Novel method for hot cutting

A new type of thermal cutting technology, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as insufficient reliability, and achieve the effect of improving driving power, low power consumption, controllable AC output, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

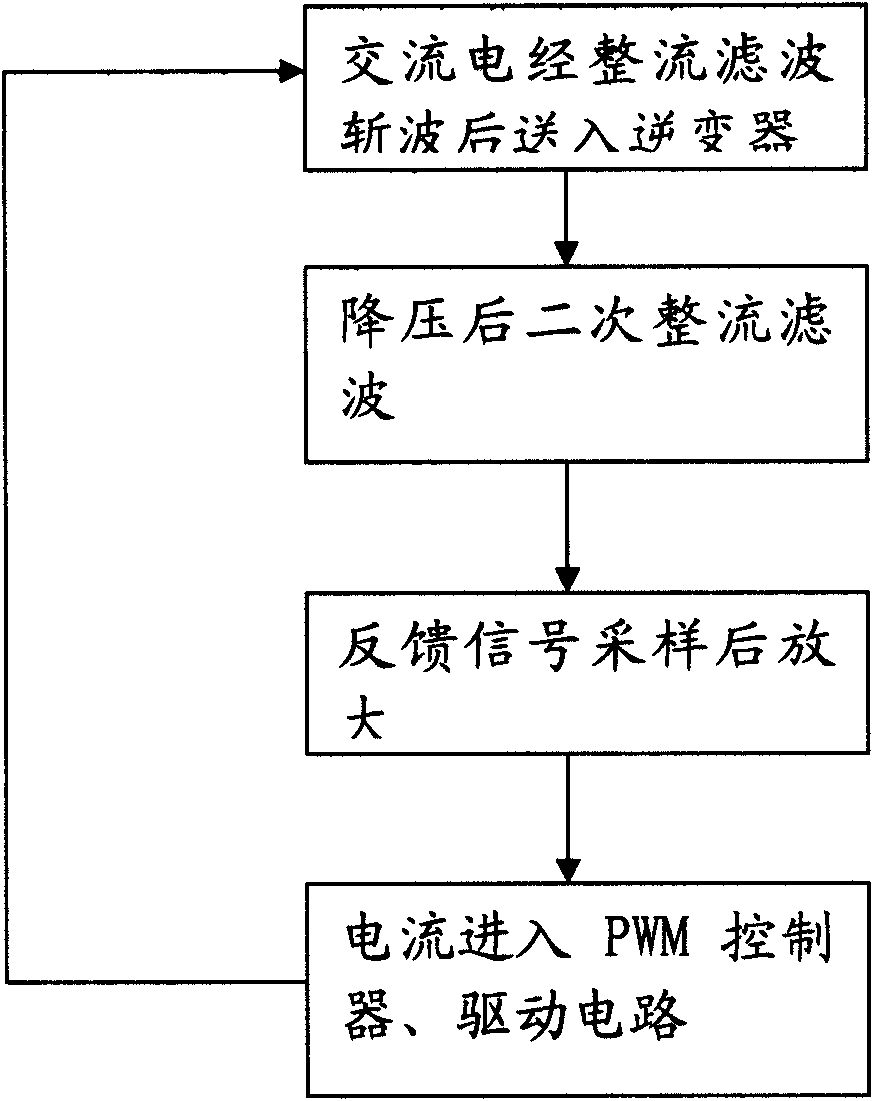

[0018] Such as figure 1 Shown, a kind of novel thermal cutting method is characterized in that comprising the following steps:

[0019] The alternating current is sent to the inverter after being rectified, filtered and chopped to generate intermediate frequency alternating current;

[0020] The intermediate frequency alternating current is stepped down by a power transformer, and then rectified and filtered twice to form a stable direct current to supply the cutting arc.

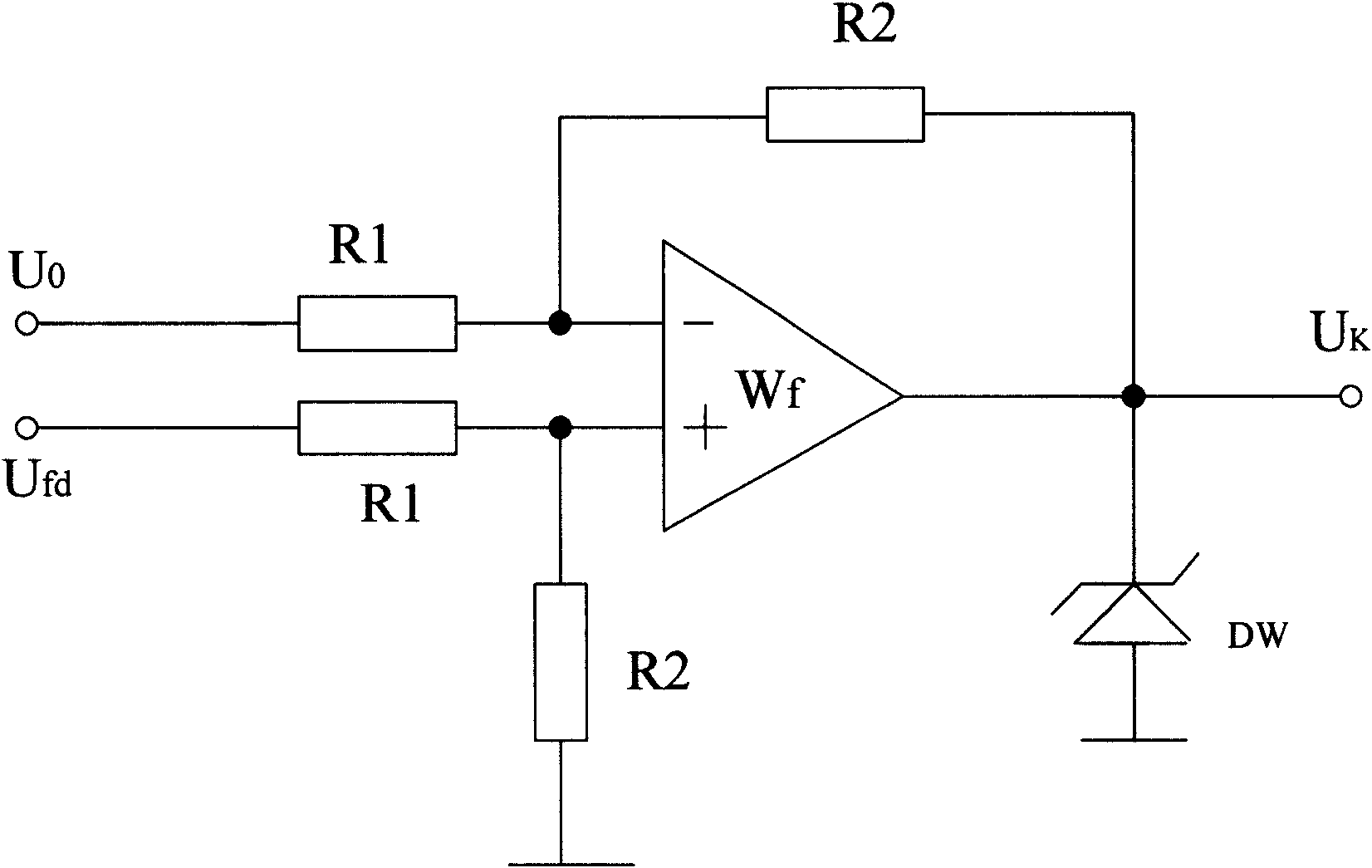

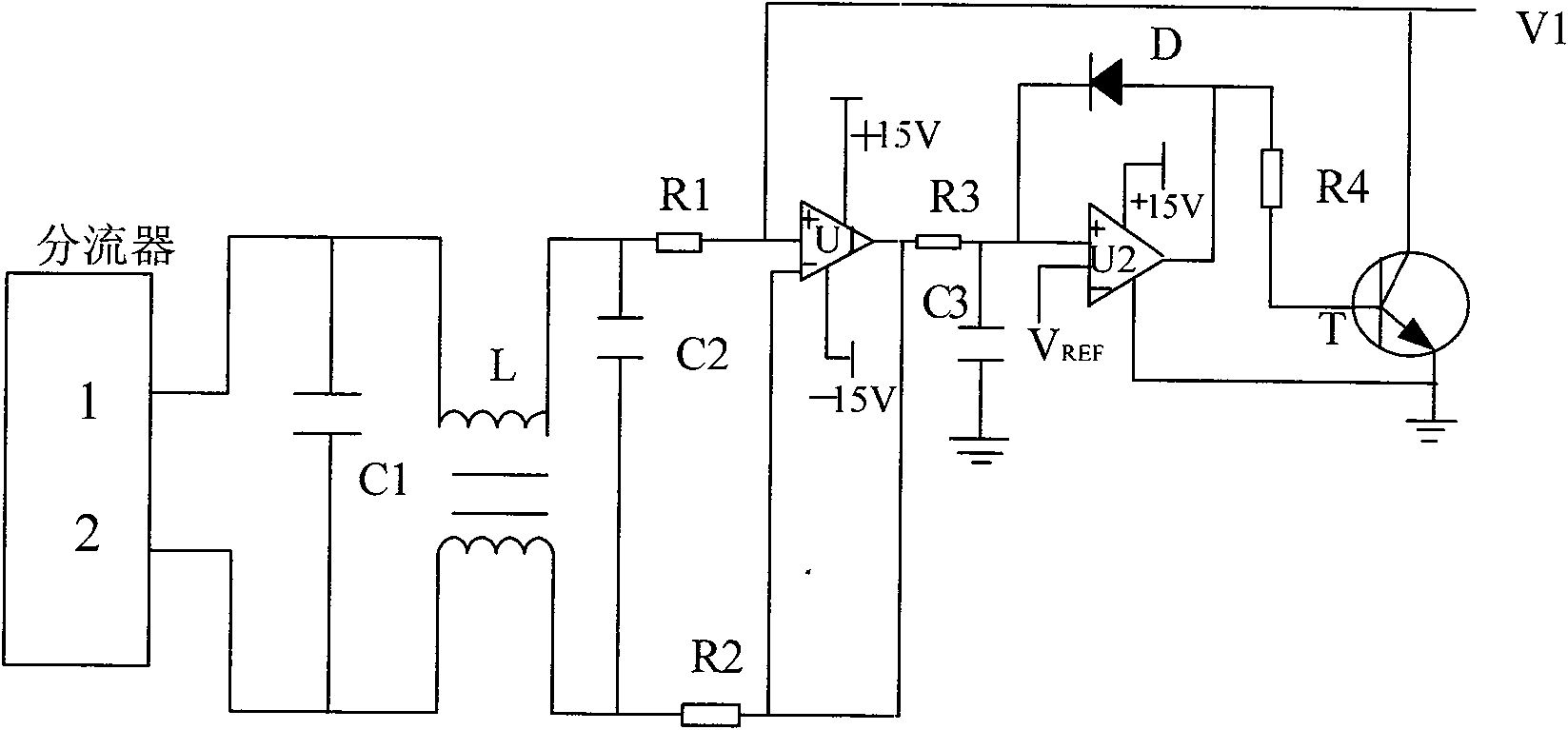

[0021] It also includes sampling the current feedback signal of the direct current and amplifying it after being processed by a filter circuit.

[0022] It also includes sending the amplified current to the PWM controller, driving the circuit and feeding it back to the inverter.

[0023] The rectification and filtering is completed by a single-phase half-wave rectification circuit modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com