Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Improve the level of lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

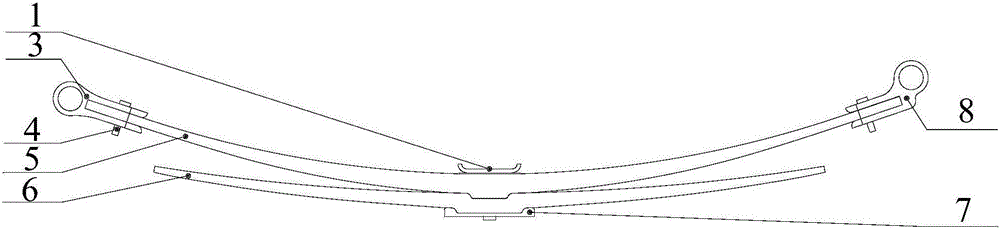

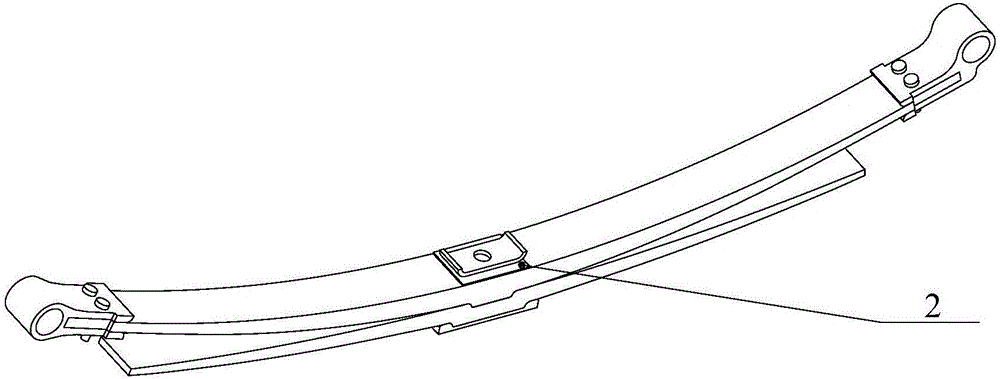

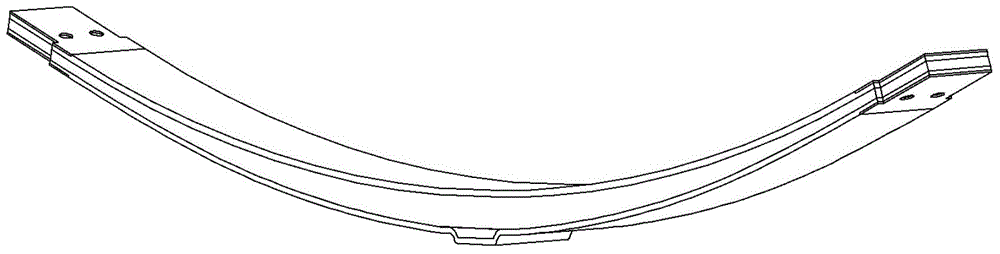

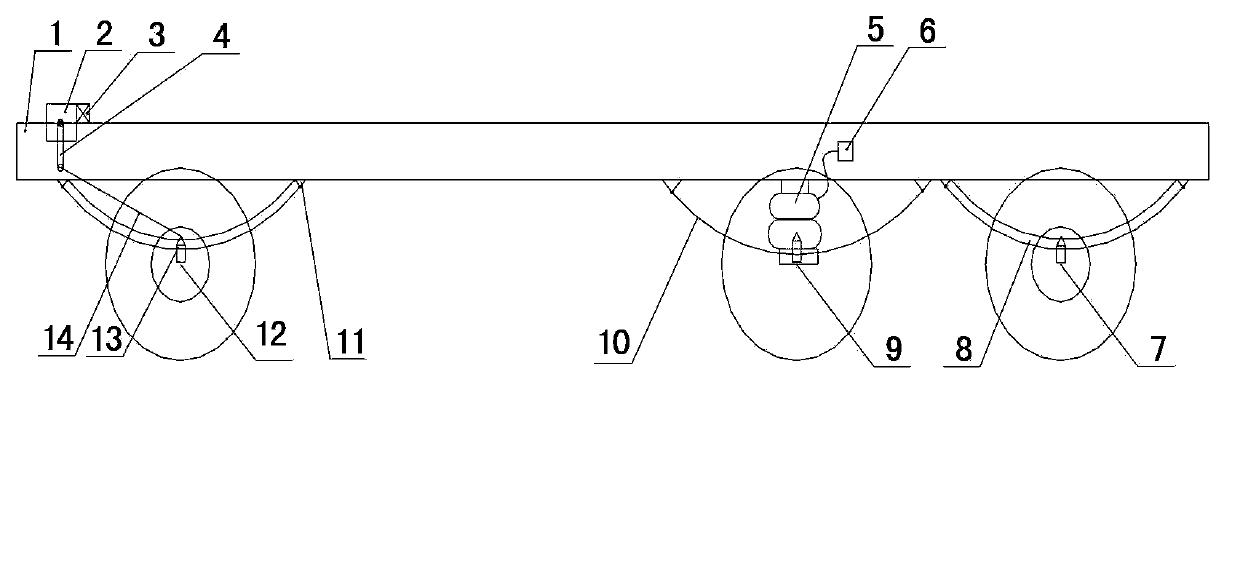

Automobile plate spring assembly with main and auxiliary springs made from composite material and assembly method for automobile plate spring assembly

ActiveCN105946489AImprove comfortImprove the level of lightweightLeaf springsResilient suspensionsInterference fitEngineering

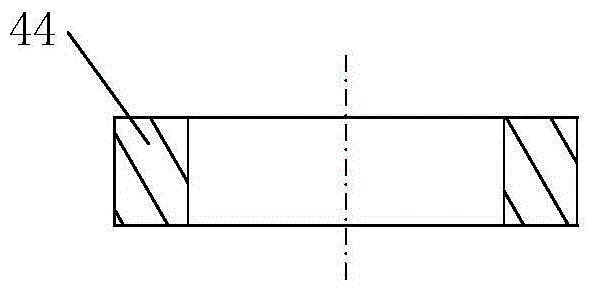

The invention relates to an automobile plate spring assembly with main and auxiliary springs made from a composite material. The automobile plate spring assembly comprises a main spring, an auxiliary spring, a lower metal clamping plate, an upper metal clamping plate and a U-shaped bolt metal clamping plate, wherein the lower metal clamping plate, the auxiliary spring, the main spring, the upper metal clamping plate and the U-shaped bolt metal clamping plate are sequentially stacked from bottom to top, and then are clamped and fixed through two U-shaped bolts; the two ends of the body of the main spring are separately connected with two metal joints through bolts; rubber bushings are in interference fit in the metal joints; and the main spring and the auxiliary spring are plate springs made from composite material. The invention further relates to an assembly method for the automobile plate spring assembly. According to the automobile plate spring assembly and the assembly method thereof, a groove is formed in the middle of the upper surface of the spring body of the auxiliary spring so as to match with a lug boss below the spring body of the main spring; a lug boss with the same shape is processed in the lower surface of the auxiliary spring so as to match with a groove in the upper surface of the lower metal clamping plate; in the case of not drilling in the middle part, positioning and transmitting of longitudinal load are completed, so that the strength of a middle dangerous section is improved, the loading application and light weight of the plate spring made from the composite material are realized, and therefore, the automobile plate spring assembly is popularized and applied, and is of great significance.

Owner:JILIN UNIV

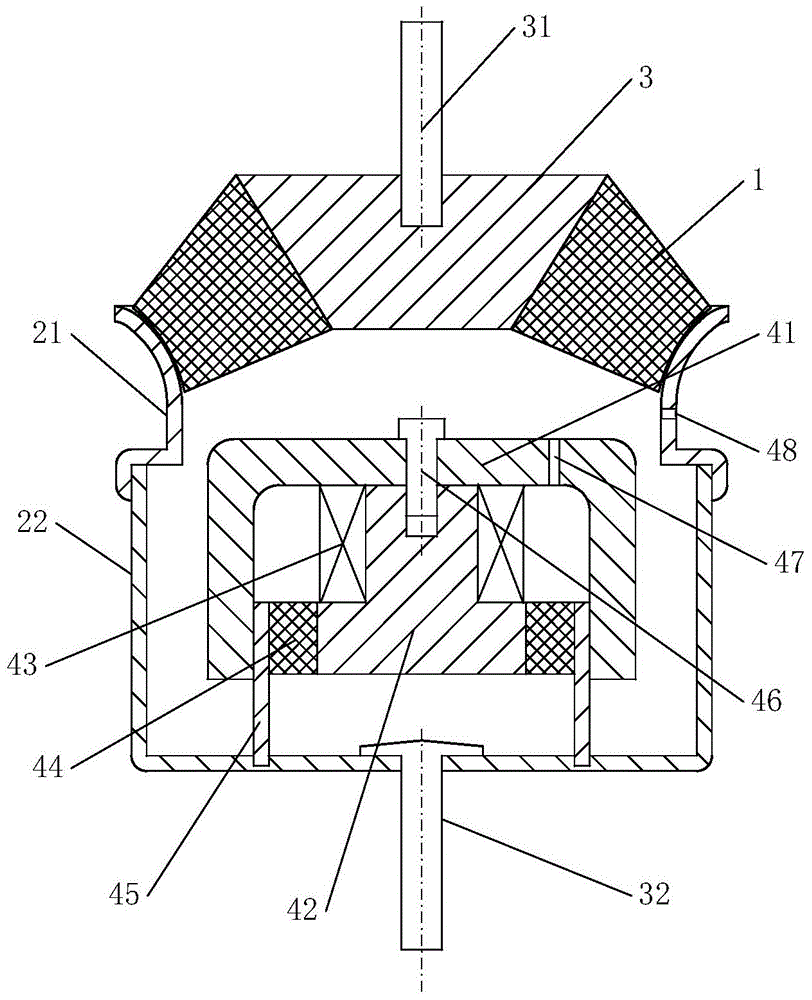

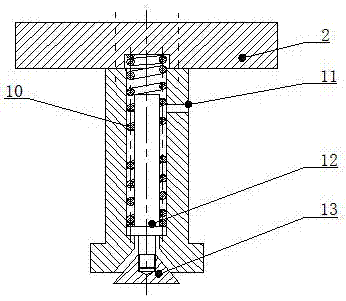

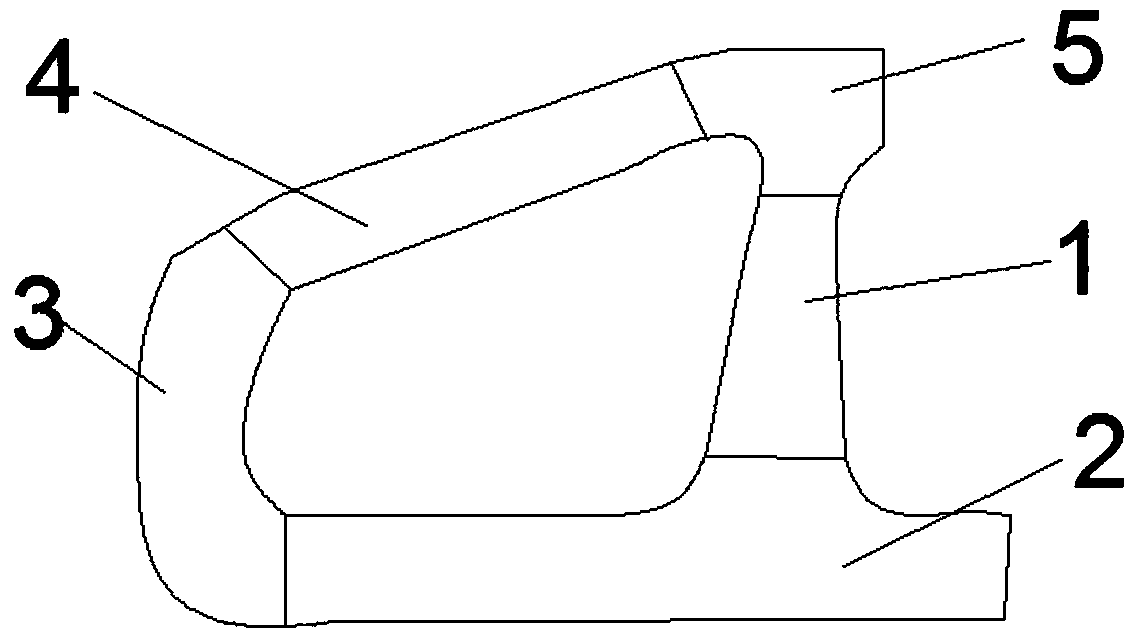

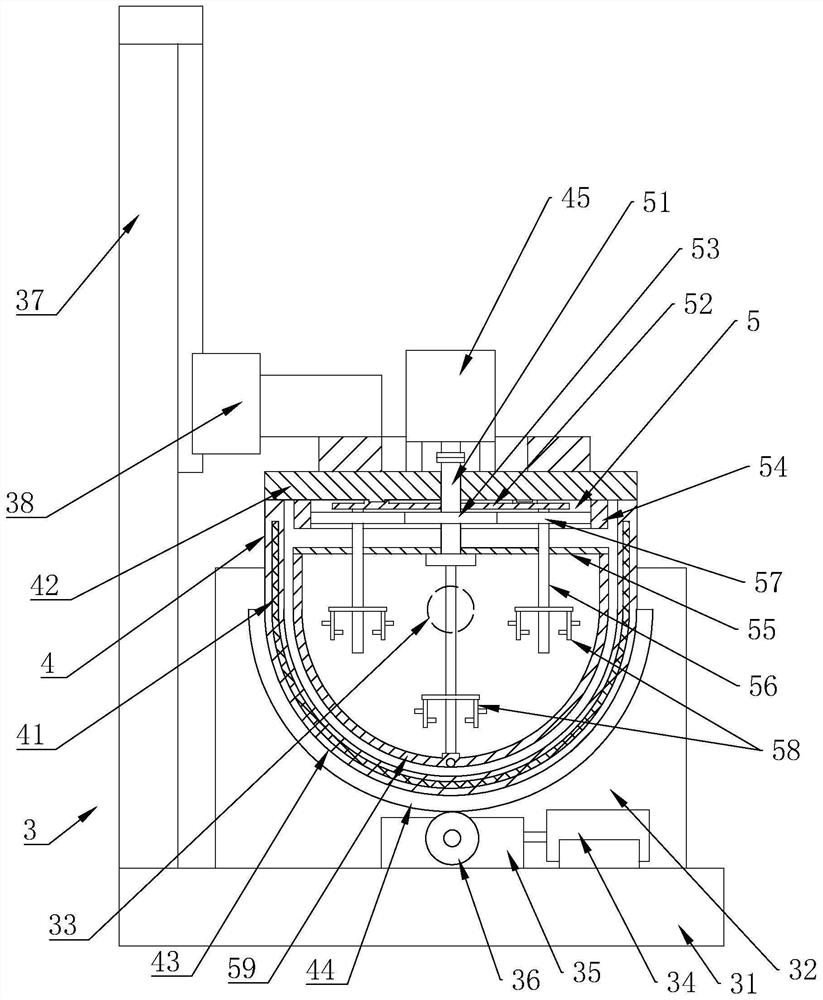

Vibration isolator with active vibration absorbing ability

The invention discloses a vibration isolator with an active vibration absorbing ability. The vibration isolator with the active vibration absorbing ability is provided with a barrel-shaped upper shell, a rubber main spring is blocked in a top end opening of the upper shell, a main spring framework runs through the rubber main spring, a connecting stud is arranged at the top of the main spring framework, and the upper end of the connecting stud is used for connecting with a base body; the vibration isolator with the active vibration absorbing ability is provided with a lower shell connected with the upper shell, a shearing sleeve is fixed on the bottom plate of the lower shell, a column-shaped iron core is supported in the shearing sleeve through a magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, a magnet exciting coil winds the column-shaped iron core, and the magnetorheological elastomer works in a shearing mode; a magnetic conductive mass block is firmly connected with the iron core; a connecting bolt is arranged at the bottom of the lower shell for connecting with a main vibration object. The vibration isolator with the active vibration absorbing ability is capable of effectively lowering the vibration energy transmitted to the base body from a rotating mechanism, reducing the vibration of related parts of the rotating mechanism and improving the service life thereof.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

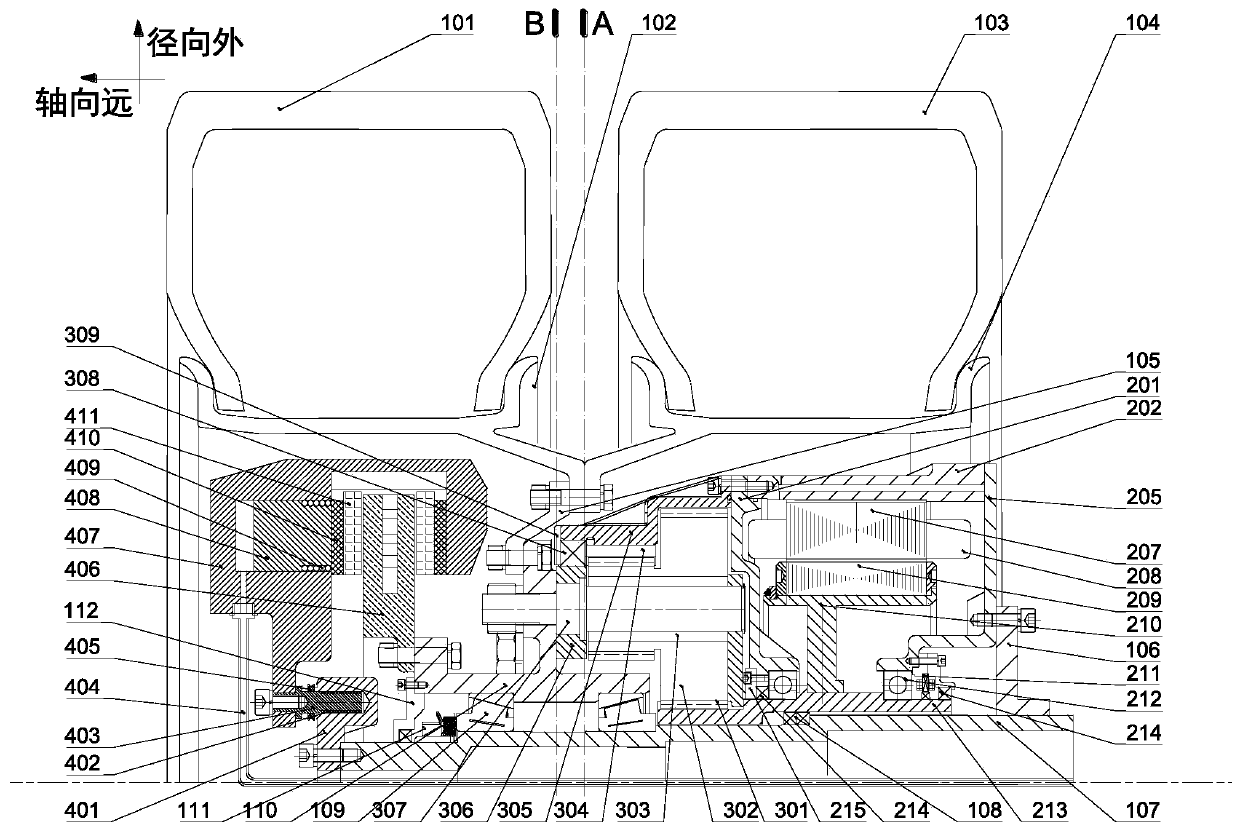

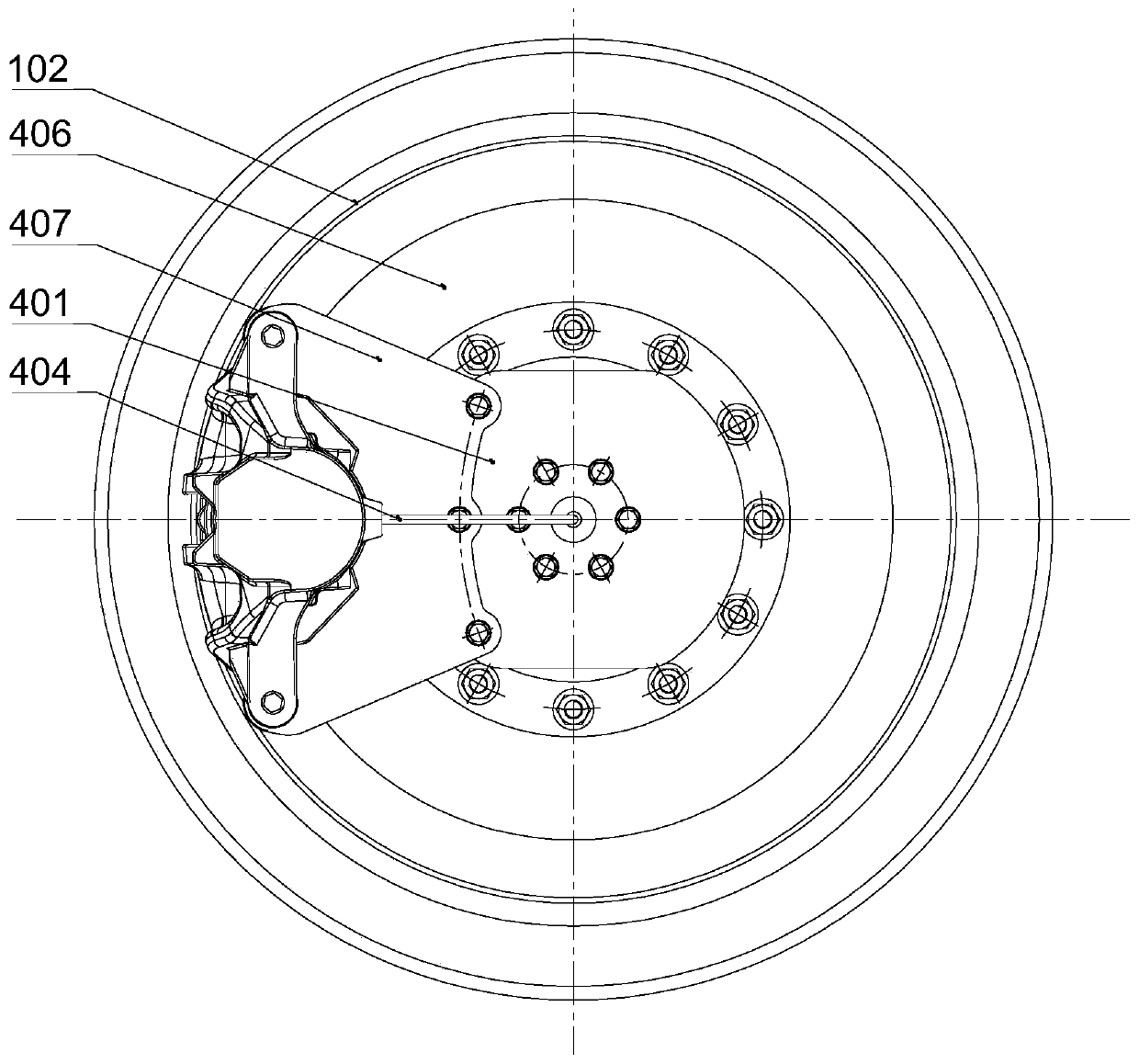

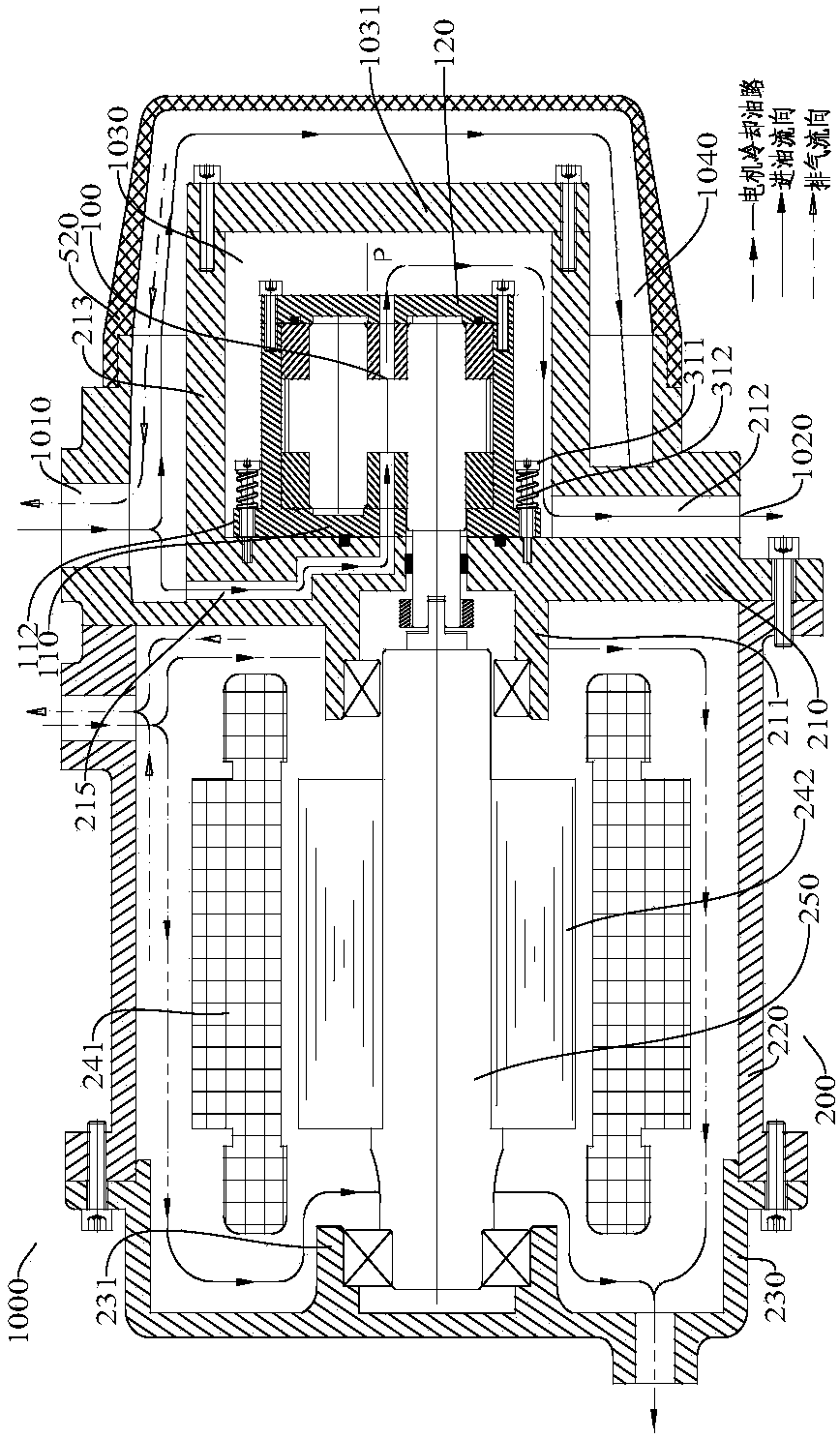

Electric wheel assembly, axle and vehicle suitable for twin tires and loading wheels

ActiveCN109130839AAxial dimension shortCost controlBraking element arrangementsBrake coolingReduction driveGear wheel

The invention discloses an electric wheel assembly, axle and vehicle suitable for twin-tire parallel loading wheels. The electric wheel assembly comprises wheels and a support shaft assembly, an innerrotor hub motor, a planetary gear reducer and a braking system. A planet carrier is connected with a wheel hub, the wheel hub connects a spoke and a wheel rim, a wheel support shaft passes through arotor sleeve, and hub bearings are arranged on the wheel support shaft to support the wheel hub and the whole wheel. The sun gear at one end of the rotor sleeve of the inner rotor hub motor is the power input of the planetary gear reducer, and the planet carrier is the power output. The planetary gear of planetary gear reducer adopts tower gear to realize larger transmission ratio under smaller axial length. The brake system adopts drum brake, the brake drum is connected with the rotor sleeve, and the braking force is amplified through the planetary gear reducer, which can reduce the braking force required by the brake system, and the electric motor can provide the electric braking force when braking. The electric wheel assembly can be used for the non-independent suspension of the commercial vehicle, and the cooling lubrication mode of the integrated cooling lubrication can be adopted to improve the performance.

Owner:南京清研易为新能源动力有限责任公司

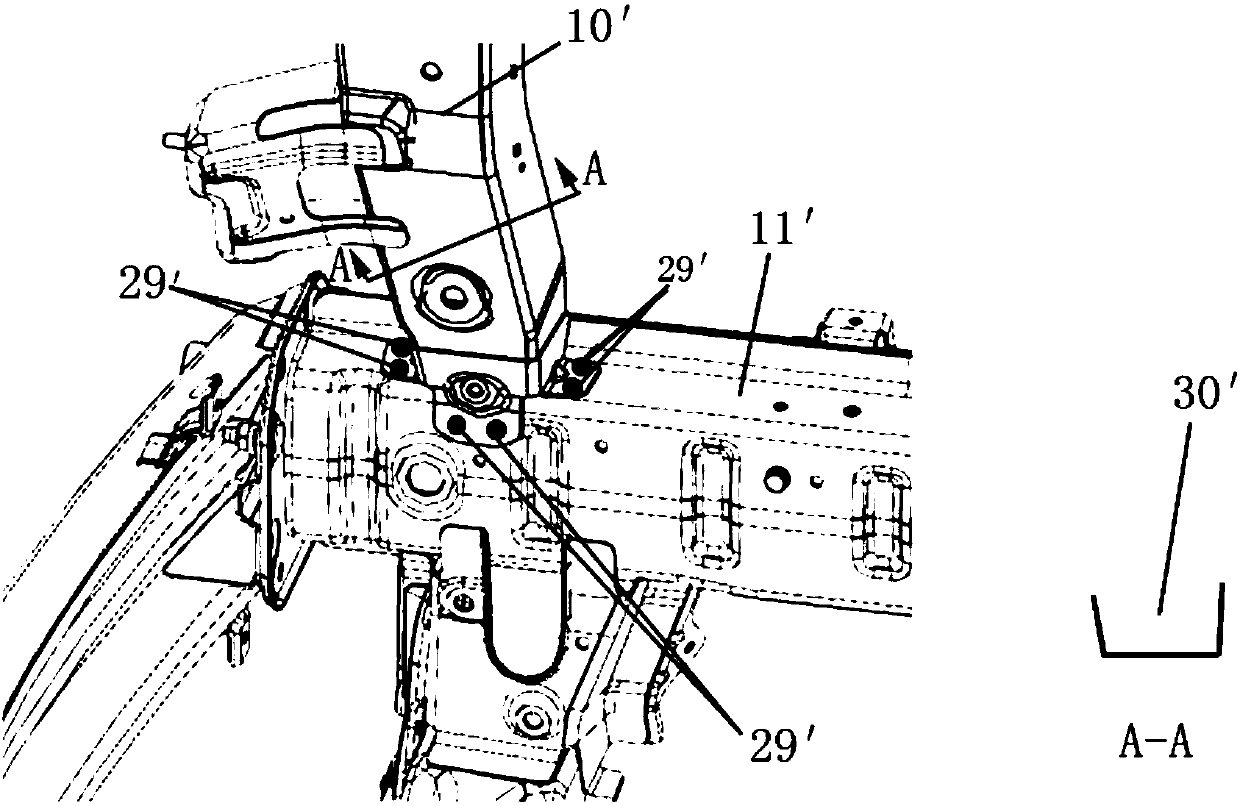

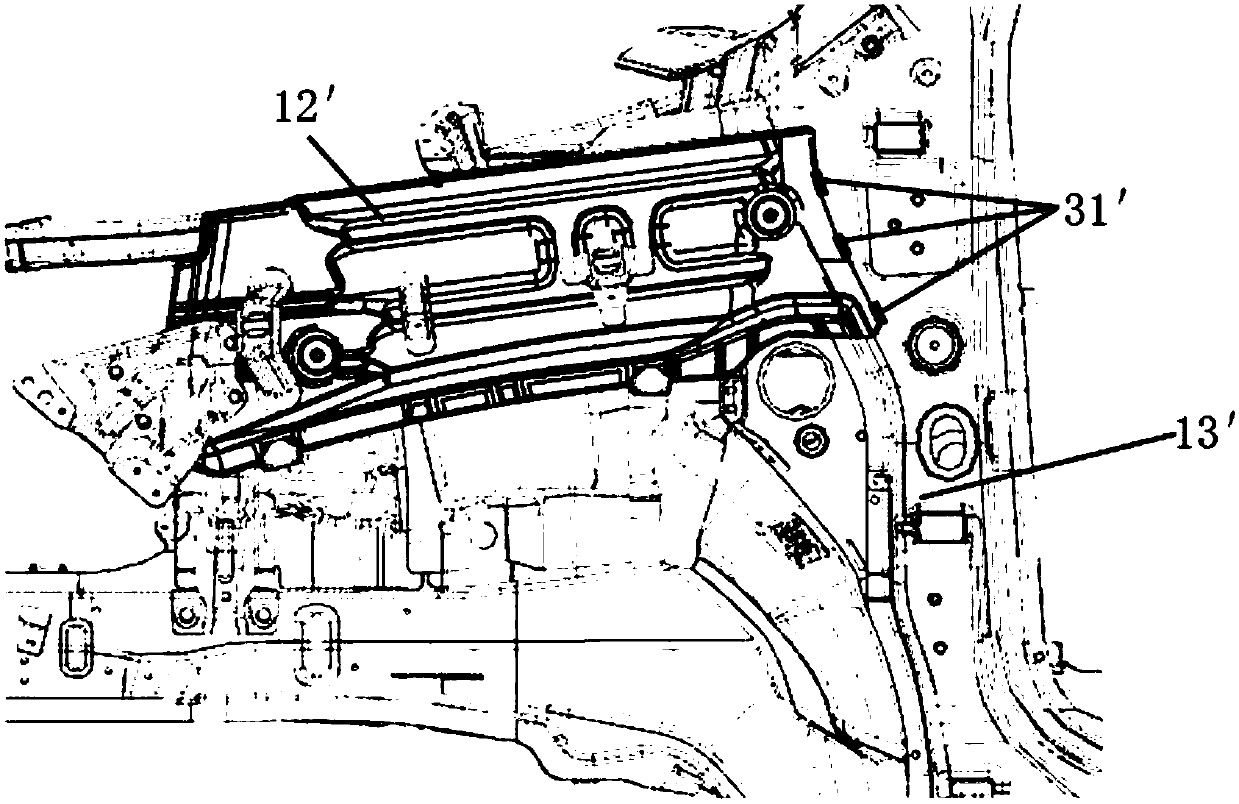

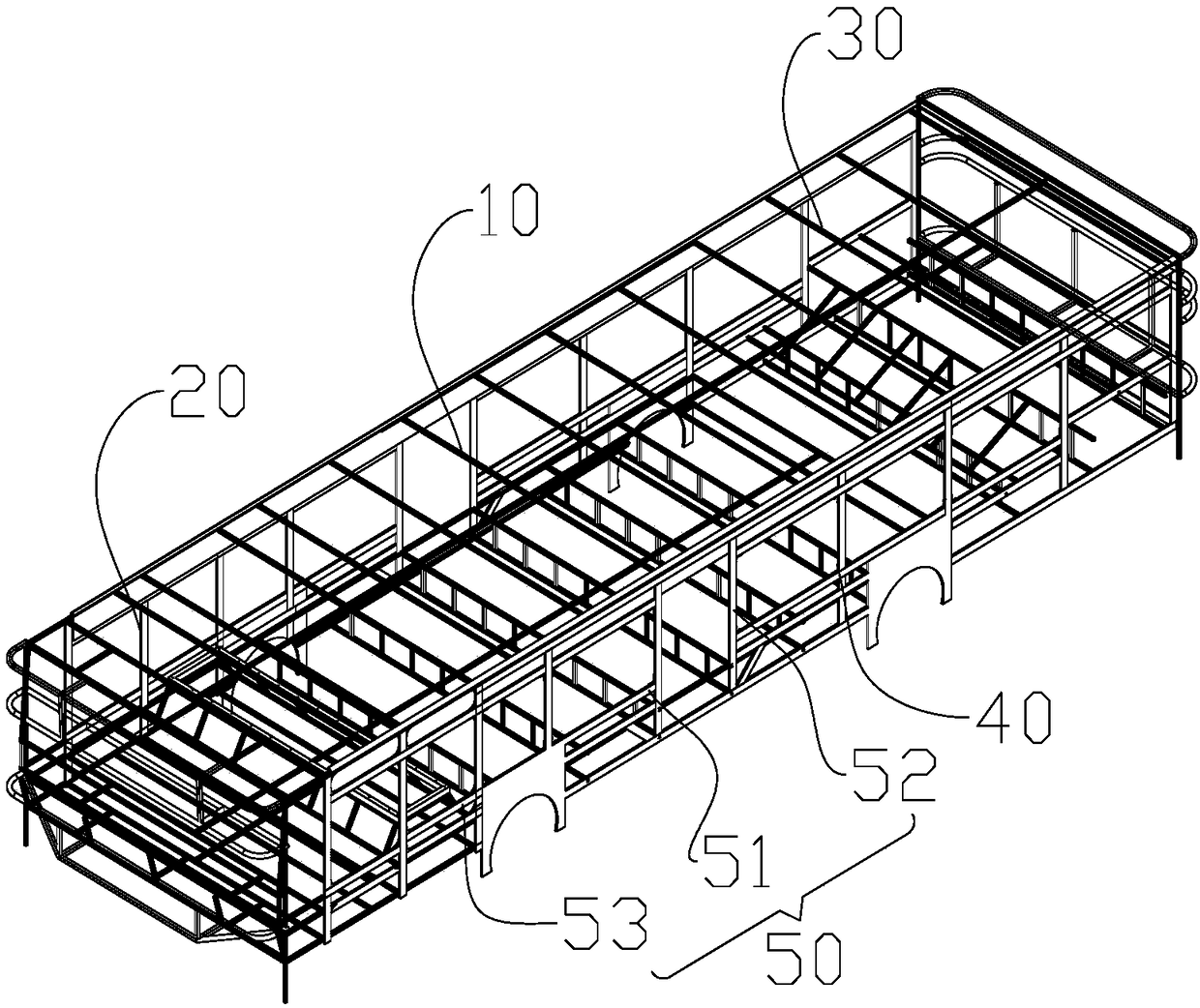

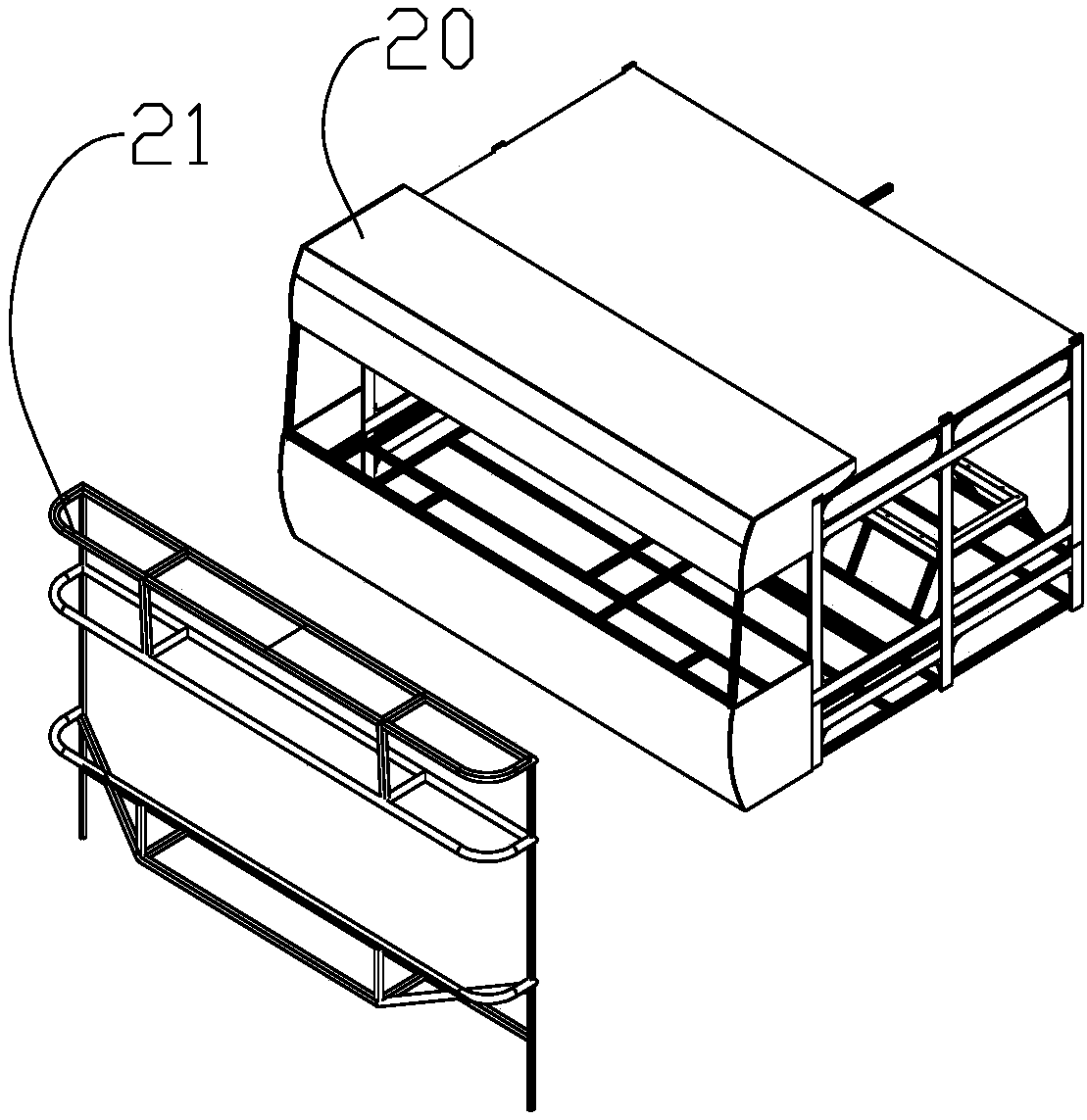

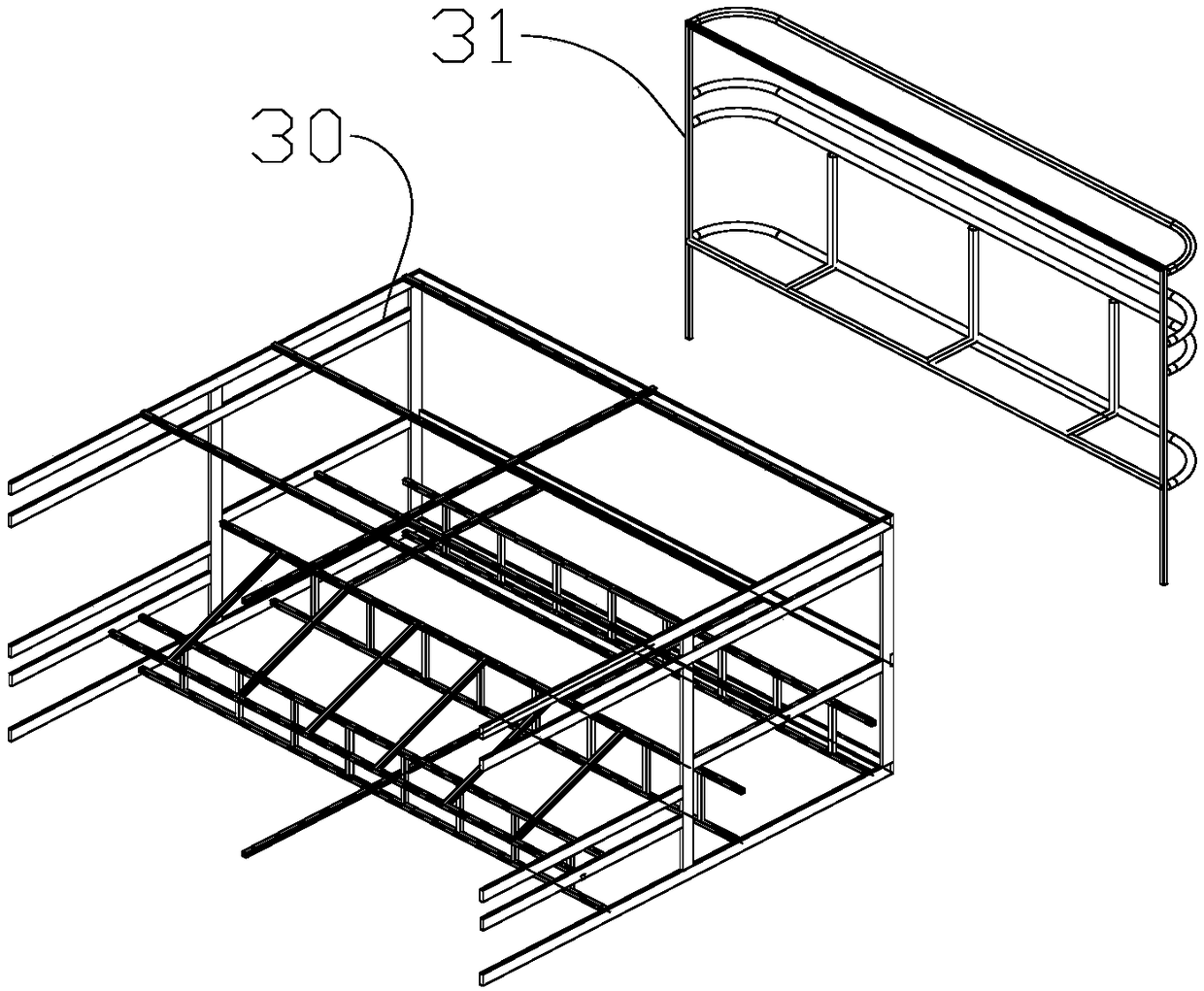

White car body frame assembly

PendingCN110341805ATroubleshoot weak connectionsImprove securitySuperstructure subunitsSuperstructure connectionsEngineeringBending beam

The invention discloses a white car body frame assembly. The white car body frame assembly comprises a car body frame body, a front end frame and two side wall frames, wherein the front end frame is fixed to the front side of the car body frame body; the two side wall frames are fixed onto the left and right side faces of the car body frame body respectively; the left and right ends of the front end frame are fixedly connected with the front ends of the two side wall frames respectively; the front end frame comprises two upper bending beam upright post reinforced plates; and the two upper bending beam upright post reinforced plates extend from top to bottom respectively to be fixed to the rear sides of corresponding car body upper bending beam upright posts. The white car body frame assembly disclosed by the invention solves the problem that the connection between the upper bending beam upright posts and front longitudinal beams is weak, front face column collision longitudinal beams do not collide, the front face column collision performance is improved, moreover, the rigidity of headlamp mounting points is increased, and the safety of passengers is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

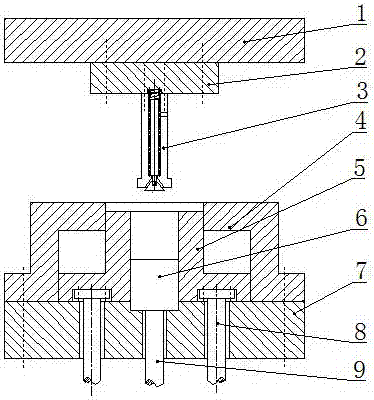

Cup-shaped part reverse extrusion molding device and method

InactiveCN106862290AReduce frictionSmall forming forceExtrusion diesExtrusion containersHydraulic cylinderBarrel Shaped

The invention discloses a cup-shaped part reverse extrusion molding device and method. The molding device comprise an upper mold plate, a base plate, a reverse extrusion punch, a compression spring, a limiting sleeve, a reverse extrusion barrel, an ejector block, an ejector rod, hydraulic cylinder pull rods and a lower mold plate. The base plate is arranged below the upper mold plate, the bottom of the base plate is connected with the reverse extrusion punch, the reverse extrusion barrel is arranged inside the limiting sleeve, the ejector block is arranged inside the reverse extrusion barrel, the ejector rod is arranged at the bottom of the ejector block, the hydraulic cylinder pull rods are fixed between the reverse extrusion barrel and the lower mold plate, the reverse extrusion punch is of a two-section stepped cylindrical structure, and a three-section through hole is formed in the punch. The reverse extrusion barrel is a barrel-shaped part with an inner cavity being a through hole. The upper portion of the through hole inner cavity is a containing cavity, and the lower portion of the through hole inner cavity is in clearance fit with the ejector block. The lower end of the reverse extrusion barrel is connected with the four hydraulic cylinder pull rods. Each hydraulic cylinder pull rod is of a T-shaped structure, and the reverse extrusion barrel is controlled to move up and down. The friction force between the punch and a blank and the friction force between the blank and the wall of the reverse extrusion barrel are reduced, the equipment service life is prolonged, and the cost is saved.

Owner:ZHONGBEI UNIV

Light-weight magnesium alloy passenger vehicle body framework

PendingCN108177697ASolve the defective technical problems of poor welding performanceSolve the problem of riveting costSuperstructure connectionsPassenger vehicle superstructuresStress concentrationMetal

The invention discloses a light-weight magnesium alloy passenger vehicle body framework which comprises a vehicle body framework body, a vehicle head framework installed at the front end of the vehicle body framework body, a vehicle tail framework installed at the rear end of the vehicle body framework body and multiple connecting mechanisms. Each of the vehicle head framework, the vehicle body framework body and the vehicle tail framework is composed of multiple magnesium alloy section bars in a connected mode, and every two magnesium alloy section bars are buckled and connected into a wholethrough the corresponding connecting mechanism. The potential quality hazards of welded metal fatigue and stress concentration are effectively overcome, the technical problem that a magnesium alloy ispoor in welding performance and the problem that magnesium alloy frameworks are high in riveting cost are solved as well, and connection of the magnesium alloy frameworks of a whole vehicle is reliable.

Owner:深圳市鑫镁金实业有限公司

Heavy-load electric wheel

PendingCN111361358AAxial dimension shortCost controlBraking element arrangementsMagnetic circuit rotating partsReduction driveGear wheel

The invention discloses a heavy-load electric wheel, and belongs to the field of electric vehicle power devices. A brake, a planetary gear reducer and a hub motor are sequentially arranged on the outer side of a supporting shaft from the distant to the near; the outer side of a hub is connected with a spoke mounting plane of a rim through a spoke, and the hub is mounted on the outer side of the supporting shaft through a pair of hub bearings; a brake caliper support in the brake is installed outside the distal facet of the wheel supporting shaft through a bolt, and a brake disc is installed ona brake disc installation flange of the hub; a hub part of the hub motor rotor support is sleeved on the rotor shaft; and a sun gear in the planetary gear reducer is disposed outside the distal end side of the rotor shaft. The axial size of the whole electric wheel assembly is short, and the hub motor, the planetary gear reducer and the brake are all arranged in the space defined by the rim on the inner side and the outer side of the electric wheel assembly, so that the electric wheel assembly can be suitable for common commercial vehicle double-tire parallel loading wheels.

Owner:南京清研易为新能源动力有限责任公司

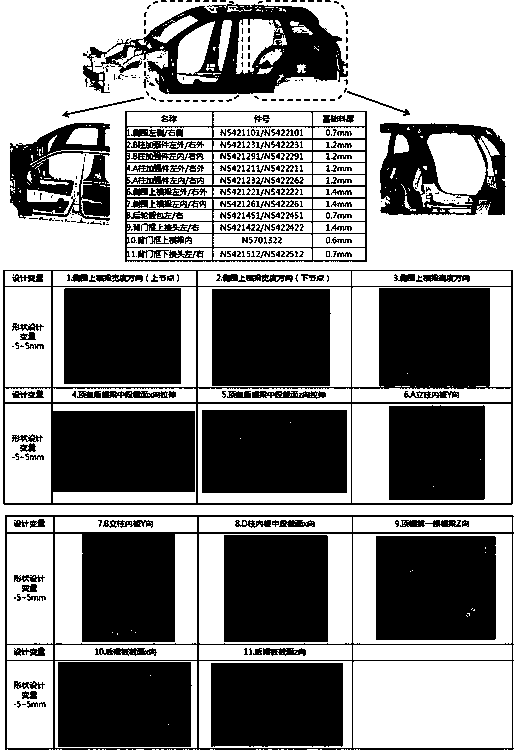

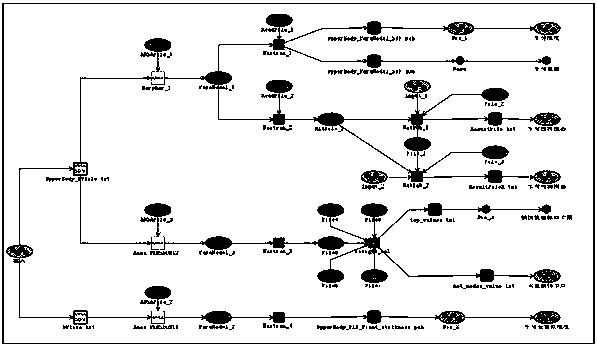

Upper vehicle body structure optimization method based on MDO technology

ActiveCN111125946AMeeting Multidisciplinary Performance RequirementsMultidisciplinary performance requirements to avoidGeometric CADSustainable transportationElement modelPerformance index

The invention relates to an upper vehicle body structure optimization method based on an MDO technology, and the method comprises the following steps: 1, building a vehicle body finite element model,and achieving the multidisciplinary performance simulation analysis of a vehicle body; step 2, establishing a parameterized model based on the upper vehicle body joint cavity and the upper vehicle body key sheet metal part thickness as design variables; 3, according to the step 2, building a simulation optimization process based on the upper vehicle body connector cavity and the key sheet metal part material thickness as design variables; 4, performing DOE sampling calculation of each design variable according to the step 3; 5, constructing a response surface approximation model meeting the precision requirement according to the DOE sampling calculation result in the step 4; and 6, according to the response surface approximation model in the step 5, taking the limit value of the multidisciplinary performance index of the vehicle body as a constraint condition, and taking the lightest weight of the vehicle body as an optimization target to carry out optimization design and obtain an optimization scheme. According to the method, the lightweight optimization scheme meeting the multidisciplinary performance requirements of the vehicle body can be quickly found.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

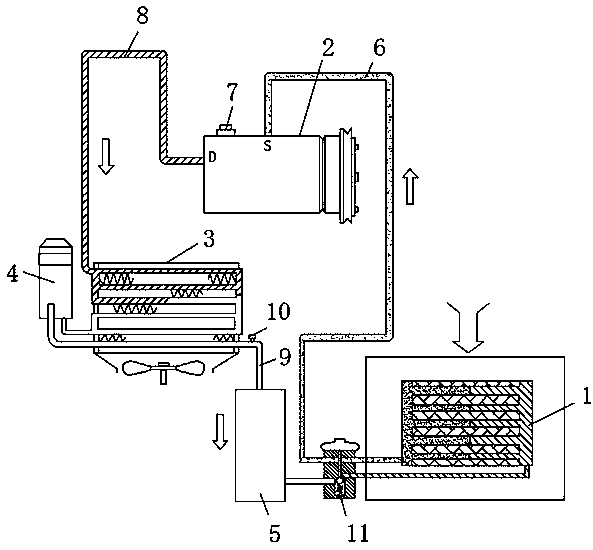

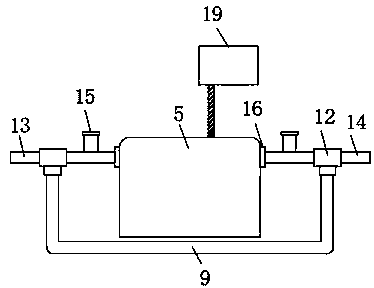

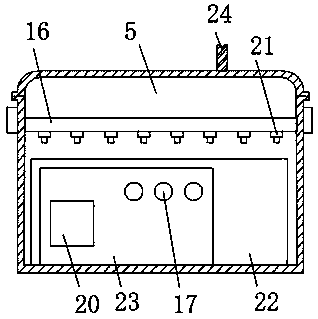

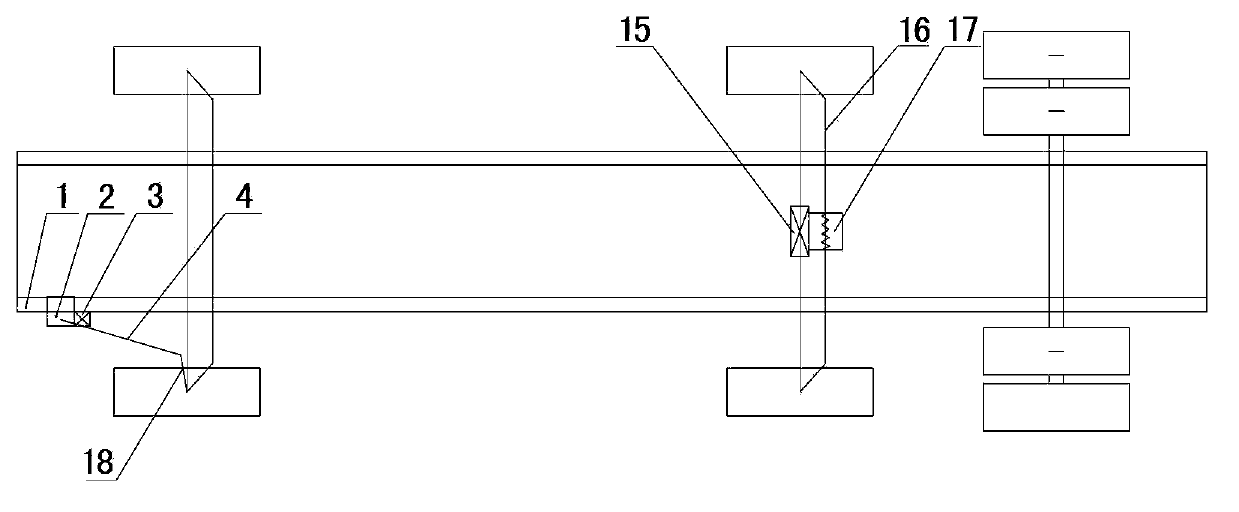

Automatic fire extinguishing system for power battery system of passenger vehicle and control method of automatic fire extinguishing system

PendingCN110075448AImprove the level of lightweightDoes not take up extra bulkProgramme controlAir-treating devicesElectrical batteryAutomobile safety

The invention discloses an automatic fire extinguishing system for a power battery system of a passenger vehicle and a control method of the automatic fire extinguishing system, and belongs to the technical field of automobile safety fire-fighting. The automatic fire extinguishing system comprises an air conditioner cooling sub system and an automatic fire extinguishing sub system which is connected to the inner part of the air conditioner sub system, wherein the automatic fire extinguishing sub system comprises a controller, a solenoid valve, a sensor, an alarm and a battery pack; the controller processes received signal data, and outputs an instruction according to processed information; the input end of the solenoid valve is connected to the output end of the controller for receiving afire extinguishing signal output by the controller, so that fire extinguishing is started; the output end of the sensor is connected to the input end of the controller for detecting environment data inside battery pack; the input end of the alarm is connected to the output end of the controller for receiving an alarm signal output by the controller, so that alarm is started; and the battery pack is further connected to a BMS. The automatic fire extinguishing system does not occupy extra size, facilities layout, and improves lightweight level of the whole vehicle.

Owner:泰州盛飞新能源汽车部件有限公司

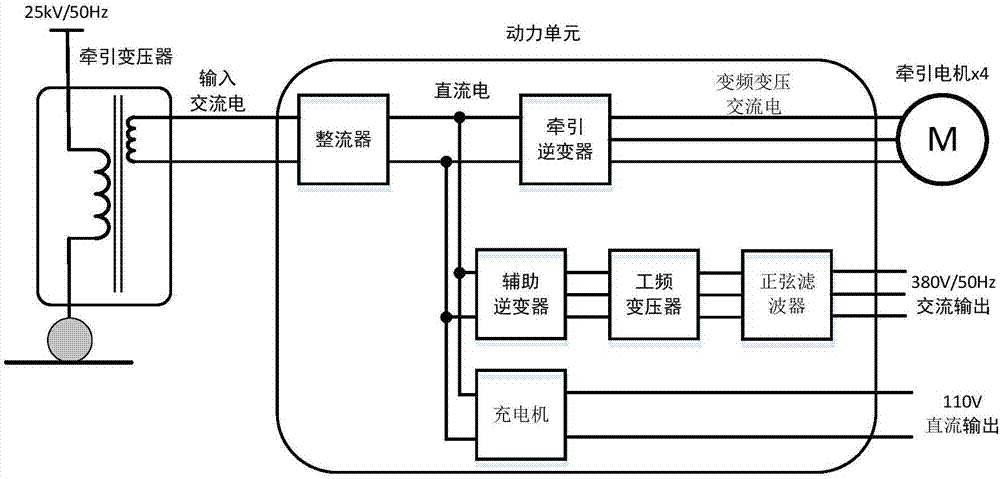

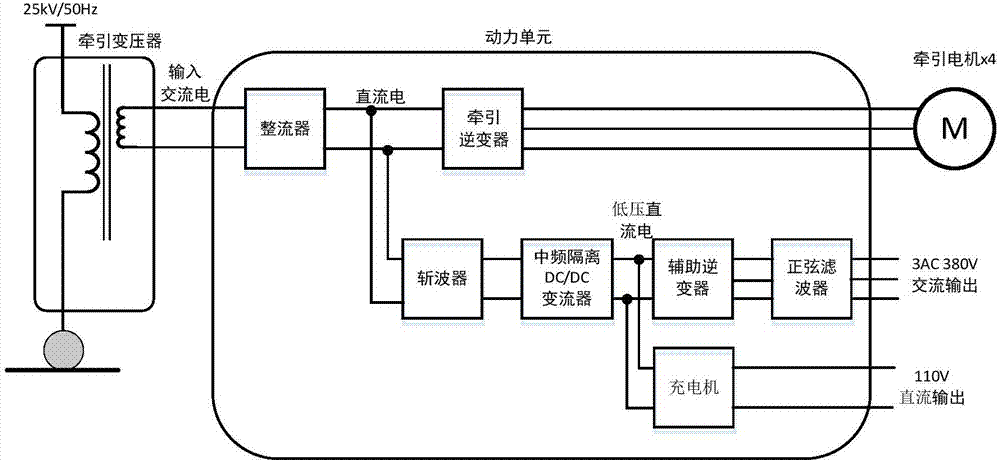

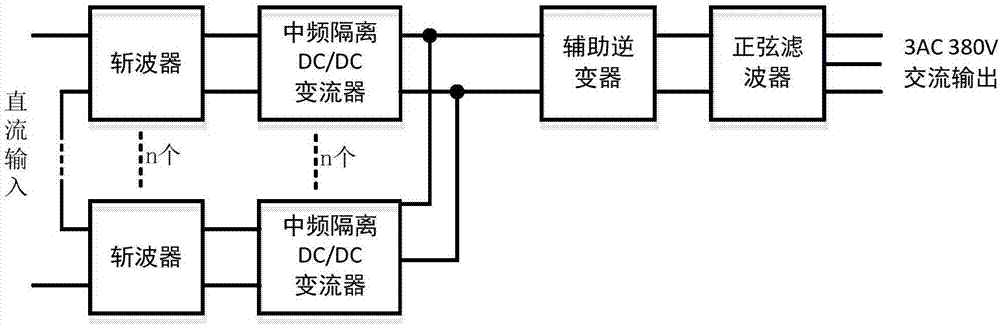

Traction power device

PendingCN107070255AIncrease working frequencyEasy to cutBatteries circuit arrangementsAC motor controlLow voltageTraction transformer

The invention provides a traction power device which comprises a rectifier, a traction inverter and an auxiliary current converting unit; wherein the rectifier is connected with a traction transformer secondary side winding on a train and is used for rectifying single-phase alternating current of the traction transformer secondary side winding into direct current; the traction inverter is used for inverting the direct current into frequency amplitude controllable alternating current to tract a motor; the auxiliary current converting unit comprises a chopper, an medium frequency isolation DC / DC converter, an auxiliary inverter and a sine filter; the chopper is used for regulating the voltage of direct current; the medium frequency isolation DC / DC converter is used for performing medium frequency inverter on direct voltage outputted by the chopper, isolation transforming is performed on the square-wave voltage of the medium frequency, and the square-wave voltage is rectified as low voltage direct current; the auxiliary inverter is used for inverting the low voltage direct current into three-phase power frequency alternating current; the sine filter is connected with the auxiliary inverter and is used for filtering the three-phase power frequency alternating current to generate sine three-phase alternating current for providing alternating current load of the train.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

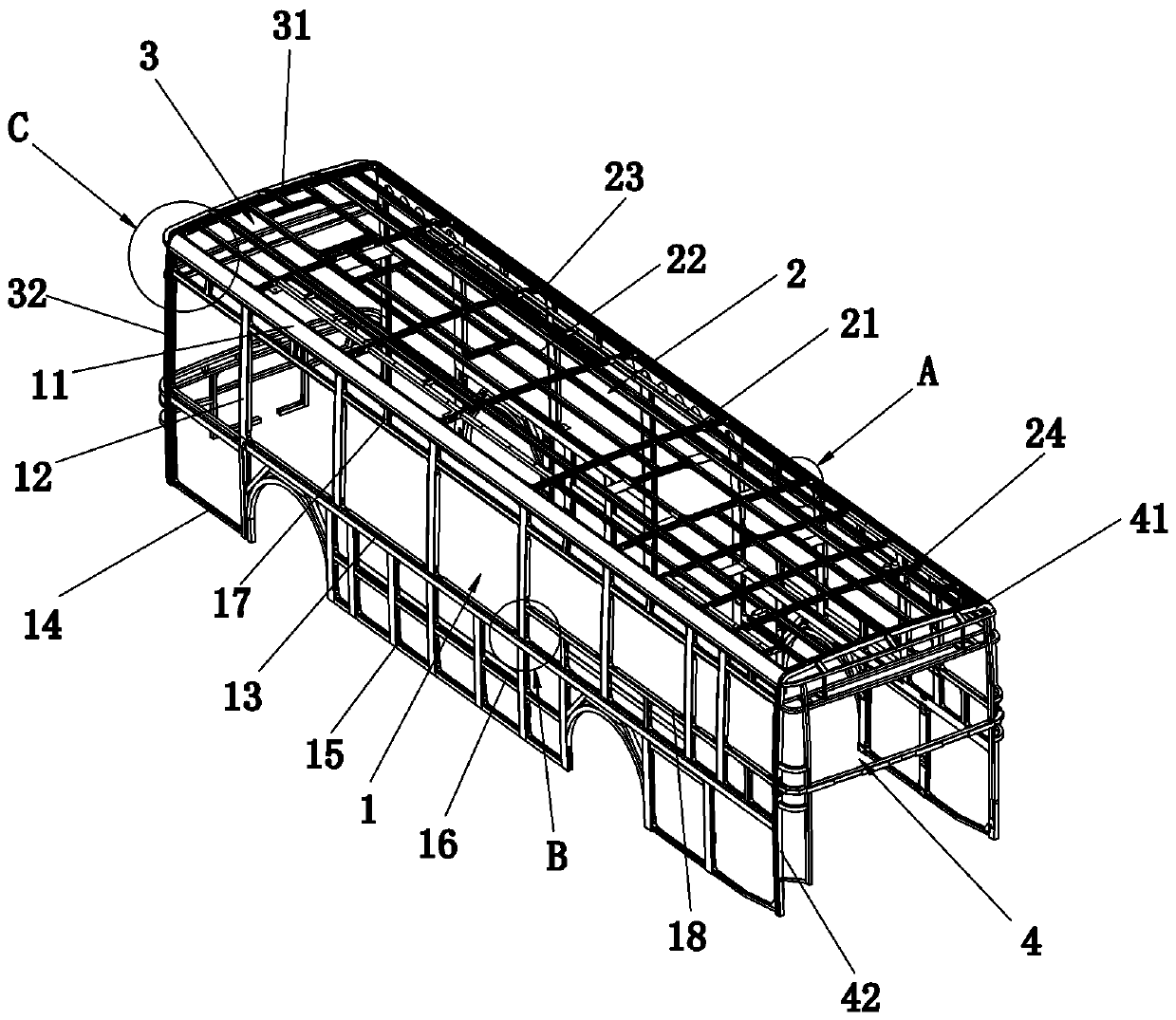

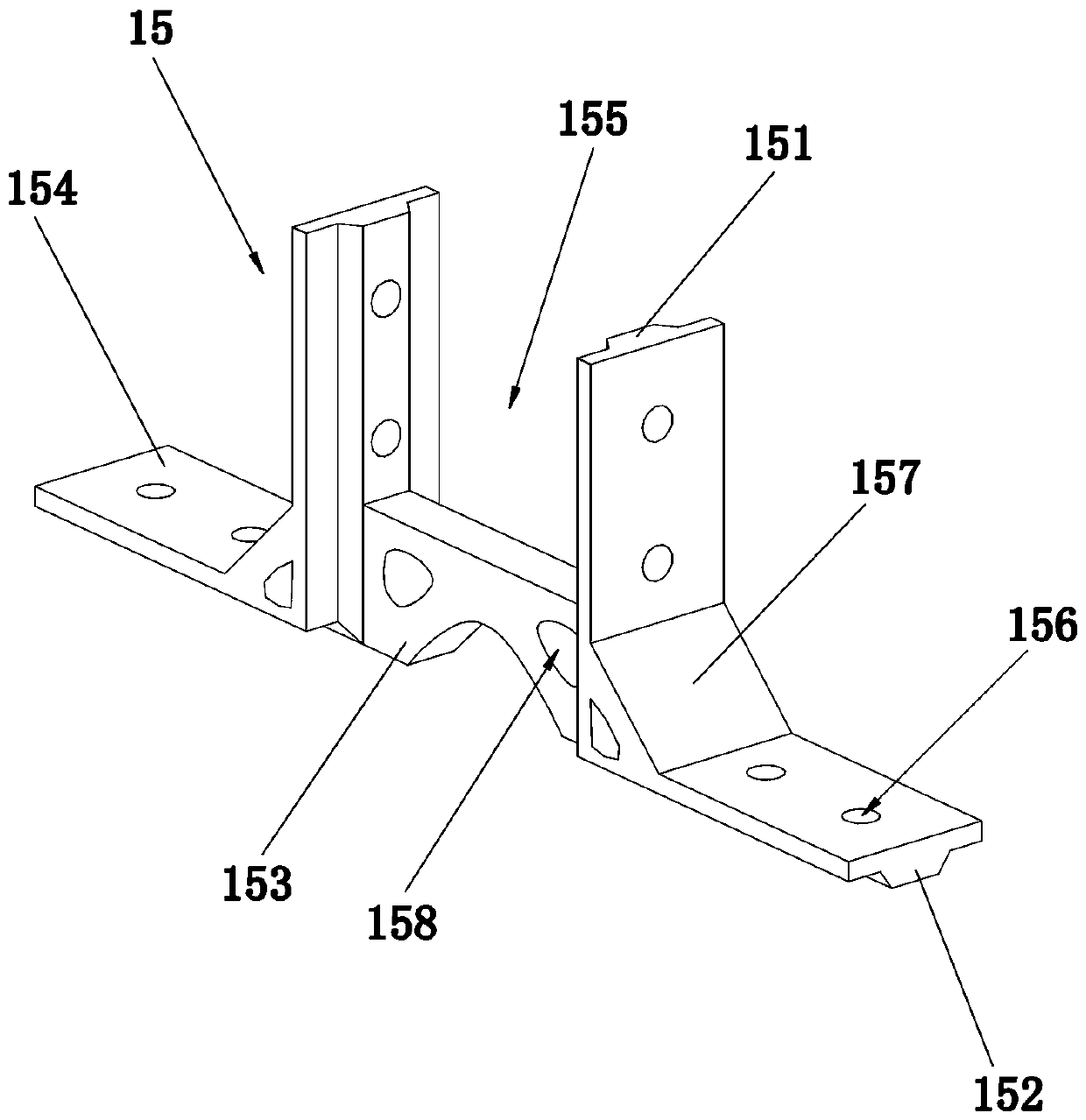

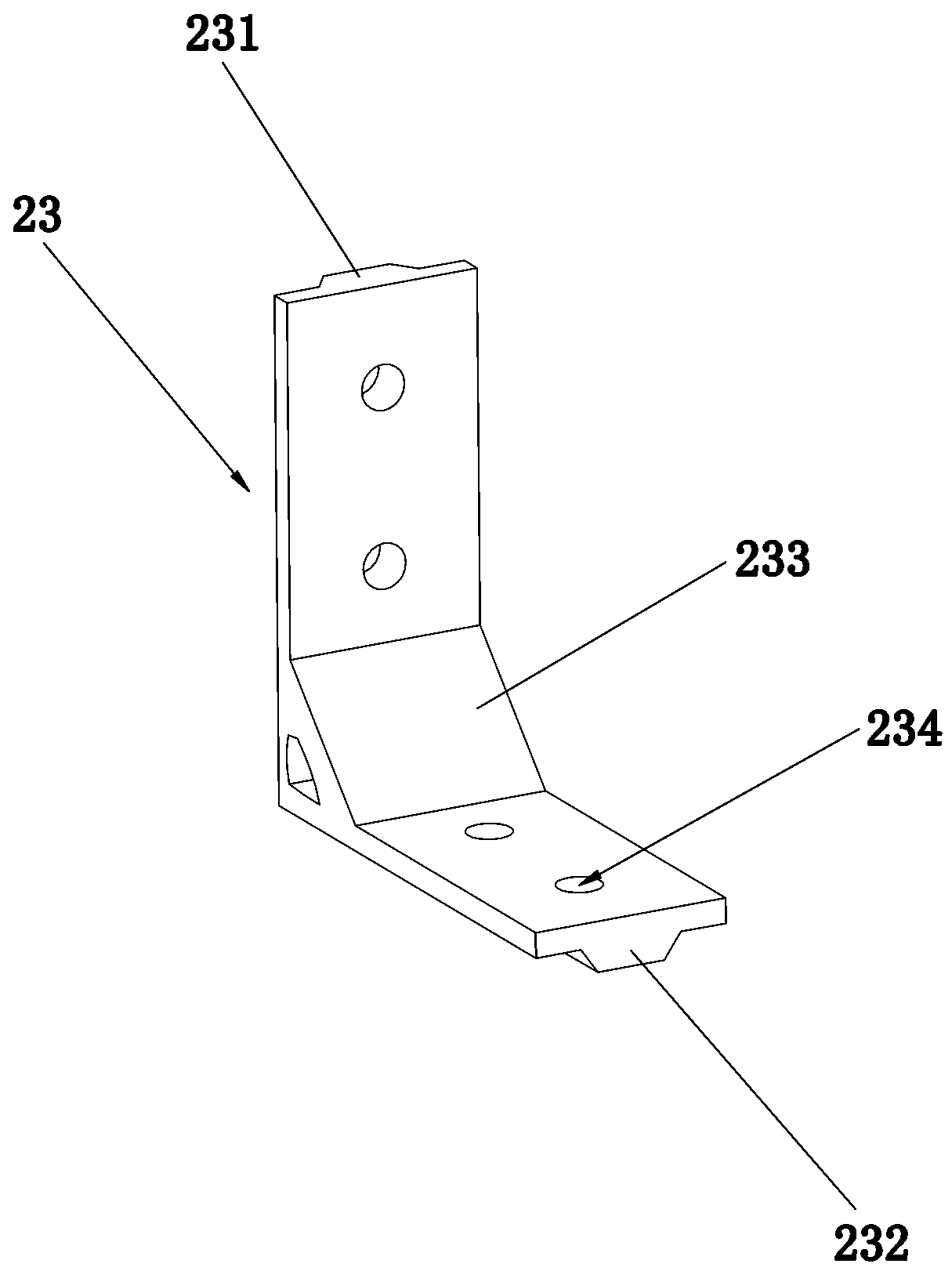

Automobile skeleton, automobile roof skeleton and automobile sidewall skeleton

PendingCN109969272AWill not cause interferenceQuick removable installationSuperstructure subunitsPassenger vehicle superstructuresStructural stabilityAutomotive engineering

The invention discloses an automobile skeleton, an automobile roof skeleton and an automobile sidewall skeleton, and relates to the technical field of automobiles. The automobile skeleton includes a plurality of connecting points formed by plural vehicle beams being vertically connected with each other, the multiple connecting points include first connecting points, and the first connecting pointsare formed by connecting a first vehicle beam and a second vehicle beam through first connecting pieces; the first connecting pieces include a connecting plate and two L-shaped guard plates, the twoL-shaped guard plates with internal corners outwards are oppositely arranged at the two ends of the connecting plate, so that a U-shaped installation part is formed on one sides of the first connecting pieces, and an installation surface is formed on the other sides of the first connecting pieces; and one end of the first vehicle beam is connected to the installation part in an inserted mode, andthe side wall of the second vehicle beam is fixedly arranged on the installation surface. The automobile skeleton, the automobile roof skeleton and the automobile sidewall skeleton have the beneficialeffects that the defects in the prior art are overcome, the skeletons are suitable for the large-scale design and manufacture of bus body skeletons, and have the advantages of being high in lightweight level, high in material utilization rate, high in structural stability, good in technical condition adaptability, and the like.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

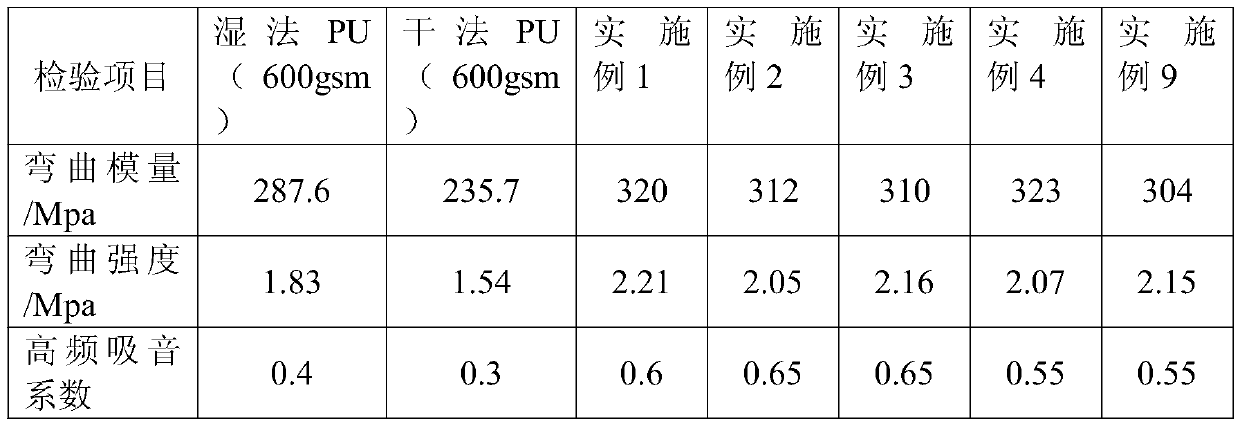

Ultra-light high-sound-absorption GMT reinforced PU thermoplastic automotive trim composite board and preparation method thereof

InactiveCN109823012AOvercome the shortcomings of poor rigidity, fully sealed without openings, and poor sound absorptionMeet lightweight requirementsSynthetic resin layered productsSuperstructure subunitsEngineeringComposite plate

The invention provides an ultra-light high-sound-absorption GMT reinforced PU thermoplastic automotive trim composite board and a preparation method thereof. The composite board provided by the invention sequentially comprises a non-woven film, a GMT reinforcing layer, a non-woven film, a PU foam light plate, a non-woven film, a GMT reinforcing layer and a non-woven film from top to bottom, and the composite board is obtained by thermally compounding the GMT reinforcing layer with a 3D structure and the PU foam light plate which are bonded through the non-woven film, so that the defects of poor rigidity, full sealing, no hole and poor sound absorption in a traditional dry PU board are overcome, and the sound absorption performance and light weight of the PU composite board material are further improved.

Owner:浙江华江科技股份有限公司

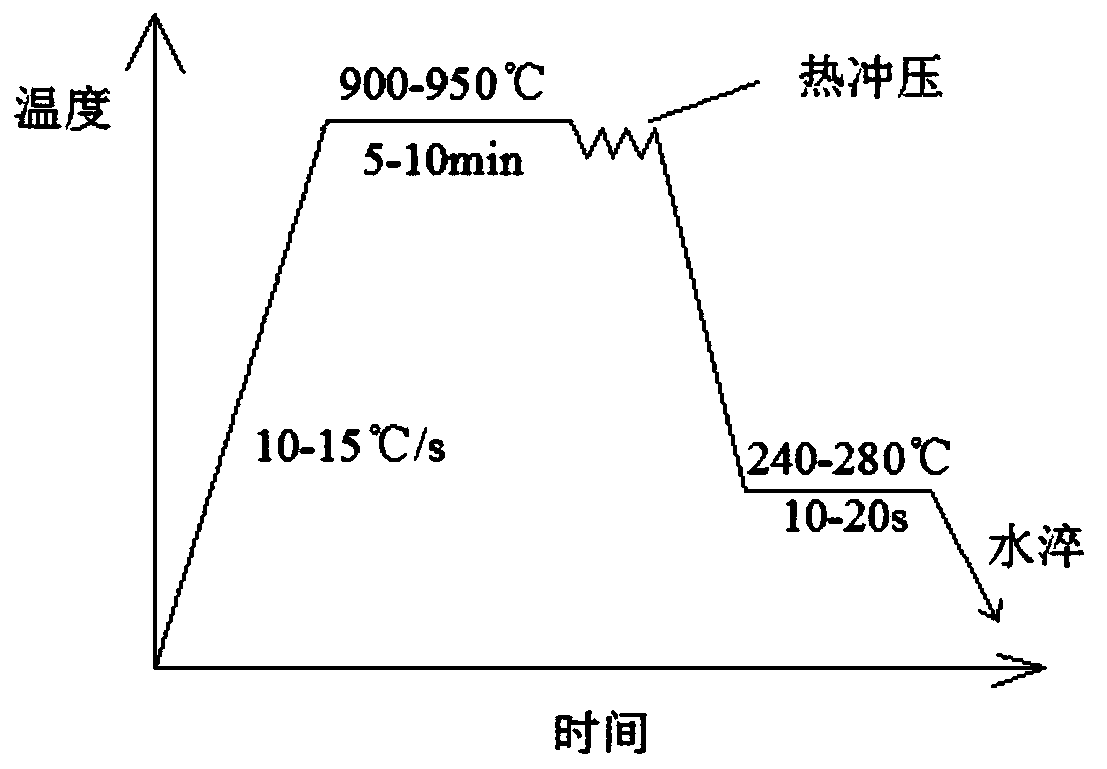

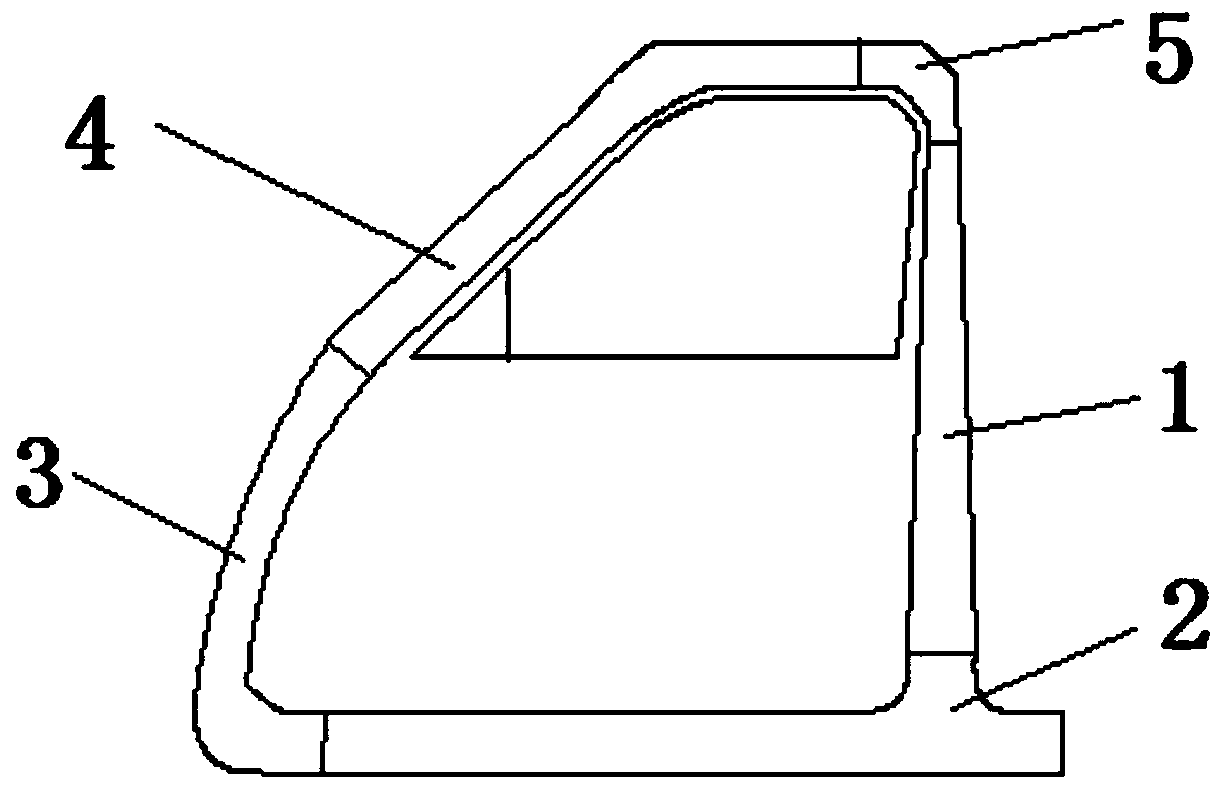

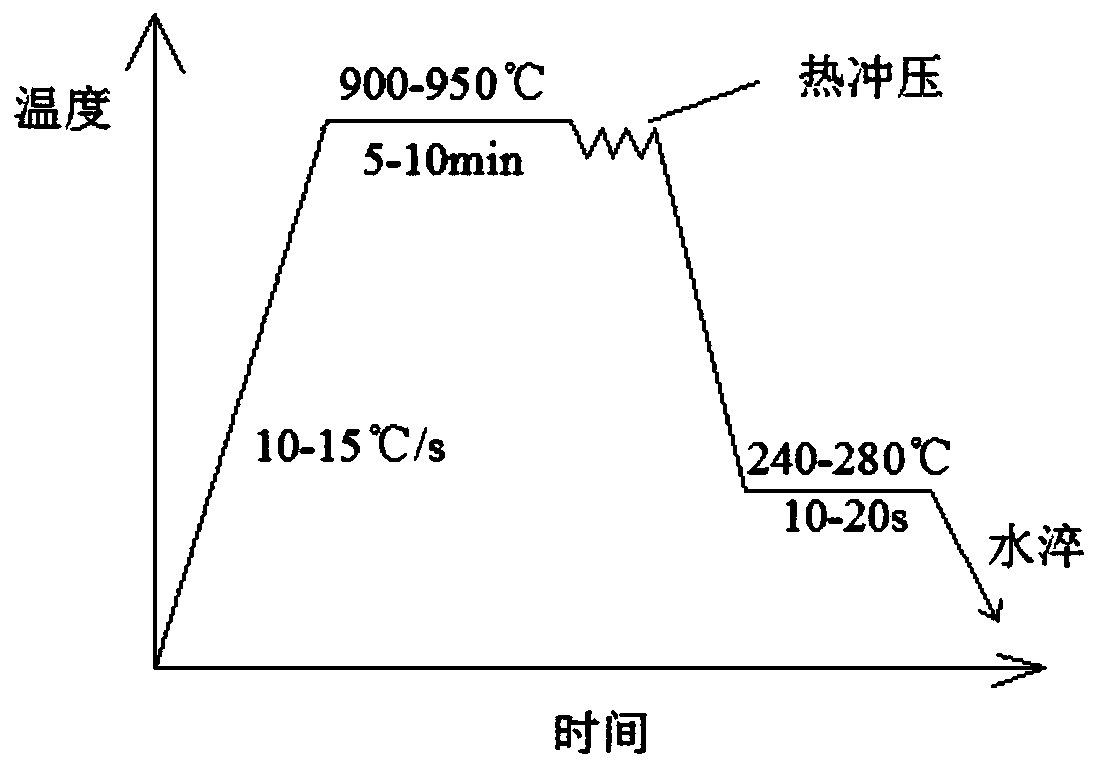

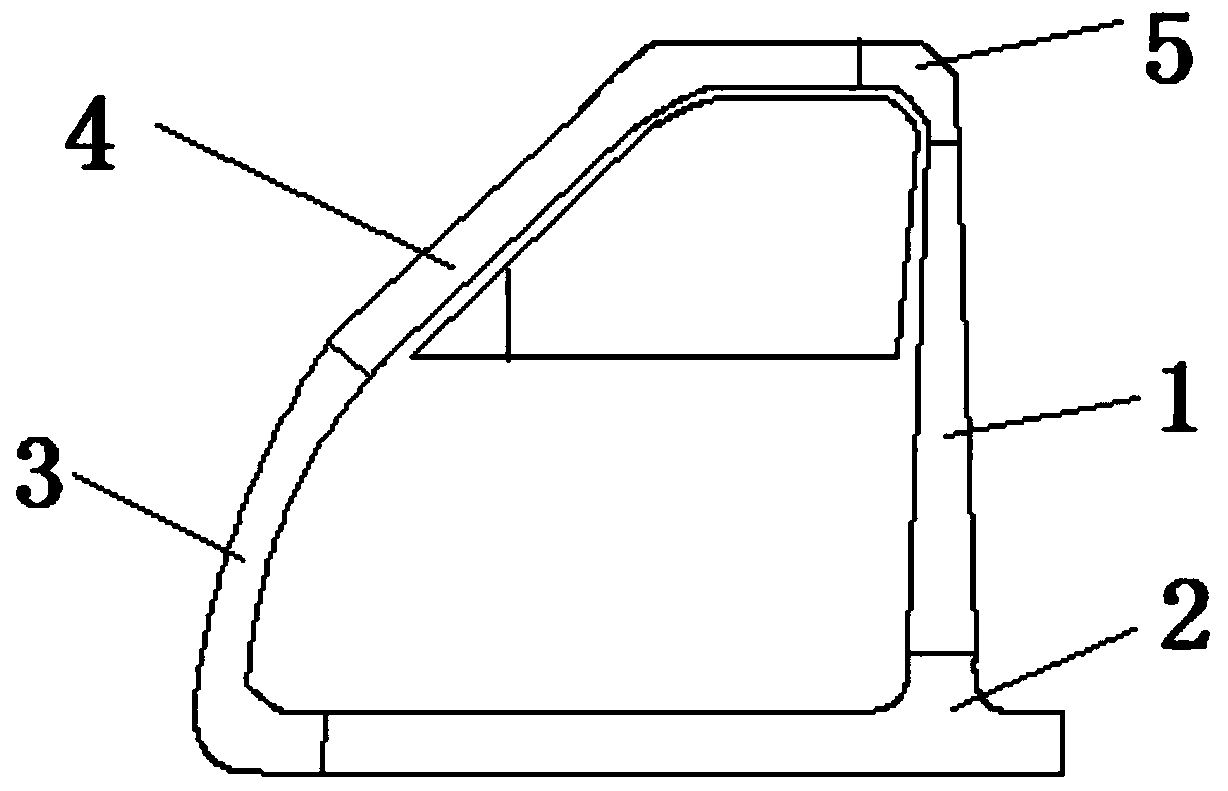

Light dissimilar steel integral hot formed vehicle door frame preparation method

InactiveCN108620510AImprove the immunityImprove impact performanceShaping toolsVehicle componentsVehicle frameAcid washing

The invention provides a light dissimilar steel integral hot formed vehicle door frame preparation method. A vehicle door frame consists of five parts; and according to different mechanical performance requirements, high-strength steel plates with different characteristics are selected. The machining process comprises (1) laser cutting, (2) laser welding, (3) integral hot punching formation and (4) acid washing. The preparation method has the following beneficial effects: dissimilar high-strength steel plate materials are selected, are cut to proper sizes by laser, and are welded by laser forintegral hot punching formation; the overall strength and plasticity of a vehicle front door frame are greatly improved; the rigidity is higher; the deformation resistance and the impact resistance ofthe vehicle door frame are improved; the vehicle safety is improved; the door frame is high in forming precision and low in rebound through hot punching; and needed punching equipment is lower in tonnage. The weight of the vehicle frame is reduced, so that the vehicle lightness level is improved. In addition, the machining process is simple and higher in efficiency, and meets large-batch production requirements of products; and the products are excellent in strength and plasticity and stable in quality.

Owner:SHANDONG JIANZHU UNIV

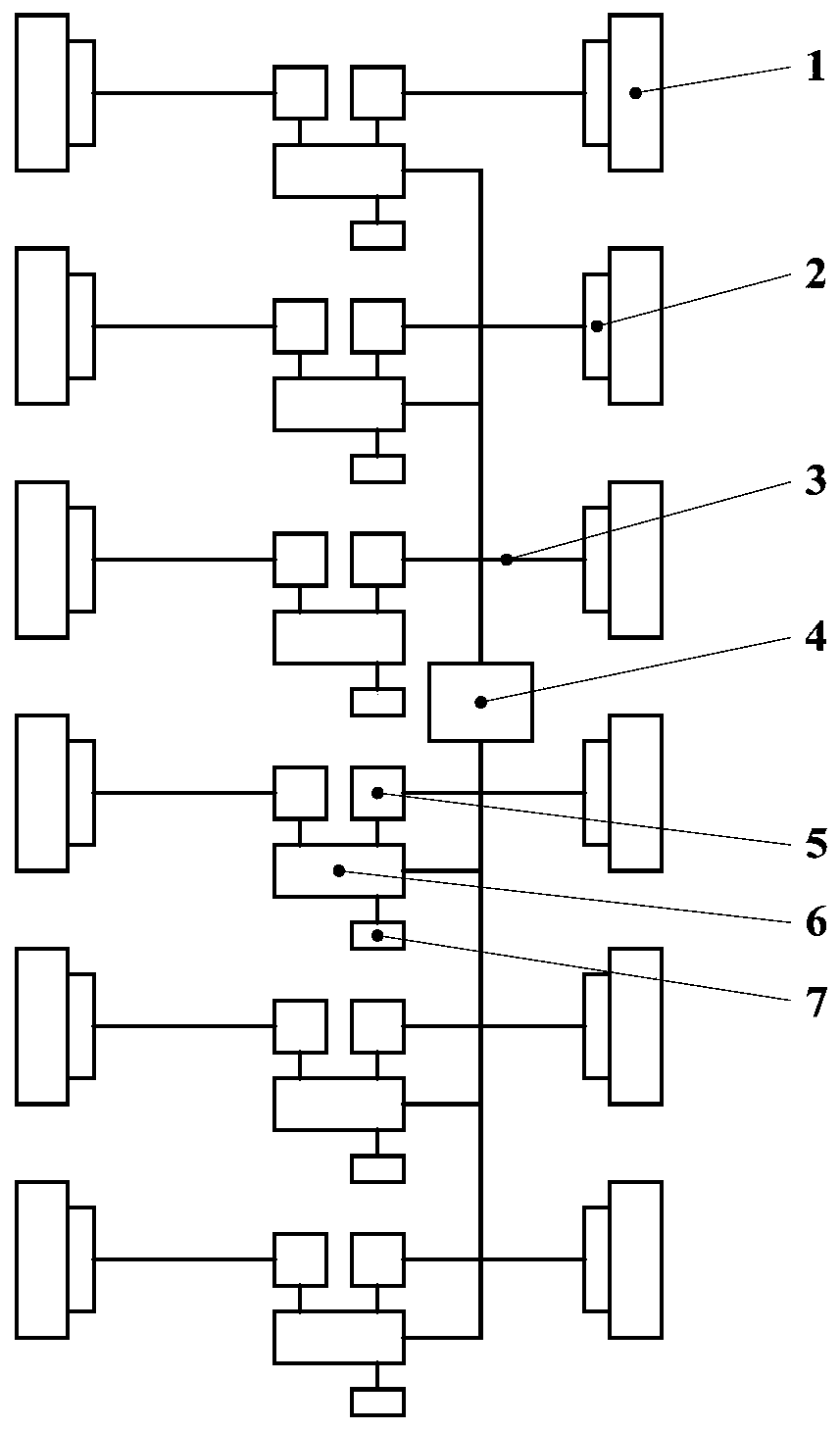

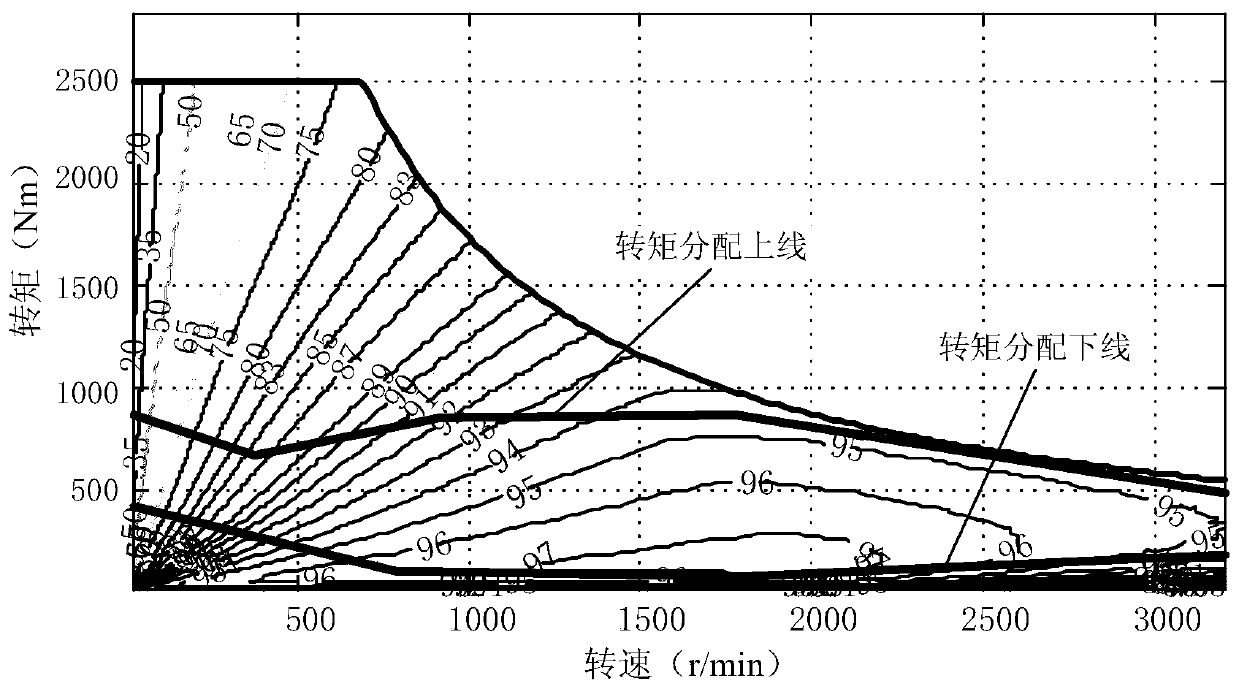

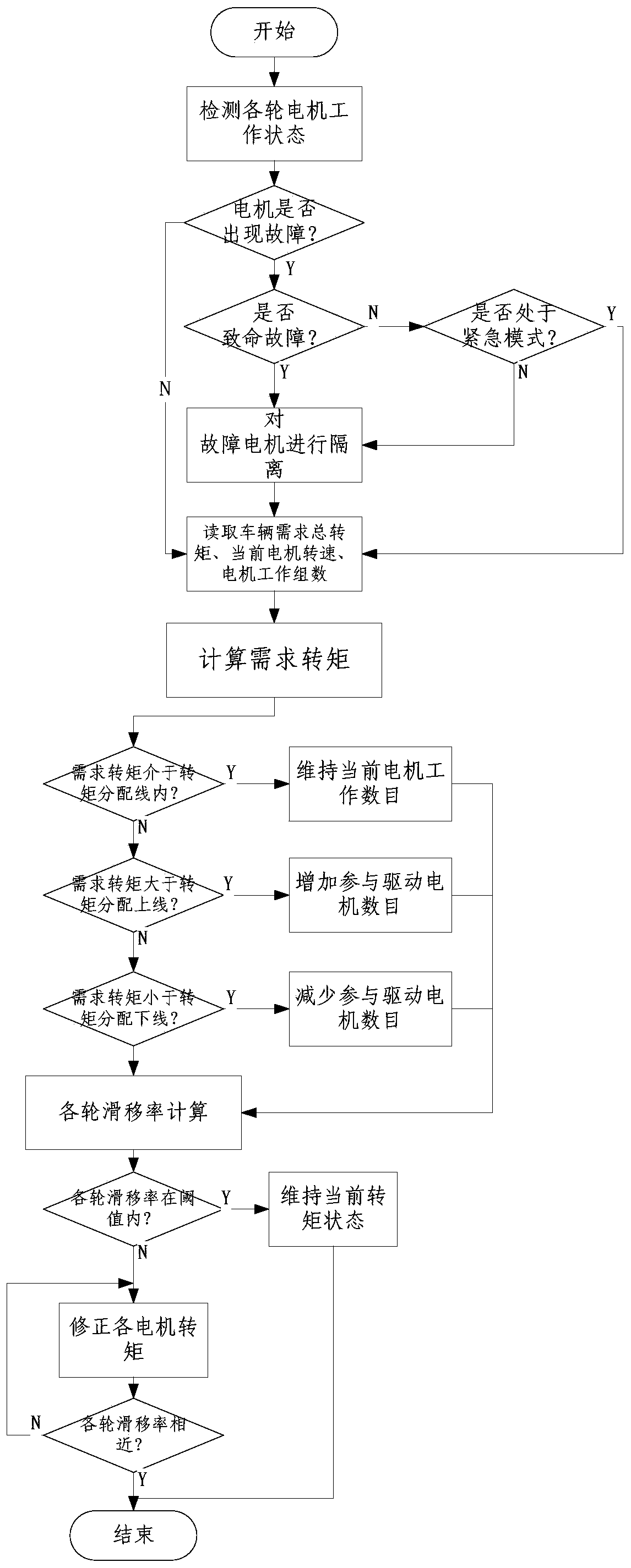

Distributed all-electric drive system and grouping control method

ActiveCN109849689AImprove scalabilitySimple structureSpeed controllerElectric energy managementElectricityDrive shaft

A distributed all-electric drive system and a grouping control method are disclosed. The distributed all-electric drive system comprises a plurality of modular electric drive devices and a drive controller; each modular electric drive device comprises a wheel, a wheel set, a wheel side drive shaft, a motor and an integrated motor controller; each group of modular electric drive device is equippedwith one integrated motor controller, all integrated motor controllers are interconnected with the drive controller to realize the reading of the working state of the motor and the transmission of control signals; the drive controller sends corresponding control signals to each integrated motor controller respectively, and each integrated motor controller drives the motor in the modular electric drive device to work according to the received corresponding control signal, and transmits the control signal to the wheel set through the wheel side drive shaft, and finally drives the wheel to rotate. According to the invention, by adopting multi-motor cooperative control based on rules, intelligent grouping control and the like, the driving conditions are adaptively identified, the power cycle in the driving process is reduced, the optimal system efficiency is achieved, the tire wear is reduced, and the chassis driving safety is improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

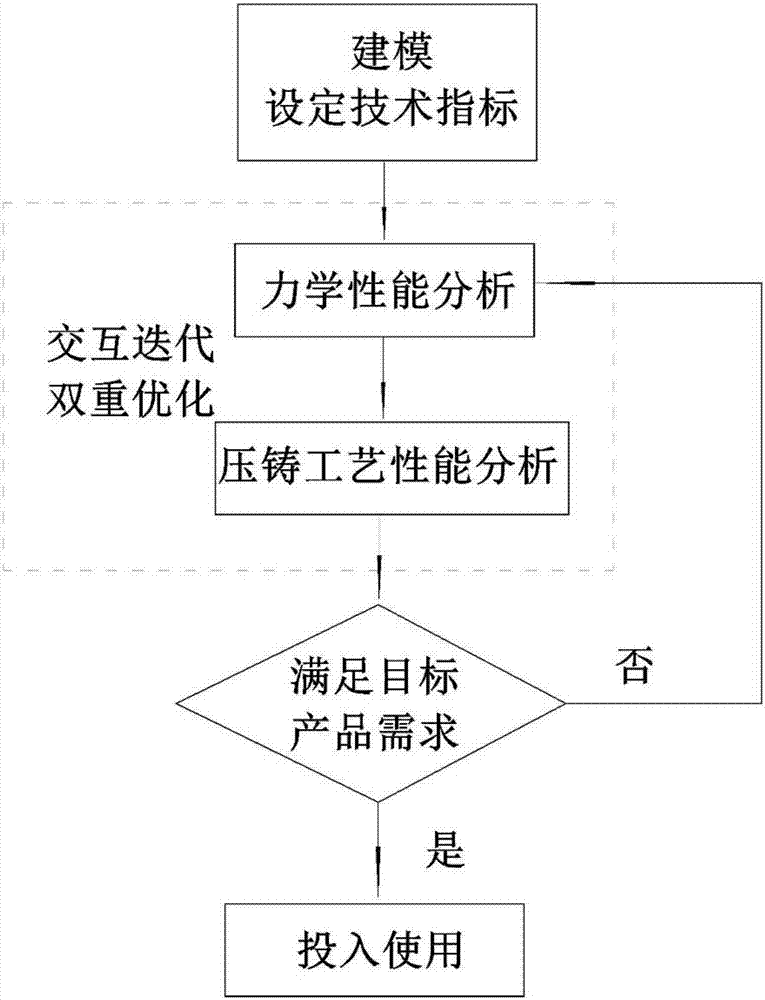

Complex thin wall aluminum alloy stair die casting forming technology

InactiveCN106975736AReaching a New Level of Lightweight Die CastingLeading technology levelEscalatorsThin walledSoftware

The invention provides a complex thin wall aluminum alloy stair die casting forming technology. Special software is adopted for conducting the mechanical performance analysis on a complex thin wall aluminum alloy stair structure, then special software is applied to conduct the die casting technology performance analysis on a complex thin wall aluminum alloy stair, the above two steps are repeatedly conducted, interactive iteration is conducted, and dual optimization is conducted. A method of interactive and iterative optimization of the mechanical performance analysis and the die casting technology performance analysis is adopted, and accordingly dual optimization for lightweight and casting forming performance of the complex thin wall aluminum alloy stair structure is achieved. The tread face wall thickness of the aluminum alloy stair obtained through the technology is smaller than or equal to 1.88 mm, the kicking face wall thickness of the aluminum alloy stair obtained through the technology is smaller than or equal to 1.81 mm, and the overall weight of the stair is smaller than or equal to 10.5 kg; after 500-3,000 N of static load, permanent deformation is avoided; and during supporting of the largest inclination angle (35 degrees) under the dynamic load of 500-3,000 N, permanent deformation is smaller than or equal to 2.1 mm, damage is avoided, and the technology level of a die casting product is domestically advanced.

Owner:NANTONG JIANGZHONG PHOTOELECTRIC

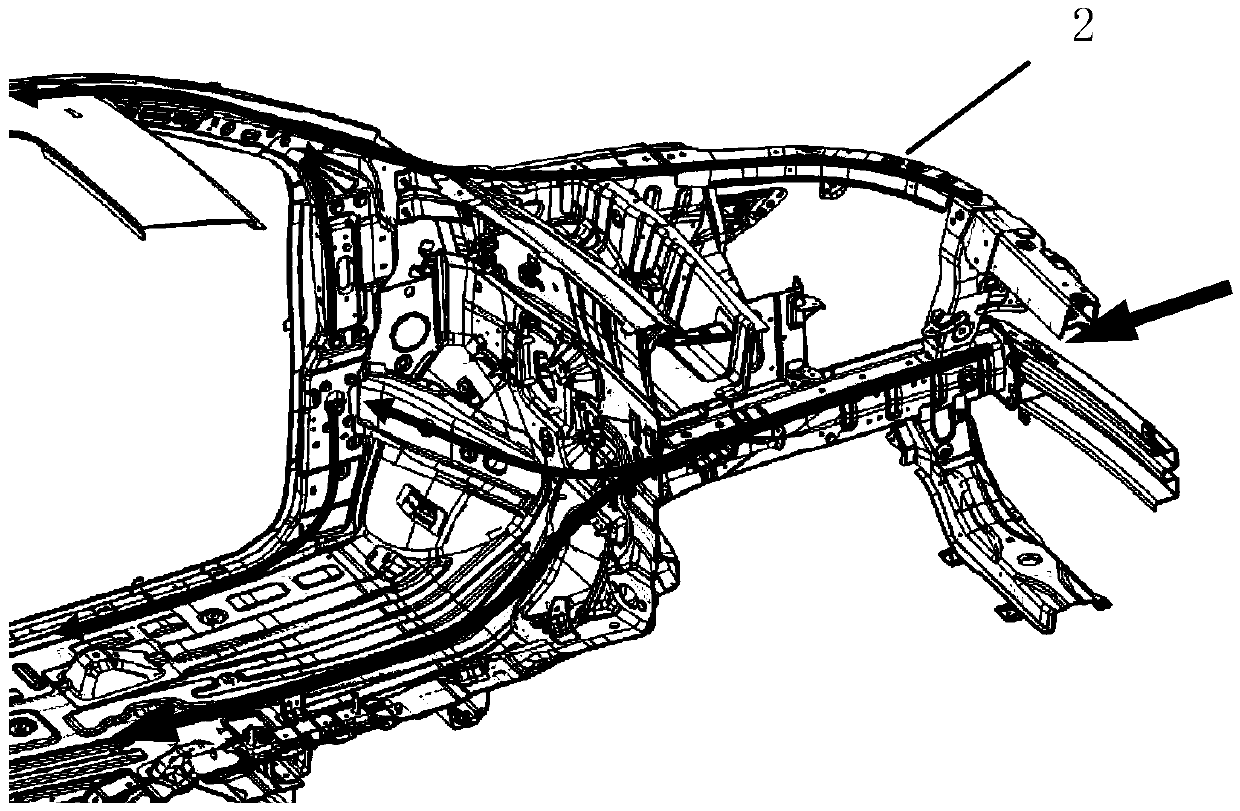

Reinforced body-in-white frame

PendingCN110962941AIncrease lateral stiffnessIncreased installation areaSuperstructure subunitsBumpersHead-on collisionEnergy absorption

The invention discloses a reinforced body-in-white frame, which comprises a vehicle body front end frame, a lower vehicle body frame, a side wall frame, a top cover frame and a tail frame. The upper portion of the vehicle body front end frame is fixedly connected with the front portion of the top cover frame. The rear portion of the vehicle body front end frame is fixedly connected with the frontportion of the lower vehicle body frame. The rear portion of the lower vehicle body frame is fixedly connected with the front portion of the tail frame. The upper portion of the tail frame is fixedlyconnected with the rear portion of the top cover frame. The longitudinal section of a front buffer beam and the longitudinal section of an energy absorption box of the vehicle body front end frame areboth in a shape like a Chinese character 'mu', and anti-collision supporting plates are arranged in the middle of the front buffer beam and a front end module. According to the reinforced body-in-white frame, the energy absorption capacity of the energy absorption area of the vehicle body front structure in the head-on collision process is increased, the transverse rigidity and the forecabin yawing mode of the vehicle body front structure are improved, the head-on collision safety performance and the force transmission efficiency are improved, the overall strength of the vehicle body frame isimproved, and therefore the riding comfort is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

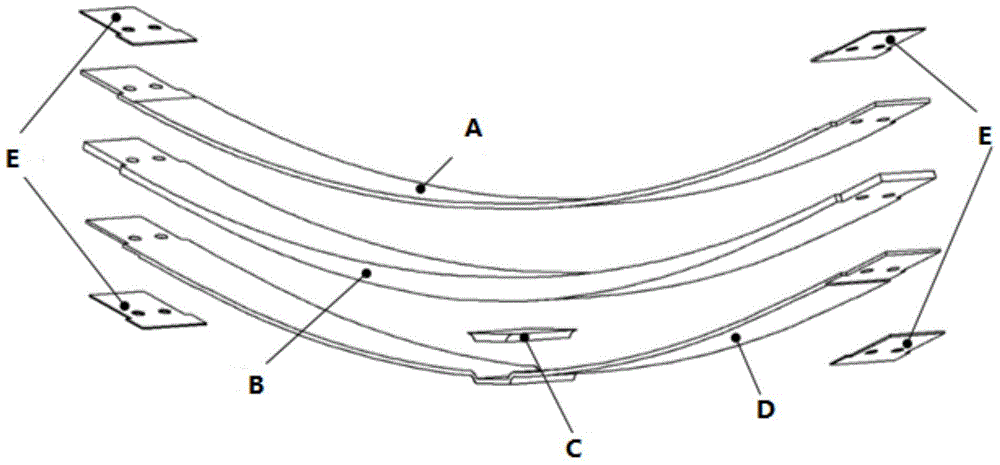

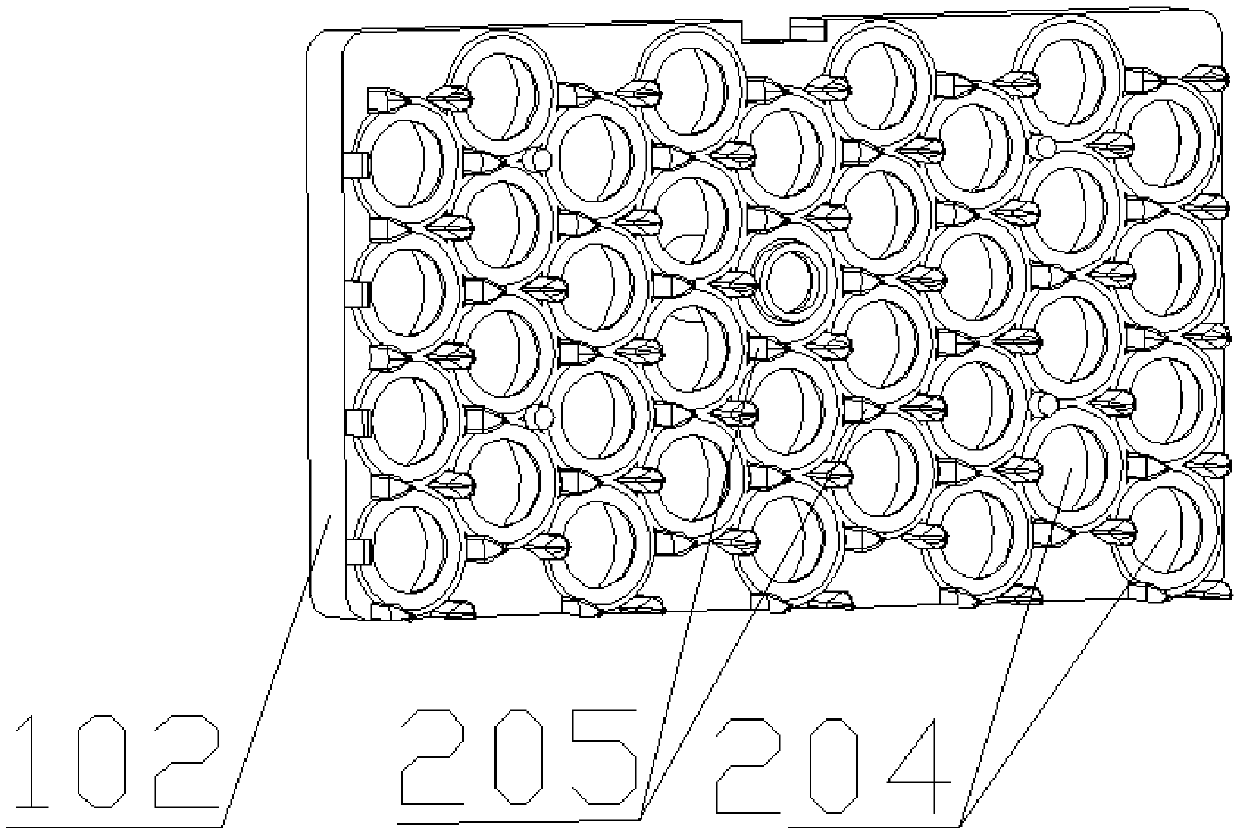

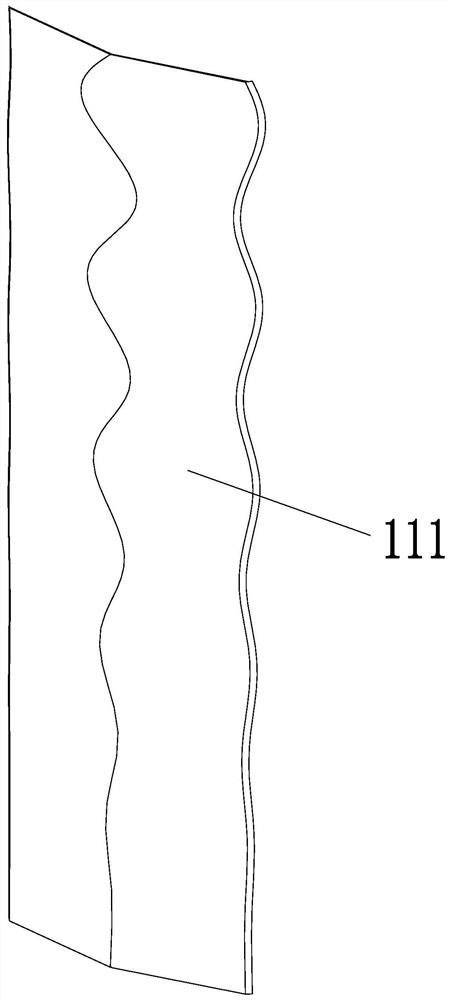

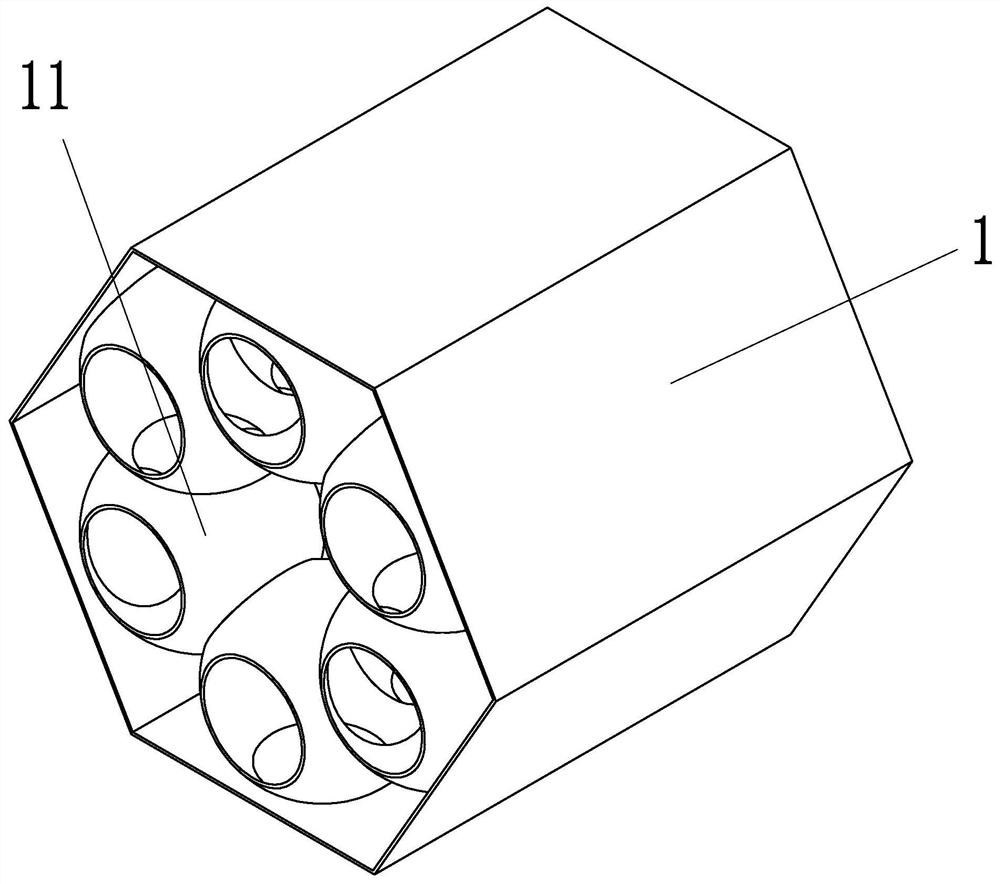

Composite material plate spring

ActiveCN104963978AImprove the level of lightweightImprove fatigue lifeLeaf springsMultiple spring combinationsFiberEngineering

The invention belongs to the field of plate springs, and particularly relates to a composite material plate spring. A spring body is in a parabola shape, and a boss structure is arranged in the middle of the spring body. Laying layers of the composite material plate spring are divided into an area A, an area B, an area C, an area D and an area E from top to bottom. Equilong long laying layers of a certain layer number are arranged in the area A and the area D. Equilong long laying layers and laying layers with gradually-changing length of a certain layer number are arranged in the area B, the long laying layers and the short laying layers are arranged alternately, and a genetic algorithm is adopted in the area B to optimize the sequence of the laying layers. The area C is of a boss structure formed by short laying layers of a certain layer number. Plain cloth laying layers of a certain layer number are arranged in the area E. The fiber arrangement direction of all the laying layers in the area A, the area B and the area D is consistent with the longitudinal direction of the spring body of the composite material plate spring. The composite material plate spring has the advantages that the spring is light, no hole needs to be drilled in the middle, the fatigue life is prolonged, and the strength of an end connector is improved.

Owner:JILIN UNIV +1

Multi-shaft steering system and automobile

InactiveCN103863384ASimple structureReasonable load distributionSteering linkagesAutomatic steering controlTransducerActuator

The invention relates to the technical field of automotive steering and discloses a multi-shaft steering system. The multi-shaft steering system comprises a steering gear, a front steering axle, an auxiliary steering axle and a rear drive axle, and also an angular transducer, an electronic control unit and an executer, wherein the angular transducer is mounted beside the steering gear, and the executer is mounted on a tie rod of the auxiliary steering axle; the angular transducer is used for obtaining the steering information of the front steering axle and transmitting the steering information to the electronic control unit; the electronic control unit is used for controlling the executer to work according to the received steering information; the executer is used for driving the tie rod to move from side to side so that the auxiliary steering axle and the front steering axle are turned synchronously. The multi-shaft steering system is simple in structure, and the electrically control assisted steering mechanism of the multi-shaft steering system enables the axle spread arrangement of two steering axles not to be limited by space, and a dual-axle steering synchronization mechanism is completely realized by the electronic control unit and the executer without a connecting rod mechanism.

Owner:CHANGSHA FOTON AUTOMOBILE TECH

Preparation method of automobile door frame integrally thermoformed by light-weight dissimilar steel

InactiveCN109759522AImprove the immunityImprove impact performanceShaping toolsVehicle componentsHot stampingHigh volume manufacturing

The invention provides a preparation method of an automobile door frame integrally thermoformed by light-weight dissimilar steel. The automobile door frame is formed by five parts and selects high-strength steel plates with different characteristics according to different mechanical property requirements. The processing technology comprises the steps of (1) laser cutting; (2) laser butt-welding; (3) integrally hot stamping and forming; and (4) acid pickling. The preparation method of the automobile door frame integrally thermoformed by the light-weight dissimilar steel provided by the invention has the beneficial effects that the high-strength steel plate material is selected and laser-cut into appropriate size, and integral hot-stamping and forming is adopted after laser butt-welding. Theoverall strength and the plasticity of an automobile front door frame are greatly improved, and the automobile door frame has high rigidity. The deformation resistance and the impact endurance of theautomobile door frame are improved, so that the safety of an automobile is improved; through hot stamping, the door frame is high in forming accuracy and low in resilience; and the tonnage of required stamping equipment is less. The weight of an automobile frame is reduced, so that the lightweight level of the automobile is improved. In addition, the preparation method of the automobile door frame integrally thermoformed by the light-weight dissimilar steel provided by the invention is simple in processing technology and high in efficiency, and meets the requirement of mass production, and the product is excellent in strength and plasticity and stable in quality.

Owner:SHANDONG JIANZHU UNIV

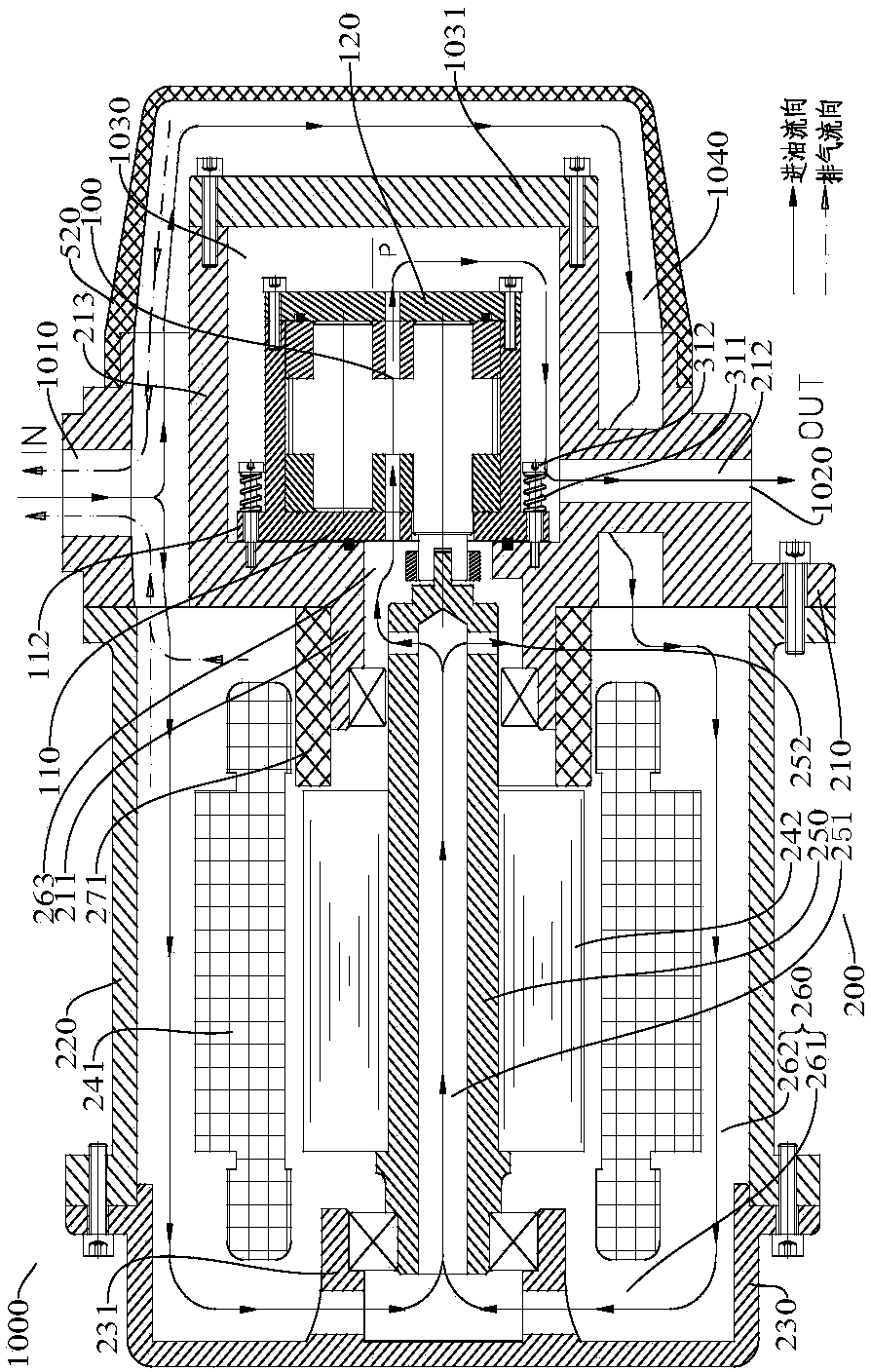

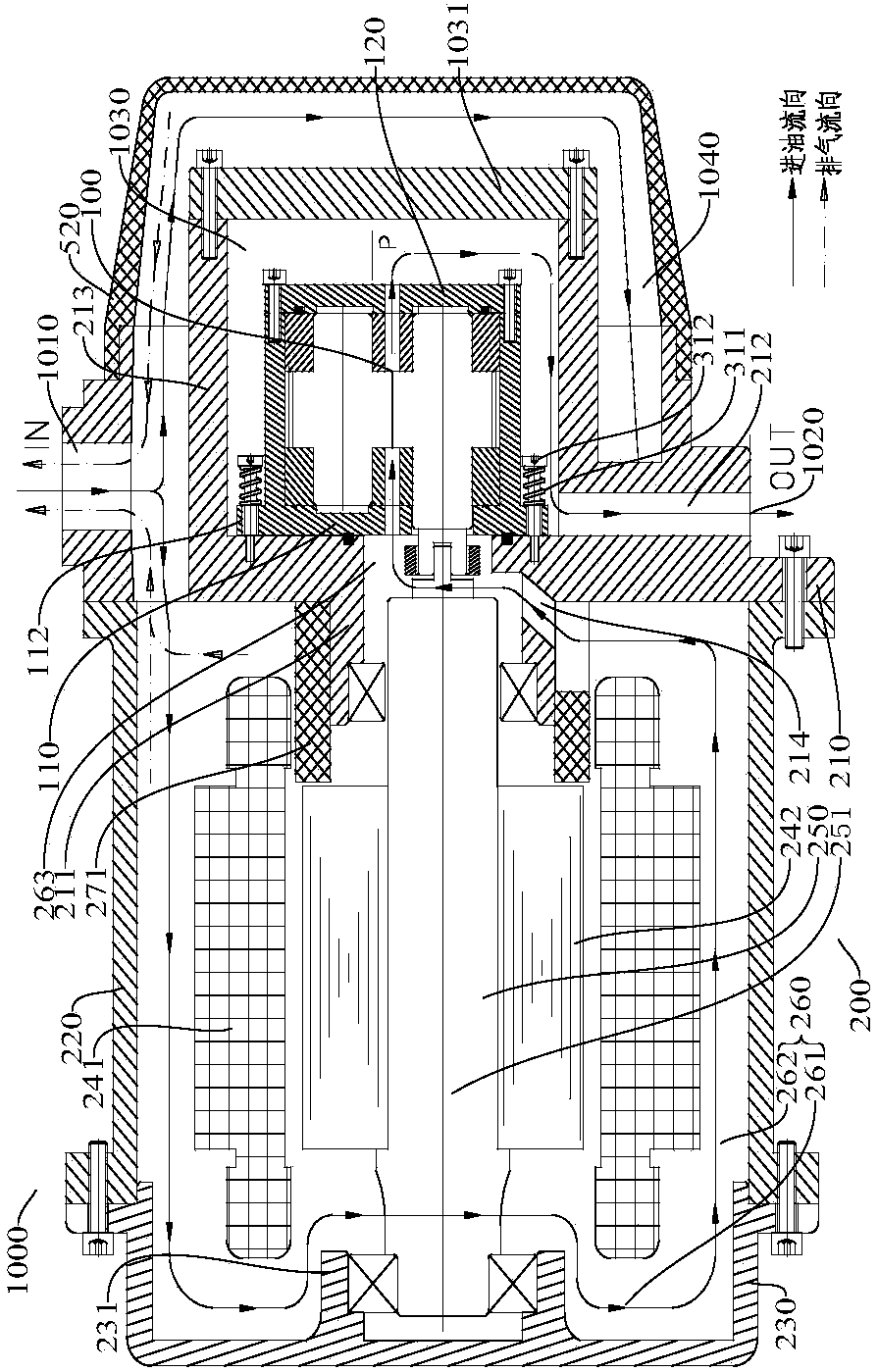

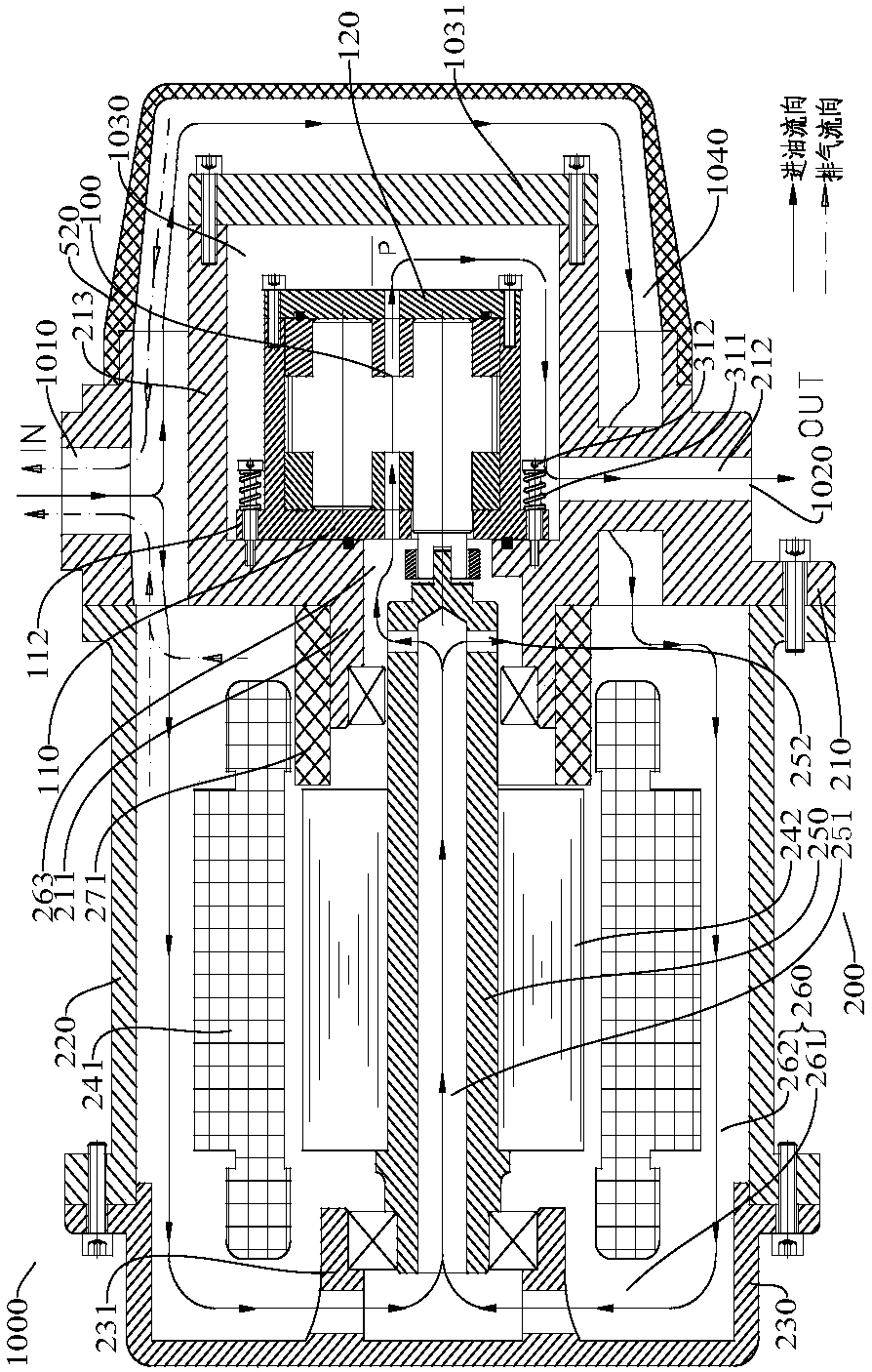

Electric oil pump assembly, steering system and lubricating system

ActiveCN109113954AImprove cooling effectImprove job stabilityPositive displacement pump componentsRotary/oscillating piston combinationsPower couplingMotor shaft

The invention discloses an electric oil pump assembly, a steering system and a lubricating system. The electric oil pump assembly is provided with a total oil inlet and a total oil outlet, and comprises a motor assembly and an oil pump assembly, wherein the motor assembly is provided with a liquid cooling cavity which is in communication with the total oil inlet, the liquid cooling cavity comprises circulating oil channels, and the circulating oil channels are located between a stator of the motor assembly and a motor shell of the motor assembly; the oil pump assembly is installed at the end part of the motor assembly and is in power coupling connection with a motor shaft of the motor assembly; and an oil suction port of the oil pump assembly is in communication with the circulating oil channels, and an oil discharge port of the oil pump assembly is in communication with the total oil outlet. According to the electric oil pump assembly, the oil absorption of the oil pump assembly and the heat dissipation of the motor assembly are realized through the arrangement of the circulating oil channels, the heat dissipation performance and the working stability of the electric oil pump assembly are improved, the integration degree is high, and the light weight level is high.

Owner:BYD CO LTD

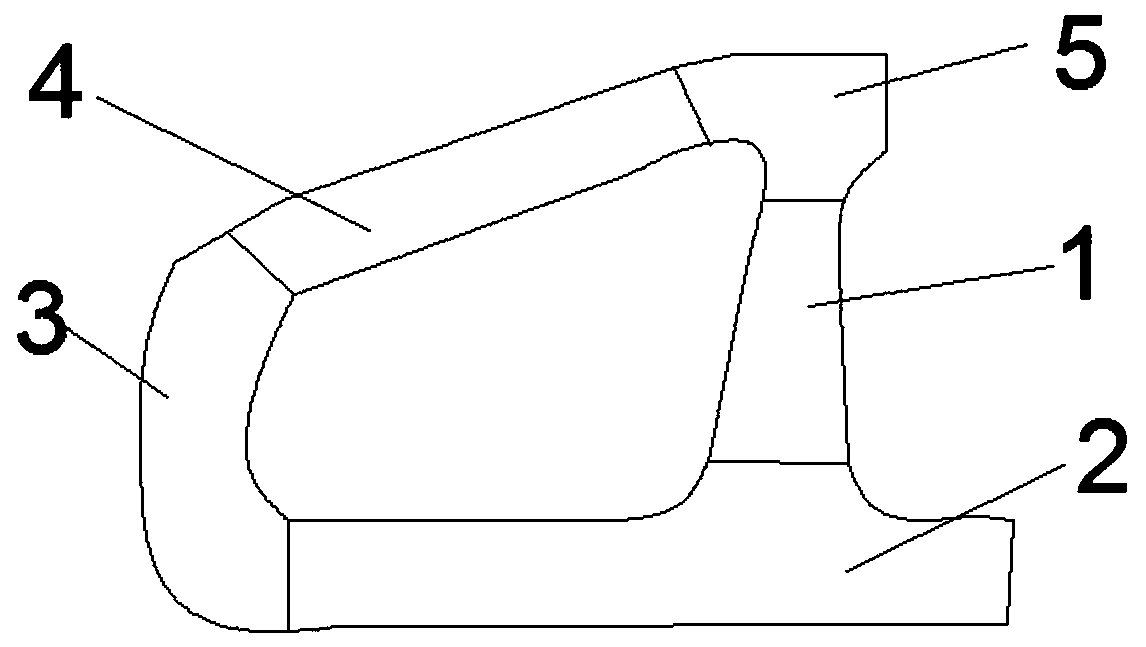

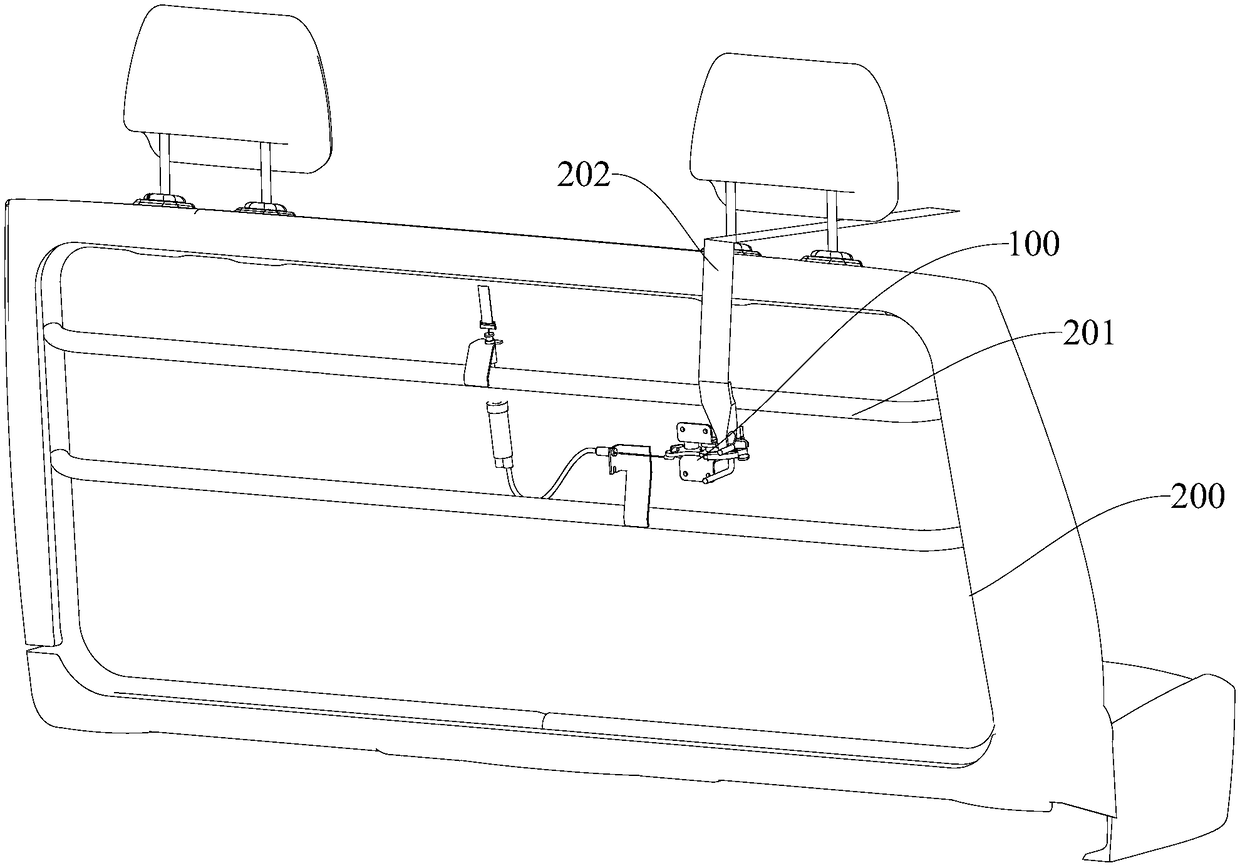

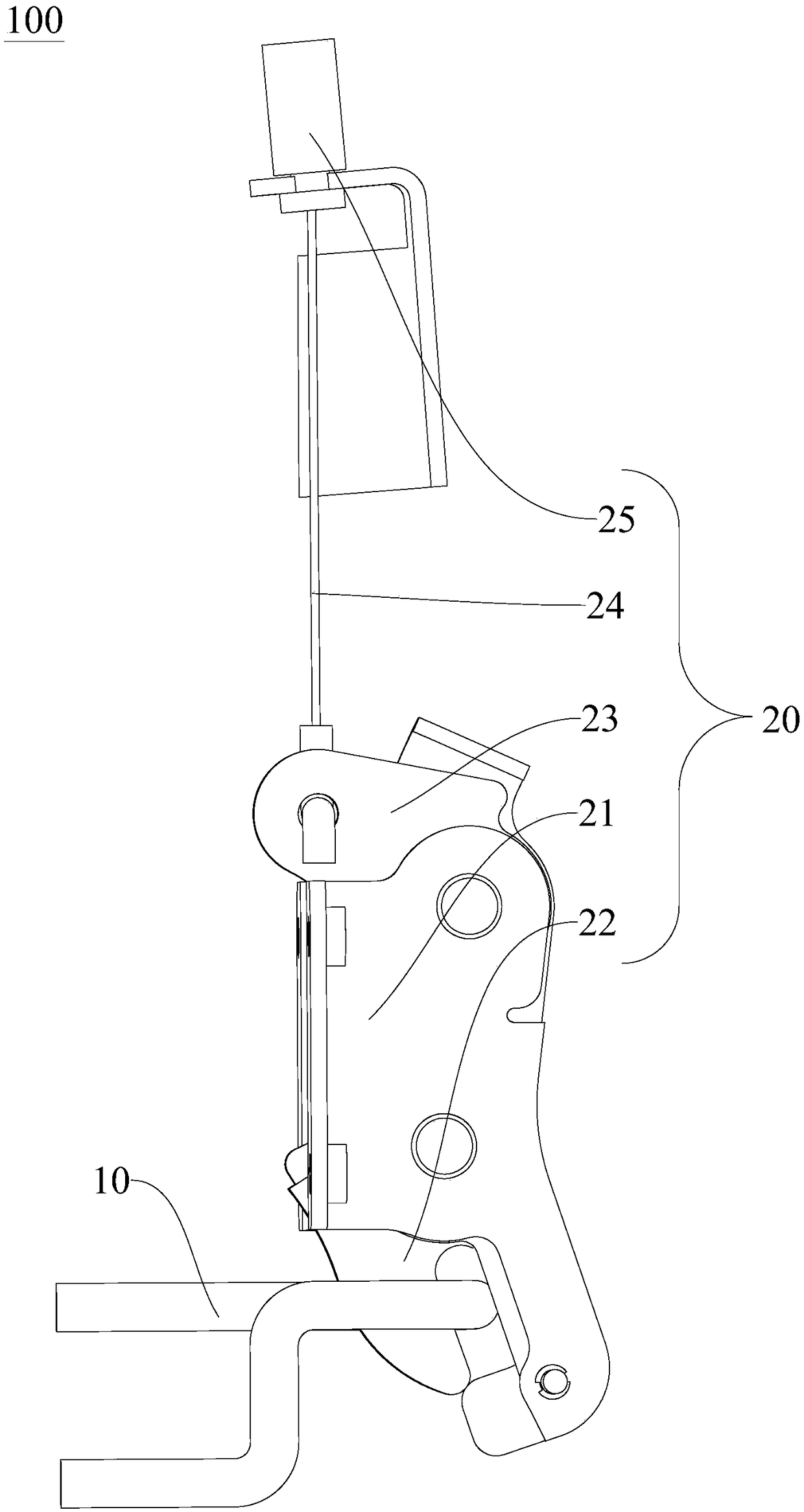

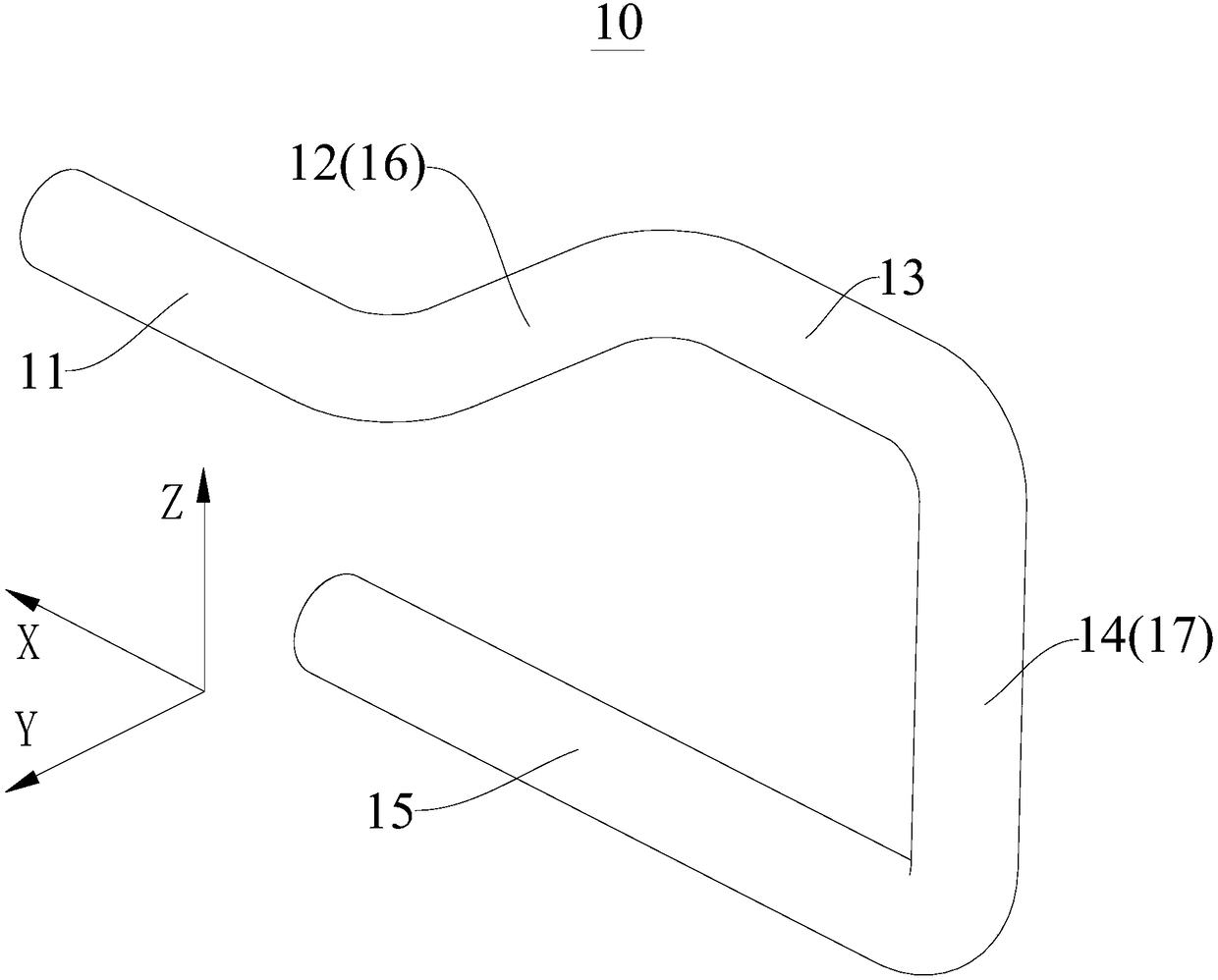

Backrest locking mechanism and vehicle

ActiveCN108608911ASpeed up R&D progressImprove the level of lightweightKids chairsMovable seatsLocking mechanismEngineering

The invention discloses a backrest locking mechanism and a vehicle. The backrest locking mechanism comprises a locking member and a lock body. The locking member comprises an integral lock hook and anupper drawstring fixing portion, and the upper drawstring fixing portion is suitable for being connected with an upper drawstring of a child seat. The lock body is selectively locked with the lock hook. One of the lock member and the lock body is mounted on a backrest, and the other one is mounted on a rear end panel of the vehicle. The backrest locking mechanism integrates the functions of fixing of the upper drawstring of the child seat and locking of the seat, does not require additional structural reinforcement design, can effectively accelerate the development progress of the whole vehicle, reduces the production cost, and contributes to improve the light weight level of the whole vehicle.

Owner:GREAT WALL MOTOR CO LTD

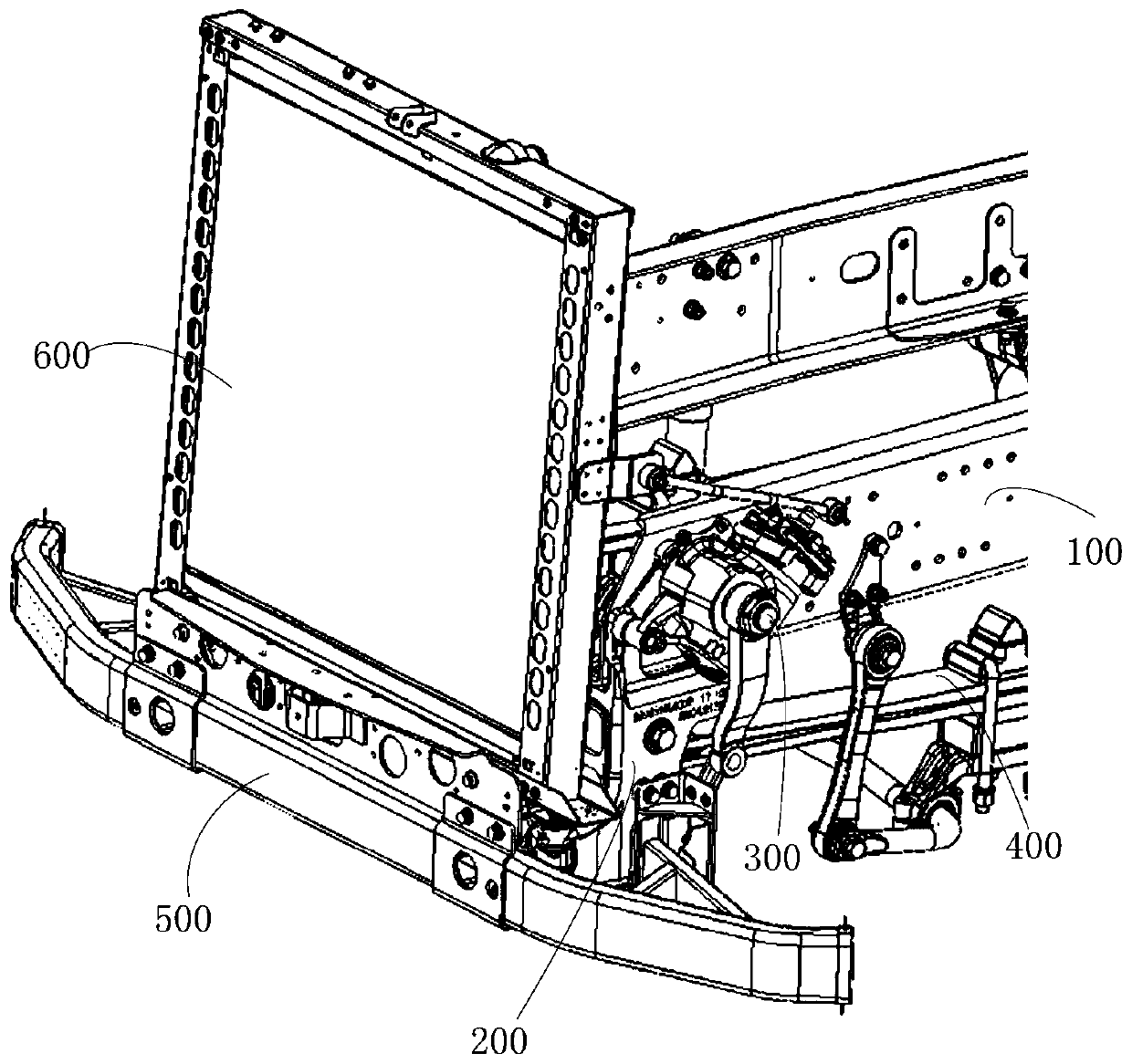

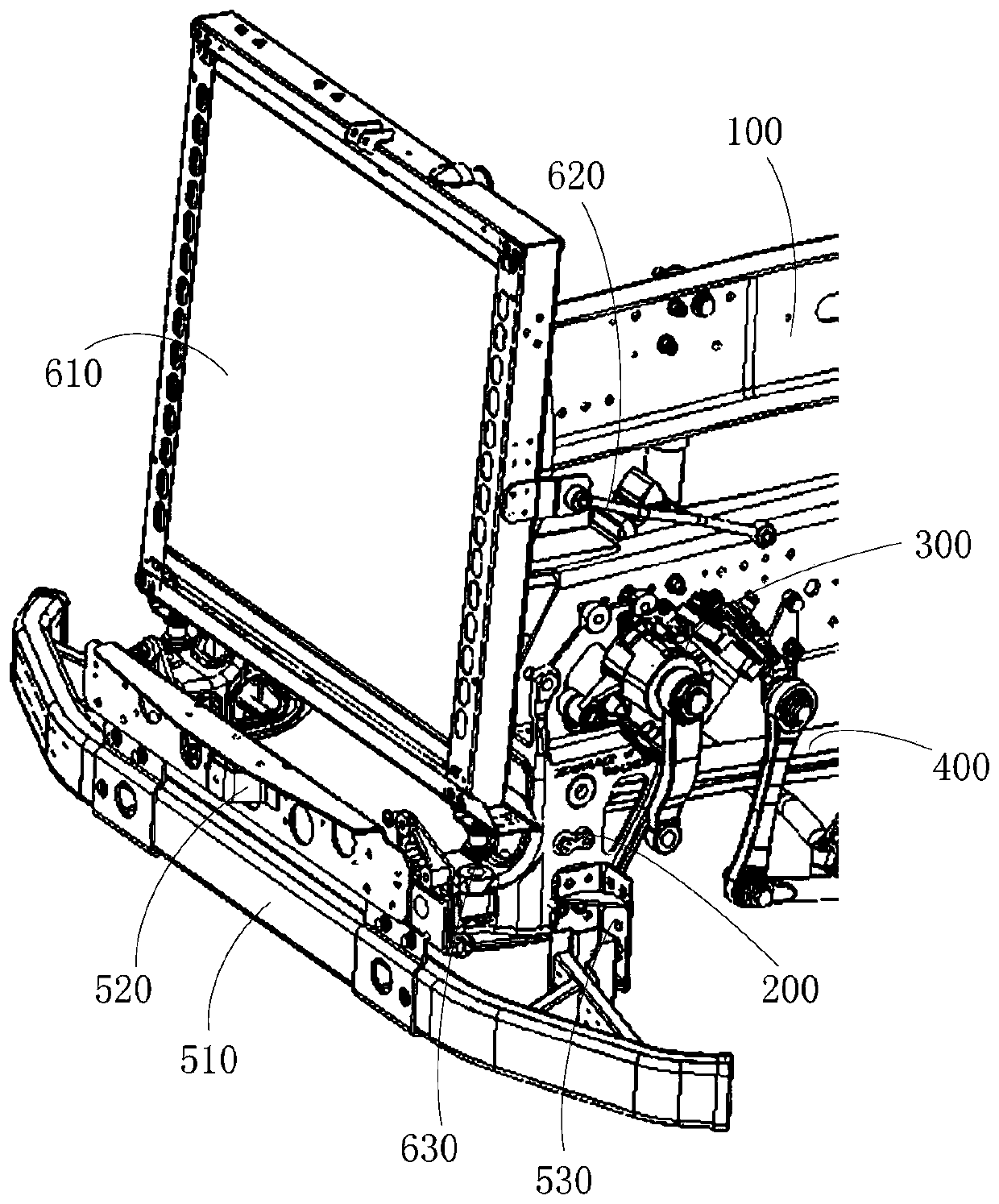

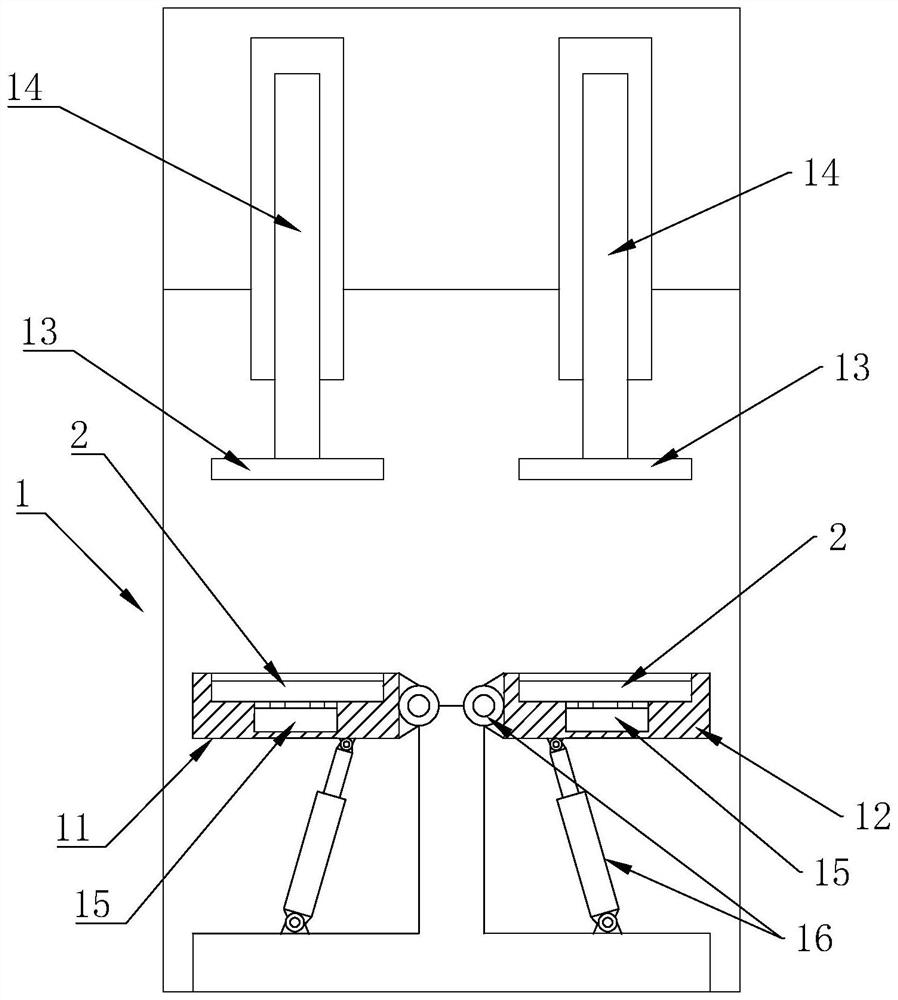

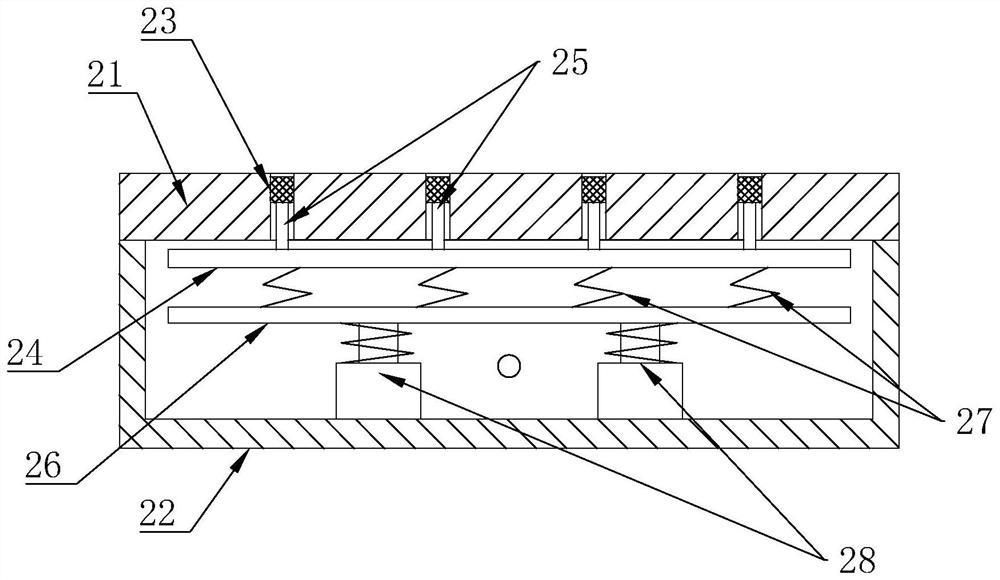

Heavy truck chassis front end module structure and chassis frame structure

ActiveCN110861712ALarge assembly spaceImprove assembly efficiencyUnderstructuresVehicle frameControl theory

The invention relates to a heavy truck chassis front end module structure and a chassis frame structure. The heavy truck chassis front end module structure comprises a chassis front end bracket, two front combined bracket structures arranged on the two sides of the chassis front end bracket respectively, a steering engine assembly arranged on the outer side of the front combined bracket structures, a front steel plate spring assembly arranged between the inner sides of the two front combined bracket structures, a radiator assembly and a front protection assembly. The bottom of the radiator assembly is arranged at the front ends of the two front combined support structures, the upper part of the radiator assembly is connected to the chassis front end bracket, the middle part of the front protection assembly is installed at the front ends of the two front combined bracket structures, and the two sides of the front protection assembly are correspondingly connected to the outer sides of the two front combined bracket structures respectively. The heavy truck chassis front end module structure aims to solve the problem that in a traditional technology, the front end structure of a chassis cannot meet the assembly performance and manufacturability requirements of a whole vehicle.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation process of EVA composite sole

PendingCN113370416AImprove skid resistanceNot easy to breedSolesSynthetic resin layered productsAnti bacteriaWear resistance

The invention discloses a preparation process of an EVA composite sole. The surface layers of adjacent shoe pieces of an EVA antibacterial and wear-resistant layer shoe piece, an EVA elastic and folding-resistant layer shoe piece and an EVA wear-resistant and slip-resistant layer shoe piece are heated and melted, then the adjacent shoe pieces are bonded together through a pressing mold, and the EVA composite sole with the EVA antibacterial and wear-resistant layer shoe piece, the EVA elastic an folding-resistant layer shoe piece and the EVA wear-resistant and slip-resistant layer shoe piece arranged on the upper layer, the middle layer and the lower layer correspondingly is finally formed. Due to the fact that the same EVA base material is adopted for bonding, when increasing influences of sunlight, temperatures and the like happen, the situation that the bonding position qualitatively changes, and consequently a shoe is damaged is not prone to happening, the overall structural strength is high, and the service life is long. The produced EVA composite sole has the composite performance of antibacterial performance, wear resistance, elasticity, folding resistance, wear resistance and slip resistance, and the EVA antibacterial and wear-resistant layer on the surface layer is not prone to breeding germs in a relatively warm and humid environment in summer when feet of a wearer sweat during sports.

Owner:晋江鲤峰鞋业有限公司

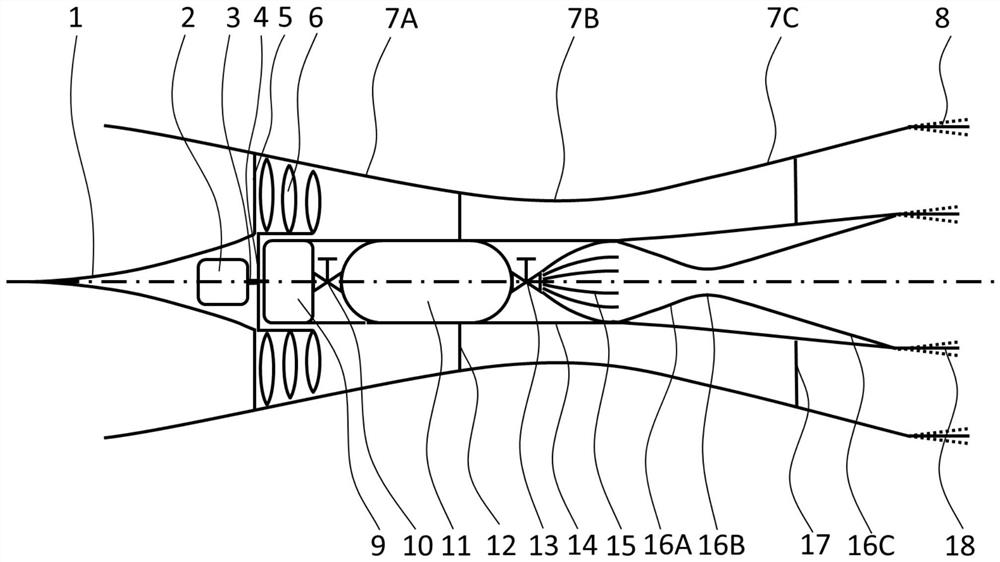

Double-duct hybrid power device, hovercar and control method

ActiveCN114103572AMeet supersonic flight requirementsIncrease top flight speedAircraft navigation controlEfficient propulsion technologiesClassical mechanicsAir compressor

The invention relates to the technical field of vehicles, in particular to a double-duct hybrid power device, a hovercar and a control method.The device comprises an outer duct, an inner duct and a compression propulsion system using compressed air as a working medium, the inner duct is arranged in the outer duct, and the outer duct and the inner duct are coaxially arranged; the outer duct comprises an air inlet end and an air outlet end, and an electric fan is arranged in the outer duct at the air inlet end; according to the description, the endurance mileage can be increased by using the compressed air, so that the unmanned aerial vehicle can achieve supersonic flight at a lower flight height; the air compressor and the outside atmosphere are used for supplementing pressure for the high-pressure air tank, the thrust ratio of the inner duct and the outer duct can be flexibly adjusted, and the hovercar can have higher thrust performance at the cost of sacrificing a certain mileage.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

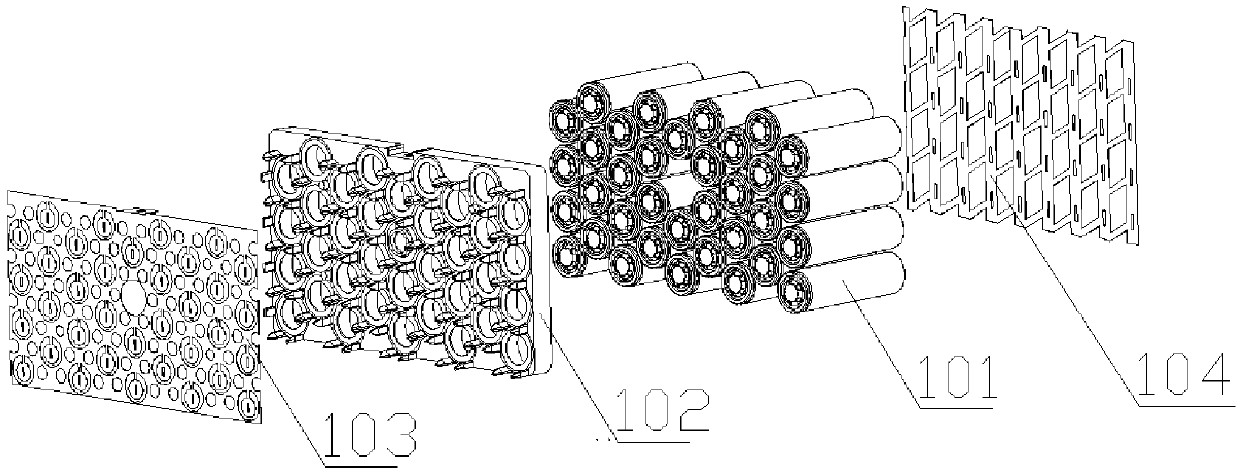

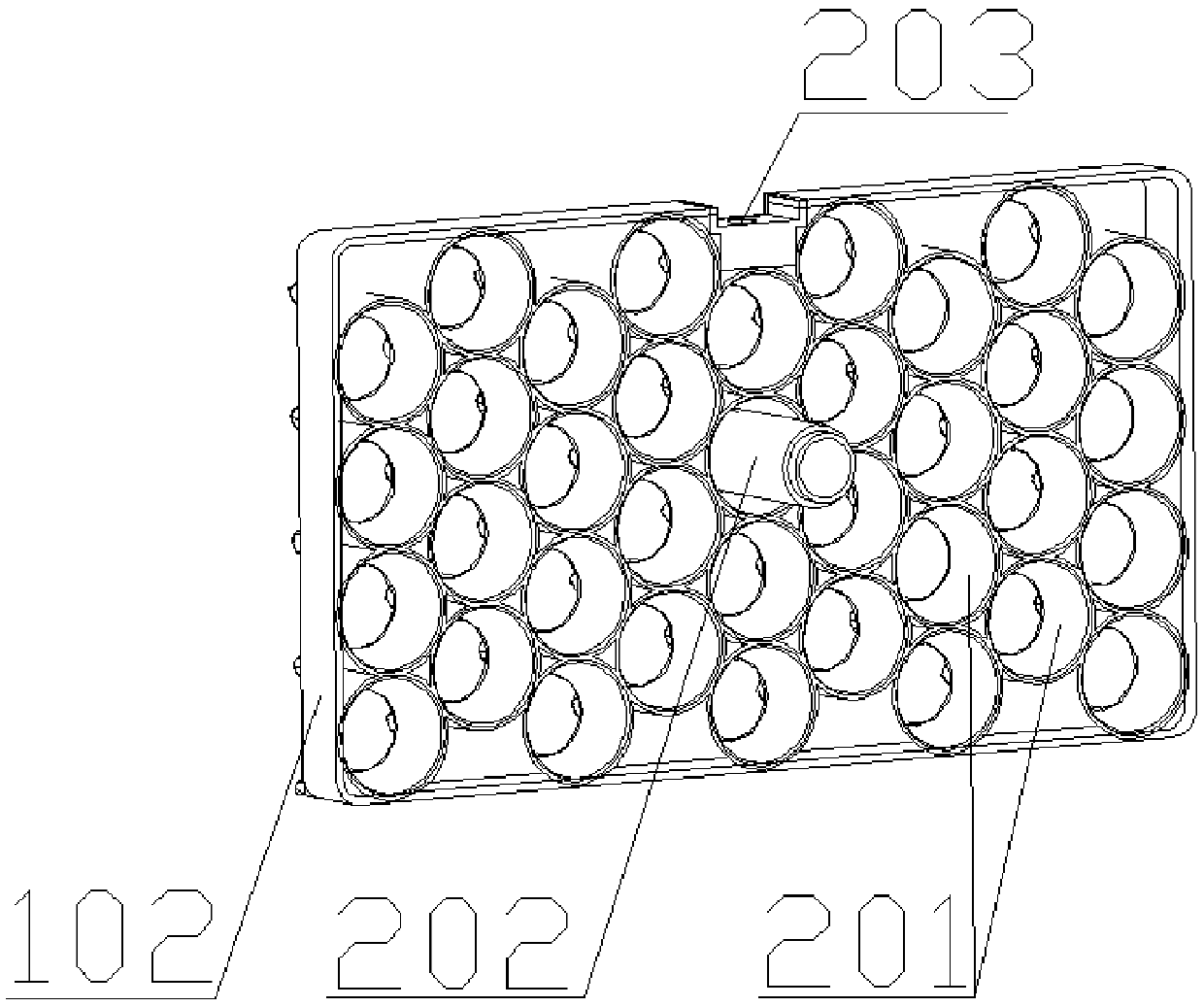

Battery module

PendingCN109659464AReduce manufacturing costReduce manufacturing qualityFinal product manufactureSmall-sized cells cases/jacketsBiochemical engineeringElectrical battery

The invention relates to the technical field of electric cars, in particular to a battery module. The battery module comprises a plurality of cells, an electric core fixing plate, a positive electrodeconflux sheet and a negative electrode conflux sheet, wherein the positive electrode conflux sheet is fitted to the electric core fixing plate, and are fixed on the end surfaces of the positive electrodes of the plurality of cells, and the negative electrode conflux sheet is fixed on the end surfaces of the negative electrodes of the plurality of cells; cellular units for fixing the cells, corresponding to the quantity of the cells are arranged at the inner side of the electric core fixing plate; a plurality of support posts are arranged at the outer side of the electric core fixing plate; and the support posts are used for fixing the positive electrode ends of the cells in single battery module, and the positive electrode end and the negative electrode end of the corresponding cell in the serially connected battery module. The battery module has simple structure, and design and reasonable design, can effectively reduce the manufacturing cost and total quality of the battery module, can improve the energy density of the battery module, can ensure the safety and reliability of the battery module, and can improve the light weight level of the battery module.

Owner:ZHENGZHOU BIKE NEW ENERGY AUTOMOBILE

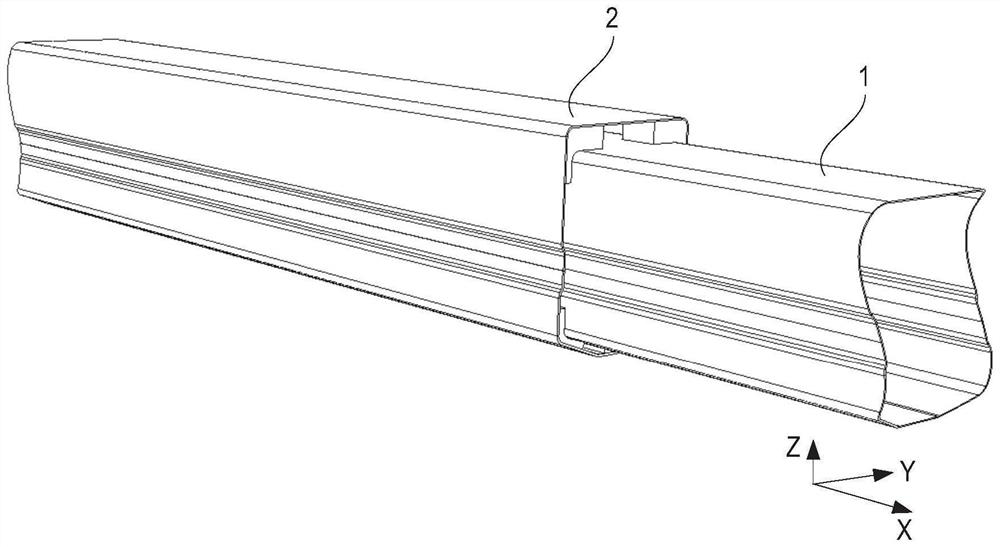

Cantilever crane, overhead working truck and cantilever crane manufacturing method

The invention discloses a cantilever crane, an overhead working truck and a cantilever crane manufacturing method, relates to the field of engineering machinery, and aims to improve the structure of the cantilever crane and improve the bearing capacity of the cantilever crane. The arm frame comprises at least two nested arm sections. And at least one arm section comprises a first cover plate and a second cover plate. The first cover plate is constructed to be integral and comprises a first side plate, a top plate and a second side plate which are arranged in sequence; the first side plate and the second side plate are oppositely arranged, and the free ends, away from the top plate, of the first side plate and the second side plate are both convex or concave. The second cover plate is constructed to be integral and comprises a third side plate, a bottom plate and a fourth side plate which are arranged in sequence; the third side plate and the fourth side plate are oppositely arranged, and the free ends, away from the bottom plate, of the third side plate and the fourth side plate are configured to be convex or concave. The free ends of the first side plate and the third side plate are fixedly connected, and the free ends of the second side plate and the fourth side plate are fixedly connected, so that the first cover plate and the second cover plate define a closed contour.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

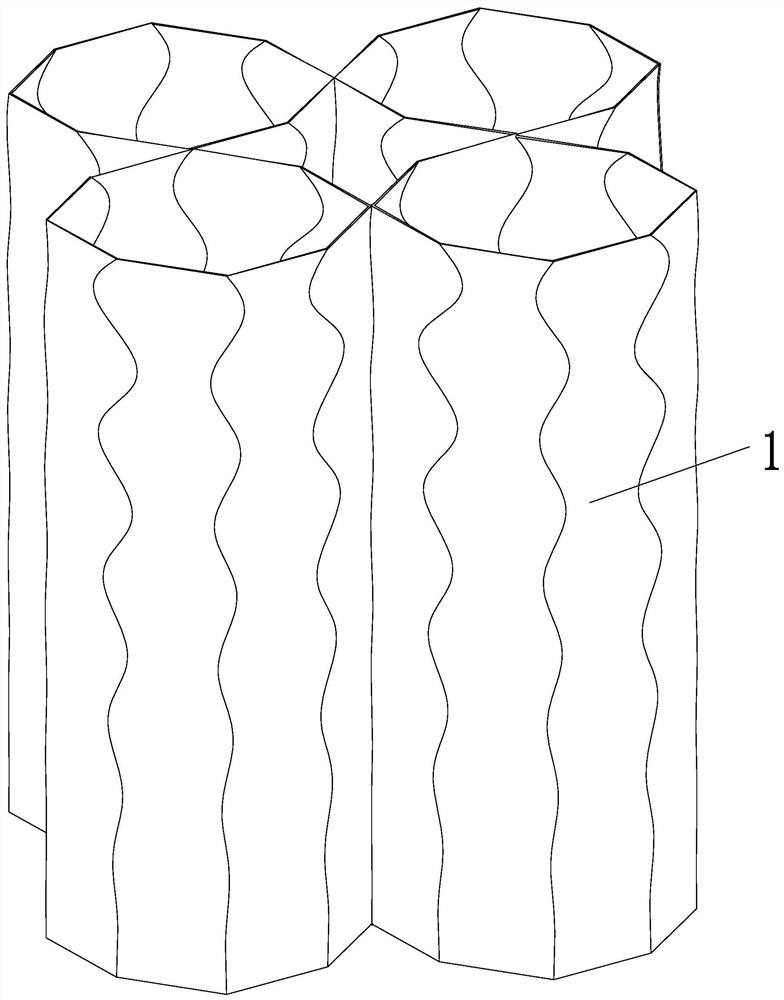

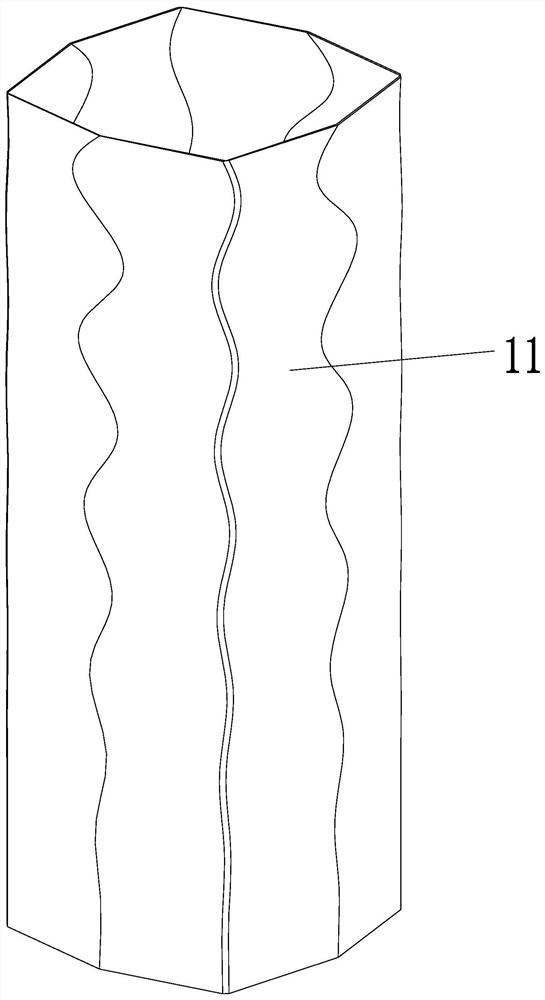

Corrugated energy absorption structure

PendingCN112900324AImproved energy absorptionContinuityRoadway safety arrangementsEnergy absorptionHigh energy

The invention provides a corrugated energy absorption structure which comprises a plurality of energy absorption columns, and each energy absorption column is formed by splicing a plurality of corrugated units pairwise. Each corrugated unit is formed by splicing two corrugated sheets; An angle is formed between the two corrugated sheets, and each corrugated sheet comprises straight line edges arranged on the upper side and the lower side; a corrugated curved surface is arranged between the two straight line edges, and the side view of the curved surface is a curve. By means of the technical scheme, the energy absorption structure can have high energy absorption capacity in the collision process.

Owner:HUAQIAO UNIVERSITY

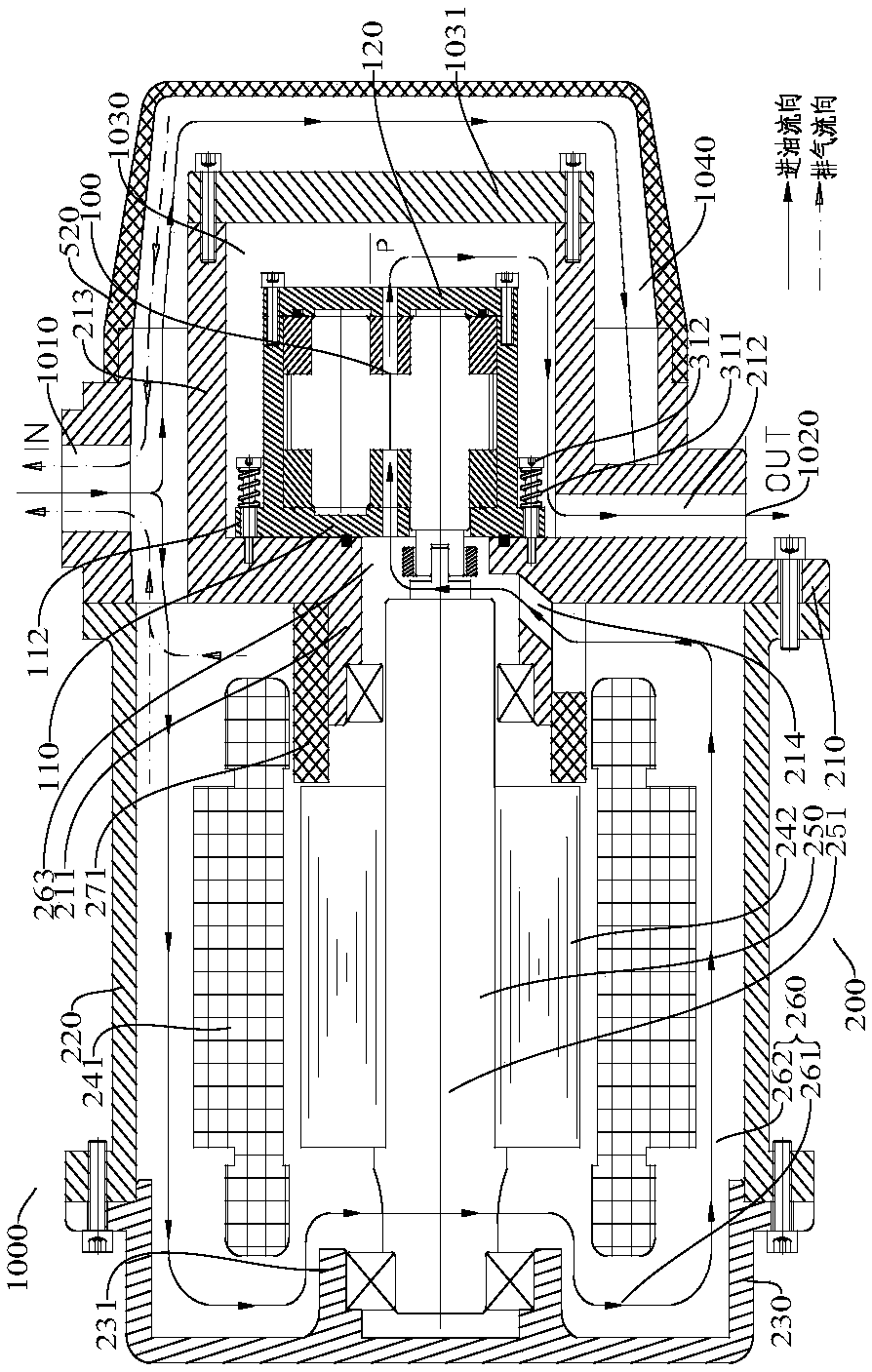

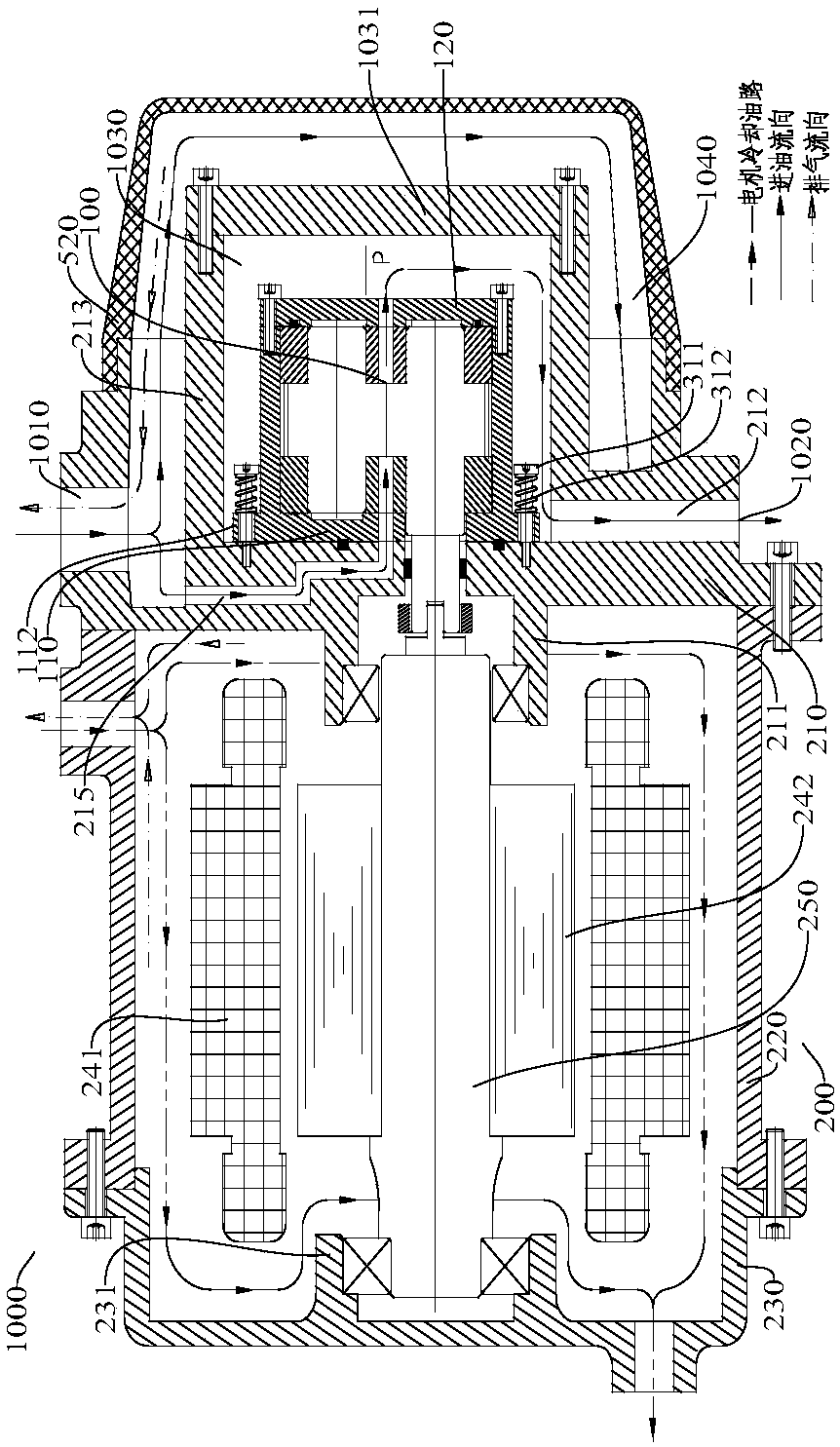

Electric oil pump assembly, steering system and lubricating system

ActiveCN109113962AImprove cooling effectImprove job stabilityPositive displacement pump componentsRotary/oscillating piston combinationsPower couplingMotor shaft

The invention discloses an electric oil pump assembly, a steering system and a lubricating system. The electric oil pump assembly is provided with a main oil inlet and a main oil outlet. A motor assembly, an oil pump assembly and a buckle are further included. The motor assembly is provided with a liquid cooling cavity communicating with the main oil inlet. The liquid cooling cavity comprises a circulation oil way located between a stator of the motor assembly and a motor shell of the motor assembly. The oil pump assembly is in power coupling connection with a motor shaft of the motor assembly. An oil suction port of the oil pump assembly communicates with the circulation oil way, and an oil outlet communicates with the main oil outlet. The buckle is connected between the oil pump assemblyand the motor assembly and is in clearance fit with one of the oil pump assembly and the motor assembly, and accordingly the oil pump assembly is supported at the end portion of the motor assembly ina floating manner. According to the electric oil pump assembly, the work energy efficiency of the oil pump assembly can be improved, the output pulse of the oil pump assembly is reduced, the heat dissipation performance and the work stability of the electric oil pump assembly are improved, and the machining precision and assembling precision requirement of the electric oil pump assembly can be lowered.

Owner:BYD CO LTD

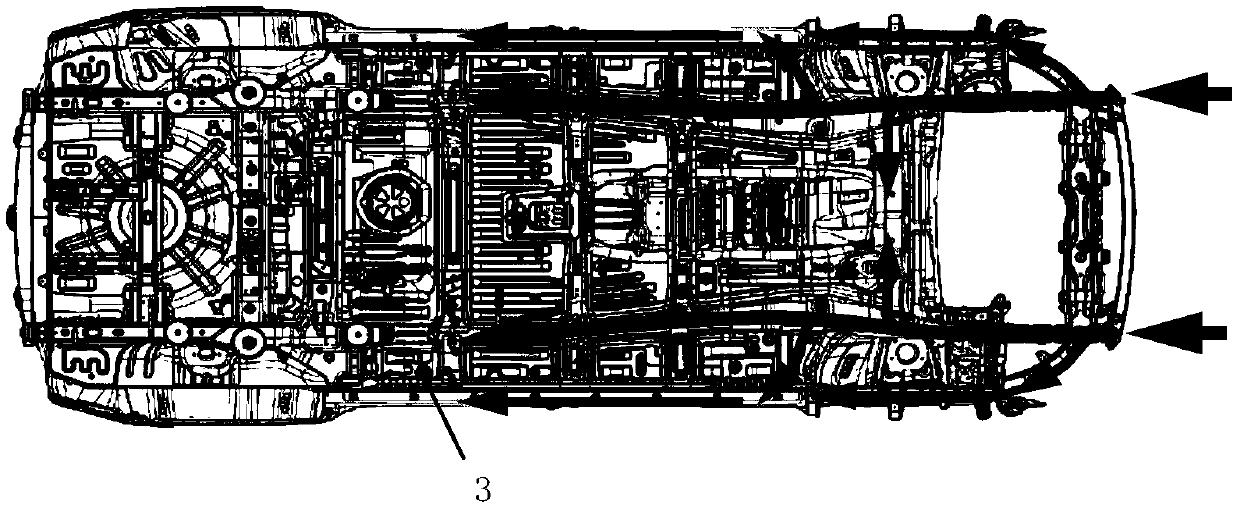

Body back panel of vehicle, bumper installation assembly and vehicle

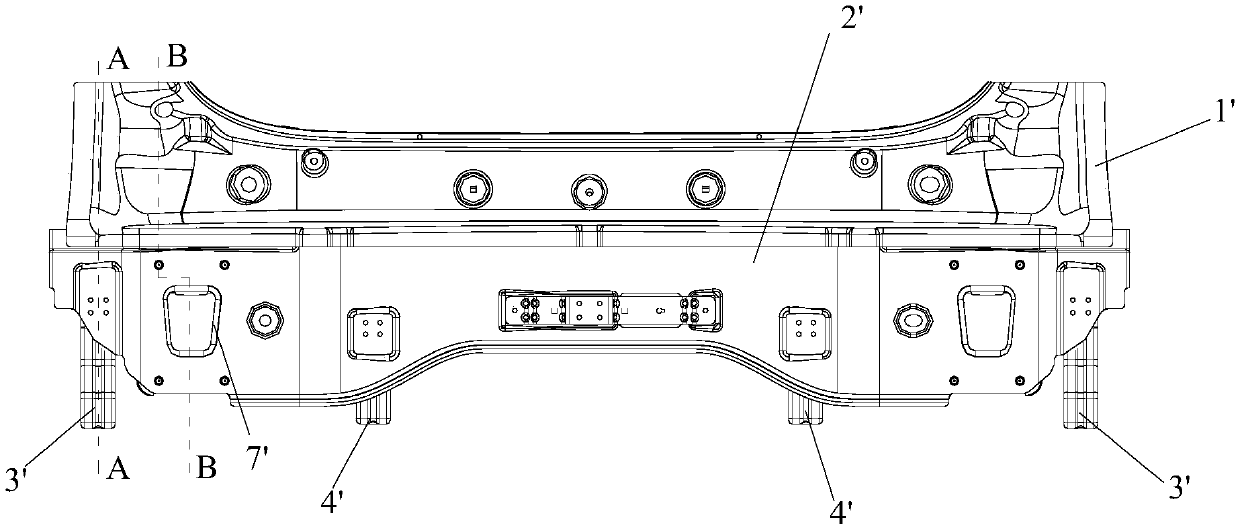

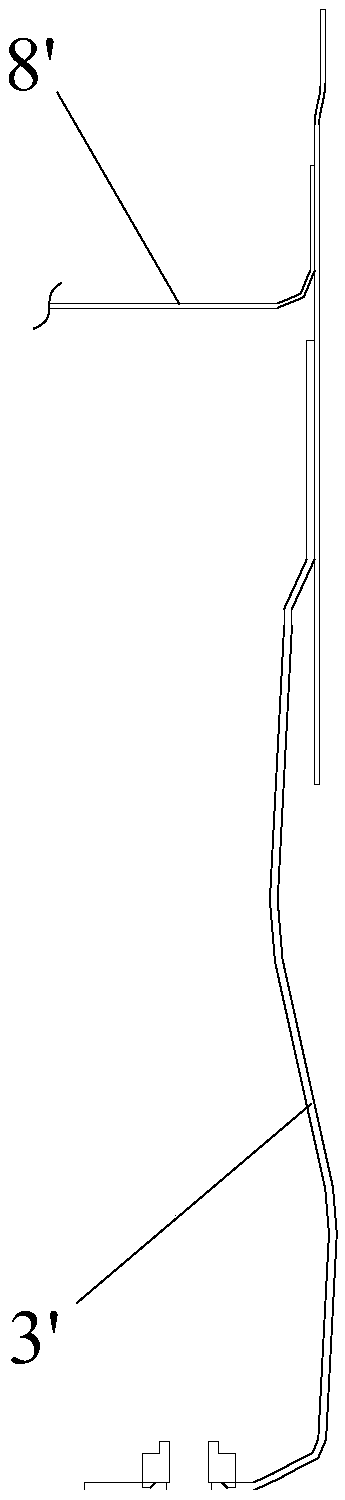

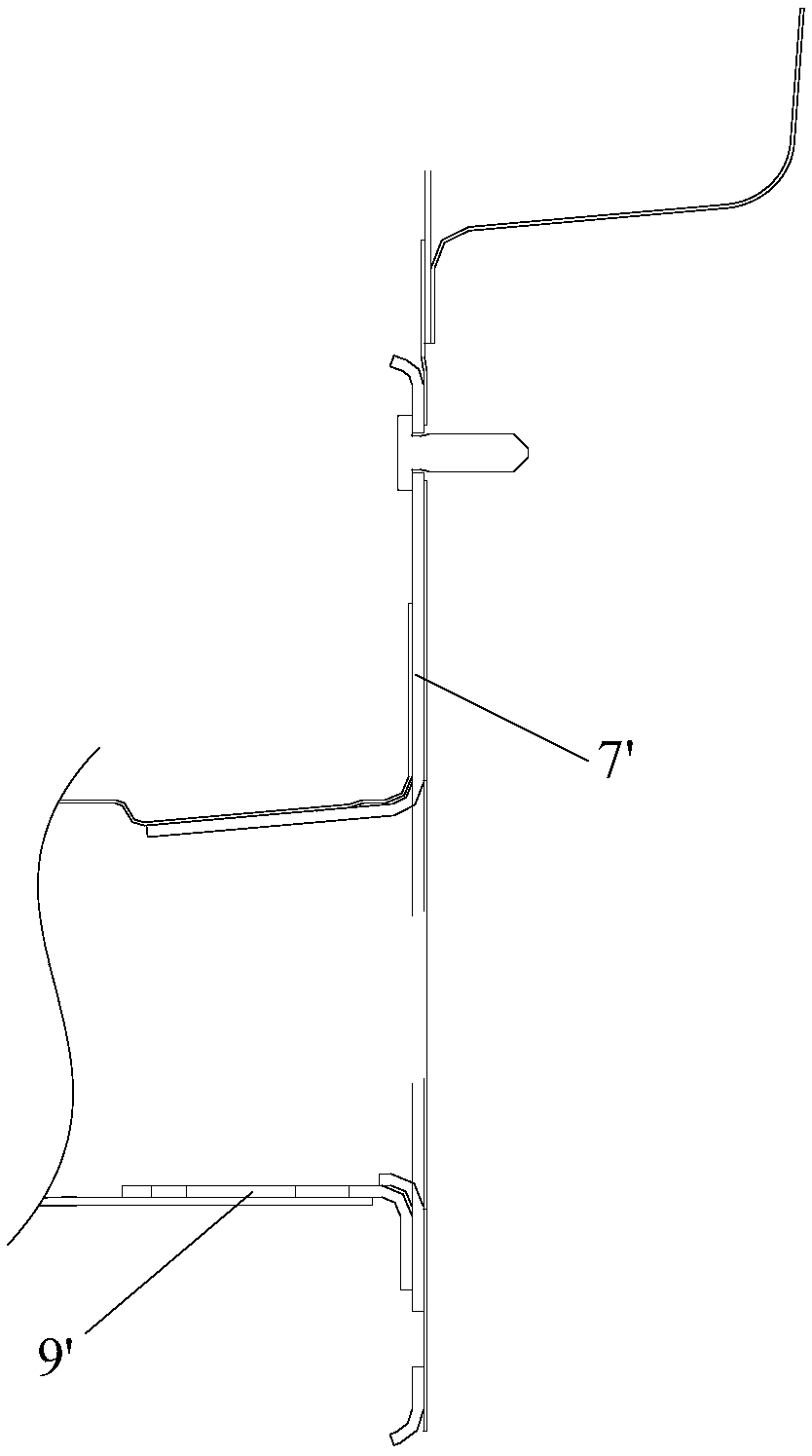

InactiveCN110282023AImprove the level of lightweightReduce weightSuperstructure subunitsBumpersEngineering

The invention provides a body back panel of a vehicle, a bumper installation assembly and the vehicle. The body back panel of the vehicle comprises a back wall inner plate (2). The middle portion, in the length direction, of the back wall inner plate (2) downwards protrudes relative to the two ends. When back longitudinal beam cover plates (3) of the vehicle are connected to the ends of the back wall inner plate (2), a part of each back longitudinal beam cover plate (3) protrudes downwards and is exposed at the end of the back wall inner plate (2). The body back panel of the vehicle effectively solves the problem that in the prior art, a body back panel of the vehicle is large in mass.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

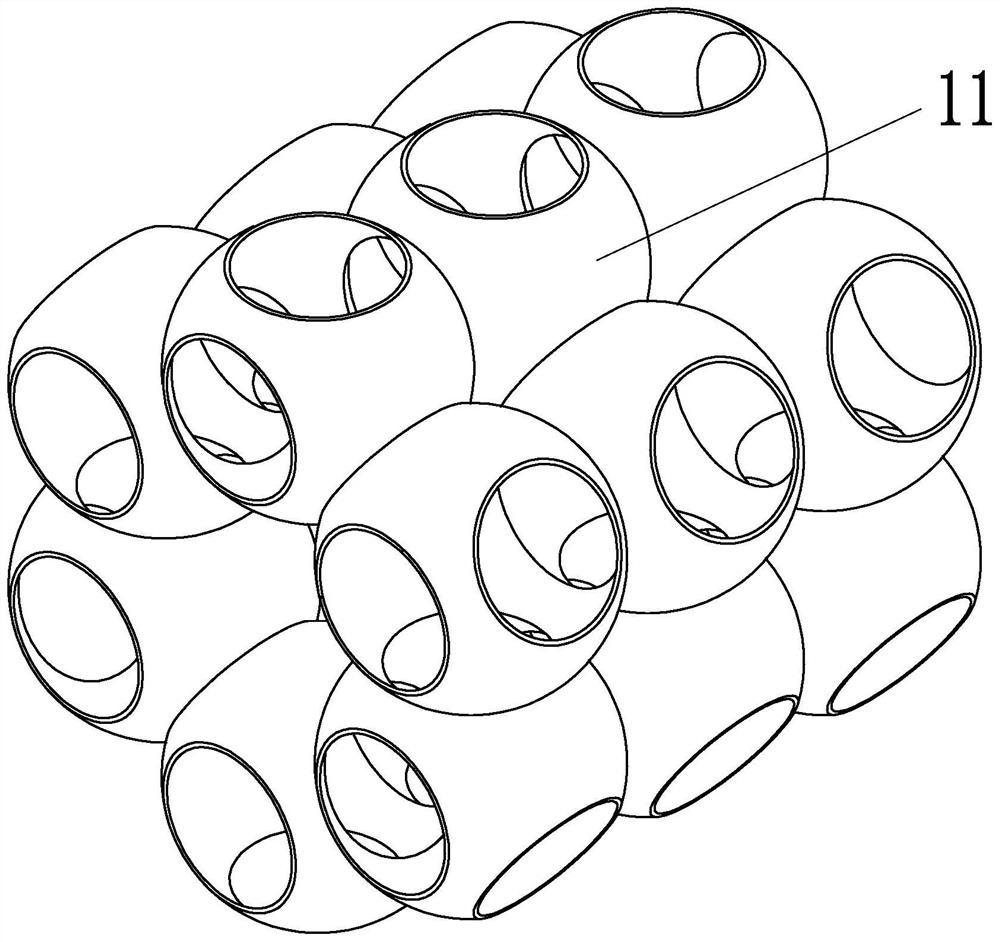

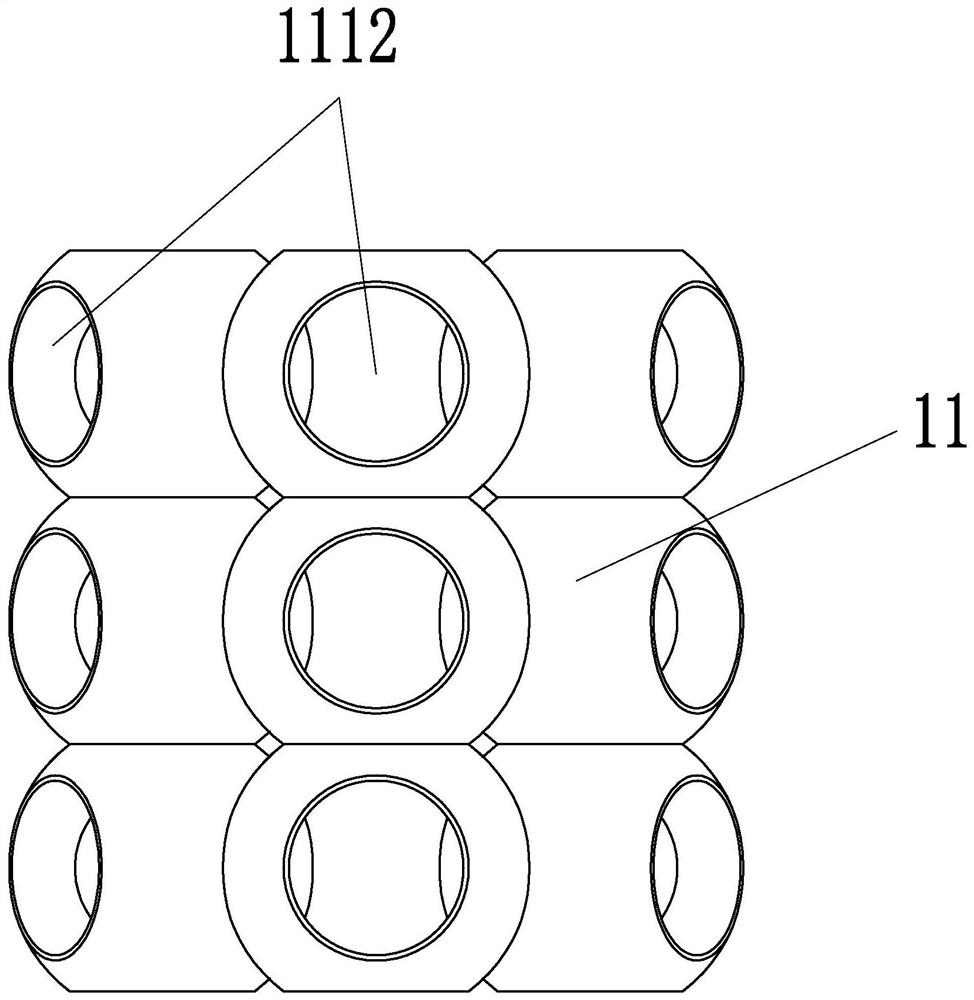

Metamaterial energy absorption structure based on Boolean operation

PendingCN112861270AMaximize Mechanical PropertiesGood mechanical propertiesGeometric CADNon-rotating vibration suppressionTriacontagonEnergy absorption

The invention provides a Boolean operation-based metamaterial energy absorption structure, which comprises an energy absorption box, and is characterized in that the energy absorption box consists of a plurality of metamaterial structures; the metamaterial structure is composed of a plurality of metamaterial monomers; a thin spherical shell is arranged in a regular polygon prism, and the vertical distance between the center of the regular polygon prism and each side face and the bottom face of the regular polygon prism is smaller than the radius of the thin spherical shell. Then Boolean operation is carried out on the thin spherical shell and the regular polygon prism in a manner that: the part, which is arranged in the regular polygon prism and overflows out of each side surface and the bottom surface of the regular polygon prism, of the thin spherical shell is an overflow part, and the overflow part of the thin spherical shell is removed to obtain the metamaterial monomer. By applying the technical scheme, lightweight protection and efficient energy absorption of the energy absorption box can be achieved.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com