A method for controlling the gas flow of an air plasma cutting machine

An air plasma and gas flow technology, applied in plasma welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of time-wasting materials, processing quality impact, finished product use and delivery troubles, etc., to achieve arc stability and improve arc ignition success. rate and ensure the effect of cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

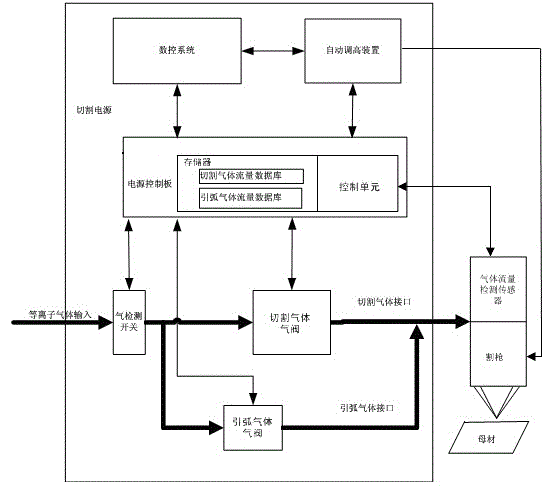

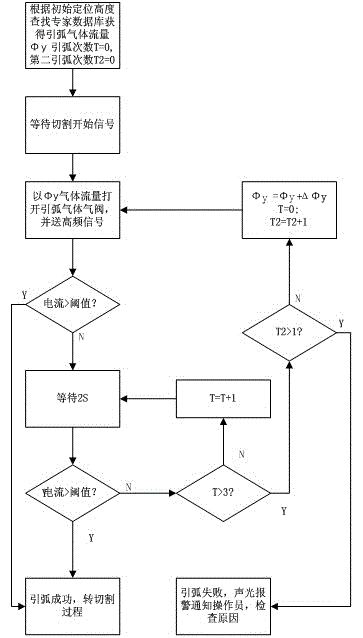

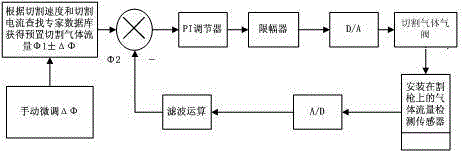

[0029] Such as Figure 1 to Figure 3 , use the cutting current and cutting speed to establish the gas flow database, and store it in the flash memory FLASH of the micro control unit MCU in the plasma cutting machine. Before the cutting starts, the operator sets the cutting thickness H, cutting Current I, cutting speed S and other parameters, and send these parameters to the micro control unit MCU in the plasma cutting machine, the MCU in the plasma cutting machine searches the database according to the cutting current and cutting speed During the cutting process, the gas flow sensor detects the gas flow in a timely manner, and after signal processing by the filter circuit, it is sent to the MCU in the plasma cutting machine for A / D sampling, and the actual gas is obtained after software filtering and calculation. Flow Φ2, compare Φ1 and Φ2 to get the deviation signal, the deviation signal is calculated by the limit weakening integral PI control algorithm, the calculated deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com