Ultra-light high-sound-absorption GMT reinforced PU thermoplastic automotive trim composite board and preparation method thereof

A technology of automotive interior and thermoplastic, applied in the field of automotive interior and exterior decoration, can solve problems such as poor air permeability, glue sealing, complex process, etc., and achieve the effect of increasing specific strength, improving sound absorption level, and improving light weight level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

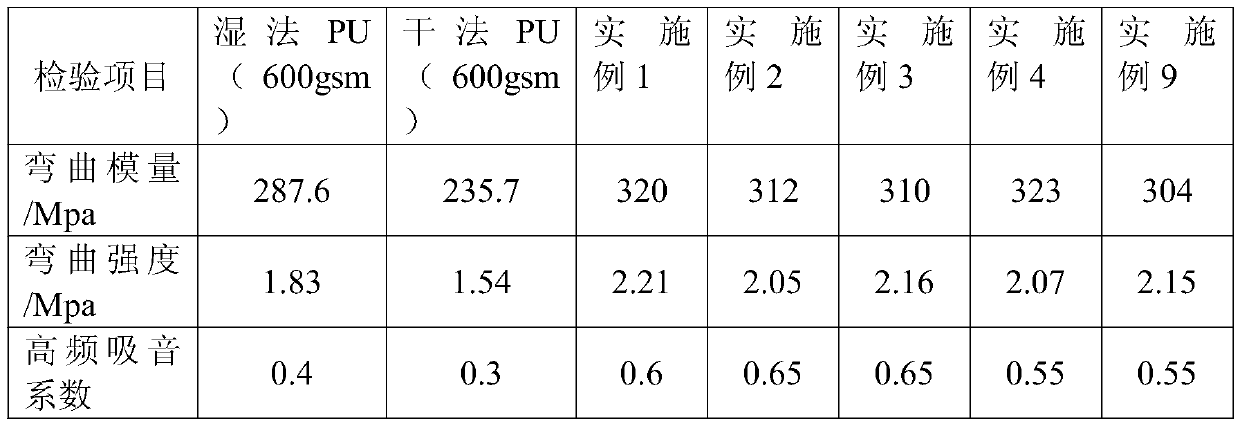

Examples

Embodiment 1

[0031] This embodiment is an ultra-light and high-sound-absorbing GMT reinforced PU thermoplastic automotive interior composite board. layer, non-woven film.

[0032] The GMT reinforcement layer is prepared by a non-woven needle punching reinforcement process with a mass proportion of 50% thermoplastic resin fibers and a mass proportion of 50% reinforcement fibers. The thermoplastic resin fiber is modified polypropylene fiber PP, and the reinforcing fiber is modified glass fiber. The process parameters of nonwoven needling reinforcement are: needle depth 8cm, needle density 50 times / cm 2 .

[0033] The non-woven film is PP for bonding, and the weight is 40g / m 2 , The melt index of thermoplastic resin is 10g / 10min, and the non-woven film is manufactured by hot rolling process, showing a network structure.

[0034] It is prepared as follows:

[0035] The polypropylene fiber with a mass fraction of 50% and the glass fiber with a mass fraction of 50% were opened, then cross-l...

Embodiment 2

[0039] This embodiment is an ultra-light and high-sound-absorbing GMT reinforced PU thermoplastic automotive interior composite board. layer, non-woven film.

[0040] The GMT reinforcement layer is made of thermoplastic resin fibers accounting for 30% by mass and reinforcing fibers accounting for 70% by mass through a non-woven needle punching reinforcement process. The thermoplastic resin fiber is modified polypropylene fiber PP, and the reinforcing fiber is modified glass fiber. The process parameters of nonwoven needling reinforcement are: needle depth 5cm, needle density 30 times / cm 2 .

[0041] The non-woven film is PP for bonding, and the weight is 40g / m 2 , The melt index of the thermoplastic resin is 20g / 10min, and the non-woven film is manufactured by needle-punching process, showing a network structure.

[0042] It is prepared as follows:

[0043]After the mass fraction of 30% polypropylene fibers and 70% glass fibers are opened, then cross-laminated, and then n...

Embodiment 3

[0047] This embodiment is an ultra-light and high-sound-absorbing GMT reinforced PU thermoplastic automotive interior composite board. layer, non-woven film.

[0048] The GMT reinforcement layer is prepared by a non-woven needle punching reinforcement process with a mass proportion of 50% thermoplastic resin fibers and a mass proportion of 50% reinforcement fibers. The thermoplastic resin fiber is a mixture of 20% modified polypropylene fiber PP and 30% nylon fiber PA, and the reinforcing fiber is modified glass fiber. The process parameters of nonwoven needling reinforcement are: needle depth 5cm, needle density 30 times / cm 2 .

[0049] The non-woven film is PP for bonding, and the weight is 40g / m 2 , The melt index of thermoplastic resin is 30g / 10min, and the non-woven film is manufactured by spunlace process, showing a network structure.

[0050] It is prepared as follows:

[0051] After the mass fraction of 20% polypropylene fiber, 30% nylon fiber PA and 50% glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com