Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve the quality of dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel building construction dust removal device

InactiveCN106731271AImprove dust removal efficiencyImprove the quality of dust removalCombination devicesDispersed particle filtrationArchitectural engineeringDust collector

The invention relates to a novel building construction dust removal device which comprises a base and traveling wheels, wherein a dust collection box is connected above the base through bottom rods; the inside of the dust collection box is divided into a left cavity and a right cavity through a partition; partition through holes are formed in the partition; a first dust filter net is arranged on the left side of the partition; a dust collection opening and a dust collector are arranged at the top of the left side of the left cavity; the dust collector is connected with a dust collection hose and a dust collection hood; a motor is arranged on the top wall of the left cavity; the output shaft end of the motor is connected with a screw rod; the screw rod is in threaded fit with a lifting block; the right end of the lifting block is connected with a brush rod; an air outlet is formed in the top wall of the right cavity; a cleaning box is arranged right below the left cavity; a dust discharging opening of the left cavity communicates with a dust guide opening of the cleaning box through a dust guide barrel. Due to the structure, the novel building construction dust removal device can be effectively improved in dust removal efficiency and dust removal quality, so that the usability of the novel building construction dust removal device is greatly improved.

Owner:CHENGDU JIAMEIJIA SCI & TECH

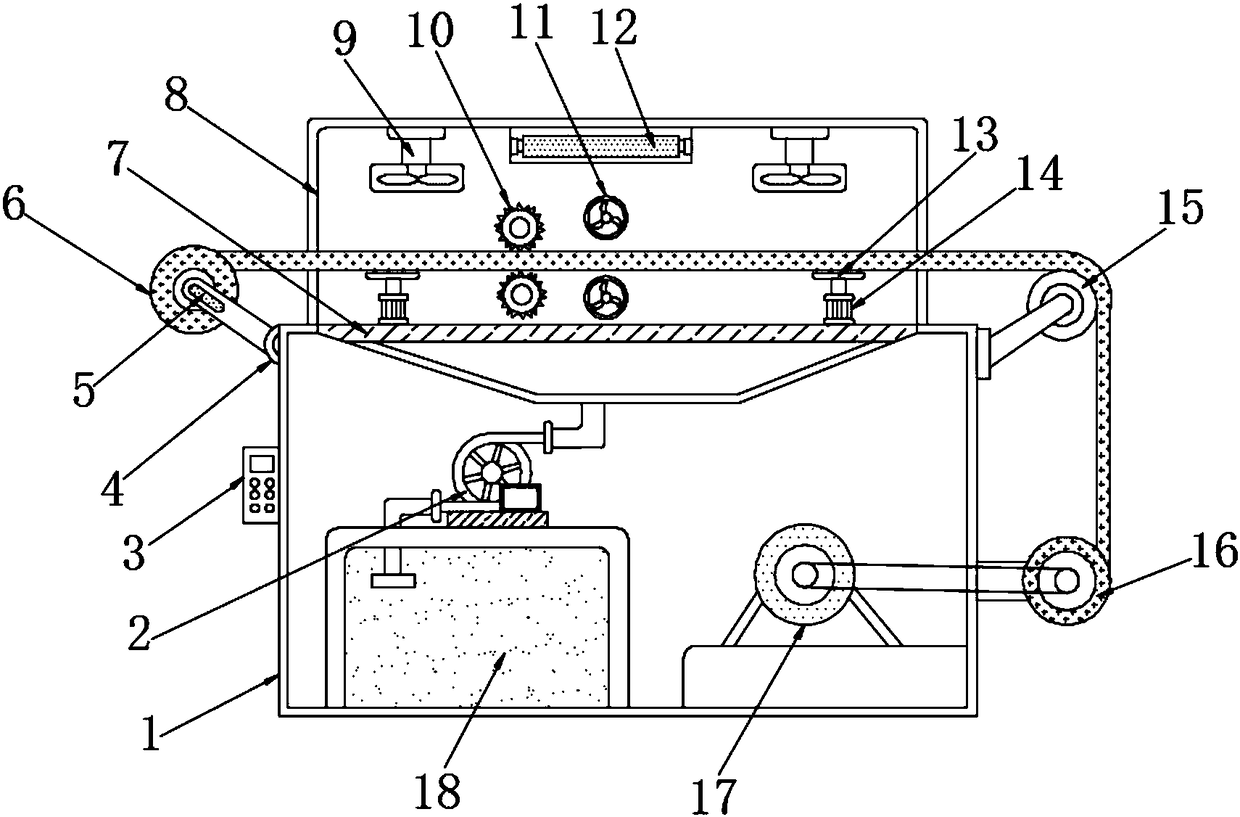

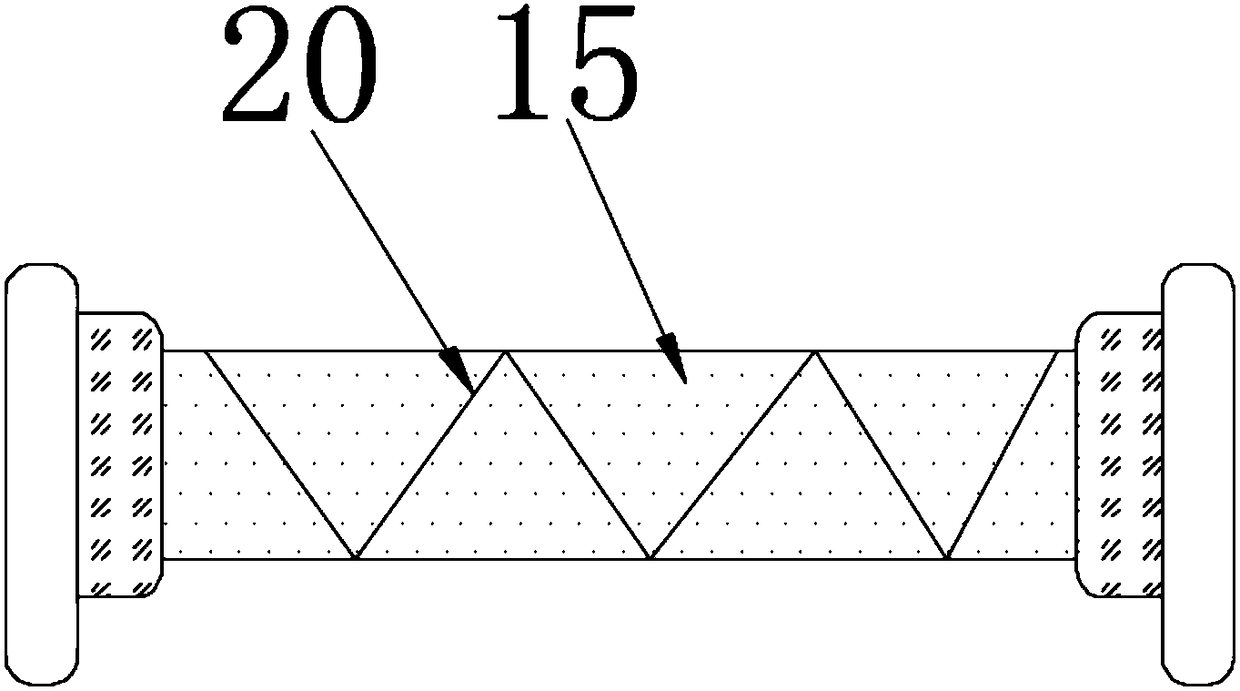

Dust removing device for textile use

InactiveCN108130702AAvoid problems that cannot be blown offImprove the quality of dust removalMechanical cleaningPressure cleaningEngineeringVirus

The invention discloses a dust removing device for textile use, comprising a case. A dust box is arranged inside the case. A grille is arranged on the upper end of the case. A vibration motor is arranged on the upper end of the grille. A shaking board is arranged on the upper end of the vibration motor. A cover is arranged on the upper end of the shaking board. The vibration motor and the shakingboard cooperate with a dust removing fan to shake textile cloth in order to remove the dust impurities on the textile cloth. The dust impurities on the texture cloth can be brushed off through a dustremoving brush roll and the grille, and the dust impurities can be easily collected. The bacteria and viruses on the texture cloth can be killed conveniently through an ultraviolet lamp tube, and willnot affect the sanitary quality of the textile cloth. The textile cloth can be heated and dehumidified conveniently through a cloth guide roll and a heating wire. Moreover, the texture cloth can alsobe ironed and prevented from wrinkling, and thus, the textile cloth looks more beautiful.

Owner:响水县嘉亿纺织有限公司

Prop plate dust removal device

InactiveCN110404832AImprove handling efficiencyImprove efficiencyCleaning using toolsCleaning using gasesMechanical equipmentEngineering

The invention discloses a prop plate dust removal device, and belongs to the field of display prop machining mechanical equipment. A plate moving mechanism of the device is fixedly arranged on the upper side of a plate placing support, a dust removal mechanism is fixedly arranged on the upper side of the guide plate support, a plurality of guide plate rotating rollers are arranged on the upper side of the guide plate support, a lifting support is horizontally and fixedly arranged on the lower side of a lifting connecting plate, a translation guide plate is arranged on a moving plate guide rodin a sliding mode in the horizontal direction, a plurality of moving plate suckers are uniformly and fixedly arranged on the lower side of the translation guide plate, a dust removal support is horizontally and fixedly arranged on the upper side of a rotary roller support, a dust brushing mechanism and a dust collection material pipe are sequentially arranged on the dust removal support in the horizontal direction, and a dust pastingmechanism is horizontally arranged on the upper side of the rotary roller support on one side of the dust collection material pipe. The device has the advantages that the structural design is reasonable, and prop plates can be rapidly and stably lifted and transferred one by one, so that the prop plates are subjected to efficient and smooth continuous dust removal processing, the automation degree of dust removal and machining of the prop plates is high, and the requirements of machining and use are met.

Owner:浙江高人道具有限公司

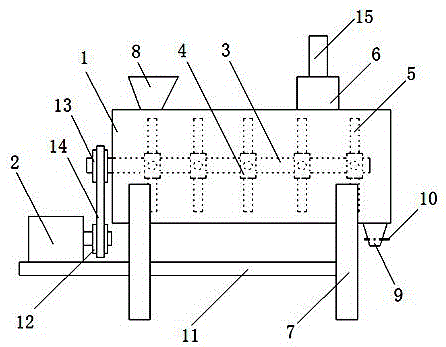

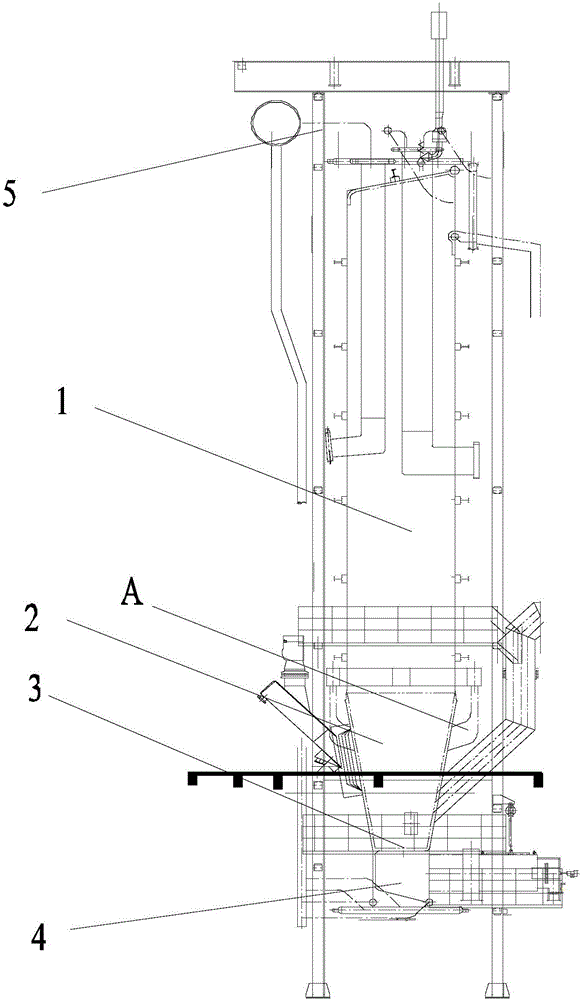

Dust removal device for rice processing

InactiveCN105583021AEasy to separateImprove dust removal efficiencyDirt cleaningGrain treatmentsDrive wheelEngineering

The invention discloses a dust removal device for rice processing. The dust removal device for rice processing comprises a dust chamber, a motor, a rotary shaft, installation blocks, stirring rods and a dust collection motor. The dust removal device for rice processing is characterized in that the dust chamber is arranged on supports, and a feeding port and a discharging port are formed in the dust chamber; a bearing plate is arranged between the supports; the motor is arranged on the bearing plate; one end of the rotary shaft is arranged outside the dust chamber, and the other end of the rotary shaft is arranged in the dust chamber; a driven wheel is arranged at the end, located outside the dust chamber, of the rotary shaft; the installation blocks are arranged on the portion, located in the dust chamber, of the rotary shaft. According to the dust removal device for rice processing, the multiple installation blocks are arranged on the rotary shaft, the multiple stirring rods are arranged on the installation blocks, and rice in the dust chamber can be fully stirred through the stirring rods, so that the rice is completely separated from dust on the surface of the rice, and the dust is discharged through the dust collection motor and a dust discharging pipe; the dust removal efficiency and the dust removal quality of the rice are improved, and accordingly the quality of the rice is improved.

Owner:周兆平

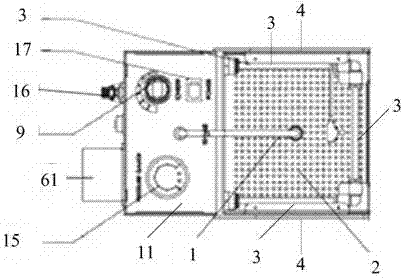

Dedusting antistatic device

InactiveCN104259137AImprove the quality of dust removalCreate pollutionElectrostatic cleaningCleaning using gasesProduction lineEngineering

The invention relates to a dedusting antistatic device. The dedusting antistatic device comprises a static electricity eliminator, a workbench and an air curtain generation element. The static electricity eliminator comprises an ionic wind jet orifice above the workbench, and the ionic wind jet orifice is used for jetting ionic wind to the workbench so as to remove dust and static electricity on to-be-cleared articles on the workbench; the workbench is arranged below the ionic wind jet orifice of the static electricity eliminator and used for placement of the to-be-cleared articles and guiding dust out; the air curtain generation element is arranged above the workbench and used for jetting air to the workbench to form an air curtain around the to-be-cleared articles. By the technical scheme, functions of static electricity elimination, dedusting, dust collection and the like are integrated to facilitate operations; in addition, after static electricity and dust on components are removed, surrounding environments cannot be polluted, and integral dedusting quality of components on a production line is improved.

Owner:BOE OPTICAL SCI & TECH +1

Dust removal device with vibration function for building material workshop

InactiveCN109865370AEasy to disassemble and fixGuarantee the quality of dust removalDispersed particle filtrationDirt cleaningActivated carbon filtrationEngineering

The invention discloses a dust removal device with a vibration function for a building material workshop, and belongs to the technical field of building materials. The dust removal device comprises adust removal shell; a dust removal pipe which communicates with the inner cavity of the dust removal shell is arranged at the center of the bottom of the dust removal shell; a collecting bag fixing ring is arranged on the outer wall of the dust outlet pipe; a filter element is arranged in the inner cavity of the dust removing shell; and two groups of cams respectively sleeve the top and the bottomof the outer wall of a rotating rod. According to the invention, a driving motor drives the rotating rod to rotate, so that the two groups of cams push the filter element to move leftwards to extrudean elastic telescopic rod. When protruding ends of the cams are not in contact with the filter element, the elastic telescopic rod drives the filter element to reset, then the filter element moves left and right, and a coarse filter screen, a fine filter screen and an activated carbon filter screen can move left and right to vibrate, so that dust left on outer walls of the coarse filter screen, the fine filter screen and the activated carbon filter screen falls downwards, and dust removal quality during use is guaranteed.

Owner:南通巨大机械制造有限公司

Solid wood plate polishing device

InactiveCN112658909AClamp firmlyPolished evenlyGrinding carriagesGrinding drivesSolid woodDust control

The invention discloses a solid wood plate polishing device. The solid wood plate polishing device comprises a platform, four supporting legs are fixedly installed at the bottom of the platform and are symmetrically arranged in pairs, four stand columns are fixedly installed at the top of the platform and are symmetrically arranged in pairs, and a same transverse plate is fixedly installed at the top ends of the four stand columns. A positioning base and two fixing bases are fixedly installed at the bottom of the transverse plate, and a same transverse transmission shaft is rotationally installed on the two fixing bases. The device is reasonable in design, good in practicability, capable of achieving automatic polishing work on the surface of a solid wood plate, uniform in polishing on the surface of the solid wood plate, good in polishing effect, free of manual polishing of workers, capable of reducing labor intensity, capable of saving time and labor, capable of improving working efficiency, and capable of cleaning and removing dust and chippings in the polishing process. The dust removal effect is good, the dust removal quality is improved, the air quality around the working environment is improved, and harm to the health of workers is not prone to being caused.

Owner:罗时多

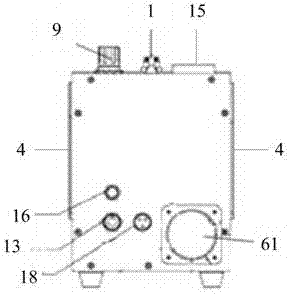

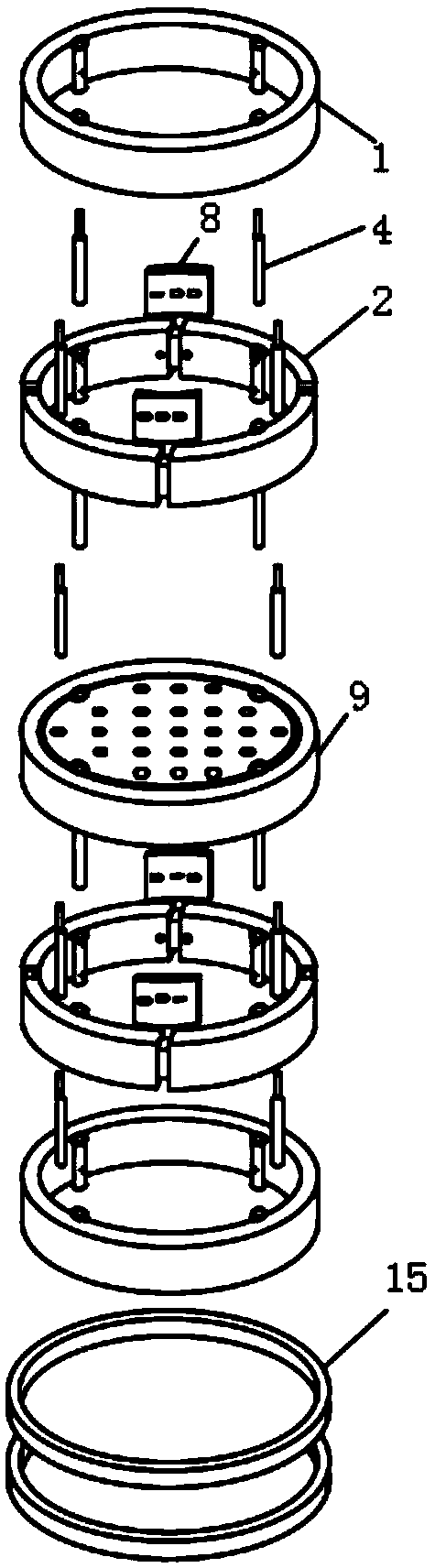

Efficient dust-removing equipment for raw materials before plastic product production

InactiveCN108890918AAdd at a constant speedEasy to remove dustGas current separationDust particlesRaw material

The invention relates to efficient dust-removing equipment for raw materials before plastic product production. The equipment comprises a tank, wherein the tank is a hollow cylinder having two ends which are communicated with each other, and is soldered by a steel plate; a top cover is arranged at the top opening of the tank, and a bottom cover is arranged at the bottom opening of the tank; a feeding device is arranged on the outer wall of the tank; a dust removing device is arranged inside the tank; a suction filter device is arranged on the outer wall of the tank symmetric to the feeding device. According to the equipment, the raw materials are added at a uniform speed by virtue of the feeding device, dust removal can be sufficiently performed on the raw materials, and occurrence of incomplete dust removal caused by over addition of the raw materials can be avoided; dust can be separated from the raw materials by virtue of the dust removing device, and efficient dust removal can be facilitated; blowing air can be added by utilizing a heater, the wet raw materials can be dried by utilizing hot air after the raw materials are washed; and an air flow is formed inside the tank by virtue of the suction filter device, dust particles among the raw materials can be carried away by utilizing the air flow, and the cleanliness of the raw materials can be improved.

Owner:HEFEI JINGMEI GRAPHIC TECH CO LTD

Processing device for plank

PendingCN108499772AImprove practicalityQuick adjustment to useSpraying apparatusElectrostatic cleaningEngineeringWood plank

The invention relates to the field of plank painting processing equipment and discloses a processing device for a plank. The processing device for the plank comprises a conveying platform and an oil paint box. The oil paint box is connected with a main spray head and an auxiliary spray head. The main spray head is located in the auxiliary spray head, the width of the main spray head is smaller than that of the auxiliary spray head, and a blower is arranged above the conveying platform. The conveying platform is provided with a plurality of through holes, and the through holes are connected with an air bag. An air flow channel for air flow to pass through is arranged below the conveying platform, the bottom of the air flow channel is provided with a sliding groove, the air flow channel is internally provided with an arc-shaped elastic piece, and the two ends of the elastic piece are both connected into the sliding groove in a sliding manner. The two ends of the air flow channel are connected with an air inlet pipe and an air outlet pipe correspondingly. The air outlet pipe is internally provided with an upper air outlet pipe and a lower air outlet pipe, the upper air outlet pipe isinternally provided with a pressure valve, an air flow drive painting mechanism is connected between the lower air outlet pipe and the main spray head, and an air flow drive painting mechanism is connected between the upper air outlet pipe and the auxiliary spray head. By means of the processing device for the plank, the problem that the painting range of a painting head cannot be adjusted can besolved, painting processing for planks with different specific specifications is achieved, and the practical effect of the device is enhanced.

Owner:重庆木头木脑文化创意有限公司

Tunneling hydraulic cylinder

ActiveCN110319072ASmooth transmissionAvoid bondingFluid-pressure actuatorsCleaning using toolsHydraulic cylinderHydraulic structure

The invention relates to the field of hydraulic cylinders, in particular to a tunneling hydraulic cylinder. The tunneling hydraulic cylinder comprises a fixing sleeve, a hydraulic structure, a filterscreen, a dust removal structure, an end cover and a lubricating structure, wherein the dust removal structure is matched with the use of the hydraulic structure, so that the hydraulic structure drives a cleaning assembly in the dust removal structure and a hydraulic shaft in the hydraulic structure to rotate while the hydraulic structure extends; the dust removal structure drives the lubricatingstructure, so that lubricating oil liquid is extruded, and the lubricating oil is uniformly smeared on the hydraulic shaft through the dust removal structure, so that the transmission of the hydraulicstructure is more stable; meanwhile, later-stage waste residue is prevented from being adhered to the hydraulic shaft; meanwhile, the dust removal structure blows the hydraulic shaft through gas, sothat the lubricating oil is further smeared on the hydraulic shaft more uniformly, and the waste residue in a coal mine can be prevented from being adhered to the hydraulic shaft during hydraulic driving; and when the hydraulic structure is shortened, the hydraulic structure drives the cleaning assembly in the dust removal structure to rotate, so that sweeps on the hydraulic shaft are scraped, andthe sweeps are prevented from entering the interior of the hydraulic structure.

Owner:济源市丰泽特钢实业有限公司

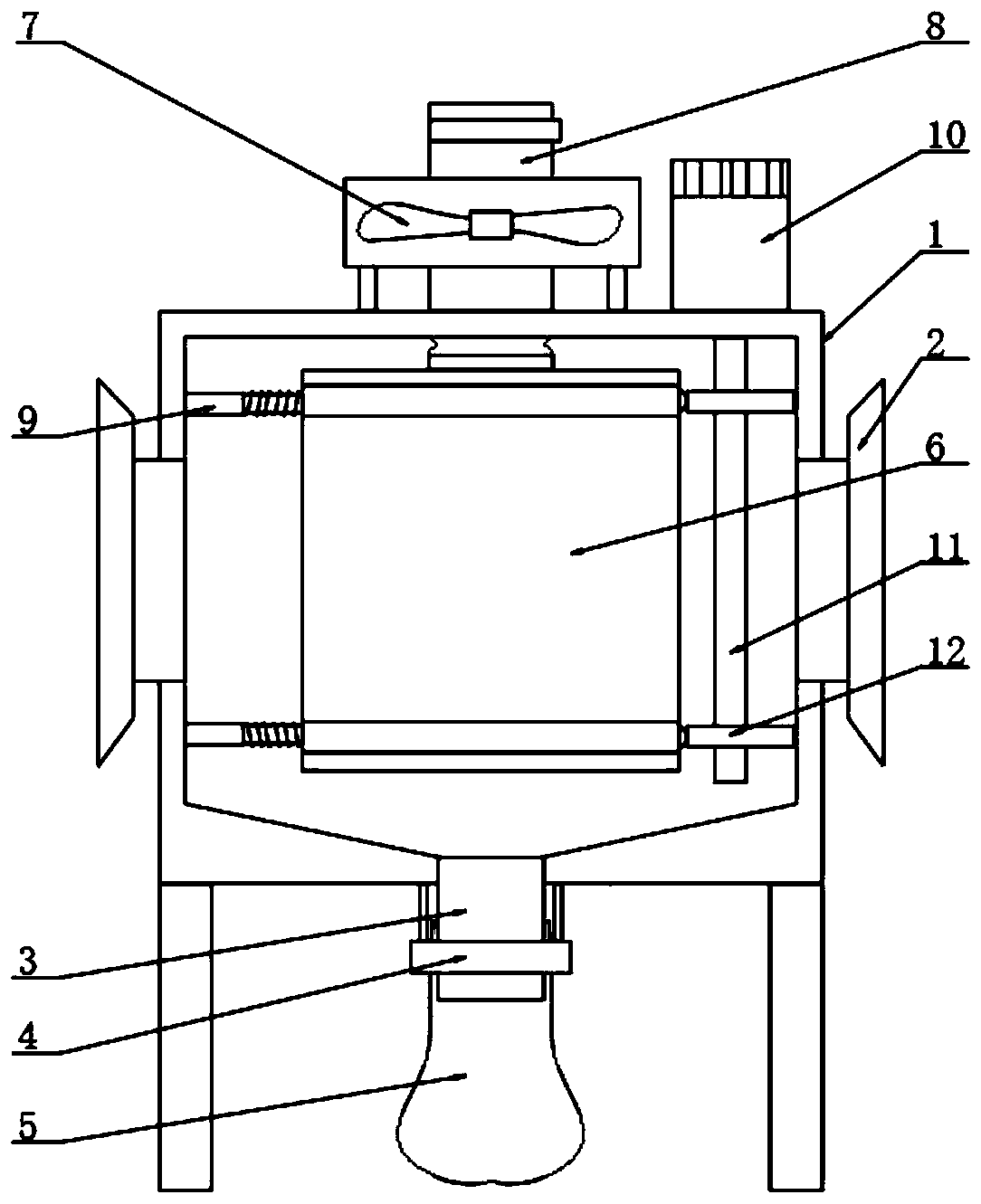

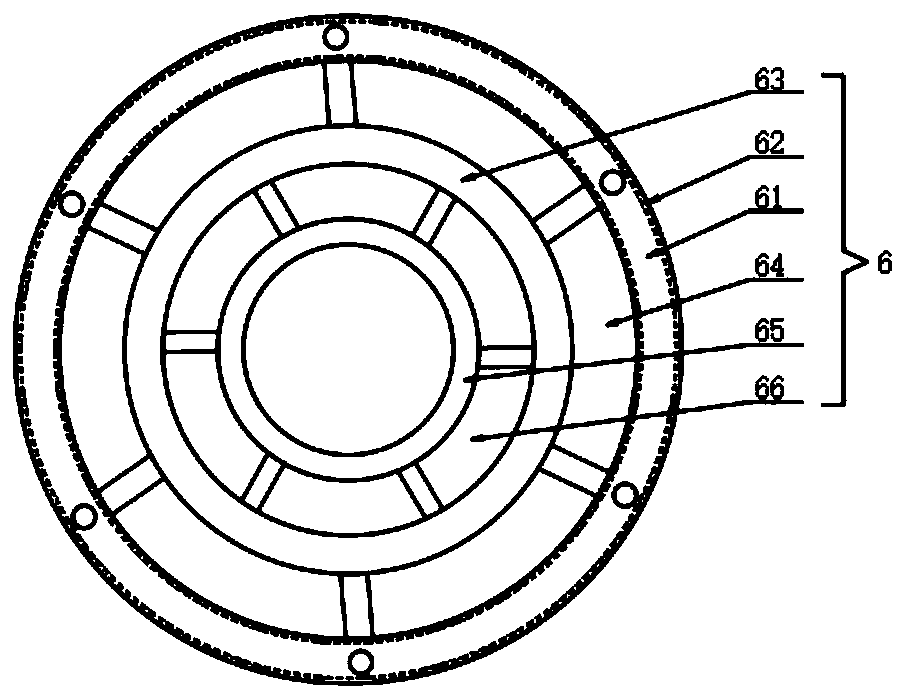

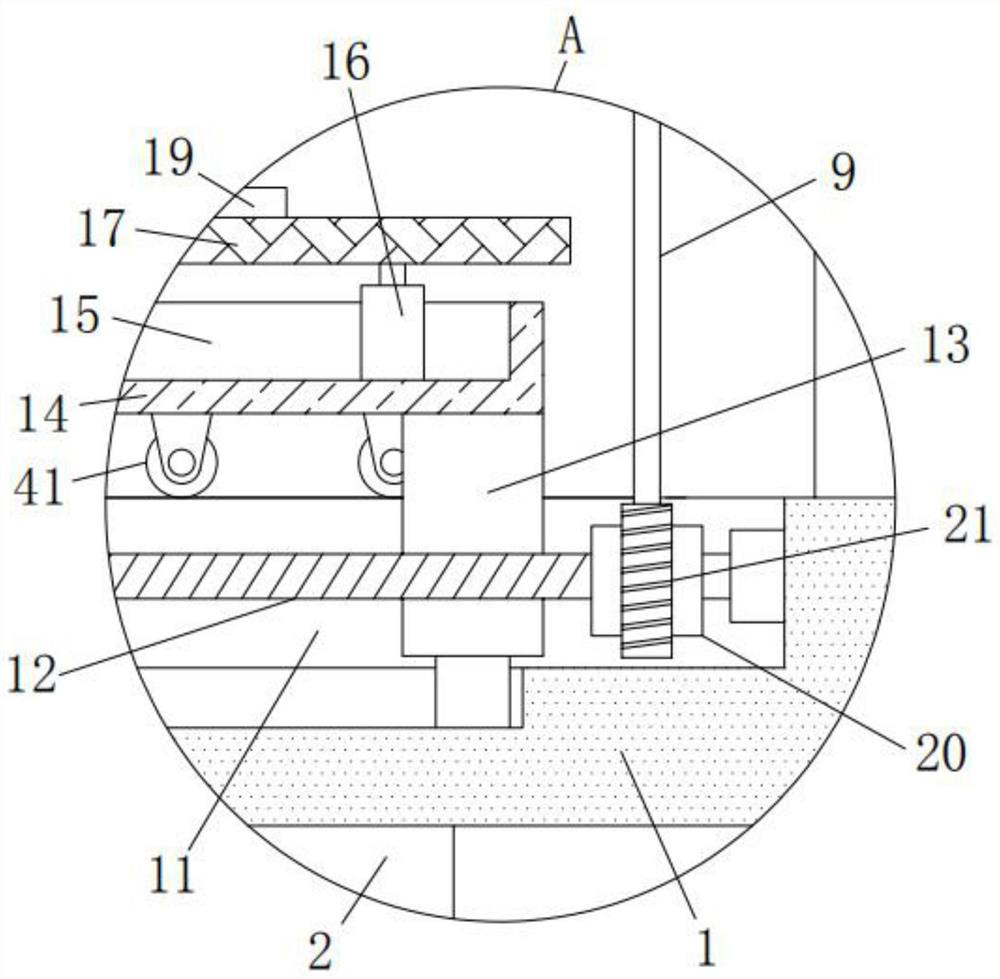

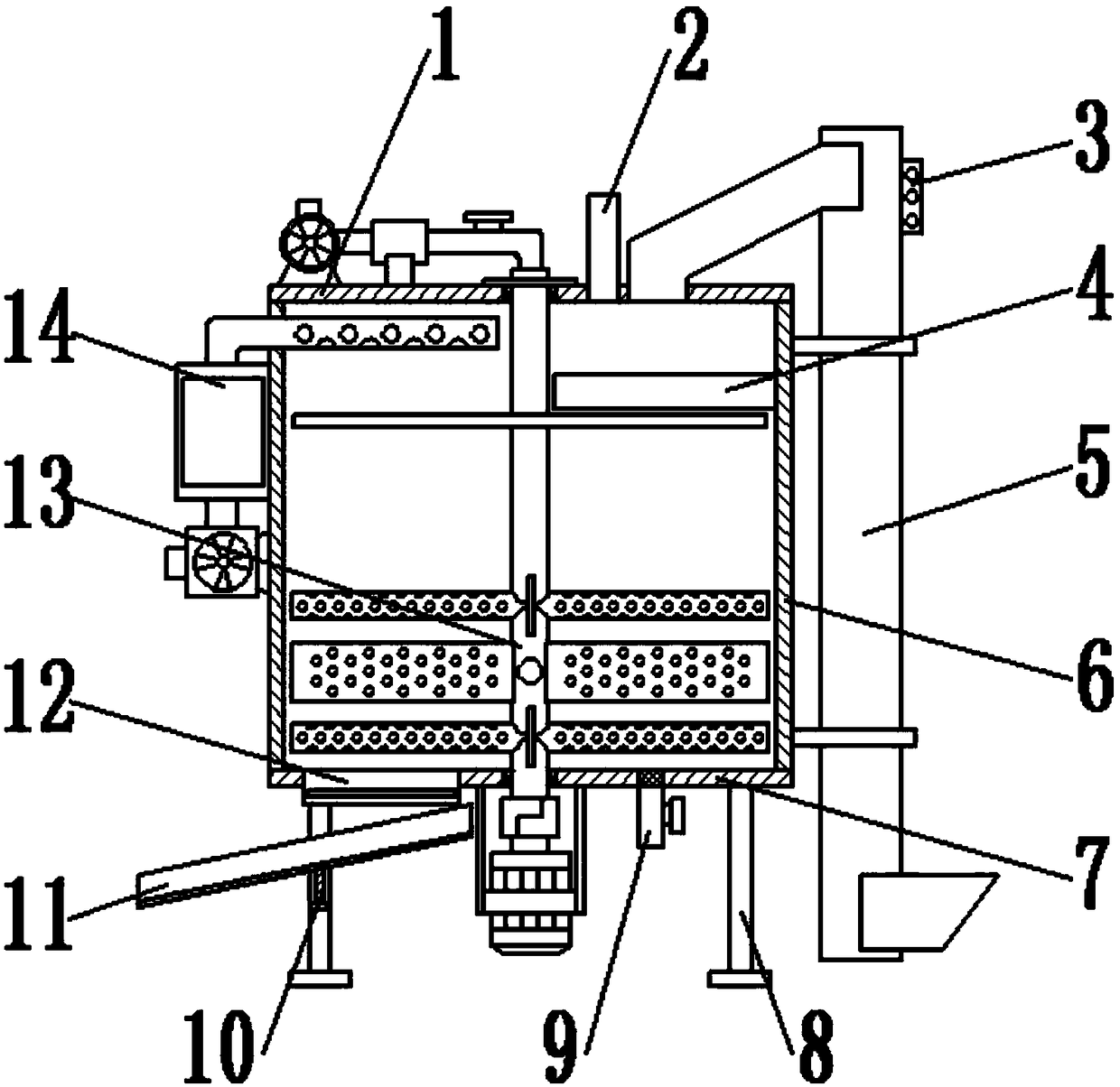

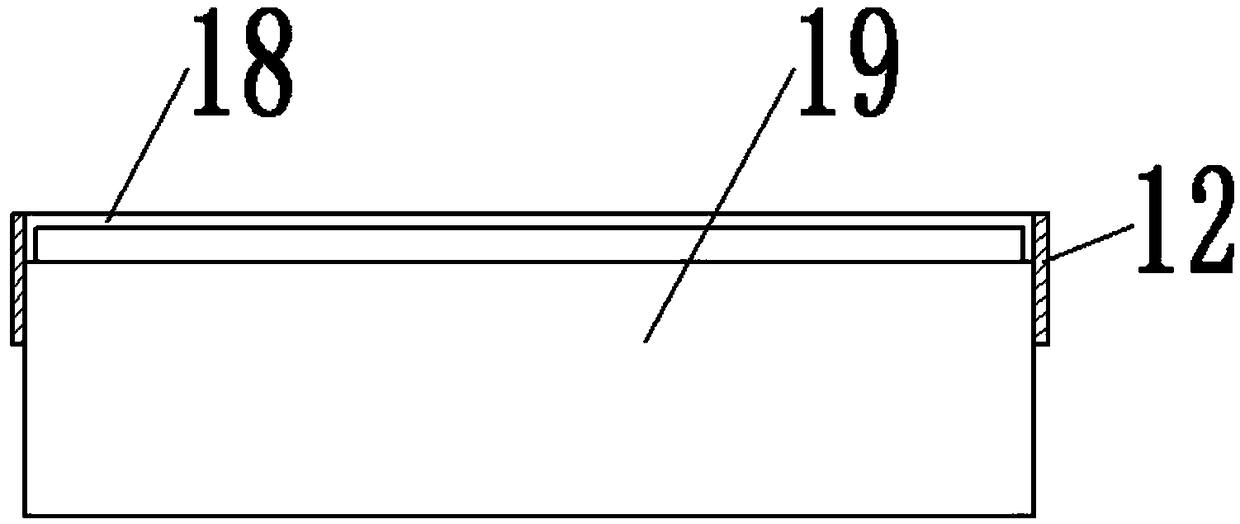

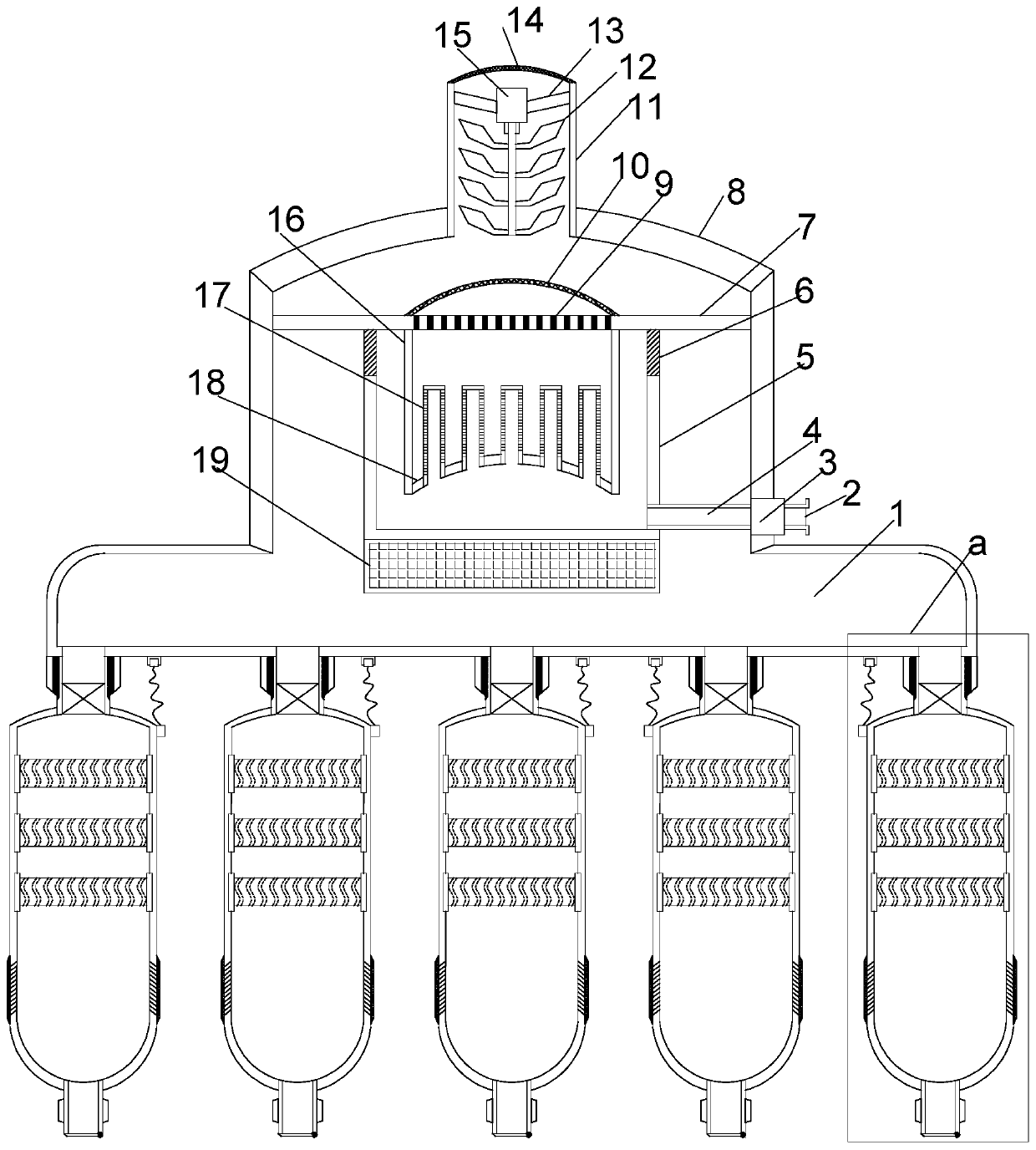

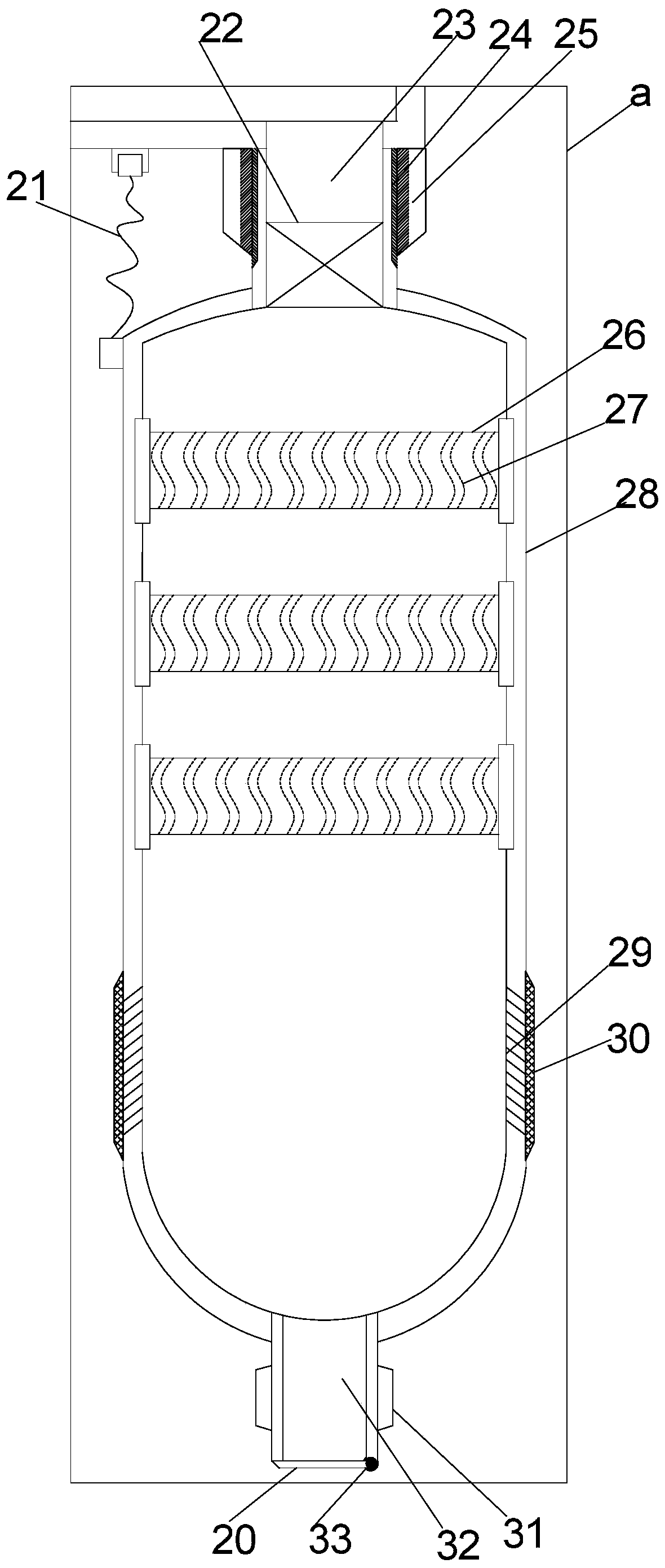

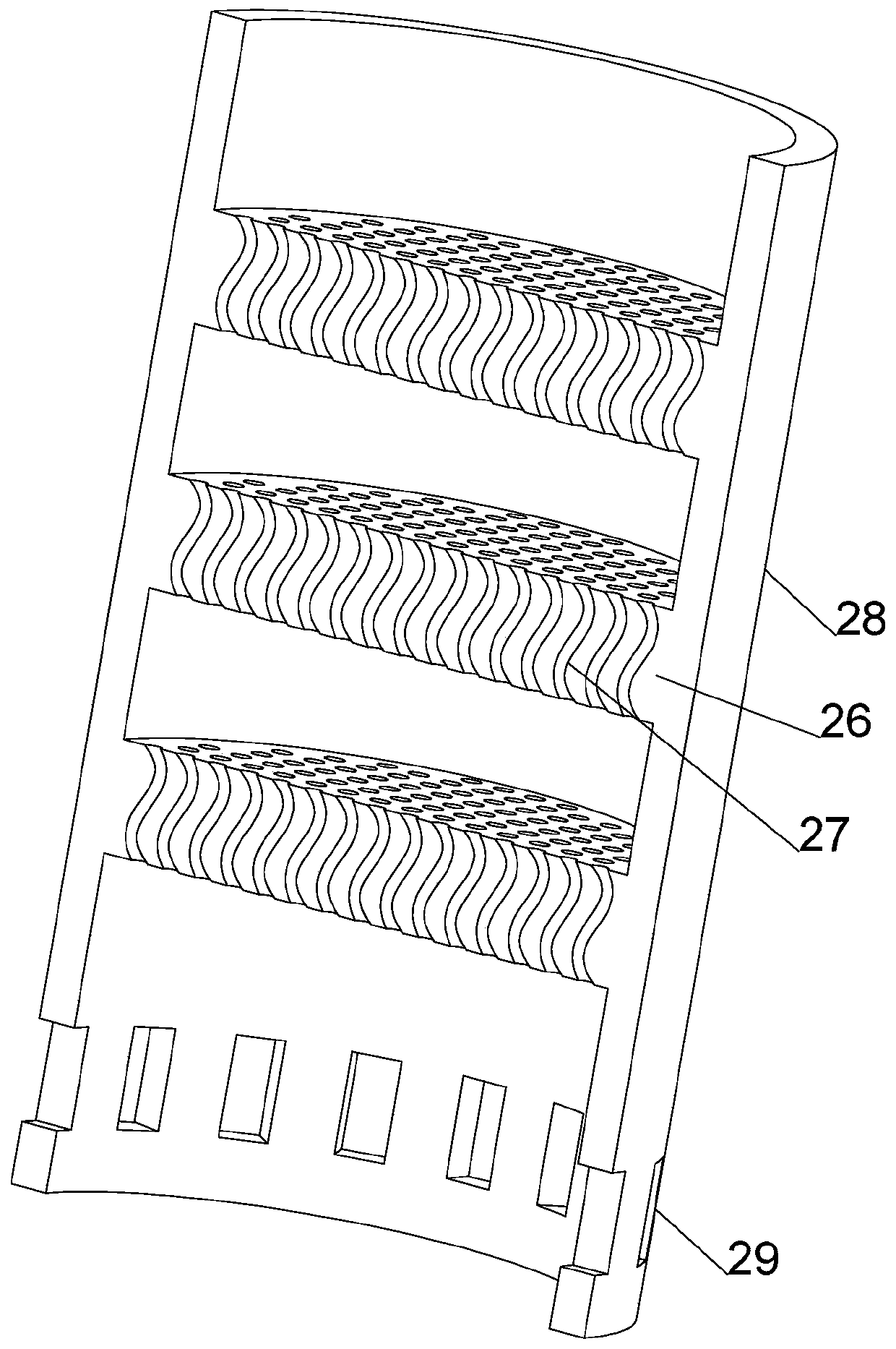

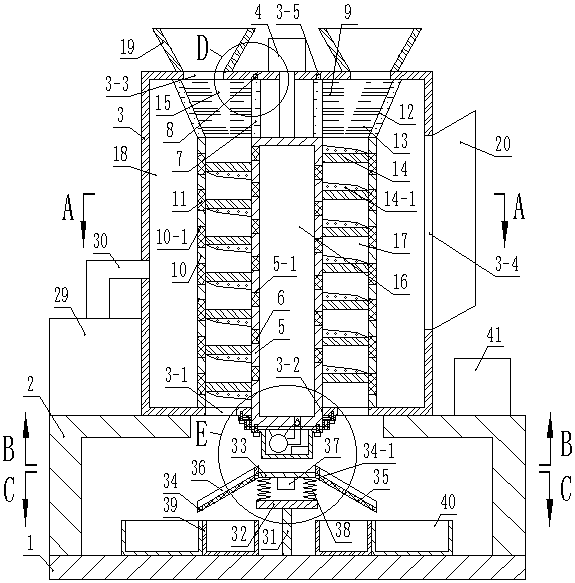

Multi-channel multi-stage environment-friendly dust removal device

PendingCN111558259AReduce the burden onReal-time replacementCombination devicesGas treatmentEnvironmental engineeringMechanical engineering

The invention relates to the field of dedusting equipment, and concretely relates to a multi-channel multi-stage environment-friendly dust removal device. The device comprises a vertically arranged support mounting cylinder, a uniform guide cylinder is horizontally arranged at the lower end of the support mounting cylinder, a driving guide cylinder is vertically arranged in the middle of the upperend of the uniform guide cylinder, a flow guide filter screen is arranged at the upper end of the driving flow guide cylinder, a plurality of flow guide mounting cylinders are arranged below the uniform flow guide cylinder at equal intervals, the flow guide mounting cylinders are vertically arranged, and a partition mounting plate is horizontally arranged at the upper half section of the supportmounting cylinder. A plurality of groups of detachably mounted flow guide structures are combined, so multi-channel synchronous flow guide operation is realized; through cooperation with a multi-stageslow flow structure, large-particle dust in the dust removal process is firstly settled and discharged by the device, the burden of aeration dust removal is reduced, the aeration quality and the continuous operation duration are improved, and the environmental protection performance of the device is improved; and an internal liquid can be replaced in real time in the aeration process, so the dustremoval efficiency and quality of the device are further improved.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Biomass particle processing equipment in new energy field

InactiveCN108176635AImprove efficiencyImprove dust removal efficiencySievingScreeningNew energyElectric machinery

The invention discloses biomass particle processing equipment in the new energy field. The biomass particle processing equipment comprises a bottom plate. L-shaped supporting frames are symmetricallyfixed to the top face of the bottom plate. A box body is fixed to the top faces of the L-shaped supporting frames. A through hole A is formed in the center of the bottom face of the box body. A motoris fixed to the top face of the box body. The driving end of the motor penetrates into the box body. A barrel is fixedly connected with the driving end of the motor. The bottom of the barrel is slidably connected with the through hole A. A cavity A is formed in the barrel. A plurality of through holes B are evenly formed in the barrel. Filtering screens A are fixed in the through holes B. An annular groove is formed in the top face of the inner wall of the box body. An annular rod matched with the annular groove is slidably arranged in the annular groove. A sleeve A is fixed to the top face ofthe barrel. The top face of the sleeve A is fixed to the bottom face of the annular rod. Through the biomass particle processing equipment, biomass particles can be dedusted, in addition, the dedusting efficiency is high, the dedusting quality is good, dust in the particles can be screened out, the using efficiency of the biomass particles is improved, the material collection speed is high, and the biomass particle processing equipment is quite practical and reliable.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

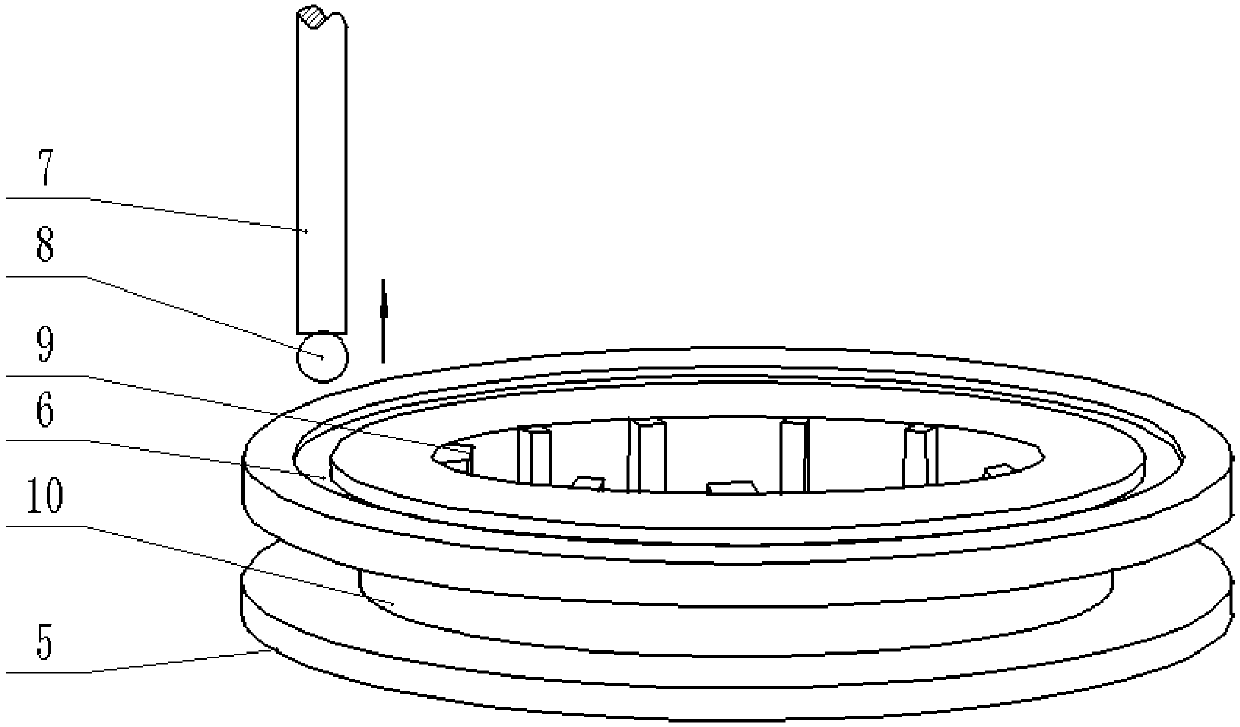

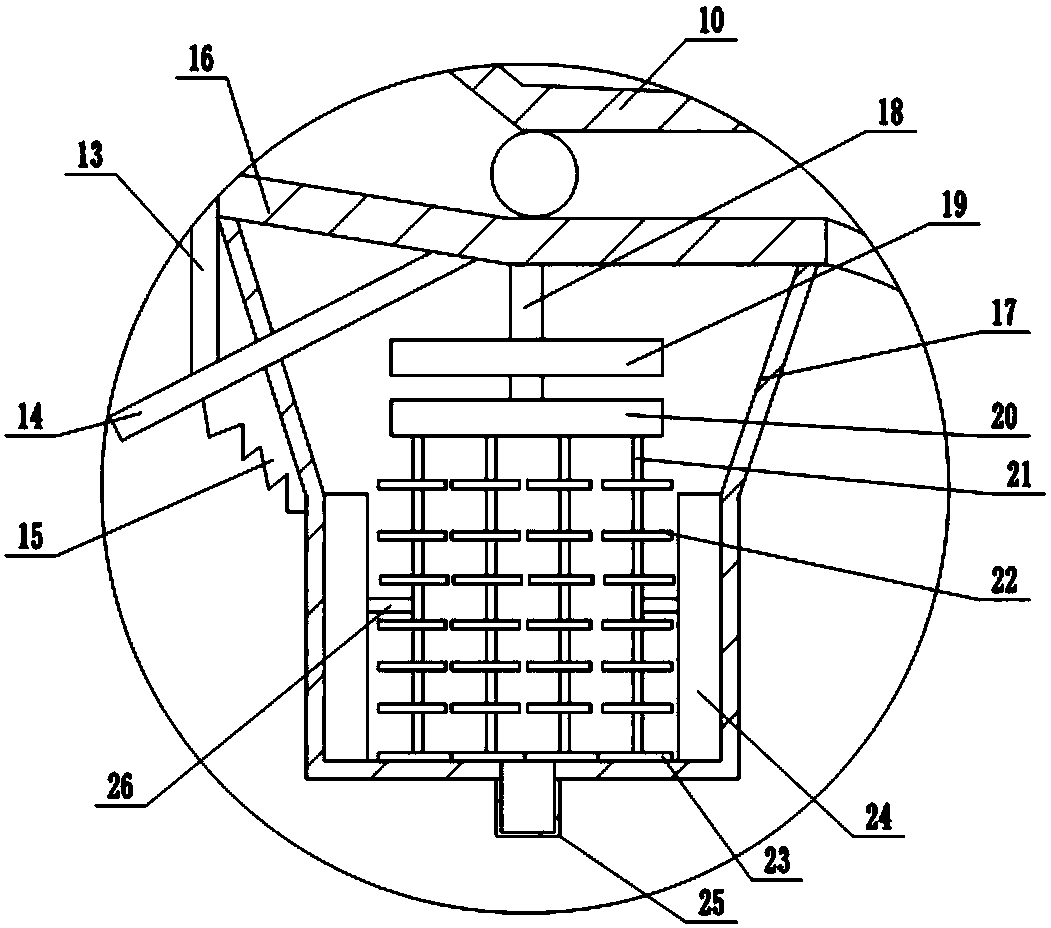

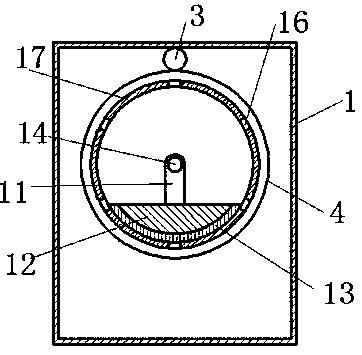

Bag dust collector

InactiveCN107930269AAvoid entanglementConvenience to workDispersed particle filtrationEngineeringDust collector

The invention relates to the technical field of dedusting processing, and discloses a bag dust collector. The bag dust collector comprises a cabinet, a plurality of dedusting bags which surround the center of the cabinet and are sequentially distributed in a circular manner are arranged in the cabinet, the dedusting bags are surrounded to form a dedusting cylinder, the cabinet is provided with anair discharging tube, every dedusting bag is provided with elastic strips, the lower ends of the dedusting bags are sealed and are connected to the cabinet, the upper ends of the dedusting bags respectively stretch into the air discharging tube, an air inlet is arranged at the bottom of the dedusting cylinder, a circular ring sleeves the external of the dedusting cylinder, the circular ring is provided with a slide rail, slide rods are slidably connected in the slide rail, the slide rods are fixed on the cabinet, a plurality of convex teeth are arranged on one side, facing the dedusting cylinder, of the circular ring, a belt groove is arranged at the side part of the circular ring, a rotating shaft is rotatably connected in the cabinet, the rotating shaft is connected with a motor, a beltis jointed between the rotating shaft and the belt groove, the rotating shaft is fixedly connected with a straight arm, a swing arm is hinged to the straight arm, and the swing arm is connected with aswing hammer. The problem of accumulation of dusts on filter bags in existing dedusting devices is solved in the invention.

Owner:ZUNYI CITY GUI KE TECH

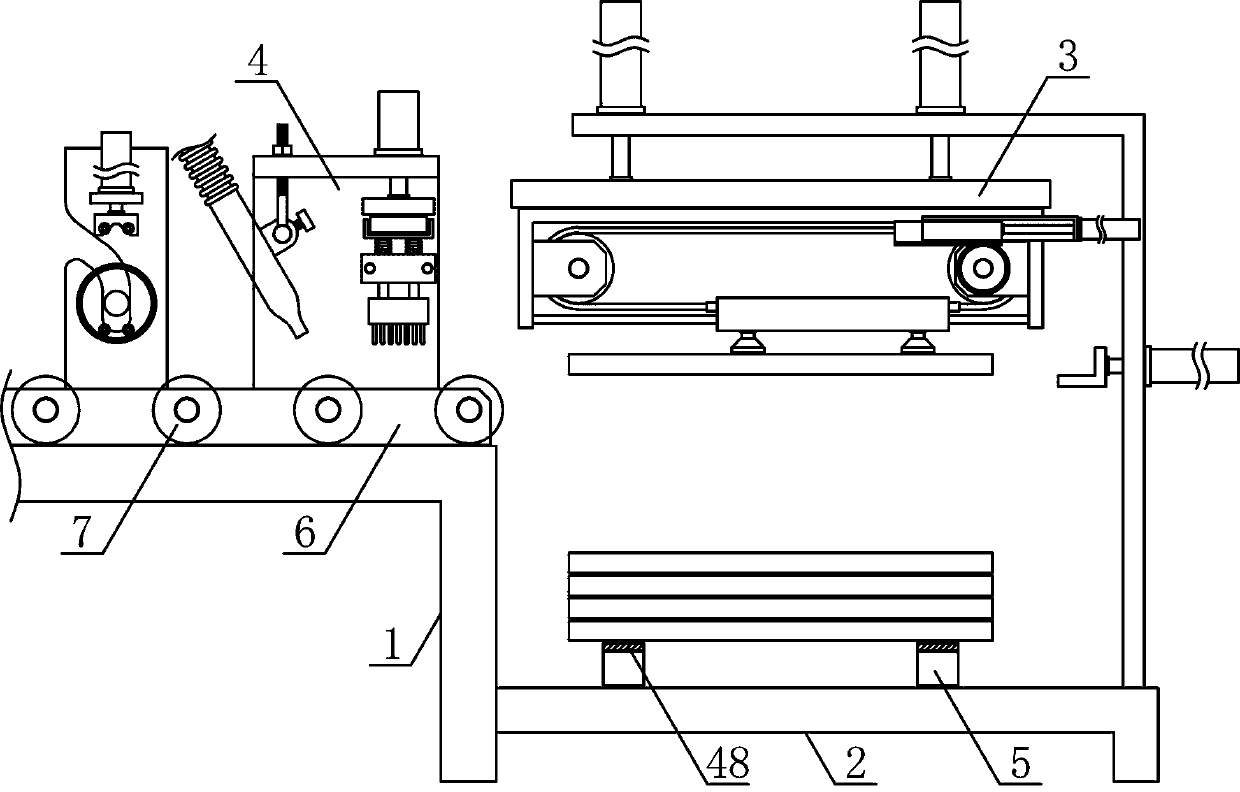

Dedusting method for assembly line

InactiveCN107127174AImprove the quality of dust removalRealize full coverage dust removalElectrostatic separationCleaning using toolsAssembly lineSurface layer

The invention discloses a dedusting method for an assembly line. The method comprises the following steps of placing a to-be-dedusted workpiece on a conveying belt operated at a low speed, adjusting the positions of a brush and a static gun to enable the brush to adequately make contact with the to-be-dedusted workpiece; and rotating the brush to wipe the surface layer of the to-be-dedusted workpiece, and moving the brush and the static gun in the direction intersecting with the conveying belt at a high speed. According to the dedusting method for the assembly line, the brush adequately make contact with the to-be-dedusted workpiece and then rotationally wipes the surface of the to-be-dedusted workpiece, thus the dust in grooves or narrow seams of the to-be-dedusted workpiece is brought out, and full-covering dedusting for the to-be-dedusted workpiece is achieved in high speed movement, and the dedusting quality is improved.

Owner:SUZHOU BOHAN PLASTIC IRONWARE

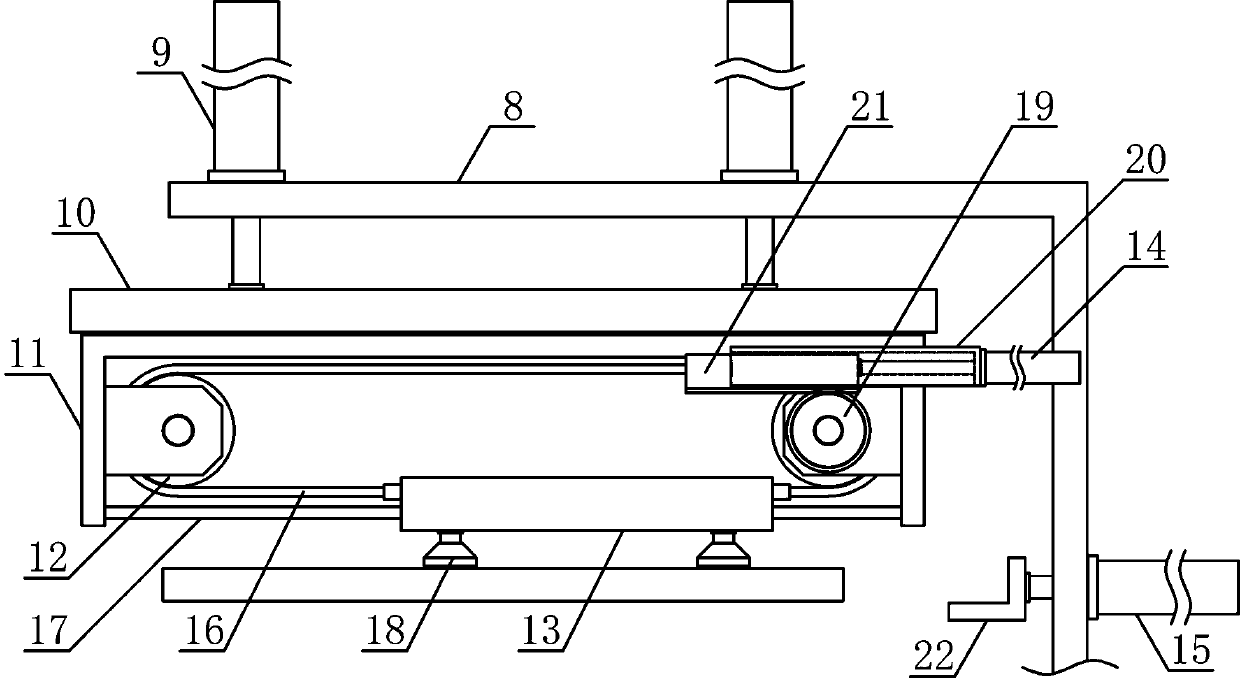

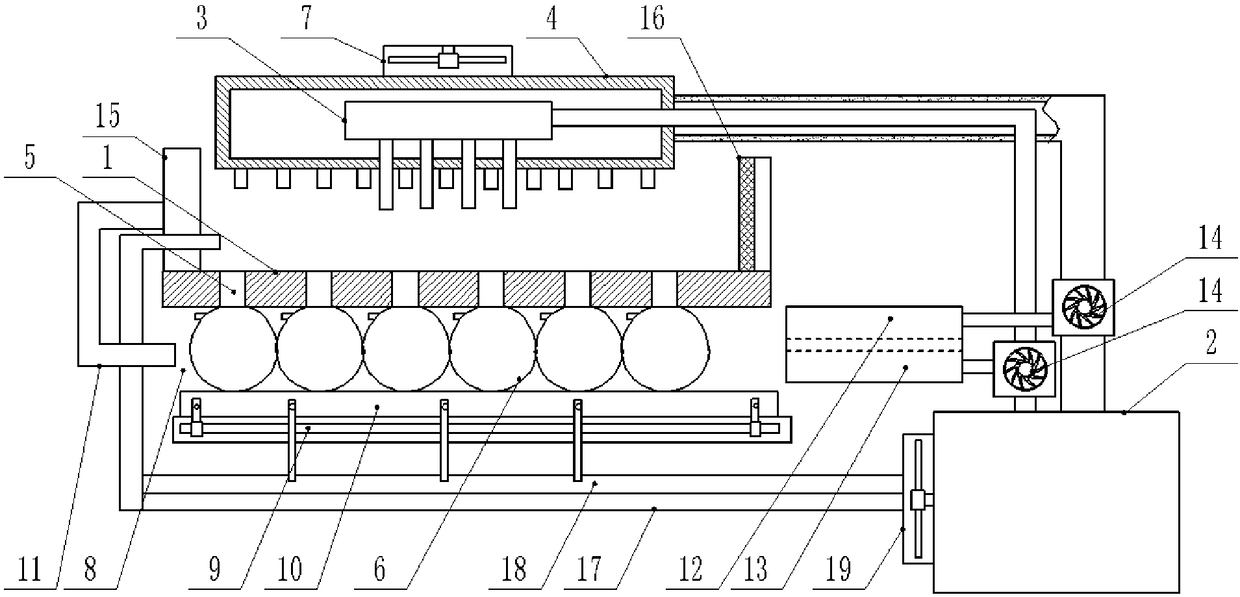

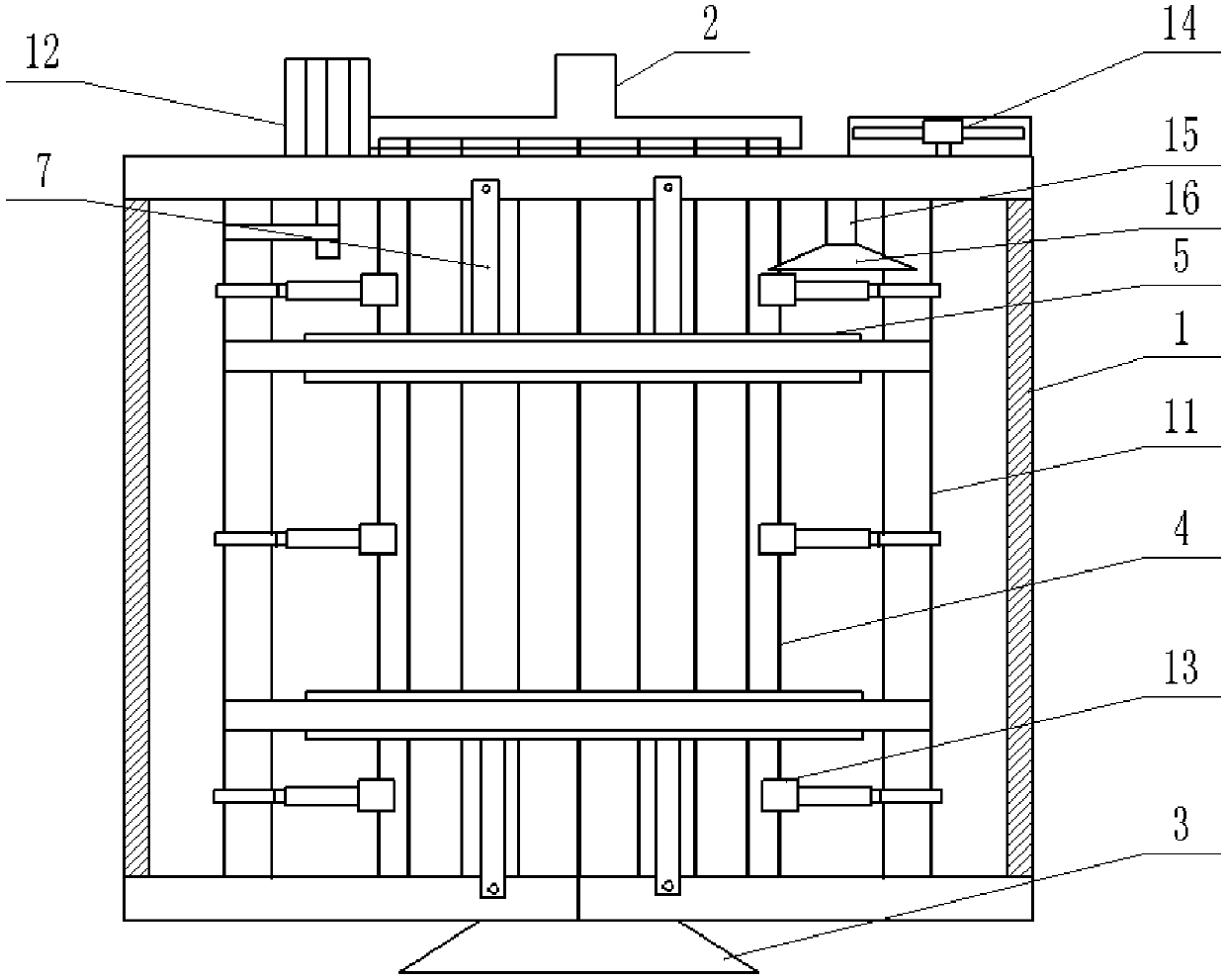

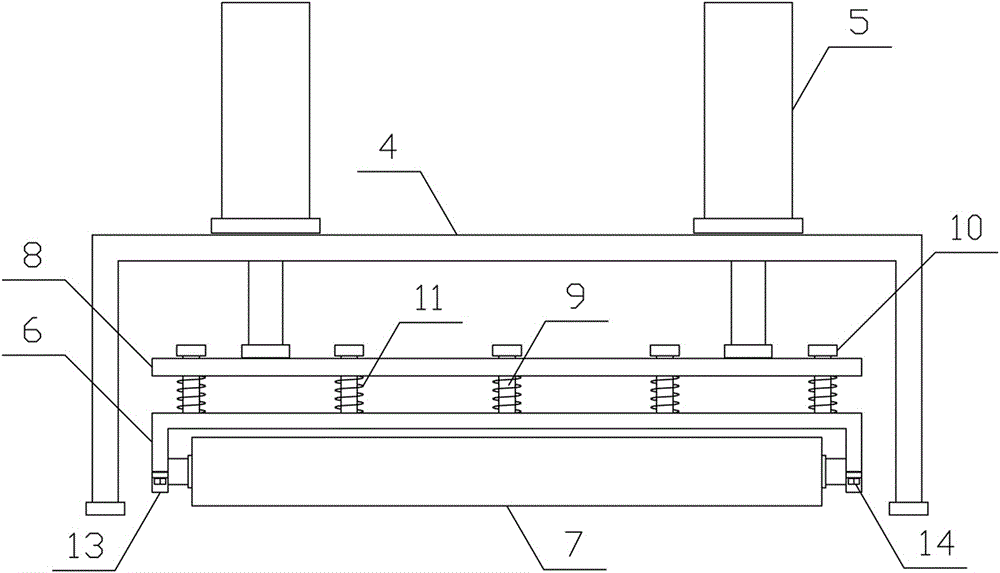

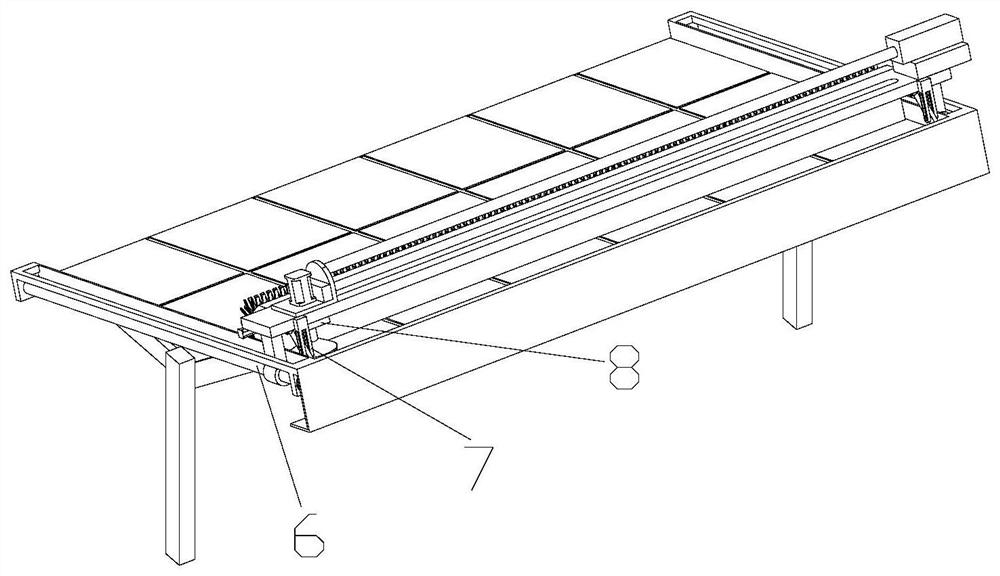

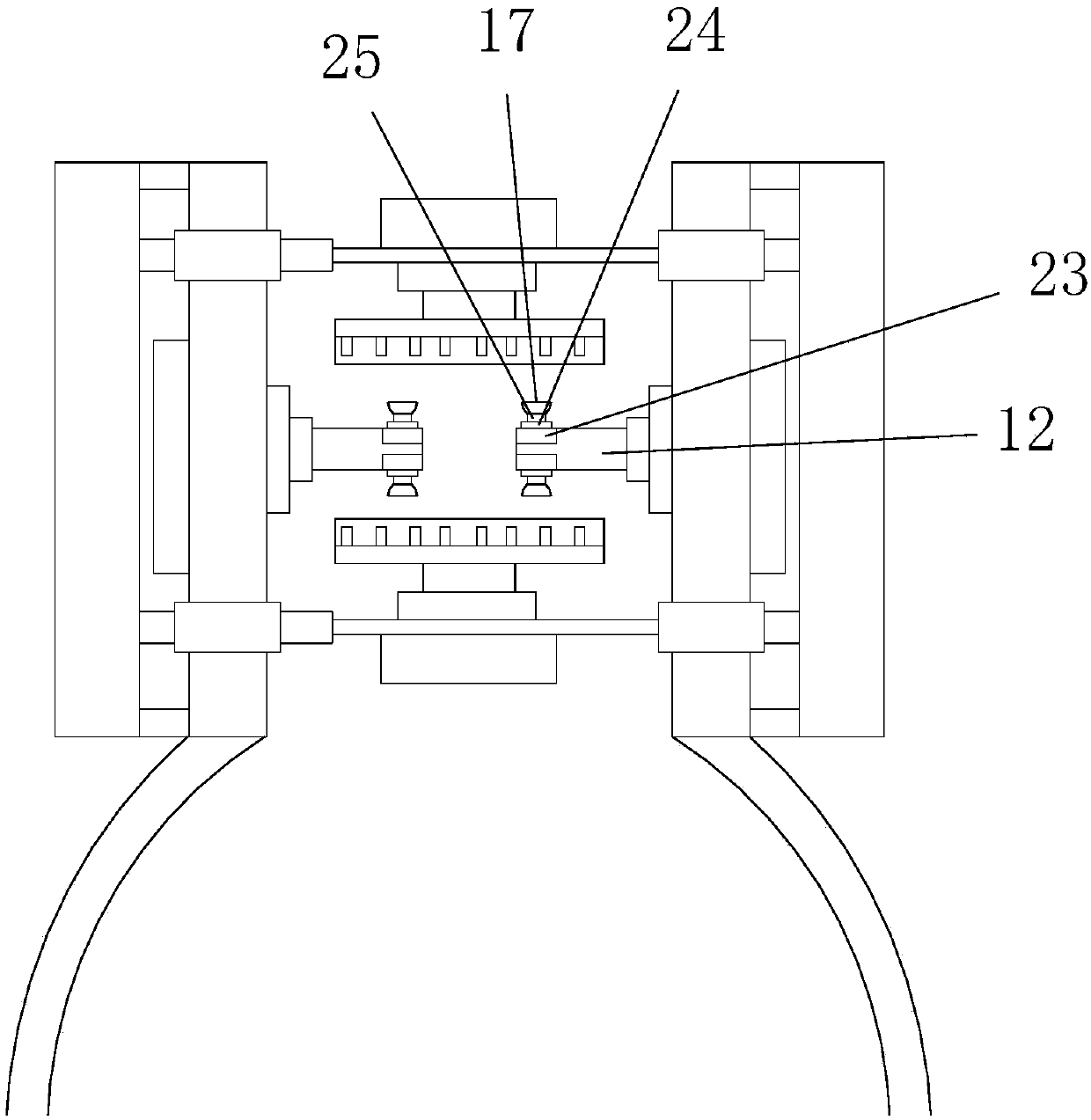

Conveying and dust removing mechanism for aluminum plate

InactiveCN106064731AImprove dust removal efficiencyImprove the quality of dust removalConveyorsCleaningEngineeringMechanical equipment

The invention discloses a conveying and dust removing mechanism for an aluminum plate and belongs to the field of aluminum material machining mechanical equipment. The conveying and dust removing mechanism for the aluminum plate comprises a conveying supporting frame, plate guiding rollers and a dust removing mechanism. The plate guiding rollers are horizontally connected at two sides separately on the conveying supporting frame in a rotary manner and the aluminum plate is arranged on the plate guiding rollers. The dust removing mechanism is vertically arranged on the part, between the two plate guiding rollers, of the conveying supporting frame. The dust removing mechanism comprises a fixing supporting frame, lifting cylinders, a dust sticking supporting frame and a dust sticking roller. The dust sticking supporting frame is horizontally arranged below a lifting plate and a plurality of lifting guiding rods are arranged on the lifting plate vertically and uniformly in a sliding manner. A limiting stopping plate is horizontally arranged at the upper ends of the lifting guiding rods. Pressing springs are arranged on the parts, between the lifting plate and the dust sticking supporting frame, of the lifting guiding rods. The dust sticking roller is horizontally arranged at and rotatingly connected with the lower portion of the dust sticking supporting frame. The mechanism is reasonable in structure and design and capable of realizing rapid and efficient dust removing on the surface of the aluminum plate during conveying and meeting the requirements of production and use.

Owner:桐乡守敬应用技术研究院有限公司

Granulation dedusting device

PendingCN108379988AImprove dust removal effectImprove adsorption capacityCombination devicesEngineeringBiofuel

The invention relates to the field of biofuel and discloses a granulation dedusting device. The granulation dedusting device comprises a granulator, a dedusting tube, a screw rod, a special-shaped tube, a bent pipe and a conveying pipe. A plurality of sponge balls are arranged in the dedusting tube, the bottom of the special-shaped tube is provided with a screen, a dedusting tank is fixed to the bottom of the screen, a first rotating blade and a connection plate are fixed to the bottom of a rotating shaft which is rotationally connected to the screen, and the connection plate is provided witha plurality of retarding units for reducing waste gas flow rate. Each retarding unit comprises a rotating rod fixed to the connection plate, a plurality of second rotating blades are fixedly arrangedon each rotating rod, the bottom of each rotating rod is rotationally connected to the dedusting tank, a supporting rod for cleaning the bottom of the dedusting tank is fixed to the bottom of each rotating rod, and the supporting rods on adjacent rotating rods contact with each other. A water extruding unit for enabling the screen to extrude the sponge balls is arranged at the bottom of the screen. The granulation dedusting device has advantages that repeated dedusting of waste gas generated by the granulator can be realized, and granulation dedusting effects are greatly improved.

Owner:遵义双河生物燃料科技有限公司

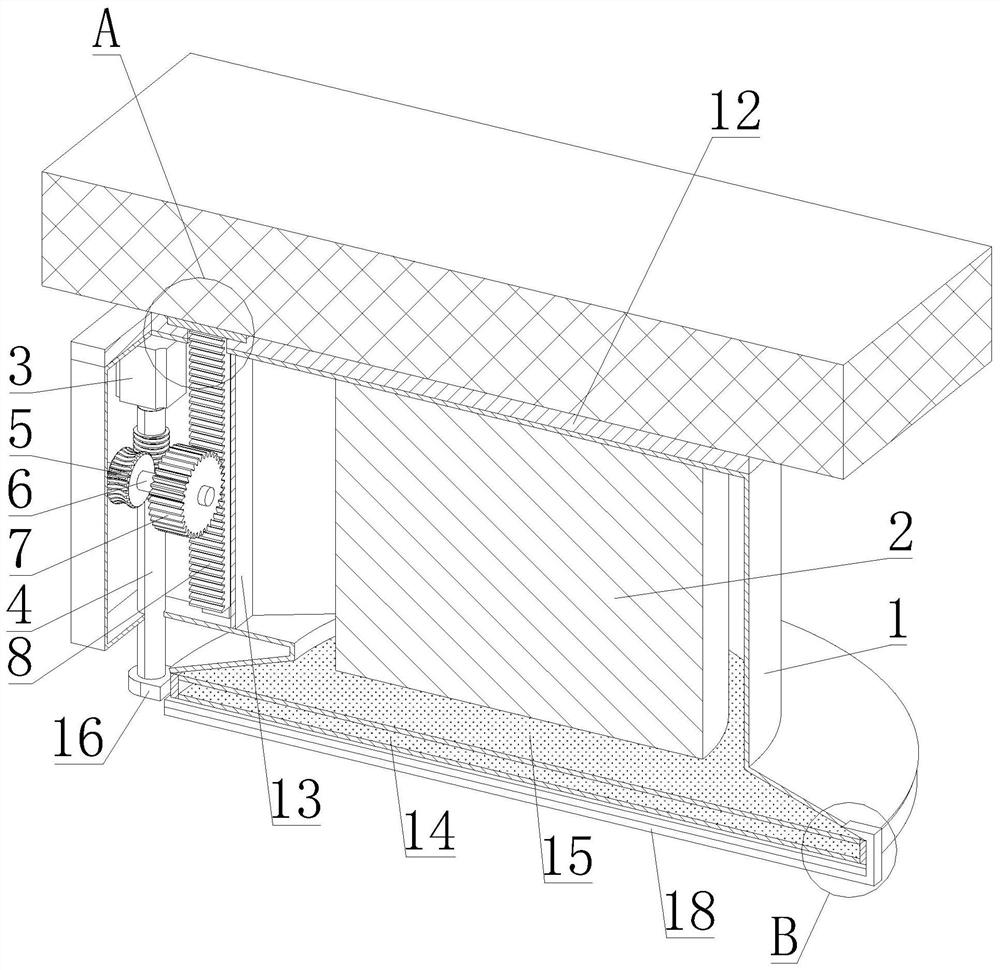

Intelligent sound box control method and intelligent sound box

ActiveCN112995813AImprove the quality of lifeEasy to assemble and disassembleMicrophonesLoudspeakersGear wheelDust control

The invention discloses an intelligent loudspeaker box control method and an intelligent loudspeaker box. The intelligent loudspeaker box comprises a cover body, a sound production module, a motor, a worm, a worm gear, a mounting shaft, a gear, a rack, a sliding rail, a sliding block, a fixed plate, a first dustproof net cover, a mounting ring, a connecting frame, a cleaning brush, a voice interaction module and a central controller. The top of the cover body is provided with a through hole for the rack and the sliding rail to pass through, the bottom of the cover body is provided with a circular sounding port, and the sounding module is arranged in the cover body and faces the sounding port; the motor is arranged on the inner surface of the cover body, the motor is in driving connection with the worm, the worm is vertically arranged and rotationally arranged on the cover body, the bottom end of the worm penetrates through the lower portion of the cover body, the worm is in meshed connection with the worm wheel, the worm wheel and the gear are coaxially arranged on the mounting shaft, and the mounting shaft is rotationally arranged on the inner wall of the cover body. The sound box can be conveniently disassembled and assembled and can be firmly installed, when music is played, the dustproof net cover can be moved away, the sound quality can be fully displayed, dust removal treatment can be conducted on the dustproof net cover, labor is saved, and the intelligent degree is high.

Owner:深圳市吉之礼文化股份有限公司

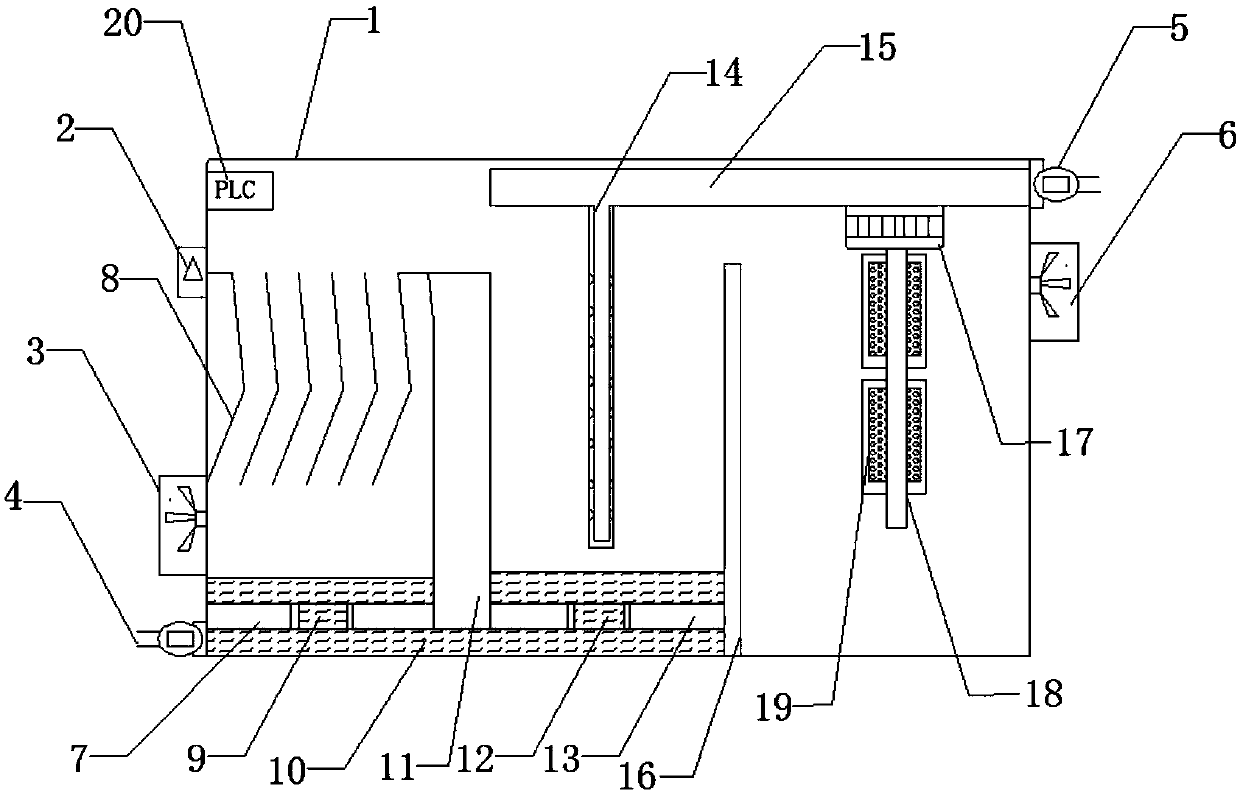

An intelligent energy-saving environmentally friendly dedusting device

InactiveCN107551749AImprove dust removal efficiency and qualityRealize distributed dust removalCombination devicesEnvironmentally friendlyEngineering

An intelligent energy-saving environmentally friendly dedusting device is disclosed. The device includes a shell. One side of the shell is provided with a dust sensor, a first draught fan, and a waterdischarge control valve from top to bottom, and the other side of the shell is provided with a water feeding control valve and a second draught fan in order from the top. One side of the bottom innerwall of the shell is provided with a water discharging channel. One end of the water discharging channel is fixedly connected to the water discharge control valve, and the other end of the water discharging channel is provided with a second baffle plate. The top of the water discharging channel is provided with a first separating plate, a first baffle plate and a second separating plate in order.A plurality of V-shaped plates are provided above the first separating plate. Through the dust sensor, a PLC controller, the first draught fan and the second draught fan, the device is automaticallyoperated when the outside dust concentration is high and removes dust in the air. Through the V-shaped plates, a spraying pipe, a motor and hanging plates, distributed dedusting for dust in the air can be achieved and the dedusting efficiency and quality are improved.

Owner:湖州慧峰环保科技有限公司

New computer dust removal device

InactiveCN108015031AAvoid shockAvoid damageCleaning using toolsCleaning using gasesEngineeringMechanical engineering

The invention discloses a new computer dust removal device. A device body is included; a dust sucking port is formed below the front side of the device body, and is embedded in the device body; a cleaning brush is arranged above the dust sucking port, and adheres to the device body through super glue; a cleaning liquid inlet is formed in the right rear portion of the cleaning brush; a motor is arranged in the right rear portion of the cleaning liquid inlet; and the motor and the device body are connected in a sleeved manner. The new computer dust removal device is improved in many aspects according to the defects, the device body is provided with a speed adjusting rotary knob, the water outflow speed of a cleaning liquid outlet and the rotating speed of the cleaning brush can be adjusted,the speed can be decreased when computer precise elements are cleaned, and impacting on the computer precise elements is avoided.

Owner:大连锐进科技发展有限公司

Material and method used for dust removal and dust prevention in air

The invention relates to a material and a method used for dust removal and dust prevention in air. Effective components include maltose, sodium lignosulphonate, corn hemicelluloses, sodium alginate, guar gum, glycerinum, rosin resin, calcium chloride and urea. The material can effectively adsorb the dust to result in aggregation and settlement, and a proper dosage of material is used for processing a solid surface on which dust tends to raise or air in regions with formed haze or other dust or aerosol pollution by adopting an atomizing manner. According to the invention, the technical scheme of taking the material with nano micro viscosity as the basis can be used initiatively, and small dust particles can be captured in different ranges, so that the dust can settle through agglomeration; dust of 10 microns, 2.5 microns and below in air can be effectively removed, so that the danger to human health caused by fine particulates can be alleviated.

Owner:昆山瑞程新美新材料有限公司

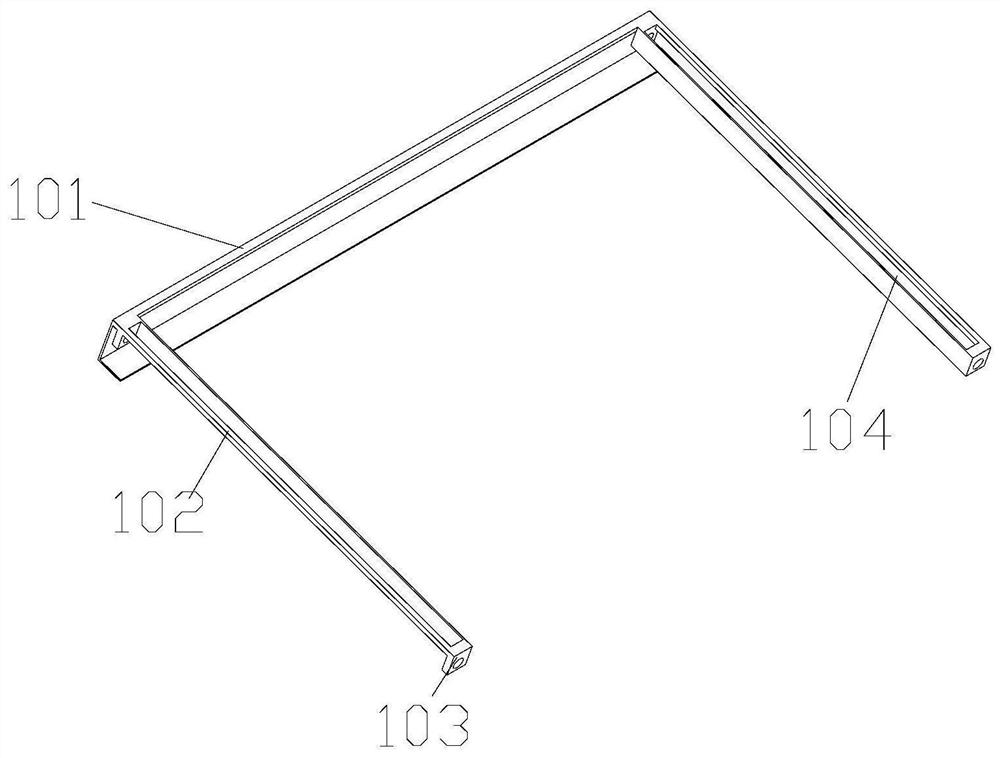

Solar photovoltaic panel efficient cleaning device

ActiveCN113967624AImprove cleanlinessWon't scratchCleaning using toolsCleaning using liquidsDust controlEngineering

The invention discloses a solar photovoltaic panel efficient cleaning device. The solar photovoltaic panel efficient cleaning device comprises a frame, a transmission mechanism is installed on the frame, a support is installed on the transmission mechanism, an air cylinder, a sweeping assembly, a water spraying assembly, a dust removal assembly and a wiping assembly are installed on the support, the air cylinder is installed at one end of the top of the support, one end of a piston rod of the air cylinder is installed on the sweeping assembly, the sweeping assembly is installed at the top of the support, and the water spraying assembly is installed on the sweeping assembly. The transmission mechanism can drive the support to move front and back, so that the purpose of driving the sweeping assembly, the water spraying assembly, the dust removal assembly and the wiping assembly to move front and back is achieved, the dust removal assembly can remove dust on a solar photovoltaic panel, the sweeping assembly cooperates with the water spraying assembly to clean away bird droppings and plant juice left on the solar photovoltaic panel, the wiping assembly can wipe away cleaning water sprayed out by the water spraying assembly, and soil and dust are prevented from adhering to the solar photovoltaic panel again.

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

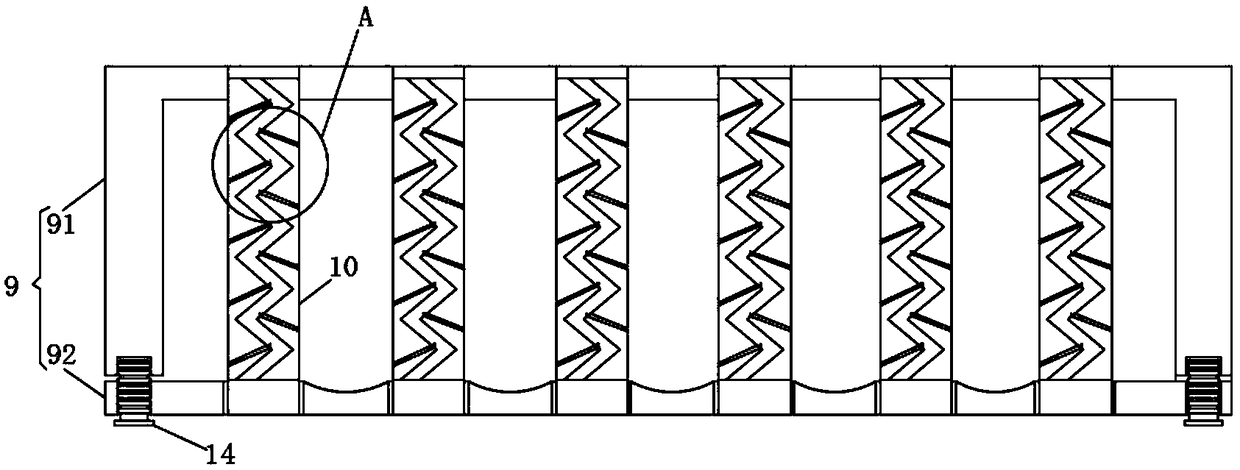

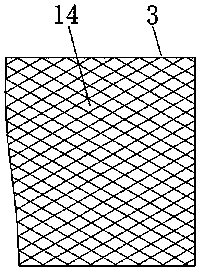

High-temperature-resistant dedusting filter bag based on multiple filter subunits

InactiveCN108722050AReasonable structureFunctionalDispersed particle filtrationButt jointEngineering

Owner:YANCHENG BAOYING FILTER

Boiler furnace device

PendingCN106813239AImprove combustion efficiencyImprove the quality of dust removalFluidized bed combustionCasings/liningsBoiler furnaceNitrogen oxides

The invention discloses a boiler furnace device which comprises a boiler furnace, wherein the upper part of the boiler furnace is a cuboidal furnace, namely, a dilute phase zone; the bottom of the boiler furnace is a conical furnace, namely, a dense phase zone; a water-cooled air distribution plate is arranged at the bottom of the conical furnace; a plurality of air caps are arranged on the surface of the water-cooled air distribution plate; a primary air compartment is also arranged at the bottom of the water-cooled air distribution plate, and the air caps on the water-cooled air distribution plate are communicated with a primary air inlet pipe; through holes in the air caps are used for introducing primary air from the primary air compartment; the conical furnace is also communicated with a secondary air inlet pipe; a wearproof layer is also arranged at the inner top of the boiler furnace; a membrane water wall is integrally arranged on the outer layer of the boiler furnace. According to the boiler furnace device, complete combustion of a biomass fuel is ensured, the combustion efficiency is improved, production of a large amount of nitrogen oxide is avoided, and the device also has the structural characteristic of the membrane water wall.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

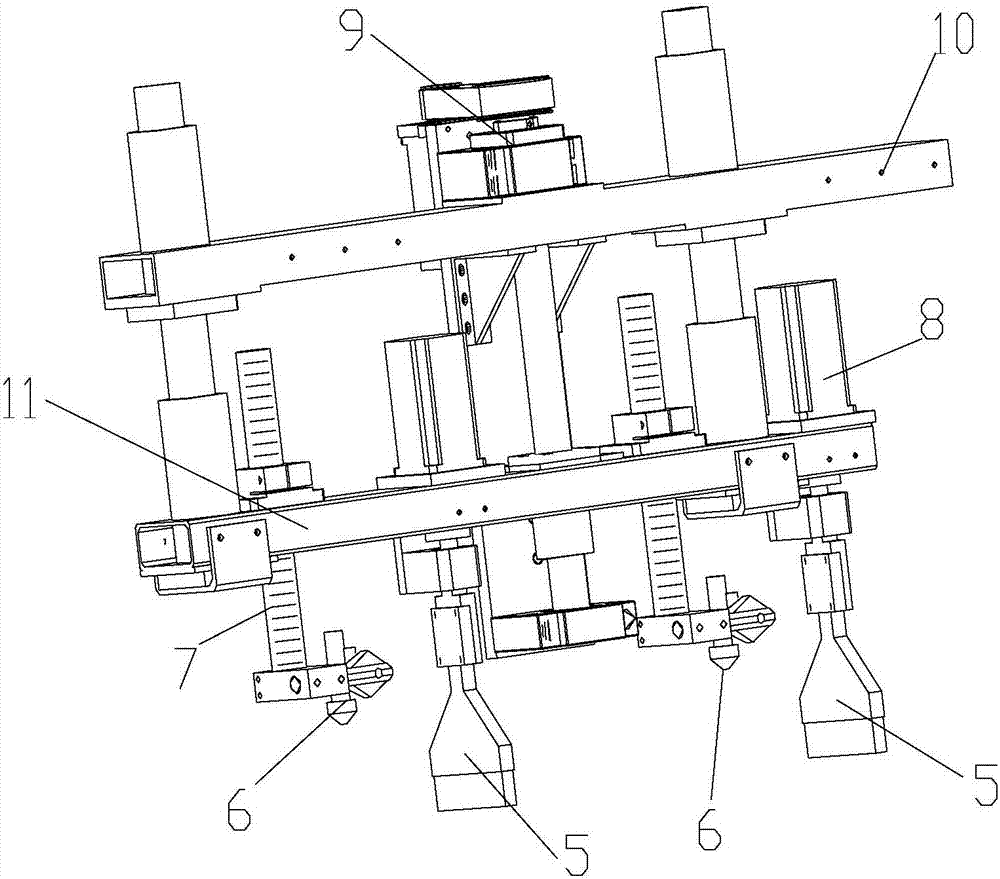

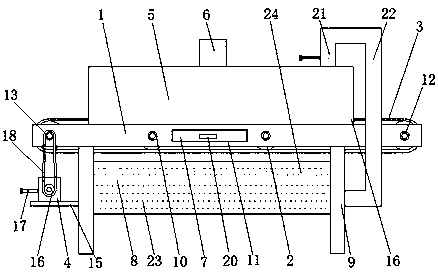

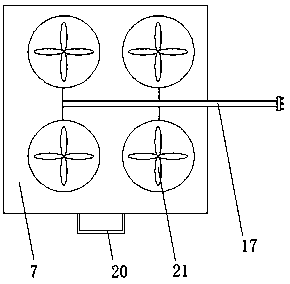

Novel transverse blowing pipe of traveling cleaner

InactiveCN103320922AGuaranteed blowing effectImprove the quality of dust removalTextiles and paperAir volumeEngineering

The invention relates to a novel transverse blowing pipe of a traveling cleaner. The transverse blowing pipe is characterized by comprising a plurality of transverse blowing pipe bodies (1) which are arranged in parallel, the rear end of each transverse blowing pipe body (1) is hinged to a rear section of an air blowing pipeline (3), openings at front ends of the transverse blowing pipe bodies (1) are air blowing openings, and adjusting plates (2) are installed inside rear ends of all transverse blowing pipe bodies (1). According to the novel transverse blowing pipe of the traveling cleaner, the transverse blowing pipe bodies are arranged on the rear section of the air blowing pipeline in parallel, and the rear ends of the transverse blowing pipe bodies are hinged to the air blowing pipeline, so that the transverse blowing pipe bodies can rotate by 360 degrees, and dust removing can be conducted in all directions; meanwhile, the adjusting plates are installed inside rear ends of all transverse blowing pipe bodies and can adjust the air volume of each transverse blowing pipe body, so that the air blowing effect is guaranteed, and the dust removing quality is improved.

Owner:JIANGSU JINGYA ENVIRONMENT TECH

Dust collection device for printing plate roller of printing machine

InactiveCN107618262ARealize dust removal and dryingImprove dust removal efficiencyPrinting press partsEngineeringPrinting press

The invention provides a dust collection, cleaning and drying device for a printing plate roller of a printing machine. A first motor is mounted on one side of a mounting plate through a first motor support, the first motor penetrates through the mounting plate and is provided with a rotating shaft, a rotating shaft mounting sleeve is arranged on the mounting plate, the rotating shaft penetrates through the rotating shaft mounting sleeve, a second motor and an air blower are mounted at the upper end of the rotating shaft, a first piston is mounted at the end, which is away from the second motor, of the rotating shaft, a first piston shaft is mounted at the end, which is away from the rotating shaft, of the first piston, a nozzle mounting seat is mounted at the end, which is away from the first piston, of the first piston shaft, and a nozzle is mounted at the end, which is away from the first piston shaft, of the nozzle mounting seat. The efficiency and quality of dust collection to theprinting plate roller can be improved effectively, and therefore, the service life of the printing plate roller is prolonged.

Owner:平湖市燎原印刷厂

Dust removal equipment for wood plate production of packing box

InactiveCN108858539AAvoid polluting the environmentImprove environmental performancePaper-makingBox making operationsEngineeringMechanical engineering

The invention discloses dust removal equipment for wood plate production of a packing box, comprising cross beams, conveying rollers, a conveying belt, a motor, a fixed frame, production equipment, anadjusting plate and a feed liquid box, and is characterized in that: the cross beams are arranged on the supports; a pad plate is arranged on one of the support; connecting shafts are arranged on both sides of the conveying rollers; the conveying belt is arranged between the conveying rollers; the motor is arranged on the pad plate; the fixed frame is arranged between cross beams; the productionequipment is arranged on the fixed frame; a handle and a fan are arranged on the adjusting plate; the feed liquid box is arranged between the supports; the feed liquid box is connected with the fixedframe through a connecting pipe, and is provided with dust absorption liquid. According to the invention, the dust removal equipment for the wood plate production of the packing box has beneficial effects that: a filter screen is arranged on the upper part of the dust absorption liquid in the feed liquid box, the dust absorbed by the dust absorption liquid is refiltered through the filter screen,so that the efficiency and quality of dust removal are improved.

Owner:芜湖三华包装科技有限公司

Novel dust collecting device

InactiveCN106807175AImprove separation efficiencyEfficient removalCombination devicesDispersed particle filtrationLow noiseFlue gas

The invention discloses a novel dust collecting device. The novel dust collecting device comprises a fixed bracket, and a cyclone dust collector unit, a flue gas conveying pipeline and a bag-type dust collector unit which are arranged on the fixed bracket in sequence, wherein a flue gas inlet is formed in the bottom of each cyclone dust collector; the outlet of each cyclone dust collector is communicated with the flue gas conveying pipeline; the middle part of the flue gas conveying pipeline is communicated with each bag-type dust collector of the bag-type dust collector unit in sequence; a flue gas outlet is formed in the tail end of the flue gas conveying pipeline; an air pump power system and a purging system are also arranged in the positions, at the top of the bag-type dust collector unit, of the fixed bracket; the novel dust collecting device provided by the invention has the technical advantages of remarkable dust collecting and purifying effects, high dust collecting quality, low noises, capacity of eliminating sparks and the like.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

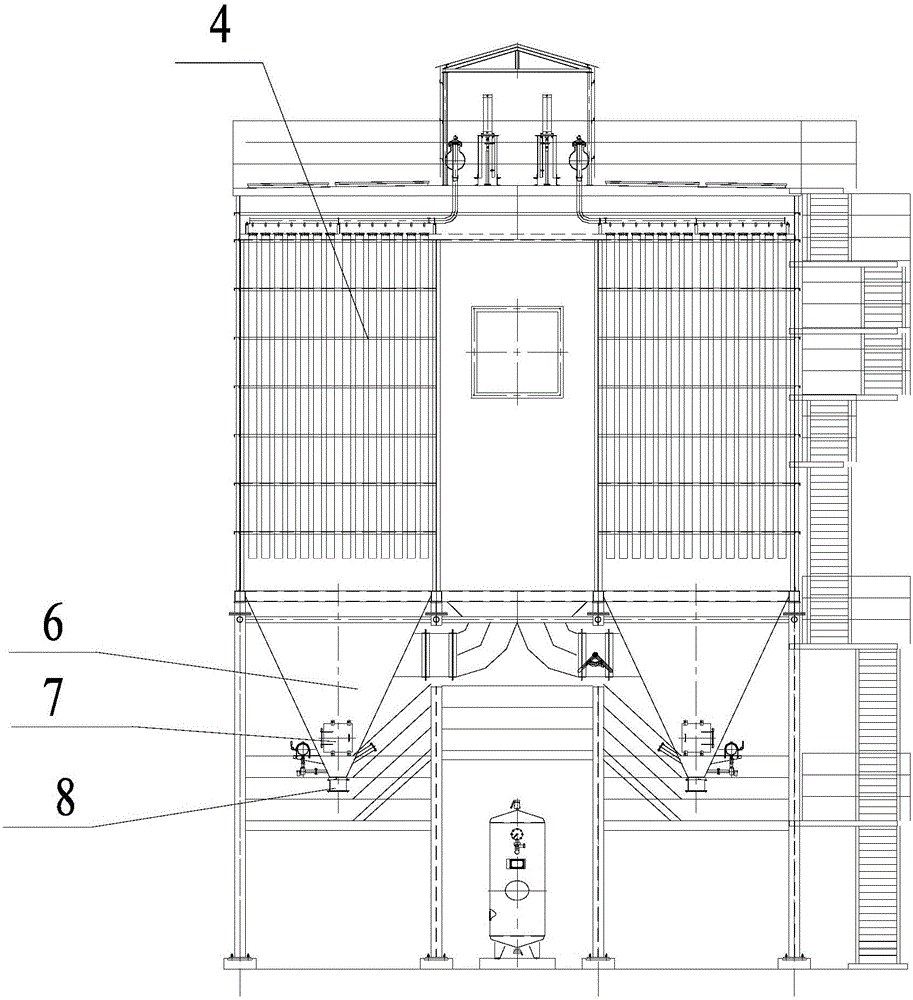

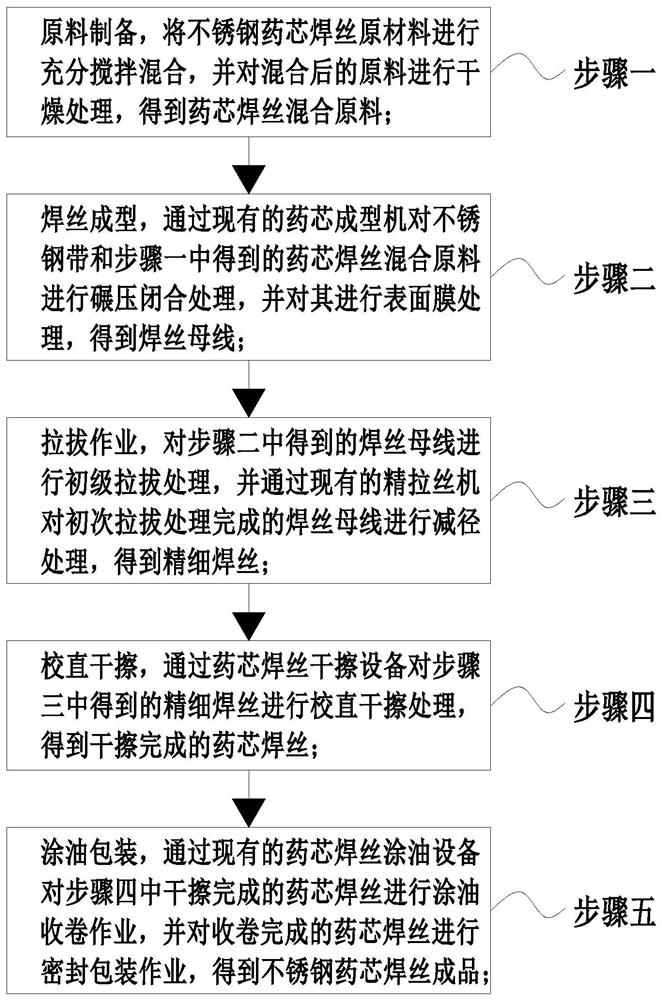

Preparation method of high-strength stainless steel flux-cored wire

ActiveCN113732569AImprove dust removal efficiencyImprove the quality of dust removalCleaning using toolsWelding/cutting media/materialsDust controlMaterials science

The invention relates to a preparation method of a high-strength stainless steel flux-cored wire. The preparation method mainly comprises the following steps of raw material preparation, wire forming, drawing operation, straightening and dry wiping, oil coating and packaging and the like, and used flux-cored wire dry wiping equipment comprises an operation table, a dry wiping unit, a straightening unit, a water washing unit and a drying unit. The method can solve the following problems existing during dust removal treatment of an existing high-strength stainless steel flux-cored wire: a, the dust removal efficiency of the flux-cored wire is affected due to the fact that the time for replacing dry wiping cloth of existing dust removal equipment for the flux-cored wire is long, and wire drawing powder on the surface of the flux-cored wire is not completely wiped and needs to be wiped again, so that the dust removal efficiency of the flux-cored wire is affected; and b, after the flux-cored wire is subjected to water washing by the existing dust removal equipment for the flux-cored wire, residual water on the surface of the flux-cored wire cannot be completely cleaned, so that the oiling quality of the flux-cored wire is influenced, and the production quality of the flux-cored wire is reduced.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

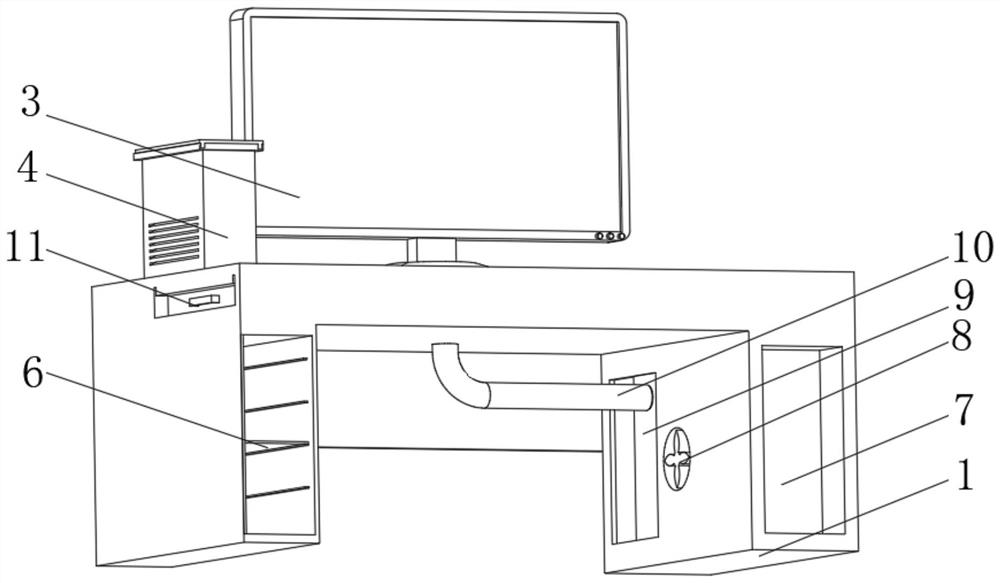

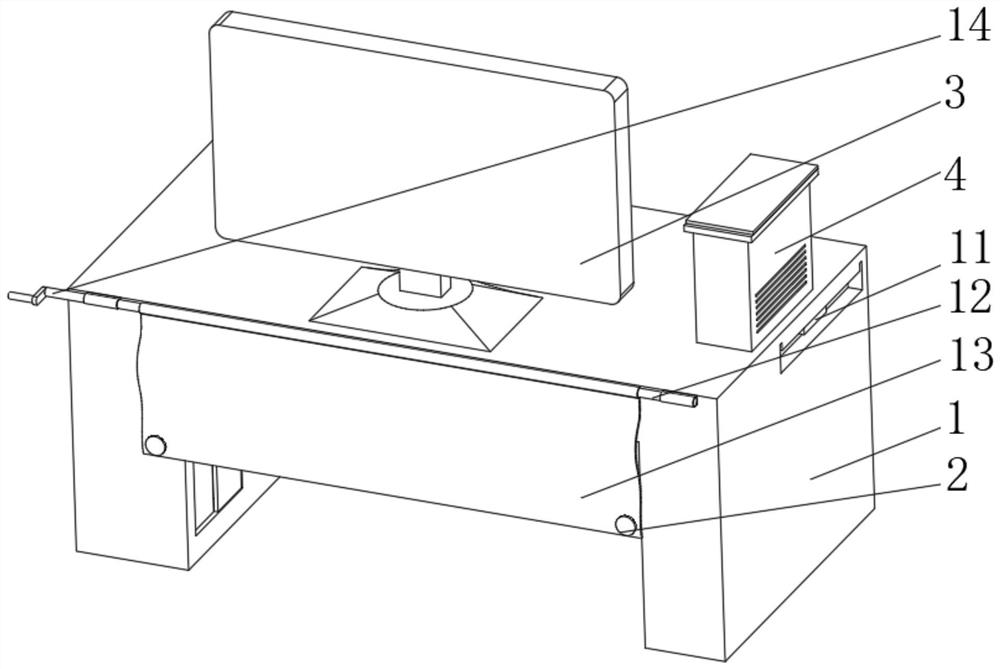

Auxiliary device for software development

InactiveCN112189994AStable positionSpeed up the flowOffice tablesDigital data processing detailsSoftware engineeringWorking environment

The invention relates to the technical field of software development, and discloses an auxiliary device for software development, which comprises a computer desk, a displayer is fixedly installed in the middle of the top of the computer desk, a fan structure is placed at the left end of the top of the computer desk, a winder is fixedly installed at the upper end of the back face of the computer desk, and the periphery of the winder is sleeved with covering cloth. Magnets are fixedly installed at the two ends of the lower portion of the covering cloth and the two ends of the front face of the computer desk, and a crank is fixedly installed on the left side of the winder. According to the auxiliary device for software development, the purposes of comfort in use and good covering effect are achieved by arranging the covering cloth, the winder, the fan structure and the like, when a computer is not used, the whole computer desk is directly covered with the covering cloth, the covering cloth can shield dust, the dust is prevented from directly falling on the computer desk, and pollution of the dust to the working environment is reduced; the working environment of workers is improved, meanwhile, the time for the workers to wipe the computer desk is shortened, and the working efficiency is improved.

Owner:广州天域科技有限公司

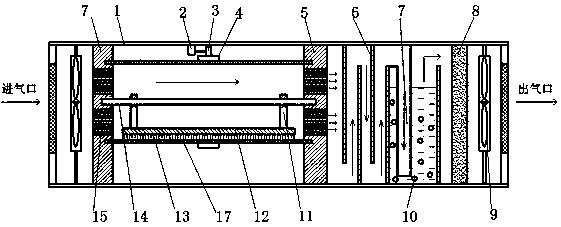

Air purifier

InactiveCN108826495AEasy to solveAvoid depositionMechanical apparatusLighting and heating apparatusParticulatesAir purifiers

The invention discloses an air purifier. The air purifier comprises a machine body (1). The front end of the machine body (1) is provided with an air inlet, and the rear end is provided with an air outlet. From the air inlet of the machine body (1) to the air outlet, an electrostatic dedusting mechanism, a buffering chamber, a reaction chamber and a drying layer (8) are successively installed in the machine body (1). The electrostatic dedusting mechanism is used for removing solid particulate matters in air. The buffering chamber is used for enabling the air to be circuitously flowed in the buffering chamber so that the solid particulate matters in the air are removed. The reaction chamber is used for removing harmful gases in the air. The drying layer (8) is used for drying the air. The air purifier is capable of effectively removing the solid particulate matters in the air.

Owner:朱森

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com