A control method of a non-high frequency plasma cutting machine

A technology of a plasma cutting machine and a control method, which is applied to the control field of the plasma cutting machine, can solve the problems of slow arc striking speed, low arc striking success rate, inability to realize arc striking, etc., so as to improve the arc striking speed and the discharge speed. , The effect of improving the success rate of arc ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

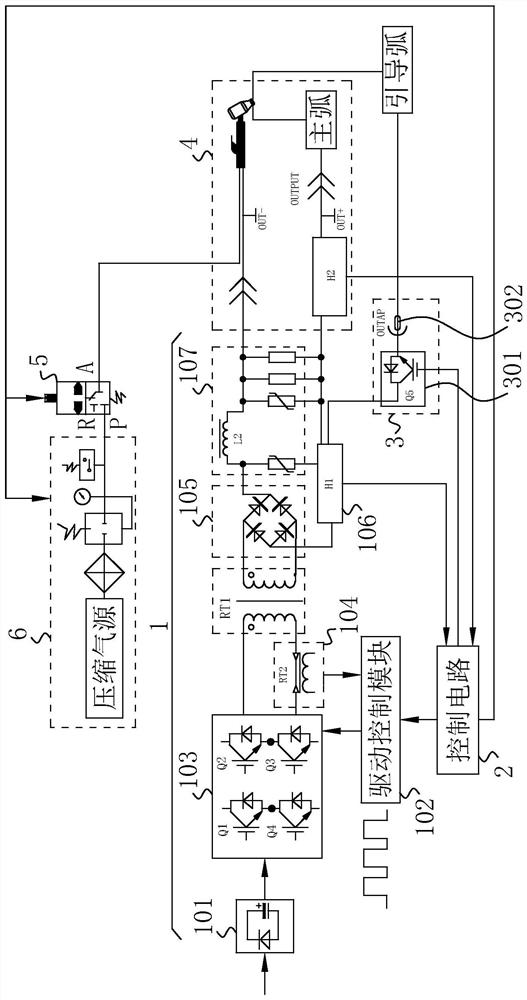

[0037] A control method for a non-high-frequency plasma cutting machine, such as figure 1 As shown, it is based on cutting power supply circuit 1, control circuit 2, arc striking circuit 3 and main arc circuit 4.

[0038] The cutting power supply circuit 1 includes a gun-shaped cutting torch and an inner electrode of the cutting torch. The cutting torch communicates with a gas pipe for blowing air to the inner electrode of the cutting torch through a three-way valve 5 , and the gas pipe communicates with an external compressed gas source 6 . The compressed gas source 6 can be a high-pressure gas tank, which is equipped with a solenoid valve to receive external control signals to control whether the high-pressure gas tank outputs high-pressure gas. The three-way valve 5 mark can be a two-position three-way solenoid valve. Among them, the two-position means that the spool of the solenoid valve has two different working positions, that is, conduction and blocking, and the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com