A circuit for improving the success rate and stability of small current arc ignition of inverter argon arc welding machine

A technology of argon arc welding machine and inverter welding machine, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems that no information has been collected, no explanation or report has been found, and the volume can be reduced and the success rate can be improved. and stable, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

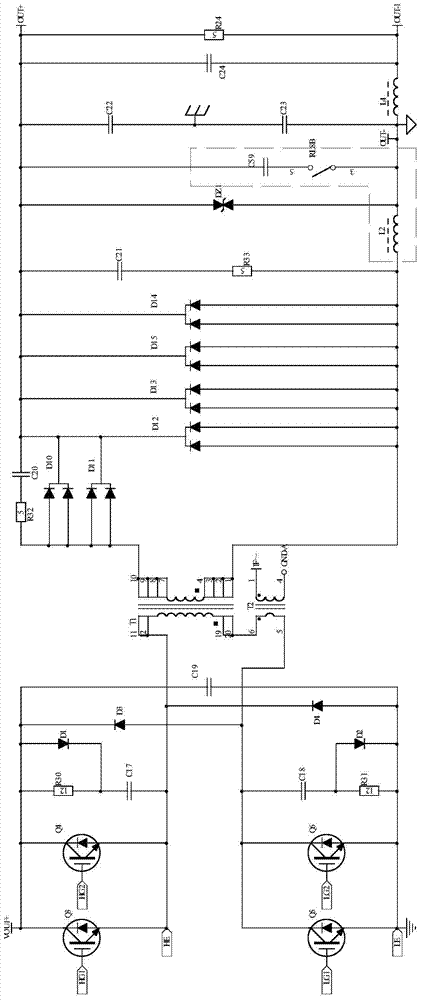

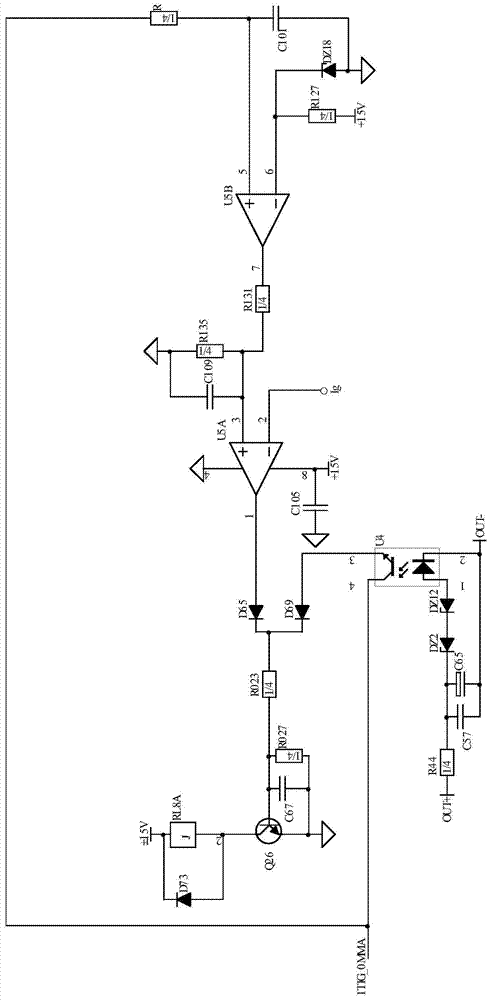

[0056] This embodiment provides a circuit for improving the success rate and stability of small-current arc striking of an inverter argon arc welding machine. The circuit part includes a main circuit circuit of the inverter welding machine and an output circuit arc stabilization circuit. in:

[0057] The main circuit circuit of the inverter welding machine adopts a dual-tube single-ended forward topology circuit, which inverts the rectified DC power into high-frequency square wave power, and then rectifies it into low-voltage power required by the inverter welding machine. direct current.

[0058] In the output loop arc stabilization circuit, a capacitor and a switch are connected in series in the output rectified circuit, and the switch is controlled by a control circuit to realize state control of the arc stabilization circuit.

Embodiment approach

[0060] A circuit for improving the success rate and stability of low-current arc ignition of an inverter argon arc welding machine, including a main circuit circuit of an inverter welding machine and an output circuit arc stabilization circuit; wherein:

[0061] The main circuit circuit of the inverter welding machine adopts a double-tube single-ended forward topology circuit, which inverts the rectified DC power of the input AC power into a high-frequency square wave power, and then rectifies it into the low-voltage DC power required by the inverter argon arc welding machine. output;

[0062] The output circuit arc stabilization circuit is connected in series with the main circuit circuit of the inverter welding machine, and is used to control the working state of the inverter argon arc welding machine.

[0063] Such as figure 1 As shown, the dual-tube single-ended forward topology circuit mainly includes:

[0064] The inverter circuit composed of power tubes Q3, Q4, Q5, Q6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com