High-density flat carbon fiber gradient stitching preform and preparation method thereof

A technology of carbon fiber and prefabricated body, which is applied in the field of high-rise dense flat carbon fiber gradient stitched prefabricated body and preparation, which can solve the problems of high porosity, low retention rate of mechanical properties and frequent processing of carbon/carbon composite materials, and achieve high utilization rate of fiber strength , Solve the effect of poor accuracy of structural parameters and improvement of densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

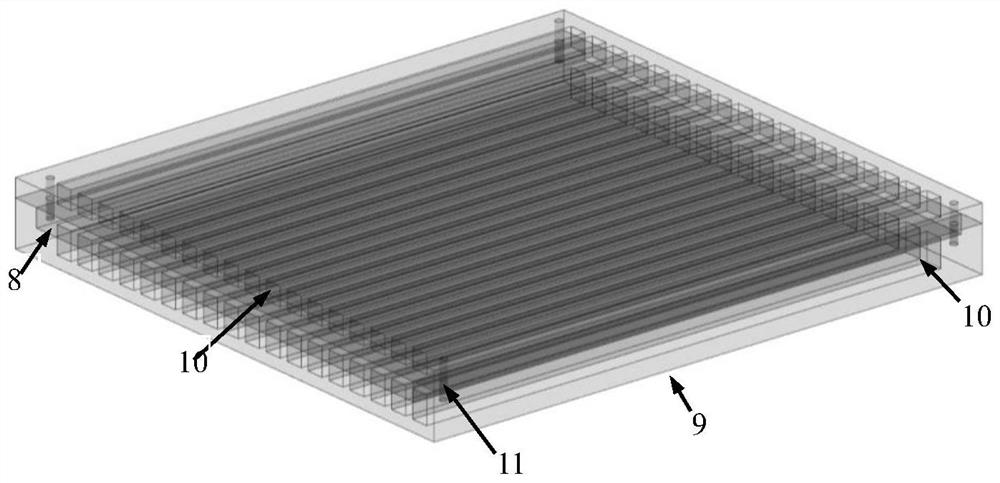

[0042] A high-rise dense flat carbon fiber gradient stitched prefabricated body, the length of which is 300mm, the width is 300mm, the thickness is 6mm, the number of layers is 50, and the adjustable range of gradient pores in the thickness direction is 100%;

[0043] A method for preparing a high-density flat carbon fiber gradient stitching prefabricated body, comprising the following steps:

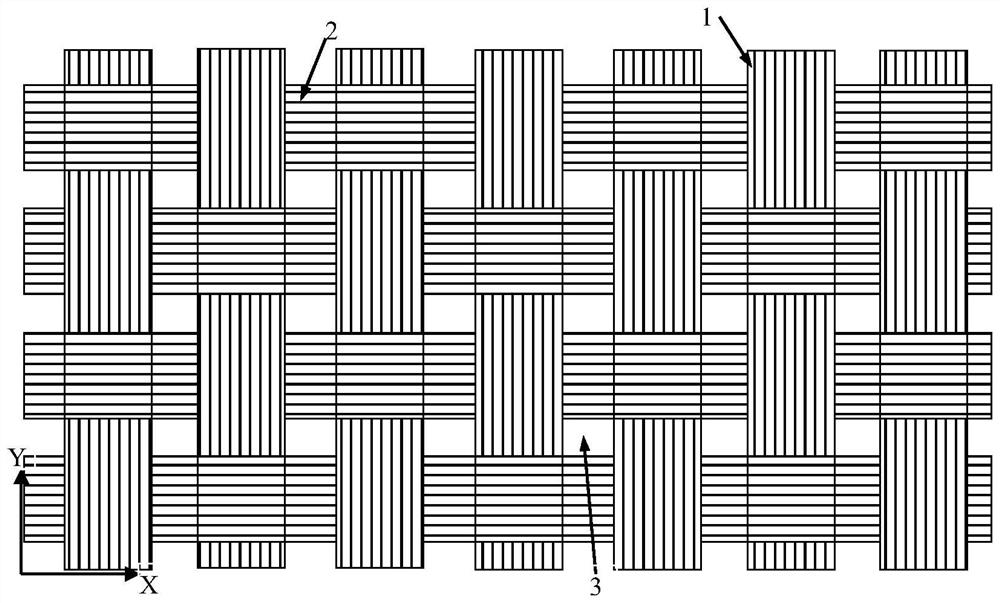

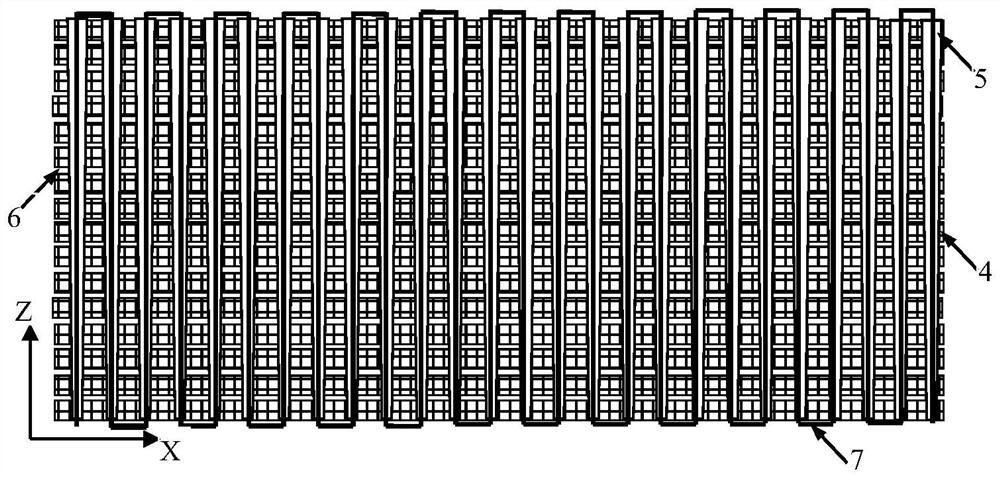

[0044] (1) The carbon fiber T700-12K is processed by a mechanical stretching process to obtain a 20mm wide flat carbon fiber bundle; after that, a 20mm wide flat carbon fiber bundle is used according to the warp and weft yarns, and the pores of the adjacent warp yarns and adjacent weft yarns are 0.1 and 0.12 respectively , 0.14, 0.16, 0.18mm, weaving plain fabric, surface density is 60g / cm 2 -70g / cm 2 , obtained the single-layer flat carbon fiber planar prefabricated body (structure such as figure 1 );

[0045] (2) Lay 10 layers of single-layer flat carbon fiber planar prefabricated ...

Embodiment 2

[0051] A high-rise dense flat carbon fiber gradient stitched prefabricated body, the length of which is 500mm, the width is 500mm, the thickness is 6mm, the number of layers is 60, and the adjustable range of gradient pores in the thickness direction is 100%;

[0052] A method for preparing a high-density flat carbon fiber gradient stitching prefabricated body, comprising the following steps:

[0053] (1) The carbon fiber T700-12K is processed by a mechanical stretching process to obtain a 23mm wide flat carbon fiber bundle; after that, 23mm wide flat carbon fiber bundles are used according to the warp and weft yarns, and the pores of the adjacent warp yarns and adjacent weft yarns are 0.1 and 0.12 respectively , 0.14, 0.16, 0.18mm, weaving plain fabric, surface density is 45g / cm 2 -55g / cm 2 , obtained the single-layer flat carbon fiber planar prefabricated body;

[0054] (2) Spread 12 layers of single-layer flat carbon fiber planar prefabricated bodies with pores of 0.1 mm ...

Embodiment 3

[0058] A high-rise dense flat carbon fiber gradient stitched prefabricated body, the length of which is 300mm, the width is 300mm, the thickness is 7mm, the number of layers is 50, and the adjustable range of gradient pores in the thickness direction is 100%;

[0059] A method for preparing a high-density flat carbon fiber gradient stitching prefabricated body, comprising the following steps:

[0060] (1) The carbon fiber T700-12K is processed by the mechanical widening process to obtain 10, 12, 14, 16, 18mm wide flat carbon fiber bundles; after that, the yarns used in the warp and weft are the same, all using 10, 12, 14, 16, 18mm wide flat carbon fiber bundles, according to the adjacent warp and adjacent weft pores are 0.4, 0.35, 0.3, 0.25, 0.2mm, weave plain weave fabric, surface density is 60g / cm 2 -100g / cm 2 , obtained the single-layer flat carbon fiber planar prefabricated body;

[0061] (2) Lay 10 layers of single-layer flat carbon fiber plane preforms with pores of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com