Complex thin wall aluminum alloy stair die casting forming technology

A technology of die-casting and aluminum alloy, which is applied in escalators, transportation and packaging, and can solve problems such as high energy consumption, high overall weight of aluminum alloy die-casting steps, and imperfect die-casting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

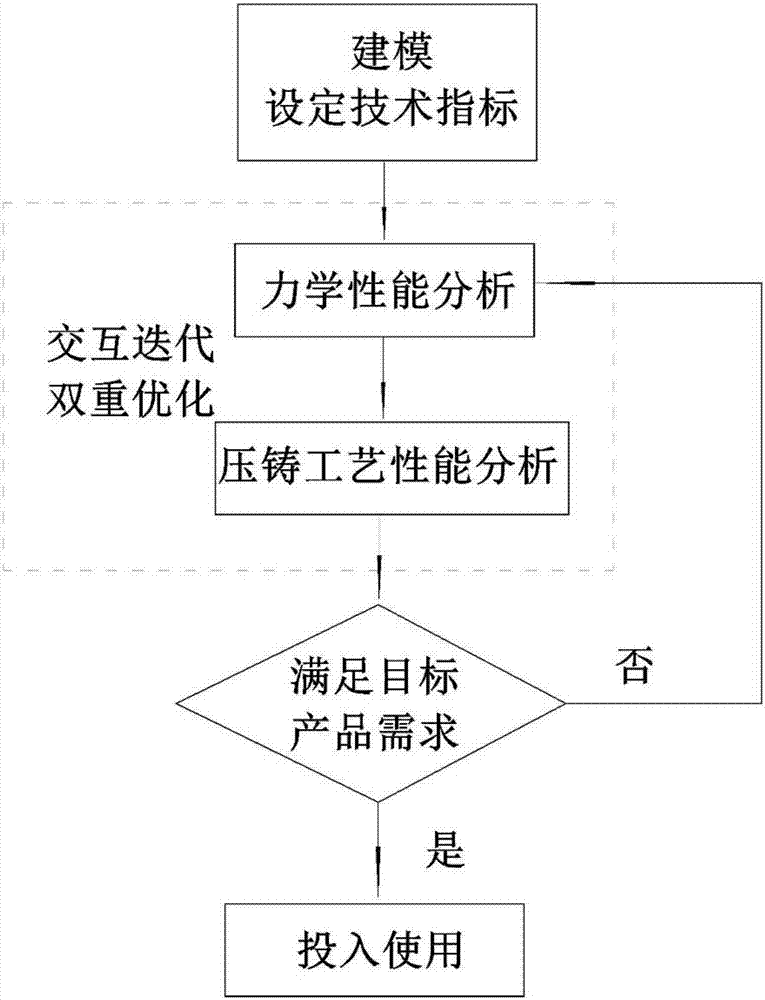

[0029] The invention provides a complex thin-walled aluminum alloy stepped die-casting forming technology, referring to figure 1 , the innovation point is: adopt the following steps:

[0030] Step 1: Based on the mechanical performance parameters of aluminum alloy, construct a complex thin-walled aluminum alloy step model and set technical indicators;

[0031] Step 2: Use professional software to analyze the mechanical properties of the complex thin-walled aluminum alloy cascade structure and optimize the structure;

[0032] Step 3: Use professional software to analyze the die-casting process performance of complex thin-walled aluminum alloy steps, predict and confirm the point and surface p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com