Intelligent shielded metal arc welding gun system with arc length change compensation for manual operation

An electrode arc welding and manual operation technology, which is applied in the direction of arc welding equipment, electrode characteristics, electrode accessories, etc., can solve the problems of high workpiece assembly requirements, inconvenient movement, and narrow application area, so as to improve the success rate of arc ignition and improve Arc stability, effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

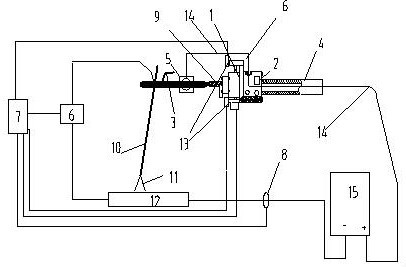

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

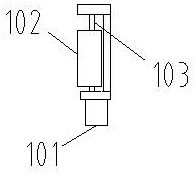

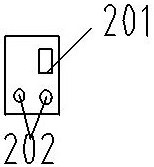

[0025] Such as Figure 1-Figure 2 As shown, a manual operation smart electrode arc welding torch system with compensation for arc length changes includes a welding tongs 3 and a handle 4, a welding cable 14 passes through the handle 4 into a hollow fixing seat 2, and then from the above the fixed seat 2, and connect the welding tongs 3 through the chuck 5, and the fixed seat 2 is fixedly connected to the miniature slide table 1, and the miniature slide table 1 includes a slide table 102, and the slide table 102 passes through a screw rod 103 and a stepper motor 101, the slide table 102 is connected with the welding tongs 3, driven by the stepper motor 101, the slide table 102 can move on the lead screw 103, the slide table 102 and The welding tongs 3 are connected and can drive the welding tongs 3 to move simultaneously. A Hall voltage sensor 6 is provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com