Smart stick arc torch system for manual operation with arc length variation compensation

An electrode arc welding and manual operation technology, which is applied in the direction of arc welding equipment, electrode characteristics, manufacturing tools, etc., can solve the problems of high workpiece assembly requirements, inconvenient movement, and narrow application area, so as to improve the success rate of arc ignition and improve Arc stability, effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

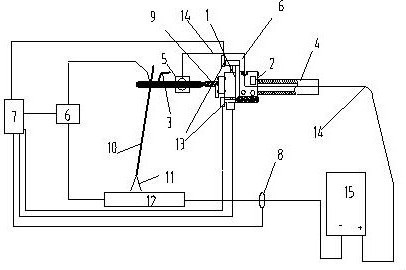

[0024] The present invention will be described in detail below with reference to the accompanying drawings.

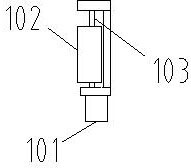

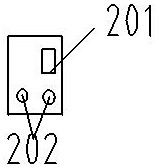

[0025] like Figure 1-Figure 2 As shown in the figure, a manual-operated intelligent electrode arc welding torch system with arc length variation compensation includes a welding tongs 3 and a handle 4, and a welding cable 14 penetrates the hollow fixed seat 2 from the handle 4, and then passes from the handle 4. The fixing seat 2 is protruded from the top, and the welding tongs 3 are connected through the chuck 5. The fixing seat 2 is fixedly connected to the micro slide table 1. The micro slide table 1 includes a slide table 102, and the slide table 102 is connected by a screw rod. 103 is connected with a stepping motor 101, the sliding table 102 is connected with the welding tongs 3, and driven by the stepping motor 101, the sliding table 102 can move on the lead screw 103, and the sliding table 102 and The welding tongs 3 are connected and can drive the welding ton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com