Bag dust collector

A bag-type dedusting and dedusting bag technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the filtration of dispersed particles, to achieve the effect of improving dust removal efficiency and dust removal effect, facilitating normal work, and preventing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

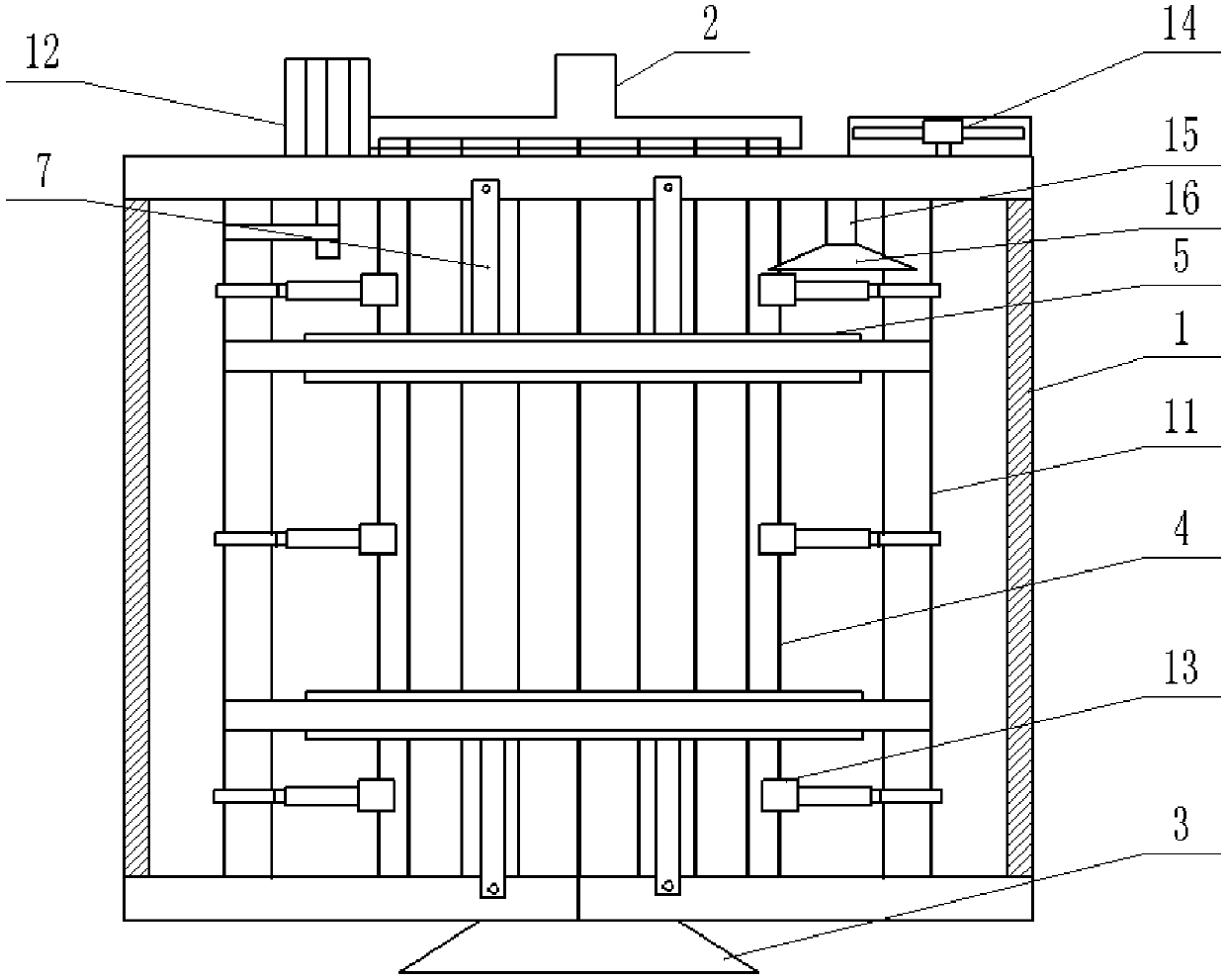

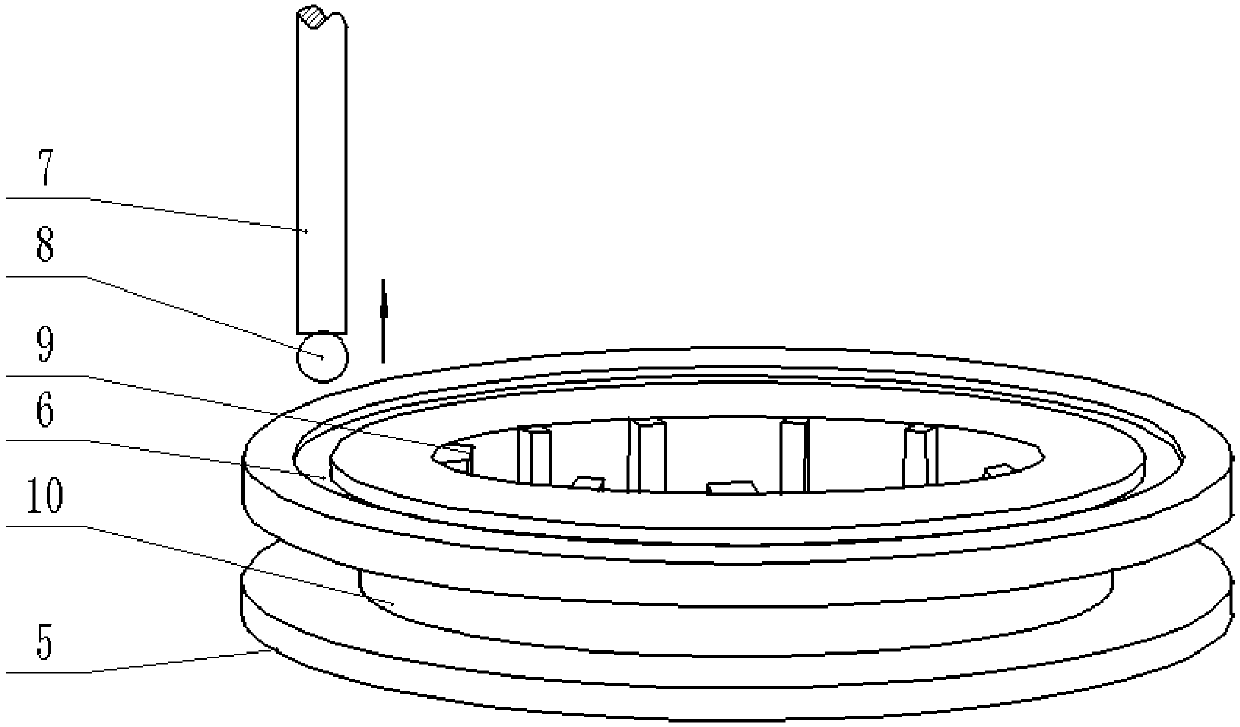

[0018] The reference signs in the drawings of the description include: chassis 1, exhaust pipe 2, air inlet 3, dust bag 4, ring 5, slide rail 6, slide bar 7, rolling ball 8, convex teeth 9, belt groove 10 , rotating shaft 11, motor 12, pendulum 13, fan 14, air suction pipe 15, tapered mouth 16.

[0019] The embodiment is basically as figure 1 Shown: a bag-type dust removal device, including a case 1, the inner wall of the case 1 is detachably connected with a rubber layer by screws. An exhaust pipe 2 is arranged on the top of the chassis 1, and a plurality of dust removal bags 4 are arranged inside the chassis 1, and elastic strips are attached to the dust removal bags 4, such as figure 2 As shown, a plurality of dust removal bags 4 are distributed in a circular manner around the center of the chassis 1 to form a dust removal cylinder, and adjacent dust removal bags 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com