Double-contravariant alternating square wave argon tungsten-arc welder and control method thereof

A technology of AC square wave and argon tungsten arc, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high power consumption of two inverters, low precision of parameter control, complex internal circuits, etc., and achieve saving Material cost, easy to break arc, display intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

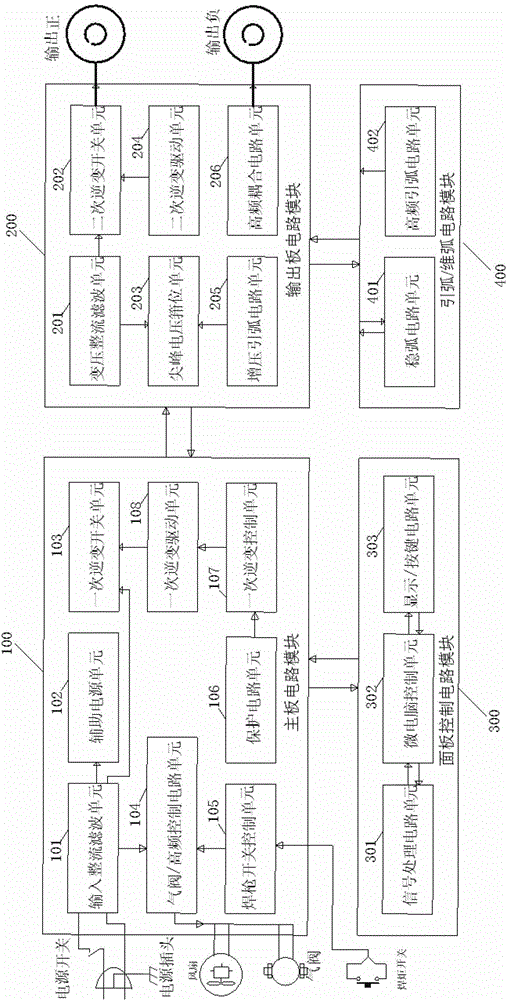

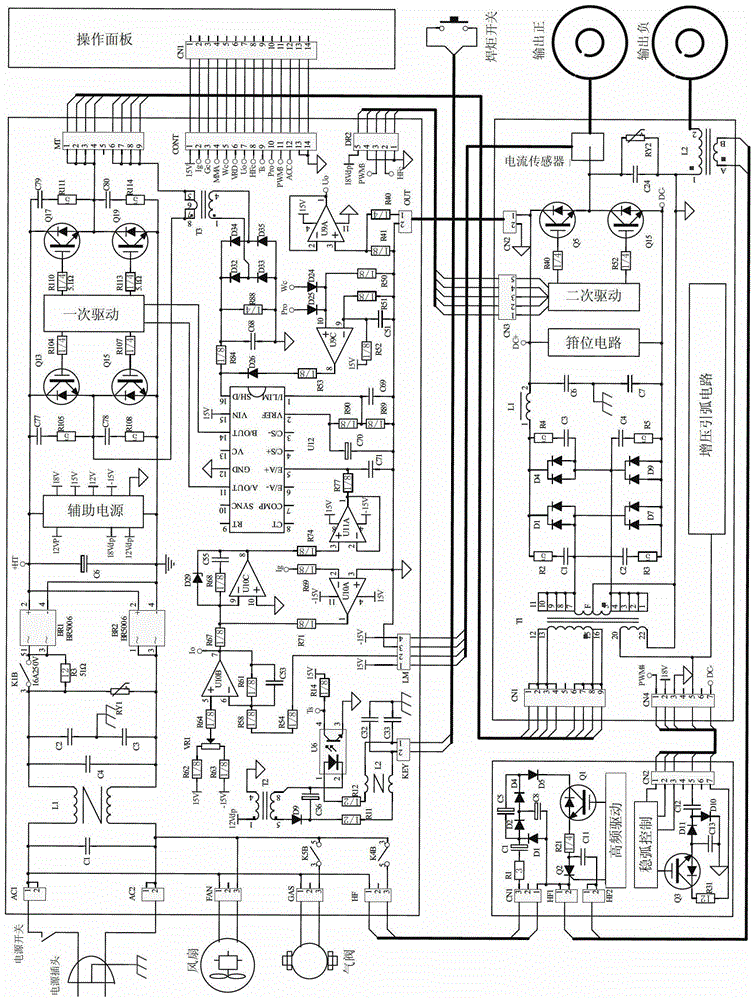

[0037] Such as figure 1 As shown, the dual-inverter AC square-wave tungsten argon arc welding machine described in this embodiment includes: a main board circuit module 100, an output board circuit module 200, a panel control circuit module 300, and an arc starting / maintenance circuit module 400 Four modules. The input end of the mainboard circuit module is connected to the external AC input power plug through the power switch, the output end of the mainboard circuit module is connected to the input end of the output board circuit module through a multi-core cable, and the output end of the output board circuit mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com