Preparation process of EVA composite sole

A composite shoe sole and preparation technology, which is applied in the direction of shoe soles, footwear, synthetic resin layered products, etc., can solve the problems of odor, wear resistance, anti-skid and light weight performance, and accumulation of sweat stains in sports shoes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

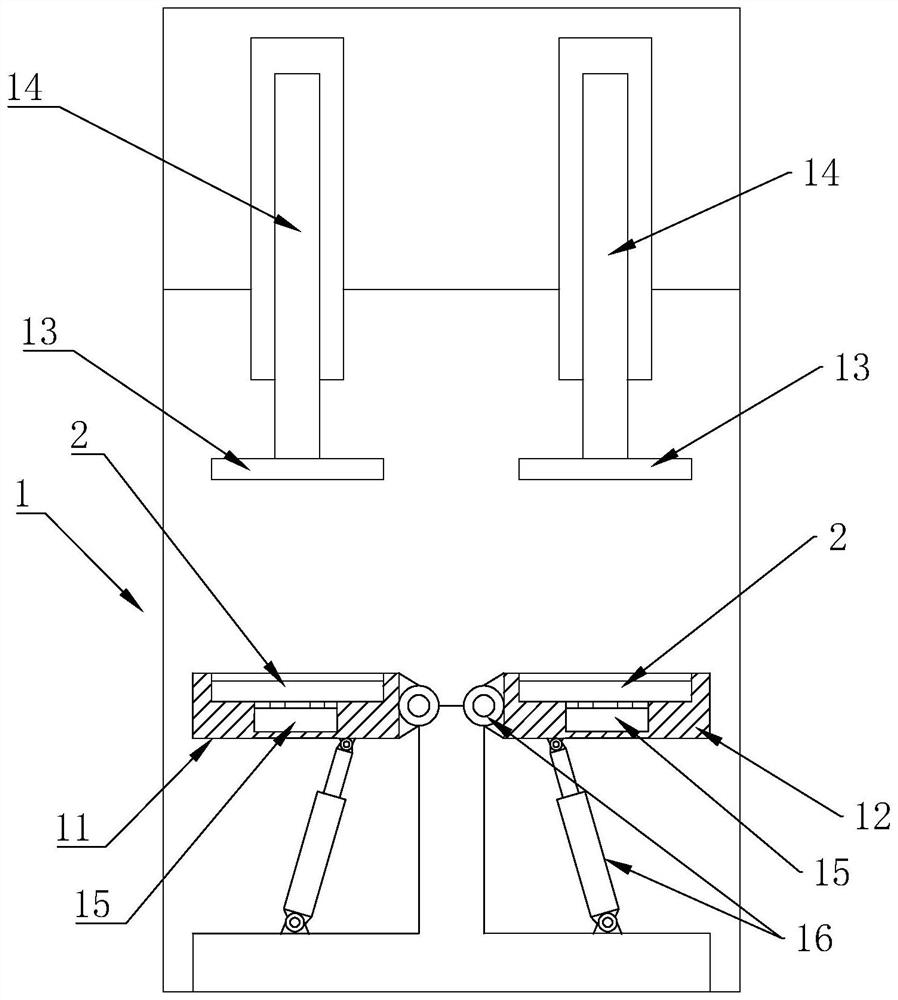

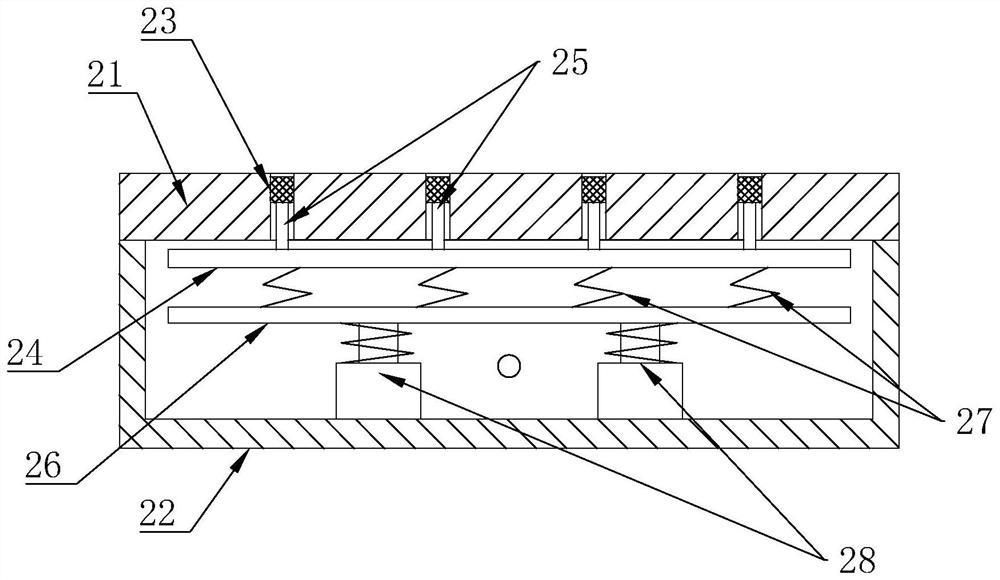

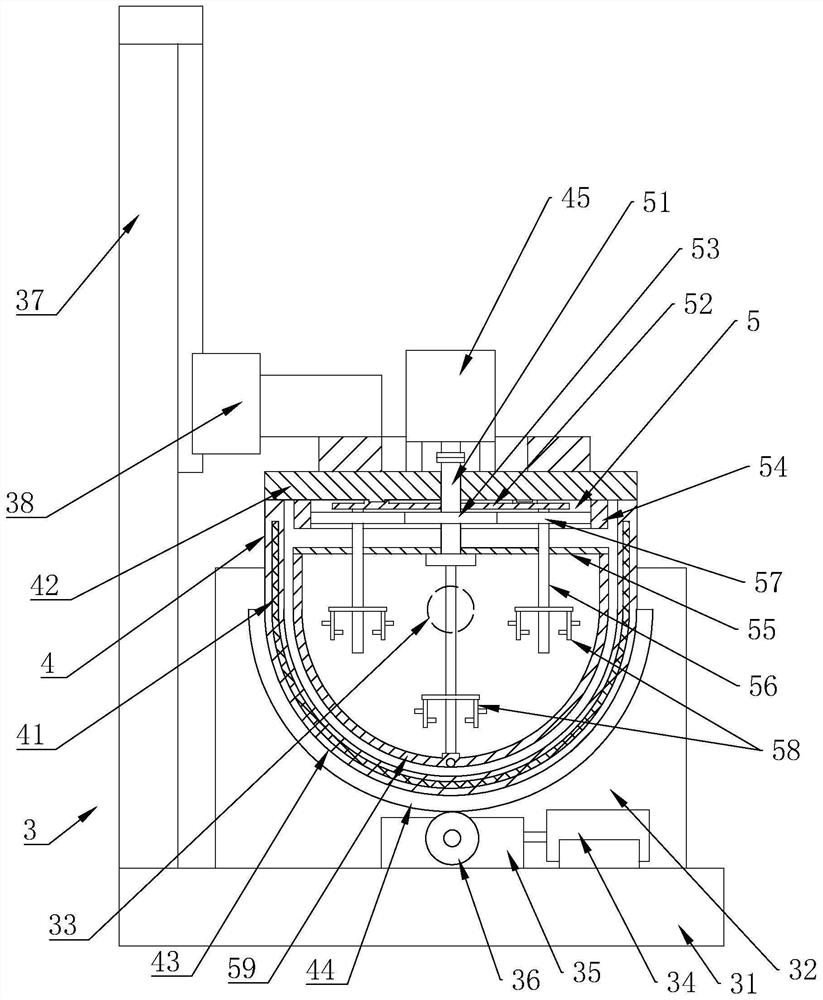

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] With reference to accompanying drawing: the preparation technology of a kind of EVA composite sole in the present embodiment is characterized in that: comprise the following steps,

[0031] Step 100, preparing the EVA antibacterial wear-resistant layer shoe piece;

[0032] Step 200, preparing the EVA elastic fold-resistant shoe piece;

[0033] Step 300, preparing the EVA wear-resistant anti-slip layer shoe;

[0034]Step 400, heat and melt the adjacent shoe surface layers of the EVA antibacterial wear-resistant layer shoe, EVA elastic fold-resistant layer shoe, and EVA wear-resistant anti-slip layer shoe, and then press the mold 1 to make the adjacent shoe pieces Bonded together, the final shape is an EVA composite sole with the upper, middle and lower layers being the EVA antibacterial wear-resistant layer shoe piece, the EVA elastic fold-resistant layer shoe piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com