Light-weight magnesium alloy passenger vehicle body framework

A magnesium alloy and skeleton technology, which is applied in the field of lightweight magnesium alloy bus body skeleton, can solve the problems of poor welding performance of magnesium alloy, riveting cost, fatigue of welded metal, stress concentration, etc., to overcome low elastic modulus, high specific strength, The effect of strong energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

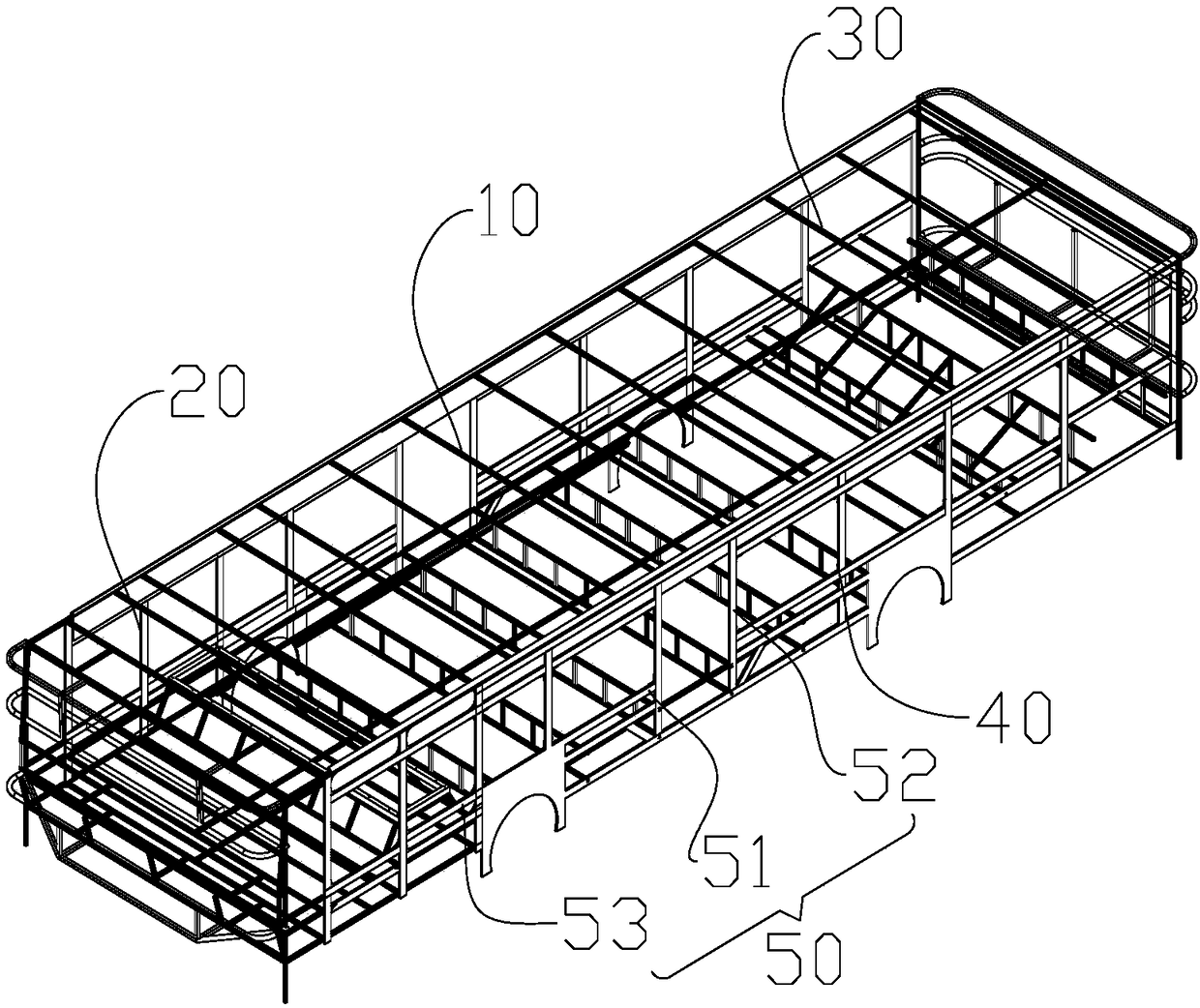

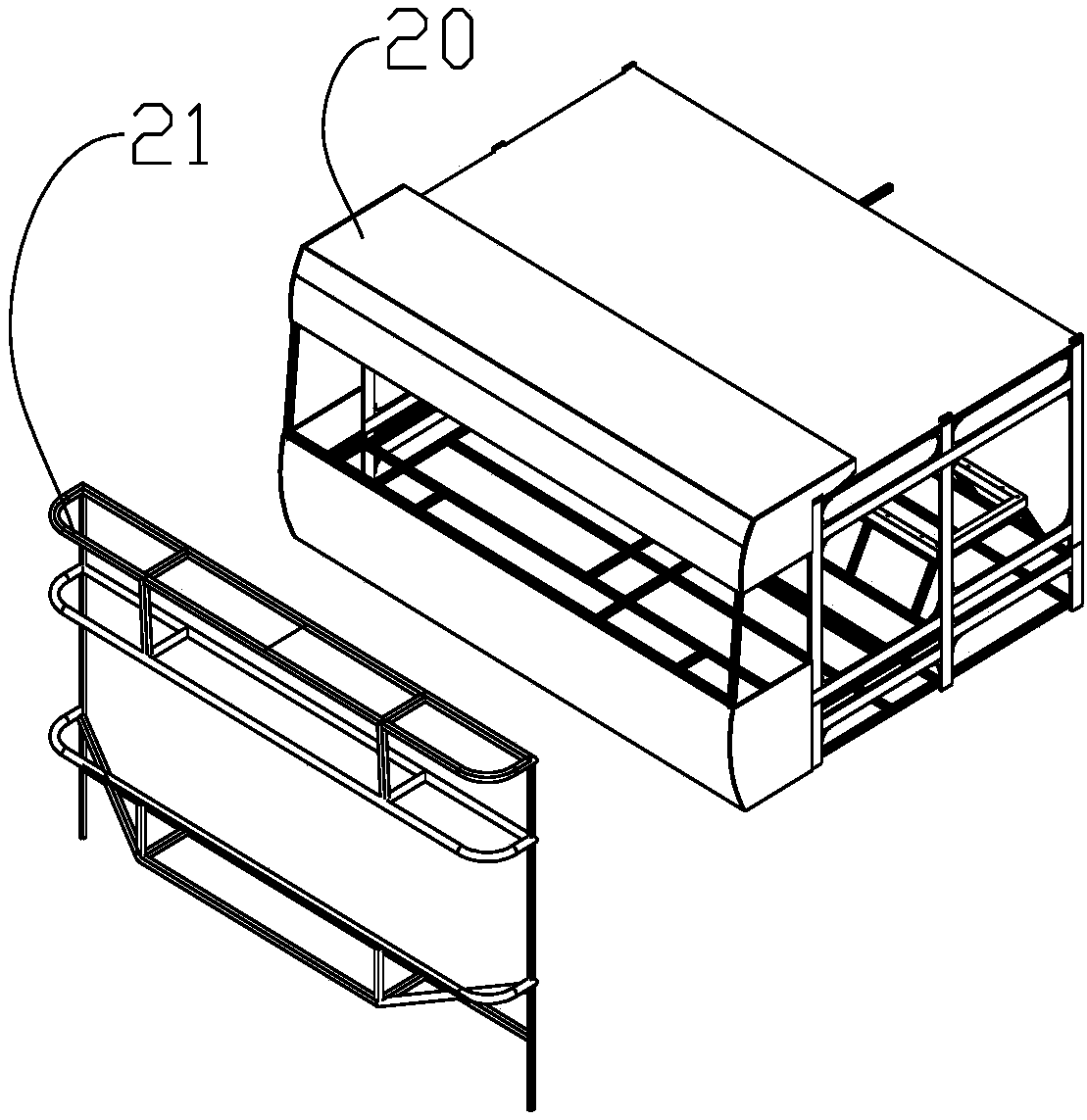

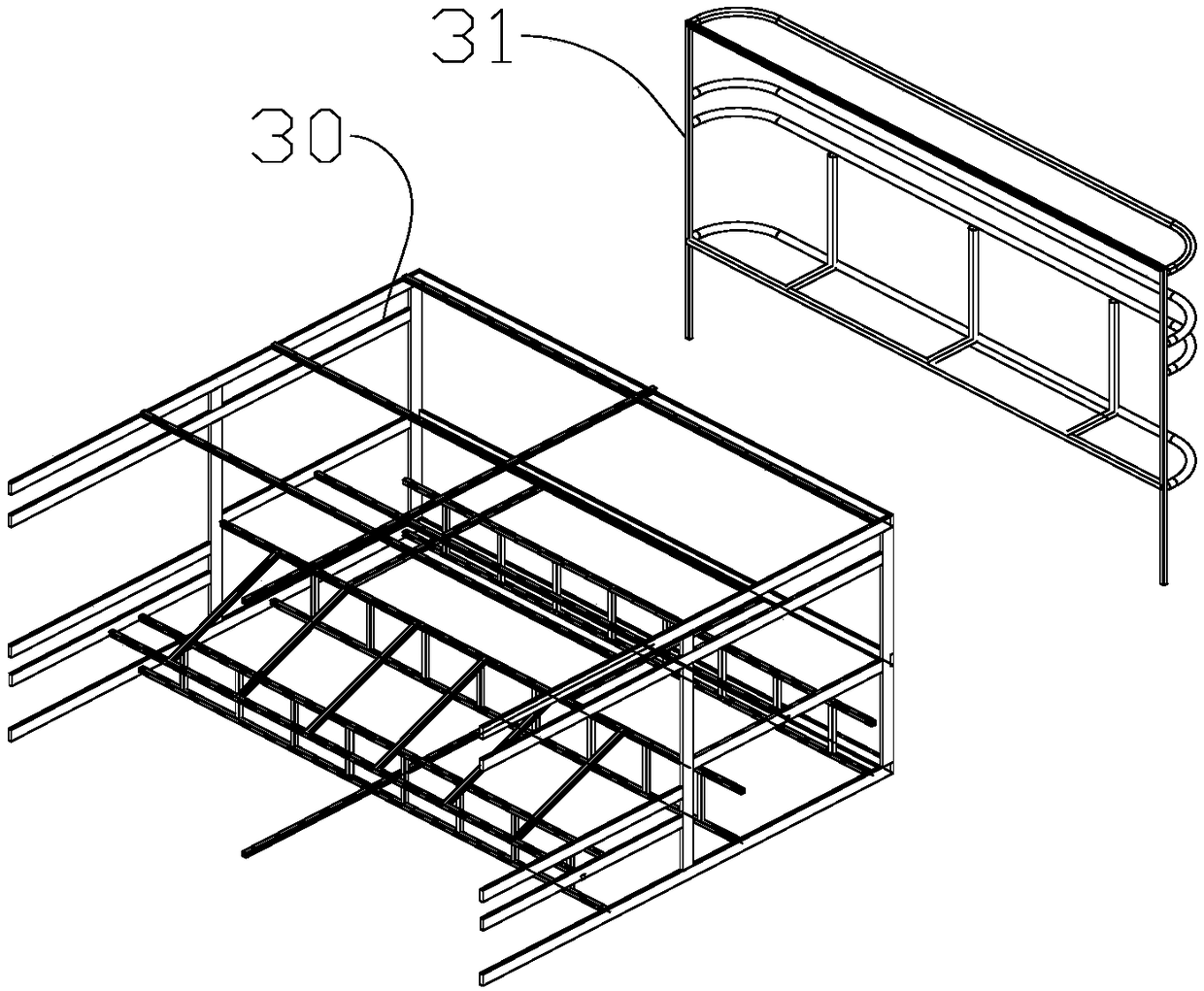

[0030] Please refer to Figure 1-9 , a lightweight magnesium alloy passenger car body frame provided by the embodiment of the present invention includes a body frame 10, a head frame 20, a tail frame 30 and a plurality of connecting mechanisms 40, wherein the head frame 20 is detachably installed on the body frame 20 On the front end of the car body, the rear frame 30 is detachable and installed on the rear end of the body frame 20. In this embodiment, the body frame 10, the front frame 20 and the rear frame 30 are all connected by a plurality of magnesium alloy profiles 50. , that is, the two contacting magnesium alloy profiles 50 are fastened and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com