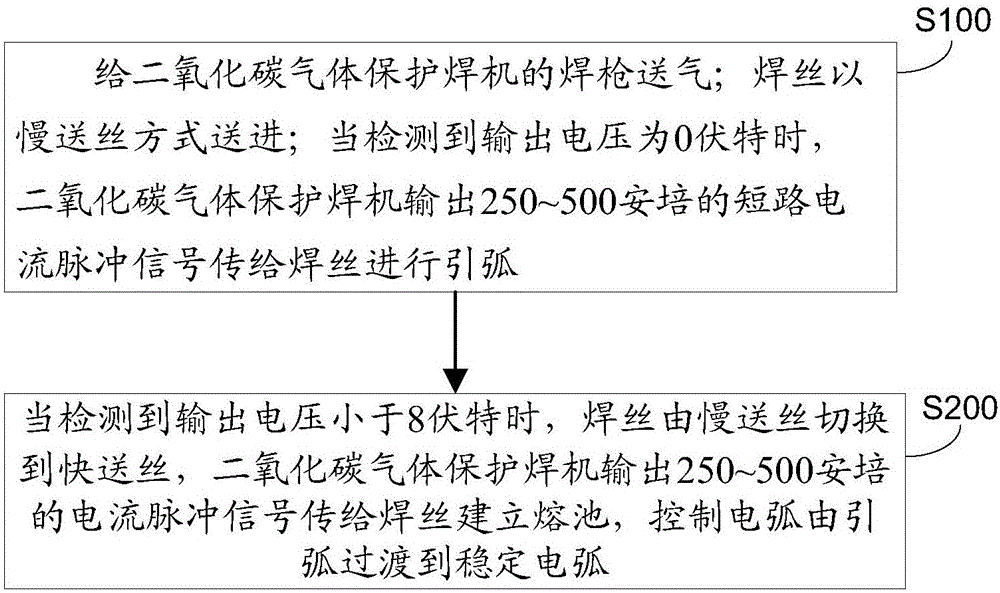

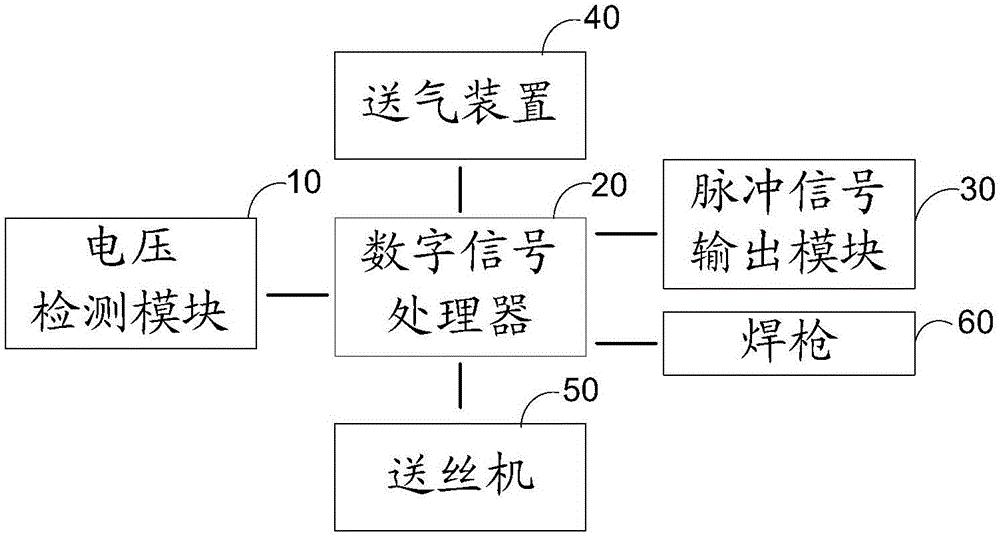

Carbon dioxide gas shielded welding machine and method of controlling arc strike by adopting digital pulse

ActiveCN104096947AReduced maximum peak powerReduce transient impact stressArc welding apparatusEngineeringImpact stress

The invention discloses a method of controlling the arc strike of a carbon dioxide gas shielded welding machine by adopting digital pulse. The method comprises the steps of feeding gas for a welding gun; feeding a welding wire in a slow wire feeding mode; when the output voltage is detected to be 0 volt, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire for arc strike; when the output voltage is detected to be smaller than 8 volts, switching from the slow wire feeding mode of the welding wire into a quick wire feeding mode, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire to build a molten pool, and controlling an arc to be subjected to transition from arc strike to a stable arc. According to the method, the transient impact stress which is borne by a hardware power device is reduced, and the service life is prolonged; the arc strike time is shortened, the arc strike process is stable, the reliability is strong, and the arc strike success rate is high; the molten pool is built in the arc strike process, and thus a basic is established for normal, stable and reliable welding in the future. The invention further discloses a carbon dioxide gas shielded welding machine.

Owner:SHENZHEN RILAND IND

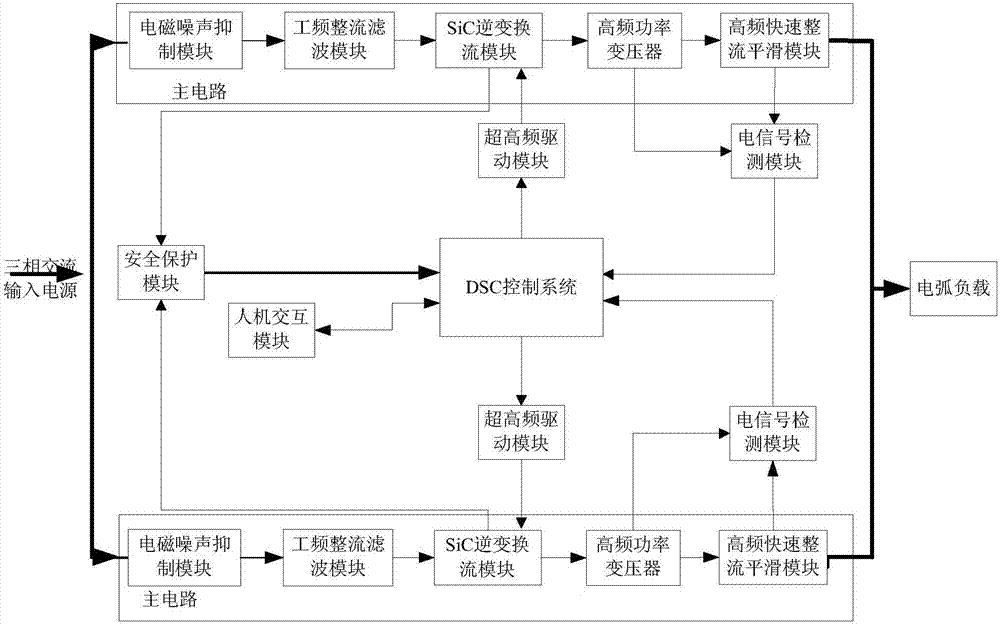

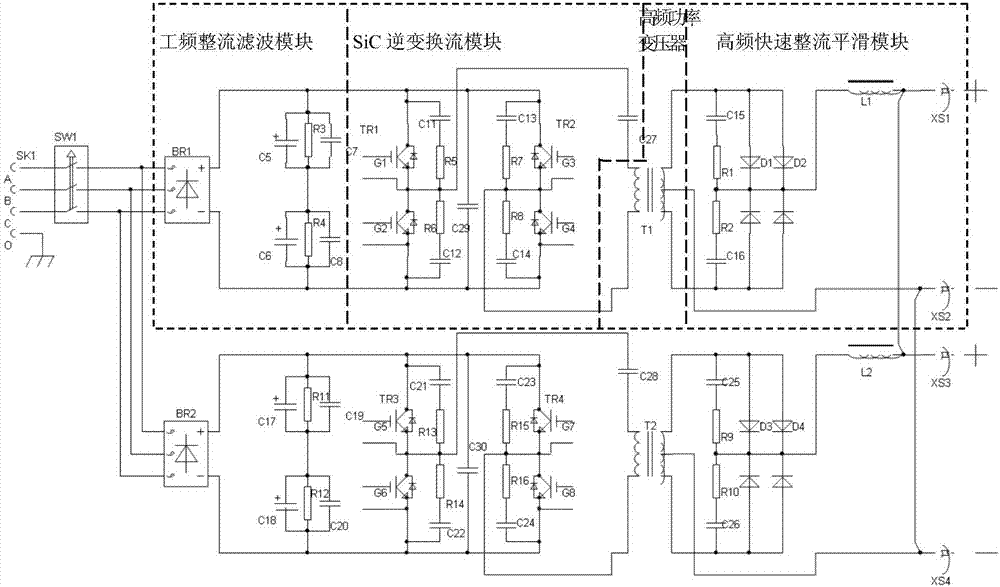

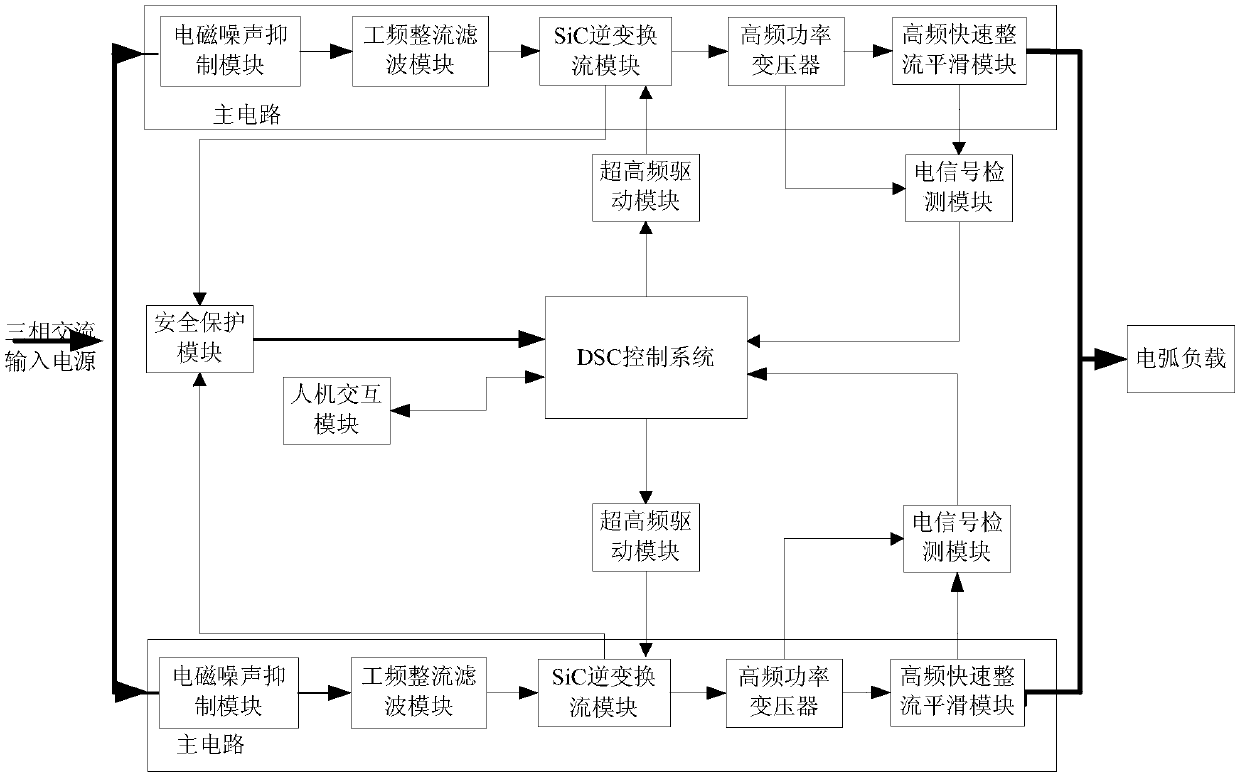

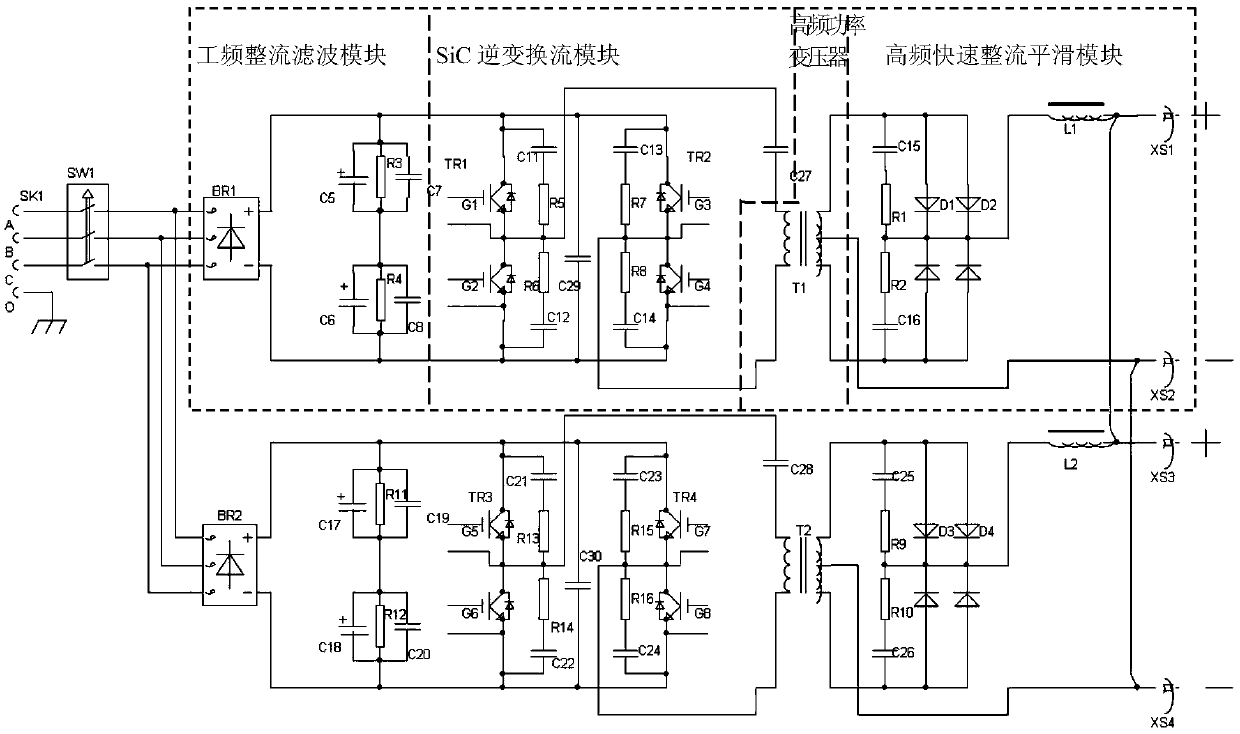

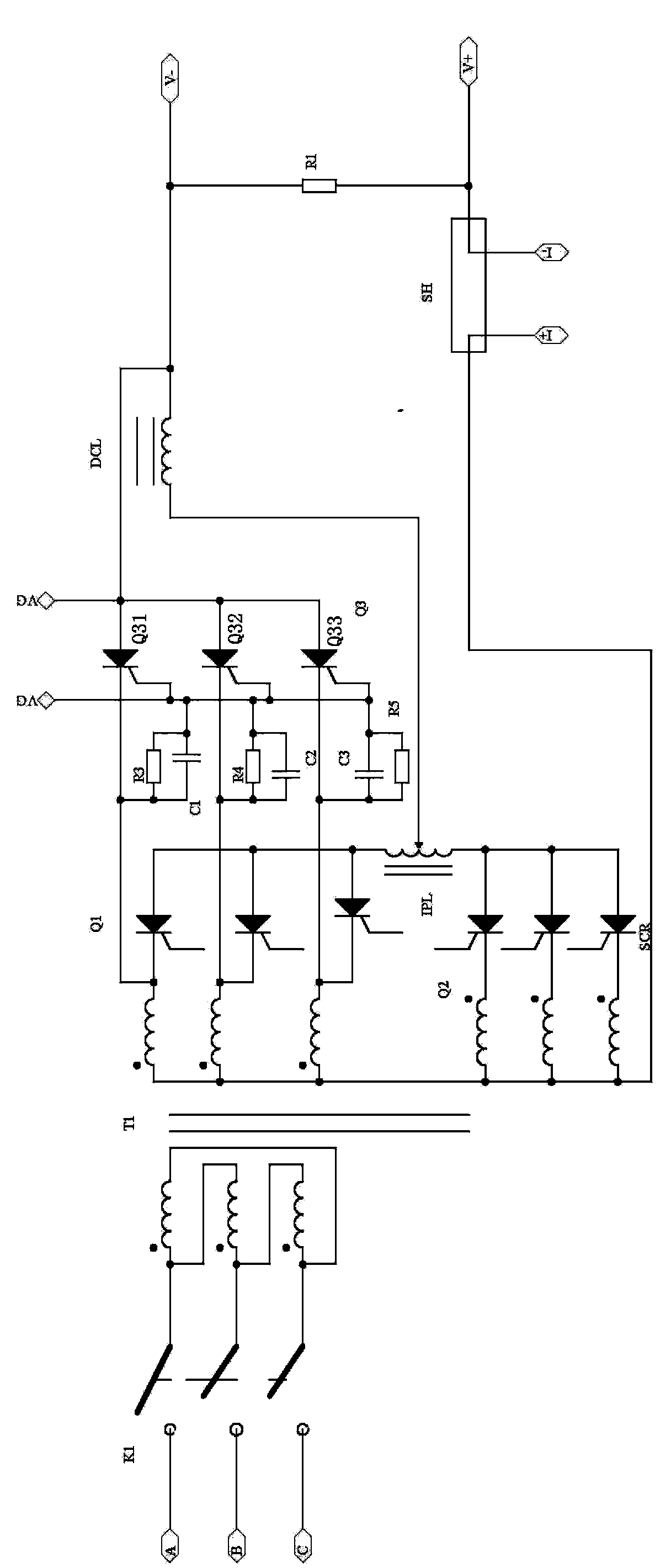

High-power SiC submerged arc welding power supply

ActiveCN107052527AImprove efficiencyReduce volumeArc welding apparatusHigh frequency powerTransformer

The invention provides a high-power SiC submerged arc welding power supply. The high-power SiC submerged arc welding power supply is characterized by comprising at least one main circuit and digital control circuit; each main circuit comprises an electromagnetic noise inhibition module, a power frequency rectification filter module, a SiC inverse transformation current module, a high-frequency power transformer and a high-frequency quick rectification smooth module connected in sequence; the high-frequency quick rectification smooth module is connected with an arc load; the digital control circuit comprises a DSC control system, a human-computer interaction module, a safety protection module, an ultrahigh-frequency driving module and an electric signal detecting module; the ultrahigh-frequency driving module is connected with the SiC inverse transformation current module; the safety protection module is connected with the SiC inverse transformation current module; and the electric signal detection module is respectively connected with the high-frequency power transformer and the high-frequency quick rectification smooth module. A SiC power switch tube can be applied to the submerged arc welding power supply, so that the inversion frequency is greatly improved, the efficiency is high, the size is small, and the welding quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

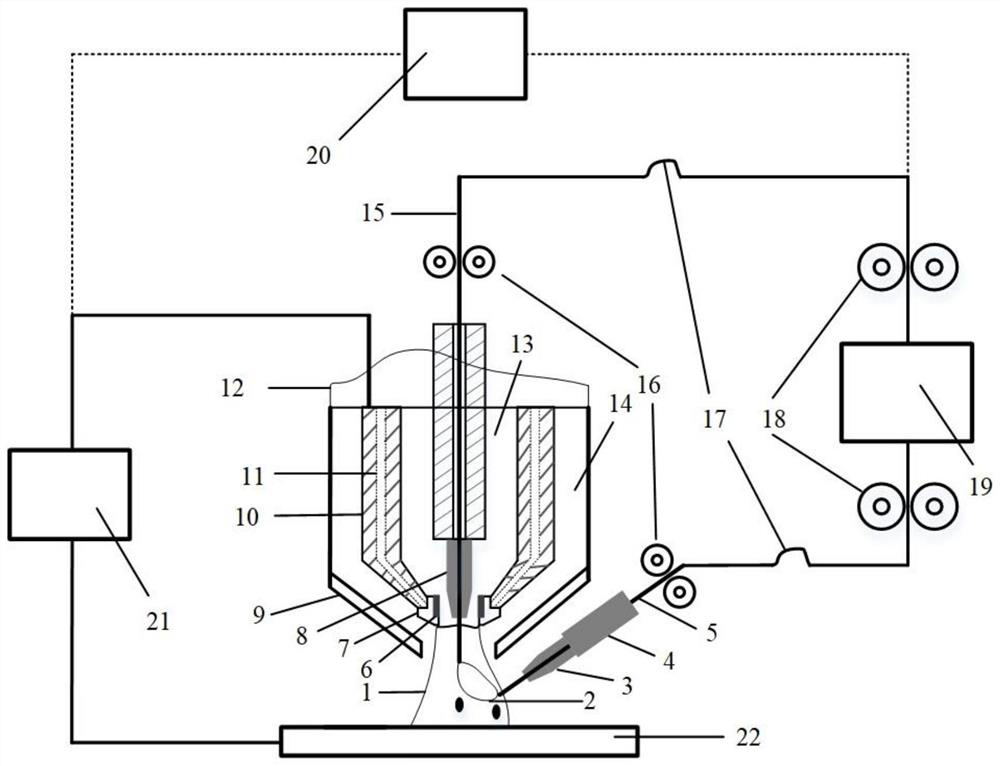

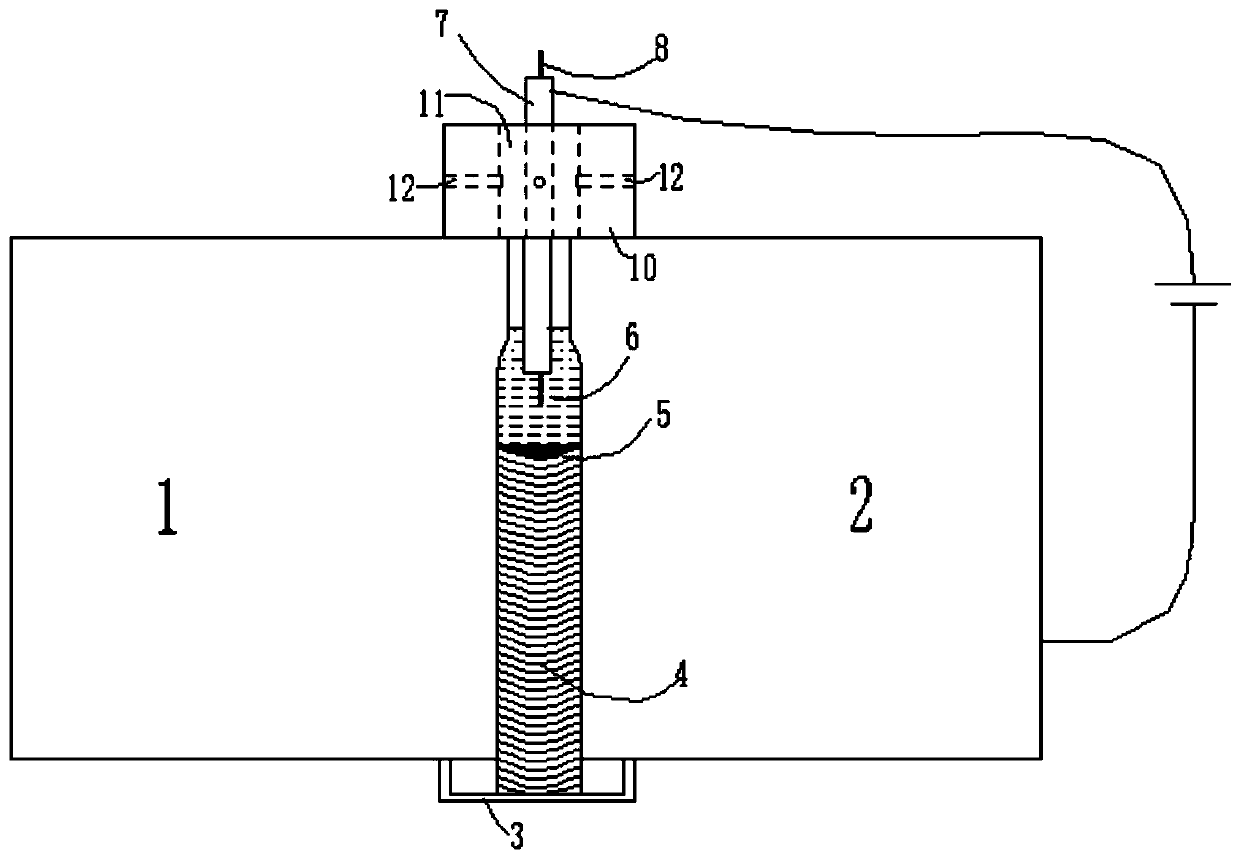

Small electric arc smelting furnace

ActiveCN110220376AGuaranteed stabilityReduce complexityCharge treatment typeCrucible furnacesCrucibleSmelting process

The invention discloses a small electric arc smelting furnace. A vacuum hearth is included, and the lower end portion of the vacuum hearth is inserted and installed on an arc striking rod in the vacuum hearth; the lower end portion of the arc striking rod is fixedly provided with a tungsten needle, and the upper end portion of the arc striking rod is connected with a power source through an electrode binding post; the bottom of the vacuum hearth is provided with a water cooling crucible of a plurality of metal molten ponds, and the metal molten ponds are used for containing a metal melt; and the bottom of the water cooling crucible is connected with the power source through an electrode binding post. The small electric arc smelting furnace further comprises a metal corrugated pipe arrangedon the arc striking rod in a sleeving manner, and the lower end of the metal corrugated pipe is installed on the shell wall of the vacuum hearth; the upper end of the metal corrugated pipe is connected with the arc striking rod through a connection piece; and the metal corrugated pipe is provided with a corrugated pipe lower limiting frame and a corrugated pipe upper limiting frame. The small electric arc smelting furnace is convenient to operate, and then the complexity degree in the electric arc smelting operation process is effectively lowered; and meanwhile, the possibility that the tungsten needle reacts with the metal melt is remarkably lowered, and the stability and the success rate in the electric arc smelting process are greatly improved.

Owner:GONGHUI METALLURGY EQUIP TECH SUZHOU CO LTD

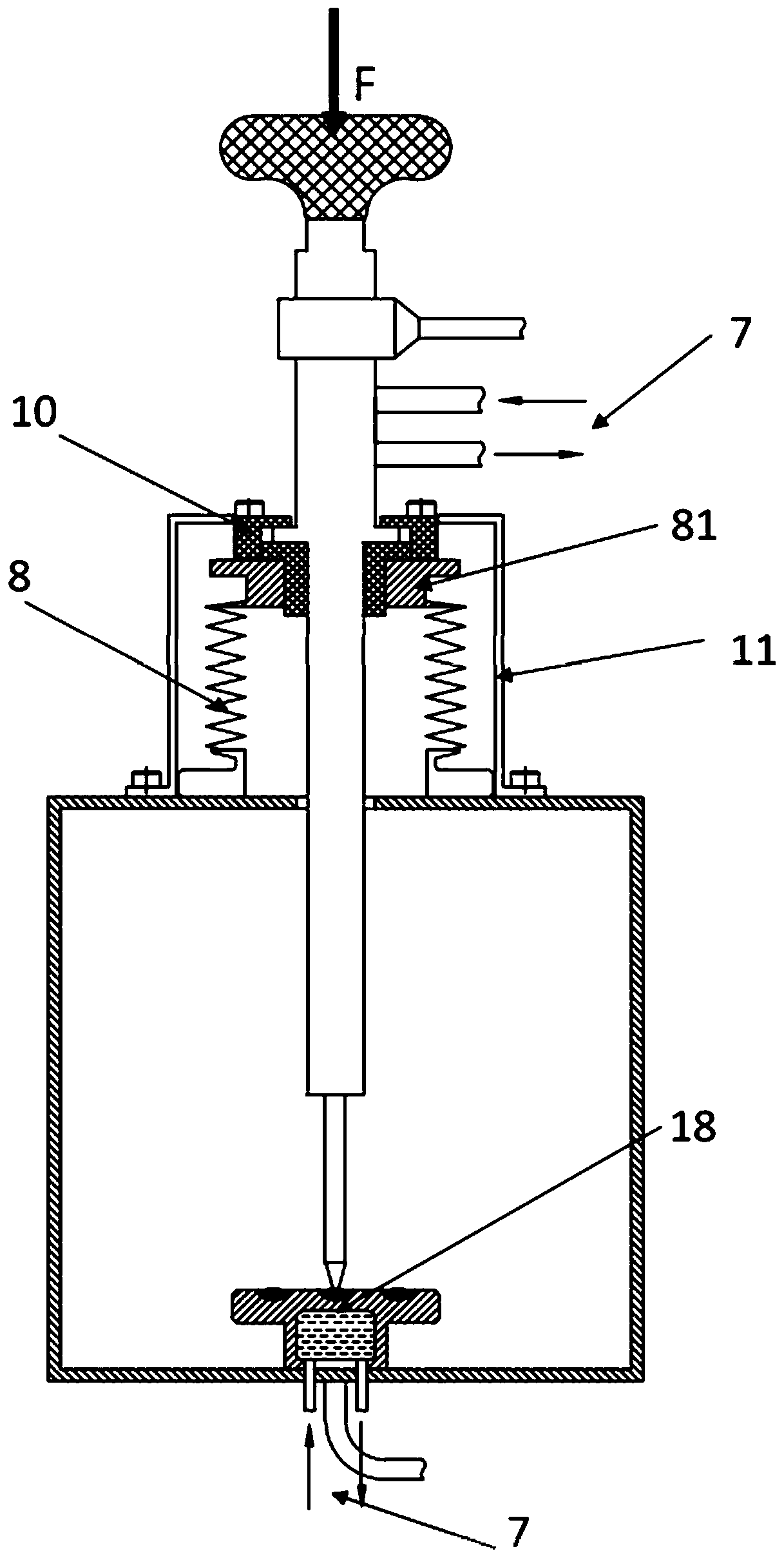

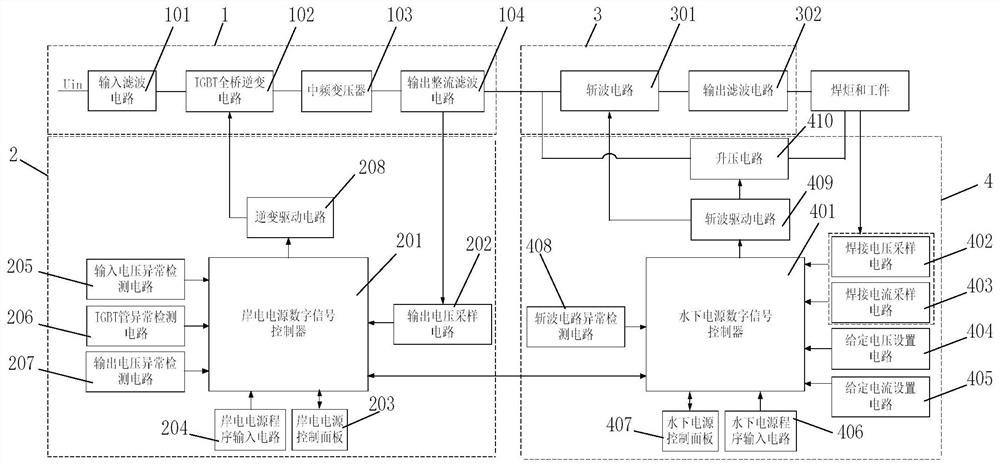

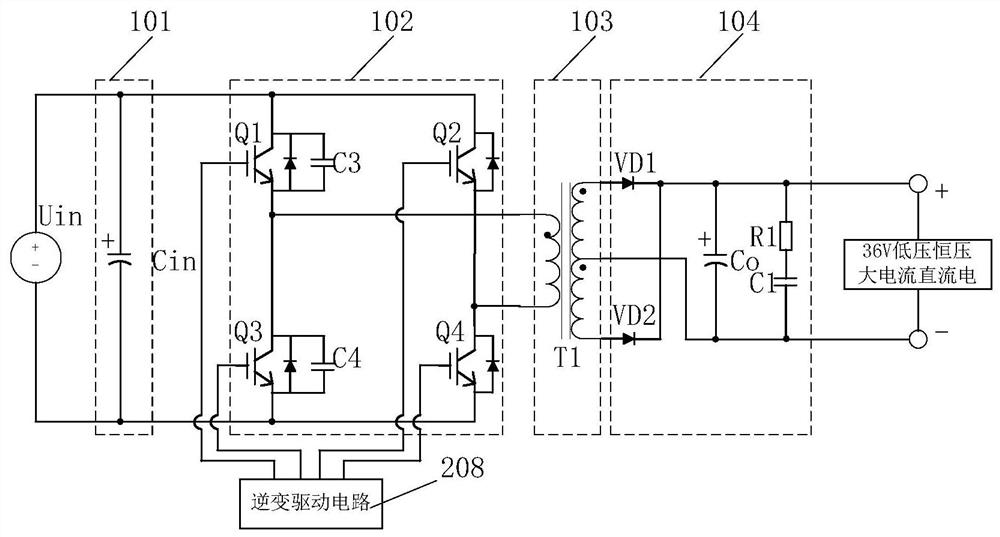

Split type multifunctional underwater arc welding power supply and working method thereof

ActiveCN113452255AReal-time adjustmentReduce the risk of underwater electric shockEfficient power electronics conversionDc-dc conversionMarine engineeringTransformer

The invention discloses a split type multifunctional underwater arc welding power supply which comprises a shore power supply module and an underwater power supply module. The shore power supply module comprises a shore power supply main circuit unit and a shore power supply control unit; the shore power supply main circuit unit comprises an input filter circuit, an IGBT full-bridge inverter circuit, an intermediate frequency transformer and an output rectification filter circuit; the underwater power supply module comprises an underwater power supply main circuit unit and an underwater power supply control unit; the shore power supply module is arranged on the shore; and the underwater power supply module is carried underwater. An integrated arc welding power supply directly arranged on the shore in the prior art is designed in a split mode, and real-time adjustment of the welding state during underwater welding can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH +2

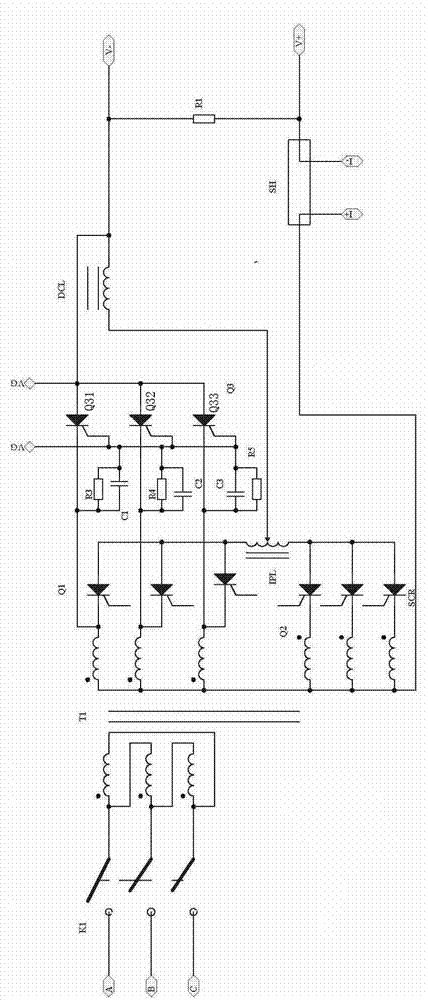

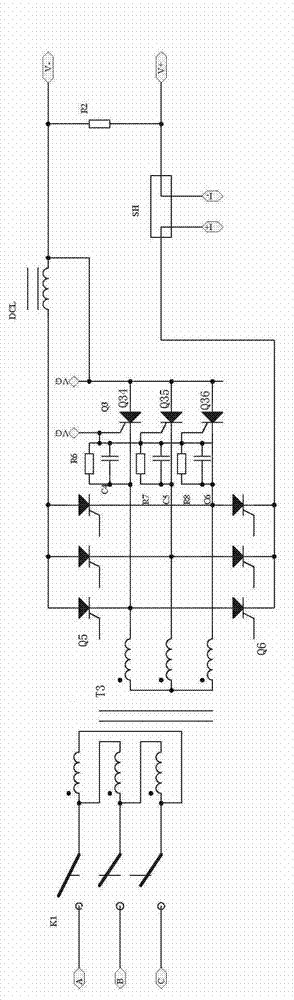

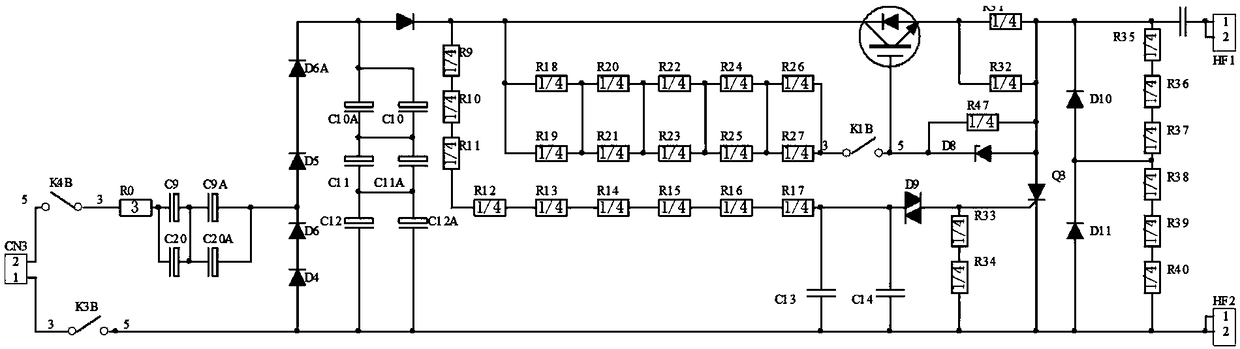

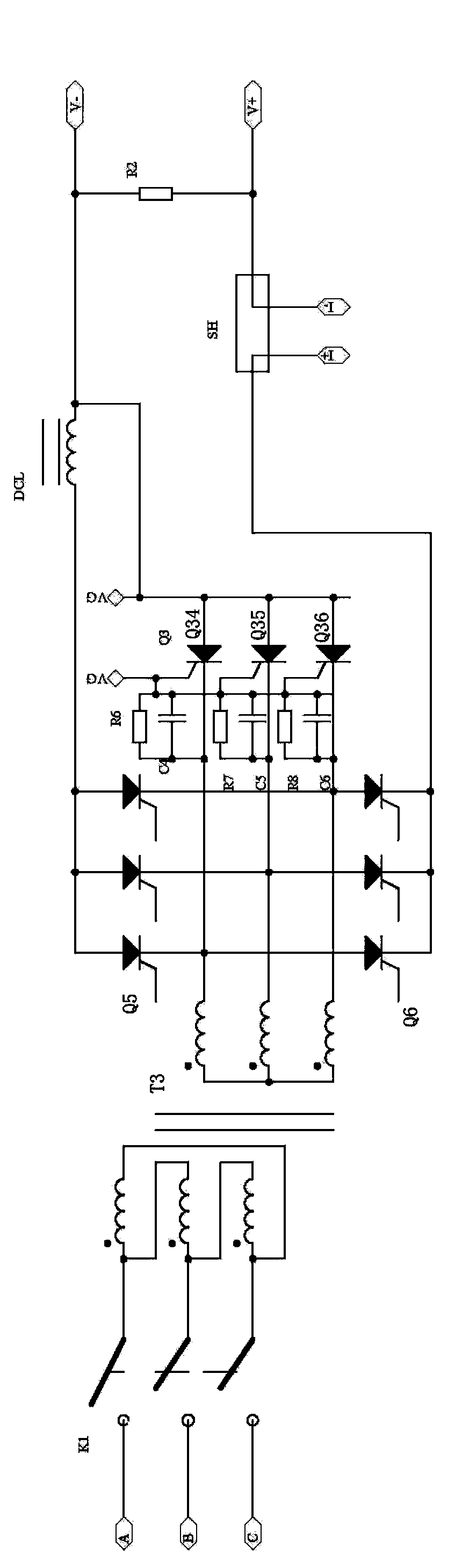

Circuit for realizing CO2/MAG (metal, active gas welding) arc welding machine arc-striking method

ActiveCN102728931AImprove the success rate of arc strikingArc striking quicklyArc welding apparatusControl signalTransformer

The invention relates to a circuit for realizing CO2 / MAG (metal, active gas welding) arc welding machine arc-striking method. The circuit comprises an arc welding machine main circuit which includes a step-down transformer and a direct current reactor. A third thyristor group is arranged on the secondary winding of the step-down transformer, one end of the direct current reactor is connected with the anode end of each thyristor in the third thyristor group and the third thyristor group is connected with the output end of a thyristor control circuit. In arc striking, the thyristor control circuit outputs a first control signal, so that the direct current reactor is formed as an arc striking bypass by the arc welding machine main circuit via the third thyristor group, and arc striking is performed by the secondary winding of the step-down transformer until arc striking is finished. After arc striking is finished, the thyristor control circuit outputs a second control signal, so that the direct current circuit output from the step-down transformer turns off the third thyristor group and required welding is performed by the direct current reactor. The inventive circuit is simple in structure, improves welding machine arc striking success rate, causes small welding splash, realizes good formed weld seam, and is convenient to operate, safe and reliable.

Owner:JIANGSU DADE HEAVY IND

Novel method for hot cutting

InactiveCN101574749AImprove the success rate of arc strikingReduce power consumptionArc welding apparatusOvervoltageDc current

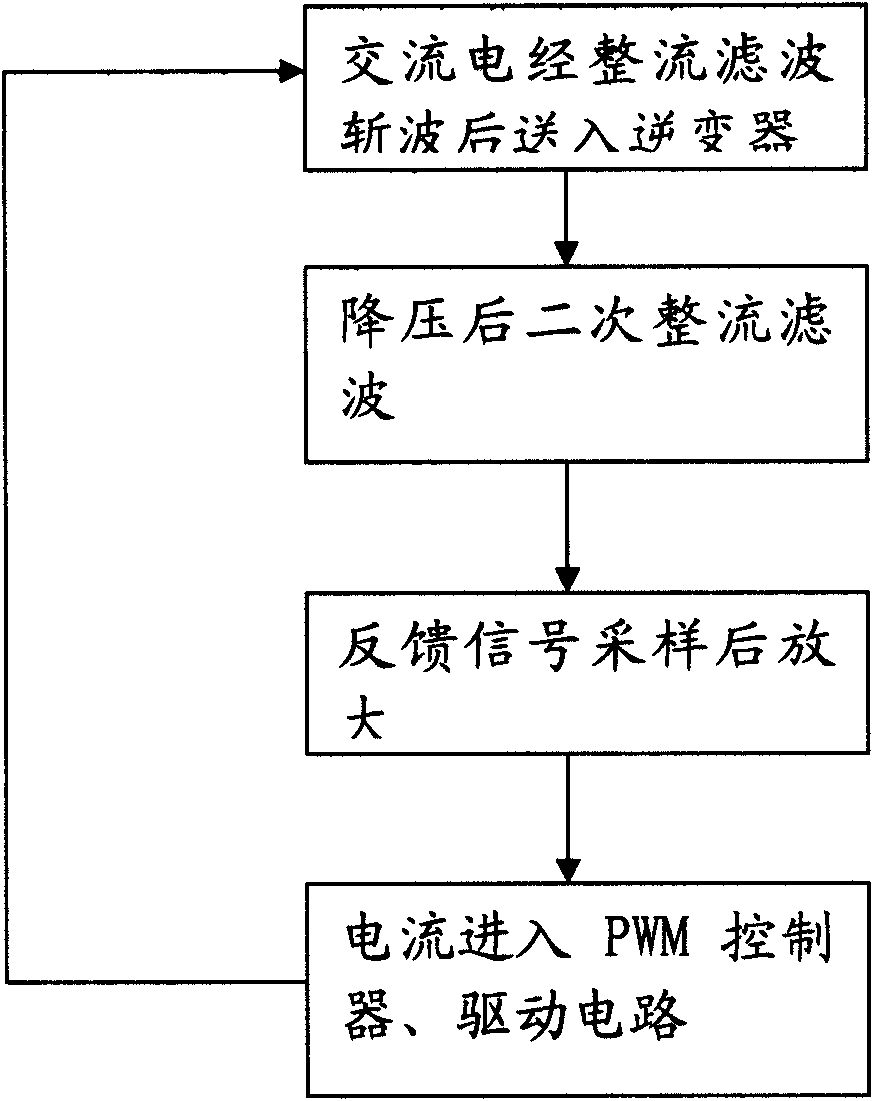

The invention provides a novel method for hot cutting. The method is characterized by comprising the following steps that: alternating current is fed into an inverter to generate medium frequency alternating current after being subjected to rectifying, wave-filtering and chopping; and the medium frequency alternating current is subjected to voltage reduction by a power transformer, and secondary rectifying and wave-filtering to form stable direct current to be supplied to cutting arc. The method has the advantages that dropping characteristic is set to generator characteristic, so that the method has high success probability of arc generation and low power consumption; inverter technology is the key point of realizing high power output by an inverse air plasma cutting power supply, IGBT is used as a switch element, and a full-bridge inverse circuit is adopted, so that quick and low power consumption controllable alternating current output can be realized; drive power can be effectively improved, optimal drive voltage is selected, and implementation of overvoltage overcurrent protection is the basic use principle of the IGBT module; and reasonable selection of the medium frequency transformer can improve system reliability.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

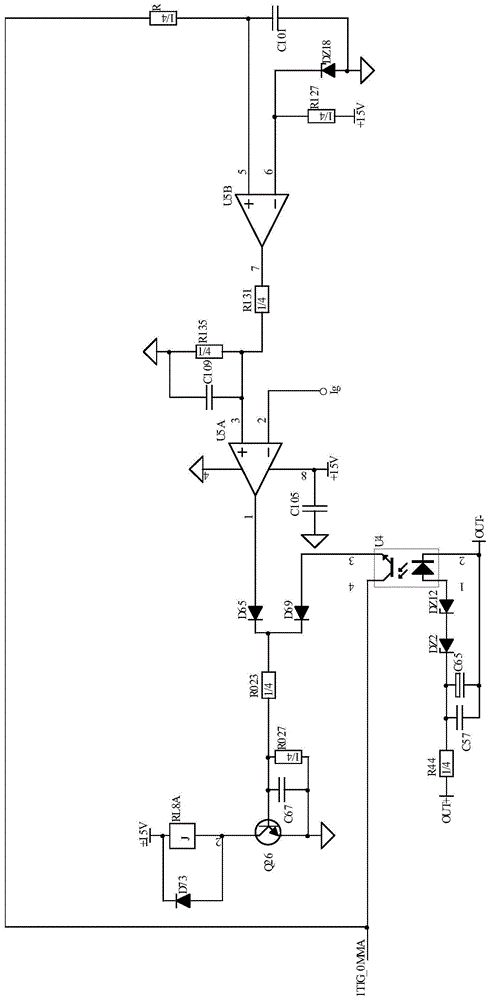

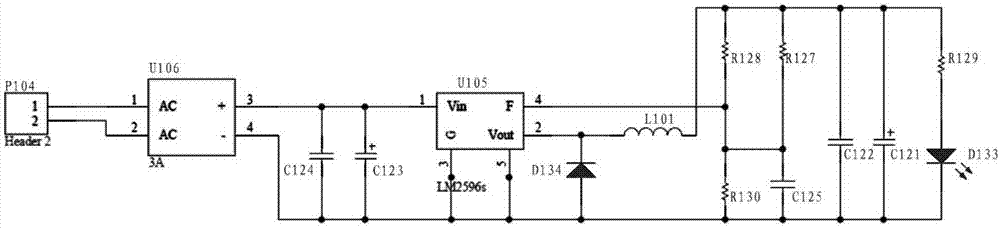

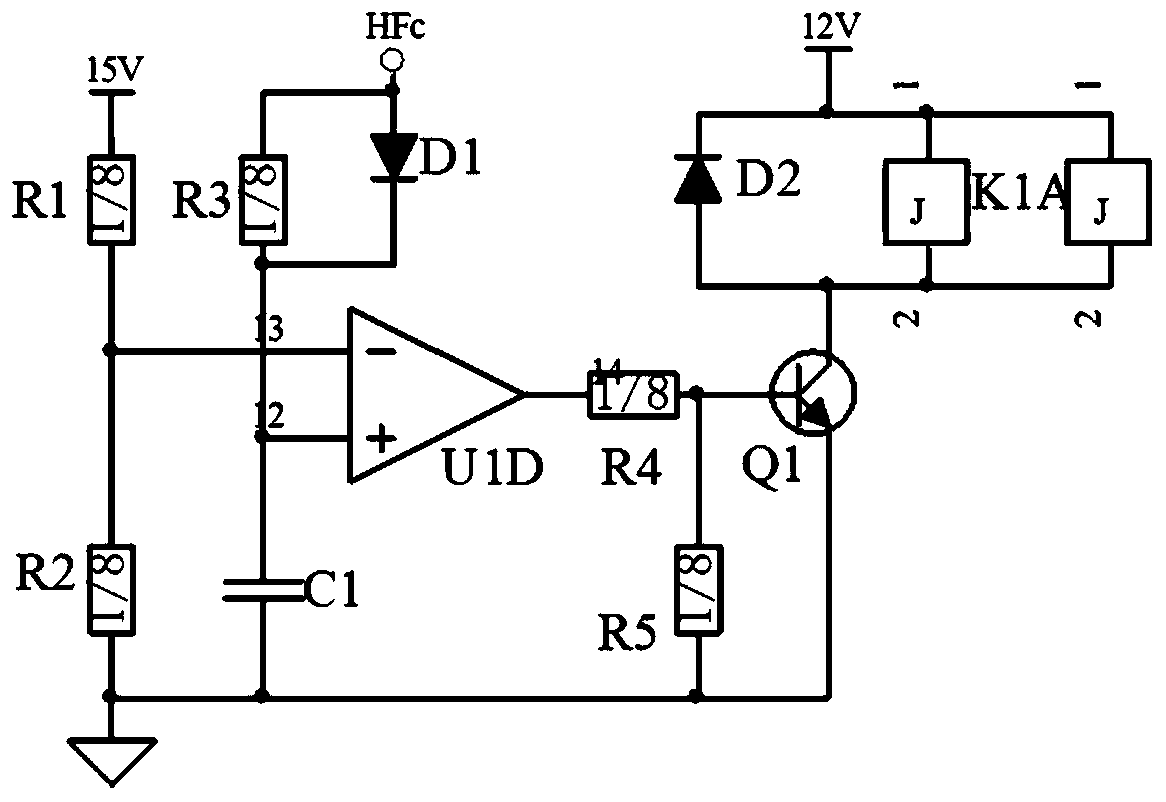

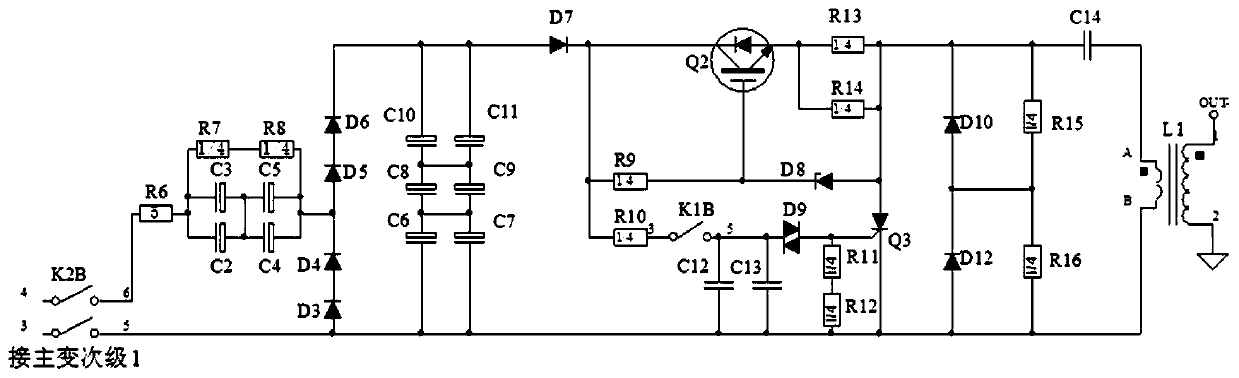

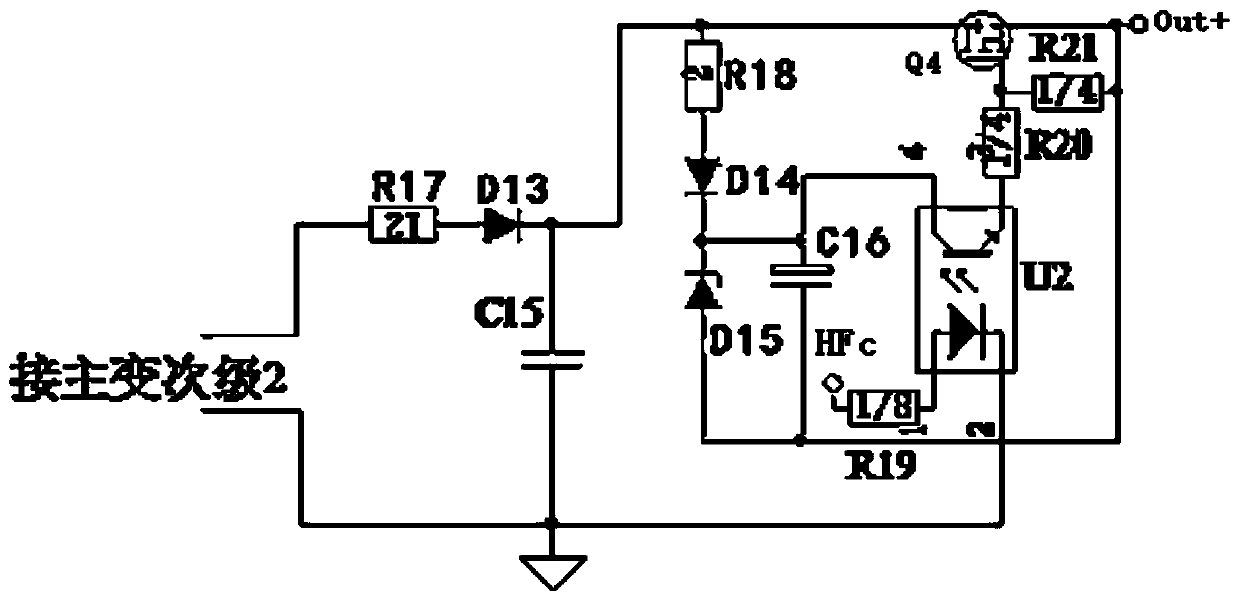

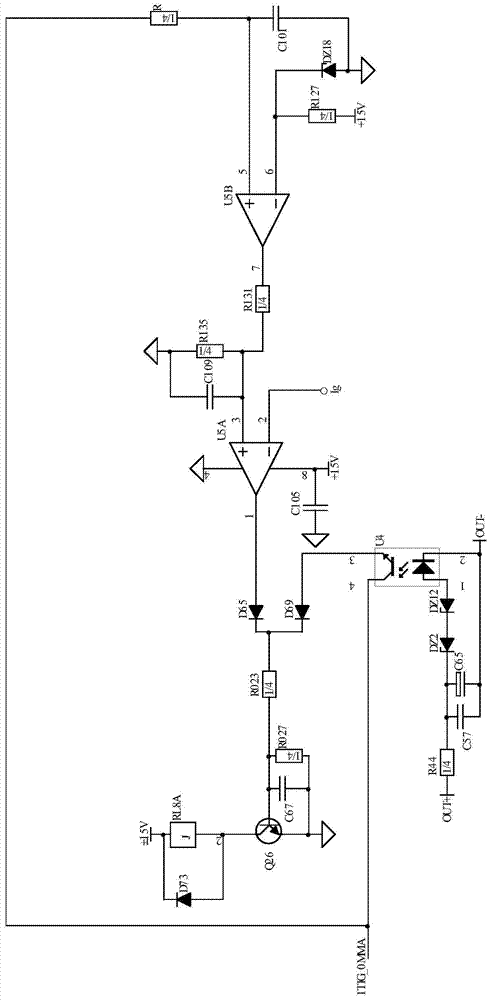

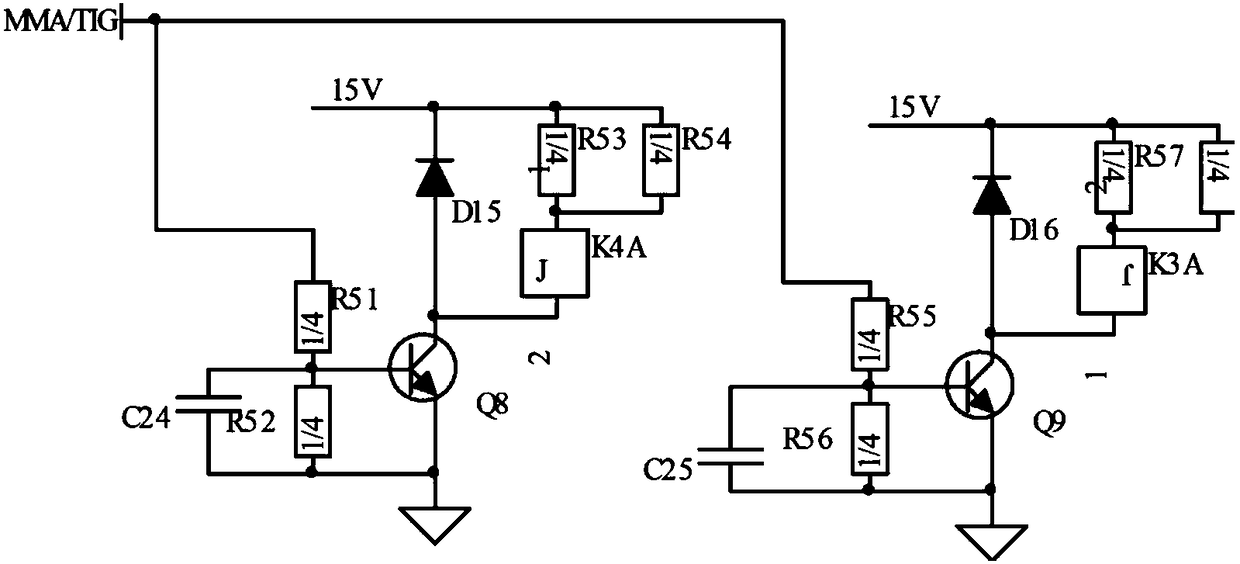

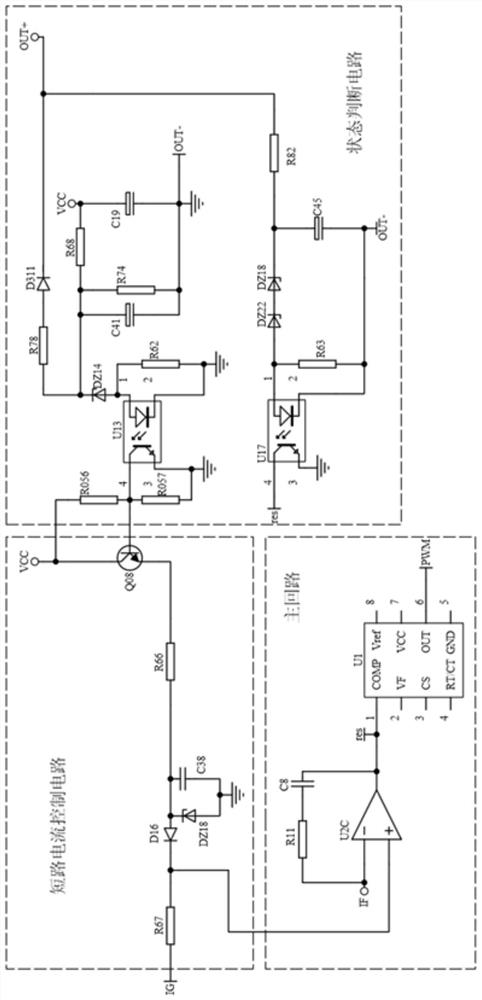

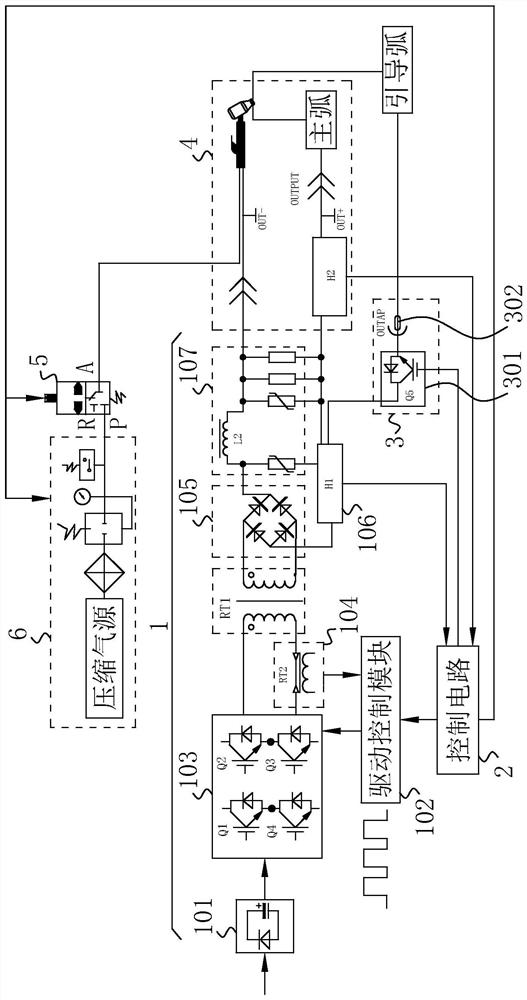

Non-contact arc ignition circuit for argon arc welding machine

ActiveCN108340048BImprove the success rate of arc strikingReduce electromagnetic interferenceArc welding apparatusEngineeringAlternating current

The invention provides a non-contact arc ignition circuit for an argon arc welding machine. The non-contact arc ignition circuit for the argon arc welding machine comprises a high-frequency arc ignition control circuit, a high-frequency arc ignition circuit and an auxiliary arc ignition circuit. When a welding gun is switch on, the high-frequency arc ignition control circuit processes a pulse signal HFc sent out by a control system, an audion Q1 is conducted, and current passes through the primary side of a switch K1 and the primary side of a switch K2; the secondary sides of the switch K1 andthe switch K2 of the high-frequency arc ignition circuit are closed, and alternating current of a main transformer primary side first secondary winding passes through a voltage doubling circuit and ahigh-frequency generating circuit, then passes through an arc ignition inducer and applies to an output negative electrode OUT- of a welding machine; the auxiliary arc ignition circuit processes an arc ignition signal HFc sent out by the control system, an MOS tube Q4 is conducted, and alternating current of a main transformer primary side second secondary winding is rectified through a diode D12and then is applied to an output positive electrode OUT+ of the welding machine through the MOS tube Q4; and consequently, an arc is ignited. With the adoption of the non-contact arc ignition circuitfor the argon arc welding machine, electromagnetic interference and arc ignition noise during arc ignition can be reduced substantially, and the success rate of the arc ignition is increased.

Owner:SHANGHAI GREATWAY WELDING EQUIP

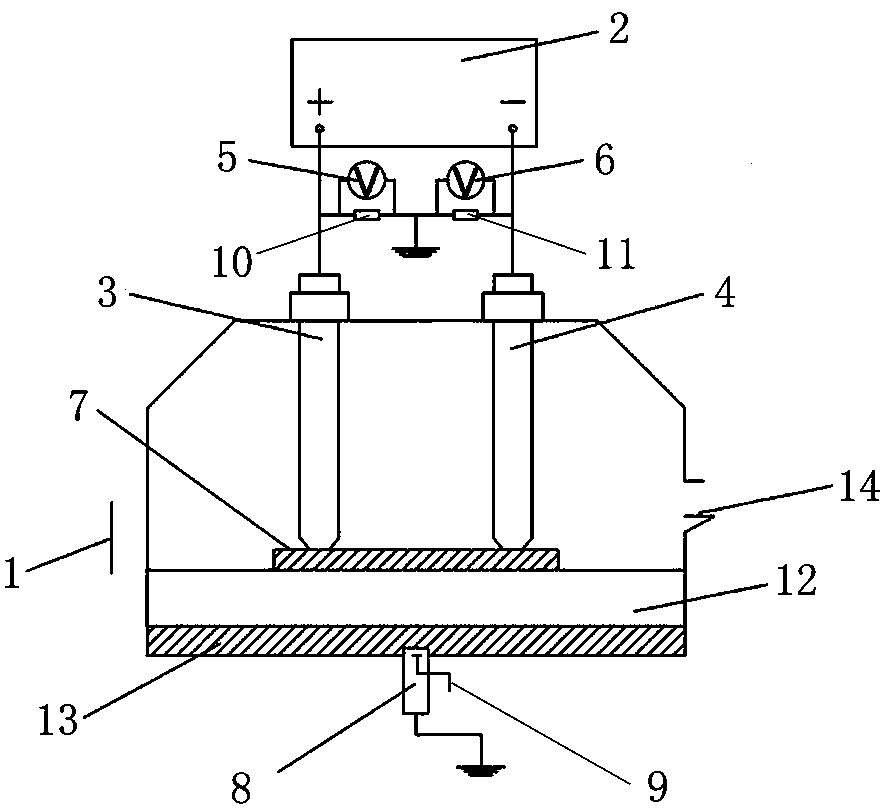

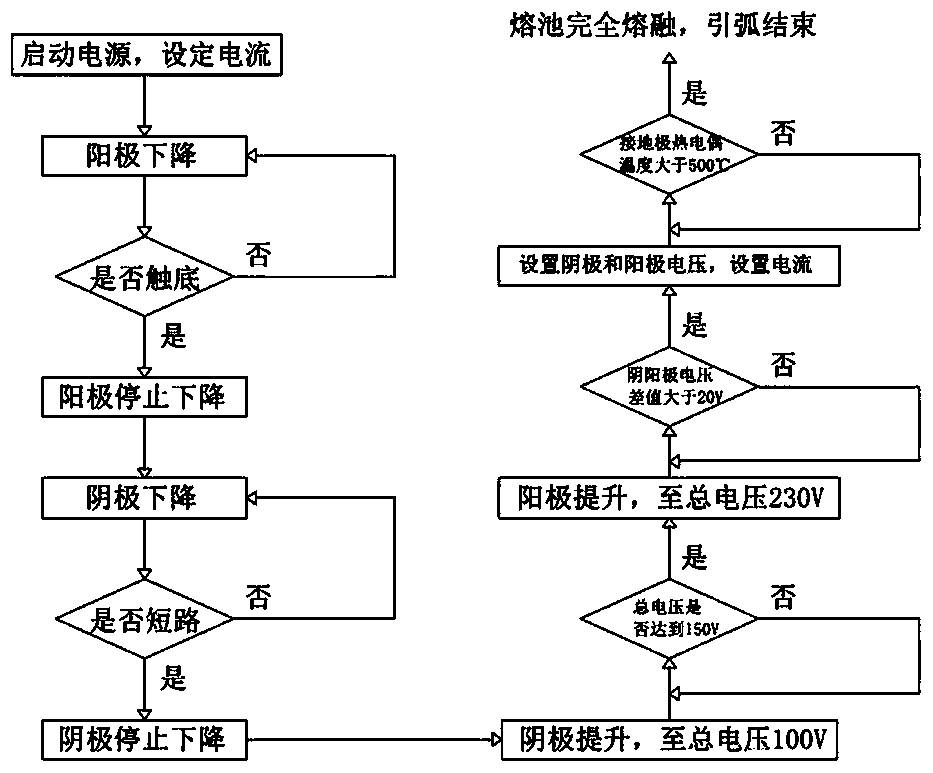

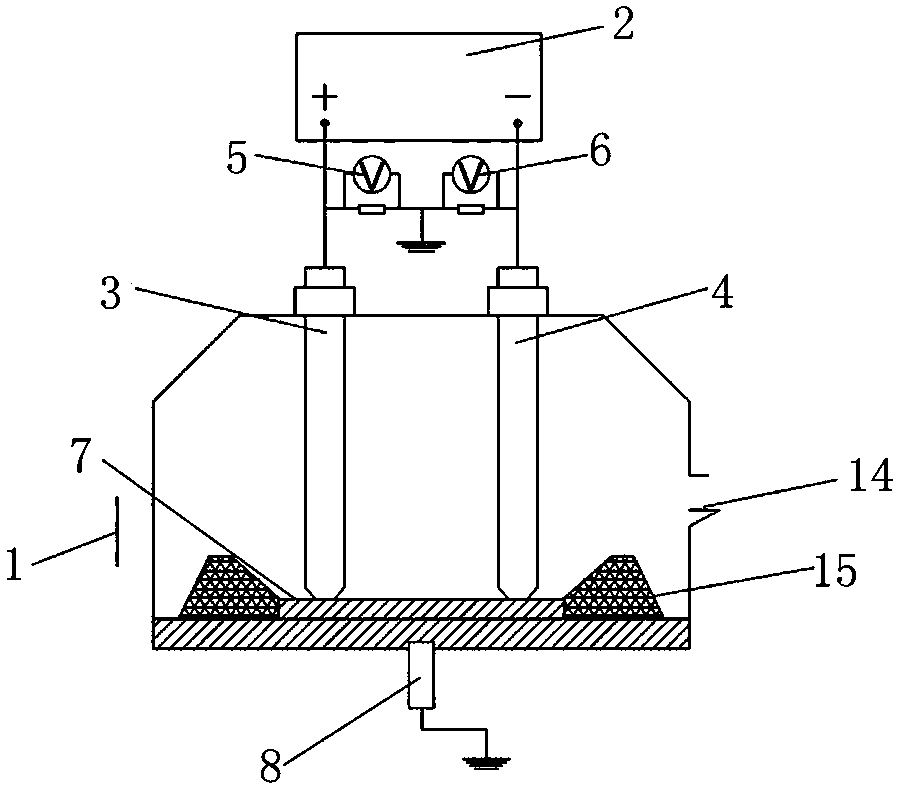

Double-electrode DC arc furnace arc ignition device and method thereof

PendingCN110167226AClear dataEasy to operateElectric discharge heatingLighting and heating apparatusDc arc furnaceAutomatic control

The invention discloses a double-electrode DC arc furnace arc ignition device and method thereof. The device includes a melting furnace, a DC power source, an anode electrode, a cathode electrode, ananode voltage measuring unit, a cathode voltage measuring unit, an arc ignition metal plate, a metal ground electrode and a thermocouple, wherein one end of an anode resistor is connected with a positive pole of the DC power source, one end of a cathode resistor is connected with a negative pole of the DC power source, the other end of the anode resistor and the other end of the cathode resistor are grounded, both ends of the anode voltage measuring unit are respectively connected with both ends of the anode resistor, both ends of the cathode voltage measuring unit are respectively connected with both ends of the cathode resistor, the arc ignition metal plate is horizontally disposed on an upper side of a solidified slag layer, the metal ground electrode penetrates into the melting furnacefrom a lower end of the melting furnace, an upper end of the metal ground electrode is in contact with a solidified metal layer, a lower end of the metal ground electrode is grounded, and the thermocouple is placed inside the metal ground electrode. The device is advantaged in that the device has strong operability and high success rate of arc ignition and can be easily transformed into an automatic control program to realize automatic arc ignition.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

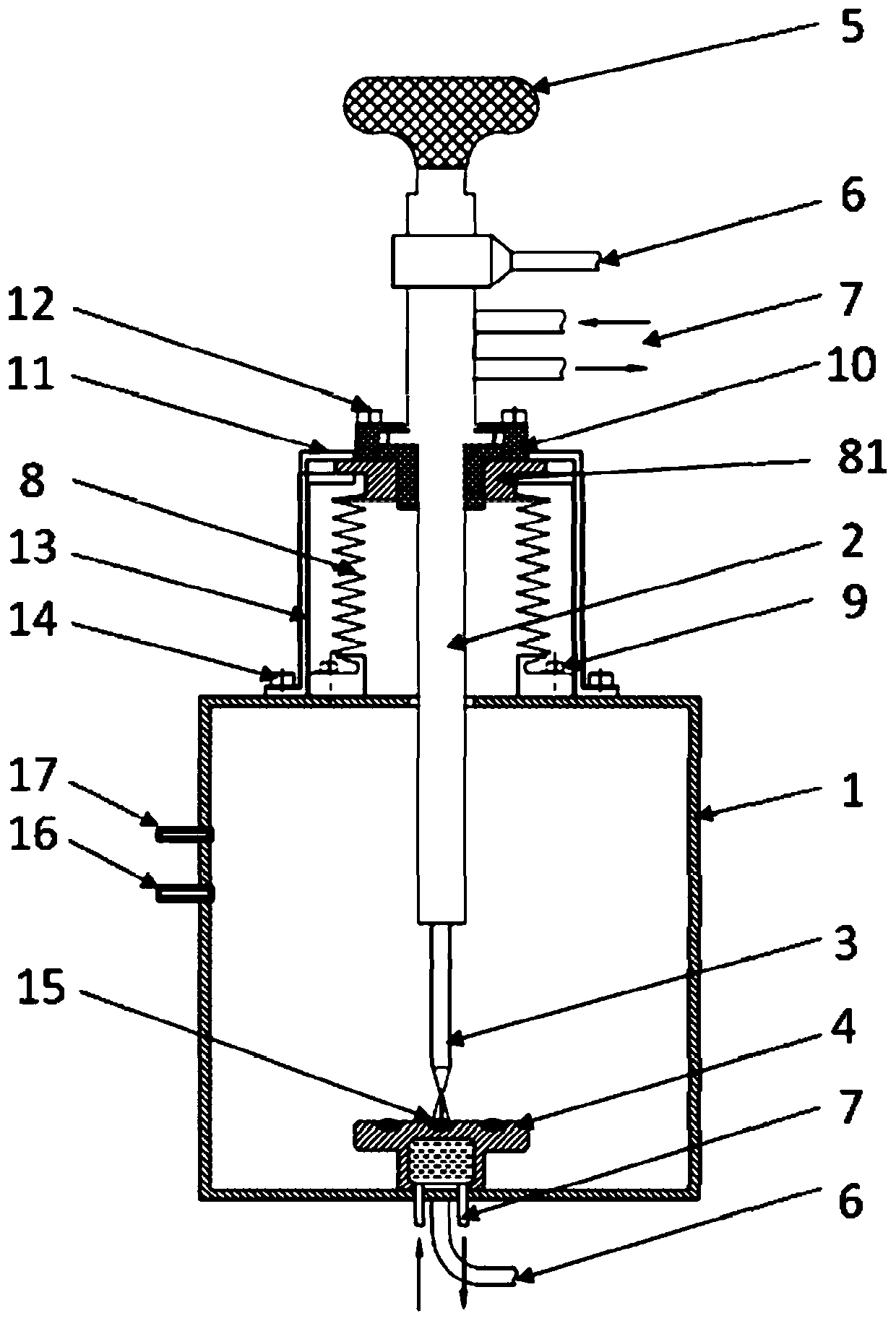

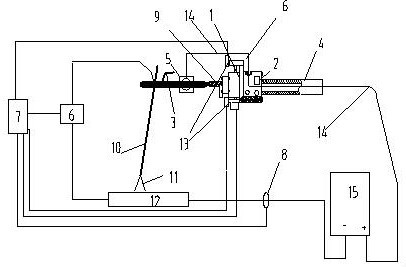

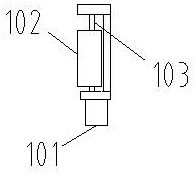

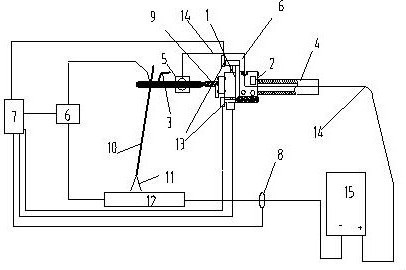

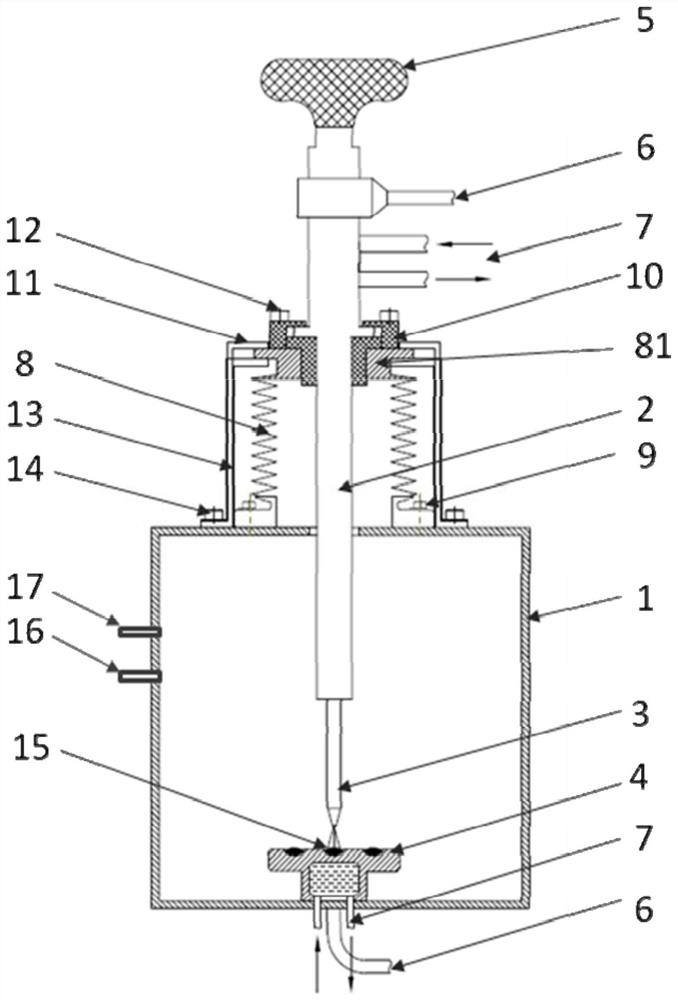

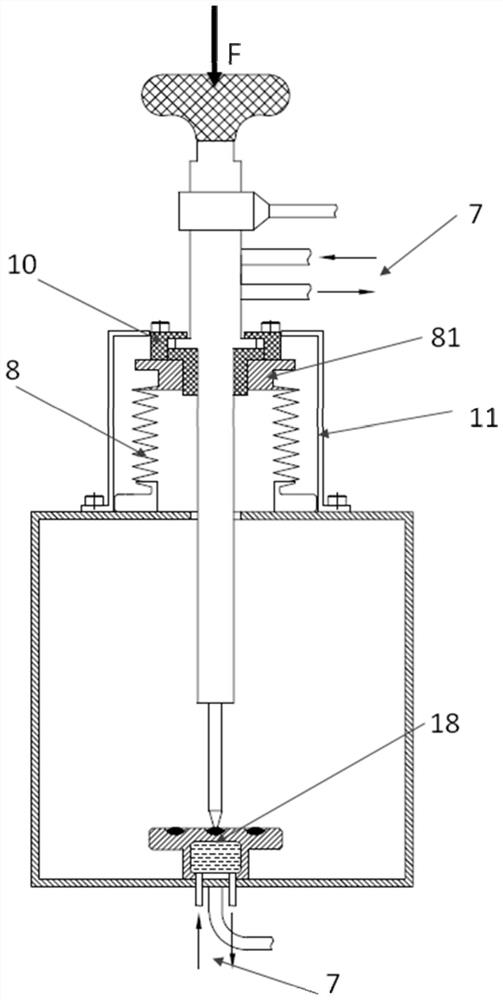

Intelligent shielded metal arc welding gun system with arc length change compensation for manual operation

ActiveCN112872552AImprove the success rate of arc strikingImproved arc stabilityElectrode supporting devicesElectrode accessoriesPhysicsArc stability

The invention provides an auxiliary arc striking and arc length control shielded metal arc welding gun system for manual operation. A device comprises a miniature sliding table mechanism capable of driving an electric arc to move up and down, a fixing seat used for installing the miniature sliding table mechanism, a welding clamp used for clamping a welding rod, a grip, a chuck used for connecting a cable and the welding clamp, a Hall voltage sensor used for detecting welding voltage, and a control circuit board used for controlling automatic arc striking, arc length compensation and the like for shielded metal arc welding. The miniature sliding table mechanism can drive an electric arc to slightly move up and down in the length direction of the electric arc or in the direction similar to the length direction of the electric arc when a welding rod is manually fed, so that the length of the welding electric arc is finely adjusted, the arc length change caused by non-uniform feeding speed of the welding rod in the manual shielded metal arc welding process is compensated, the electric arc length is kept unchanged, and the arc stability is improved.

Owner:JIANGSU MARITIME INST

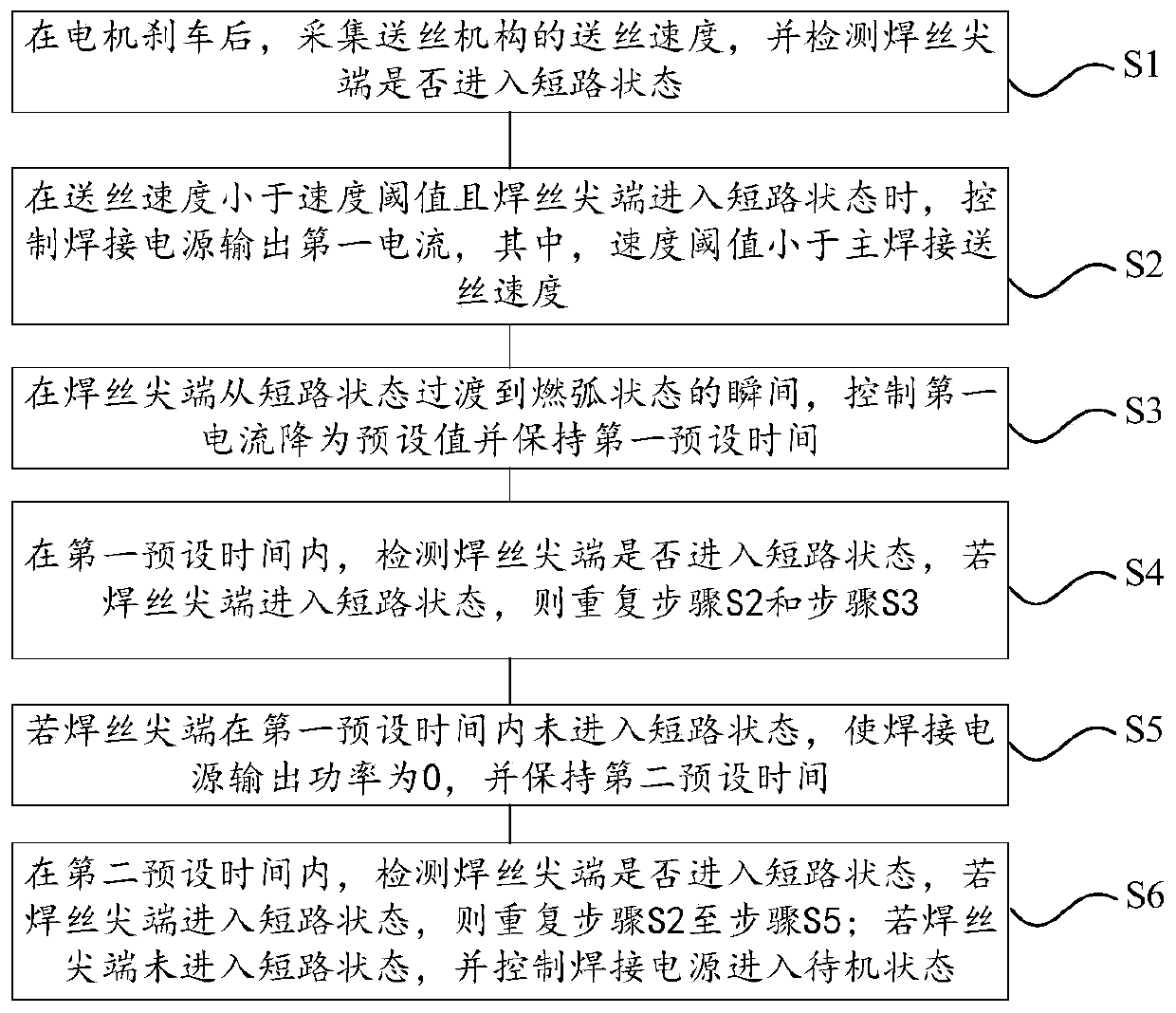

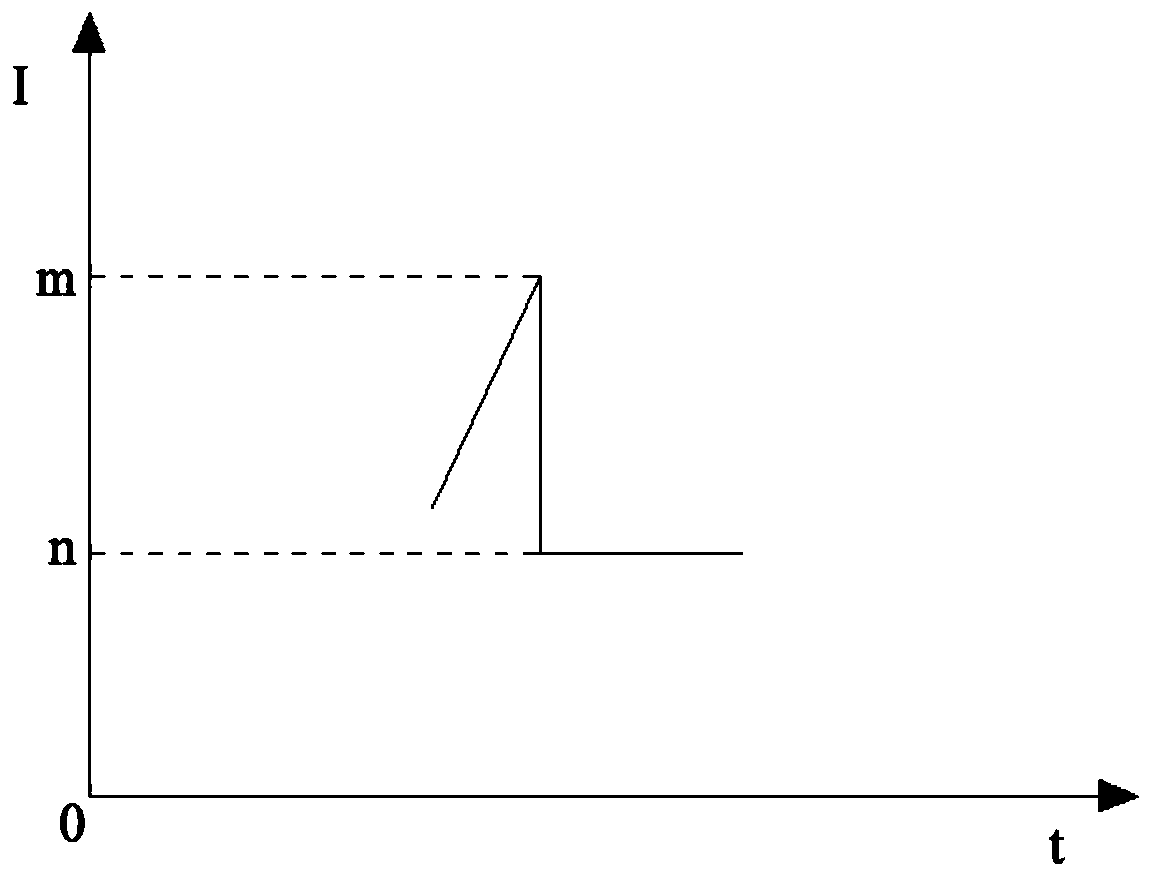

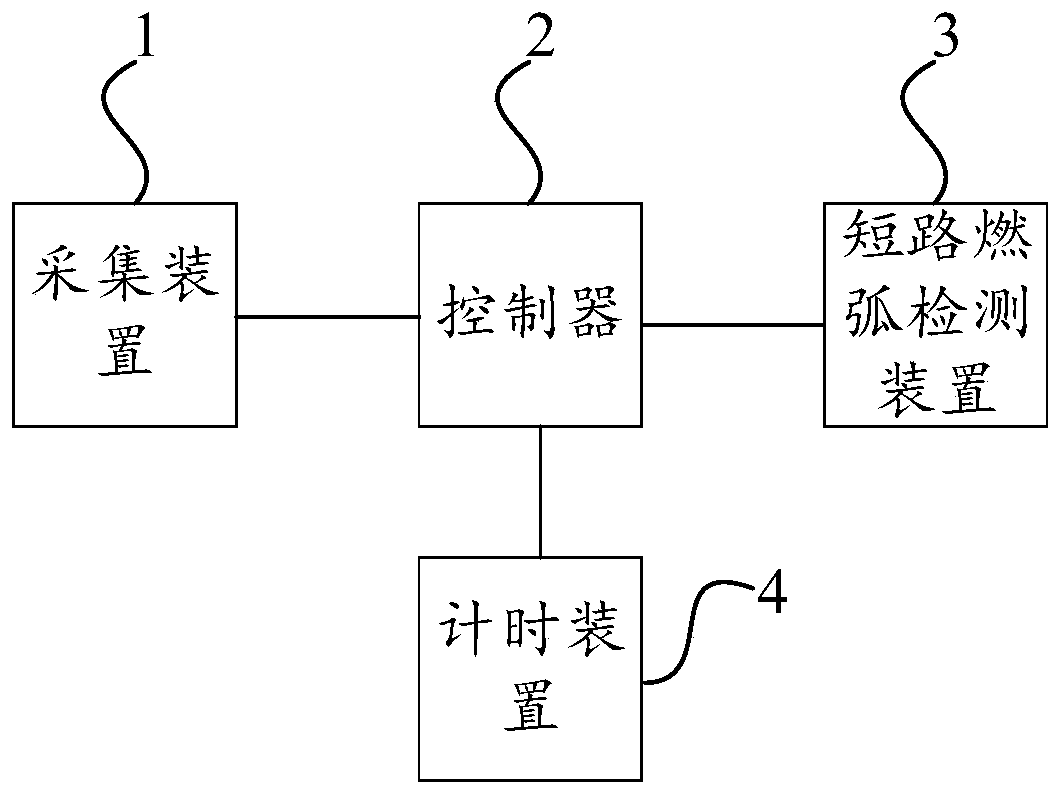

Welding device, and burn-back control device and method

ActiveCN111001896ASave energySolve the problem of excessive distanceWelding accessoriesWelding power supplyElectric machinery

The invention provides a welding device, a burn-back control device and a burn-back control method. The burn-back control method can comprise the steps: step S1, after a motor is braked, the wire feeding speed of a wire feeding mechanism is collected, and whether the tip end of a welding wire enters a short-circuit state or not is detected; step S2, when the wire feeding speed is smaller than a speed threshold value and the tip end of the welding wire enters the short-circuit state, a welding power source is controlled to output first current, and the speed threshold value is smaller than themain welding wire feeding speed; and step S3, at the moment when the tip of the welding wire is transited from the short-circuit state to an arcing state, the first current is controlled to be reducedto a preset value and kept for first preset time. The arc striking success rate can be increased, and the problem that the wire sticking risk exists due to the fact that the distance between the tipof the welding wire and a welding workpiece is too large or too small after burn-back is finished is solved.

Owner:PANASONIC WELDING SYST TANGSHAN

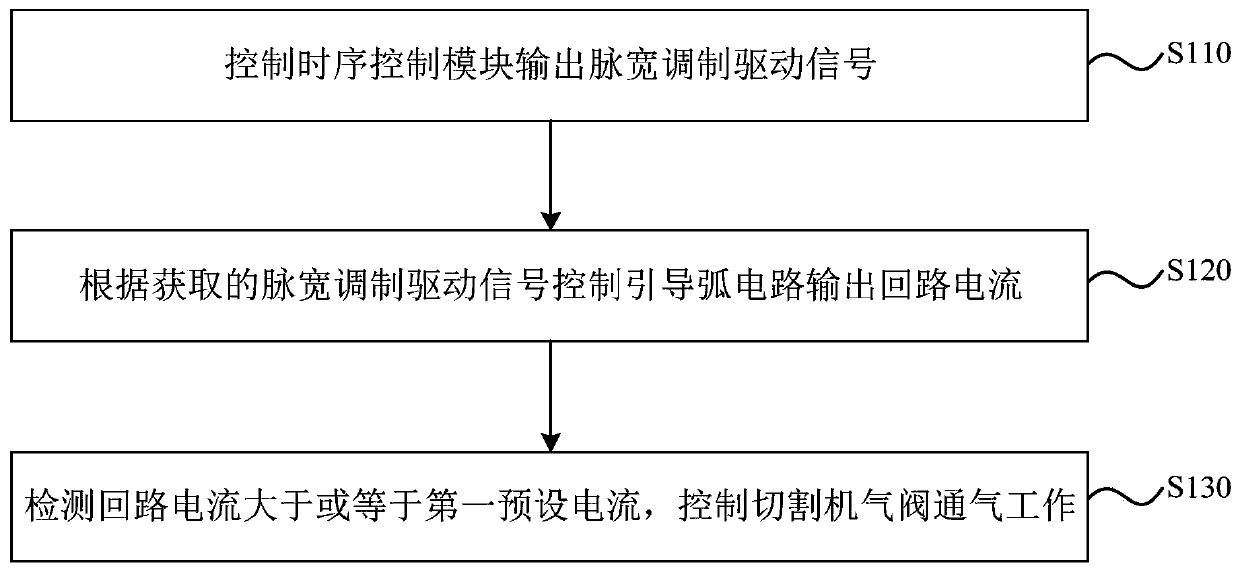

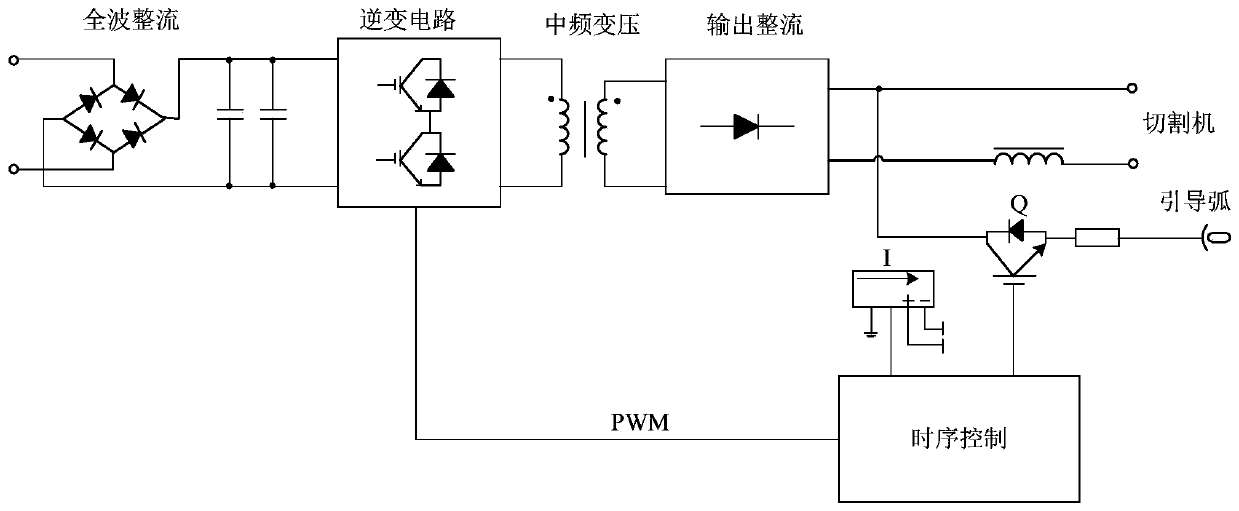

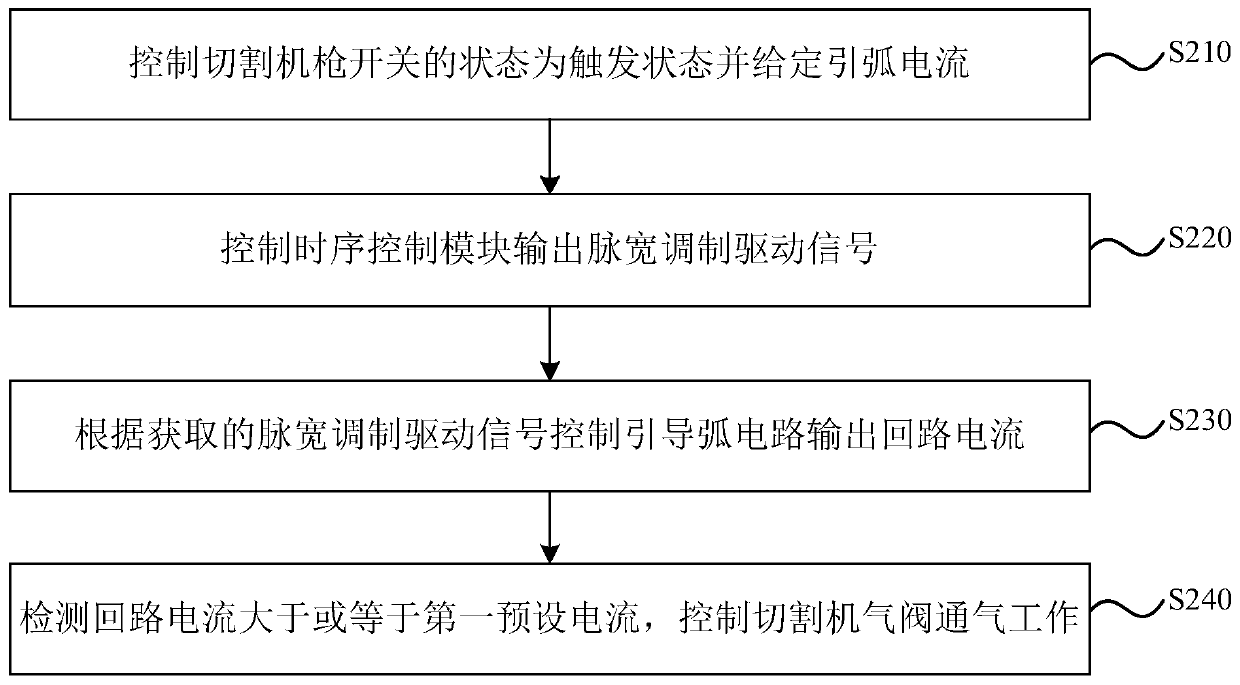

Cutting machine control method and control device

InactiveCN111545883AImprove the success rate of arc strikingReduce lossProgramme controlComputer controlMachine controlControl engineering

The invention discloses a cutting machine control method and a control device. The control method comprises the following steps of controlling a time sequence control module to output a pulse width modulation driving signal; controlling an arc ignition circuit to output loop current according to the obtained pulse width modulation driving signal; and detecting whether the loop current is greater than or equal to first preset current, and controlling a cutting machine air valve to ventilate and work. According to the technical scheme provided by the embodiment of the invention, the control module outputs the pulse width modulation driving signal to control the arc ignition circuit to output the loop current, so that the arc ignition success rate of the cutting machine is increased, the lossof a nozzle and an electrode is reduced, and the production cost is reduced.

Owner:上海气焊机厂有限公司

A high-power sic submerged arc welding power supply

ActiveCN107052527BImprove efficiencyReduce volumeArc welding apparatusHigh frequency powerTransformer

The invention provides a high-power SiC submerged arc welding power supply. The high-power SiC submerged arc welding power supply is characterized by comprising at least one main circuit and digital control circuit; each main circuit comprises an electromagnetic noise inhibition module, a power frequency rectification filter module, a SiC inverse transformation current module, a high-frequency power transformer and a high-frequency quick rectification smooth module connected in sequence; the high-frequency quick rectification smooth module is connected with an arc load; the digital control circuit comprises a DSC control system, a human-computer interaction module, a safety protection module, an ultrahigh-frequency driving module and an electric signal detecting module; the ultrahigh-frequency driving module is connected with the SiC inverse transformation current module; the safety protection module is connected with the SiC inverse transformation current module; and the electric signal detection module is respectively connected with the high-frequency power transformer and the high-frequency quick rectification smooth module. A SiC power switch tube can be applied to the submerged arc welding power supply, so that the inversion frequency is greatly improved, the efficiency is high, the size is small, and the welding quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

Carbon dioxide gas shielded welding machine and method of arc ignition controlled by digital pulse

ActiveCN104096947BReduced maximum peak powerReduce transient impact stressElement comparisonArc welding apparatusEngineeringImpact stress

The invention discloses a method of controlling the arc strike of a carbon dioxide gas shielded welding machine by adopting digital pulse. The method comprises the steps of feeding gas for a welding gun; feeding a welding wire in a slow wire feeding mode; when the output voltage is detected to be 0 volt, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire for arc strike; when the output voltage is detected to be smaller than 8 volts, switching from the slow wire feeding mode of the welding wire into a quick wire feeding mode, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire to build a molten pool, and controlling an arc to be subjected to transition from arc strike to a stable arc. According to the method, the transient impact stress which is borne by a hardware power device is reduced, and the service life is prolonged; the arc strike time is shortened, the arc strike process is stable, the reliability is strong, and the arc strike success rate is high; the molten pool is built in the arc strike process, and thus a basic is established for normal, stable and reliable welding in the future. The invention further discloses a carbon dioxide gas shielded welding machine.

Owner:SHENZHEN RILAND IND

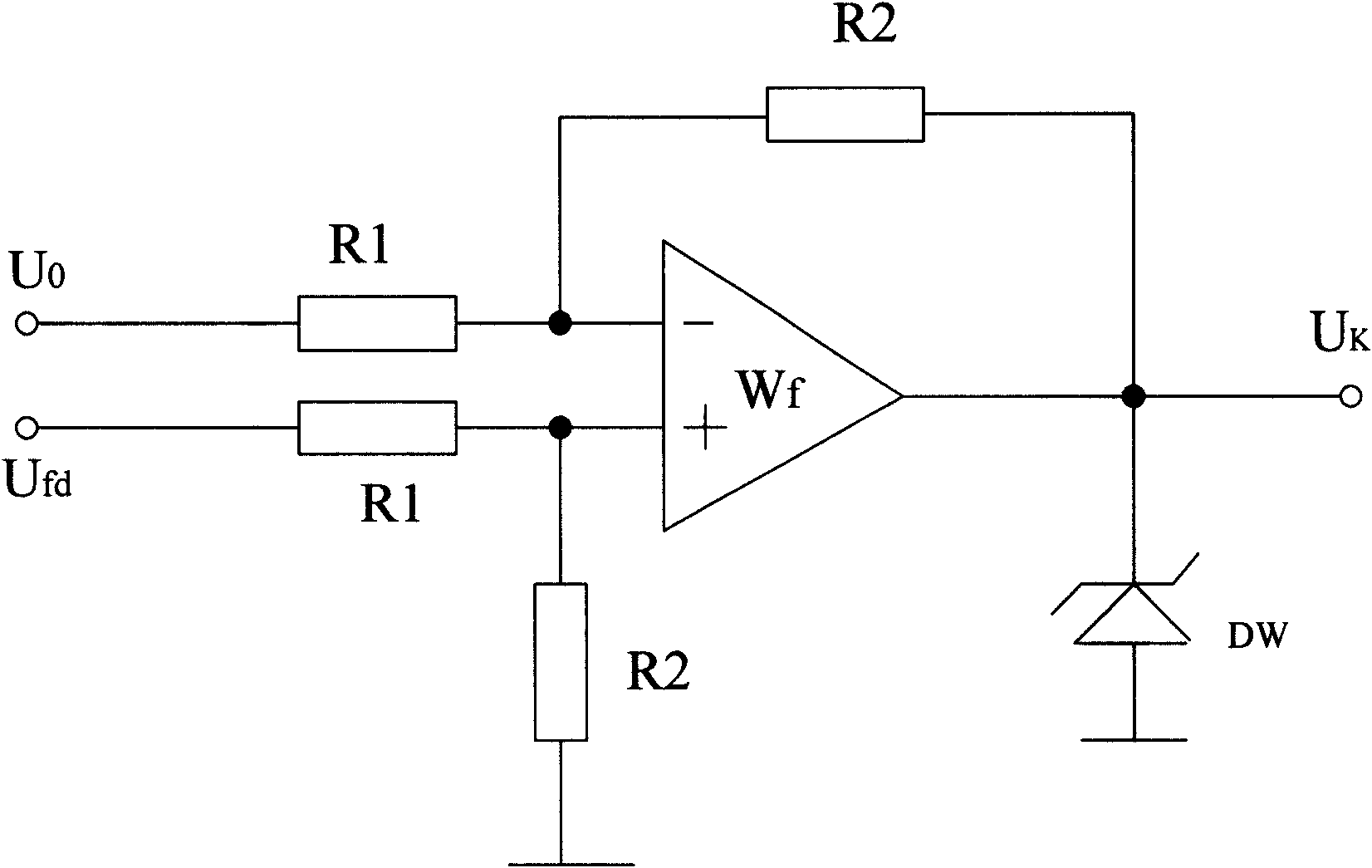

A circuit for improving the success rate and stability of small current arc ignition of inverter argon arc welding machine

The invention provides a circuit for increasing the small current arc striking successful rate and stability of an inverter argon arc welding machine. The circuit comprises an inverter welding machine main loop circuit and an output loop arc stabilizing circuit, wherein a double-tube and single-end forward topology circuit is adopted as the inverter welding machine main loop circuit which inverts direct current obtained after input alternating current is rectified into high-frequency square wave current and then rectifies the square wave current into low-voltage direct current needed by the inverter argon arc welding machine to output the low-voltage direct current; and the output loop arc stabilizing circuit is connected into the inverter welding machine main loop circuit in series and used for controlling the working state of the inverter argon arc welding machine. According to the circuit for increasing the small current arc striking successful rate and the stability of the inverter argon arc welding machine, due to the fact that the measures that the arc stabilizing circuit works during arc striking with small current and arc striking with large current and the arc stabilizing circuit only works with small current in the welding process are taken, the size of the arc stabilizing circuit is greatly reduced, cost is saved, the effect of increasing the small current arc striking successful rate and stability can be achieved, and the circuit is economical and applicable.

Owner:SHANGHAI GREATWAY WELDING EQUIP

Smart stick arc torch system for manual operation with arc length variation compensation

ActiveCN112872552BLower skill requirementsImprove the success rate of arc strikingElectrode supporting devicesElectrode accessoriesArc stabilityTorch

The invention provides a manual operation auxiliary arc starting and arc length control electrode arc welding torch system. The device includes a miniature sliding table mechanism that can drive the arc to move up and down, a fixed seat for installing the miniature sliding table mechanism, a welding tongs for clamping the welding rod, a handle, and a welding tongs for connecting cables and welding tongs The chuck, a Hall voltage sensor for detecting welding voltage, and a control circuit board for automatic arc ignition and arc length compensation for electrode arc welding. The micro-sliding table mechanism can drive the arc to move up and down slightly in the direction of the arc length or approximately the length of the arc when the electrode is manually fed, thereby fine-tuning the length of the welding arc. Compensate for the change in arc length caused by uniformity, and strive to keep the arc length constant and improve arc stability.

Owner:JIANGSU MARITIME INST

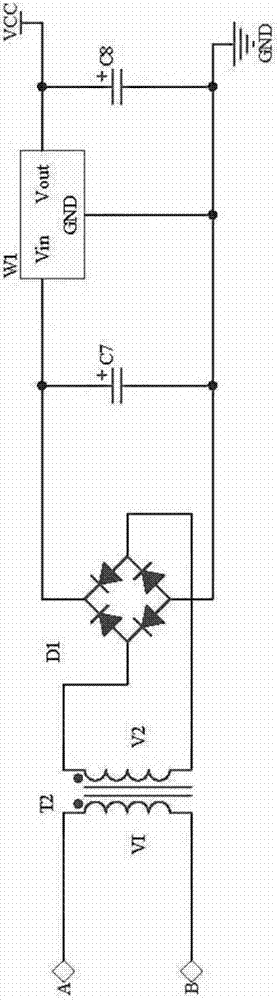

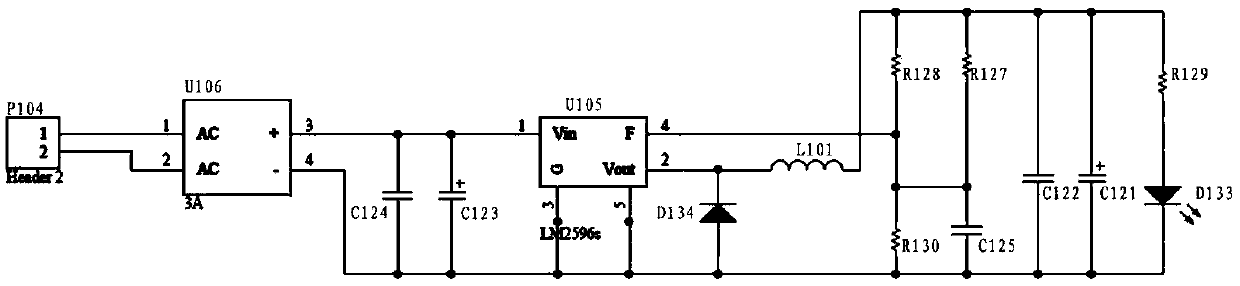

High voltage arc ignition circuit of wide voltage input argon arc welding machine

ActiveCN106216810BImprove the success rate of arc strikingIndependent of input voltageArc welding apparatusLow voltageElectronic switch

The invention provides a high voltage arc striking circuit for a wide voltage input argon arc welding machine. The high voltage arc striking circuit comprises an inverter welding machine main loop module and a high voltage arc striking module. The inverter welding machine main loop module is used for converting an input alternating current into a high frequency direct current square wave, and a low voltage direct current needed by an inverter welding machine is obtained through rectification. The high voltage arc striking module is used for generating a high voltage pulse and acts on the inverter welding machine main loop module, so that high voltage arc striking of argon arc welding is achieved. According to the high voltage arc striking circuit for the wide voltage input argon arc welding machine, the arc striking success rate is high; a high voltage circuit is not transmitted to the high voltage arc striking circuit, thus, the interference of the high voltage arc striking circuit under a manual welding rod welding mode is reduced, and reliable arc striking of the welding machine within the 85-265 Vac input wide range is achieved; and in addition, pulse high voltage arc striking is achieved by adopting an electronic switch, so that compared with a high voltage pack arc striking mode, the welding machine is more stable.

Owner:SHANGHAI GREATWAY WELDING EQUIP

The circuit realizing the method of starting the arc of co2/mag arc welding machine

ActiveCN102728931BImprove the success rate of arc strikingArc striking quicklyArc welding apparatusControl signalTransformer

The invention relates to a circuit for realizing CO2 / MAG (metal, active gas welding) arc welding machine arc-striking method. The circuit comprises an arc welding machine main circuit which includes a step-down transformer and a direct current reactor. A third thyristor group is arranged on the secondary winding of the step-down transformer, one end of the direct current reactor is connected with the anode end of each thyristor in the third thyristor group and the third thyristor group is connected with the output end of a thyristor control circuit. In arc striking, the thyristor control circuit outputs a first control signal, so that the direct current reactor is formed as an arc striking bypass by the arc welding machine main circuit via the third thyristor group, and arc striking is performed by the secondary winding of the step-down transformer until arc striking is finished. After arc striking is finished, the thyristor control circuit outputs a second control signal, so that the direct current circuit output from the step-down transformer turns off the third thyristor group and required welding is performed by the direct current reactor. The inventive circuit is simple in structure, improves welding machine arc striking success rate, causes small welding splash, realizes good formed weld seam, and is convenient to operate, safe and reliable.

Owner:JIANGSU DADE HEAVY IND

A circuit for improving the arc striking success rate and stability of inverter argon arc welding machine

ActiveCN109604772BImprove the success rate of arc strikingReduce lossArc welding apparatusControl engineeringInverter

Owner:SHANGHAI GREATWAY WELDING EQUIP

High-deposition low-heat-input plasma-twin-wire bypass arc welding device and method

PendingCN114700643ALow heat inputReduce heat affected zoneWelding apparatusElectrode pairHeating power

The invention discloses a high-deposition low-heat-input plasma-double-wire bypass electric arc welding device and method. The welding device comprises a plasma arc loop assembly, a double-consumable-electrode electric arc loop assembly and a coordination control unit. The plasma arc loop assembly comprises a plasma arc power supply, a conductive piece, a plasma annular electrode and a workpiece; the double-consumable-electrode arc loop assembly comprises an MIG / MAG power source, a composite welding gun, a bypass welding gun composed of a conductive fixing piece and a conductive nozzle, and a welding wire. During welding, the bypass welding wire electrode is used for replacing a workpiece molten pool electrode to serve as a cathode of an original MIG electric arc, that is, the bypass welding wire electrode and a welding wire anode of the original MIG electric arc form a double-consumable-electrode pair, a double-consumable-electrode electric arc arranged in a plasma arc is formed, and the high-deposition low-heat-input welding process is completed. Decoupling control between heating power input of a workpiece molten pool and metal deposition is achieved, so that heating power input of an MIG electric arc to a workpiece is reduced, the metal filling capacity of the MIG electric arc is enhanced, and the welding efficiency is improved.

Owner:YANCHENG INST OF TECH

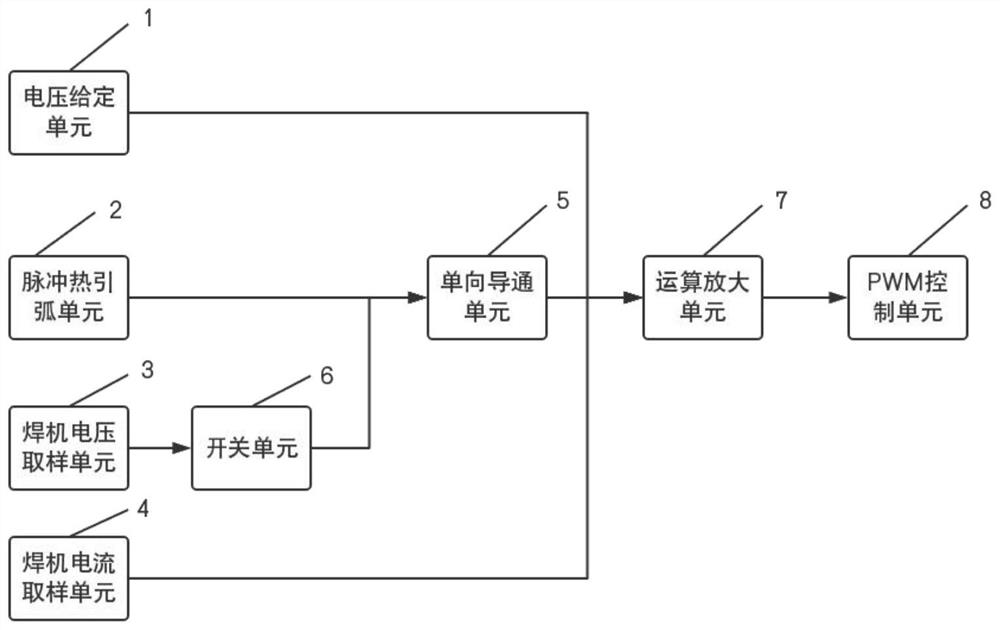

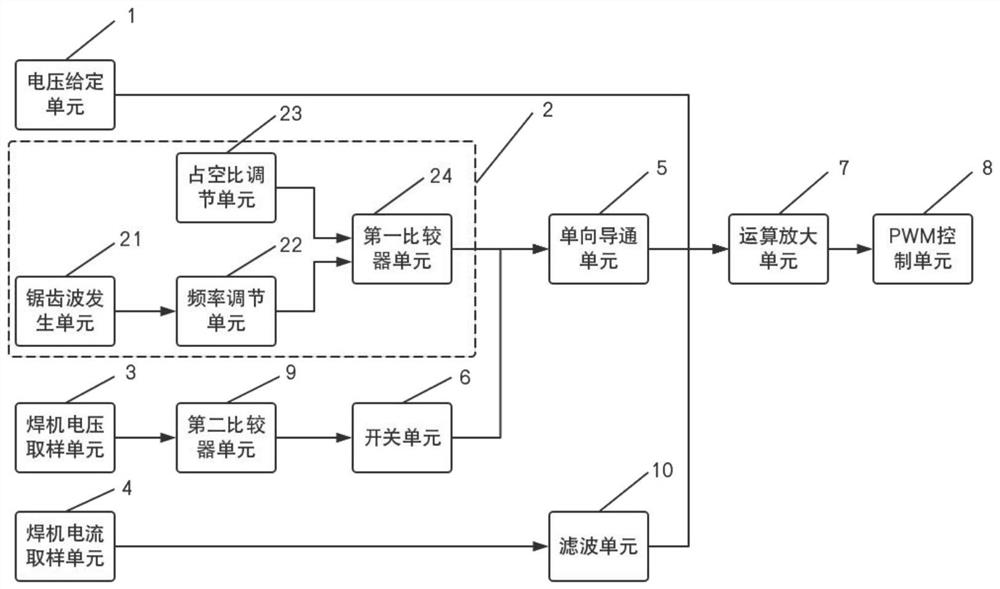

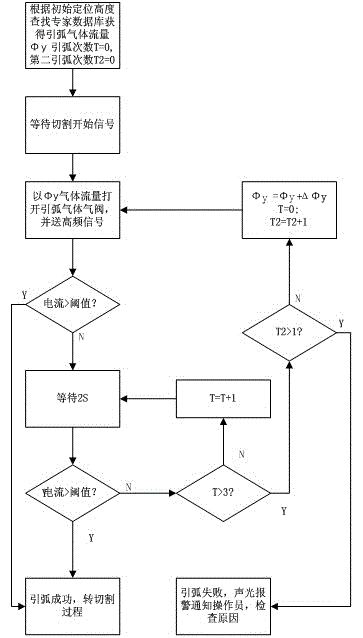

A control method of a non-high frequency plasma cutting machine

ActiveCN109807442BGuaranteed stabilityShort distance from cutting torchPlasma welding apparatusTorchIndustrial engineering

The invention relates to a non-high frequency arc ignition plasma cutting machine, and discloses a control method of the non-high frequency plasma cutting machine. Compress the gas source and control the three-way valve to conduct the cutting torch and the gas pipe, a pilot arc is formed between the electrode in the cutting torch and the guide terminal, and the control circuit controls the main arc circuit to receive the pilot arc to form a working arc; stop the cutting step, control the compressed gas source to close, Control the three-way valve to conduct the cutting torch and the outside atmosphere; repeat the start-up steps, control the three-way valve to conduct the cutting torch and the gas pipe, short-circuit the constant current between the electrode in the cutting torch and the guide terminal, and control the compressed gas source to start the gas supply to form a pilot arc. Then a working arc is formed; the three-way valve allows the residual high-pressure gas in the cutting torch to be released into the atmosphere in the opposite direction of the cutting torch, realizing rapid discharge, ensuring the stable contact between the electrode and the nozzle during re-cutting, and improving the lead-time. The arc success rate ensures the arc ignition quality.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

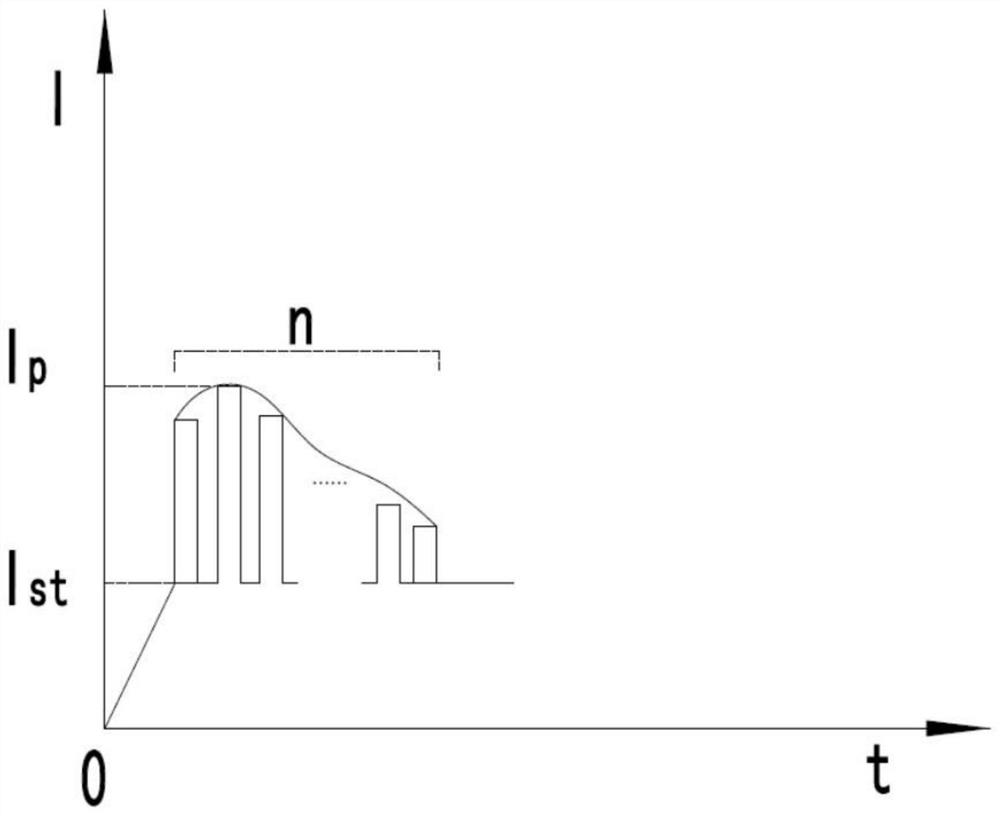

A control method and control system for arc ignition of an inverter manual arc welding machine

ActiveCN110877137BImprove arc striking effectImprove the success rate of arc strikingArc welding apparatusControl systemThin slab

The present invention relates to a control method and control system for arc ignition of an inverter manual arc welding machine. The welding current of the welding power supply becomes the pulse square wave arc ignition current. After the arc ignition of the inverter manual arc welding machine power supply is successful, the pulse thermal arc ignition signal is turned off, and the normal welding current is restored, and the arc burns normally. strike the arc. The invention is suitable for welding plates of different thicknesses, especially suitable for manual arc welding of thin plates, and has the characteristics of easy arc starting, high arc starting success rate, good welding shape, difficult welding deformation and high welding strength.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

A small electric arc melting furnace

ActiveCN110220376BGuaranteed stabilityReduce complexityCharge treatment typeCrucible furnacesSmelting processCrucible

The invention discloses a small electric arc smelting furnace, which comprises a vacuum furnace and an arc striking rod whose lower end is inserted in the vacuum furnace. Power supply connection, the bottom of the vacuum furnace is equipped with a number of water-cooled crucibles with molten metal pools, the metal molten pools are used to place metal melts, and the bottom of the water-cooled crucible is connected to the power supply through electrode terminals; among them, the small electric arc melting furnace also includes sleeves in the lead The metal bellows on the arc rod, and the lower end of the metal bellows is installed on the shell wall of the vacuum furnace, and the upper end is connected with the arc rod through the connecting piece; the metal bellows are also equipped with a bellows lower limit frame and a bellows upper limit The invention not only facilitates the operation and effectively reduces the complexity of the arc smelting operation process, but also significantly reduces the possibility of the reaction between the tungsten needle and the metal melt, and greatly improves the stability and success rate of the arc smelting process.

Owner:GONGHUI METALLURGY EQUIP TECH SUZHOU CO LTD

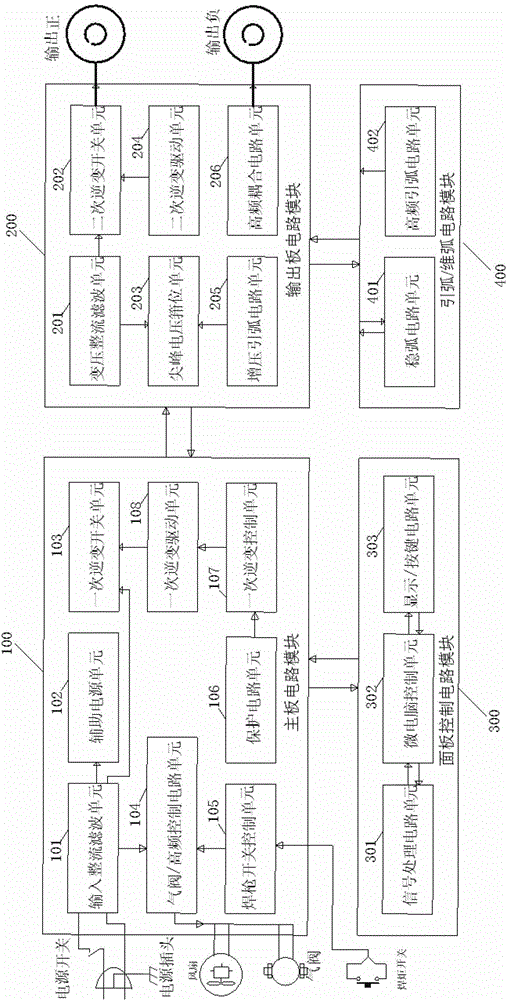

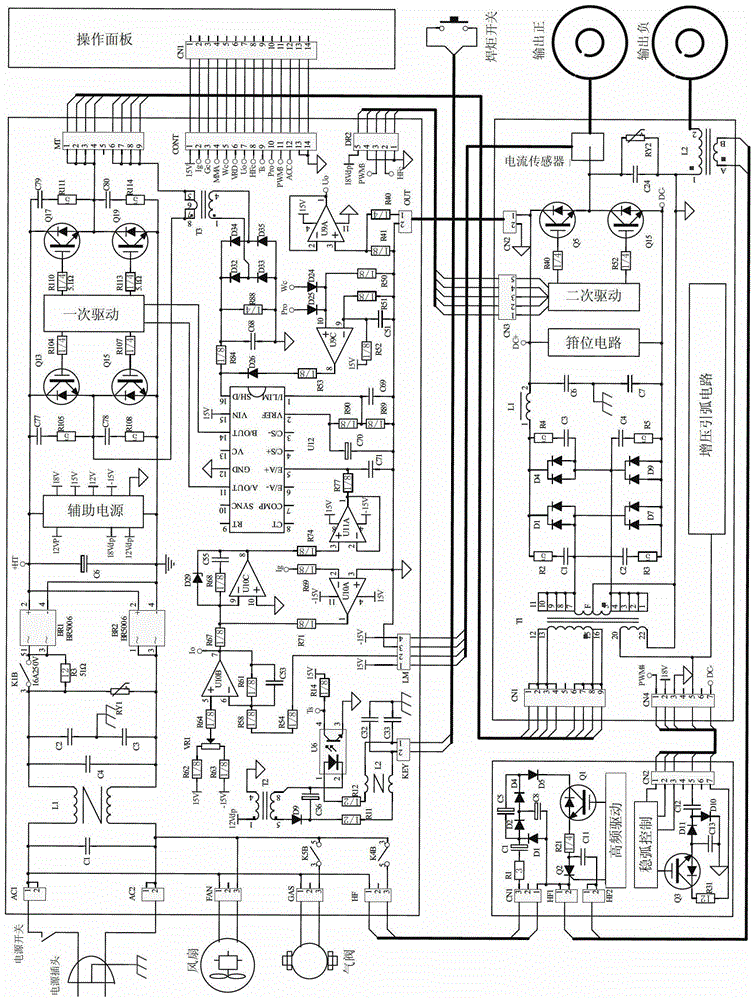

Double-contravariant alternating square wave argon tungsten-arc welder and control method thereof

ActiveCN103084711BIntuitive displayEasy to operateArc welding apparatusCoupling inductorElectric cables

The invention discloses a double-contravariant alternating square wave argon tungsten-arc welder which comprises a main board circuit module, an output board circuit module, a panel control circuit module and a striking arc / pilot arc circuit module. An input end of the main board circuit module is connected with an external alternating input power plug through a power switch. An output end of the main board circuit module is connected with an input end of the output board circuit module through multi-core range cables. A positive output connector and a negative output connector of the welder are respectively connected with an output end of the output board circuit module through copper bar cables. The panel control circuit module is connected with a control end mouth of the main circuit module through multi-core range cables. An input end of the striking arc / pilot arc circuit module is connected with a control end mouth of the output board circuit module through multi-core range cables. An output end of the striking arc / pilot arc circuit module is connected with an output end mouth of the output board circuit module through a high frequency coupling inductor. The double-contravariant alternating square wave argon tungsten-arc welder is used for reducing power consumptions of a power supply, saving material costs, volume of compressing whole machine and weights of the whole machine, increasing portability of the welder, and improving duty cycle.

Owner:SHANGHAI GREATWAY WELDING EQUIP

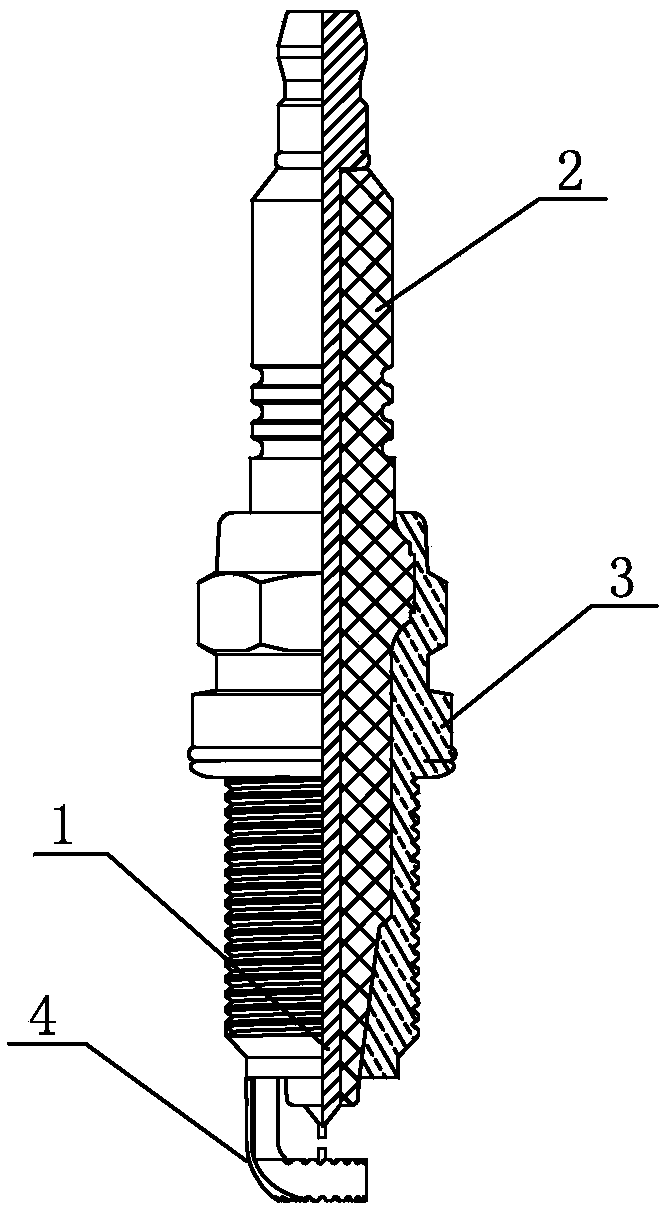

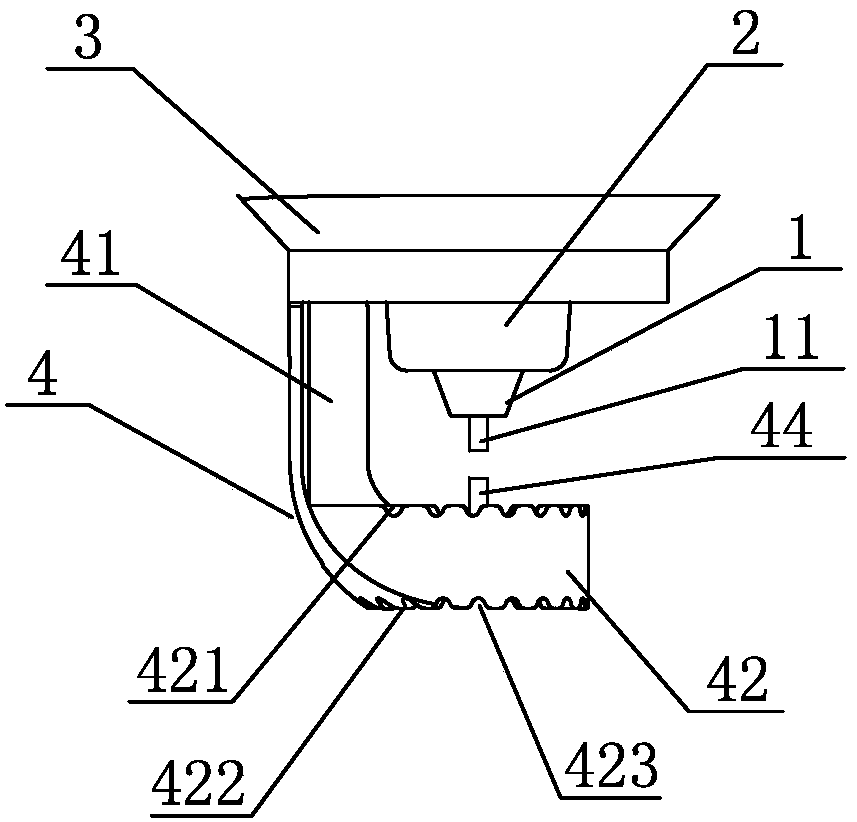

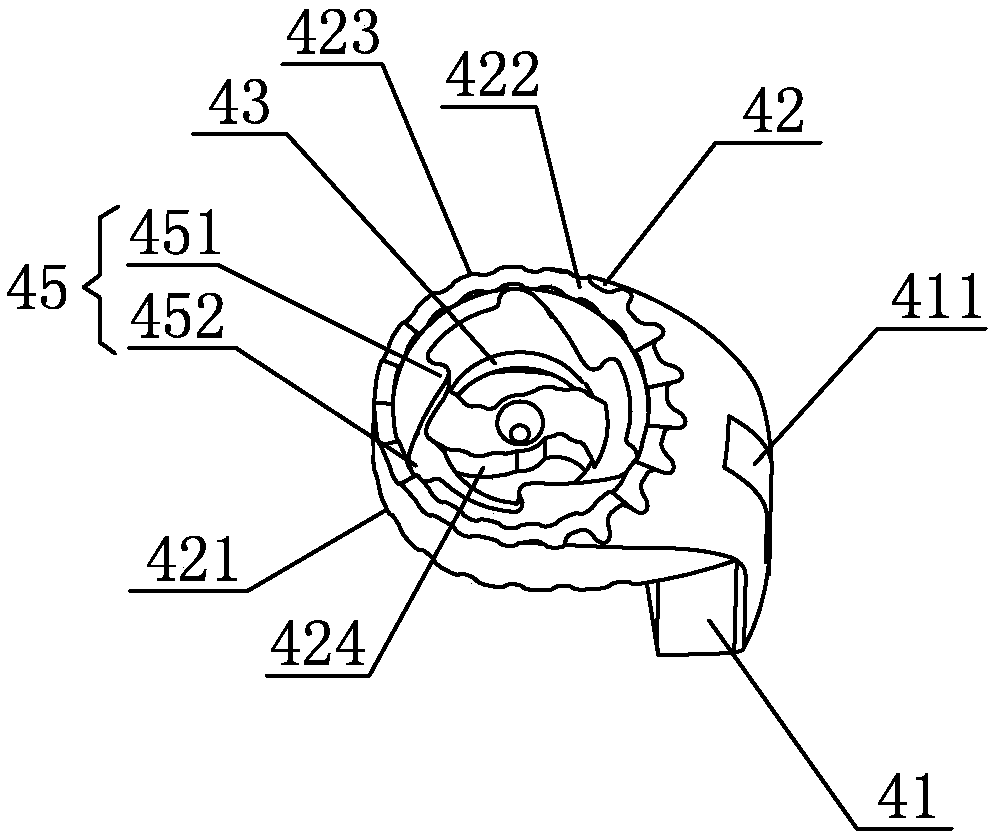

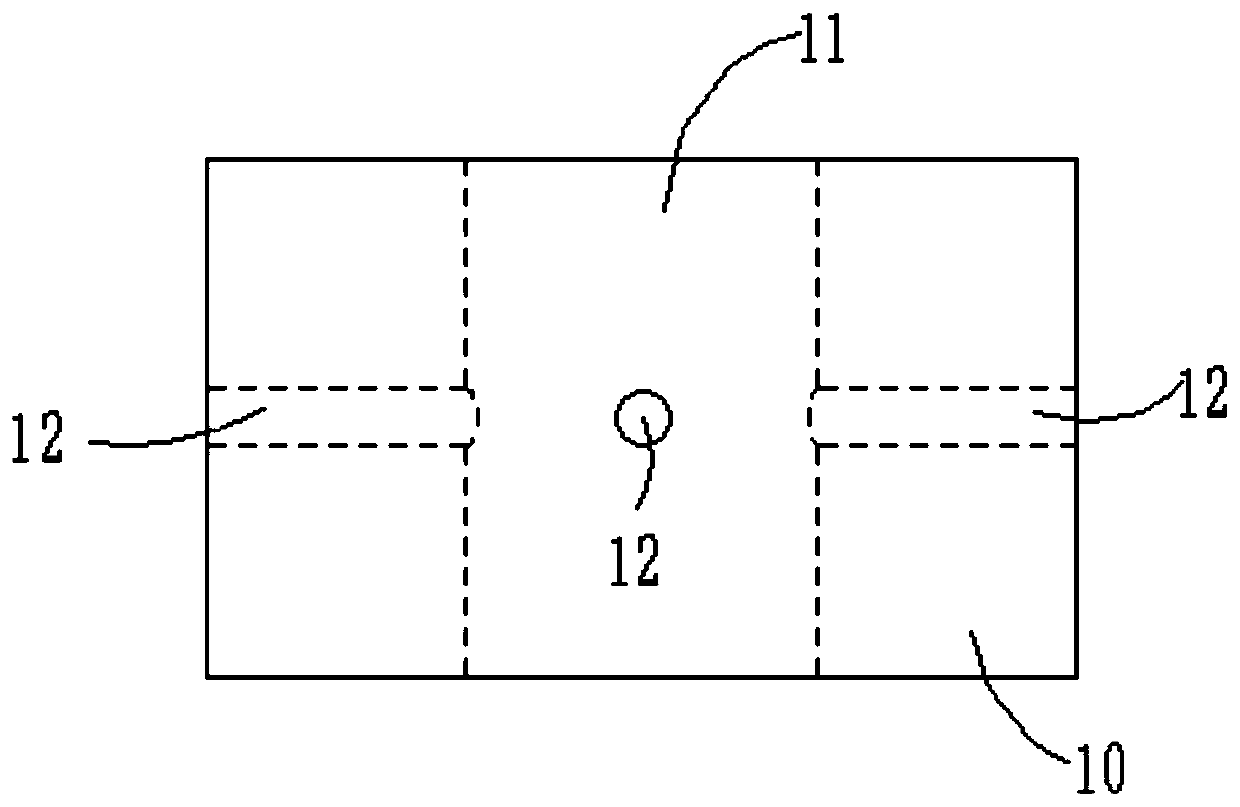

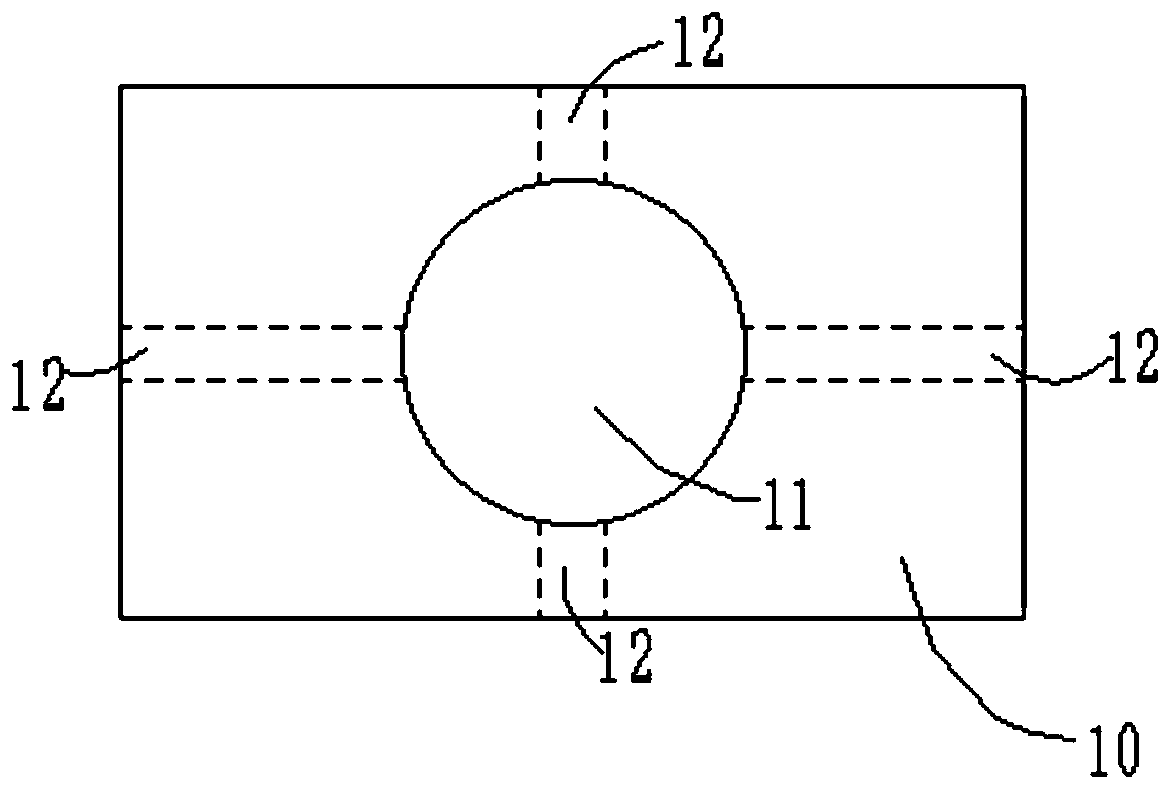

spark plug

ActiveCN106684709BSpark releaseImprove energy conversion efficiencySparking plugsEngineeringEnergy conversion efficiency

The invention discloses a sparking plug. The sparking plug comprises a central electrode, an insulating sleeve and a metal shell, wherein a side electrode is arranged at a part, corresponding to the central electrode, on the metal shell; the side electrode comprises a connecting part and a sparking generation part; a discharging gap is arranged between the sparking generation part and the central electrode; the sparking generation part comprises an upper surface and a lower surface; a guide hole, which penetrates through upper and lower surfaces, is formed in a part, corresponding to the central electrode, on the sparking generation part; a plurality of guide units, which are distributed spirally, are arranged on an inner side wall of the guide hole; a supporting part, which stretches out horizontally of the guide hole, is formed in the upper surface of the sparking generation part; and an arc striking part, which stretches out upward, is arranged at a part, corresponding to the central electrode, on the supporting part. The arc striking part corresponding to the central electrode is arranged on the side electrode of the sparking plug, so that the arc striking success rate is greatly improved and phenomenon that an engine is difficult to start and fire lacking is easy to cause are avoided; and meanwhile, the guide hole is formed in the side electrode of the sparking plug so that sparking is sufficiently released after ignition, so that the energy conversion efficiency of the automobile engine is improved.

Owner:李忠尧

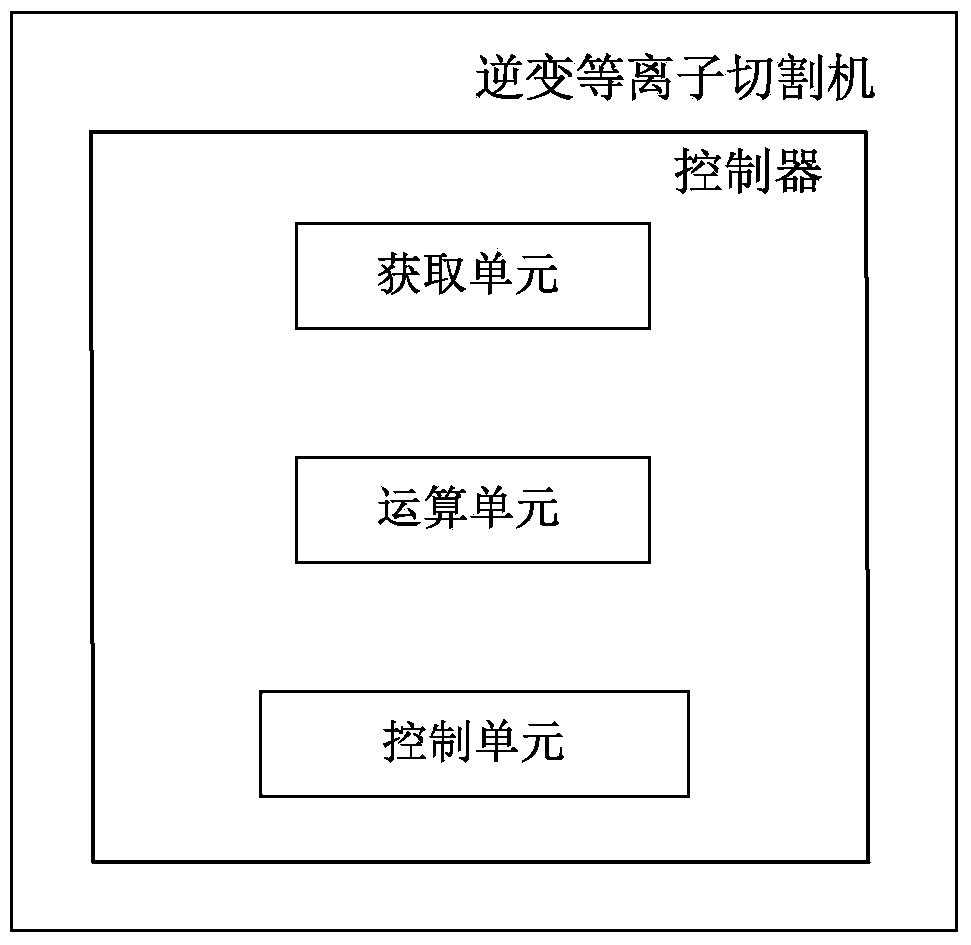

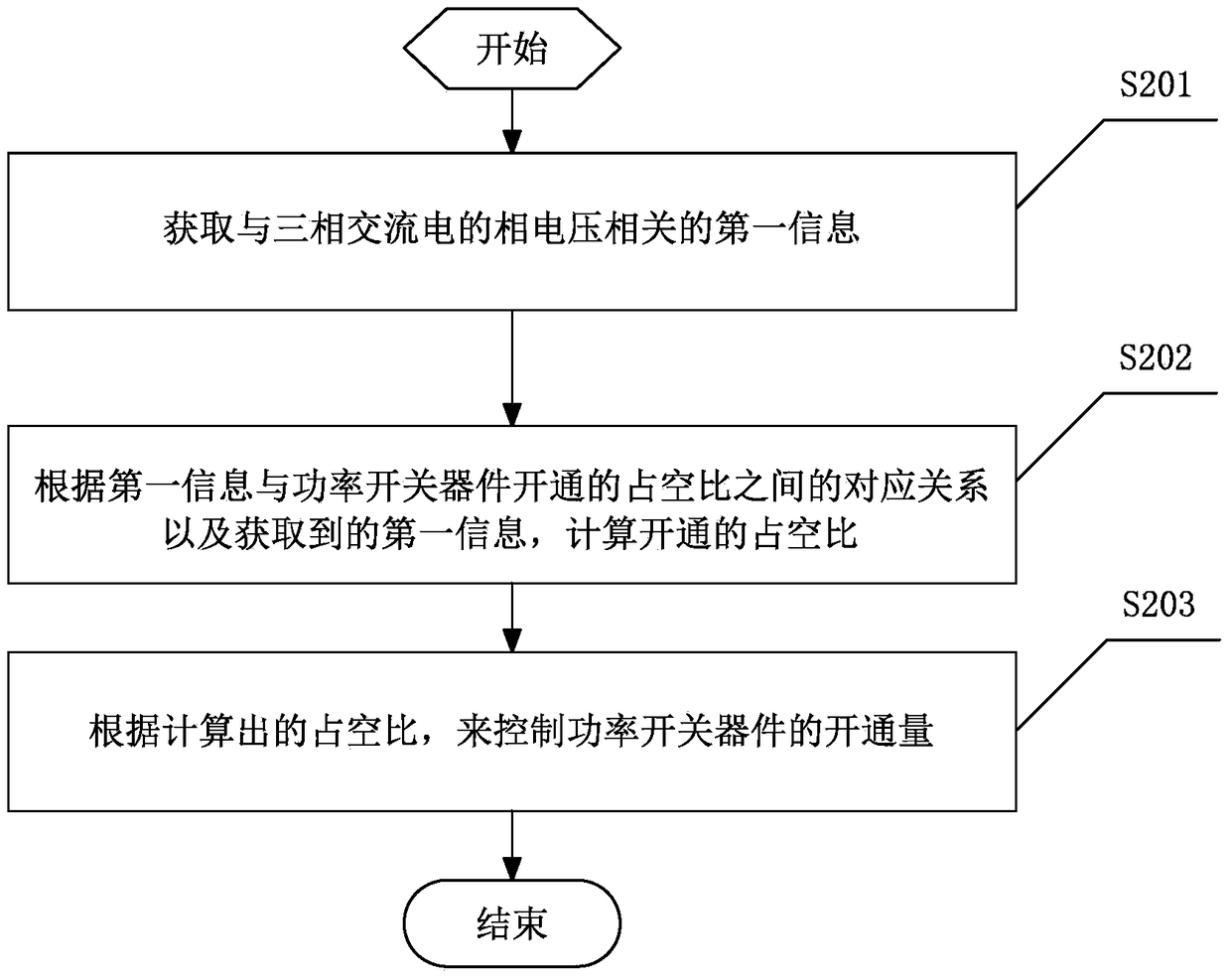

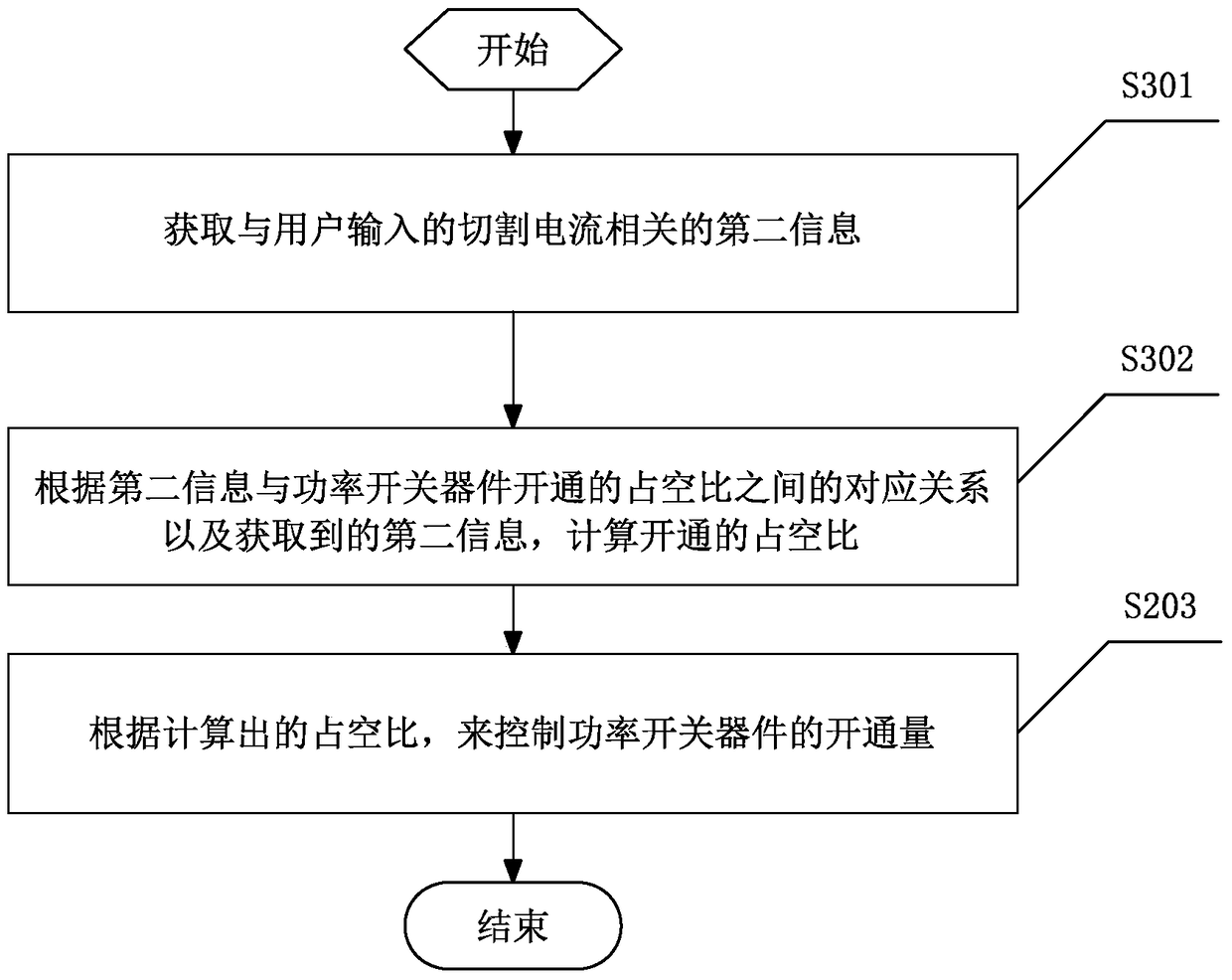

Inverter Plasma Cutting Machine and Its Control Method in Arc Starting Stage

ActiveCN105618911BGuaranteed stabilityGuaranteed reliabilityPlasma welding apparatusPower switchingEngineering

Owner:PANASONIC WELDING SYST TANGSHAN

A melting nozzle electroslag welding method and its arc extinguishing device

The invention discloses a consumable nozzle electroslag welding method and an arc quenching device thereof. The method comprises the following steps that a vertical through hole is formed in an arc quenching block, and horizontal through holes communicating with the vertical through hole are formed in the side face of the arc quenching block; to-be-welded workpieces are placed in an assembled manner through a welding gap, and the arc quenching block and an arc striking block are arranged at the upper end and the lower end correspondingly; a consumable nozzle is inserted in the welding gap through the vertical through hole, a welding wire is inserted into the consumable nozzle to make contact with the arc striking block for arc striking, continuous wire feeding is conducted, soldering fluxis smelted, a slag pool is formed, and a molten pool located below the slag pool is formed through melting of the welding wire, the consumable nozzle and the to-be-welded workpieces; continuous welding is conducted till the slag ascends and flows out of the horizontal through holes, it is observed that the molten pool ascends to the upper end faces of the to-be-welded workpieces from the verticalthrough hole, arc extinguishing is conducted, and welding is stopped. The arc extinguishing block mounting and dismounting time is saved, the arc extinguishing time is convenient to control, and the welding quality is improved. Before arc striking, the end portion of the consumable nozzle and the end portion of the welding wire make contact and rub with base metal many times, and the arc strikingsuccess rate is high. After welding interruption, a plurality of welding wire sections are used for arc striking, and the arc striking success rate is high.

Owner:CHINA HUAYE GROUP

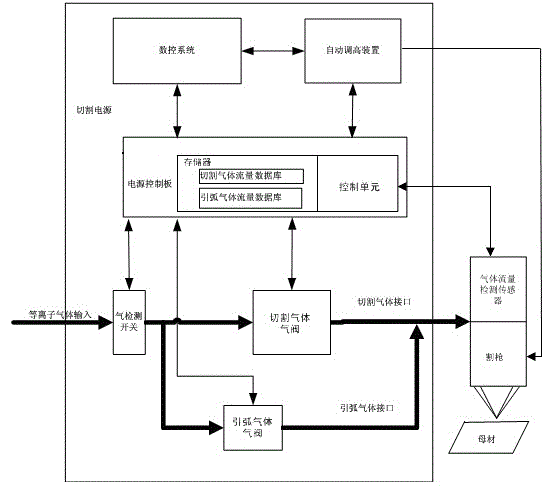

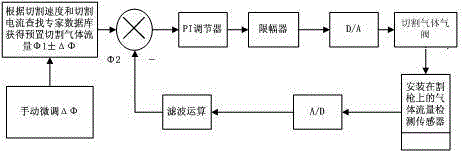

A method for controlling the gas flow of an air plasma cutting machine

ActiveCN103920979BStable formationCutting speed matchingPlasma welding apparatusPlasma jetEngineering

The invention relates to a gas flow control method of an air plasma cutting machine. The method comprises the following steps that a gas flow database is built; parameters of the board thickness H, the current I and the cutting speed S are input in a numerical control system before cutting is started, and a matched gas flow phi 1 of the gas flow database is searched; in the cutting process, an actual gas flow signal phi 2 is detected, and after a control unit compares the matched gas flow phi 1 with the actual gas flow signal phi 2, the actual gas flow phi 2 and the flow deviation delta phi are obtained; an executing mechanism controls a gas valve through the flow deviation delta phi, and the flow deviation delta phi tends to zero. The invention further relates to a gas flow control system of the air plasma cutting machine. The gas flow control system of the air plasma cutting machine comprises the numerical control system, the gas valve, a gas detection switch, a sensor and a cutting gun, and further comprises a power control board, wherein the power control board comprises a control unit and a storage; the control unit is connected with the storage; the numerical control system, the power control board, the gas detection switch and the gas valve are sequentially connected and then are connected with the sensor and the cutting gun; the control unit is connected with the sensor. The cutting gas flow is best matched with the cutting current and the cutting speed, and the gas flow control method and system have the advantages that plasma jet flow can be stably formed and an electric arc is stable.

Owner:湖南超宇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com