Biomass particle processing equipment in new energy field

A technology for biomass particles and processing equipment, which is applied in the cleaning method using tools, the cleaning method using gas flow, and solid separation, etc., can solve the problems of unreliability, affecting the working environment, and low dust removal quality, so as to improve the use efficiency. , The effect of increasing the contact area and improving the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

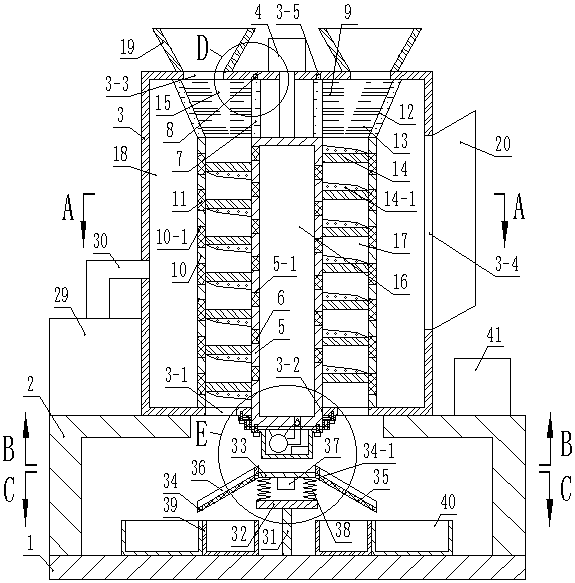

[0028] Such as Figure 1-Figure 7As shown, a biomass particle processing equipment in the new energy field includes a base plate 1, an L-shaped support frame 2 is symmetrically fixed on the top surface of the base plate 1, and a box body is fixed on the top surface of the L-shaped support frame 2 3. The central part of the bottom surface of the box body 3 is provided with a through hole A3-2, the top surface of the box body 3 is fixed with a motor 4, the driving end of the motor 4 penetrates into the box body 3, and the driving end of the motor 4 A cylinder 5 is fixedly connected, and the bottom of the cylinder 5 is slidably connected with the through hole A3-2. A cavity A16 is formed inside the cylinder 5, and a plurality of through holes B5-1 are uniformly arranged on the cylinder 5. A filter screen A6 is fixed in the through hole B5-1, an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com