The circuit realizing the method of starting the arc of co2/mag arc welding machine

An arc welding machine and circuit technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of small welding spatter, achieve small welding spatter, good seam welding shape, and improve the success rate of arc ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

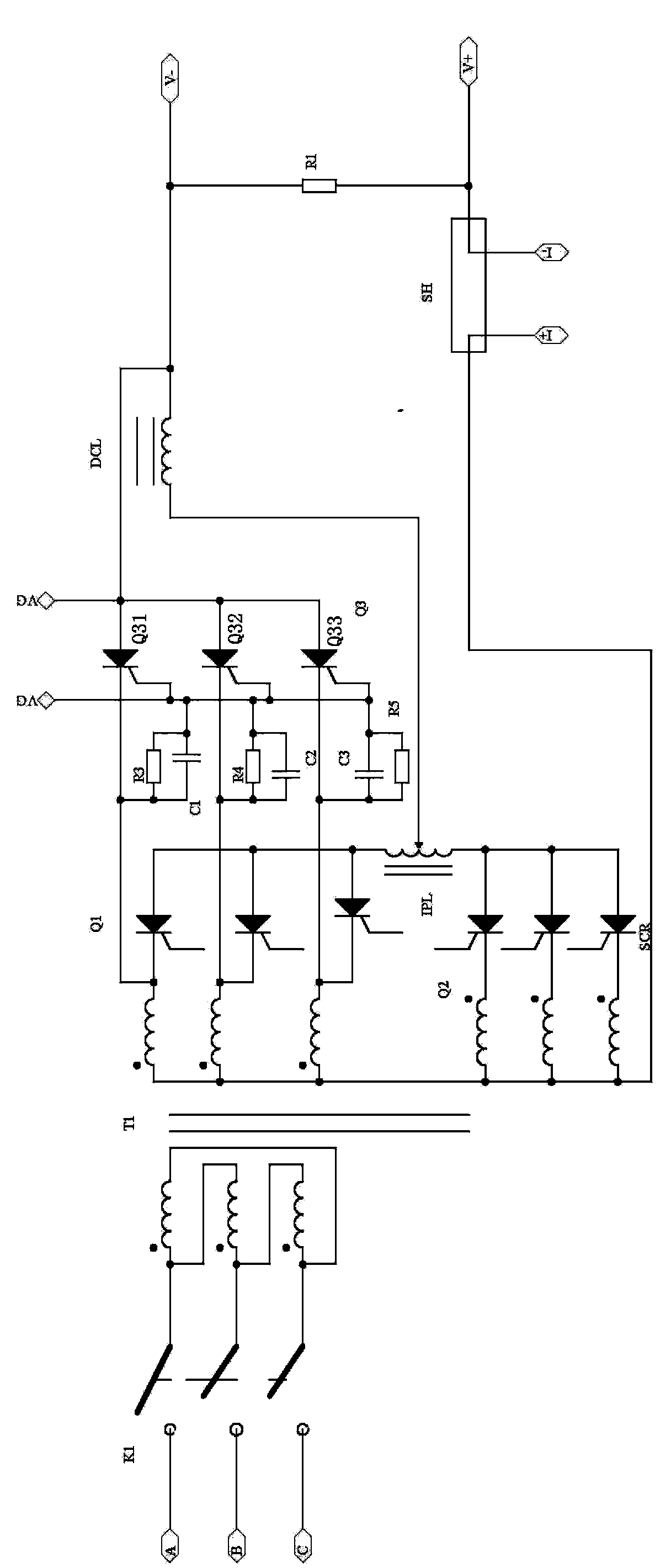

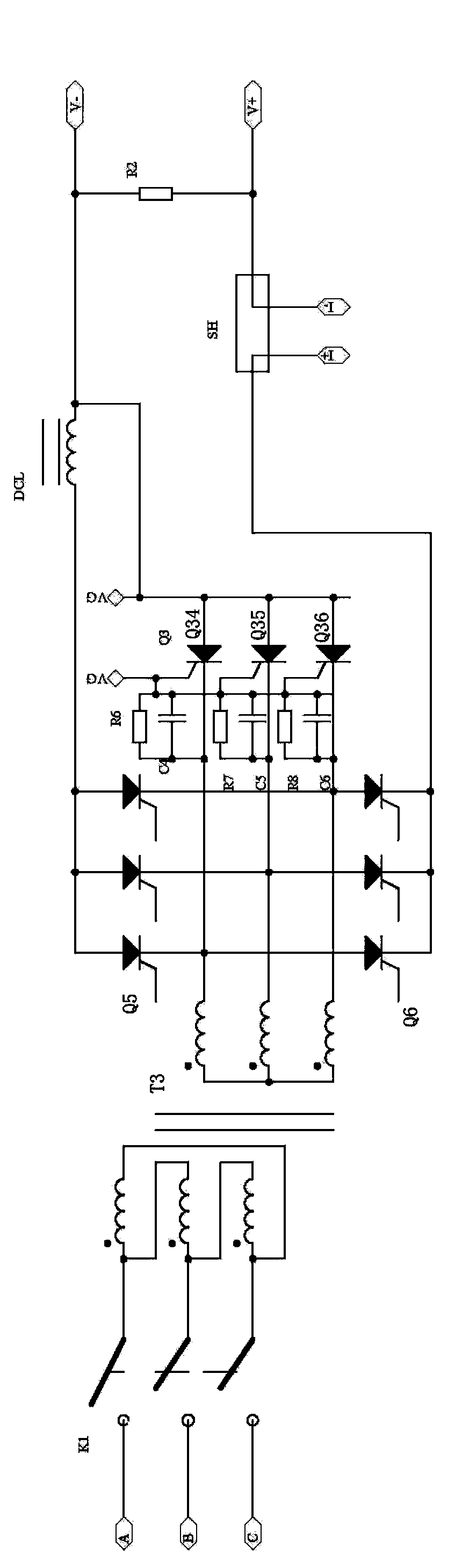

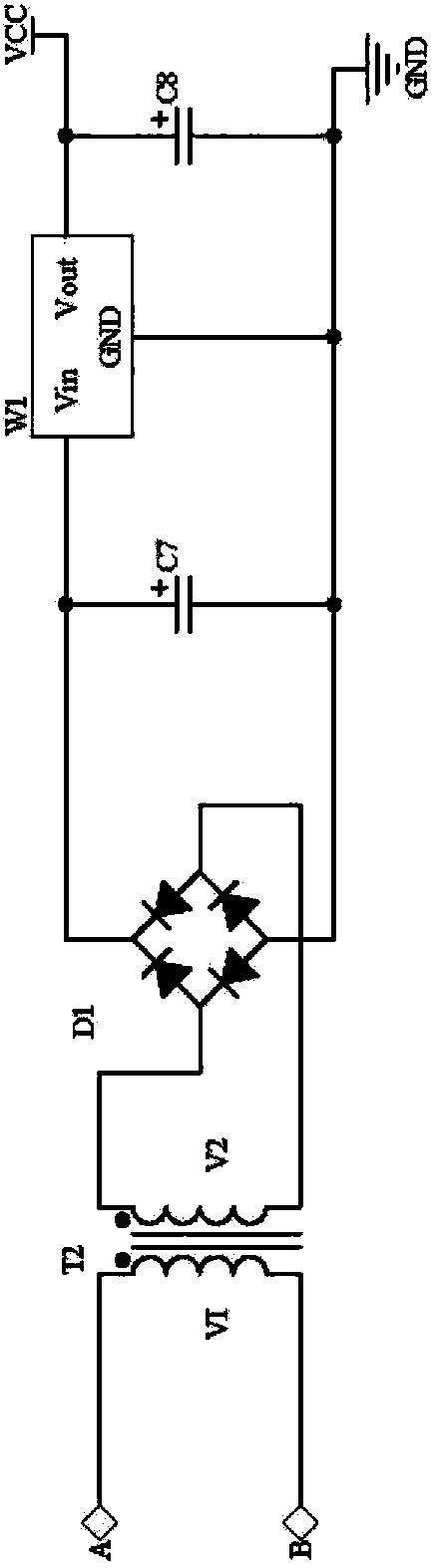

[0015] In conventional thyristor controlled CO 2 In the / MAG arc welding machine circuit, the output DC reactor DCL is added to limit the CO 2 During the dynamic welding process of / MAG arc welding machine, the short-circuit current rising rate di / dt makes the welding spatter small and the weld shape is good during the welding process. Arc striking is easy to achieve success. In order to overcome the adverse effect of the DC reactor DCL on the arc ignition of the arc welding machine in the prior art, the present invention provides a third thyristor group Q3 on the secondary winding of the step-down transformer, and one end of the DC reactor DCL is connected to the first thyristor group Q3. The anode terminals of the thyristors in the three-thyristor group Q3 are connected, and can be connected to the three-phase output terminals in the secondary winding of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com