A control method and control system for arc ignition of an inverter manual arc welding machine

A technology of manual arc welding and control system, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., and can solve the problems of insufficient precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A method for controlling the arc ignition of an inverter manual arc welding machine, providing a pulse thermal arc ignition signal to a given circuit of the inverter manual arc welding machine power supply, so that the welding current of the inverter manual arc welding machine power supply Become the pulse square wave arc striking current, after the power supply of the inverter manual arc welding machine successfully strikes the arc, turn off the pulse thermal arc striking signal, restore the normal welding current, the arc burns normally, and complete the arc striking.

[0039] Use the pulse thermal arc signal to finely and accurately control the arcing current (including thermal arc, thrust and reference) of the inverter manual arc welding machine when welding thin plate workpieces.

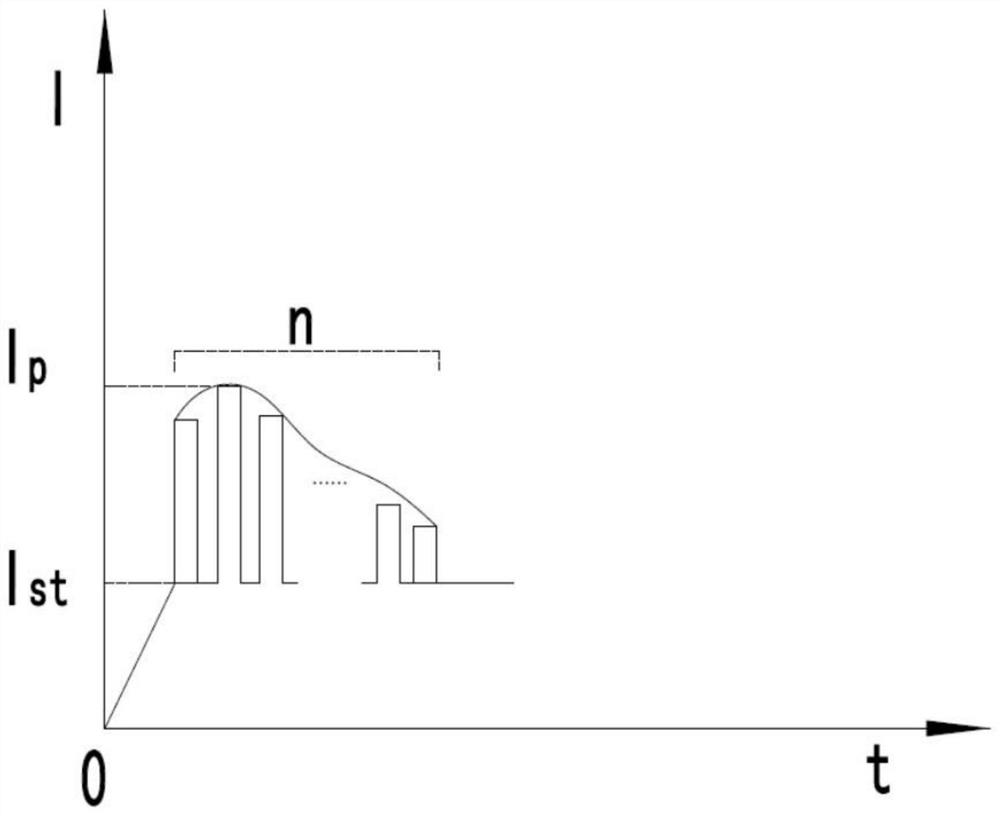

[0040] Such as figure 1 As shown, the pulsed thermal arc ignition signal is a gradual change of N pulse signals at different given values of thrust current and welding cu...

Embodiment 2

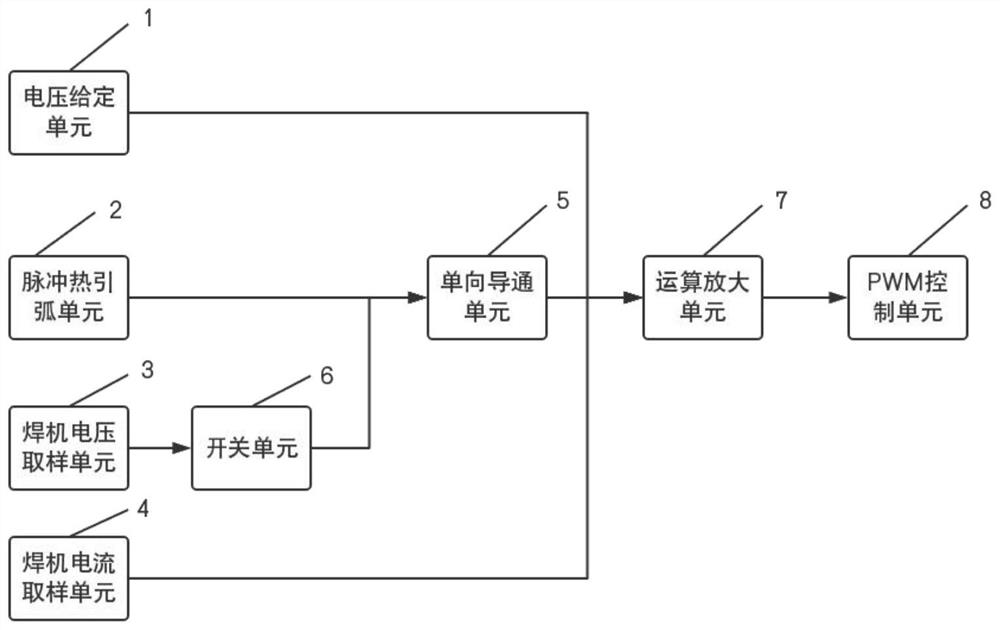

[0043] Embodiment 2: as figure 2 As shown, an arc ignition control system for an inverter manual arc welding machine includes: a voltage setting unit 1, a pulse thermal arc ignition unit 2, a welding machine voltage sampling unit 3, a welding machine current sampling unit 4, and a one-way conduction unit 5 , switch unit 6, operational amplification unit 7 and PWM control unit 8;

[0044] The voltage given signal provided by the voltage setting unit 1, the pulsed thermal arc signal provided by the pulse thermal arc starting unit 2 and the current negative feedback signal provided by the welding machine current sampling unit 4 are superimposed and summed and passed through the operational amplification unit 7. Control the pulse width of the PWM control unit 8 so that the power supply of the inverter manual arc welding machine can quickly generate an arc between the workpiece and the welding rod when the welding rod touches the workpiece. At this time, the welding machine voltag...

Embodiment 3

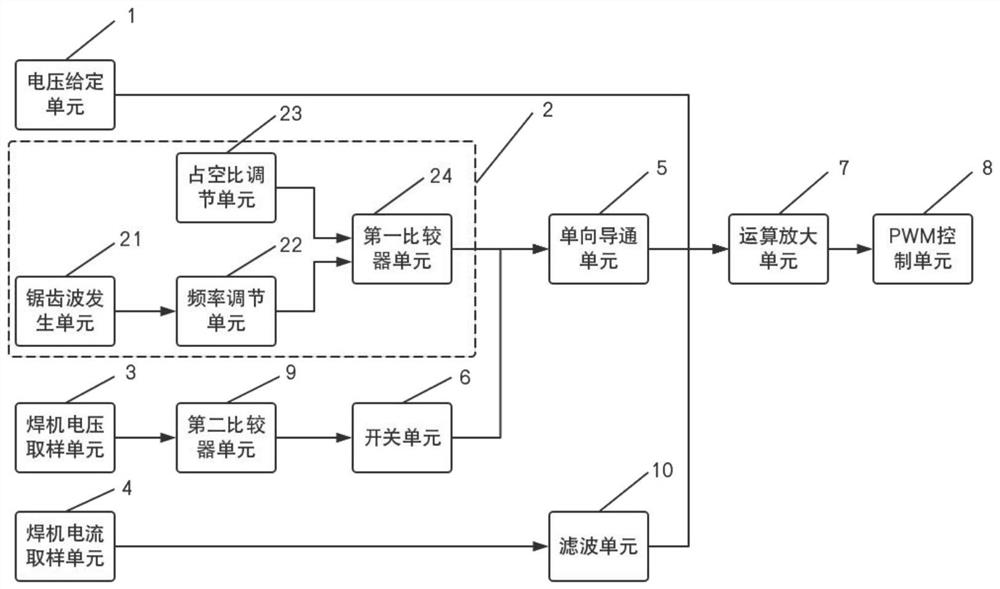

[0045] Embodiment 3: as image 3As shown, the difference from Embodiment 2 is that the pulse thermal arc striking unit 2 includes: a sawtooth wave generating unit 21, a frequency adjusting unit 22, a duty cycle adjusting unit 23 and a first comparator unit 24; The sawtooth wave generation unit 21 is connected to the frequency adjustment unit 22, and the frequency adjustment unit 22 and the duty ratio adjustment unit 23 are respectively connected to the two input terminals of the first comparator unit 24, and the first comparator The output end of the unit 24 is used as the output end of the pulse thermal arc striking unit 2 .

[0046] The frequency and duty cycle of the pulsed thermal arcing current signal can be controlled by the frequency adjustment unit and the duty ratio adjustment unit to obtain different arcing currents suitable for thin and thick plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com