Dual-arc steel section structure design method

A cross-sectional structure and design method technology, applied in the field of power equipment, can solve problems such as component buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

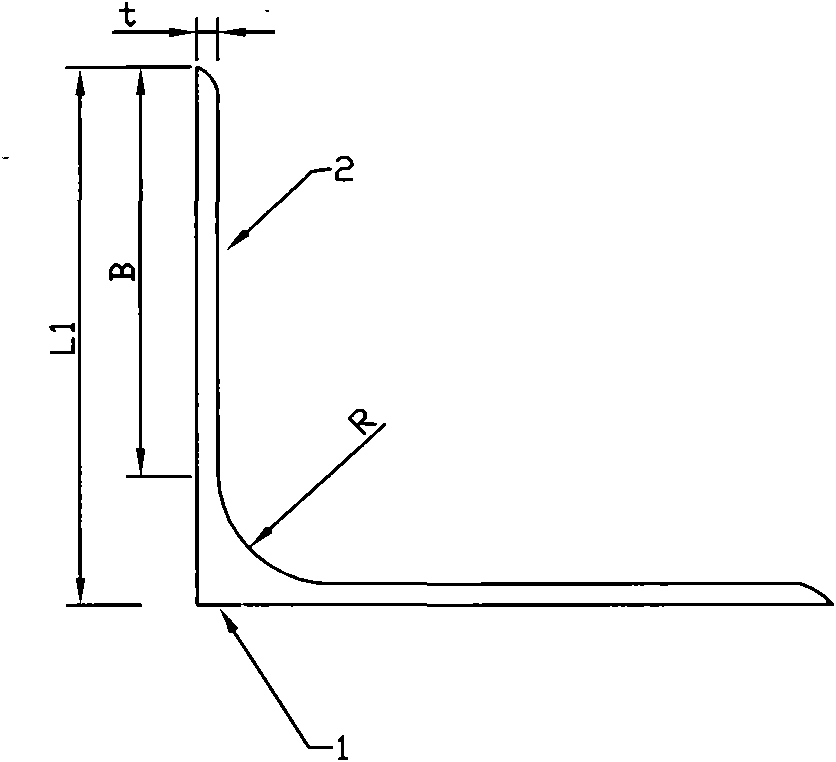

[0013] Example 1: For the traditional hot-rolled angle steel specification Q345L125×8 commonly used in power transmission towers, the limb plate width L1=125mm, the steel thickness t=8mm, the inner arc radius R=14mm, and the Q345 steel design strength f=310N / mm 2 ; Flange overhang width B = 125mm-8mm-14mm = 103mm, then the flange overhang width-thickness ratio According to technical regulations Stable strength reduction factor of compression bar Stabilization strength was reduced by 9.3%.

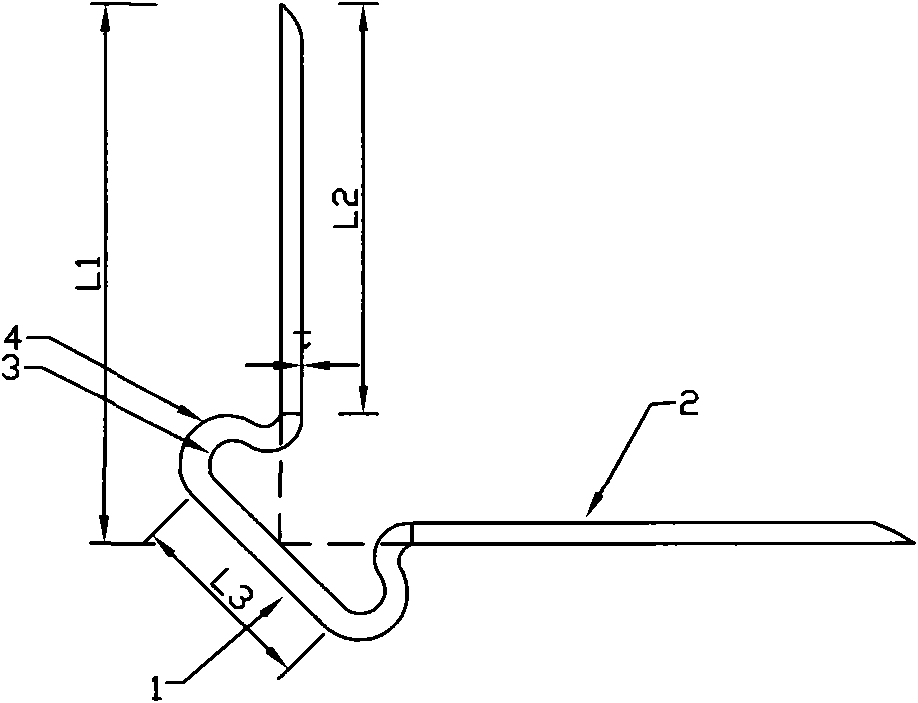

[0014] Use the same parameters to calculate the double arc steel section structure, according to the design strength of Q345 steel f=310N / mm 2 And the thickness t=8mm, determine the overhang width of the flange Round the flange overhang width L2=91mm, determined by the cold bending process, the inner arc radius R1=8mm-2mm=6mm of the corner bending part, the outer arc radius R2=R1+8mm=14mm, The length of the reinforcing plate is rounded to L3=28mm. After the above parameters are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com