Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Improve strength utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

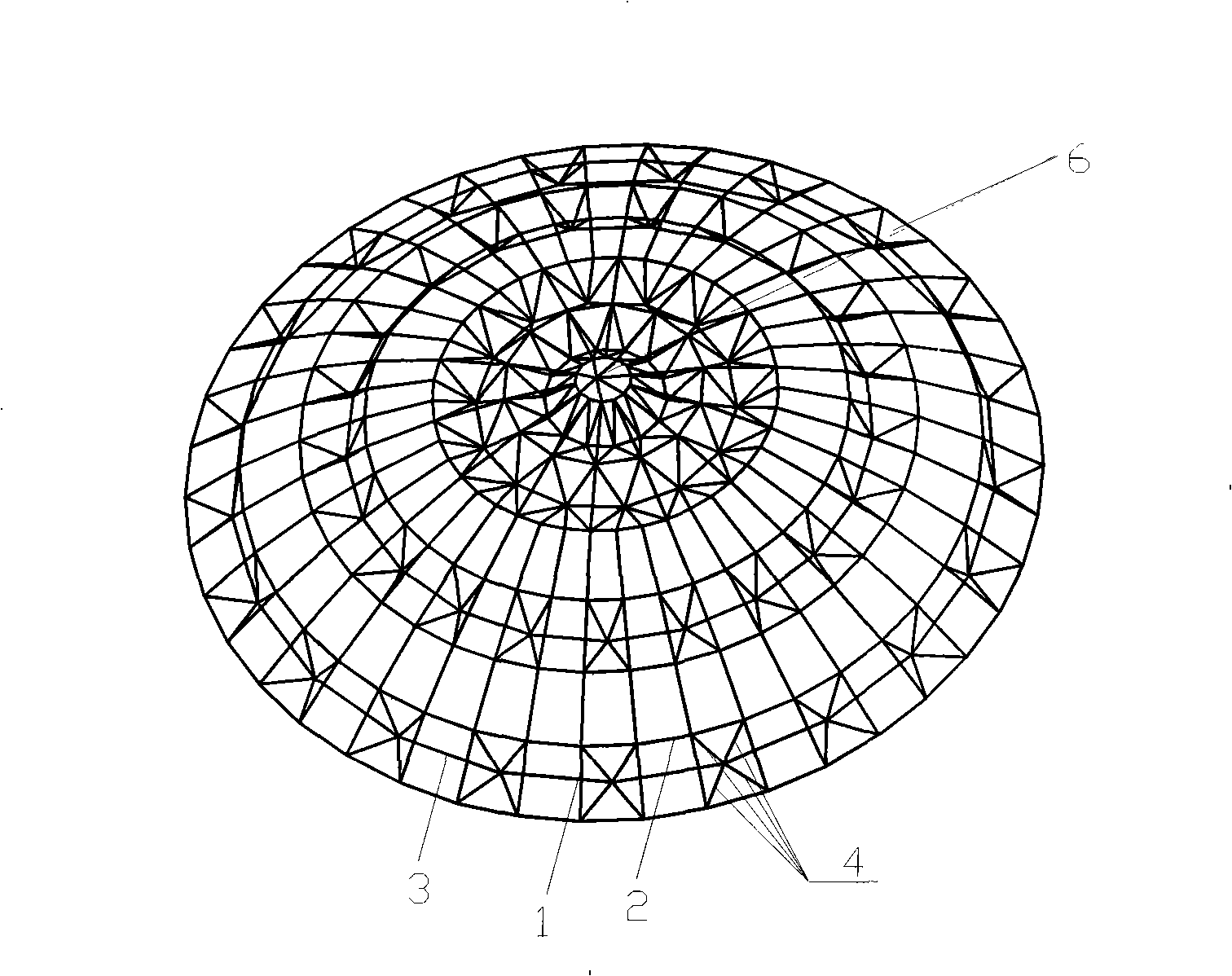

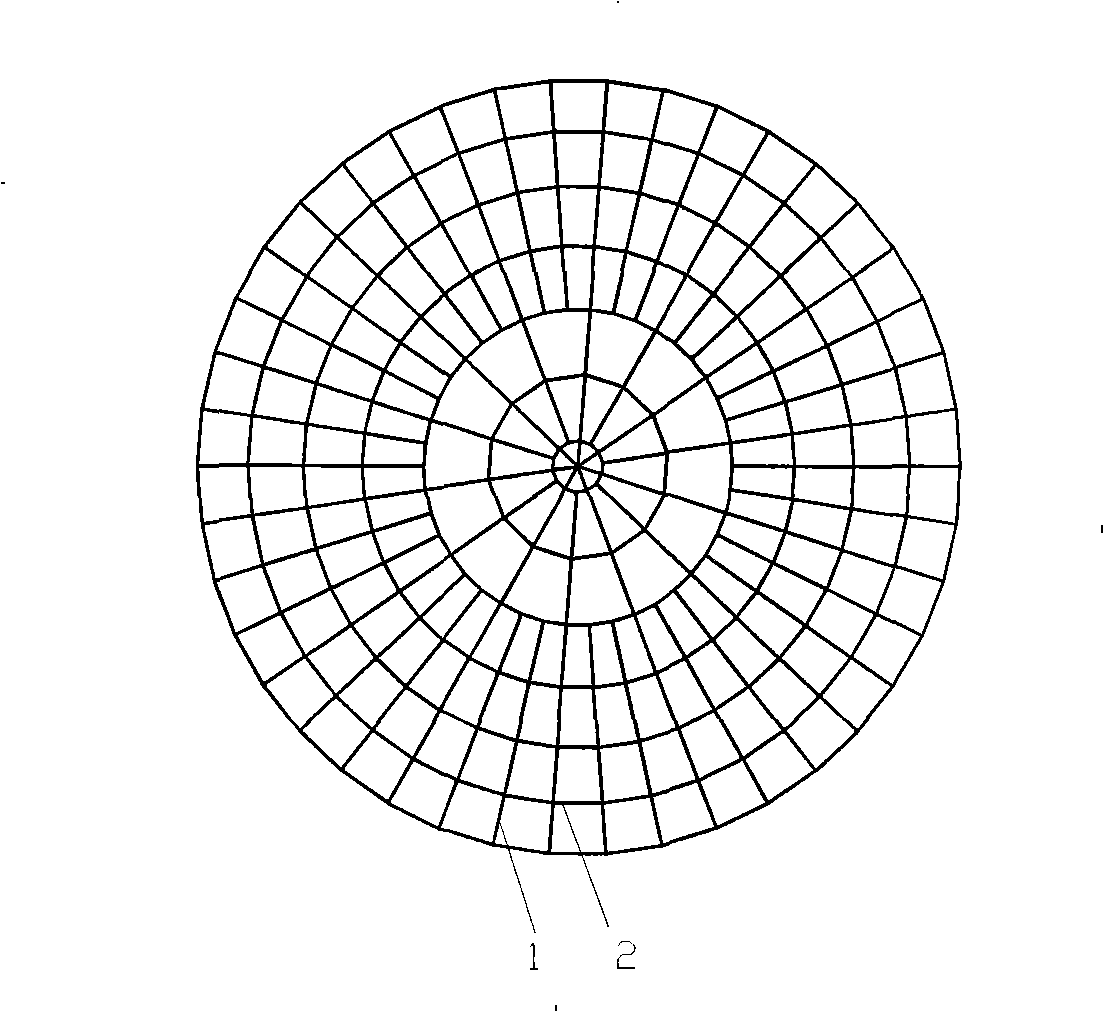

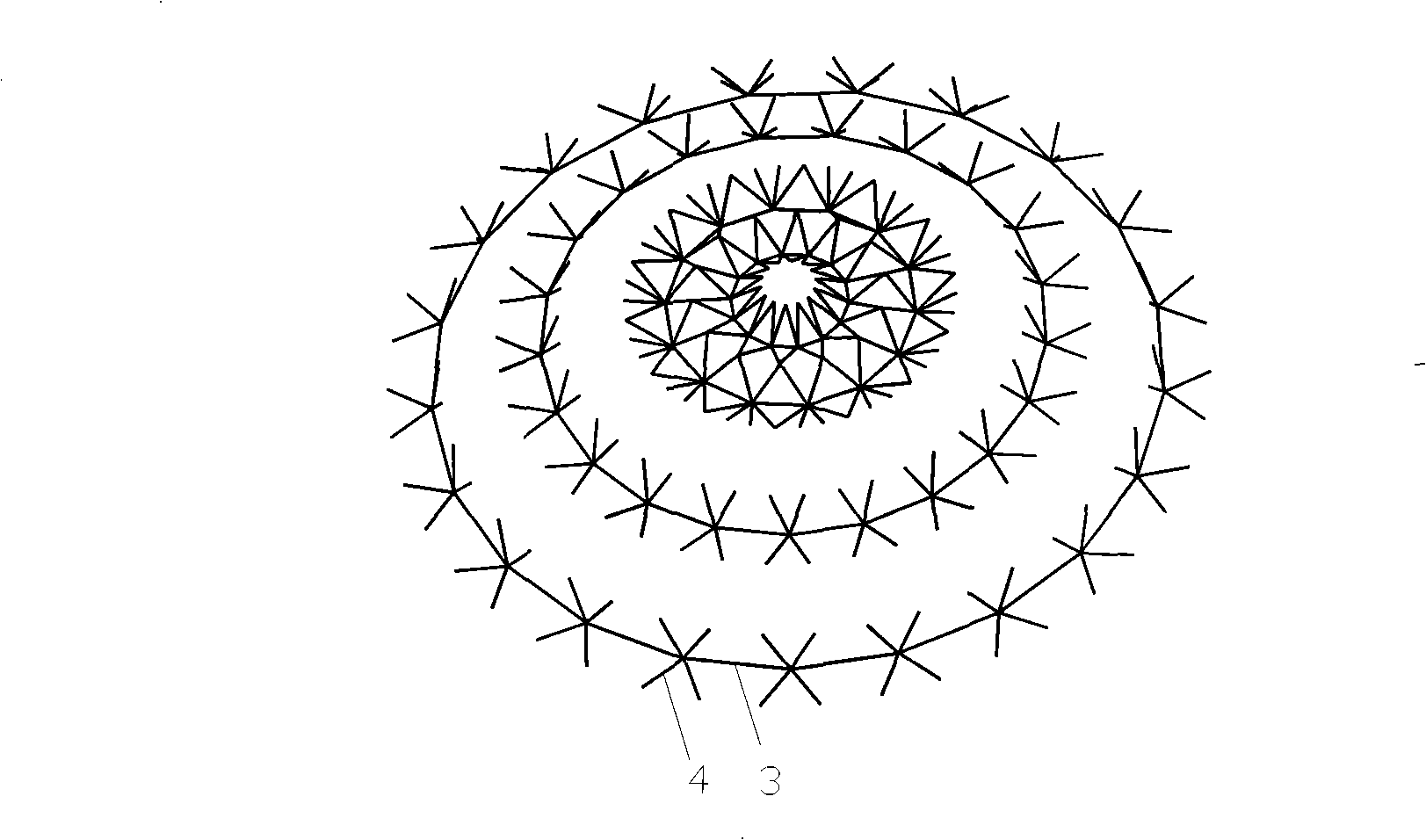

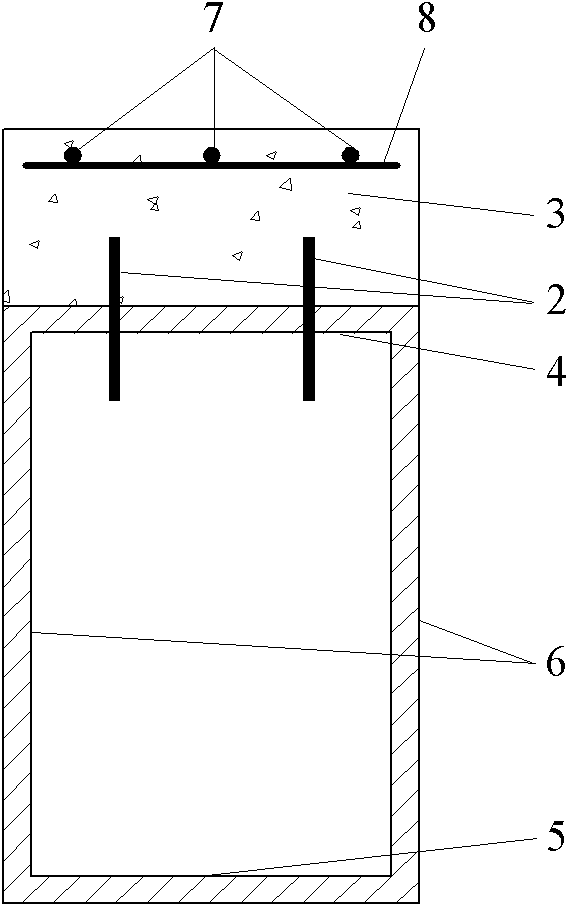

Local double layer open chord spherical reticulated shell

ActiveCN101260704AReduce steel consumptionSparsely arrangedBuilding roofsArched structuresPre stressEngineering

The invention discloses a local double-layer string reticulated spherical shell, comprising an upper layer, a middle layer and a lower layer, wherein, the upper layer is a spherical surface which consists of radial bars and circumferential bars and is arranged in a heel ring grid shape, a plurality of circumferential bars are connected to form the woof of the spherical surface, radial bars are connected between connections of the radial bars of two adjacent woofs to form the warp of the spherical surface, the connections of the circumferential bars are connected with one ends of the radial bars, while the other ends of the radial bars are hinged with the top point in the center of the spherical shell; the middle layer comprises a plurality of unit pyramids which are uniformly and alternately arranged on the heel ring grid of the upper layer along the warp direction and the woof direction and have cone tops connected with circumferential ropes of the lower layer; and the circumferential ropes are in closed arrangement along the circumferential direction, and inherent stress is exerted through tensioning the circumferential ropes in the structure. The local double-layer string reticulated spherical shell has the advantages of clear structure stress, concise and permeable construction effect, is a self equilibrating system under the deadweight effect without horizontal thrust, and has each upper chord joint provided with a web member so as to improve the stability of the structure.

Owner:SHENGYUAN GROUP +1

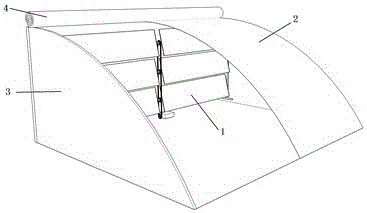

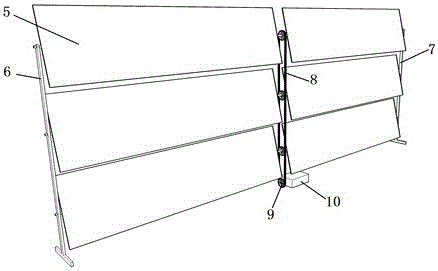

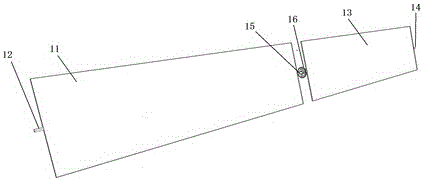

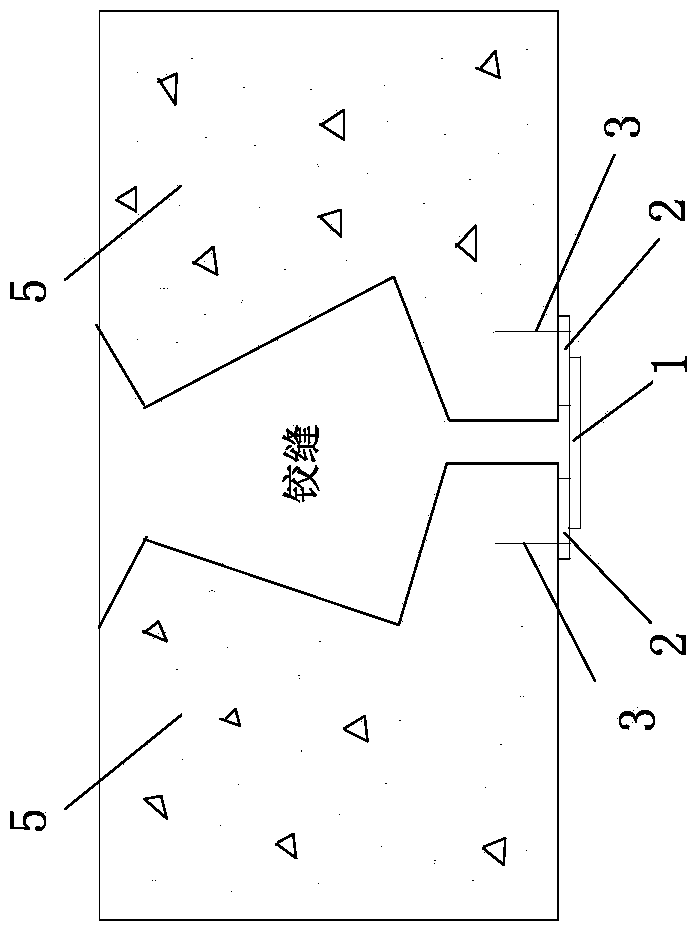

Greenhouse with adjustable light reflection device

InactiveCN106550798AUniform irradiationImprove strength utilizationClimate change adaptationRenewable energy machinesElectricityGreenhouse

The invention discloses a greenhouse with an adjustable light reflection device. The greenhouse comprises the adjustable light reflection device, a light-transmission layer, a heat preservation enclosing structure and a movable heat preservation quilt. The adjustable light reflection device is located in the greenhouse and close to the north face of the greenhouse. The movable heat preservation quilt is arranged on the light-transmission layer. The adjustable light reflection device comprises a plurality of reflector modules, a left supporting rod, a right supporting rod, a traction chain, driving gears and a motor cabinet. The reflector modules are parallelly placed in the vertical direction and connected with the traction chain through the gears. A motor in the motor cabinet drives the driving gears to rotate so as to adjust reflector angles. By adoption of the greenhouse, the solar energy utilization rate of the unit floor area is increased, meanwhile, the intensity of sunlight received by plants is improved, the heat preservation performance and the sunlight uniformity of the greenhouse are ensured, and the greenhouse is simple in structure, low in cost, attractive in appearance, and large in popularization potentiality.

Owner:NANJING SUOLEYOU ENERGY SAVING TECH CO LTD

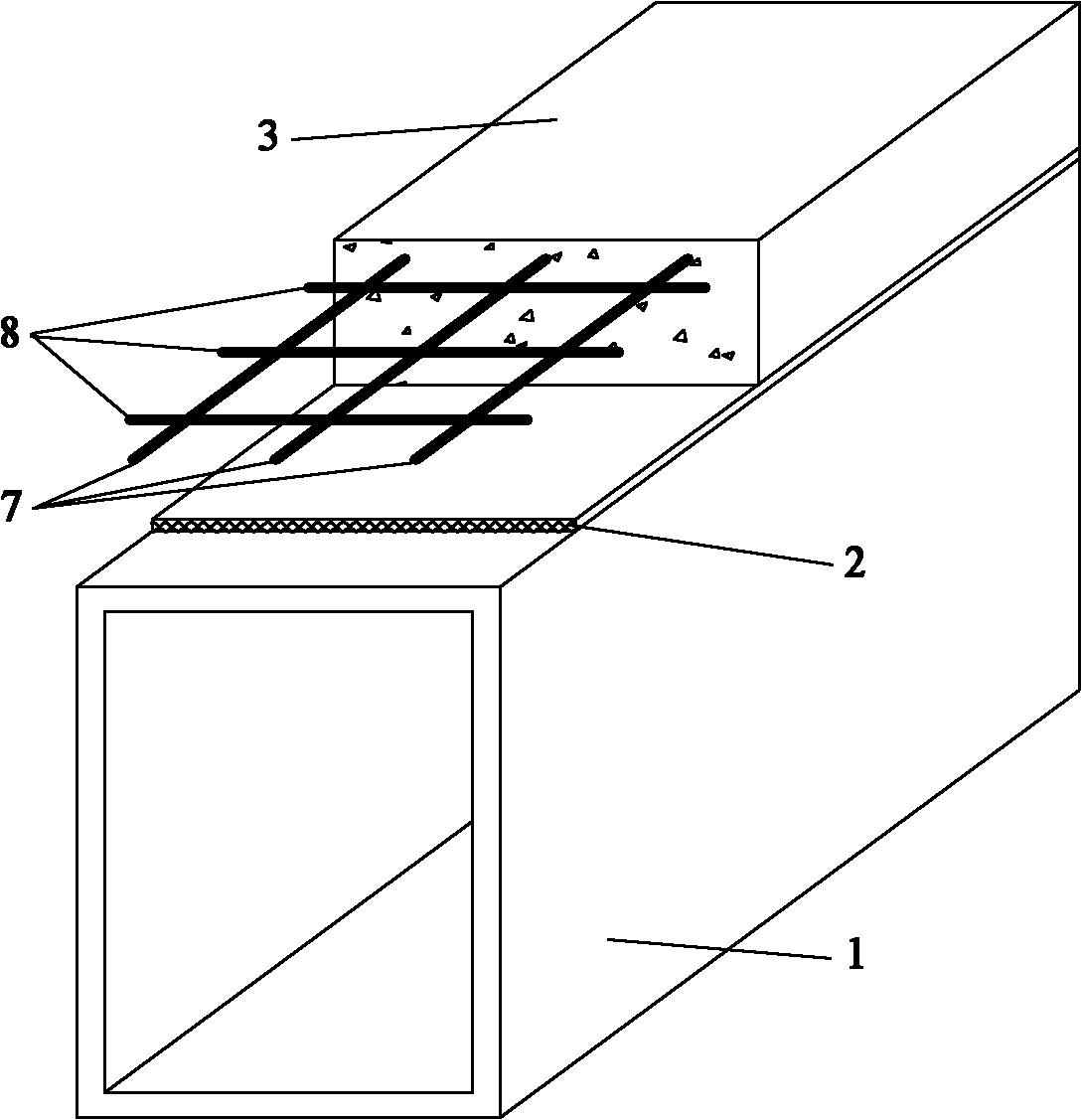

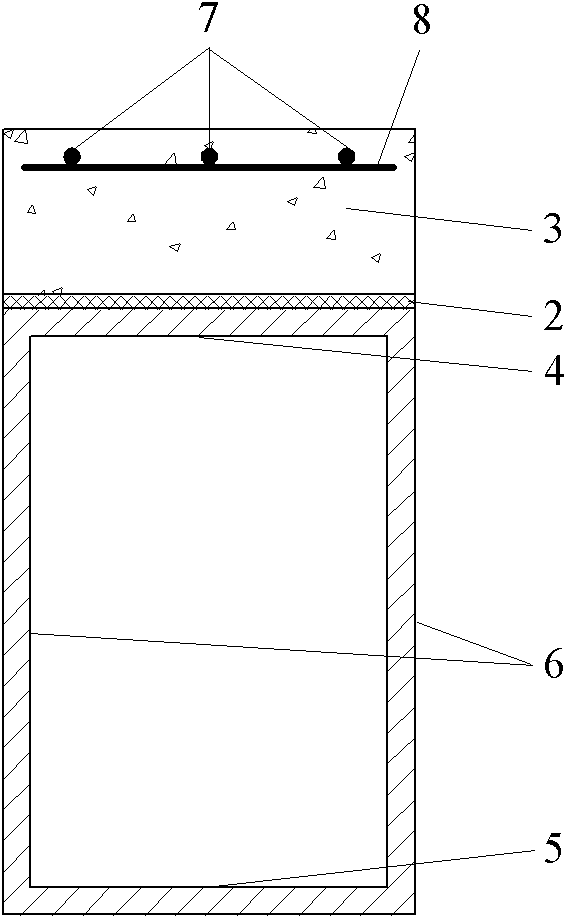

Fiber reinforced plastic-concrete composite beam

InactiveCN101985825AIncrease stiffnessLow priceBridge structural detailsGirdersBridge engineeringComposite beams

The invention relates to a fiber reinforced plastic (FRP)-concrete composite beam, which belongs to the technical field of bridge engineering. The composite beam comprises a box-shaped FRP beam or an I-shaped FRP beam, a shear connector and an FRP rib concrete slab, wherein the box-shaped FRP or the I-shaped FRP beam consists of a top flange, a lower flange and a web plate; the shear connector consists of fine stones, an adhesive or FRP shear nails and is arranged on the top flange of the FRP beam; and the FRP rib concrete slab consists of concrete, longitudinal FRP ribs and horizontal FRP ribs and is positioned above the top flange of the FRP beam. By optimally combining the tensile property of an FRP material with the compressive property of a concrete material and taking simple and reliable shear connection measures, a steel-free composite beam is realized; and the composite beam has the advantages of corrosion resistance, high rigidity, fatigue resistance, low cost and the like, is easy and convenient to construct, and is a novel choice for modern bridge construction.

Owner:DALIAN UNIV OF TECH

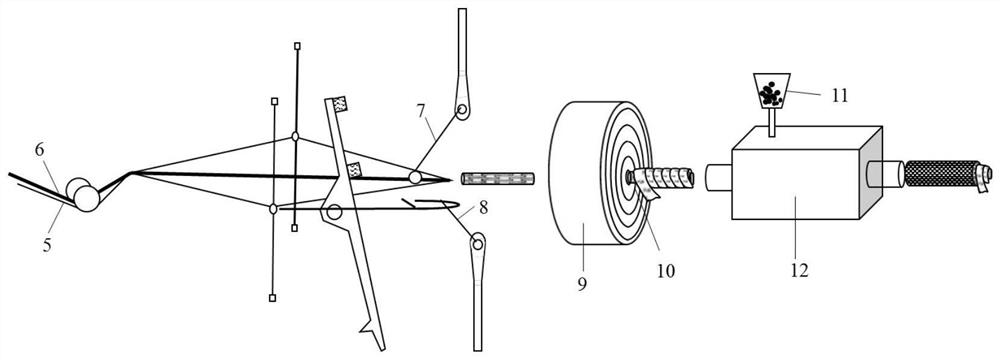

Middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor

The invention discloses a middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor, and belongs to the field of high-performance carbon fiber preparation method. The middle-modulus carbon fiber preparation method comprises following steps: PAN precursor is delivered into a pre-oxidation furnace for pre-oxidation so as to obtain a pre-oxidized fiber body with a density ranging from 1.33 to 1.36g / cm<3>; the pre-oxidized fiber body is delivered into a low temperature carbonization furnace for low temperature carbonization so as to obtain a low temperature carbonized fiber body; the low temperature carbonized fiber body is delivered into a high temperature carbonization furnace for high temperature carbonization, and the carbon fiber with tensile strength ranging from 4500 to 5100MPa, tensile modulus ranging from 270 to 310GPa, and filament diameter ranging from 6 to 10<mu>m is obtained via carbonization. The middle-modulus carbon fiber preparation method is capable of realizing synchronous increasing of carbon fiber tensile modulus and strength, and solving key problems that the tensile strength of middle-modulus carbon fiber is reduced, and cost is high.

Owner:ZHONGFU SHENYING CARBON FIBER +1

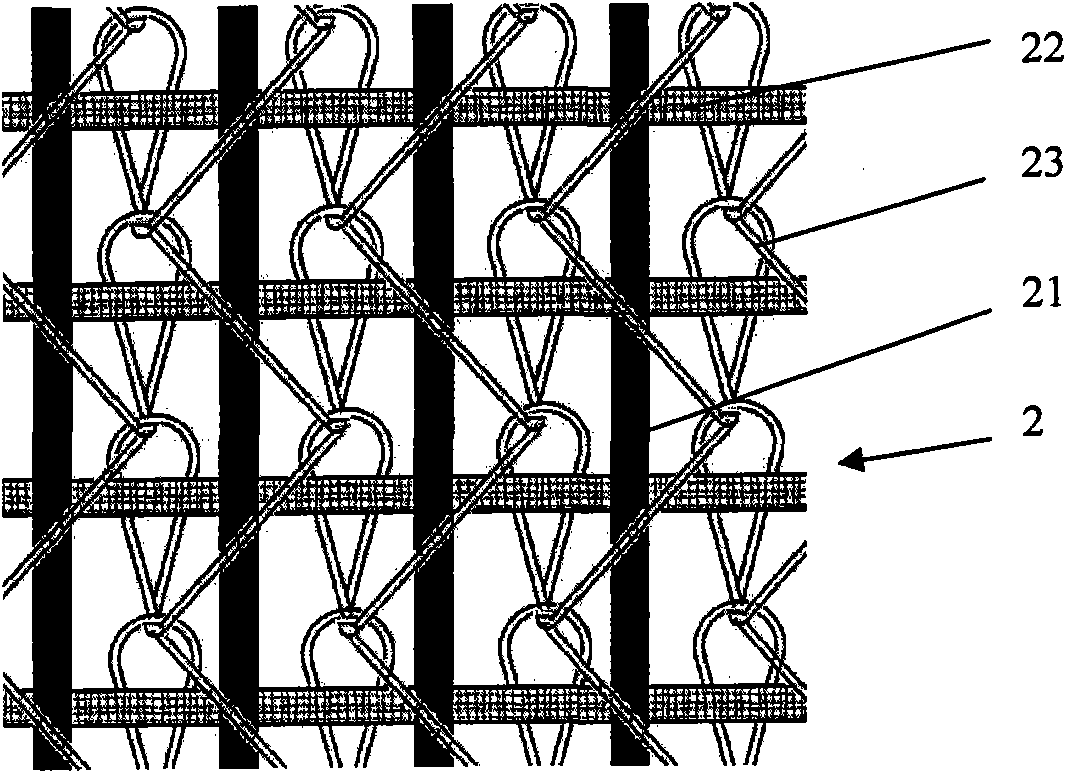

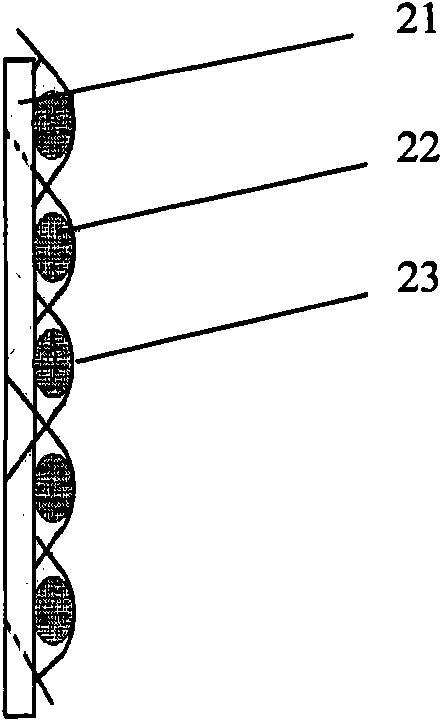

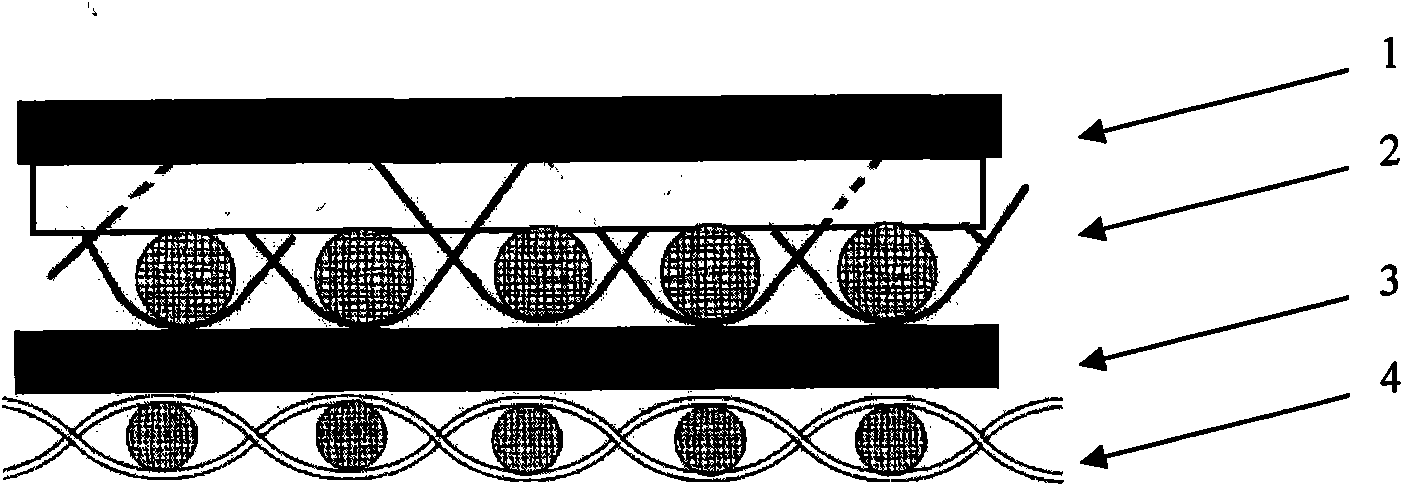

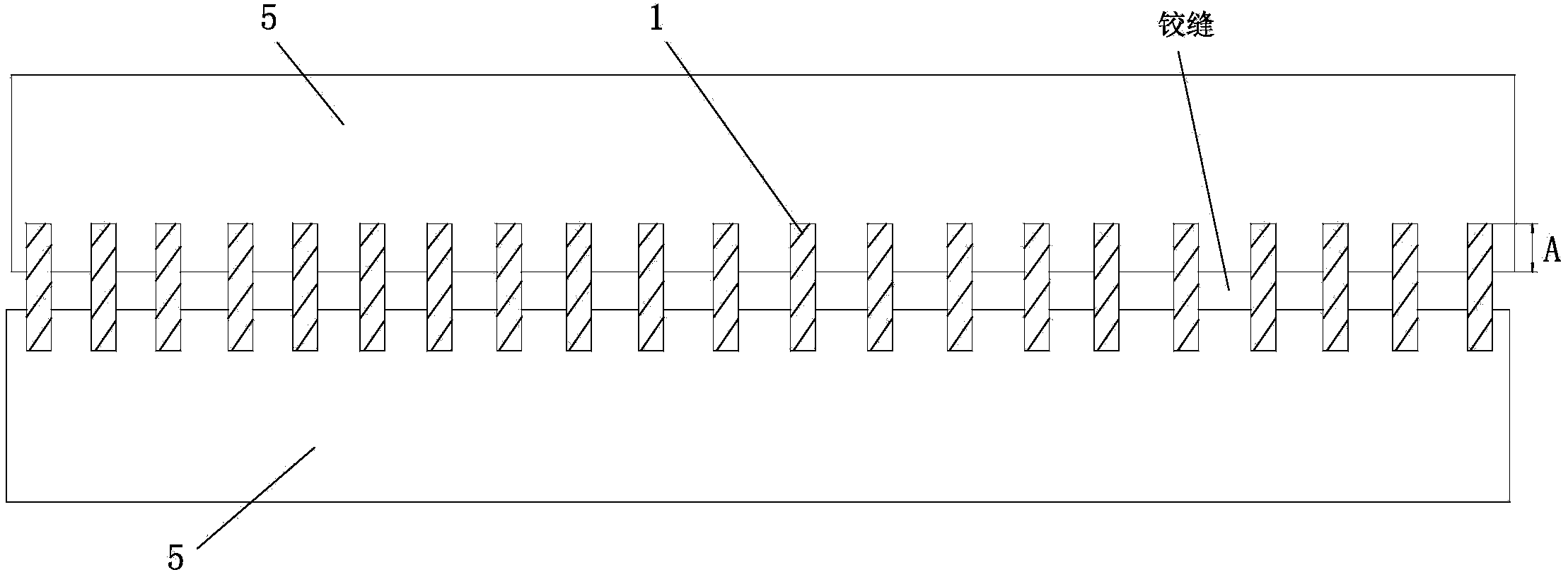

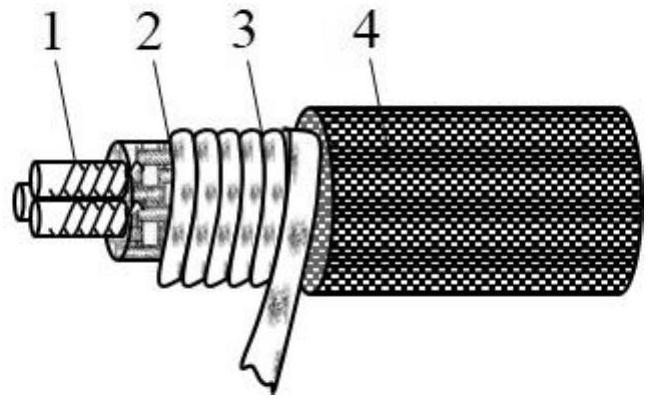

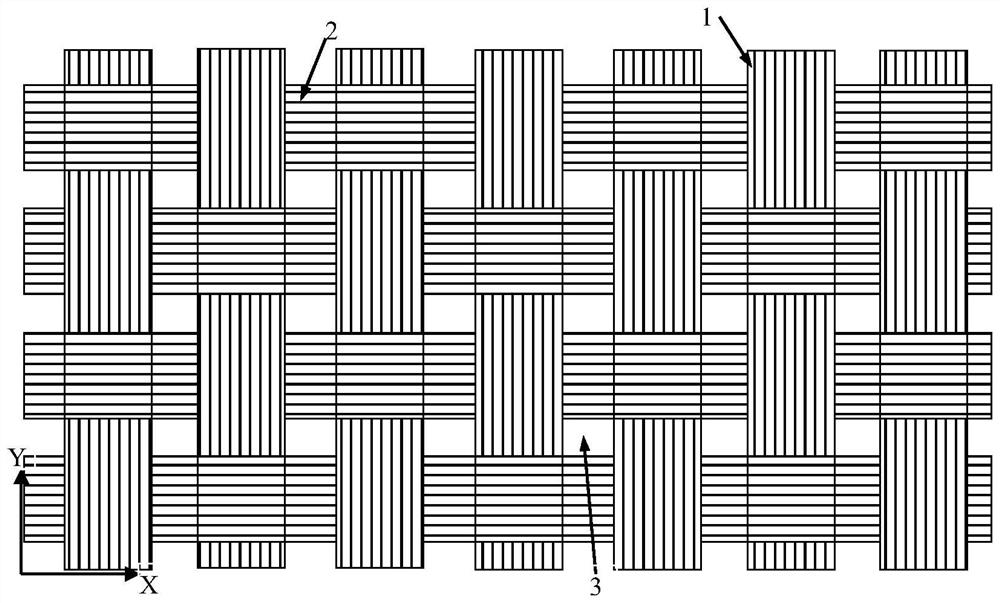

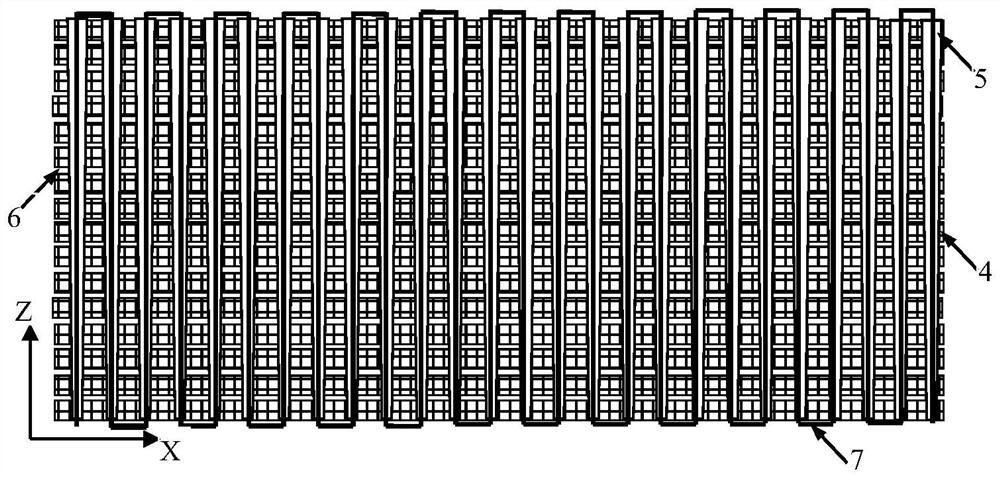

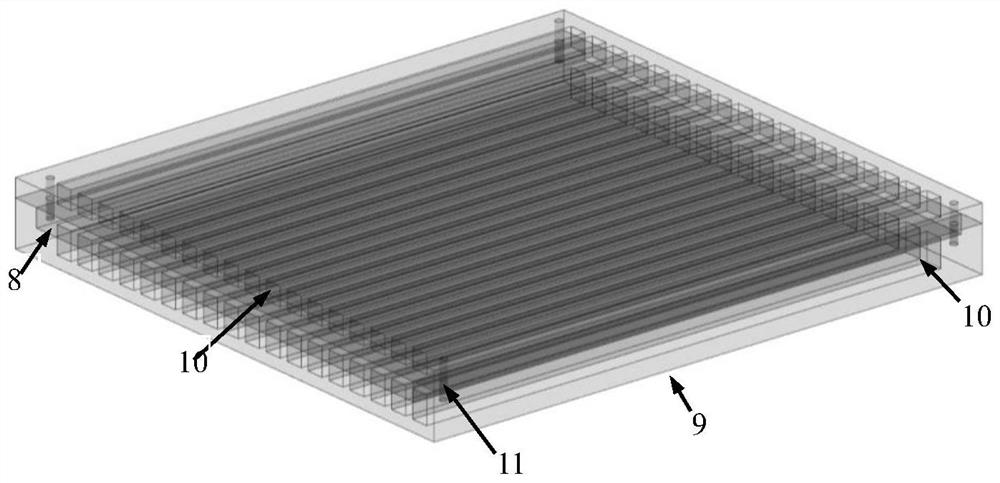

Conveyer belt taking warp-knitted bi-axial fabric as framework and manufacturing method thereof

InactiveCN101830335AHigh strength requirementsThere is no up and down staggered mutual pressure phenomenonConveyorsSynthetic resin layered productsSurface layerPolyvinyl chloride

The invention relates to a conveyer belt taking a warp-knitted bi-axial fabric as a framework and a manufacturing method thereof. The conveyer belt sequentially comprises a woven fabric, a polyvinyl chloride laminated layer, the warp-knitted bi-axial fabric and a polyvinyl chloride surface layer from bottom to top. The manufacturing method comprises the following steps of: finalizing the design of the woven fabric, carrying out primary coat, and coating polyvinyl chloride paste resin to form the laminated layer; finalizing the design of the warp-knitted bi-axial fabric, jointing with the woven fabric of the bottom layer; and carrying out surface layer coating on the warp-knitted bi-axial fabric to form the conveyer belt structure of a double-framework double- polyvinyl chloride layer. The utilization rate of the intensity of warp in the warp-knitted bi-axial fabric reaches the highest, and the warp is always in a straight state and does not have creep relaxation. Self-cementing between the PVC (polyvinyl chloride) surface layer and the PVC laminated layer can be formed, the primary coat process is left out, the racking strength is greatly enhanced, the requirements on roll diameter and tension length of a conveyer are reduced, the service life is improved, and the cost is 40% lower than the woven fabric.

Owner:SHANGHAI YONGLI BELTING +1

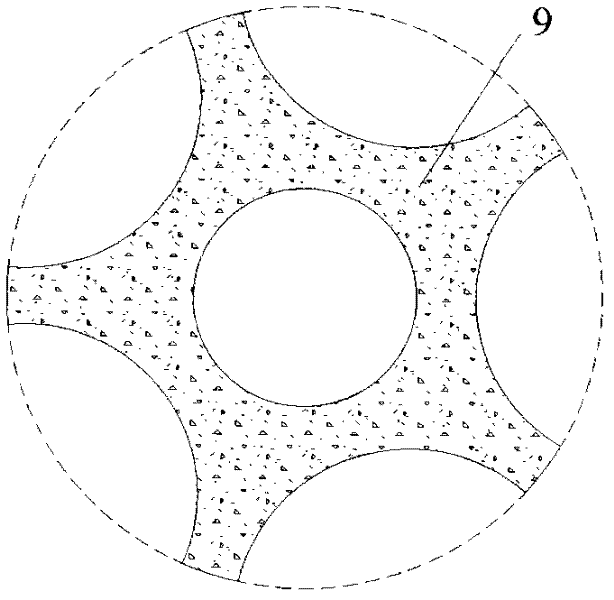

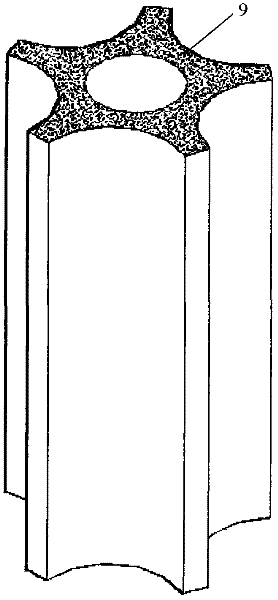

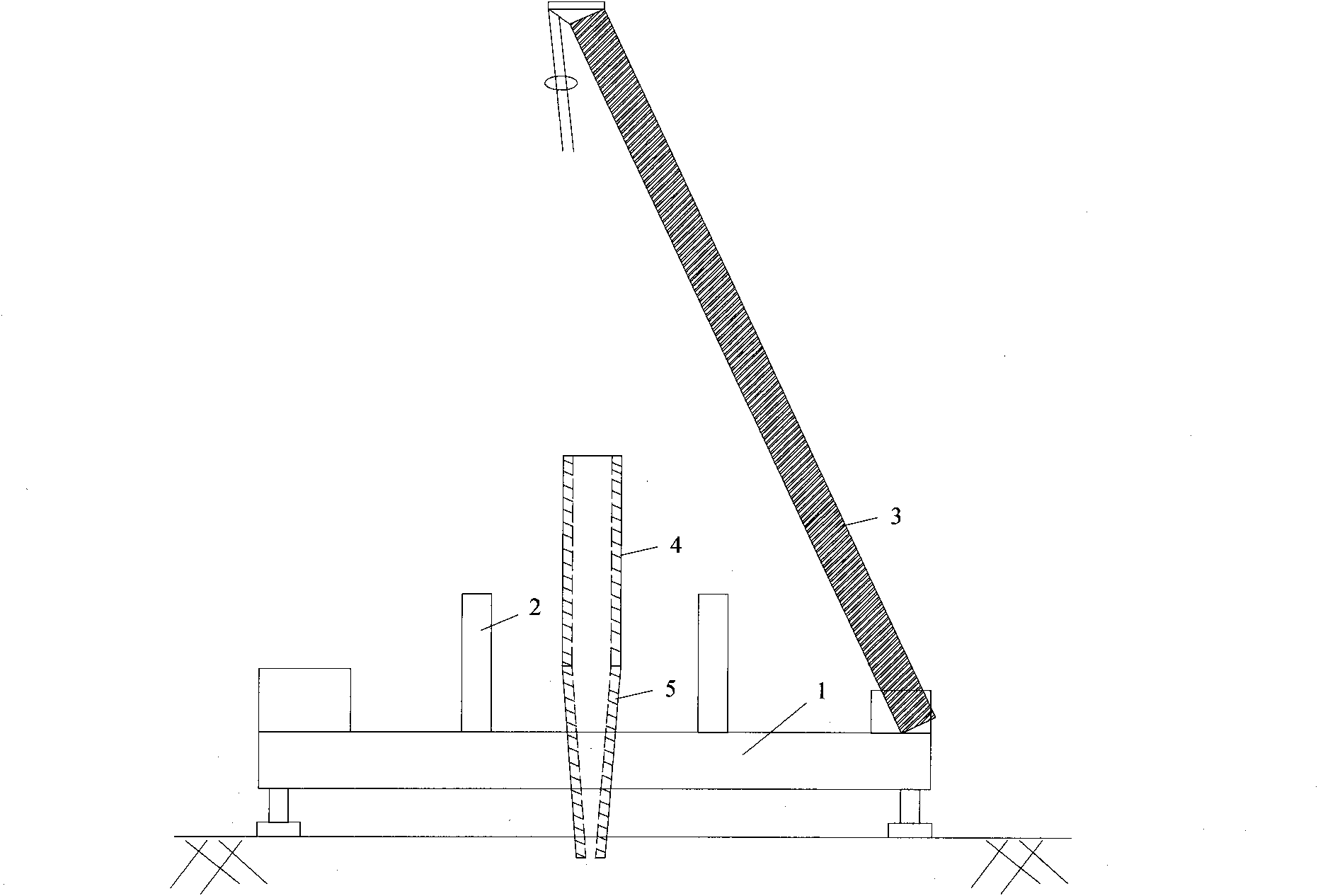

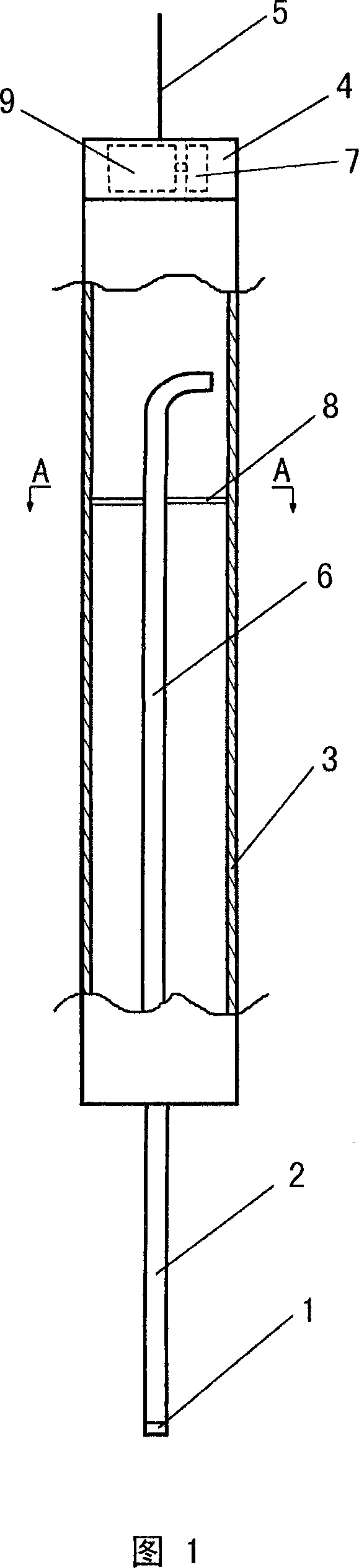

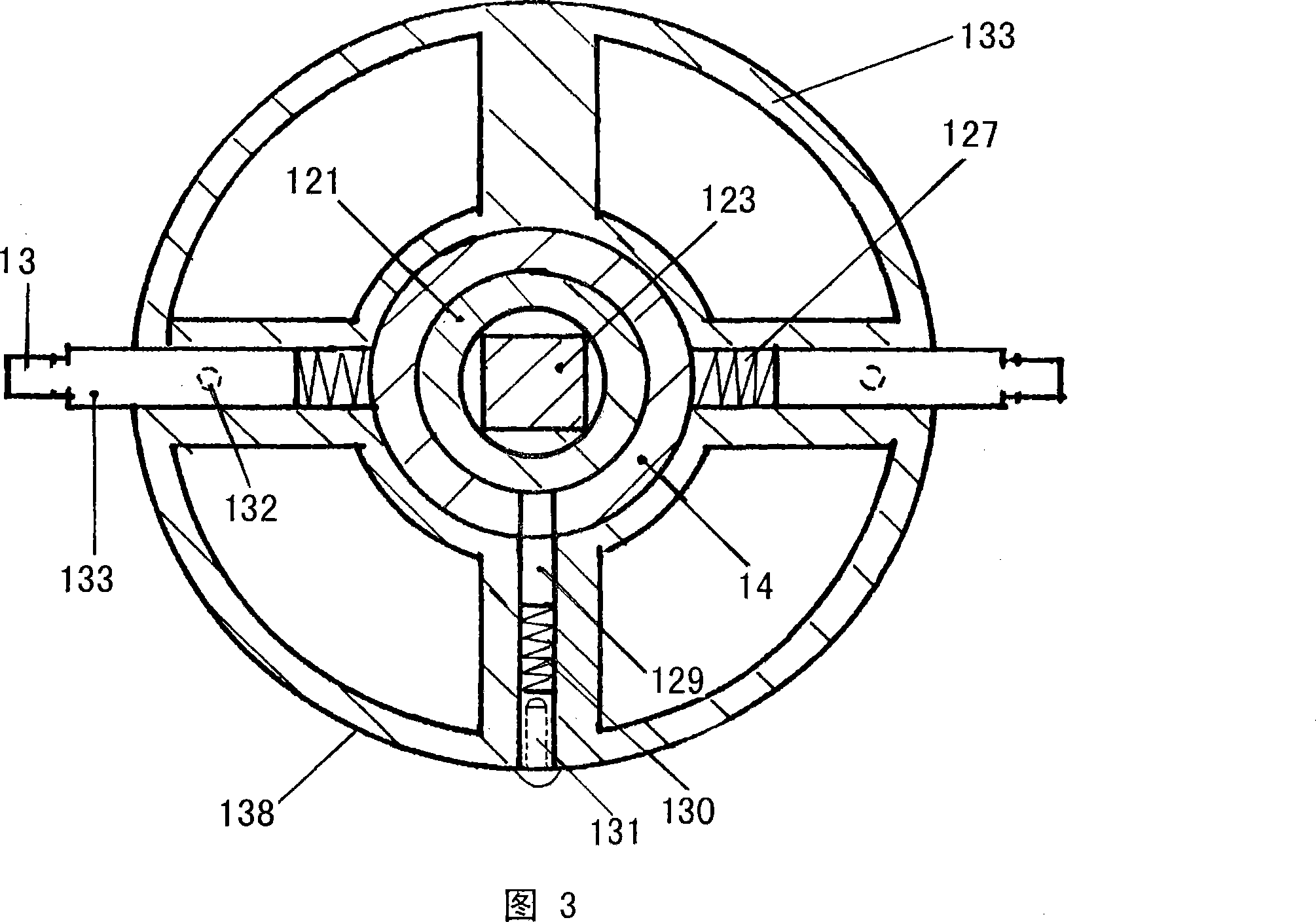

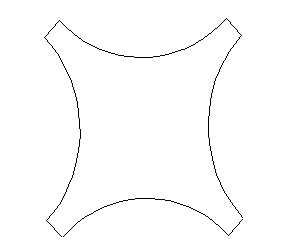

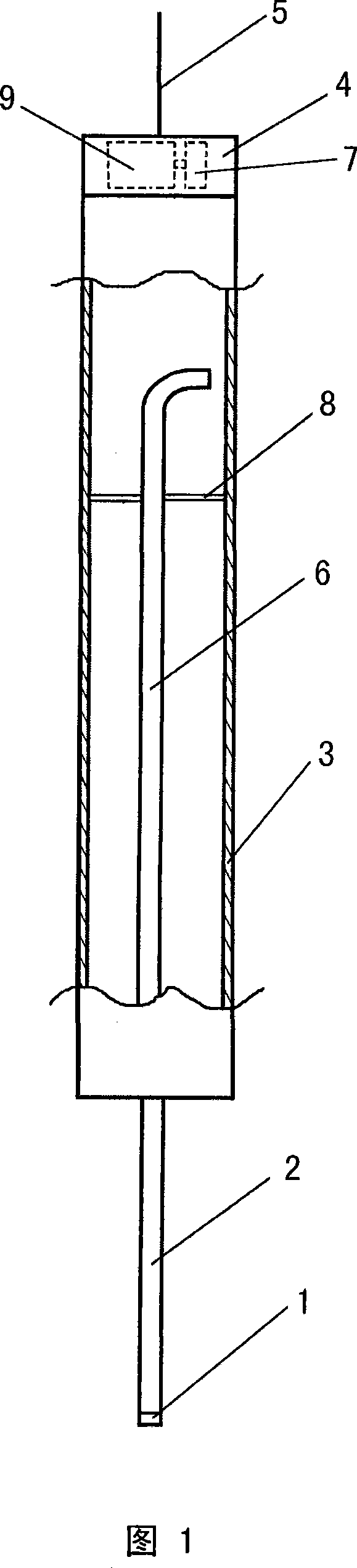

Cast-in-place concrete hollow five-star shaped pile with large diameter and construction method and special device thereof

The invention discloses a cast-in-place concrete hollow five-star shaped pile with large diameter and a construction method and a special device thereof. The side surface of the pile consists of an angular plane of the pile which is formed in intersection and arc-shaped curved surface depressed into the pile and connected with the plane smoothly. The cross section of the pile is hollow five-star shaped. A five-star shaped hollow steel sleeve is infiltrated to the foundation to designed depth by vibrating an immersed tube and then concrete is casted in a cavity of the inner and outer steel sleeves and the tube is drawn by vibration to form the cast-in-place concrete hollow five-star shaped pile with large diameter. The invention further relates to the special device of the construction method of the concrete pile. The cast-in-place concrete hollow five-star shaped pile with large diameter is a thin-wall abnormal pile which is rigid, has high strength, large processing depth, simple process, and strong maneuverability and is convenient to control the quality, monitor, and has high bearing capacity and low cost. The special device has a simple structure and is convenient and flexible to operate.

Owner:HENAN POLYTECHNIC UNIV

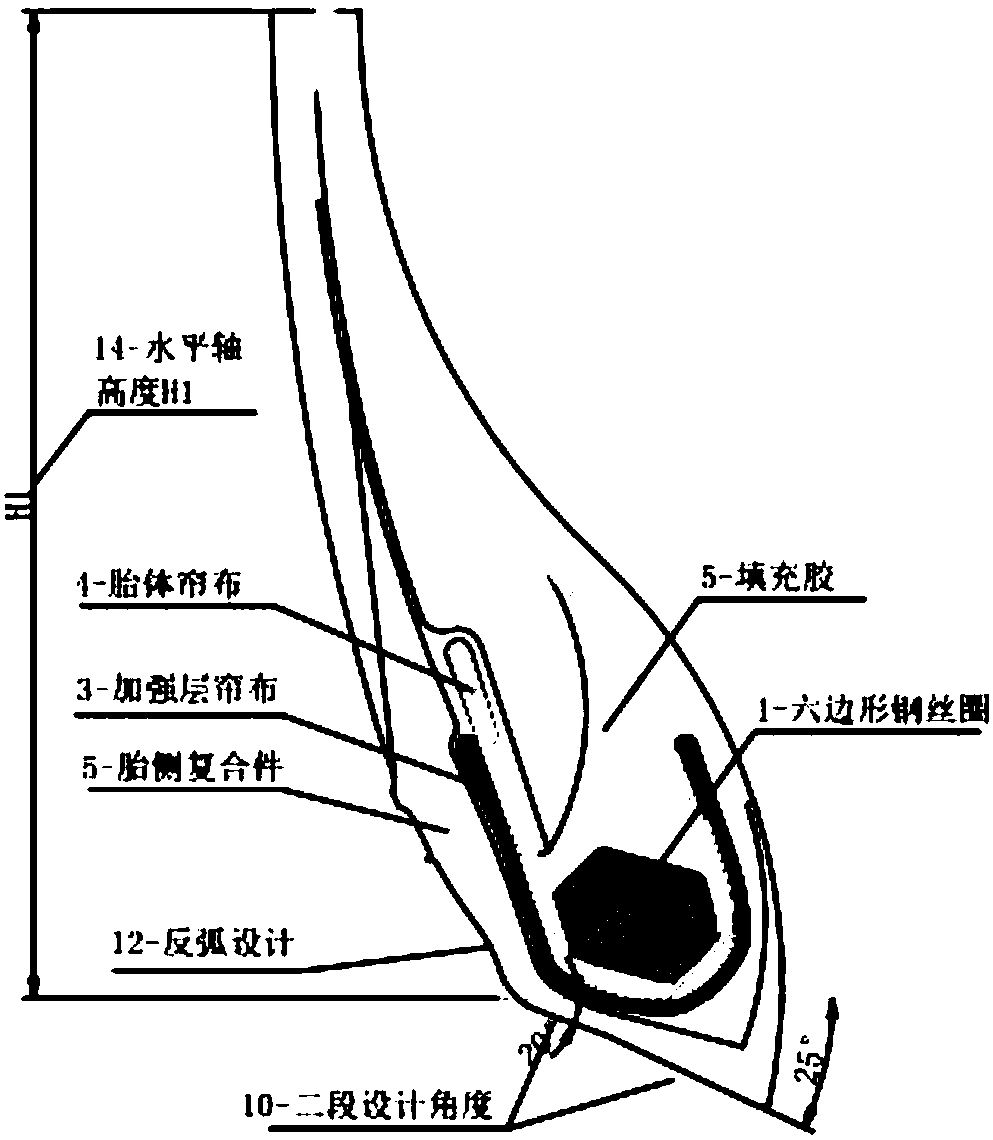

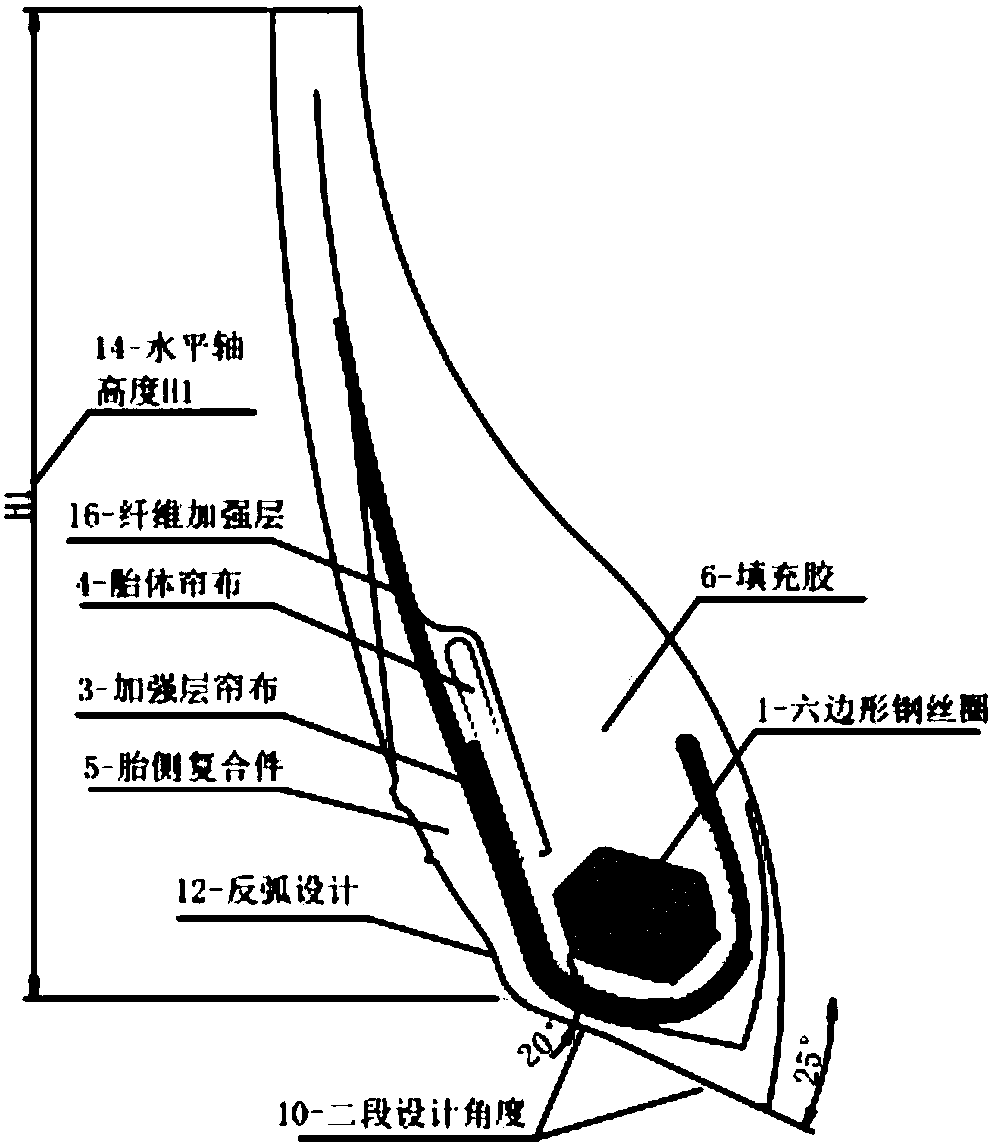

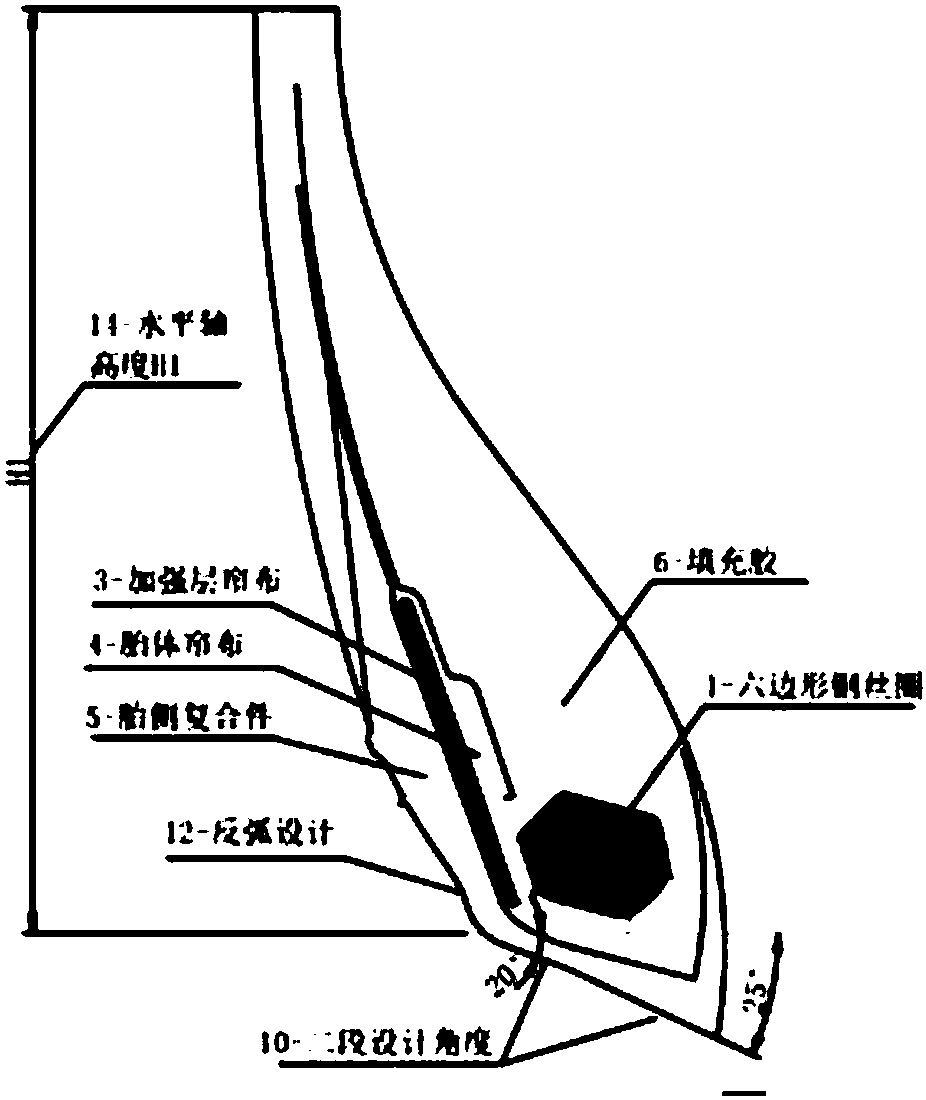

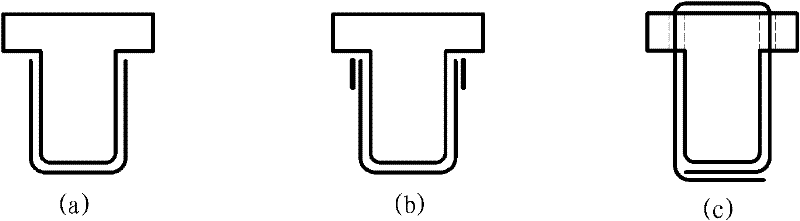

All-steel tubeless radial tire with high load performance and manufacturing method thereof

PendingCN107719029AConformationally stableImprove strength utilizationTyresTyre beadsTire beadEngineering

The invention discloses an all-steel tubeless radial tire with a high load performance and a manufacturing method thereof. A rectangular bead ring is arranged in a compound bead ring; a section designangle is adopted by a profile curve at the bottom of a bead base; a tangent design angle is adopted by the profile curve of a tire bead heel; a sizing material is thickened on a contact position of the bead heel and the rim; binding rubber slices are arranged at two endpoints of a tire cord fabric and a reinforced cord fabric; the height of reverse binding sections of the binding rubber slices isarranged close to the height H1 of a horizontal shaft; an upper filling glue and a lower filling glue for isolation are successively arranged between the reverse binding sections of the binding rubber slices and the tire body from top to bottom; a U-shaped reinforced cord fabric layer is paved on the outer layer of the tire cord fabric; an inside liner and a sidewall compound piece are respectively arranged on the inner and outer sides of the reinforced cord fabric. The bead ring is stable in construction, is free from deformation under a stressed state and is high in strength use ratio; thebottom of the bead ring is in surface contact with the rim; the stress is uniform and the load resistance is promoted; the stress between the tire body and the tire cord fabric is buffered by the isolating rubber slices; the loading capacity is promoted by the reinforced cord fabric.

Owner:SAILUN GRP CO LTD

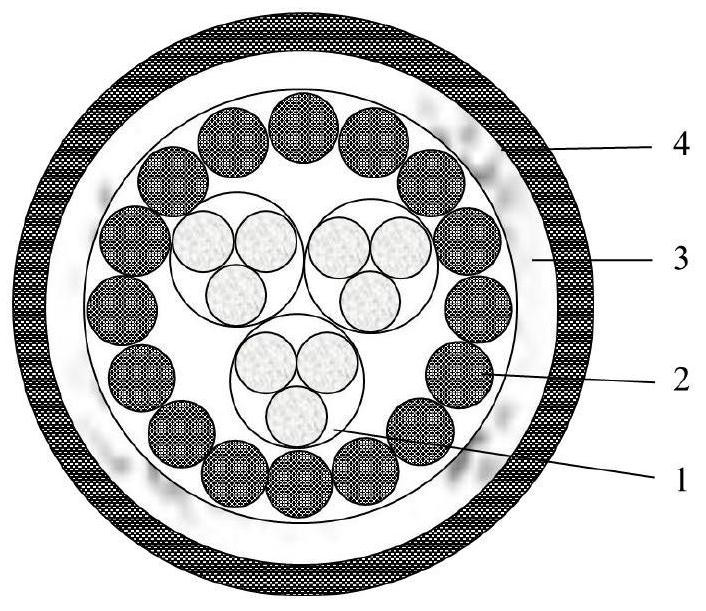

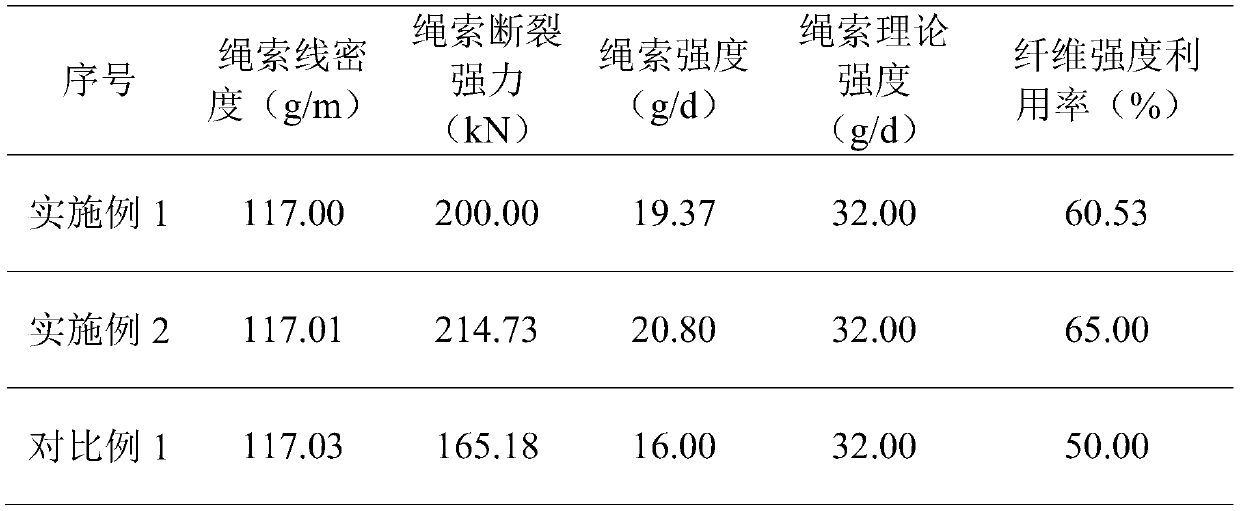

Rigging and preparation method thereof

The invention relates to a rigging and a preparation method thereof, wherein the rigging comprises a rigging body. The rigging body comprises a carrier core and a sheath sleeved on the periphery of the carrier core. The carrier core comprises a plurality of single yarns disposed integrally, and each single yarn is made by packing or packing and twisting an ultrahigh molecular weight polyethylene film or strip. The technical solution provided by the invention replaces traditional UHMWPE fibers with the single yarns for the preparation of the rigging, and the rigging is high in strength utility ratio of UHMWPE film or strips, easy to process, low in cost and environmentally friendly without glue.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

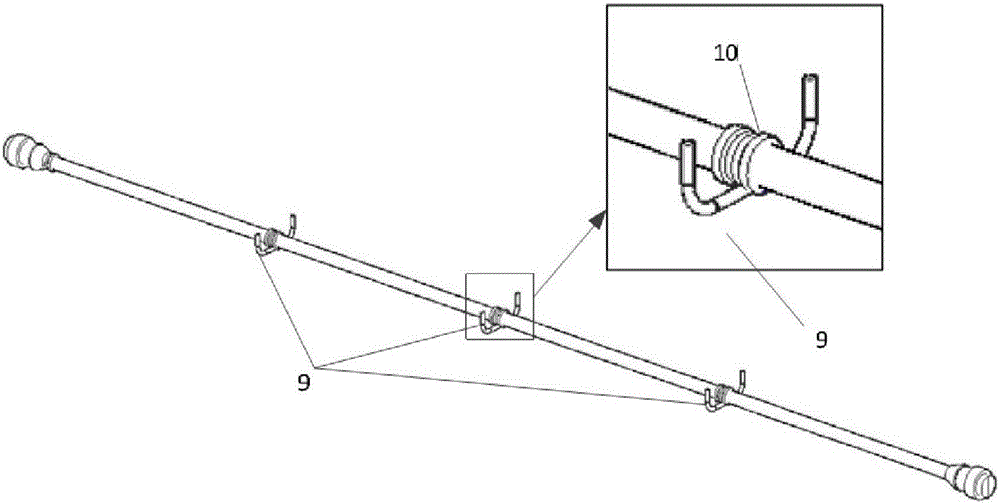

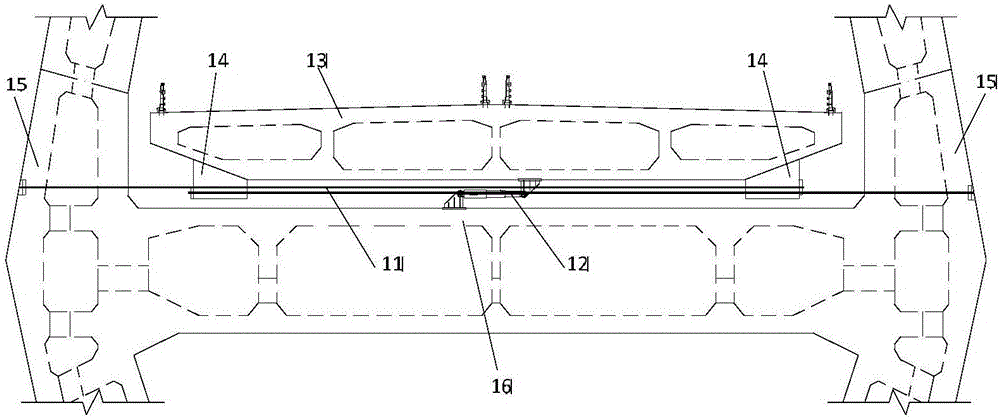

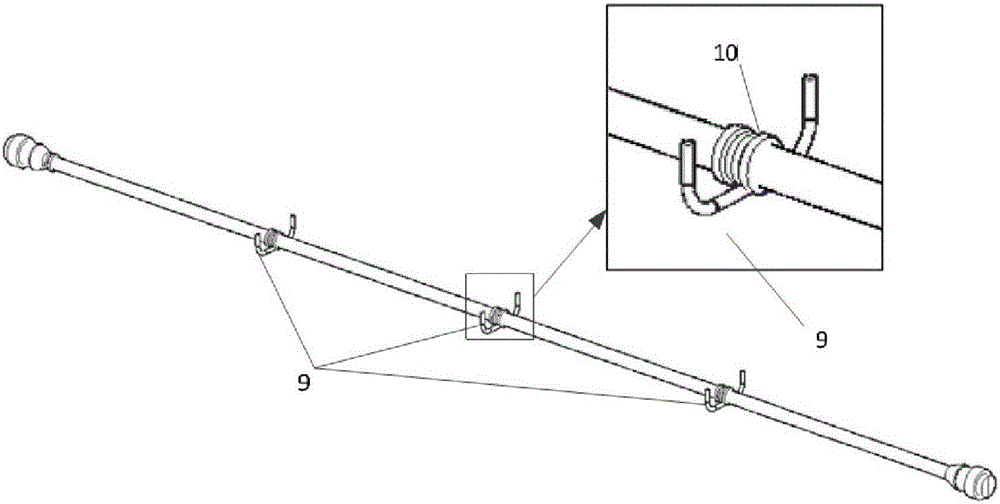

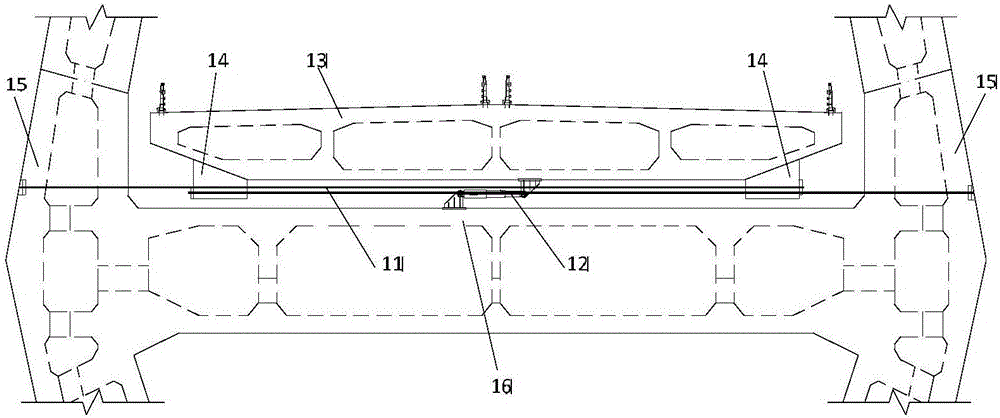

Large-span bridge elastic-plastic damping system

ActiveCN106284056ASimple shock-absorbing and isolation designImprove bearing capacityBridge structural detailsEngineeringElastic plastic

The invention relates to a large-span bridge elastic-plastic damping system. The large-span bridge elastic-plastic damping system comprises damping cable pairs composed of elastic-plastic damping cables and a transverse viscous damper. The two damping cable pairs are arranged, one ends of the damping cable pairs are anchored on anchoring blocks integrally cast with a main beam of a bridge, the other ends of the damping cable pairs are anchored on main tower columns on the other sides, and the two damping cable pairs are symmetrically arranged. One end of the viscous damper is anchored on the bottom of the main beam, and the other end of the viscous damper is anchored on a main tower cross beam of the bridge. The damping system can provide enough restraint rigidity and bearing force under the normal use condition, has enough deformation capacity and energy consumption under the strong earthquake condition, and can remarkably improve the anti-seismic performance of the large-span bridge in a highly seismic region.

Owner:CHINA ROAD & BRIDGE +1

Polyester-cotton anti-static functional fabric

InactiveCN104389072AImprove hydrophilic performanceImprove wetting propertiesCarbon fibresBiochemical fibre treatmentWeft yarnEngineering

The invention discloses a polyester-cotton anti-static functional fabric, which is woven by warp yarns and weft yarns, wherein the weft yarns are polyester-cotton blended plied yarns, the weft yarns are formed by uniformly ranging polyester-cotton blended plied yarns and polyester-cotton blended yarns / carbon fiber filament fasciated yarns according to a certain proportion at intervals, and the polyester-cotton blended yarns / carbon fiber filament fasciated yarns are spun by using carbon fiber filaments as core yarns of an inner layer and using the polyester-cotton blended yarns as the fasciated yarns of an outer layer by a parallel spinning process. Compared with the prior art, the polyester-cotton anti-static functional fabric has the advantages and beneficial effects that 1, the fabric made of anti-static fasciated yarns has the effects that the intensity utilization rate is high, the abrasion-resistant performance is better, deformation cannot easily occur, the hand feeling is soft, the fabric is well-rounded and has the special luster, and in addition, the damage of machines to carbon fiber in the post processing process of the yarns can be effectively avoided; 2, after the fabric is washed for more than 50 times, the anti-static performance is only reduced by 1 percent to 5 percent, and the technical requirements of anti-static clothing standards (GB12014-2009) can still be met.

Owner:SWOTO PROTECTION & TECH CO LTD

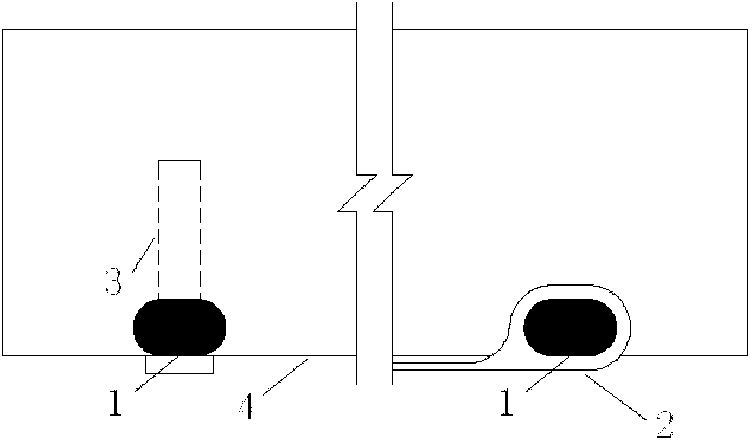

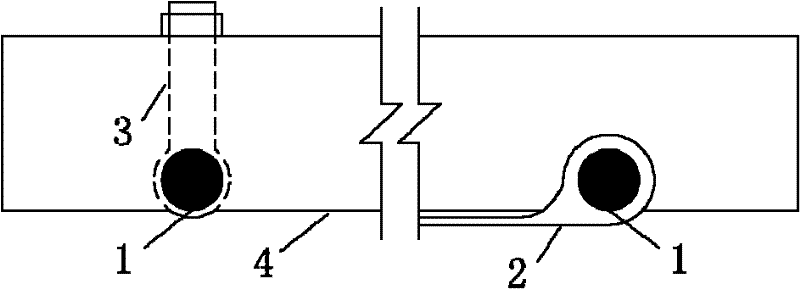

Method for lapping and anchoring fiber sheet around rod to reinforce structural component

InactiveCN101929254BImprove strength utilizationOvercomes the significant drawback of being prone to force peelingBuilding repairsBridge erection/assemblyFiberBand shape

Owner:CENT SOUTH UNIV

Coal gangue novel lightweight wall material and preparation method

InactiveCN104973883AMeet the needs of energy saving and consumption reductionReduce building energy consumptionCeramicwareSpray GranulationFoaming agent

The invention discloses a coal gangue novel lightweight wall material and a preparation method thereof. The novel lightweight wall material is prepared from the raw materials by mass percent of 43-84.5% of coal gangue, 5-20% of fluxing agent, 0.5-2% of foaming agent and 10-35% of perlite by the steps of mixing, spray granulation, die filling and sintering. The wall material disclosed by the invention has the characteristics of light weight and high impact strength and a lightweight, thermal-insulation, durable and environment-friendly novel lightweight wall material, wherein the volume weight is 250-290kg / m<3> and the impact strength is not lower than 2kJ / m<2>.

Owner:HUICHUN LYUJIA CONSTR MATERIAL CO LTD

Balanced pressure-bearing battery pack, preparation method thereof and structural integrated battery box

ActiveCN114665205AIncreased pressure and shock resistanceAvoid battery cycle life degradationCell component detailsBusbarElectrical connection

The invention relates to a balanced pressure-bearing battery pack, a preparation method thereof and a structural integrated battery box. The battery pack comprises a supporting structure unit and a top plate structure unit, the supporting structure unit comprises a bottom plate and a plurality of single batteries; the top plate structure unit comprises an insulating flat plate layer, a first supporting strip and a sheet-shaped busbar; the sheet busbar is parallel to the top cover of the single battery and is electrically connected with the pole body; the upper surfaces of all the flaky busbars are equal in height; the upper edge of the first supporting strip is as high as the upper surface of the sheet-shaped busbar; the insulating flat plate layer is erected on the upper surfaces of the first supporting strip and the sheet-shaped busbar; a fixed glue layer is arranged between the bottom plate and the shell bottom of the single battery; and the thickness of the fixed glue layer is greater than the height tolerance between the upper surface of the sheet-shaped busbar and the shell bottom. According to the invention, the height tolerance among different single batteries in the CTC battery pack is reduced to the greatest extent, so that the CTC battery pack can bear pressure in a balanced manner, the integrity and the structural strength of the battery pack are effectively improved, and the stable and normal work of the battery pack is ensured.

Owner:JIAXING MODULE BONDING TECH CO LTD +1

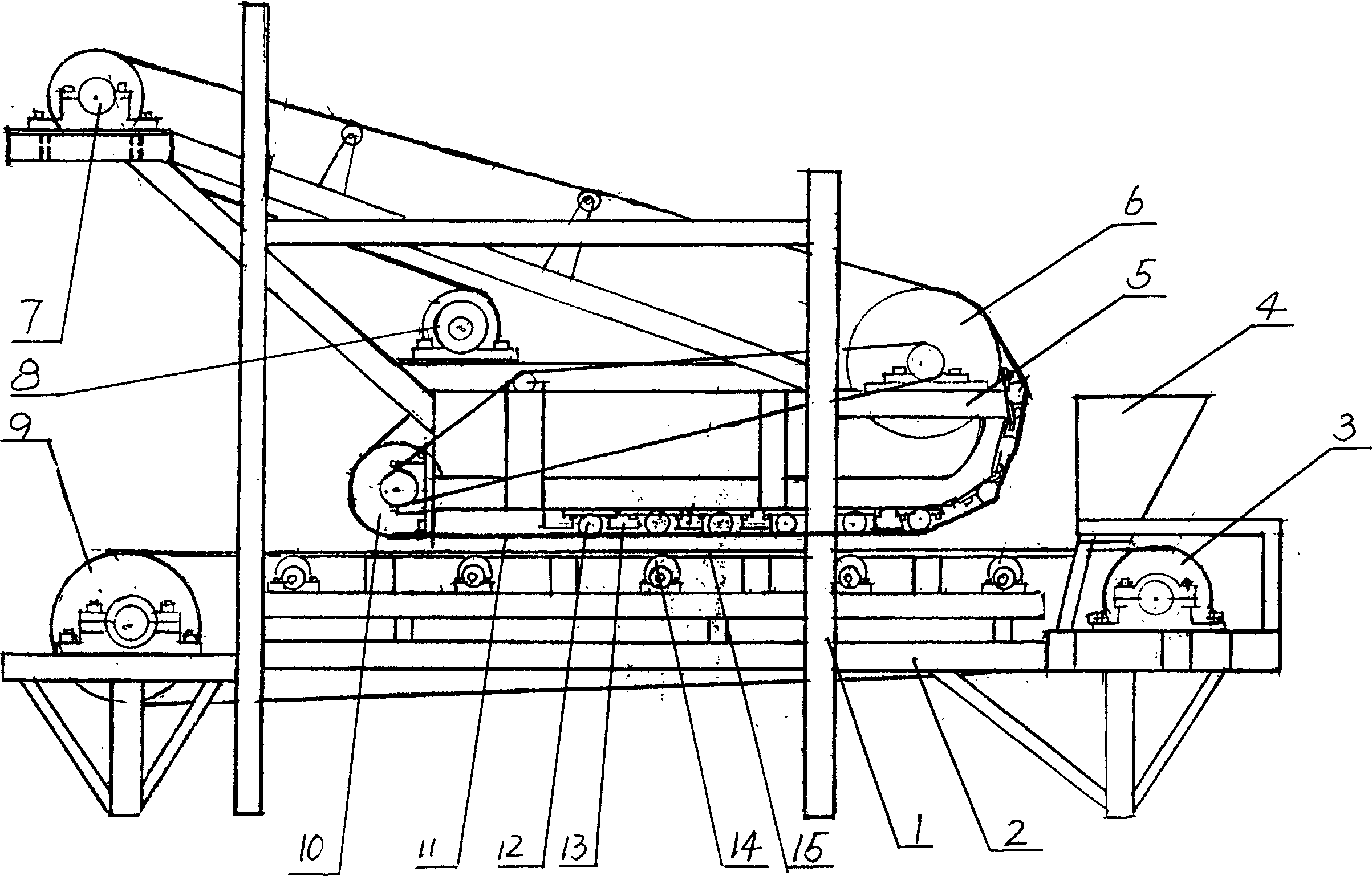

Magnetic dry lean iron ore separating machine

InactiveCN1857784AIncrease contact areaImprove strength utilizationMagnetic separationDrive wheelEngineering

The magnetic dry lean iron ore separating machine has one double-layered frame. The lower layer of horizontal frame has one magnetic wheel set on one end, one driven wheel on the other end, one belt conveyer between the magnetic wheel and the driven wheel and one feeding bin over the driven wheel. The upper layer triangular frame has one driving wheel on one end, one magnetic wheel on the other end, one driven wheel in the upper part, one belt conveyer with tightening wheel to connect the driving wheel, the magnetic wheel and the driven wheel, and permanent magnets to form suspending magnetic field inside the conveying belt between the driving wheel and the magnetic wheel. The present invention has combined magnetic field structure, increased contact area between the material and the magnetic field, raised magnetic field utilization rate, and excellent separating effect, and is especially suitable for magnetic separation of lean iron ore.

Owner:张明臣

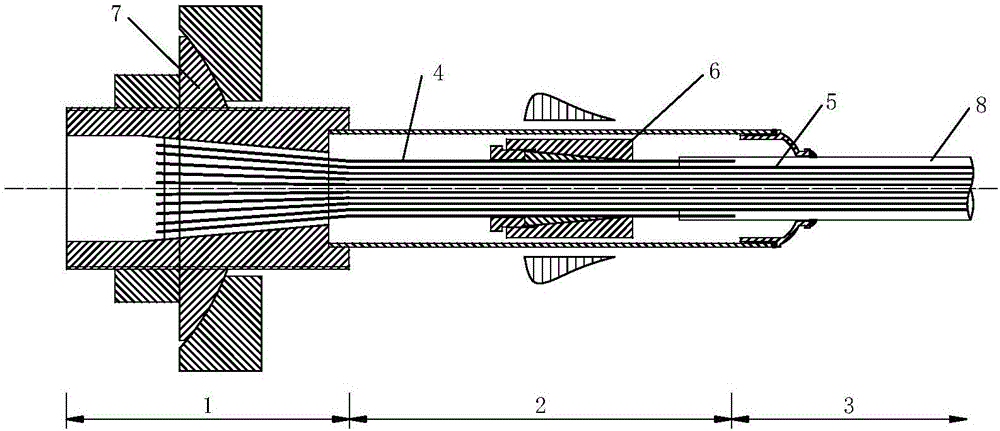

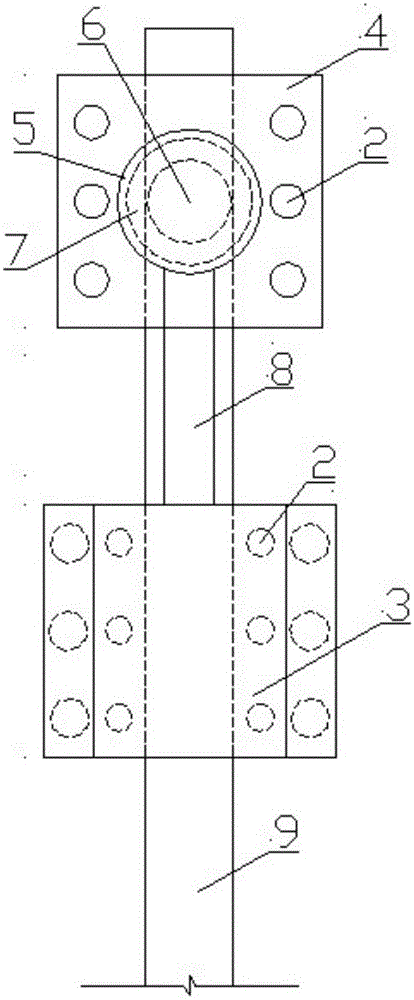

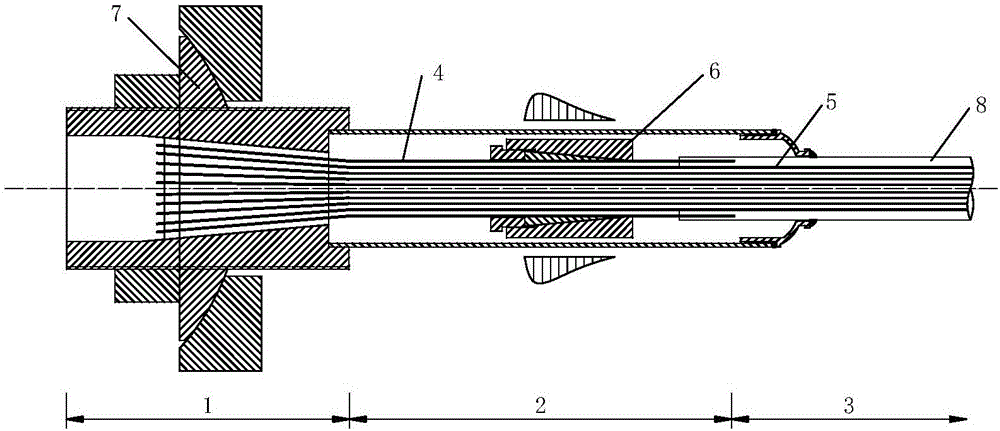

Apparatus and method for reinforcing column by prestressed fiber sheet

The present invention discloses an apparatus for reinforcing a column by a prestressed fiber sheet. The apparatus comprises a fixing end anchor and a tensioning end anchor which are anchored to a concrete column, and a convex type hydraulic jack connected with the fixing end anchor and the tensioning end anchor. The apparatus also comprises a dimidiate clamping piece type fixture, a cylinder with a column cap is welded to an upper surface of the clamping piece type fixture, and a sleeve sleeving the cylinder is connected to the convex type hydraulic jack through a jacking rod. One end of the fiber sheet is clamped by the clamping piece type fixture at a tensioning end, and the other end of the fiber sheet is anchored to the fixing end anchor. Prestress can be effectively applied to the externally wrapped fiber sheet for reinforcing the column, the thinner fiber sheet such as fiber cloth and the thicker fiber sheet such as a fiber board can be effectively clamped, higher prestress can be maintained, steel amount is reduced, reinforcing cost is saved, and construction is rapid and convenient, thereby facilitating promotion and application for engineering reinforcement.

Owner:SOUTHEAST UNIV +2

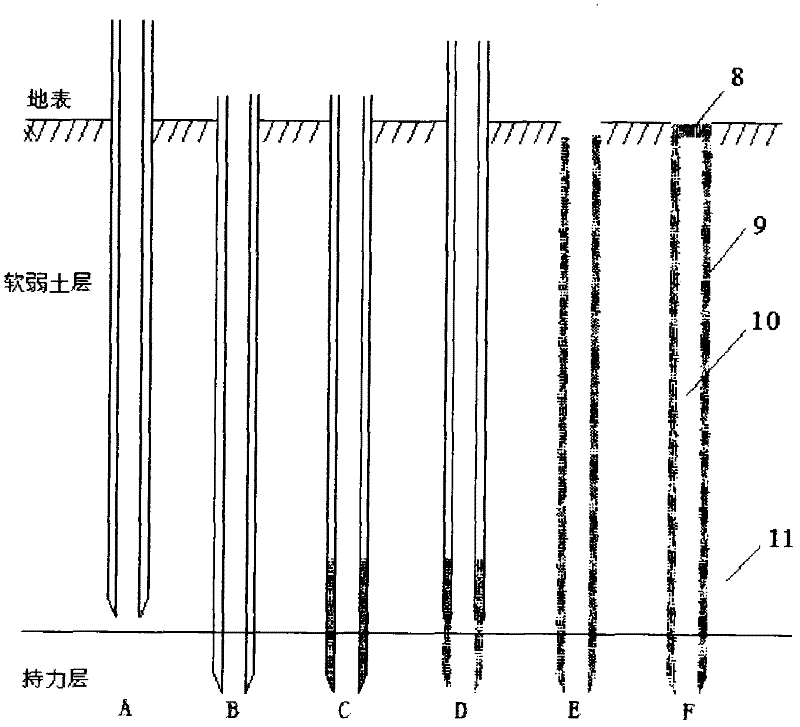

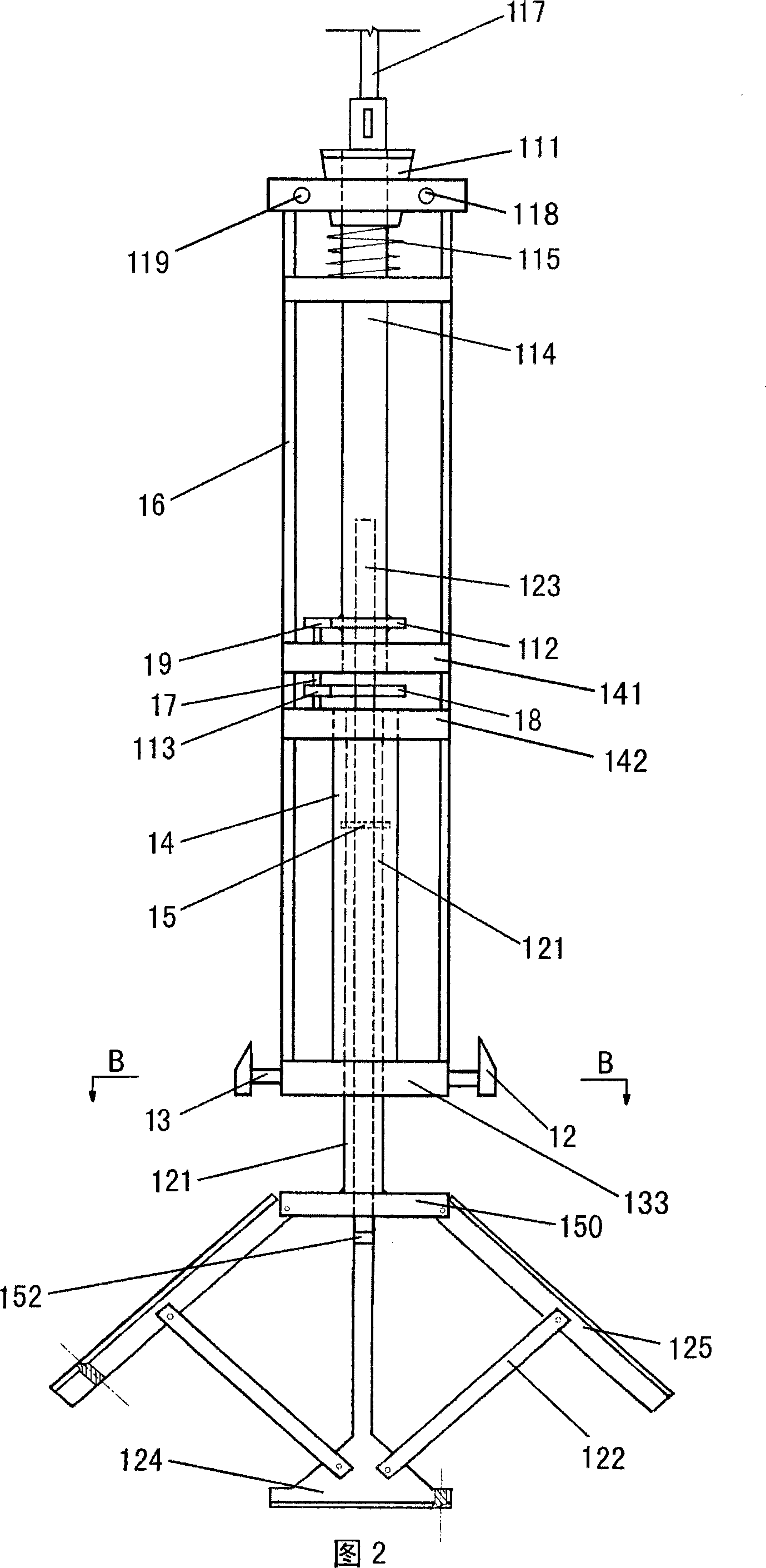

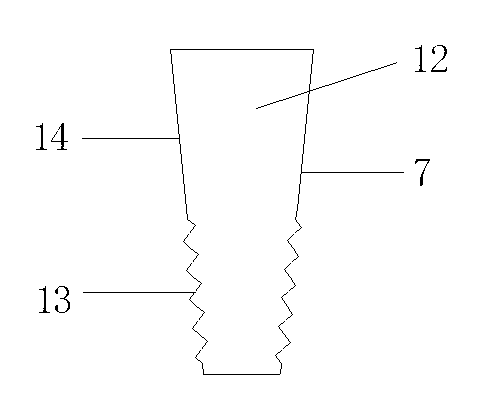

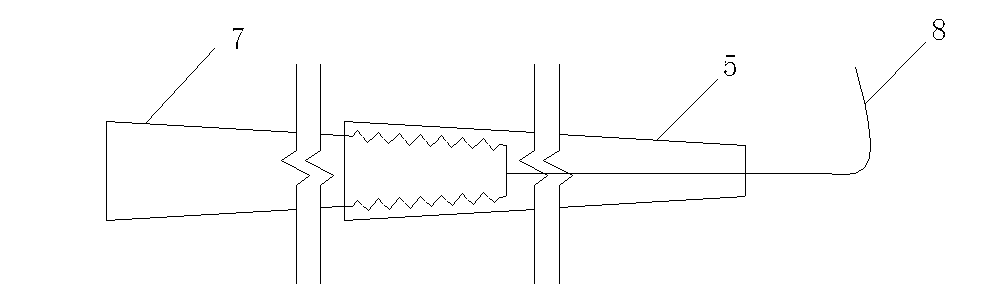

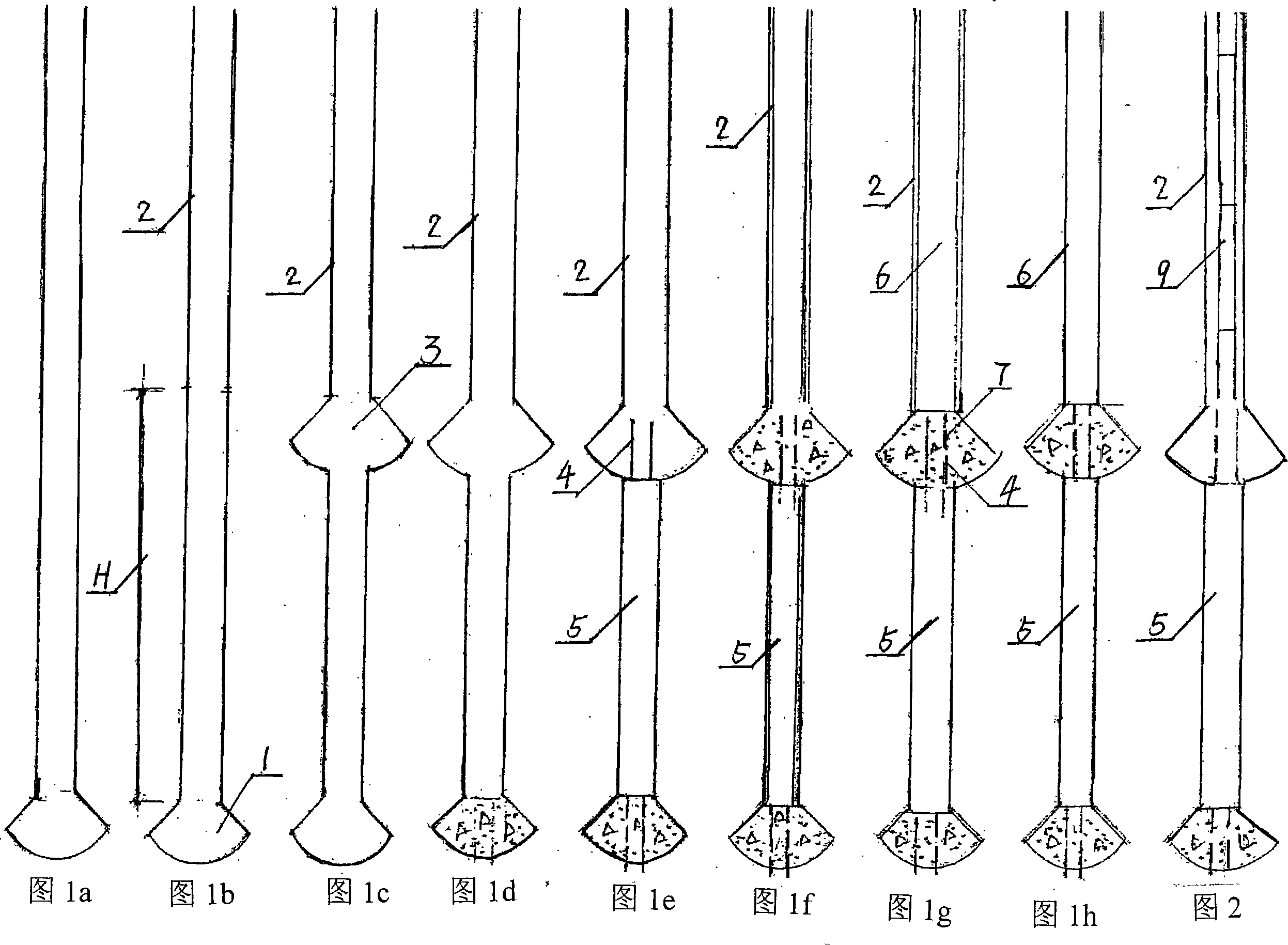

Combined pile of pre-stressed wedge-shaped pipe pile and pre-stressed pipe pile

The invention relates to combined pile of a pre-stressed wedge-shaped pipe pile and a pre-stressed pipe pile, which belongs to the technical field of building pile foundation and is characterized in that according to the soil layer properties as well as the pipe pile design and construction requirements, the combined form of the pre-stressed pipe pile and the pre-stressed wedge-shaped pipe pile is designed, so that the pile foundation achieves the best technical and economic effect; all pipe sections are connected through a threaded mechanical quick connection method; and under general circumstances, the lower part adopts pre-stressed wedge-shaped pipe pile pipe sections, and the upper part adopts the combination of pre-stressed pipe pile pipe sections. The combined pile has the advantages and the benefits that a pre-stressed conical pipe body can improve the positive friction force on the pile side, and simultaneously can effectively reduce the impact of the negative friction force to the pile body, and the prefabricated pre-stressed conical pipe pile body is easy to ensure the strength and the construction compression efficiency of the pile body; and the pre-stressed pipe pile can effectively improve the strength and the pile body and the resistance of the pile end. The pile model can improve the unit material strength utilization rate, improve the positive friction force on the pile side and the resistance on the pile end, and simultaneously can effectively reduce the impact of the negative friction force on the pile side on the pile body, so as to improve the overall bearing capability of a foundation pile.

Owner:HOHAI UNIV

Elastic-plastic damping cable for transverse damping of large-span bridge

ActiveCN106320163AEasy to solveImprove bearing capacityBridge structural detailsBridge materialsEngineeringElastic plastic

The invention relates to an elastic-plastic damping cable for transverse damping of a large-span bridge. Redundant design is adopted for inhaul cable anchoring, and a redundant cable wire reinforcing segment is additionally arranged between an anchoring zone and an effective cable segment. The number of cable wires in the anchoring zone and the reinforcing segment is larger than that of effective cable wires, redundant cable wires are cut off in the effective cable segment, a tension resisting capacity level difference between the anchoring zone and the reinforcing segment, and the effective cable segment is formed, and thus it is avoided that potential weak and destructive links occur in the anchoring zone or the reinforcing segment. Damping cables can provide sufficient restraint rigidity and bearing capacity under the normal use condition and have sufficient deformability and energy dissipation capacity under the strong earthquake condition, and therefore the seismic performance of the large-span bridge in a strong earthquake area can be significantly improved.

Owner:CHINA ROAD & BRIDGE +1

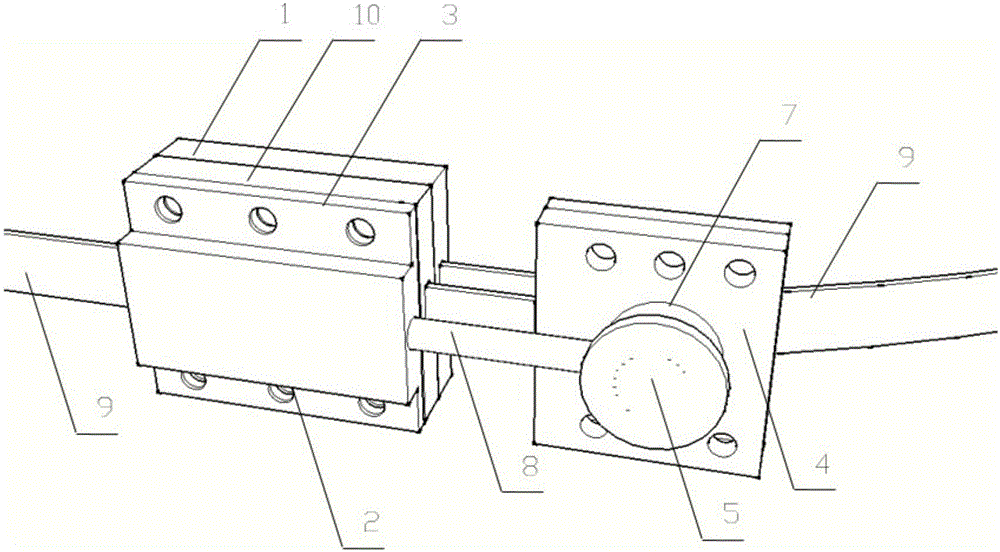

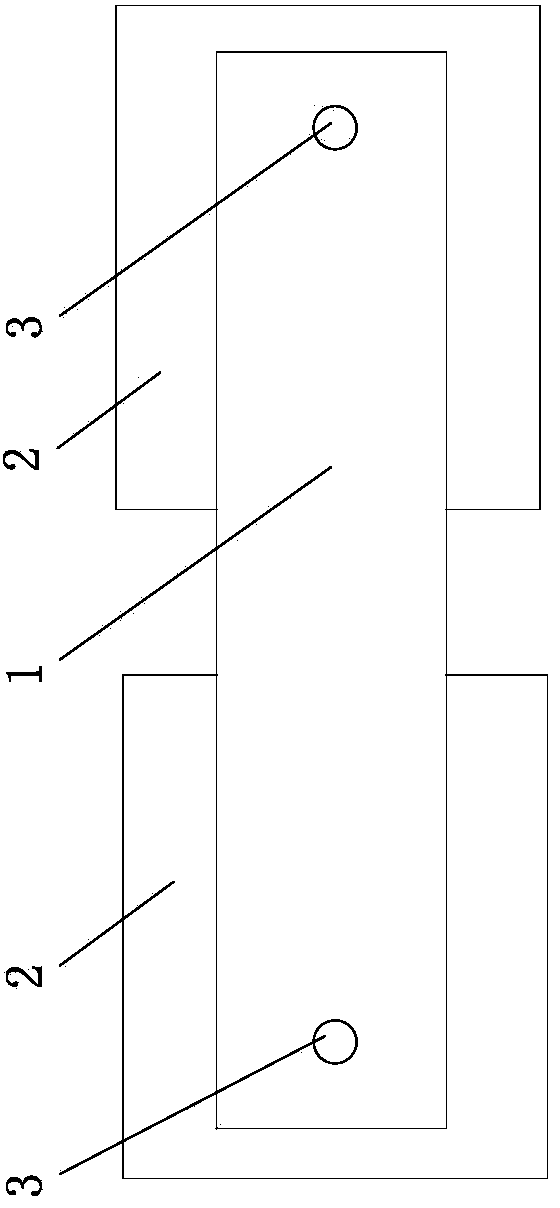

Bridge hinge joint reinforcing method through transverse anchoring steel plates

InactiveCN103911959AIncreased shear capacityImprove strength utilizationBridge erection/assemblyBridge strengtheningSteel platesHinge joint

The invention relates to a bridge hinge joint reinforcing method through transverse anchoring steel plates, and aims to improve loading resistance of bridge plates effectively and construct without interrupting traffic. The method has the advantages that construction is facilitated and rapid, and construction quality is easy to guarantee. According to the technical scheme, the bridge hinge joint reinforcing method through the transverse anchoring steel plates sequentially includes 1, cleaning the beam bottom edge portion; 2, adopting bolts to fix a plurality of sets of combined steel plates which cross hinge joints to connect two plate beams integrally on the two plate beams. Each set of combined steel plates comprises a strip steel plate and two backing plates respectively clamped between the plate beams and the strip steel plate.

Owner:GEOTECHN TECH

Novel carbon fiber composite material

The present invention discloses a novel carbon fiber composite material, which comprises, by weight, 30-34 parts of carbon fiber, 21-27 parts of epoxy resin, 17-24 parts of aqueous epoxy resin emulsion, 14-20 parts of an accelerator, 10-15 parts of a toughening agent and 1-3 parts of a curing agent. The material is able to meet the requirements of carbon fiber composite rope matrix resin, and has high comprehensive utilization of fiber strength; and the addition of aqueous epoxy resin emulsion effectively protects the carbon fiber, avoids the friction and wear between the fiber bundles, and enhances the bending resistance of the composite material.

Owner:合肥仲农生物科技有限公司

Single yarn, manufacturing method of single yarn, single yarn products and manufacturing method of single yarn product

The invention relates to a single yarn, a manufacturing method of the single yarn, single yarn products and a manufacturing method of the single yarn products. The manufacturing method of the single yarn includes bundling or bundling and twisting ultra-high molecular weight polyethylene films or strips to obtain the single yarn. The single yarn product at least comprises a body made with the single yarn. The single yarn made by bundling or bundling and twisting the ultra-high molecular weight polyethylene films or strips replaces traditional ultra-high molecular weight polyethylene fibers in developing and manufacturing various products. The single yarn has the advantages, such as wear resistance, impact resistance, corrosion resistance and ultraviolet resistance, similar to those of the ultra-high molecular weight polyethylene fibers; the single yarn further has the unique advantages, such as good structural integrity, high strength, high utilization rate of strength, high productivity, low manufacturing cost, light weight and low linear density. Therefore, the single yarn can replace the traditional ultra-high molecular weight polyethylene fibers in manufacturing the various products and is widely applicable.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

Fiber-reinforced bamboo-wood composite CLT beam (plate)

PendingCN108406983AImprove the bending capacityImprove strength utilizationWood veneer joiningFire resistanceUltimate tensile strength

The invention discloses a fiber-reinforced bamboo-wood composite CLT beam (plate) comprising an upper wood component and a lower component in the plate (beam) length direction and further comprising abamboo component and a lower reinforced fiber layer, wherein the bamboo component and the plate (beam) length direction are arranged in an orthogonal mode, and the lower reinforced fiber layer is distributed between the bamboo component and the lower wood component layer. The fiber-reinforced bamboo-wood composite CLT beam (plate) has the advantages that the fiber-reinforced bamboo-wood combinedCLT beam (plate) is the same as a traditional CLT component, the good size stability, fire resistance and heat insulation and sound insulation performance are achieved, factory modular production andprefabrication can be achieved, assembling is also convenient and rapid, and the environment friendly effect is achieved. Compared with the traditional CLT component of the same size, the anti-shearing strength, the anti-bending bearing capacity, the strength weight ratio and the like of the fiber-reinforced bamboo-wood combined CLT beam (plate) are improved, and the strength utilization rate of the component can be improved.

Owner:NANJING FORESTRY UNIV

Manufacturing method of main rope of plastic-coated water skiing rope

The invention provides a plastic-coated water skiing rope main rope. The plastic-coated water skiing rope main rope comprises a woven rope layer, a heat insulation layer and a plastic-coated layer; heat-resistant polymer fabric, non-woven fabric, a film or glass fiber cloth is adopted between the woven rope layer and the plastic-coated layer to serve as the heat insulation layer, and the thickness of the heat insulation layer is smaller than 0.5 mm; the plastic-coated layer is formed by melting and extruding raw materials and then uniformly coats the outer part of the heat insulation layer; the woven rope layer comprises a rope sheath and a rope core; the rope sheath is tightly coated outside the rope core; the rope sheath is woven into a tubular structure by adopting a weft guide knitted belt; the rope core consists of at least one three-strand twisted thread or a plurality of parallel yarns; and the diameter of the water skiing rope main rope is 4-8mm. The the water skiing rope main rope has the characteristics of high strength, small extension and the like, and the diameter can be greatly reduced under the condition of ensuring the strength.

Owner:青岛鲁普耐特绳网研究院有限公司

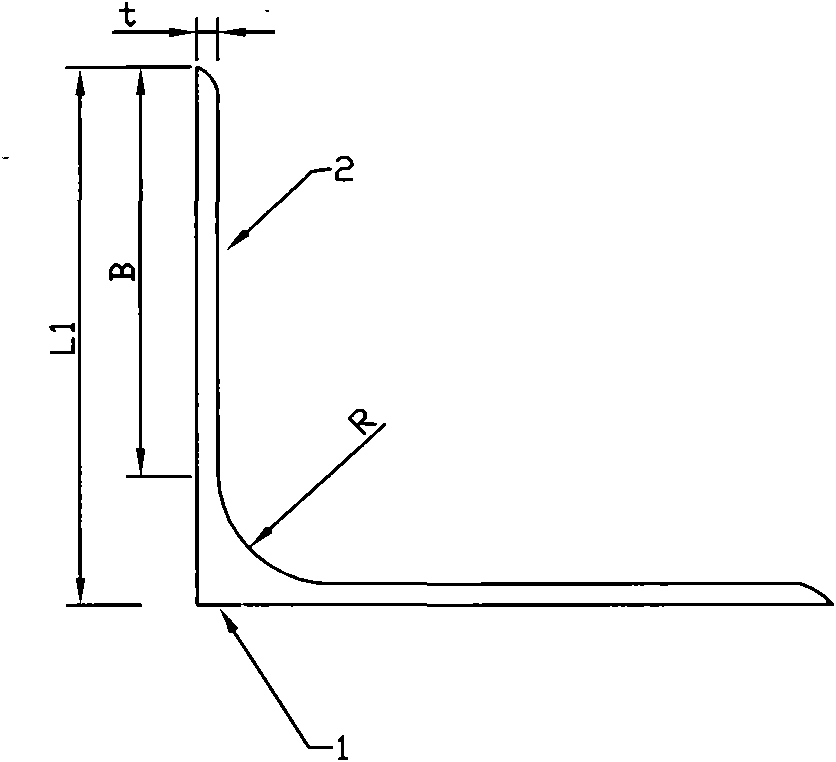

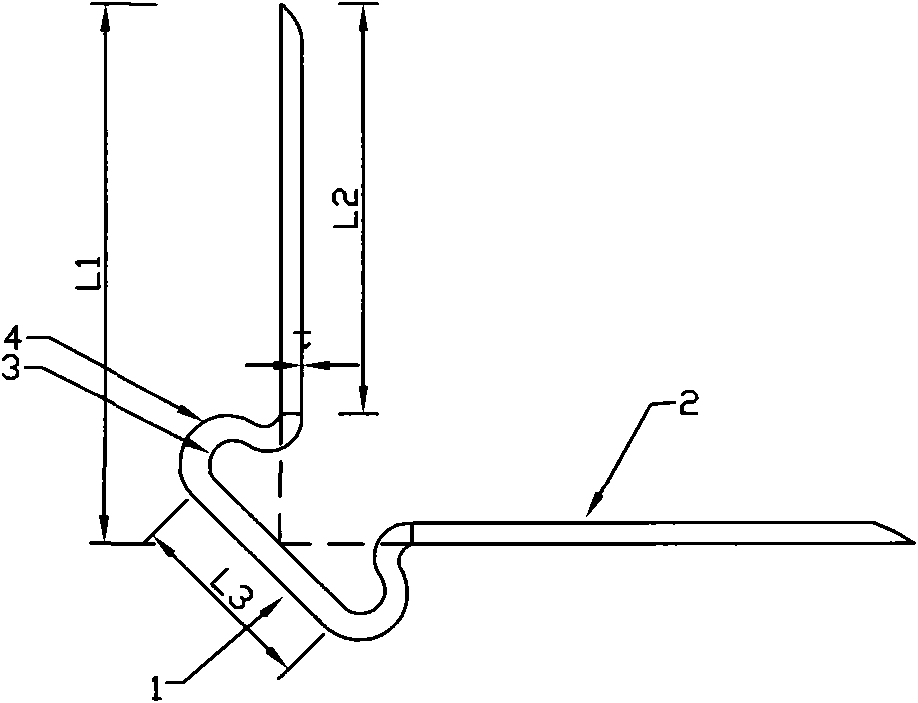

Dual-arc steel section structure design method

ActiveCN101852034AShorten the protruding lengthImprove strength utilizationTowersElectric power transmissionTransmission tower

The invention relates to a dual-arc steel section structure design method, in particular to a structure design method for a transmission tower material in the electric power transmission process. The dual-arc steel section structure of the scheme comprises a vertex angle and a limb plate, wherein the vertex angle is a flat reinforcing plate, and the connecting part of the limb plate and the reinforcing plate is in a relative S-shaped arc section. By adopting the cold-bending technology, a reasonable section shape in the optimized material distribution can be produced according to the need; and with the help of the advantages of the traditional hot-rolled angle steel and by combining the cold-bending technology, the dual-arc steel section structure of the scheme adopts a double S-shaped radian design, the ratio of the free extension length to the thickness of a flange plate can be optimized according to the need, the steel strength reduction due to stable strength is reduced, and the strength utilization ratio of member materials is improved. Compared with the traditional hot-rolled angle steel, the structure has better section characteristics through the arc design of the connecting points and the angle-strengthened protruding cold-bending processing, and the section bearing capacity is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +1

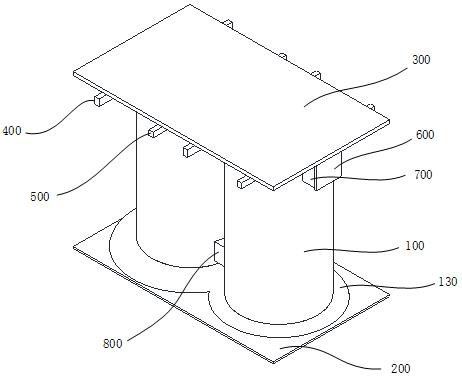

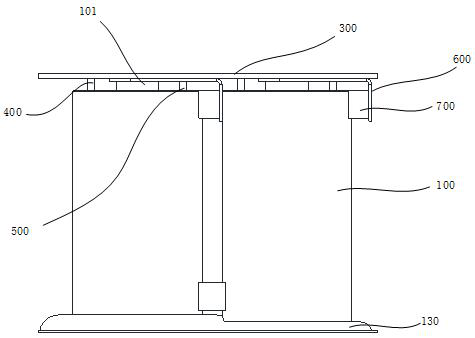

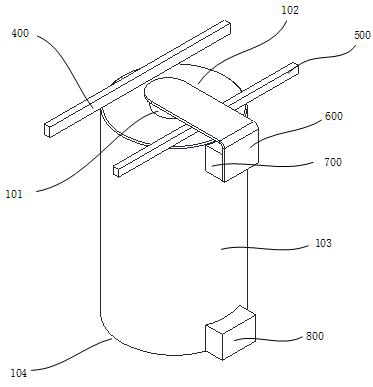

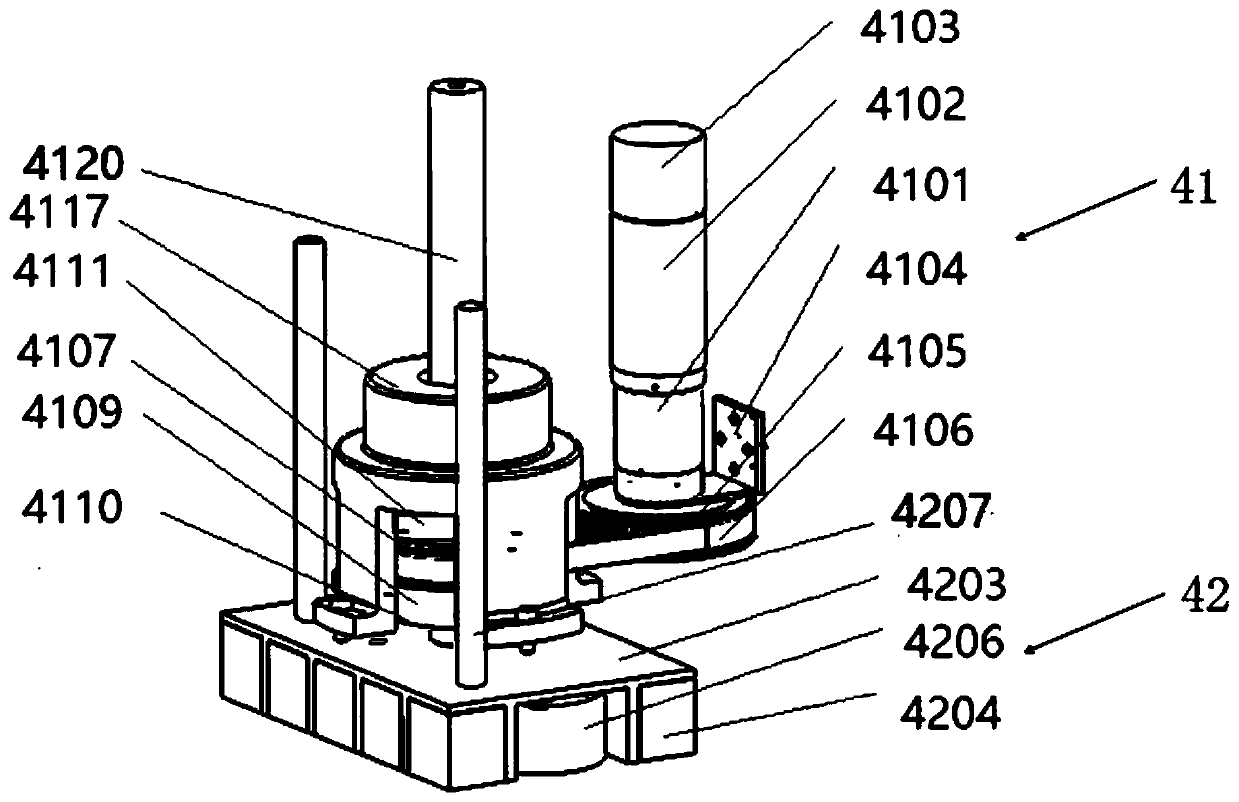

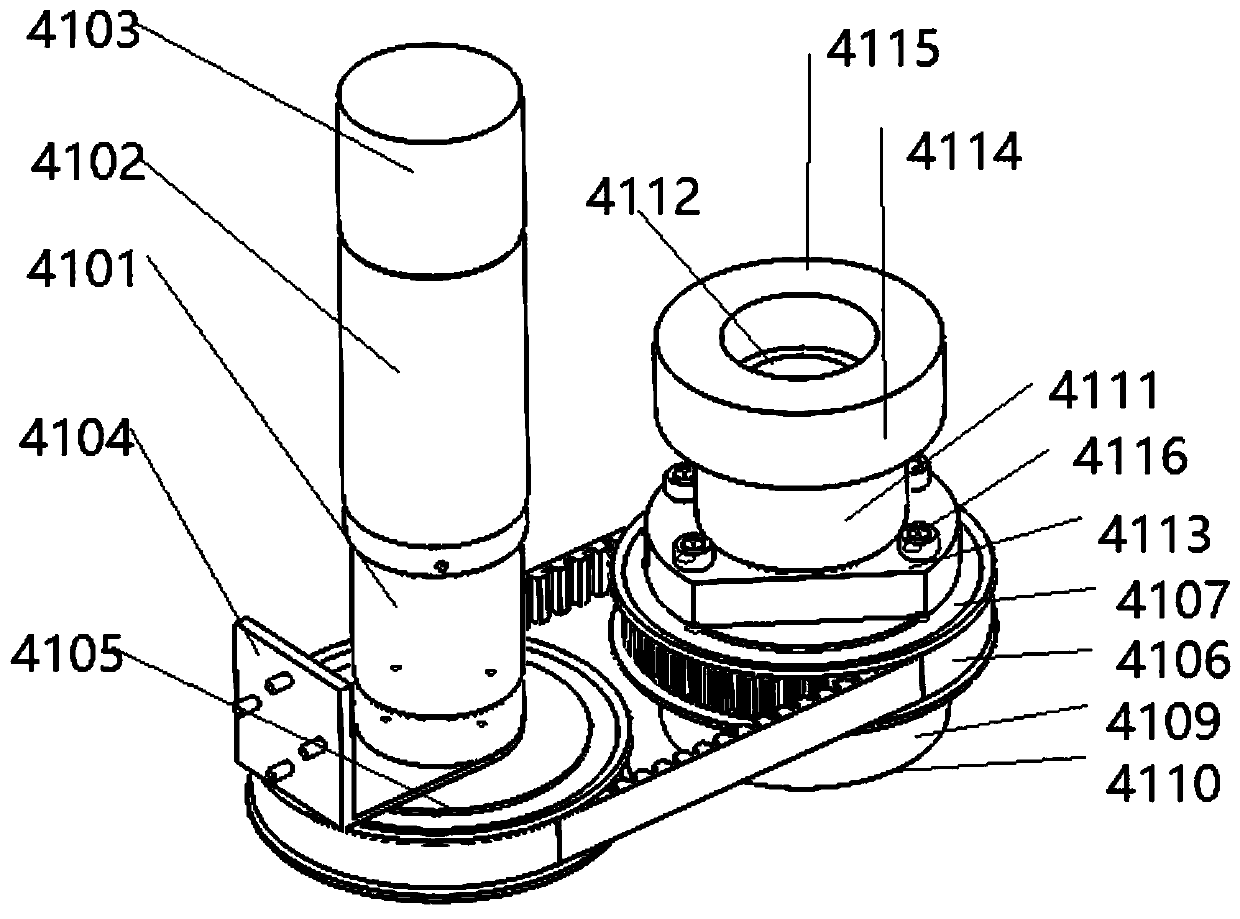

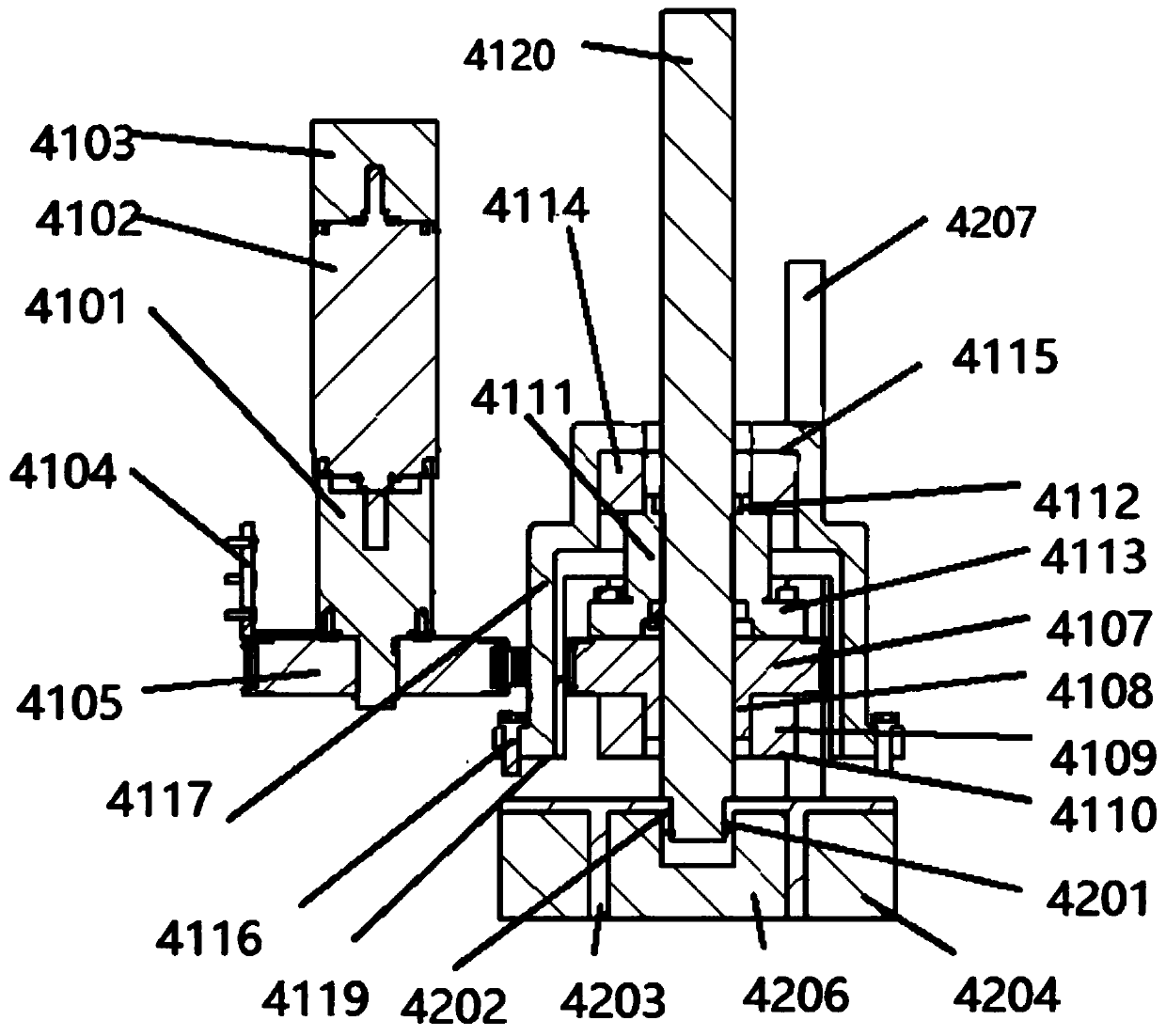

Obstacle-crossing wall-climbing robot combined variable magnetic force attraction module

The invention discloses an obstacle-crossing wall-climbing robot combined variable magnetic force attraction module. The obstacle-crossing wall-climbing robot combined variable magnetic force attraction module comprises a screw assembly and an attraction assembly; the screw assembly adopts a motor-belt wheel-belt-belt wheel-screw nut-screw power transmission mode so that a screw nut can drive a screw to move up and down, and accordingly, the attraction assembly is driven to move outside a vehicle frame up and down. The problem that when an existing permanent-magnetic wall-climbing robot operates on a large-size metal vertical face, the magnetic force cannot be changed is solved; through application of reverse motion of a screw mechanism, a permanent-magnetic attraction mechanism of the previous permanent-magnetic wall-climbing robot is perfected, thus, the magnetic force of a magnet can be changed along with changing of the shape of a wall obstacle in the robot obstacle crossing process, and the all-terrain adaptability is more excellent; magnetic induction line distribution of the combined variable magnetic force attraction module is improved, and the stability and safety of the robot in the operating process are improved; and by applying an electromagnet, the attraction force generated by the combined variable magnetic force attraction module can be adjusted more easily.

Owner:HEBEI UNIV OF TECH

High-density flat carbon fiber gradient stitching preform and preparation method thereof

ActiveCN114407227AIncrease the number of layersImprove performanceWork-feeding meansLayered productsCarbon compositesCarbon fibers

The invention discloses a high-density flat carbon fiber gradient stitching preform and a preparation method thereof, and belongs to the field of equipment materials. According to the method, the flat carbon fiber bundles are adopted and woven into the light and thin single-layer flat carbon fiber plane prefabricated body, and then the flat carbon fiber gradient stitching prefabricated body is prepared through gradient lamination and stitching, so that the requirements of high layer density, high bearing capacity, strong interlayer and low stitching damage are met; and the problems of high porosity, high cost, long period, frequent processing and low mechanical property retention rate of the subsequent carbon / carbon composite material are thoroughly solved.

Owner:JIANGNAN UNIV

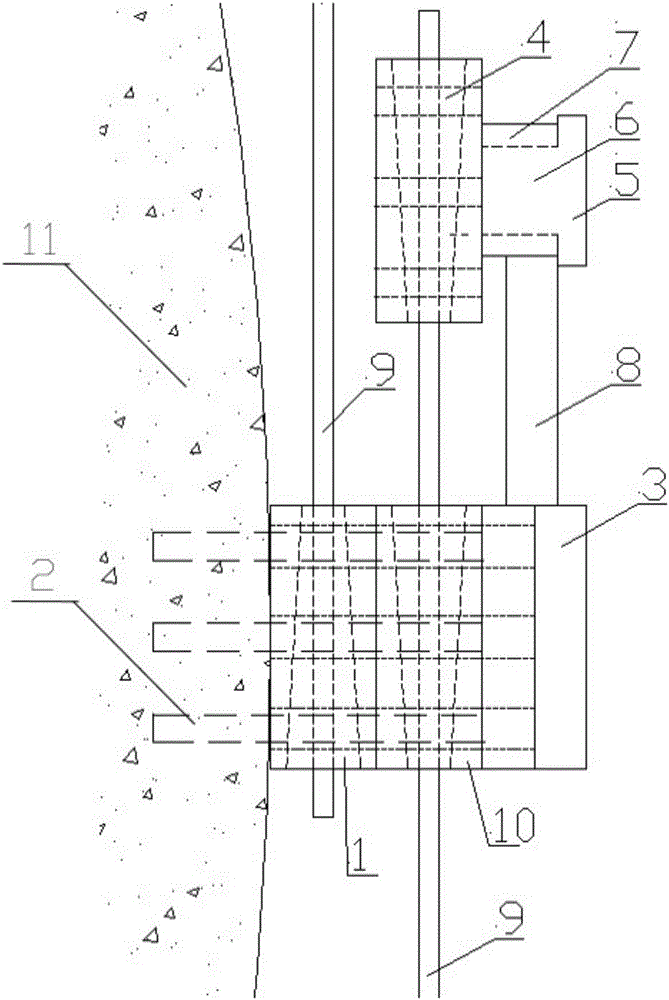

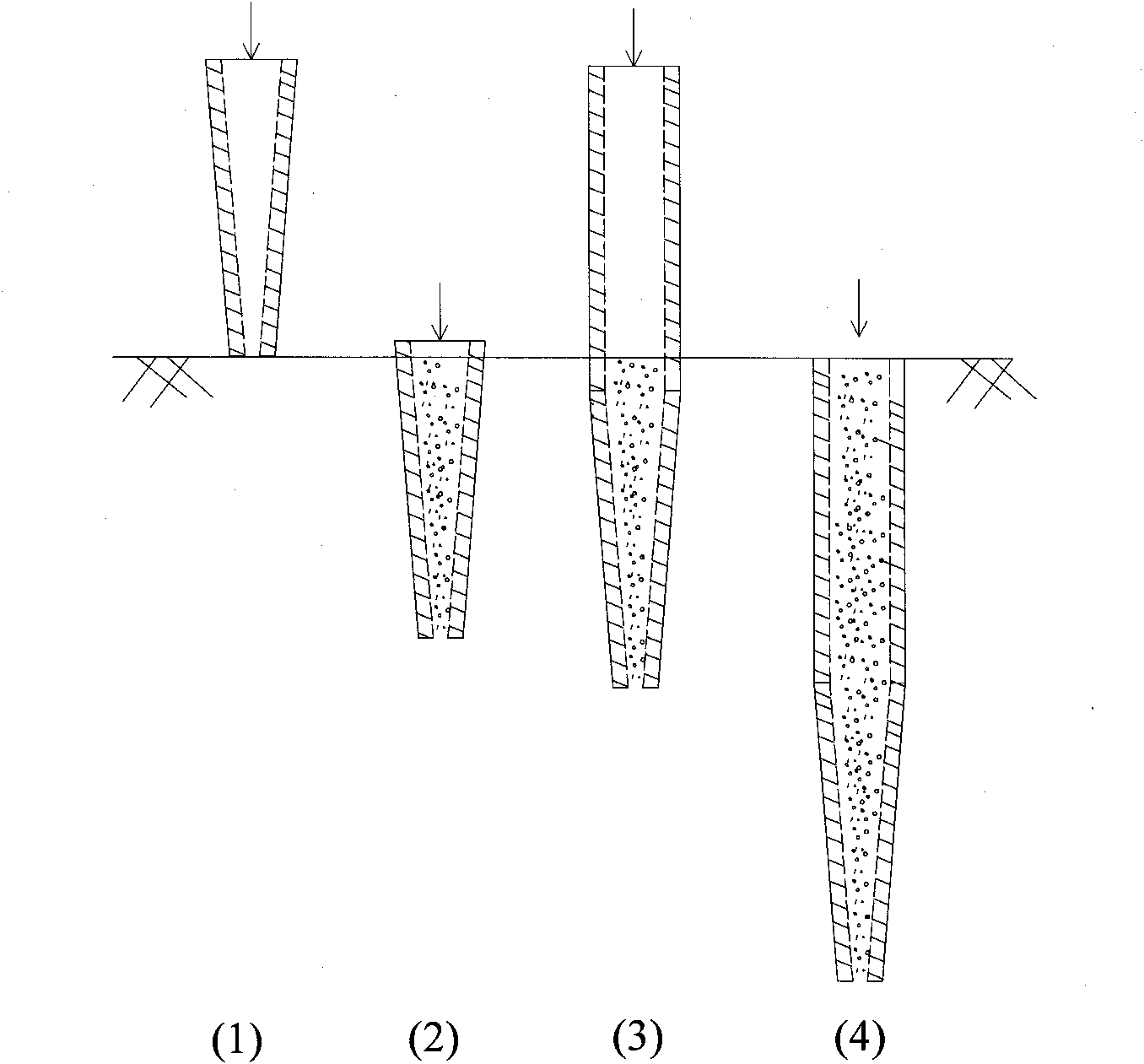

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101161948AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteBottom gate

The invention discloses a building pile foundation project and a construction method thereof, in particular a method for enlarging pedestal and forming pile of an immersed tube precast reinforced concrete pedestal pile; the method comprises the following steps that: the immersed tube is passed through a soft earth layer and pressed to a designed level hard earth layer; a metal pile head is taken out, and put into the immersed tube to enlarge the pedestal; the earth is extracted by a device which uses air to absorb earth, when a small amount of earth is left in a base, water is poured from the mouth of the immersed tube, the water is absorbed while the poured until the earth is completed absorbed; radial reinforcing steel bars are arranged in the cavity of the base, and the hard earth is hammered into the cavity of the base, the concrete precast on the ground is filled in a long barrel and the barrel is put to the bottom of the immersed tube from the mouth of the immersed tube, when iron bars arranged on the bottom of the barrel touch the hard earth, the bottom gate of the barrel is forced open, then the concrete falls into the cavity of the base to form a cast-in-situ base, the precast reinforced concrete pile body is sunk and in even joint with the cast-in-situ base through the dowel bars of the reinforced concrete pile body to be jointed and anchored into a whole; the immersed tube is extracted out and the pile is formed. The invention extracts earth completely without granular loose earth, has high efficiency, improves the bearing capacity of single pile effectively and meets the design requirements, thereby ensuring the quality of the pile foundation work project and reducing construction cost.

Owner:王国奋

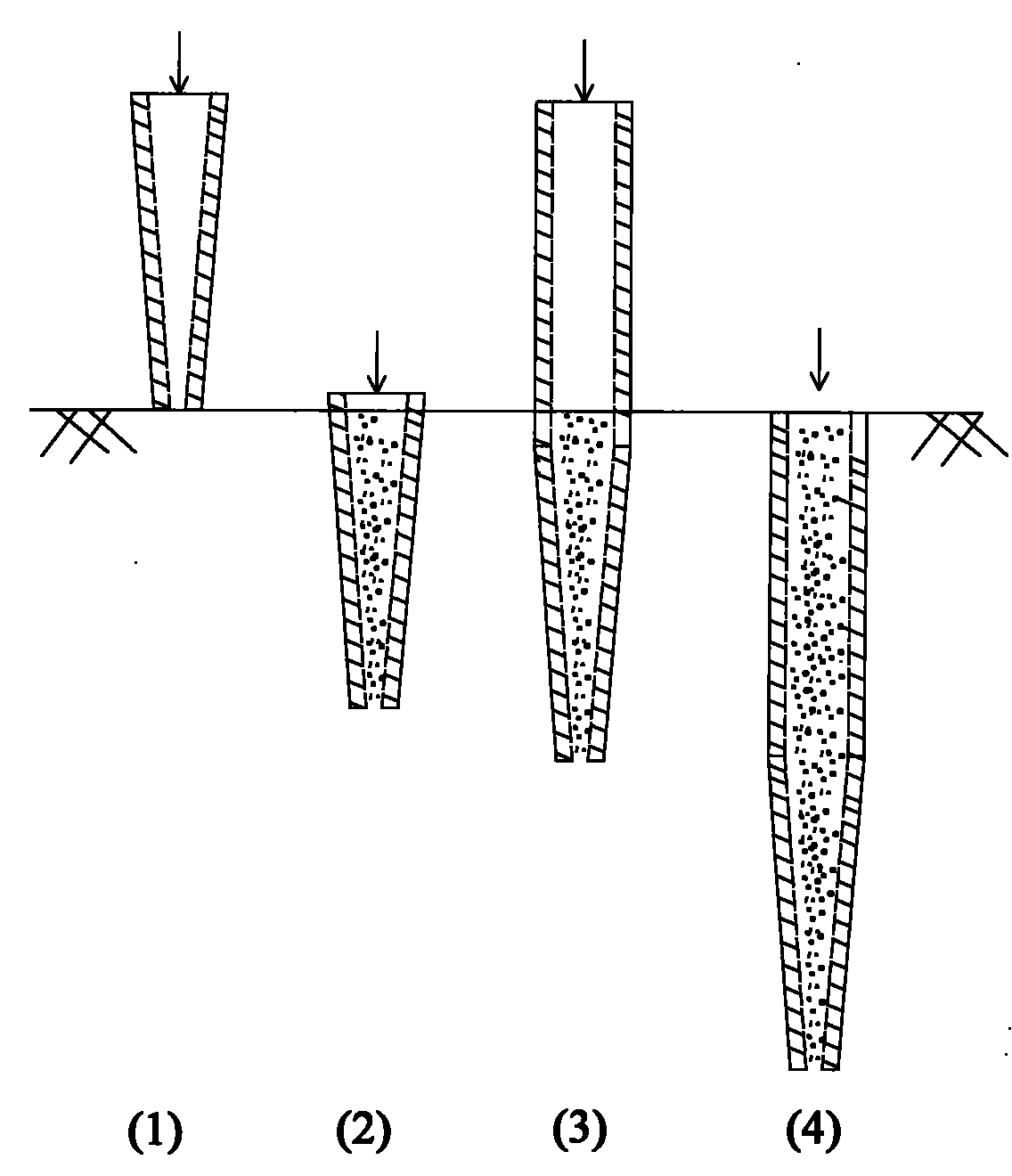

Cast-in-place X-shaped tapered pile with threaded end and construction method of tapered pile

InactiveCN102839654AReduce dosageLarge specific surface areaBulkheads/pilesOperabilityUltimate tensile strength

The invention provides a cast-in-place X-shaped tapered pile with a threaded end, which comprises a plastic casing and a pile body filled in a cavity of the plastic casing. The cross section of the pile body is X-shaped. The sectional area of the pile body is decreased gradually from the top down, and the pile body is in an inverted cone shape longitudinally. A threaded casing wall is arranged at the lower end of a casing wall of the plastic casing. The invention further provides a construction method of the cast-in-place X-shaped tapered pile with the threaded end. With the adoption of the cast-in-place X-shaped tapered pile with the threaded end, the usage of concrete is saved obviously, the unit material strength utilization ratio is increased, positive frictional resistance on the side of the pile is increased significantly, and the effect of negative frictional resistance on a pile foundation is eliminated to a greater extent. Furthermore, the construction process is simple, the operability is high, the construction indentation efficiency is high, and the bearing capacity of a single pile is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Bottom expanding and piling method by demolishing of pipe sank prefabricated steel concrete bottom expansion pile

The invention discloses a construction pile foundation project and a method for constructing the same, in particular a method for explosively expanding bottom and forming pile through immersed tube prefabrication steel concrete. The method comprises the following steps that: an immersed tube is pressed into a firm ground layer with a designed height; a metal pile head is taken out, emulsified oils or ammonium-antimony detonators are put into the immersed tube through the immersed tube orifice, and then the immersed tube orifice is sealed after the detonators are detonated; soil is taken out by using an air absorption soil device; whether the quality reaches the designed specification is checked by a camera with the light source in the base cavity; radial reinforcing steel bars are put into the base cavity and are hammered into the firm ground, stiff cement mortars which are prepared well on the ground are poured into the base cavity along the immersed tube orifice, and then carpolites are poured into the base cavity and a concrete base without sands is formed, the prestressing prefabrication hollow pile body which is put into the concrete base and the cast-in-place concrete base are butt jointed and anchor fixed to form a whole through the inserted reinforcing steel bars at the bottom of the concrete base; the immersed tube is pulled out, and then cement mortars are poured into along the gap which is formed after the immersed tube is pulled out, and then a pile is formed. The invention has the advantages that soil is cleanly taken out without granular loose soil and the efficiency is high.

Owner:王国奋

Mixed pile-forming method for multilevel expanding bottom pile with high bearing capacity

InactiveCN101130957AImprove carrying capacityImprove strength utilizationBulkheads/pilesHardpanImmersed tube

The present invention relates to construction of building pile foundation engineering, and is especially mixed piling process of multistage under-reamed pile with prefabricated pile foundation and great bearing capacity. The mixed piling process includes the following steps: immersing immersed tube with metal pile head into hardpan, taking out the metal pile head, forming the lower base space and taking out soil, drawing upwards the immersed tube to designed distance, forming the upper base space and taking out soil, pouring the lower base with concrete and inserting steel dowels, setting the prefabricated pile stem for the steel dowels to connect the lower prefabricated pile stem, the base and the upper prefabricated hollow pile stem integrally, withdrawing the immersed tube and injecting cement mortar to around the pile stem. The pile has small stem diameter, accurate location, high material strength utilizing rate and other advantages.

Owner:陈宁华

Manufacturing method of high-strength ultrahigh molecular weight polyethylene fiber rope

An embodiment of the invention discloses a manufacturing method of a high-strength ultrahigh molecular weight polyethylene fiber rope. The manufacturing method comprises the following steps of selecting a plurality of ultrahigh molecular weight polyethylene fibers with the set specifications for initial twisting, and applying tension at the strength of 0.034-0.104g / tex to the ultrahigh molecular weight polyethylene fibers in the initial twisting process, and carrying out initial twisting heat setting treatment to obtain ultrahigh molecular weight polyethylene rope yarns; carrying out re-twisting on the ultrahigh molecular weight polyethylene rope yarns, and applying tension at the strength of 0.153-0.198g / tex to the ultrahigh molecular weight polyethylene rope yarns in the re-twisting process, and carrying out re-twisting heat setting treatment to obtain ultrahigh molecular weight polyethylene re-twisted rope strands; and weaving the ultrahigh molecular weight polyethylene re-twisted rope strands into a rope, applying tension at the strength of 0.208-0.495g / tex to the ultrahigh molecular weight polyethylene re-twisted rope strands, and carrying out weaving heat setting treatment.

Owner:青岛鲁普耐特绳网研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com