High-deposition low-heat-input plasma-twin-wire bypass arc welding device and method

A plasma arc and bypass arc technology, used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of workpiece deformation, increase the heat input of the workpiece molten pool, expand the area of the weld heat affected zone, etc. Effects of heat input, reduction of heat affected zone and degree of deformation, high deposition and low welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

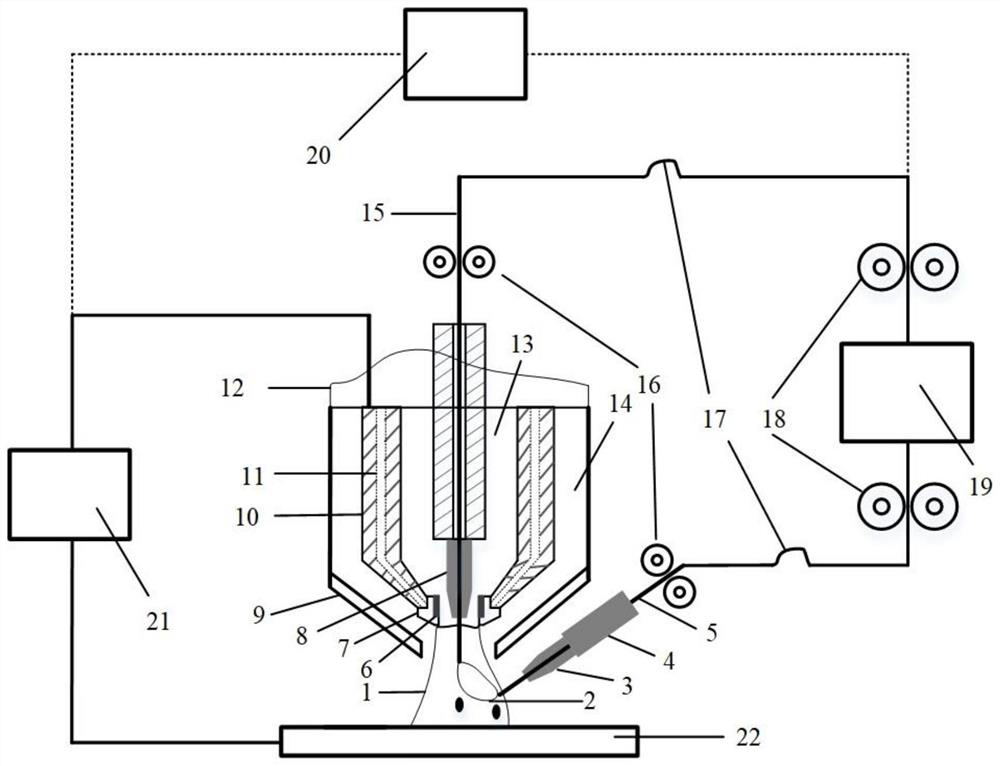

[0029] like figure 1 As shown, the plasma-twin wire bypass arc welding device with high deposition and low heat input of the present invention includes a plasma arc circuit assembly, a double melting electrode arc circuit assembly and a coordinated control unit. The plasma arc circuit assembly includes a plasma arc power source 21 , a conductive member 10 , a plasma annular electrode 7 and a workpiece 22 . The positive output terminal of the plasma arc power source 21 is connected to the plasma ring electrode 7 , and the negative output terminal is connected to the workpiece 22 .

[0030] The double-melting-pole arc circuit assembly includes a MIG / MAG power source 19, a plasma composite welding torch 12, a bypass welding gun, a wire feeding system, and welding wires 15 and 5; the output positive end of the MIG / MAG power source 19 is connected to the welding wire 15 in the plasma composite welding gun, The output negative end of the MIG / MAG power source 19 is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com