Dedusting method for assembly line

An assembly line and brush technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of easy accumulation of dust in it, inability to effectively remove dust, and workpiece quality defects, etc. To achieve the effect of improving the quality of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

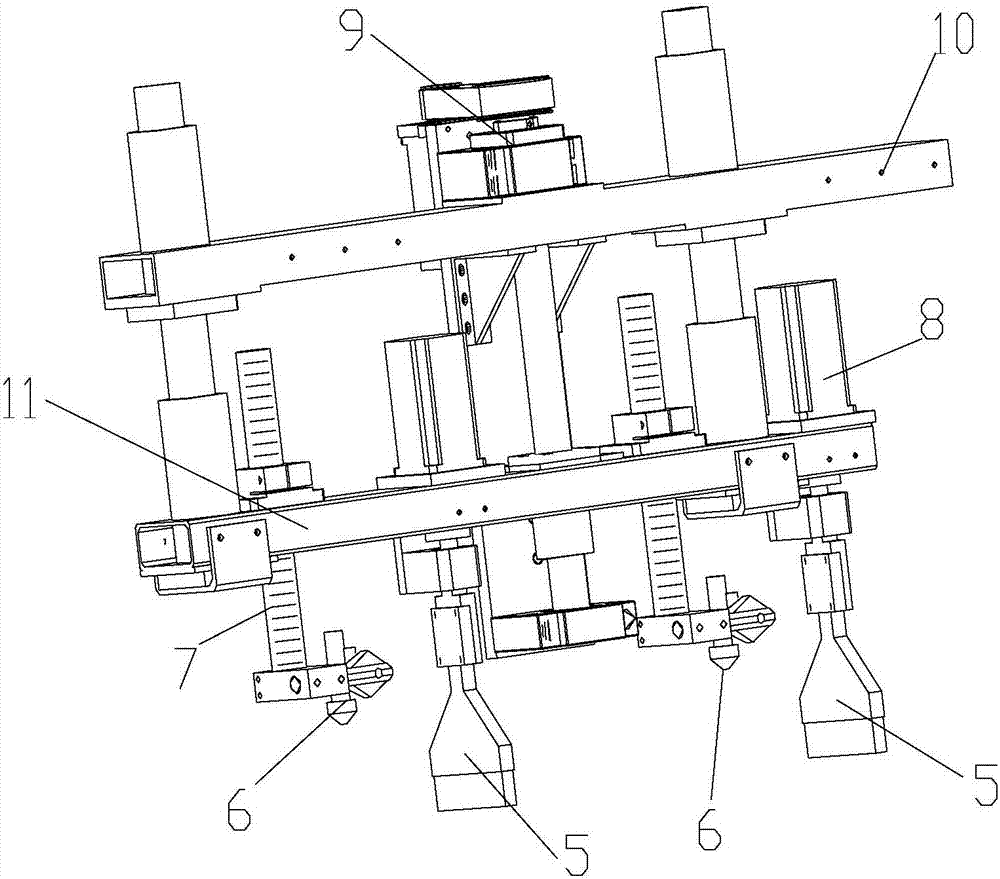

Image

Examples

Embodiment

[0022] An assembly line dust removal method, comprising the steps of:

[0023] S10: Arrange and place the workpieces to be dedusted on the horizontal conveyor belt, and the conveyor belt moves forward at a speed of 20mm / s driven by the transmission motor. The distance between two adjacent workpieces to be dedusted should be consistent, and the outer edge of the workpieces to be dedusted should be kept parallel to the edge of the conveyor belt as much as possible to facilitate subsequent dedusting operations.

[0024] S20: A longitudinally placed reciprocating frame is arranged directly above the conveyor belt, and a beam frame (using a square tube) capable of longitudinally reciprocating movement is arranged on the reciprocating frame, and the beam frame is driven by a reciprocating motor to Move back and forth at a speed of 800mm / s. In order to restrict the range of the beam frame moving back and forth, to prevent it from colliding with the reciprocating frame and causing da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com