200KW non-transferred arc plasma generator and arc-striking method

A plasma generator, non-transfer arc technology, applied in the direction of plasma, electrical components, etc., can solve the problems of unsuitability for industrialized large-scale production and application, short electrode life, small application range, etc., to improve arc voltage and arc stability. Uniform, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 200

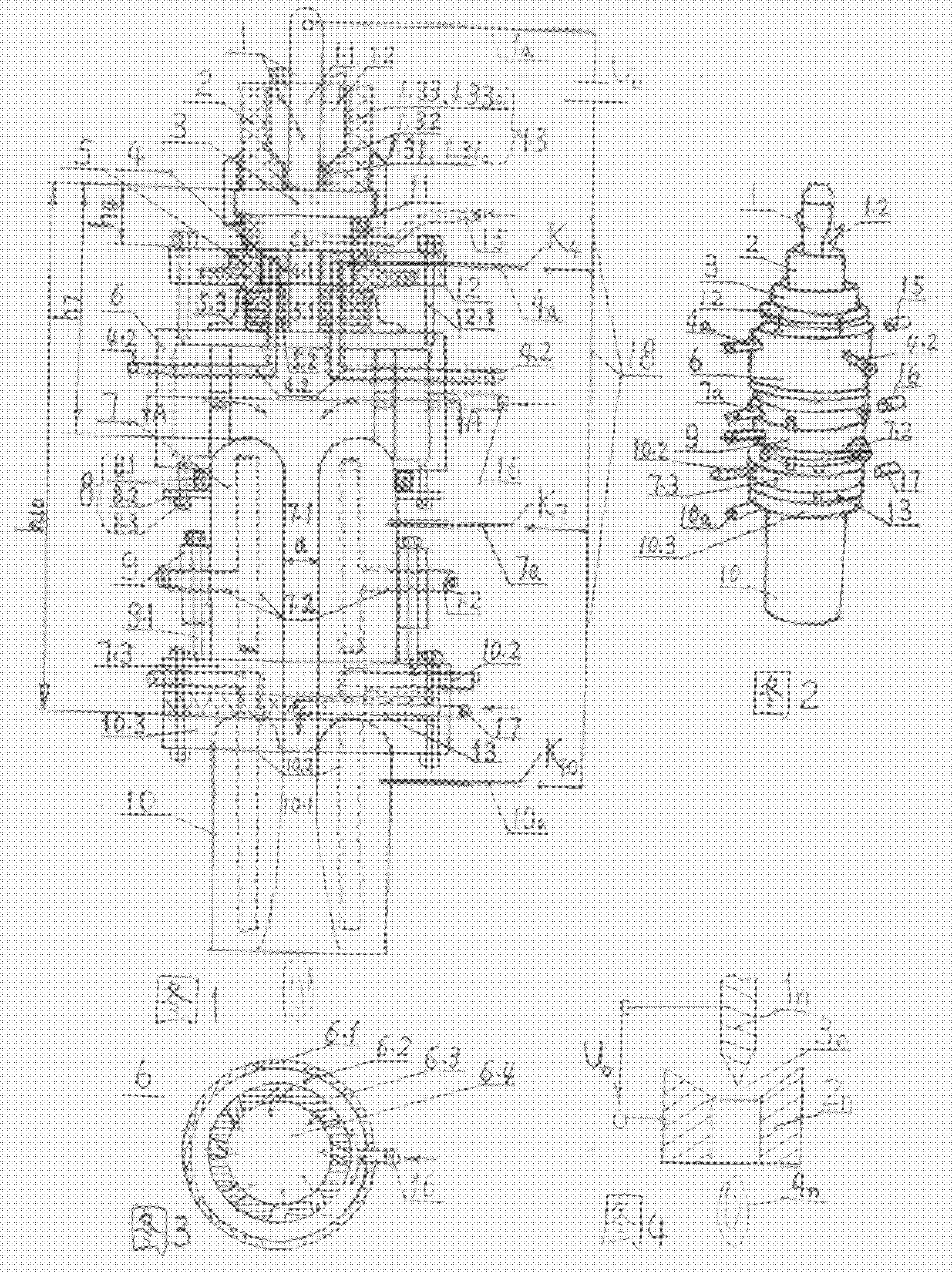

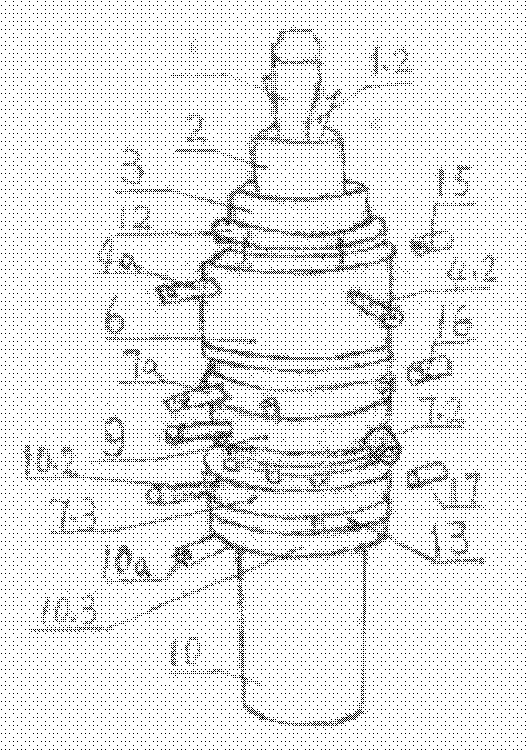

[0017] The 200KW non-transferred arc plasma generator of this embodiment is composed as follows:

[0018] 1) General layout: see figure 1, From the arc generation to the ejection direction, the cathode 1, the insulating cylinder 2 around the cathode, the gap 3, the small anode 4 and the adjustable insulating seat 5 supporting the small anode, and the main gas ring that introduces the main gas from the outside to the center hole are arranged in sequence. 6, two anodes 7, the seal between the outer upper part of the two anodes and the main gas ring 8, the adjusting nut 9 of the outer circle of the two anodes and the large anode 10 with a trumpet spout at the lowermost end.

[0019] 2) Each electrode structure: see figure 1, The cathode 1 is a solid red copper electrode 1.1, the outer ring of the cathode is a stainless steel cylinder 1.3, and the interlayer between the solid red copper electrode 1.1 and the stainless steel cylinder 1.3 is a cooling water channel 1.2. The cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com