Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Balanced force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

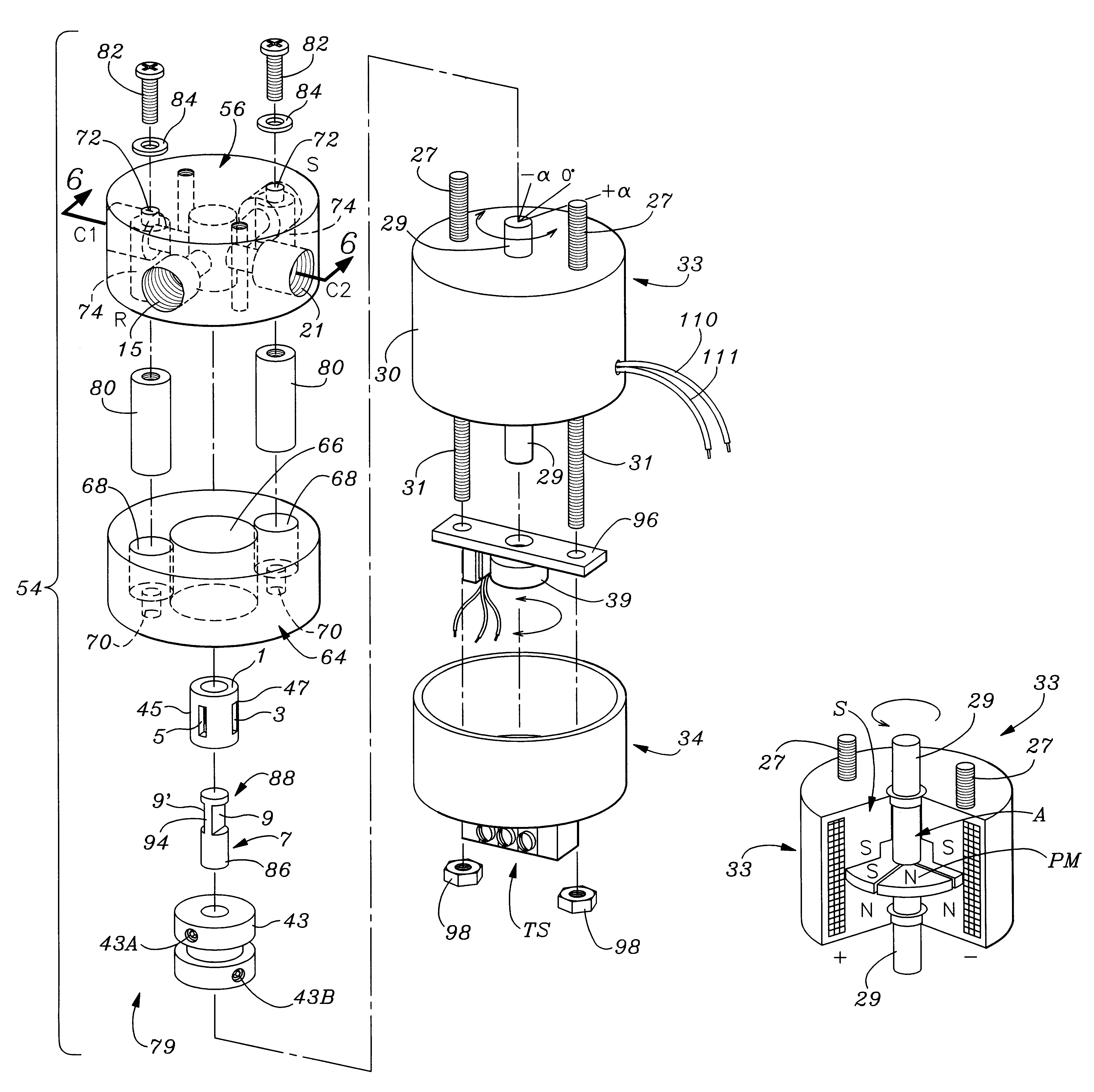

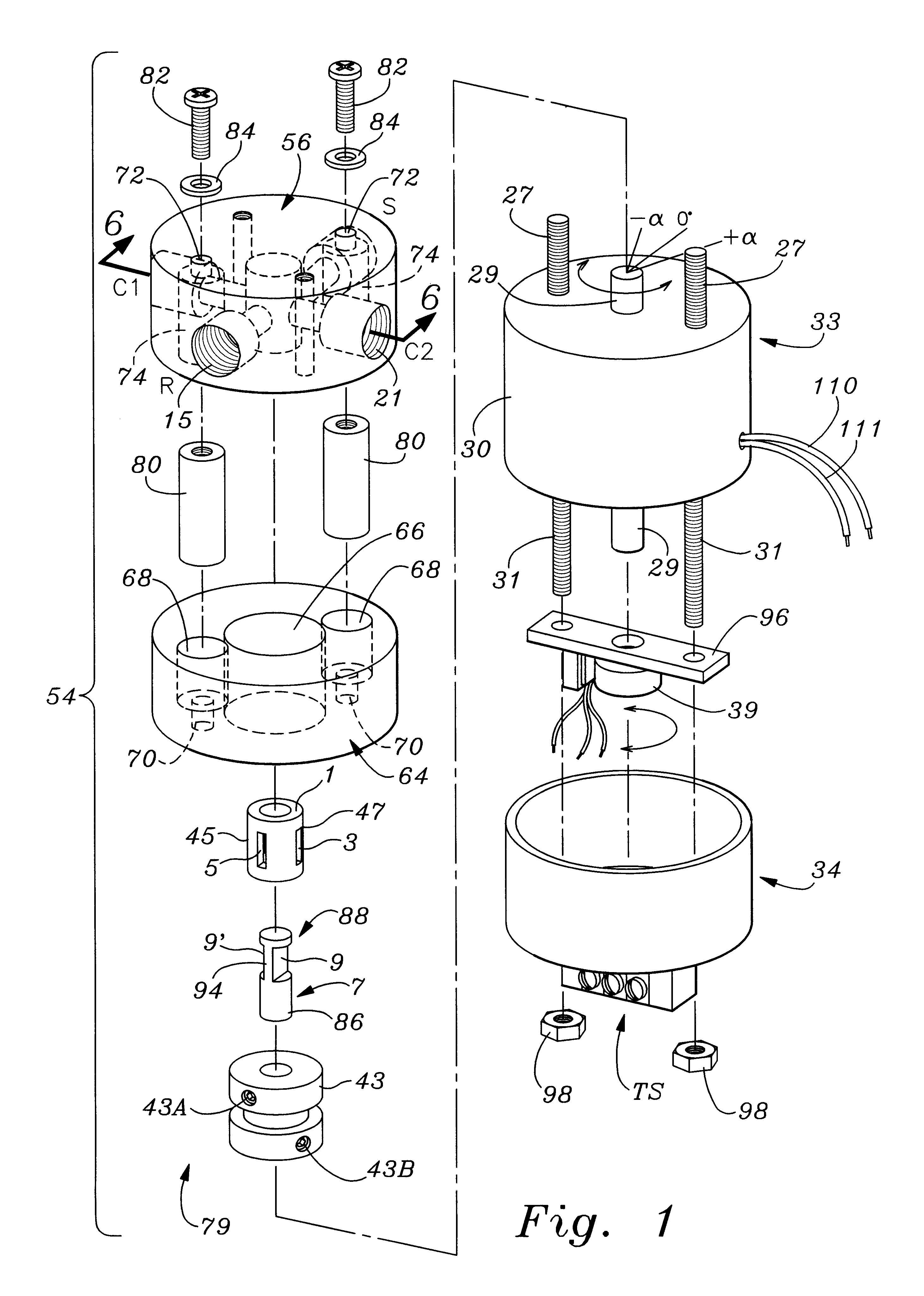

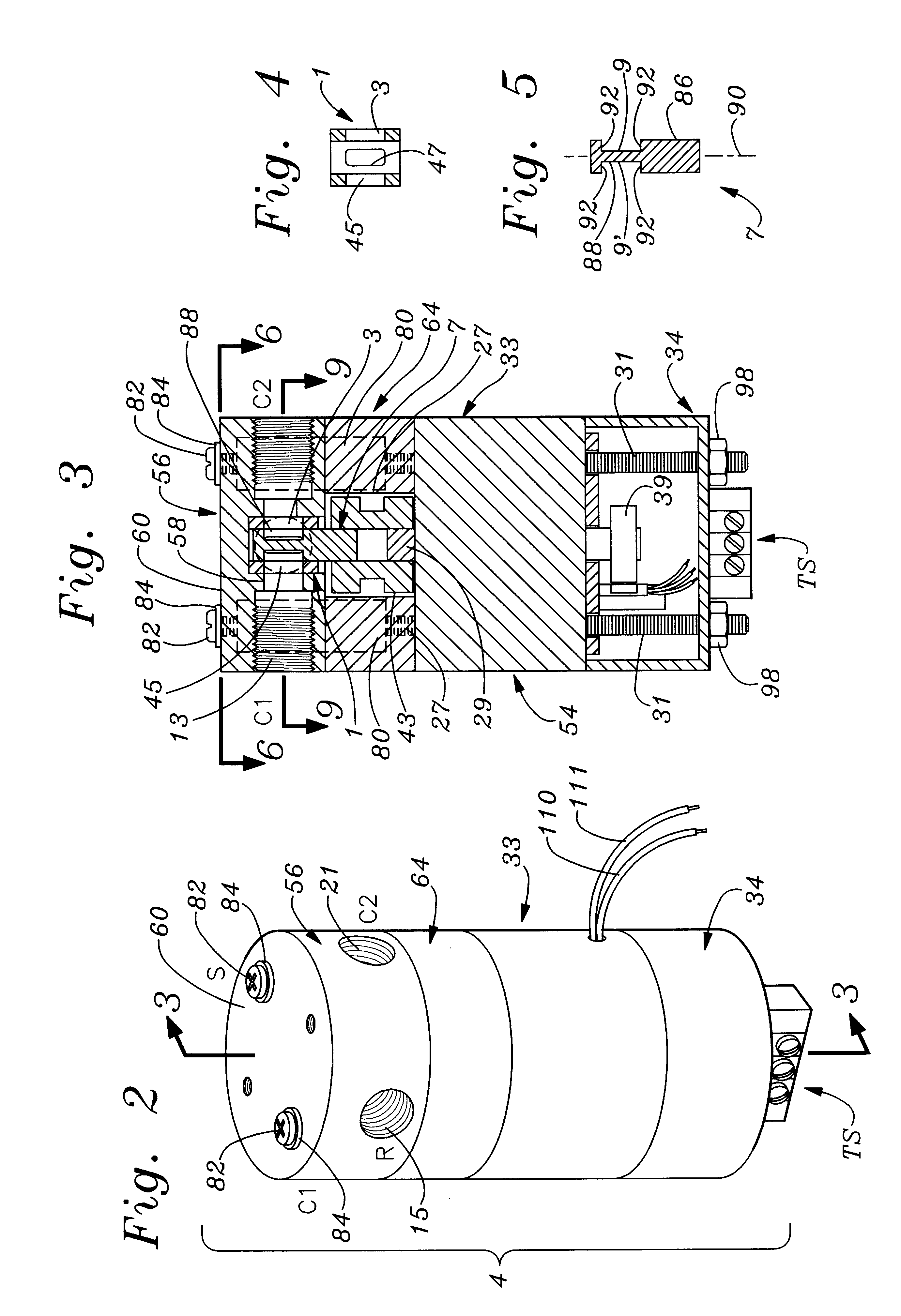

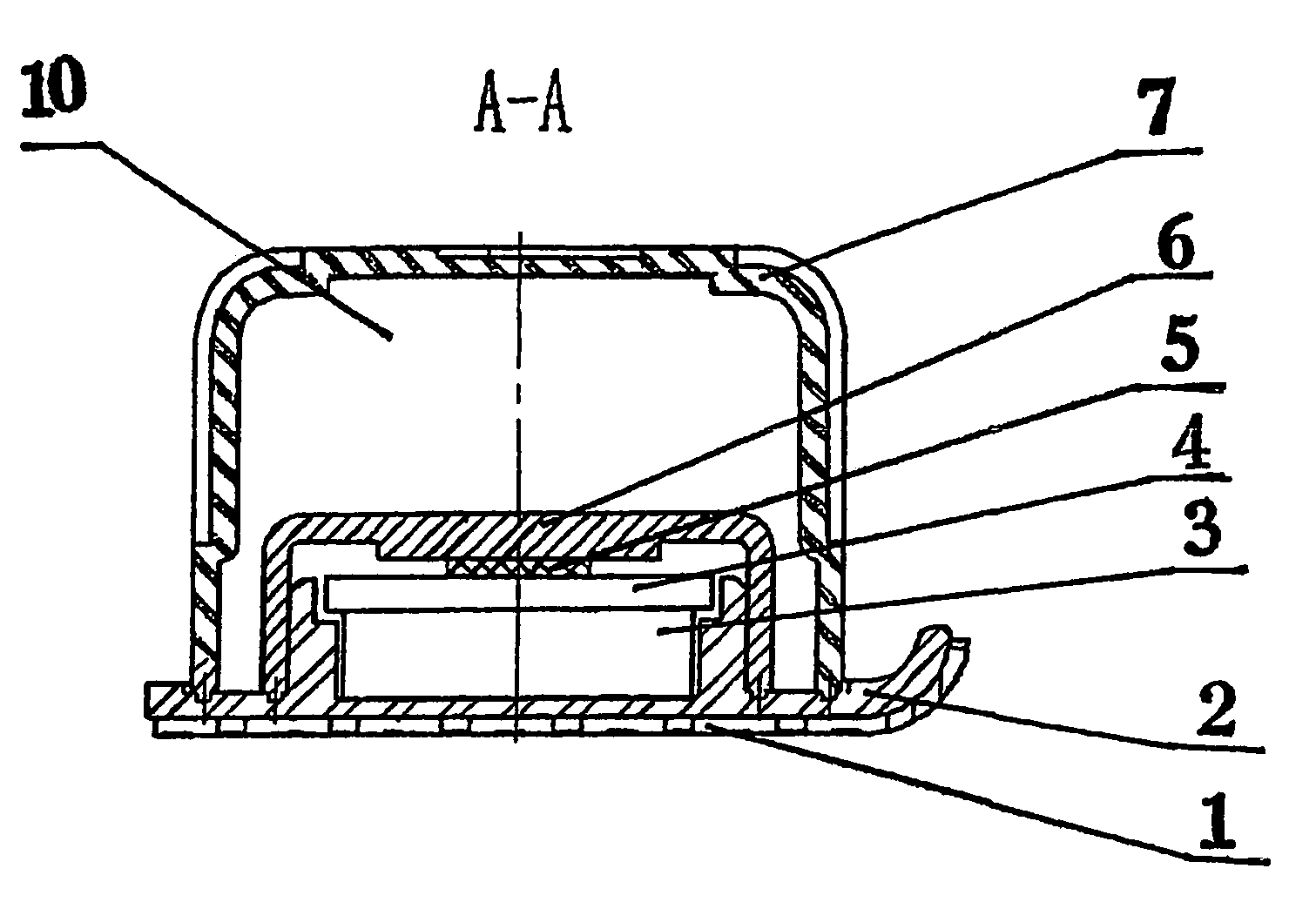

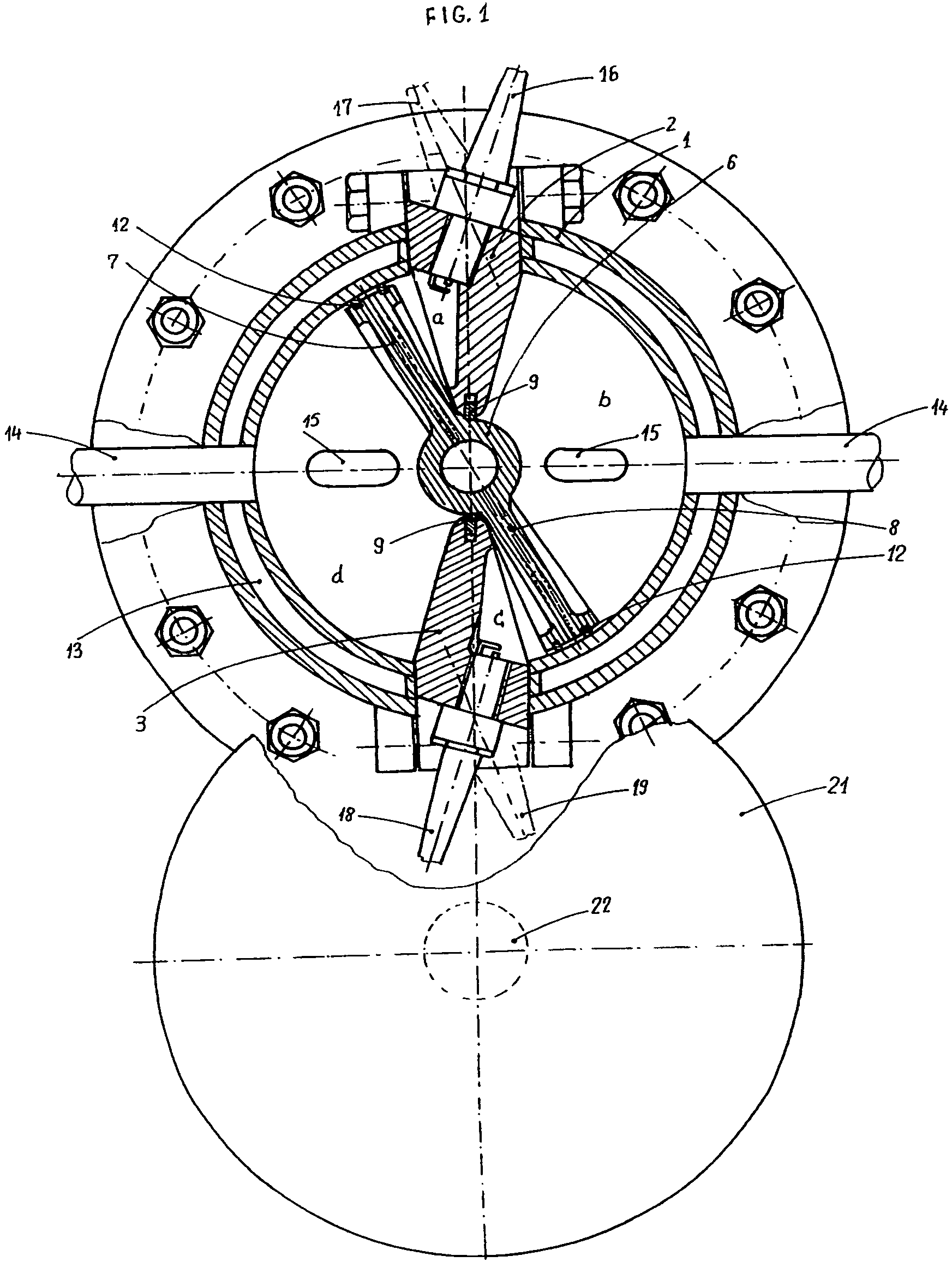

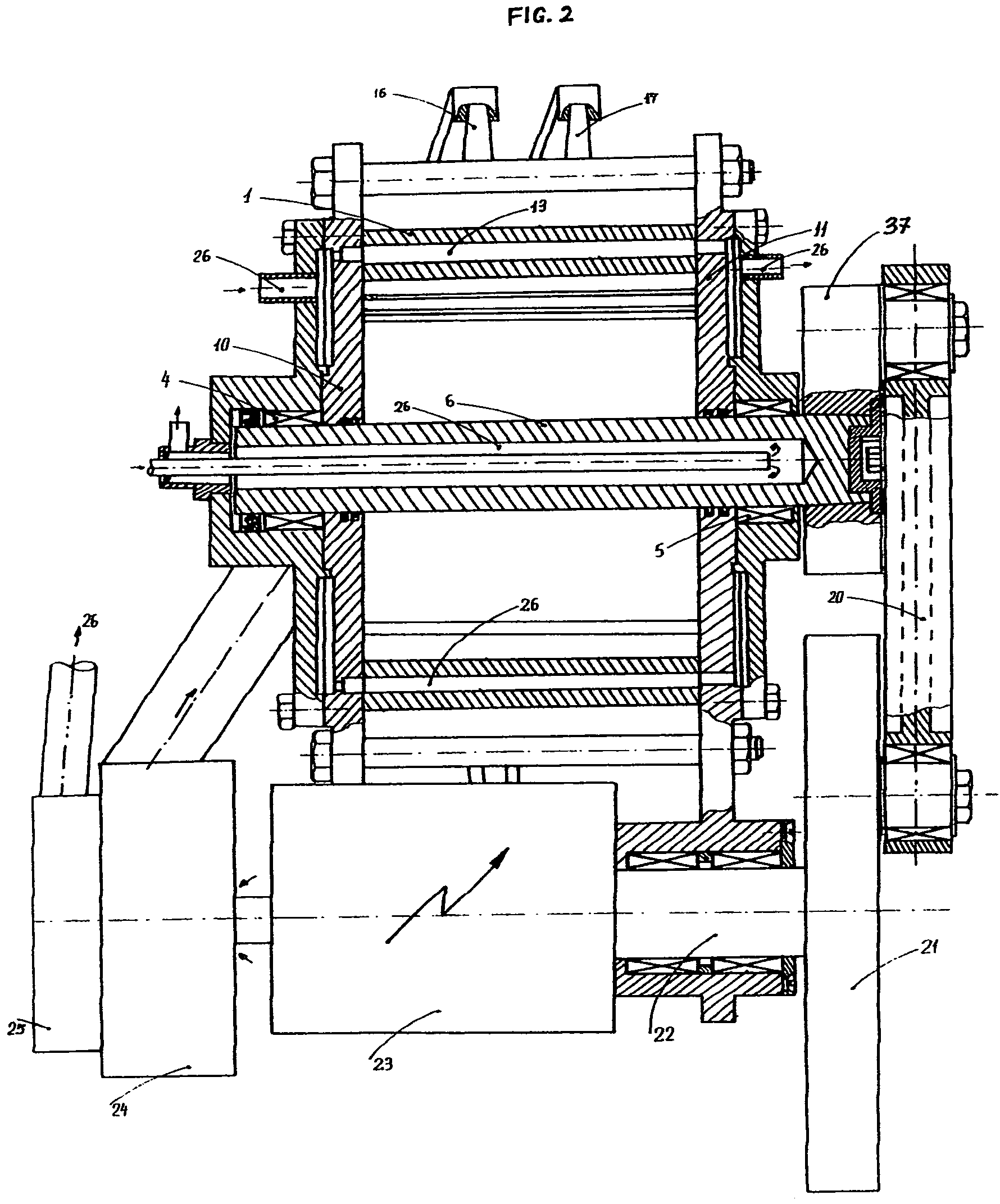

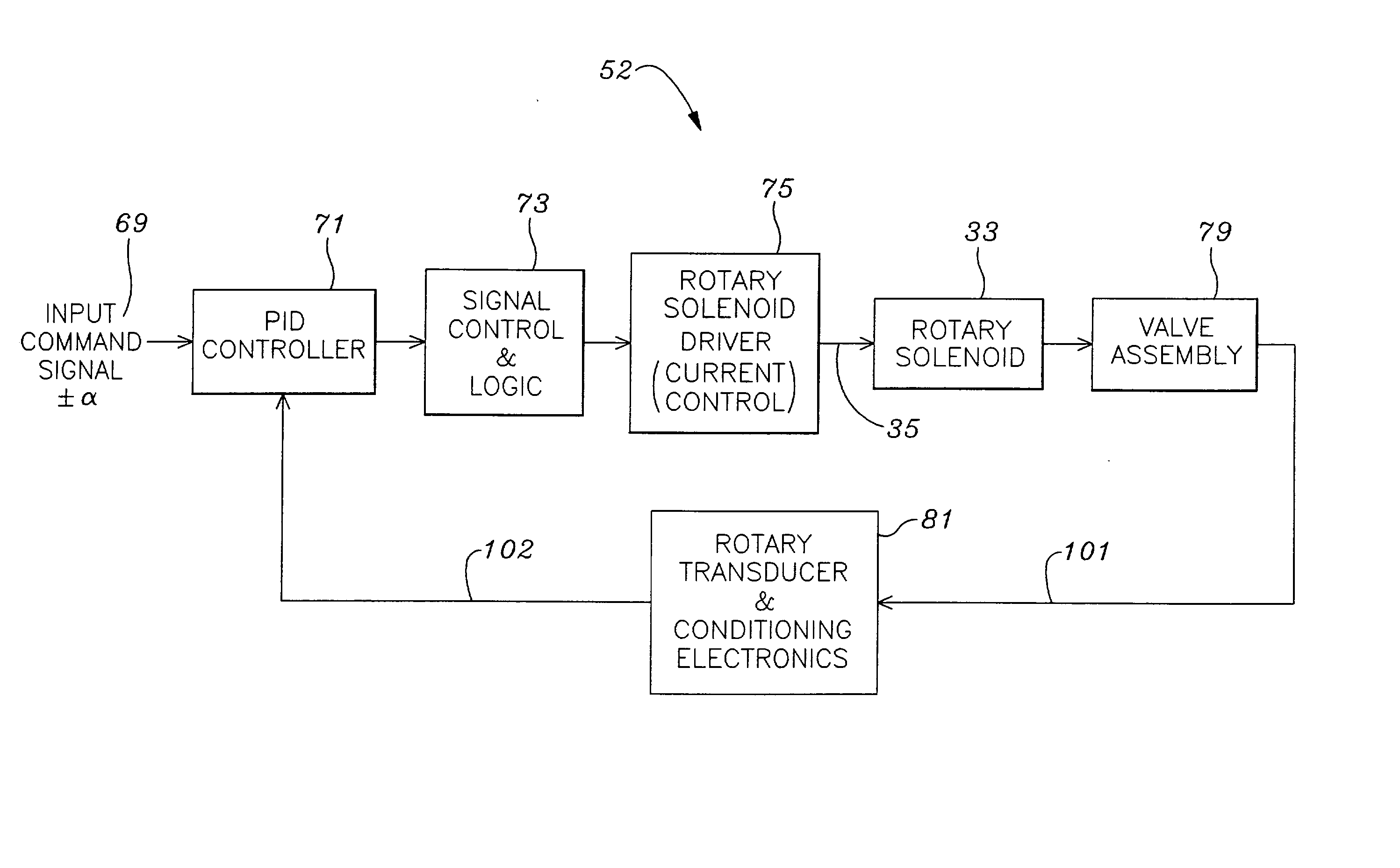

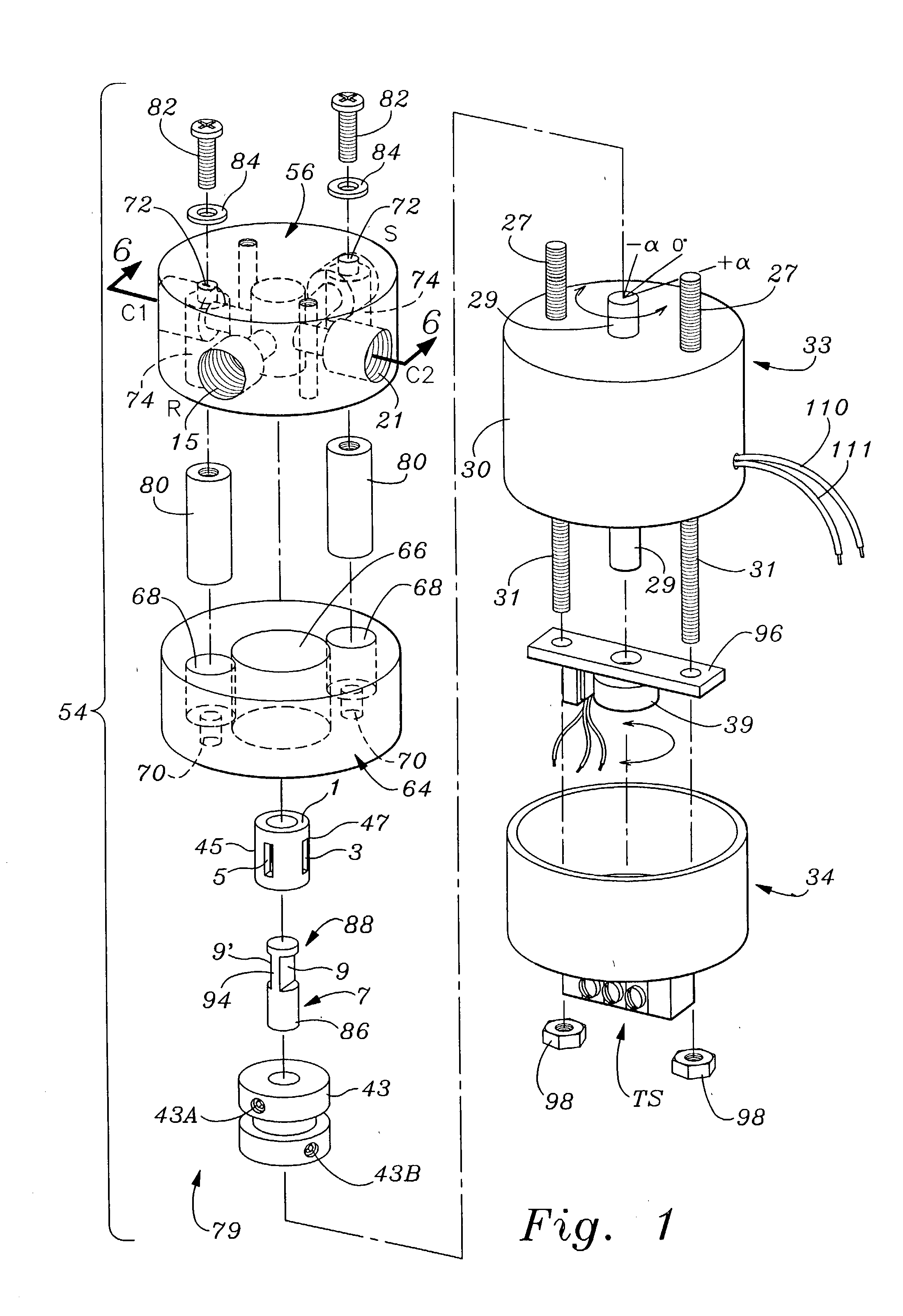

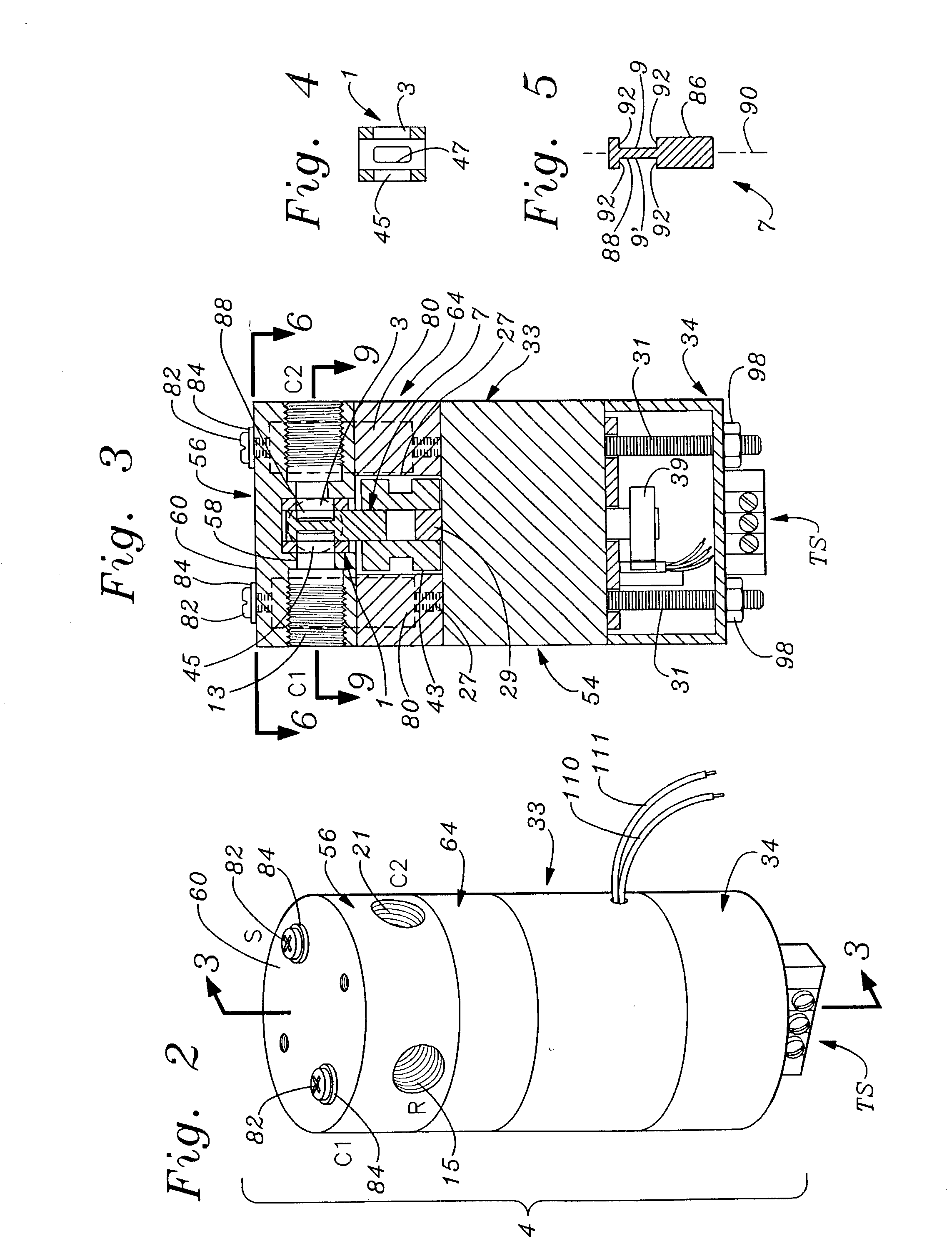

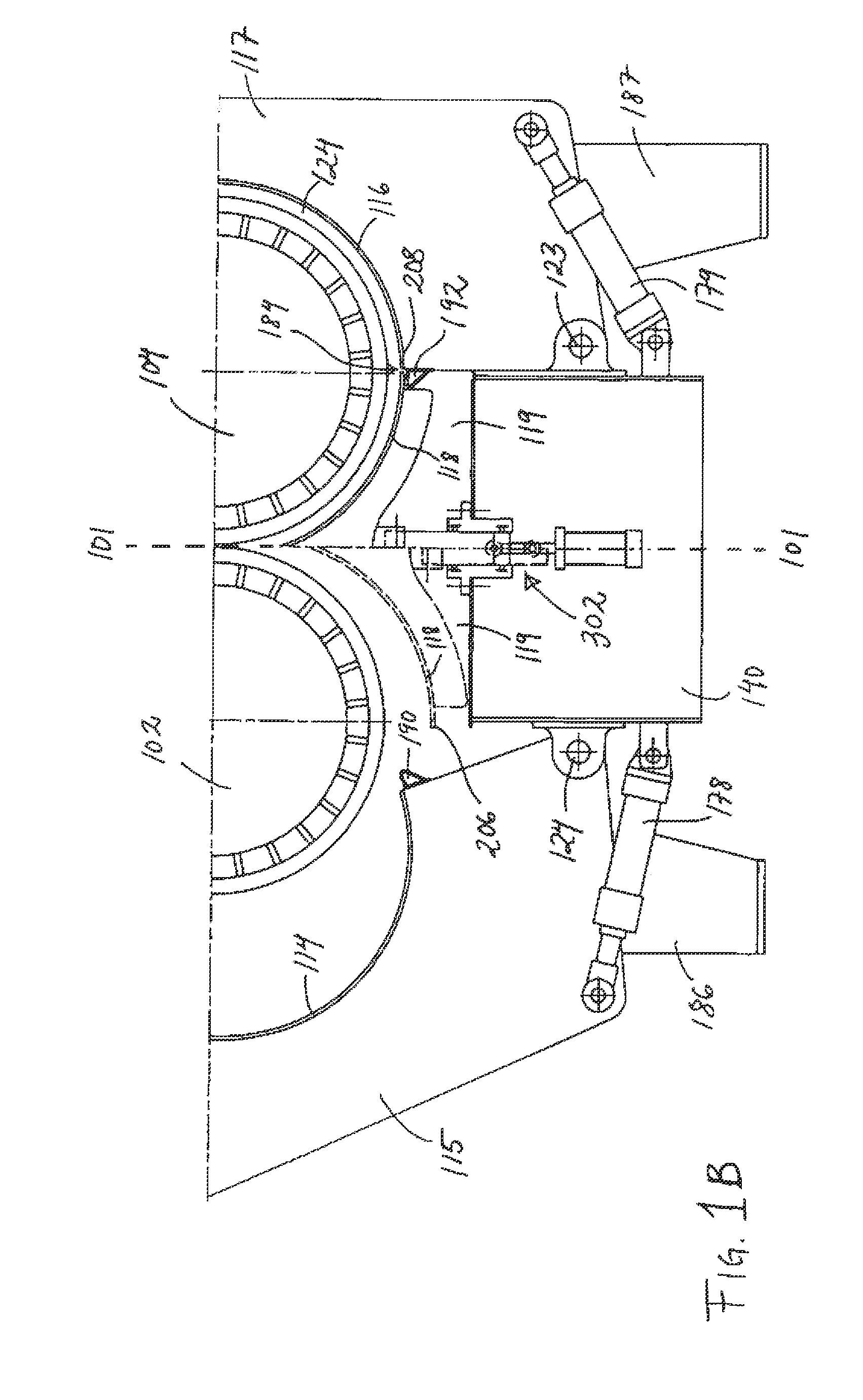

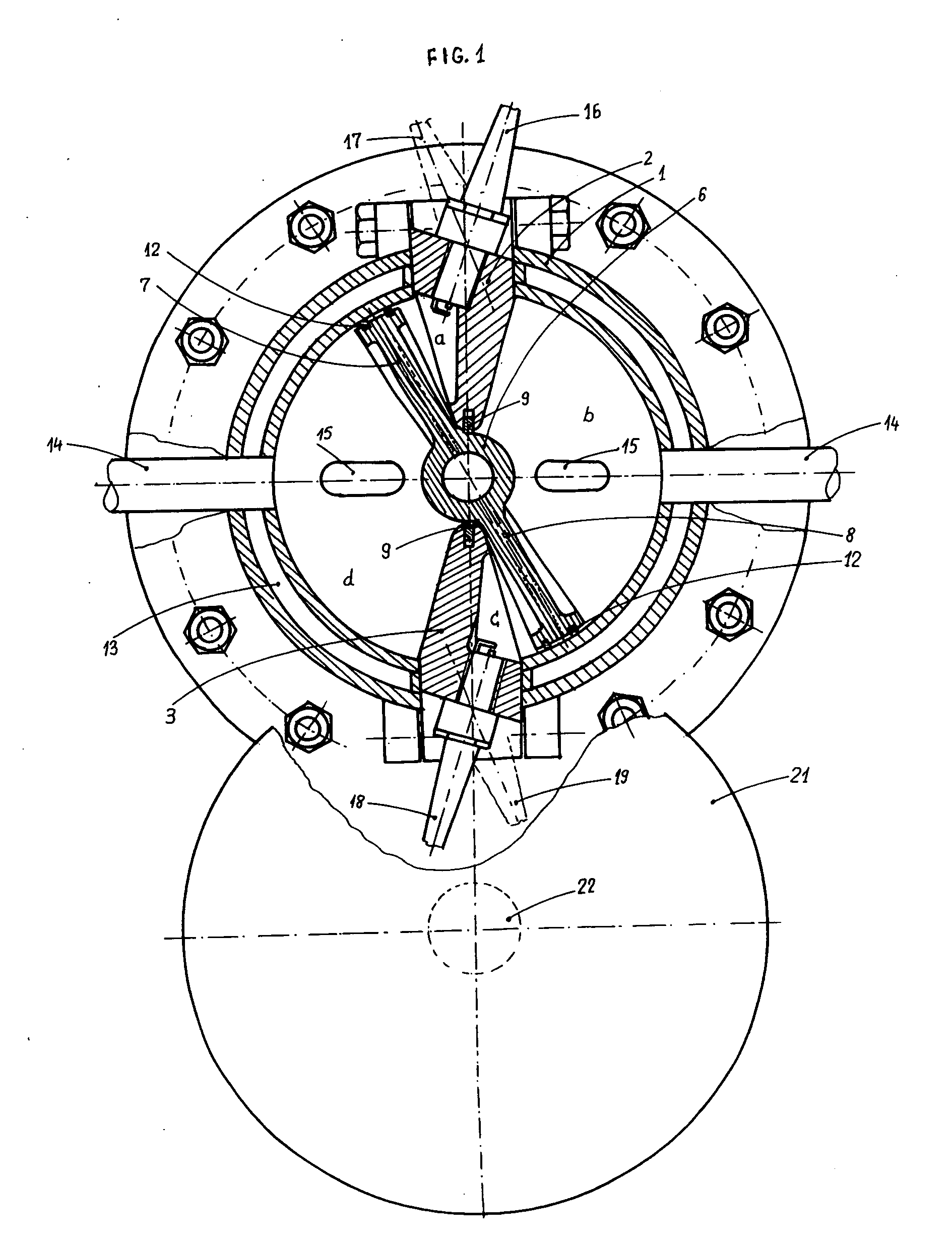

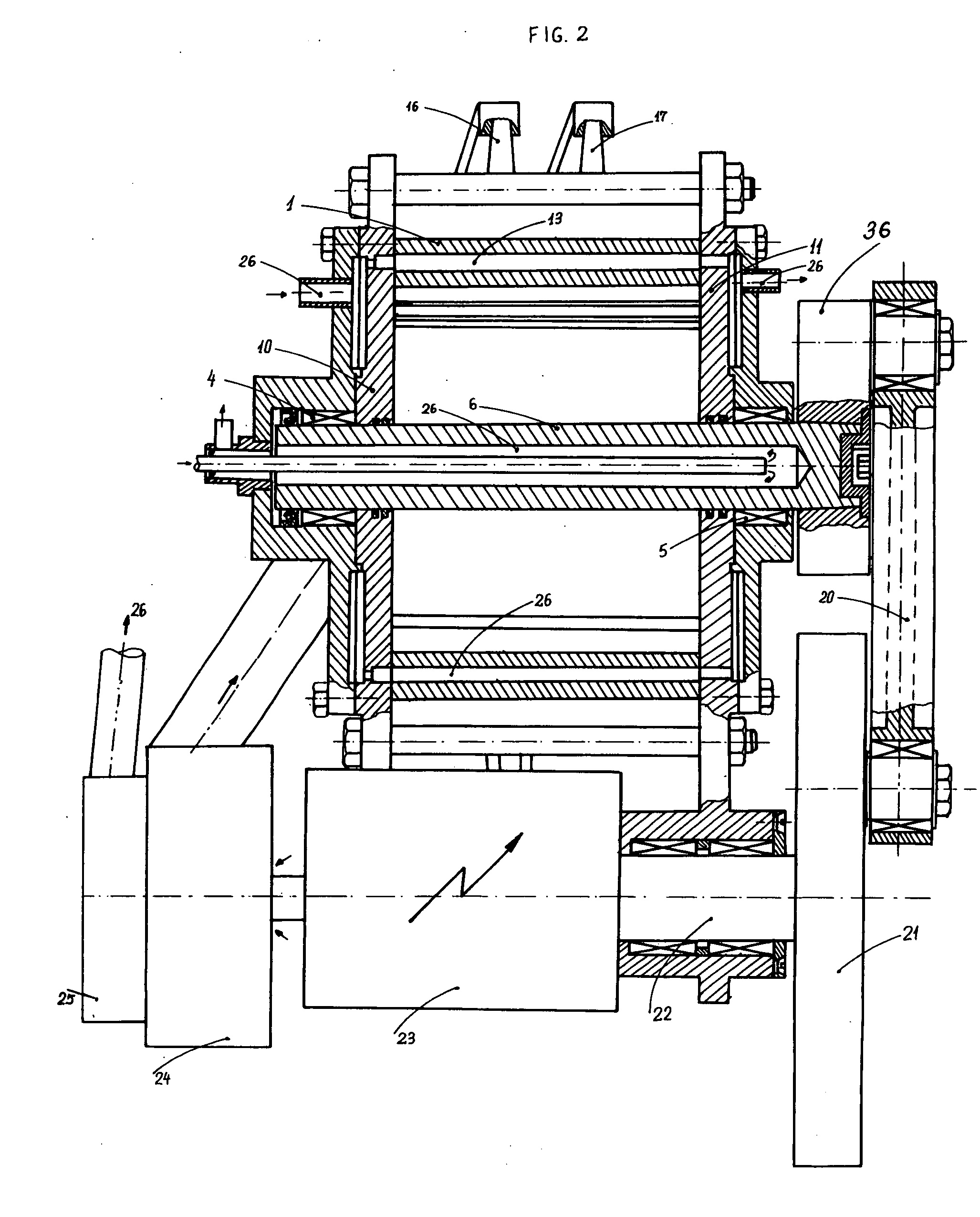

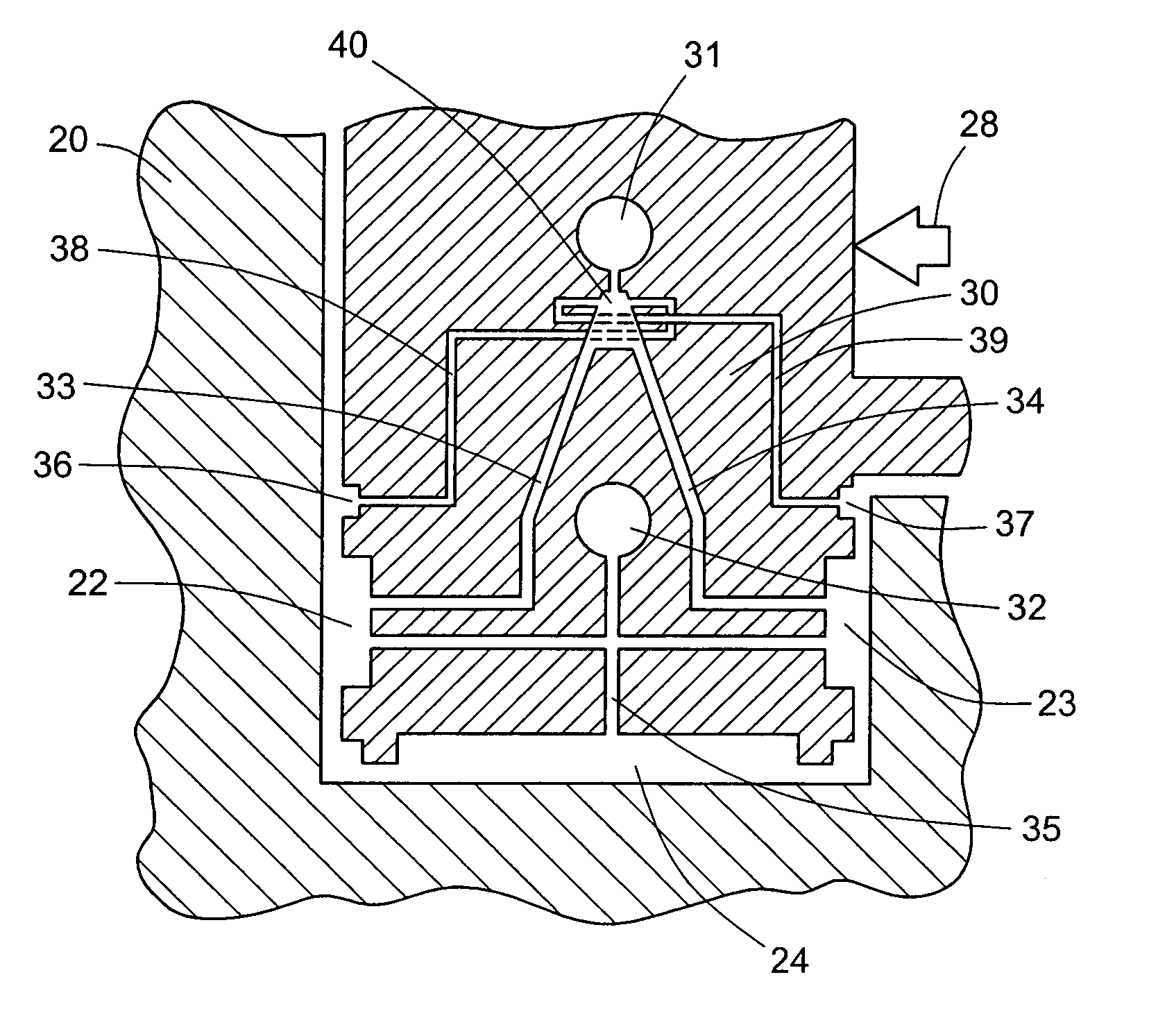

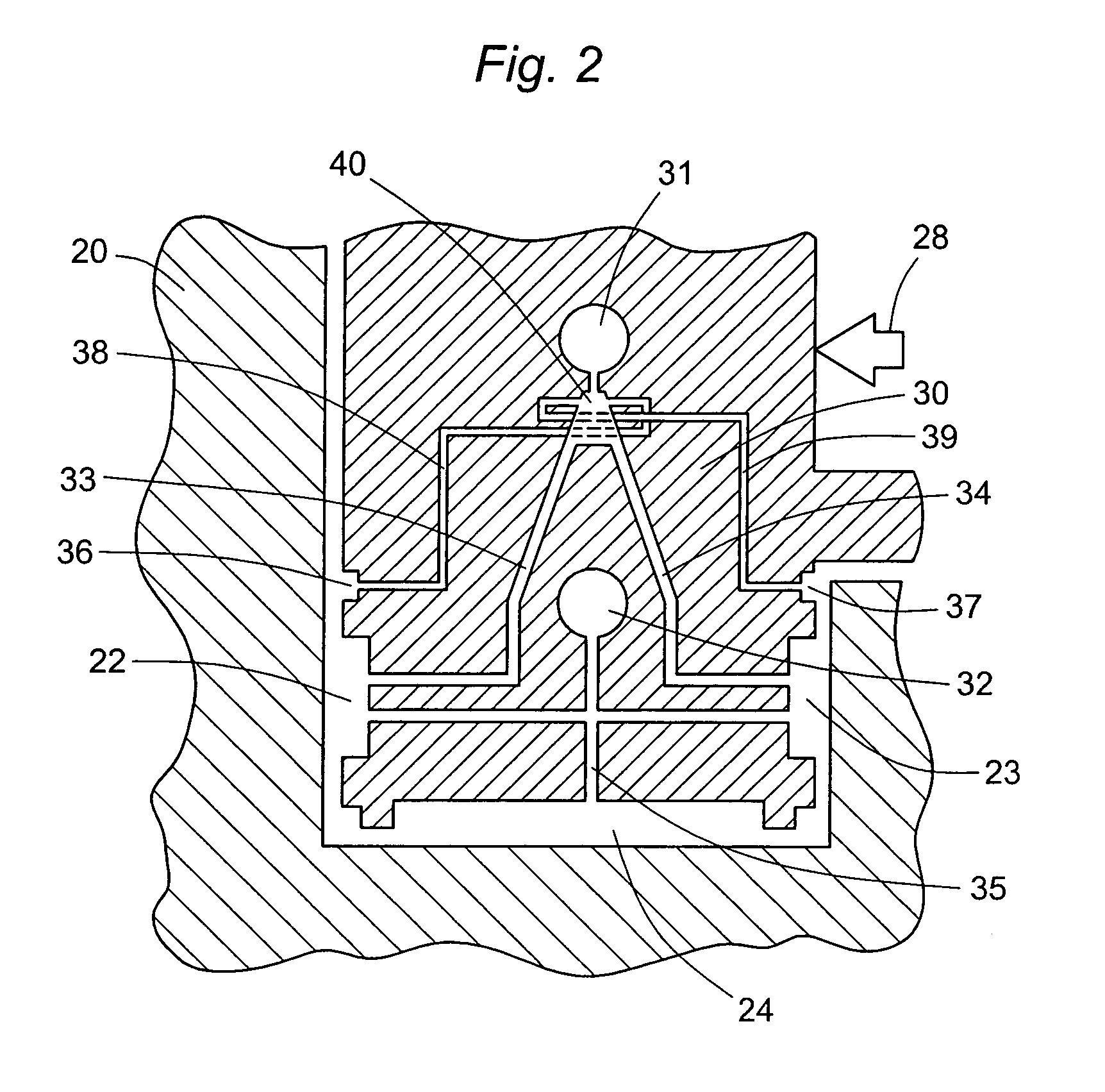

Rotary servovalve and control system

InactiveUS6269838B1Less torqueIncrease frequency bandwidth of responsivenessOperating means/releasing devices for valvesServomotor componentsFluid controlAngular rotation

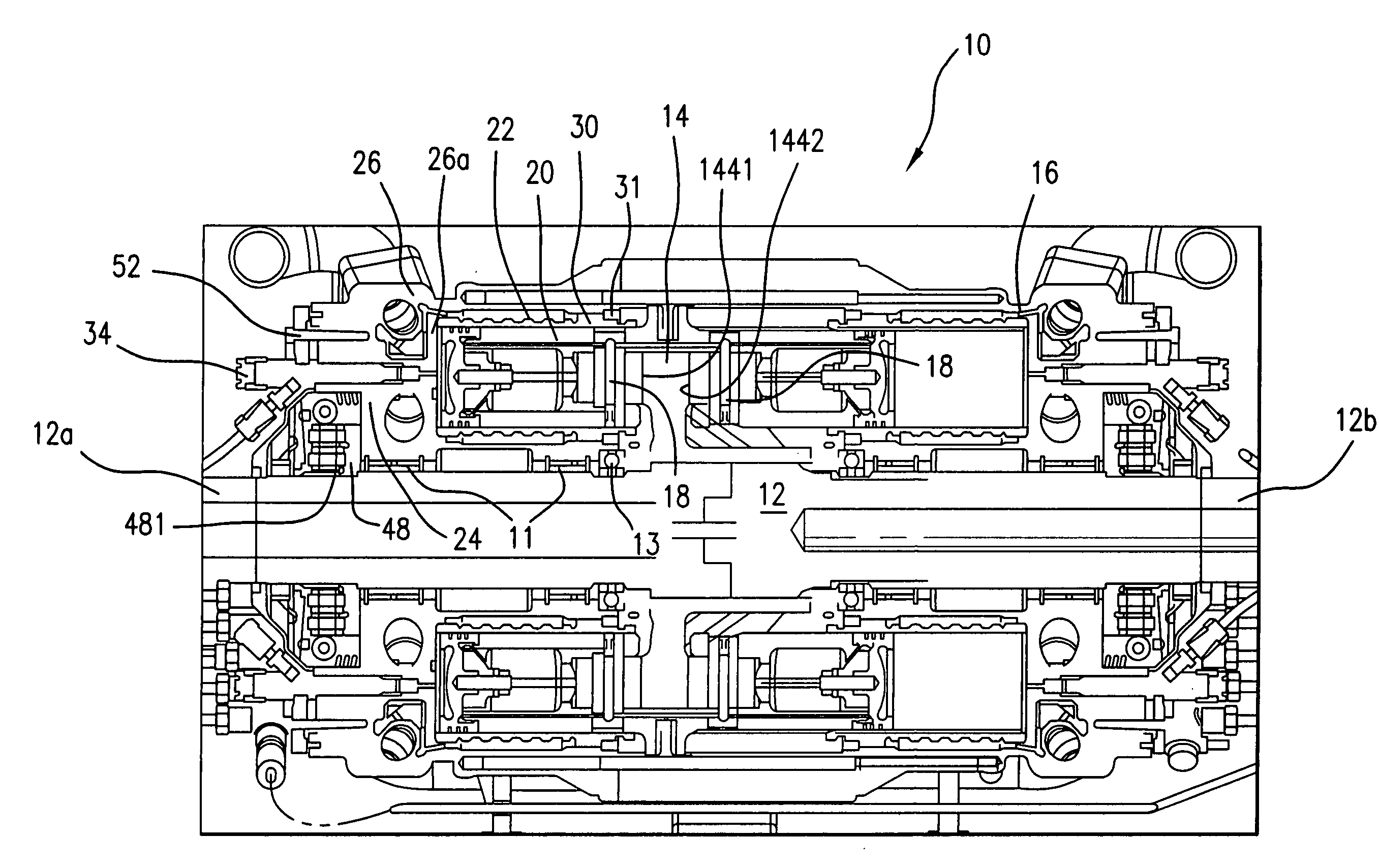

An improved rotary servovalve system employs a rotary magnetic solenoid having an armature that includes at least one permanent magnet. The armature is rotatable relative to a stator formed as an electromagnet which is energizable to create alternative electromagnetic fields having opposite polarities from each other. When deenergized, the stator allows the armature to return to a neutral, null position from positions of extreme rotation in opposite angular directions due to the magnetic force of the permanent magnet of the armature. The armature is coupled to carry a movable valve element in angular rotation therewith, so that flow through the servovalve of the system can occur in alternative directions. Also, the valve element is biased toward a position in which all of the valve ports are closed when power is removed from the rotary solenoid. The control circuit employed in the rotary servovalve system expands the bandwidth of response of the solenoid actuator by compensating for frequency variations in the input command signal and in the feedback signal. This compensation is achieved utilizing a combined proportional, integral, and differential amplification circuit. Also, imbalance of fluid forces within the servovalve mechanism can be avoided by utilizing a pair of inlet orifices, a pair of outlet orifices, a pair of first fluid control orifices, and a pair of second fluid control orifices. The orifices within each pair are located on opposite sides of the valve housing from each other.

Owner:WOODWORTH RAYMOND DEXTER

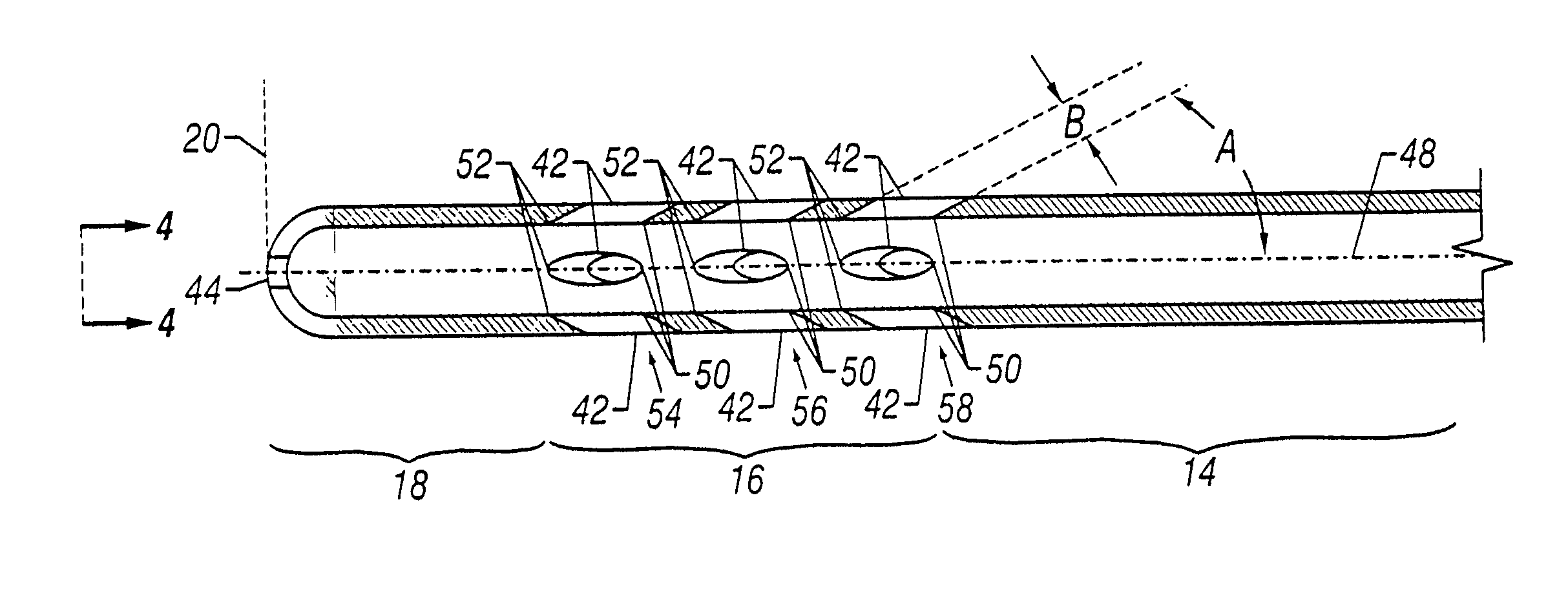

Anti-recoil catheter

A design is disclosed for a catheter assembly used during interventional and / or diagnostic procedures. The catheter includes a plurality of openings that allow for controlled fluid flow as the fluid exits the lumen of the catheter and can be inserted into the vascular system over a guidewire. As a result, the openings balance the fluid forces and, thereby, stabilize the distal tip to accommodate a wide range of injection parameters. The particular design of the catheter assembly of the present invention also reduces and / or eliminates recoil of the catheter tip during high volume injections, such as those associated with coronary or ventricular angiography.

Owner:ACIST MEDICAL SYST

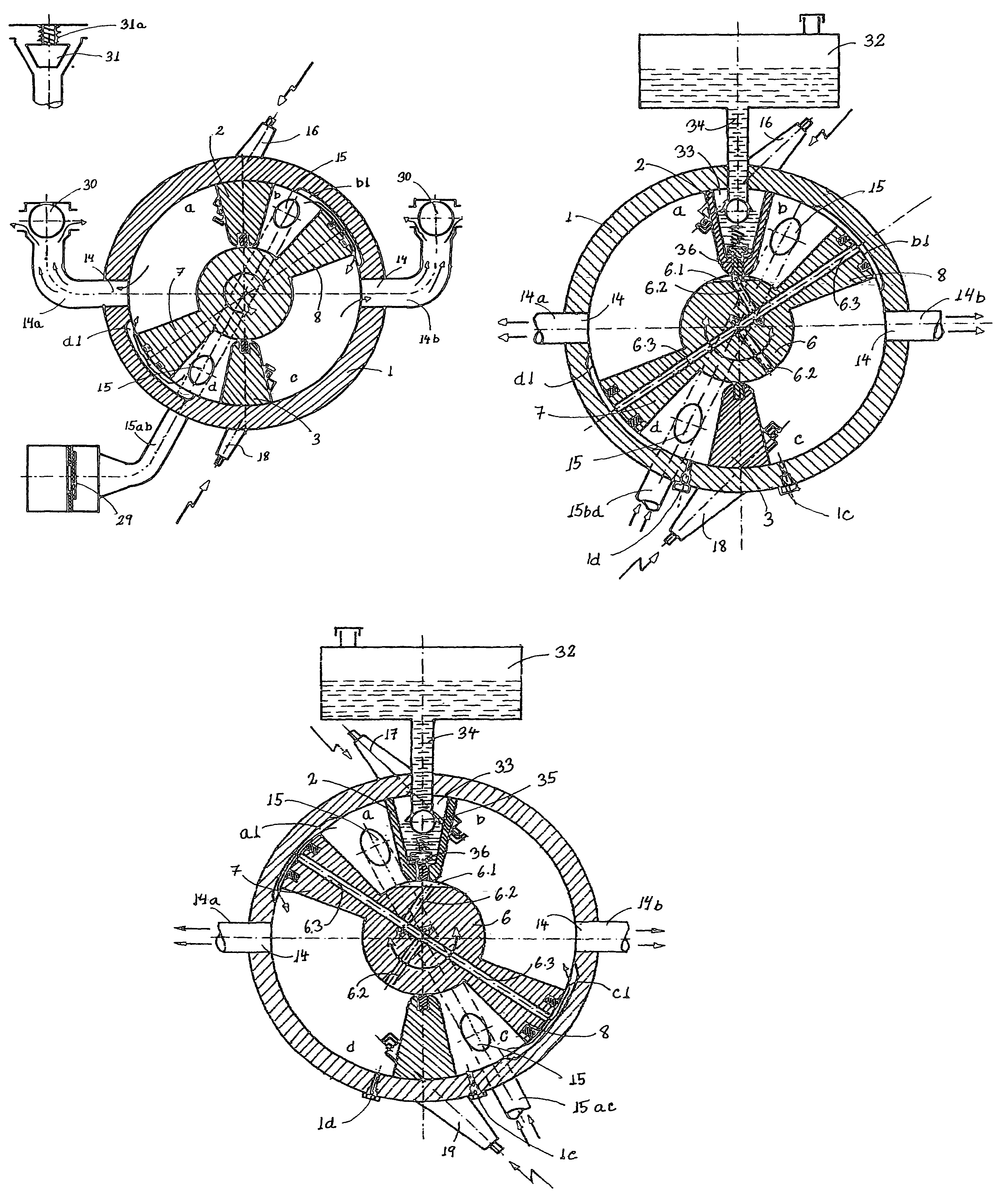

Rotary valveless internal combustion engine

InactiveUS7222601B1Quickly and efficiently and economically convertSave materialInternal combustion piston enginesEngine of arcuate-engagement typeWork cycleEngineering

A rotatably alternating air or water cooled two-stroke internal combustion engine comprising a cylindrical casing, and a rotor comprising two radially extending vanes affixed to a shaft rotatably mounted within the casing upon two end plates. Two longitudinally extending walls affixed to the casing. Sealing strips provided between said walls, the shaft, the vanes, the casing and the end plates respectively. The casing and / or the end plates equipped with plurality of ports which communicate with interior chambers formed between the vanes and the walls, allowing for intake of combustible air-fuel mixture and exhaust thereafter. Ignition means delivering a spark at the end of each working cycle. An extendable and adjustable connecting rod assembly converting the oscillating bi-directional rotary motion of the output shaft into a continuous unidirectional motion of the main shaft. A self lubricating mechanism incorporated into the engine.

Owner:KAMENOV KAMEN GEORGE

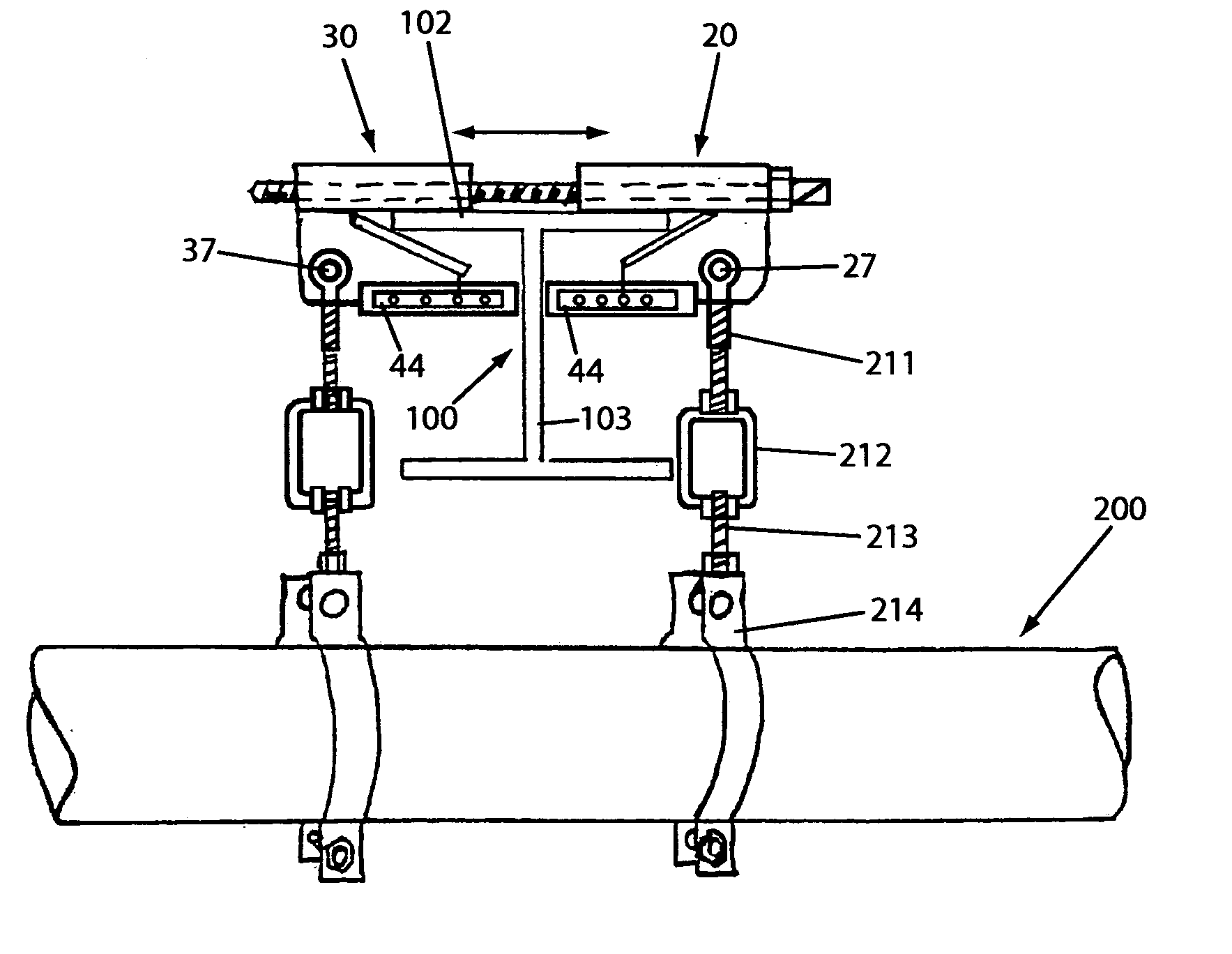

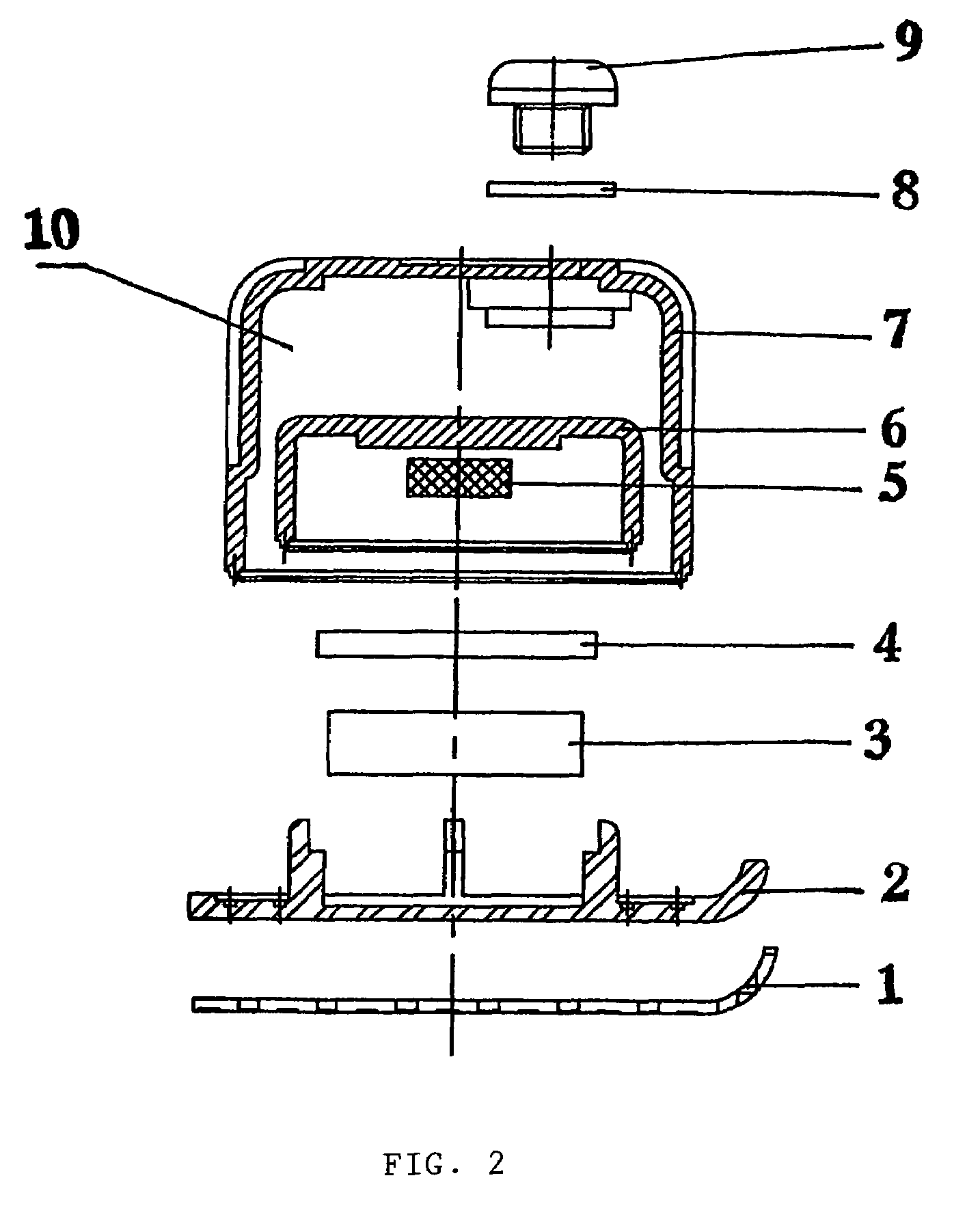

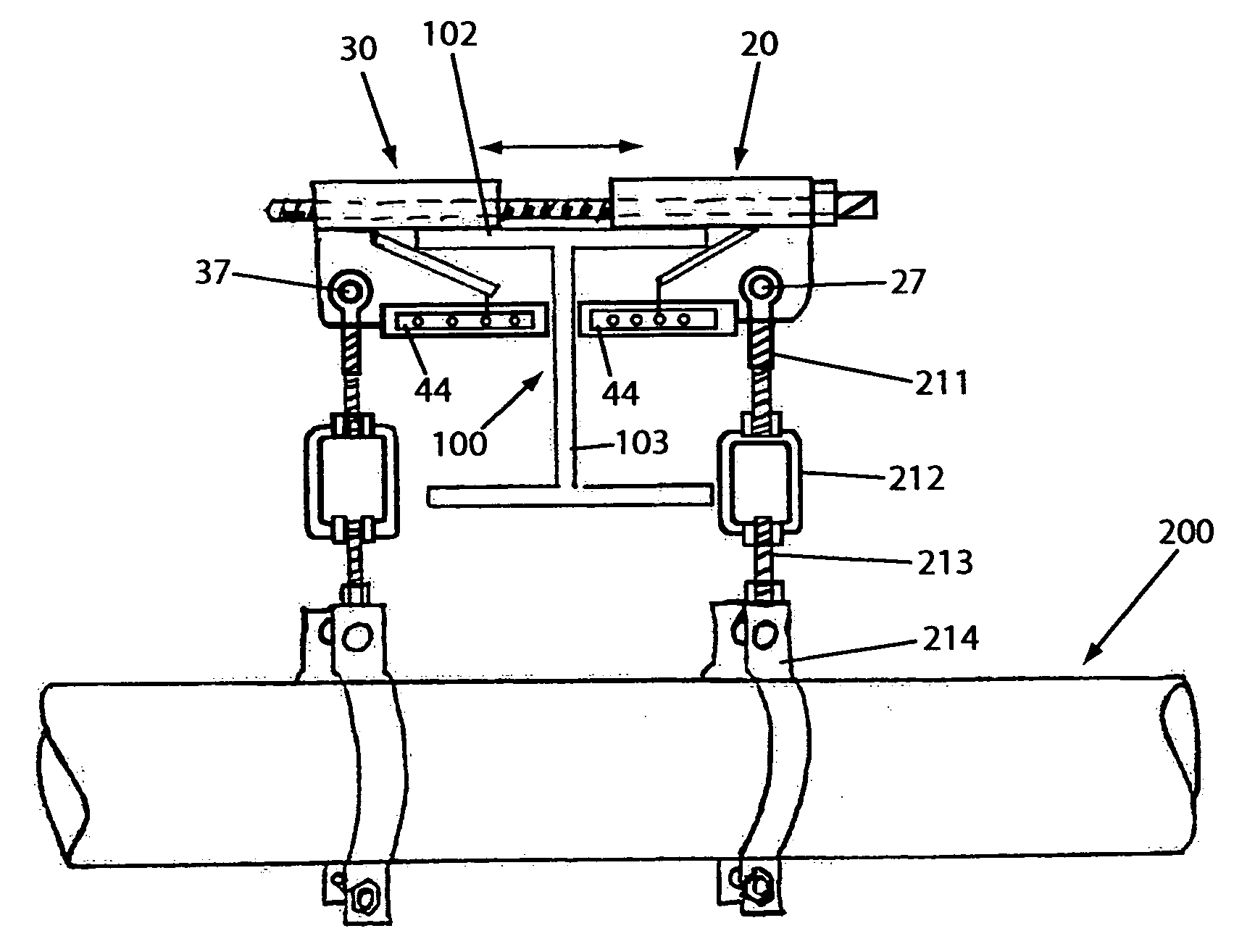

Top & bottom mount, heavy load supporting, girder clamp system

InactiveUS20040195479A1Increase heightBalanced forceRod connectionsSecuring devicesEngineeringHeavy load

A clamping system (10 / 110) for holding, supporting or lifting a heavy work piece (200; e.g. a pipe section of pipe line of hundreds of pounds) located below a girder (100) using rigging (210) attached to the clamp at attachment openings (27 / 37, 127 / 137) equally spaced from the center-line web (103) of the girder, which clamping system is attached to opposed, side edges of the top flange member (102) of the girder (vis-a-vis the bottom flange member 101), or in a second embodiment (FIGS. 9+) to either the top or the bottom. In the second embodiment a straight bar (150) with a series of spaced, locking cavities (151a / b) is used in place of the threaded rod, threaded engagement of the first embodiment, with the cavities working with spring-biased pin latches on the side gripping elements. When used on the bottom flange, a slidable, load supporting, centrally located accessory (160) is used.

Owner:GULLEY WILLIAM F

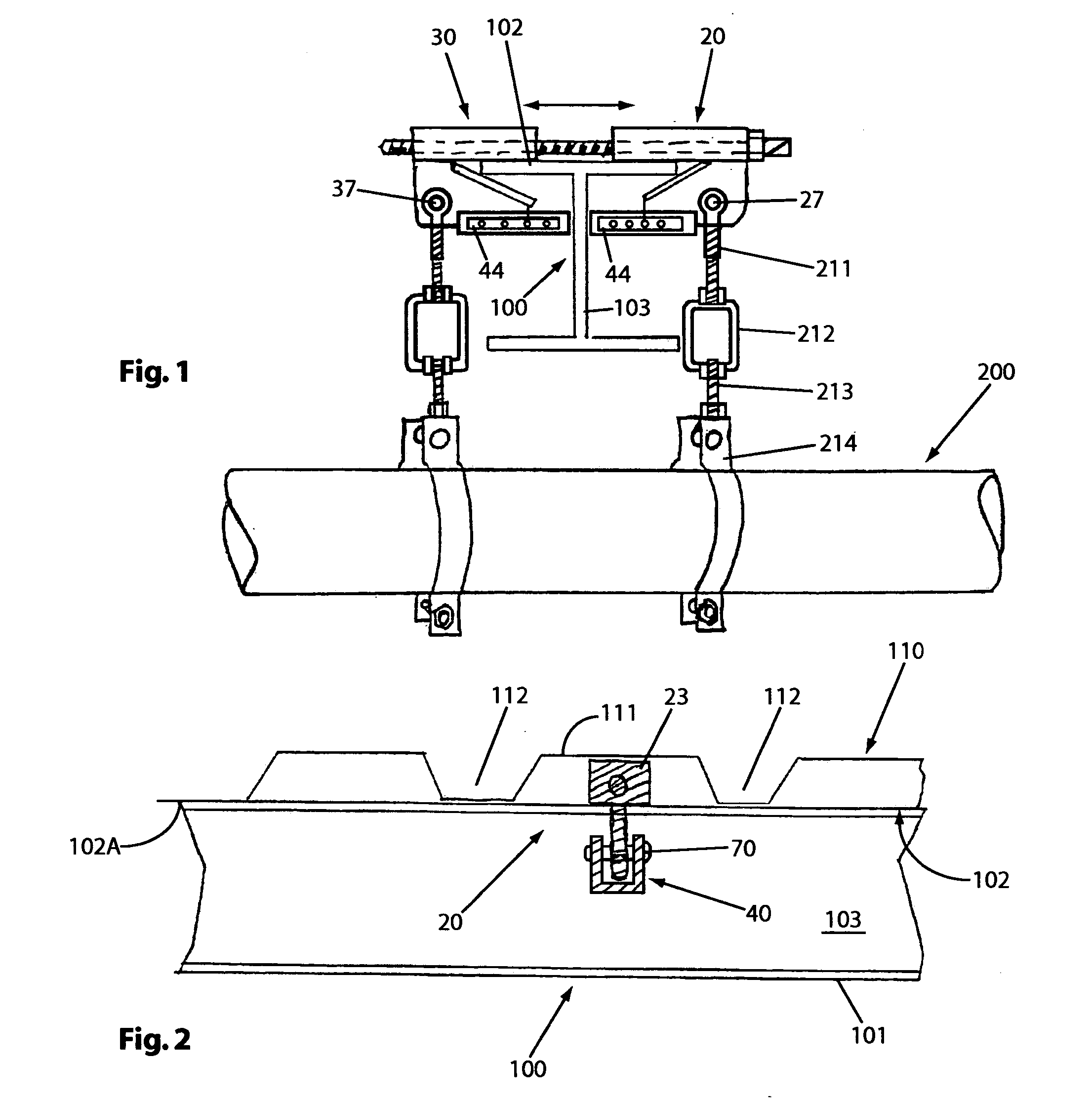

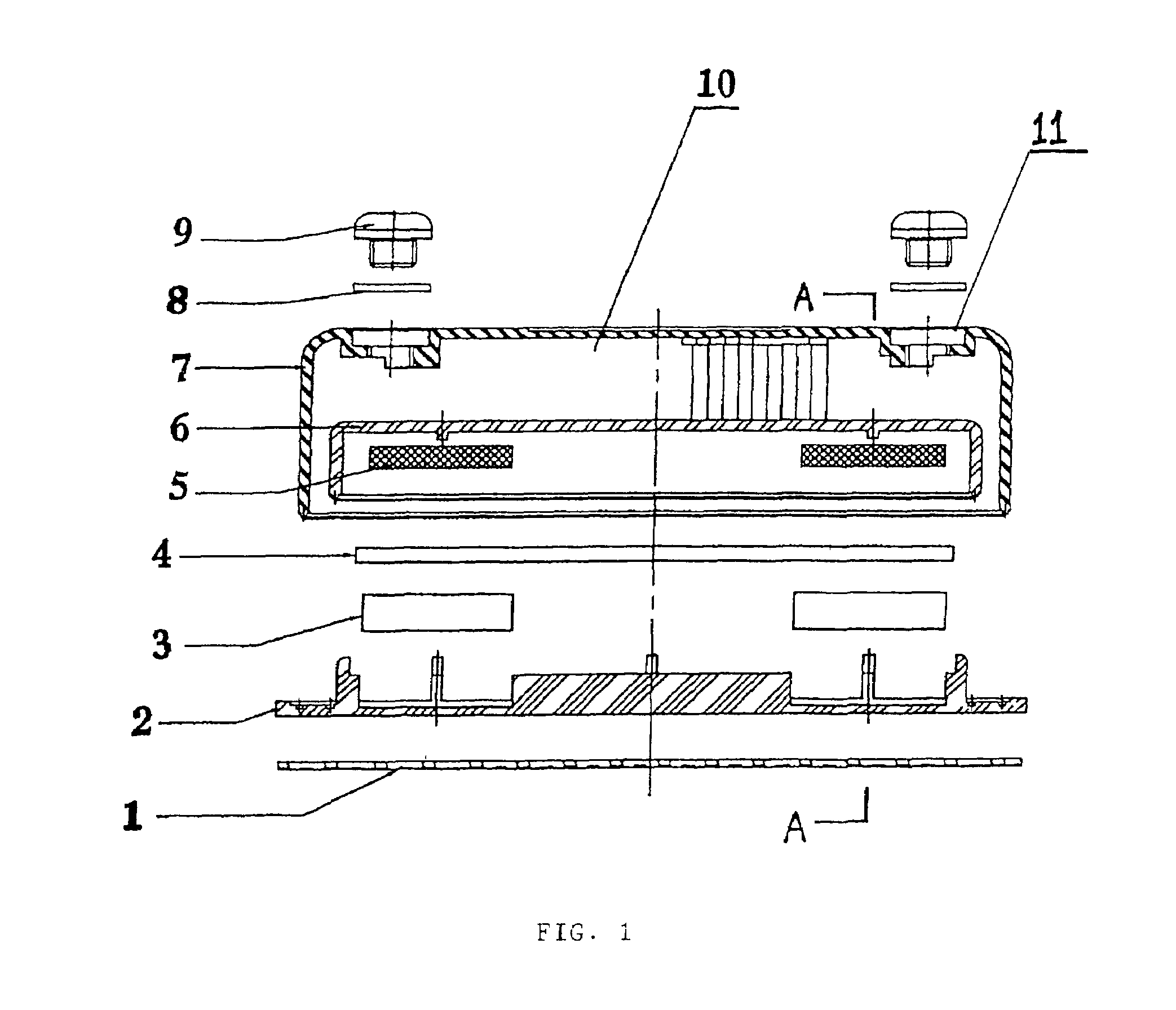

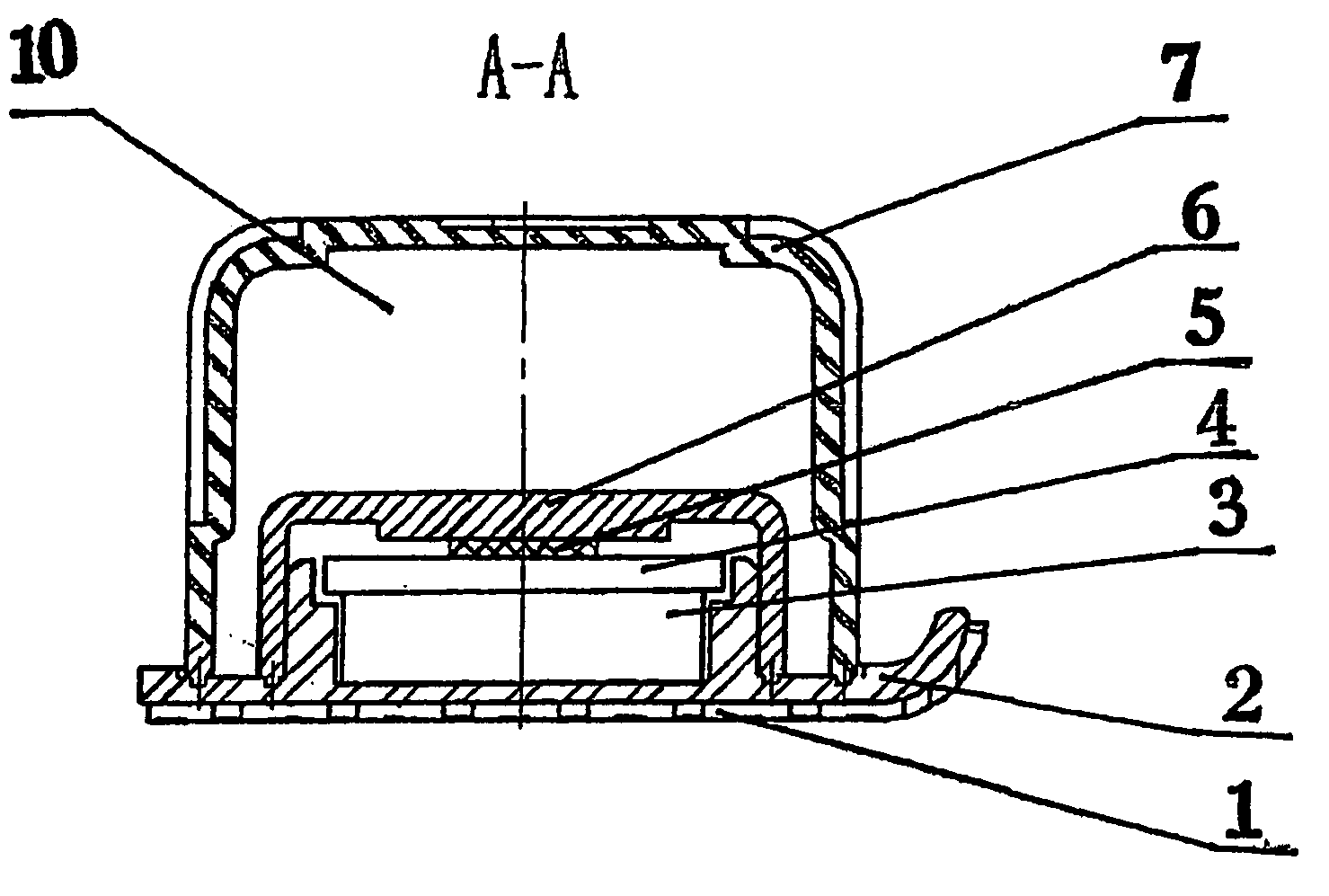

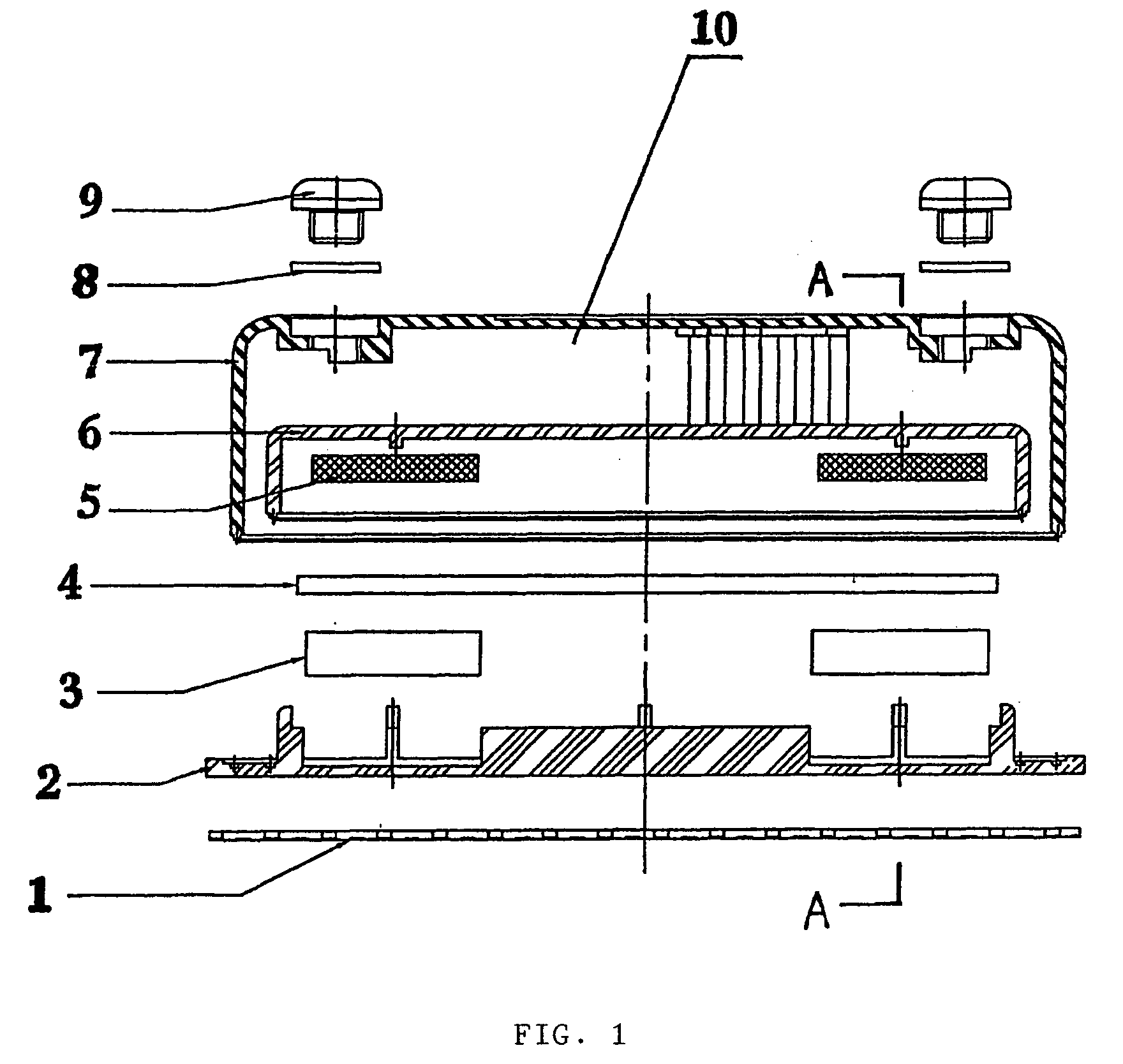

Suspendable magnetic brush for cleaning an aquarium with a curved window surface

InactiveUS7313841B2Cleaning aquariumSmooth movementPisciculture and aquariaWindow cleanersClassical mechanicsEngineering

Present invention relates a suspendable magnetic brush for cleaning an aquarium with curved window surface, characterized in that an upper cover with an air chamber is attached tightly to a bottom cover with a cleaning material layer underneath, and an inner cover with a magnet located therein is provided inside the air chamber, said inner cover being attached to the bottom cover while isolated from the air chamber. Said upper cover having through holes connecting the air chamber to the exterior of the device. It is possible to adjust the air or liquid in the air chamber through the holes connecting the upper cover and the air chamber so that the weight of the interior magnetic brush can be adjusted so as to balance all the forces exerted upon the interior magnetic brush. As a result the interior elements of the brush can suspend in the water and move smoothly on the aquarium window upon the manipulation of the exterior brush. With the convex edge(s) of the bottom cover matching the curved window surface of the aquarium the magnetic brush can clean both curved window surface and the planar window surface as well.

Owner:HUANG TONG

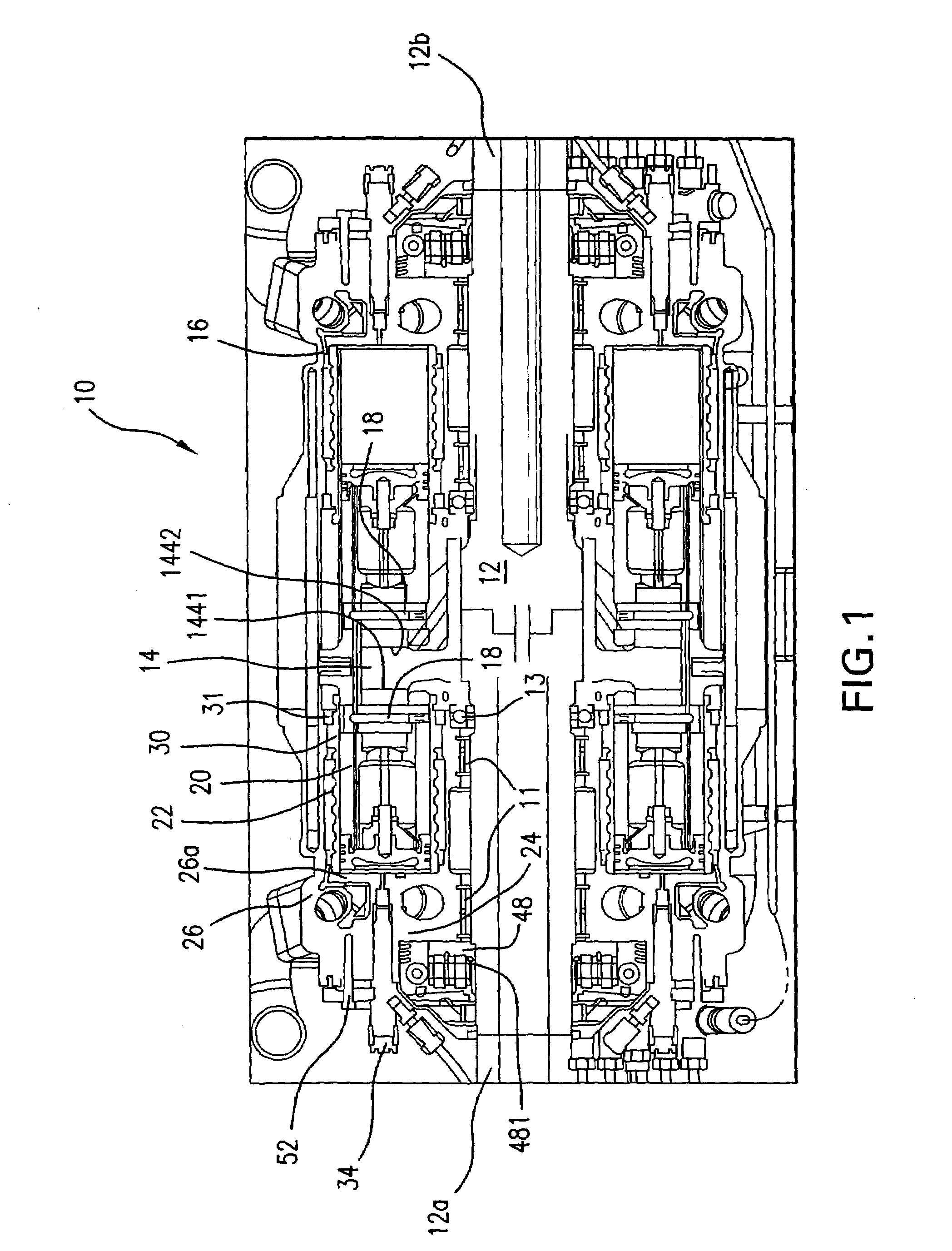

Barrel-type internal combustion engine

InactiveUS20080105224A1Minimize engine vibrationForce balanceReciprocating piston enginesLinear motionDrive shaft

An engine, e.g., a cam drive, barrel-type internal combustion engine, that includes: a main drive shaft defining a longitudinal axis; a sinusoidal main drive cam rigidly attached to the main drive shaft; a plurality of cam members that are in contact with the sinusoidal main drive cam and that are configured to follow the sinusoidal main drive cam, wherein rotation of the sinusoidal main drive cam corresponds to reciprocating linear movement of each of the plurality of cam members in a direction parallel to the longitudinal axis; for each cam member, a pair of linear pistons disposed on opposite sides of the cam member for reciprocating linear movement within respective cylinder bores.

Owner:KUBES LARRY +4

Valveless rotary internal combustion engine

InactiveUS7931006B1Quickly and efficiently and economically convertLow costInternal combustion piston enginesEngine of arcuate-engagement typeWork cycleEngineering

A rotatably alternating air or water cooled two-stroke internal combustion engine comprising a cylindrical casing, and a rotor comprising two radially extending vanes affixed to a shaft rotatably mounted within the casing upon two end plates. Two longitudinally extending walls affixed to the casing. Sealing strips provided between said walls, the shaft, the vanes, the casing and the end plates respectively. Working and supercharging interior chambers between the vanes and the walls. The casing and / or the end plates equipped with ports which communicate with the interior chambers, allowing for intake of combustible air-fuel mixture and exhaust thereafter. Ignition means delivering a spark at the end of each working cycle. An extendable and adjustable connecting rod assembly converting the oscillating bi-directional rotary motion of the output shaft into a continuous unidirectional motion of the main shaft. A self lubricating mechanism incorporated into the engine.

Owner:KAMENOV KAMEN GEORGE

Rotary servovalve with precision controller

InactiveUS20030006729A1Less torqueIncrease frequency bandwidth of responsivenessOperating means/releasing devices for valvesServomotor componentsFluid controlElectrical polarity

An improved rotary servovalve system employs a rotary magnetic solenoid having an armature that includes at least one permanent magnet. The armature is rotatable relative to a stator formed as an electromagnet which is energizable to create alternative electromagnetic fields having opposite polarities from each other. When deenergized, the stator allows the armature to return to a neutral, null position from positions of extreme rotation in opposite angular directions due to the magnetic force of the permanent magnet of the armature. The armature is coupled to carry a movable valve element in angular rotation therewith, so that flow through the servovalve of the system can occur in alternative directions. Also, the valve element is biased toward a position in which all of the valve ports are closed when power is removed from the rotary solenoid. The control circuit employed in the rotary servovalve system expands the bandwidth of response of the solenoid actuator by compensating for frequency variations in the input command signal and in the feedback signal. This compensation is achieved utilizing a combined proportional, integral, and differential amplification circuit. Also, imbalance of fluid forces within the servovalve mechanism can be avoided by utilizing a pair of inlet orifices, a pair of outlet orifices, a pair of first fluid control orifices, and a pair of second fluid control orifices. The orifices within each pair are located on opposite sides of the valve housing from each other.

Owner:RAYMOND WOODWORTH D

Screen unit

Owner:SEIKO EPSON CORP

Flat steel bifurcated pipe and manufacturing method thereof

InactiveCN102853193ABalanced forceReasonable forceBranching pipesStress concentrationArchitectural engineering

The invention relates to a flat steel bifurcated pipe and a manufacturing method thereof. The flat steel bifurcated pipe comprises a main pipe, a left branch cone and a right branch cone, wherein one end of the left branch cone is communicated with one end of the main pipe; one end of the right branch cone is communicated with one end of the main pipe; one side of the left branch cone leans against and is welded with one side of the right branch cone; another end of the left branch cone and another end of the right branch cone are respectively communicated with a left branch pipe and a right branch pipe; bottoms of the main pipe, the left branch cone, the right branch cone, the left branch pipe and the right branch pipe are located at the same one altitude. The flat steel bifurcated pipe has the advantages that the shape of the flat steel bifurcated pipe is different from the principle of the same one altitude of axial lines of various pipe joints of the other steel bifurcated pipes and ensures the same one altitude on the bottom of the various pipe joints; the same one altitude on the bottom of the pipe has independent goodness; water can flow freely to be discharged when high-pressure pipes are maintained without pumping the water by a water pump or arranging holes on the steel bifurcated pipe and connecting with a special drainage system; the drainage time is shortened greatly, and the effective work time for maintenance is prolonged; the flat steel bifurcated pipe has the advantages of regular shape, no deformity portions, reasonable force and no stress concentration phenomenon.

Owner:WUHAN UNIV

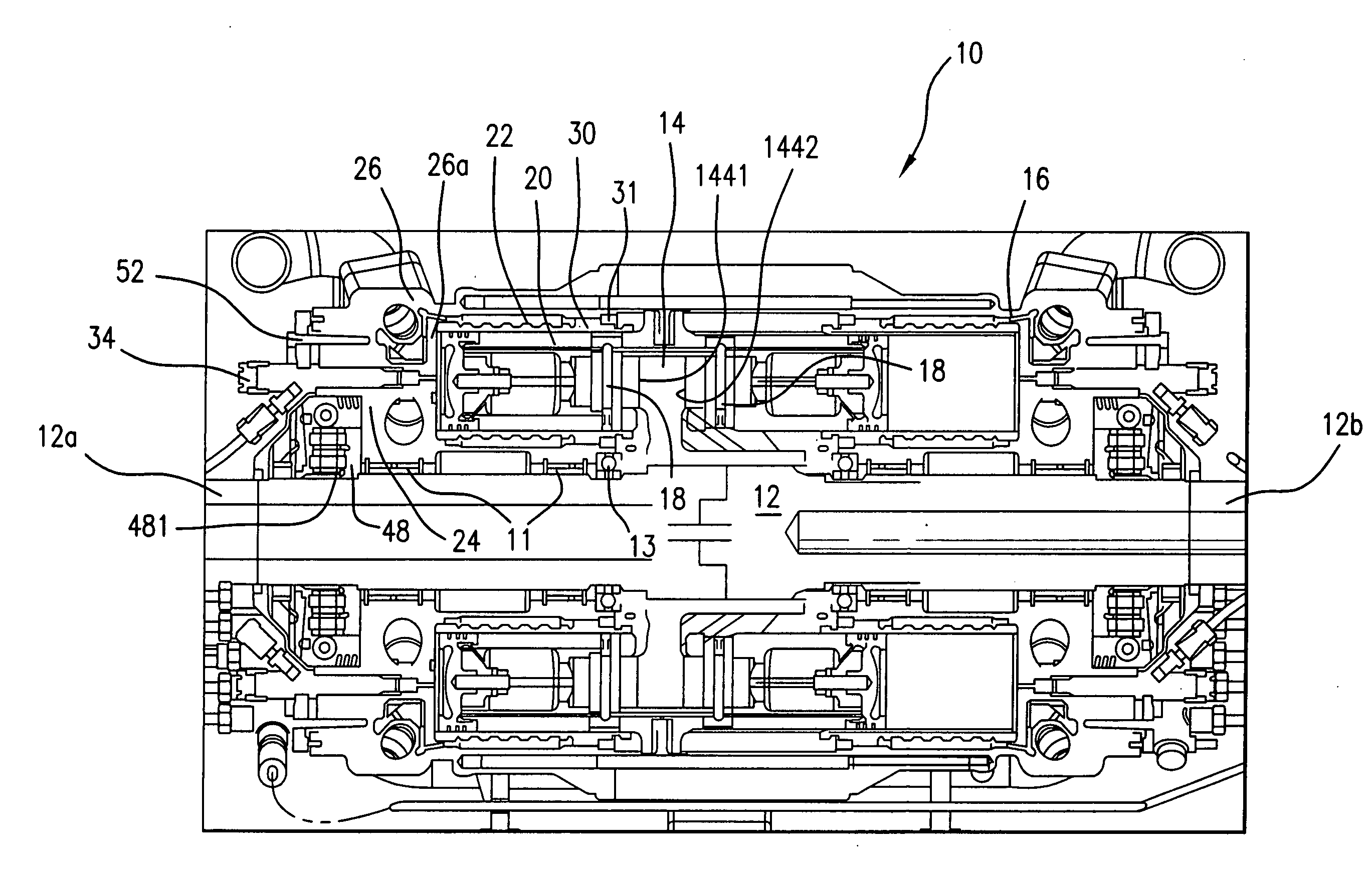

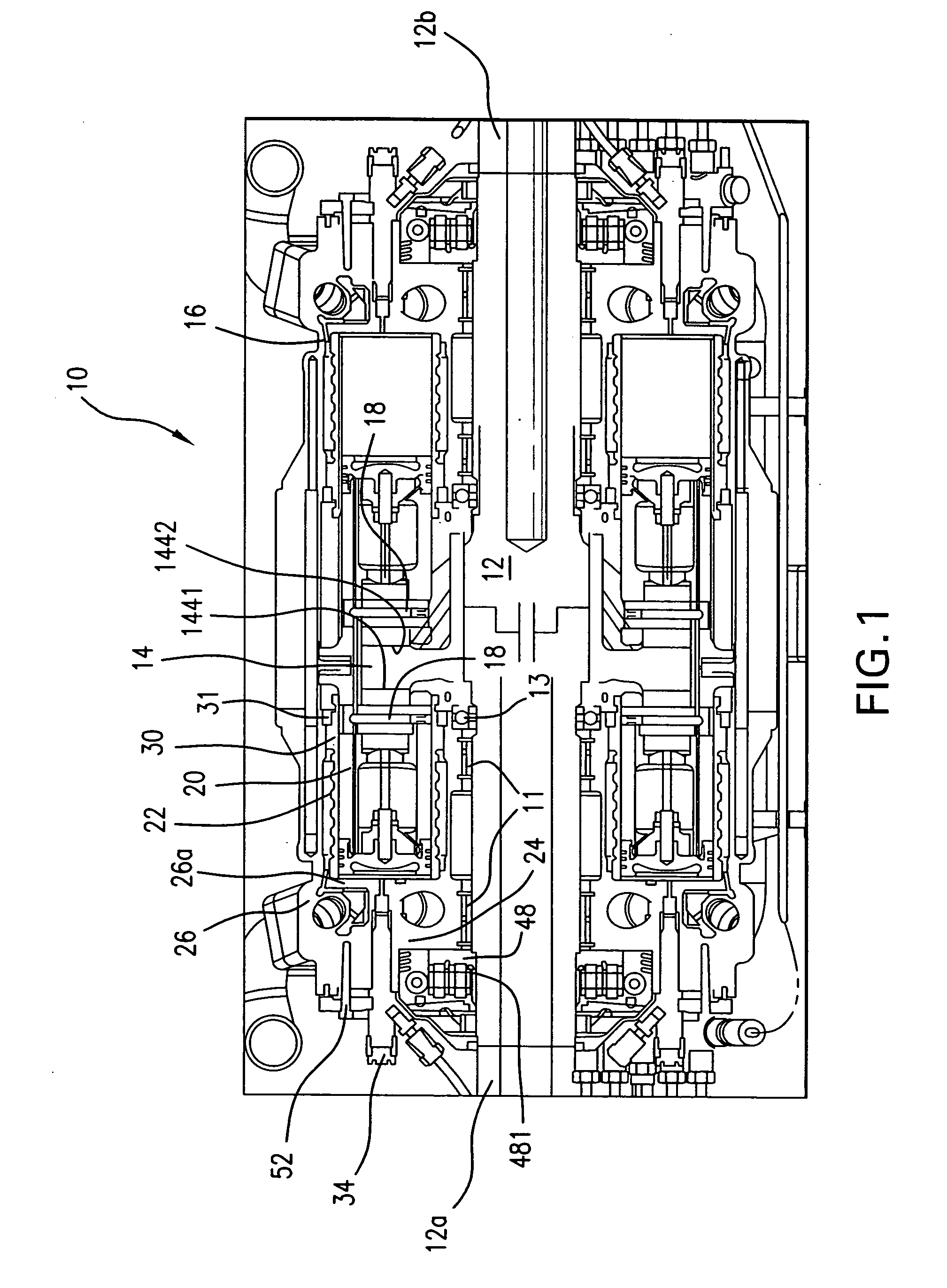

Apparatus for washing and dewatering pulp

InactiveUS20100294708A1Less materialReduce weightWashing/displacing pulp-treating liquorsPulp de-wateringMechanical engineeringEngineering

Apparatus for washing and dewatering pulp comprising rotatable press rolls including permeable outer surfaces and a casing comprising a vat in which the rolls are installed are disclosed. A feed for feeding the pulp through the gap between the vat and the outer surfaces of the press rolls is provided and the vat includes a vat segment providing at least one compartment between the vat segment and the casing, the at least one compartment extending along the longitudinal extension of one of the first and second rotatable press rolls and a pressure device to maintain the pressure in the at least one compartment corresponding to the pressure in the gap.

Owner:VALMET TECH INC

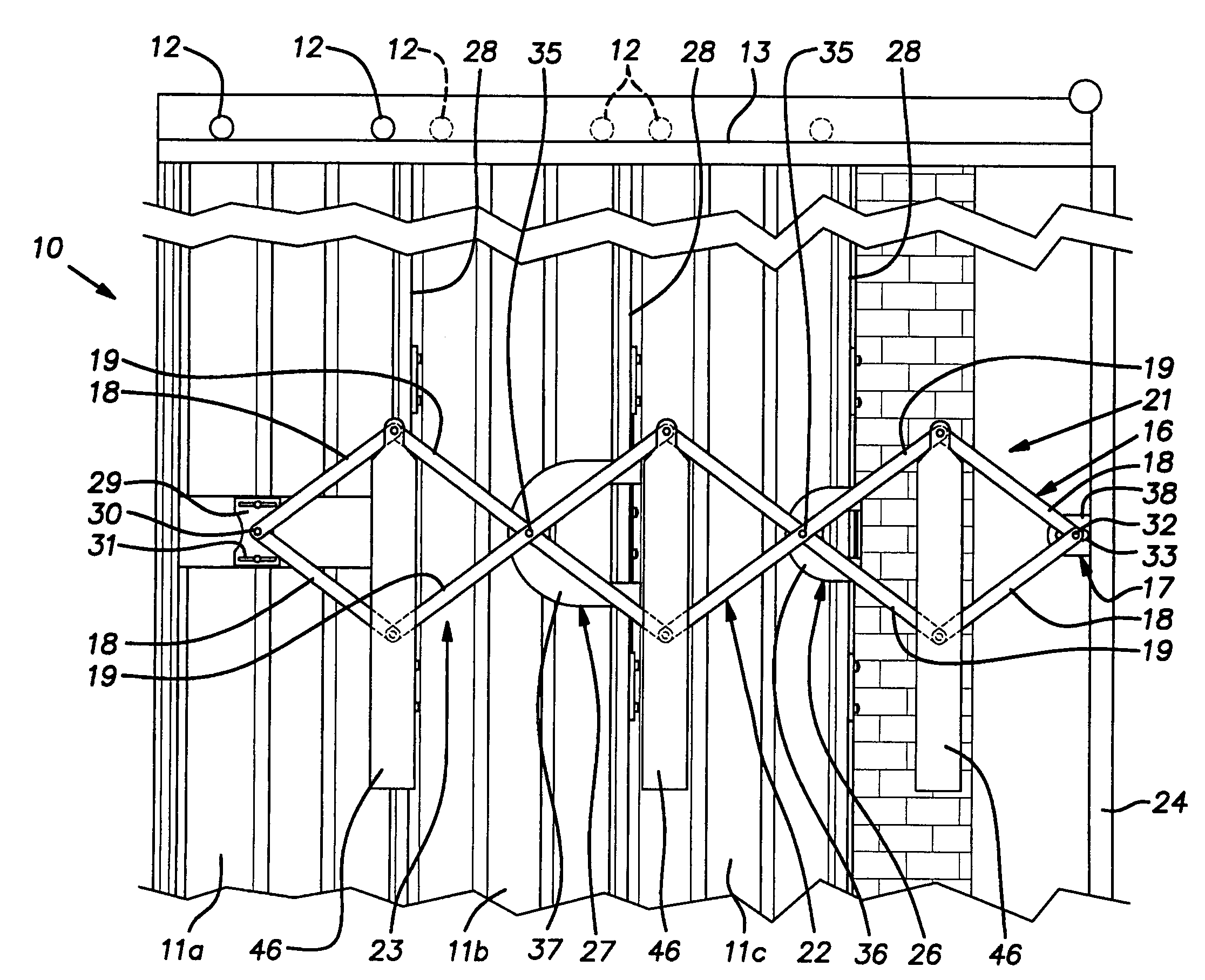

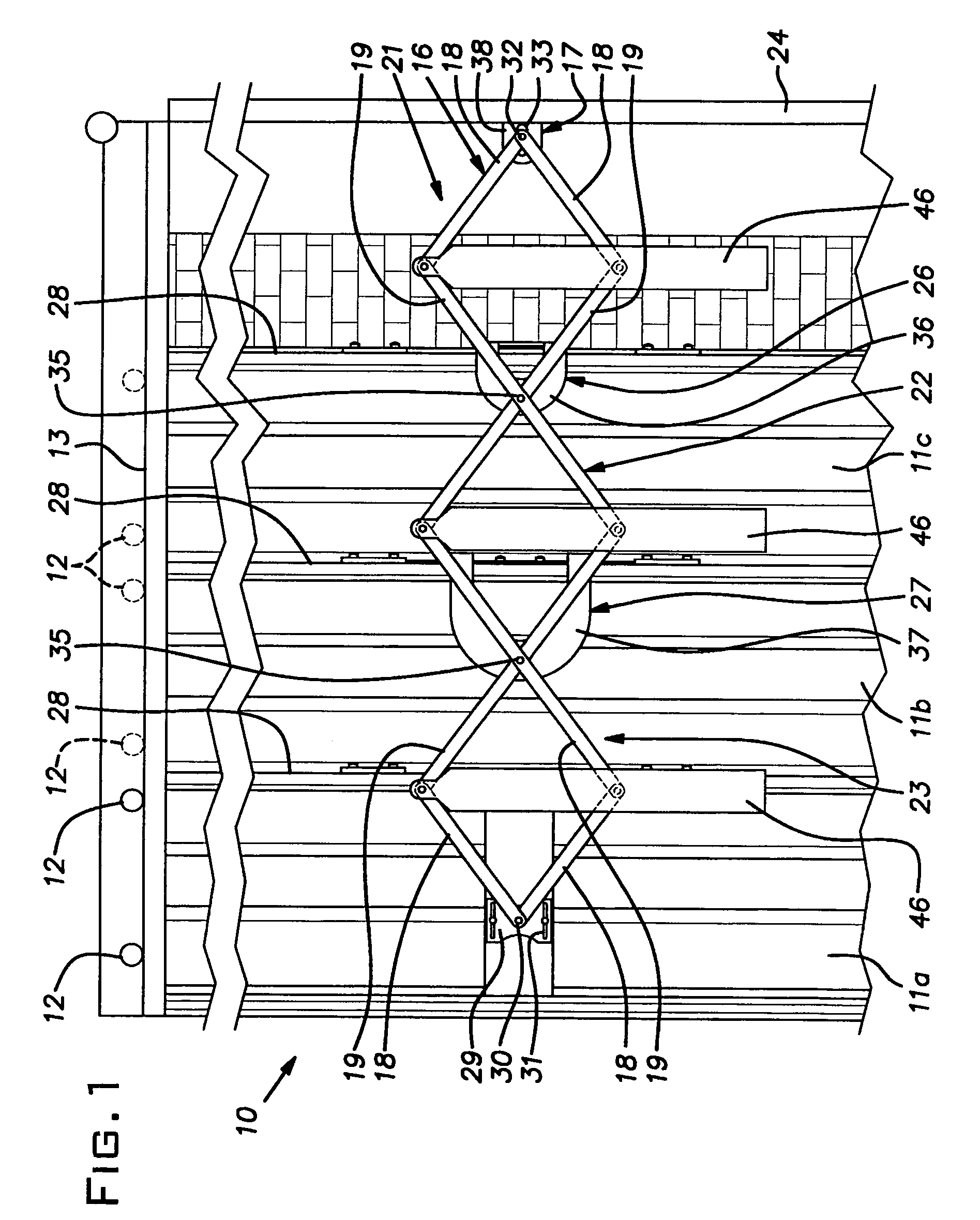

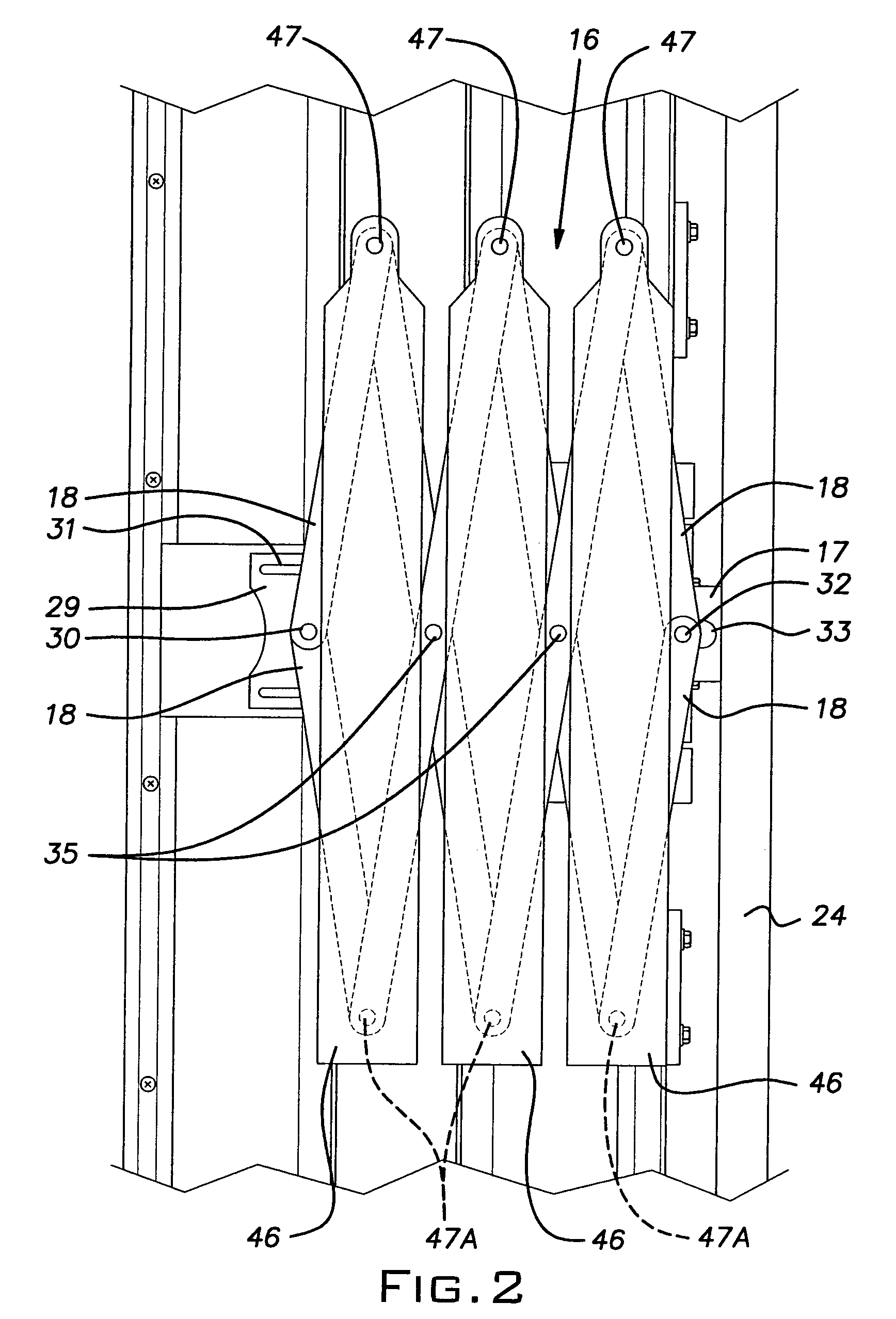

Door interlocking system

InactiveUS7308973B2Simplified linkage arrangementEasy to installExtensible doors/windowsCurtain accessoriesVertical planeEngineering

A door panel position control mechanism for a multiple panel horizontal sliding door assembly of a freight elevator landing. The mechanism comprises a multiple node scissors linkage that is configured to be easily installed and initially adjusted and which has its parts symmetrically balanced about a vertical plane such that excessive eccentric loading on the components is reduced and a long service life is obtained with reduced wear and a reduced need for periodic adjustment.

Owner:PEELLE COMPANY LTD THE

Magnetic brush for cleaning the wall of an arc aquarium

InactiveUS20060048326A1Easy to replaceEasy to stickPisciculture and aquariaWindow cleanersEngineeringMagnet

Present invention relates a suspendable magnetic brush for cleaning an aquarium with curved window surface, characterized in that an upper cover with an air chamber is attached tightly to a bottom cover with a cleaning material layer underneath, and an inner cover with a magnet located therein is provided inside the air chamber, said inner cover being attached to the bottom cover while isolated from the air chamber. Said upper cover having through holes connecting the air chamber to the exterior of the device. It is possible to adjust the air or liquid in the air chamber through the holes connecting the upper cover and the air chamber so that the weight of the interior magnetic brush can be adjusted so as to balance all the forces exerted upon the interior magnetic brush. As a result the interior elements of the brush can suspend in the water and move smoothly on the aquarium window upon the manipulation of the exterior brush. With the convex edge(s) of the bottom cover matching the curved window surface of the aquarium the magnetic brush can clean both curved window surface and the planar window surface as well.

Owner:HUANG TONG

Barrel-type internal combustion engine

InactiveUS20080105223A1Minimize engine vibrationForce balanceReciprocating piston enginesLinear motionDrive shaft

An engine, e.g., a cam drive, barrel-type internal combustion engine, that includes: a main drive shaft defining a longitudinal axis; a sinusoidal main drive cam rigidly attached to the main drive shaft; a plurality of cam members that are in contact with the sinusoidal main drive cam and that are configured to follow the sinusoidal main drive cam, wherein rotation of the sinusoidal main drive cam corresponds to reciprocating linear movement of each of the plurality of cam members in a direction parallel to the longitudinal axis; for each cam member, a pair of linear pistons disposed on opposite sides of the cam member for reciprocating linear movement within respective cylinder bores.

Owner:KUBES LARRY +4

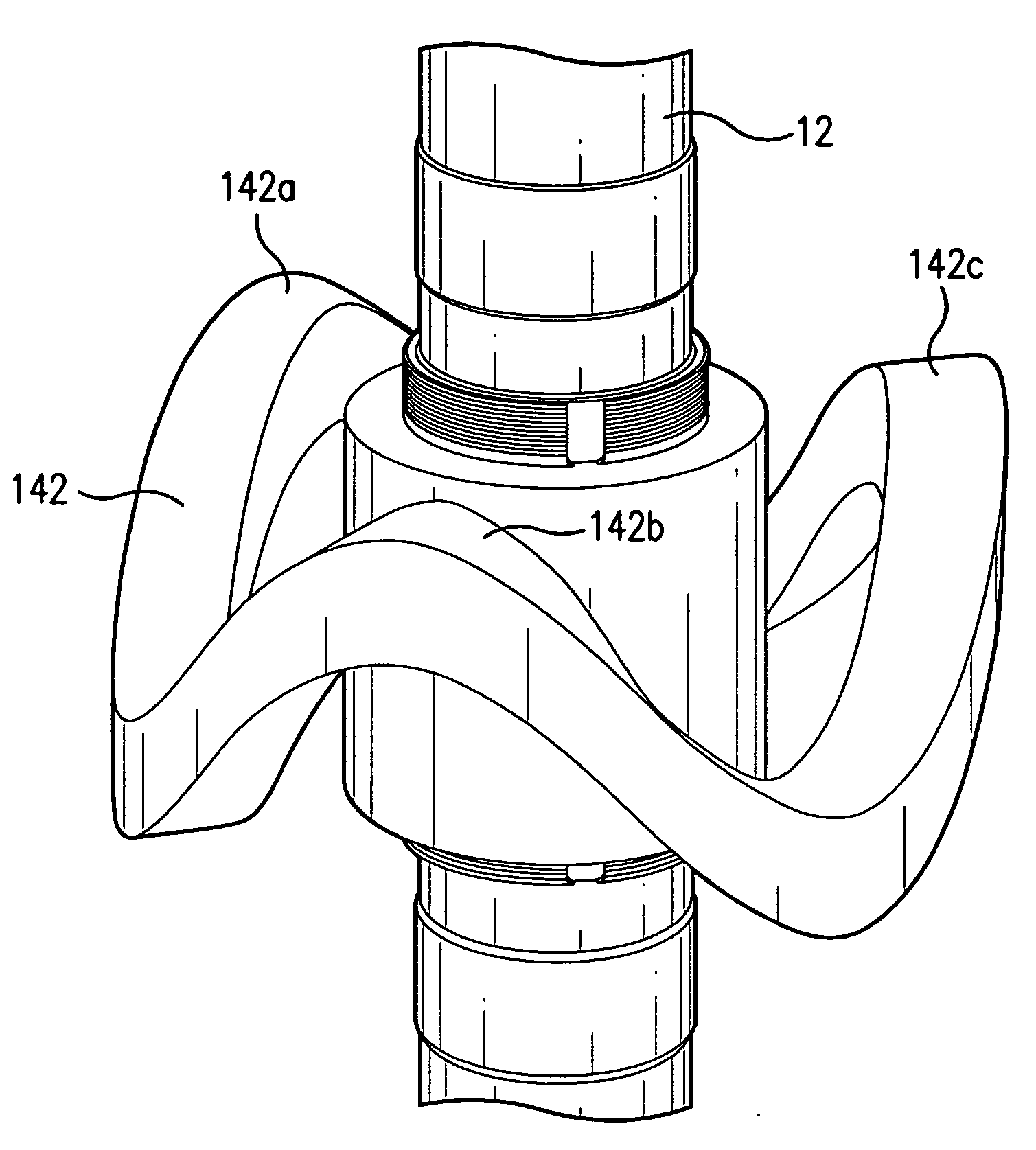

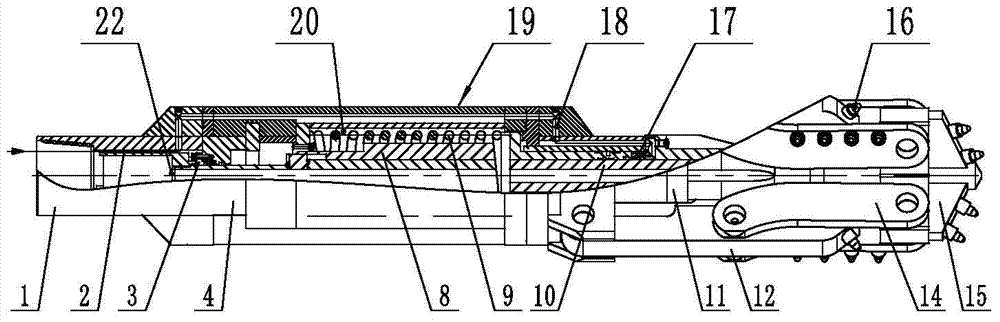

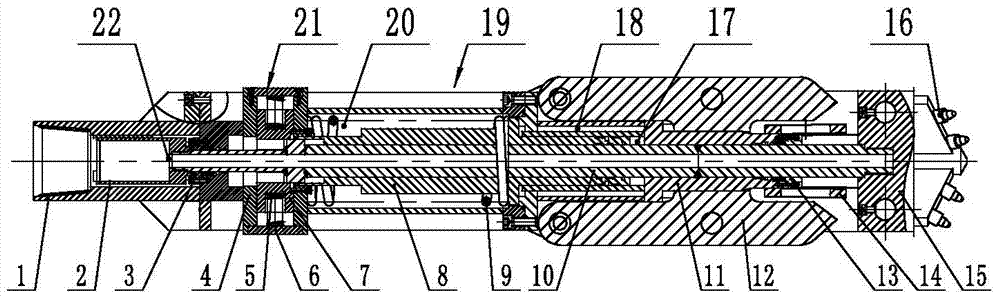

Umbrella reamer bit assembly

ActiveCN104499946AWide adjustment range of contraction angleBalanced forceDrill bitsReamerEngineering

The invention relates to an umbrella reamer bit assembly comprising a water cylinder. A hollow mandrel is fitted in the water cylinder. The water cylinder is provided with a limiter which limits axial motion of the mandrel. The two ends of the mandrel are connected with an inner connector and a bit, respectively. The water cylinder is provided with an outer connector surrounding the inner connector. At least two reamer arms are hinged to the outer wall of the water cylinder. Each reamer arm is hinged to the bit through a connecting rod. A cylinder rod is slidably fitted in the water cylinder. A water cavity is formed among one end, corresponding to the bit, of the cylinder rod, the mandrel and the water cylinder. The water cavity is communicated with the outer connector through a water passage arranged in the water cylinder. A cylinder rod return spring is disposed between one end, corresponding to the inner connector, of the cylinder rod and the water cylinder. The cylinder rod is provided with an unlocking mechanism which opens the limiter. The umbrella reamer bit assembly has drilling and reaming functions, has a large contraction angle adjusting range, is capable of evenly bearing stress, high in structural strength and simple in structure and can meet the requirements on drilling and reaming.

Owner:江苏谷登重型机械装备科技有限公司

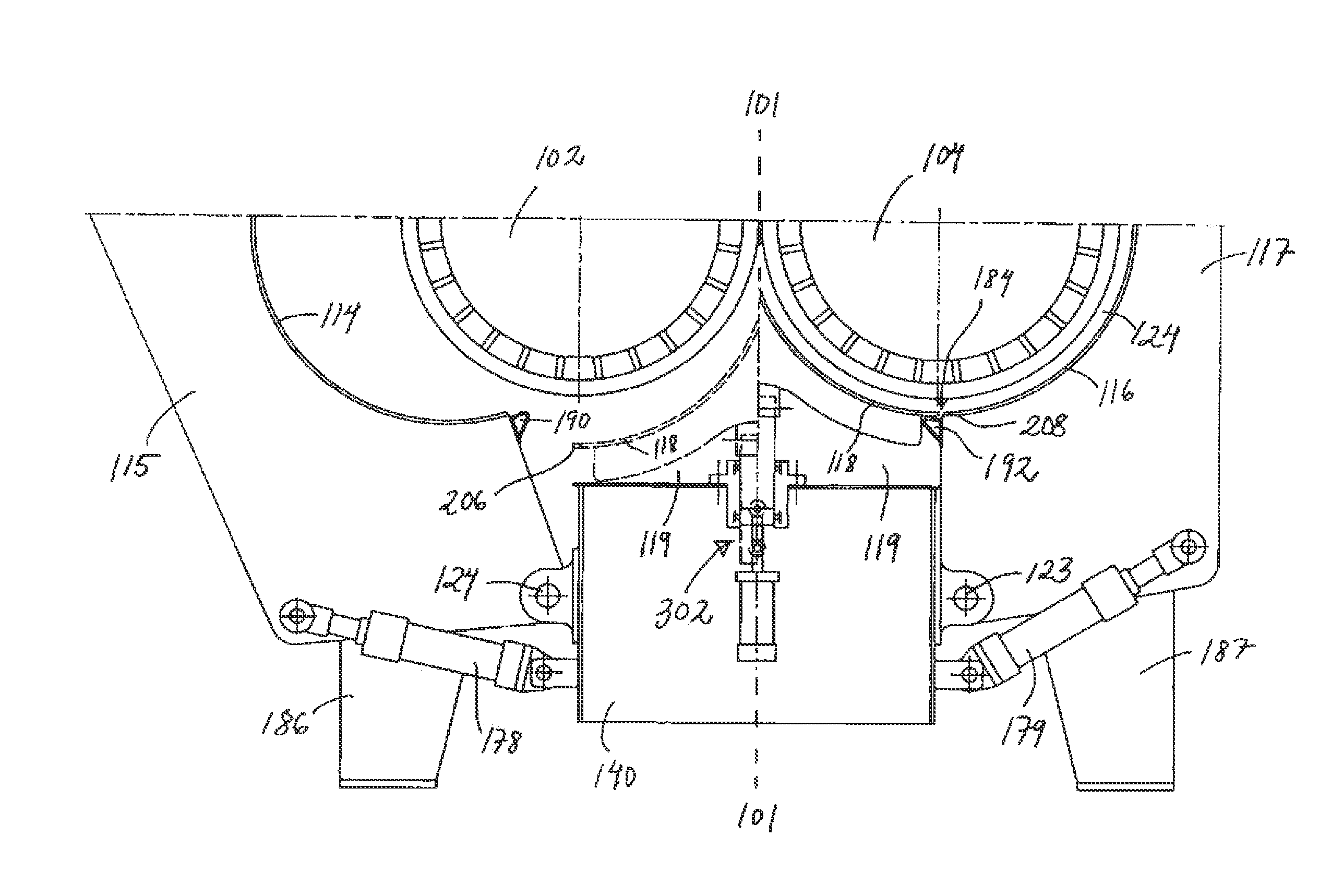

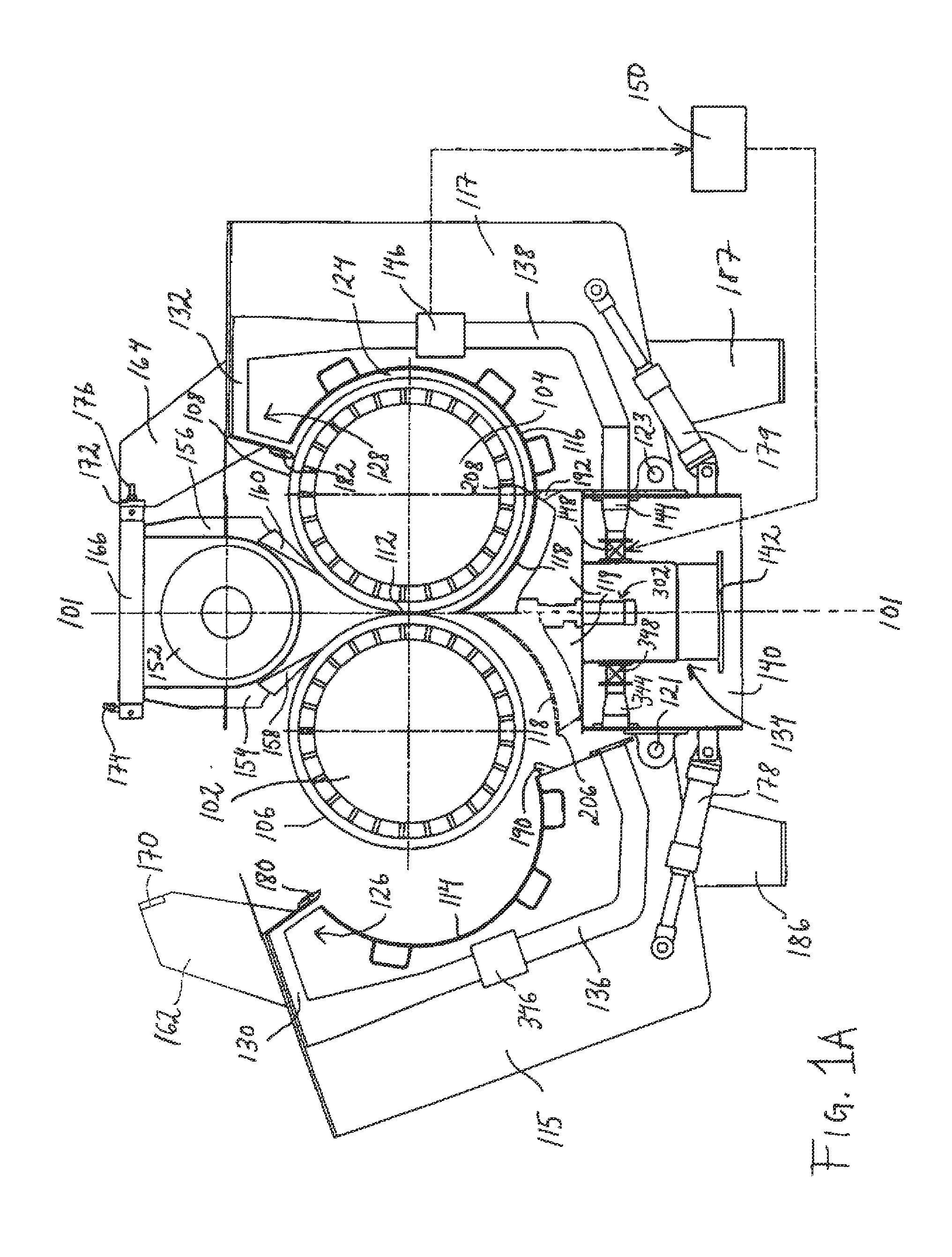

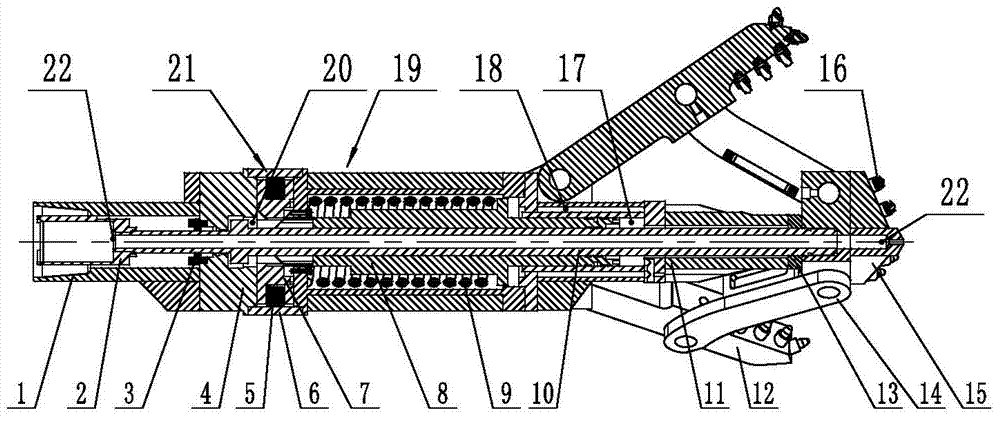

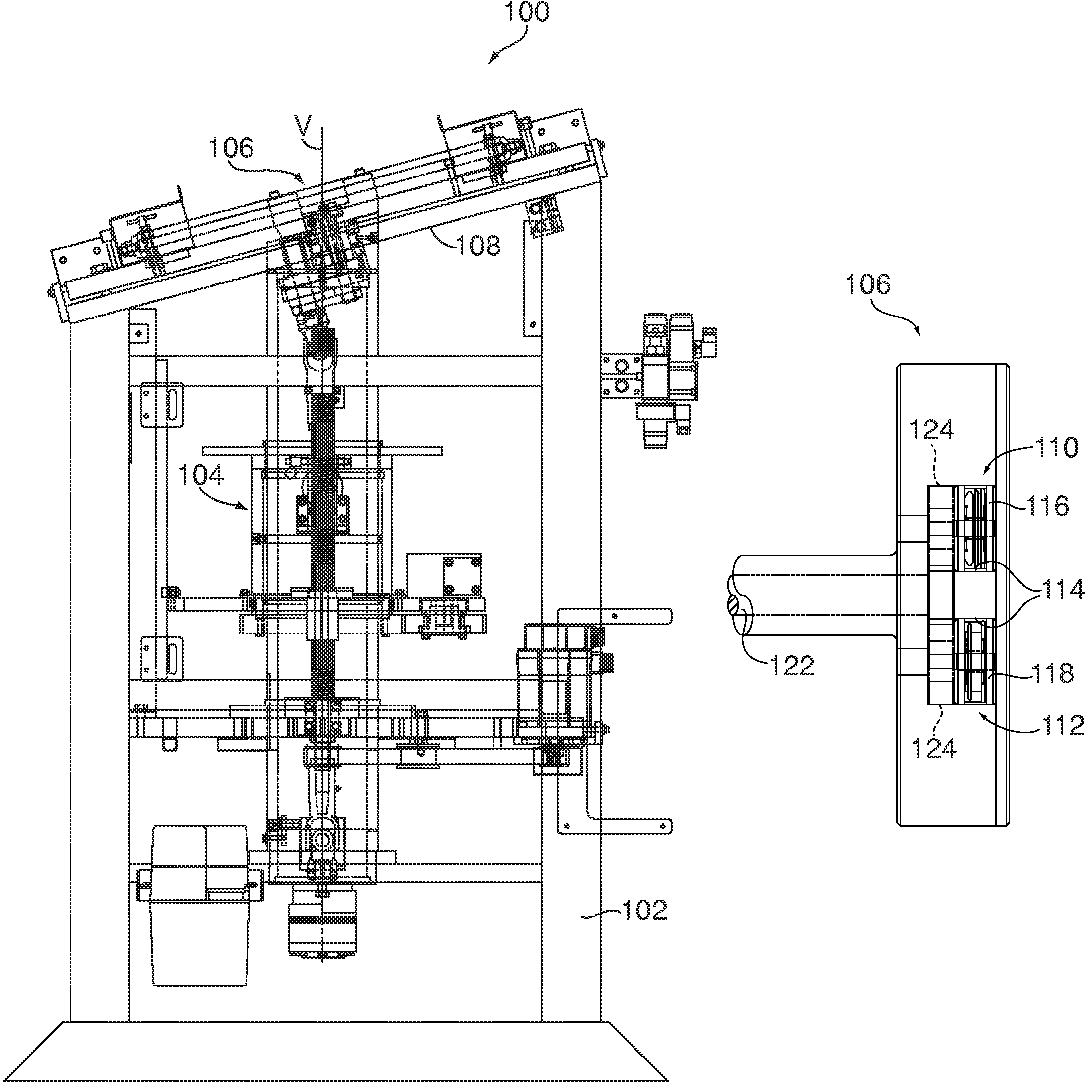

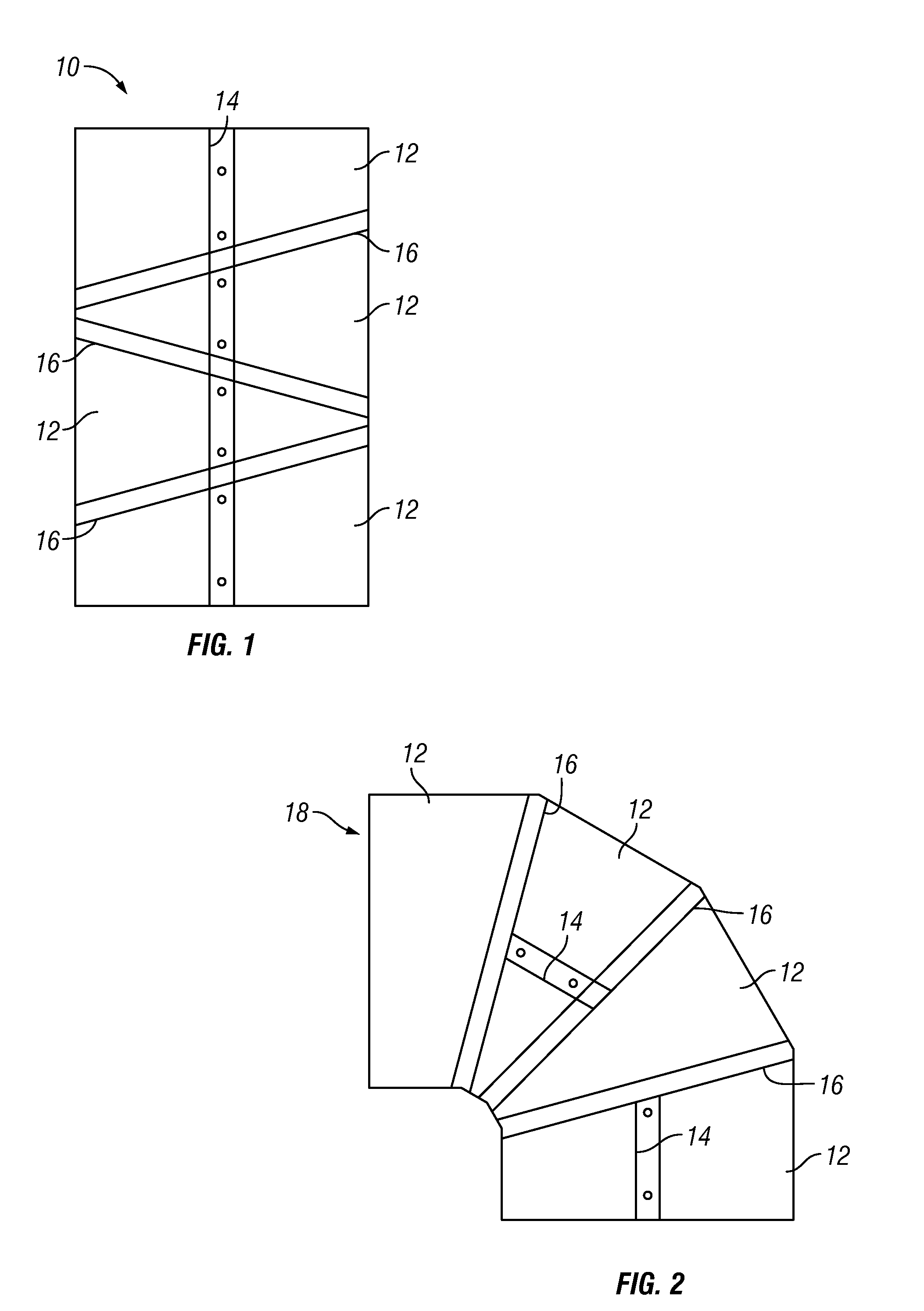

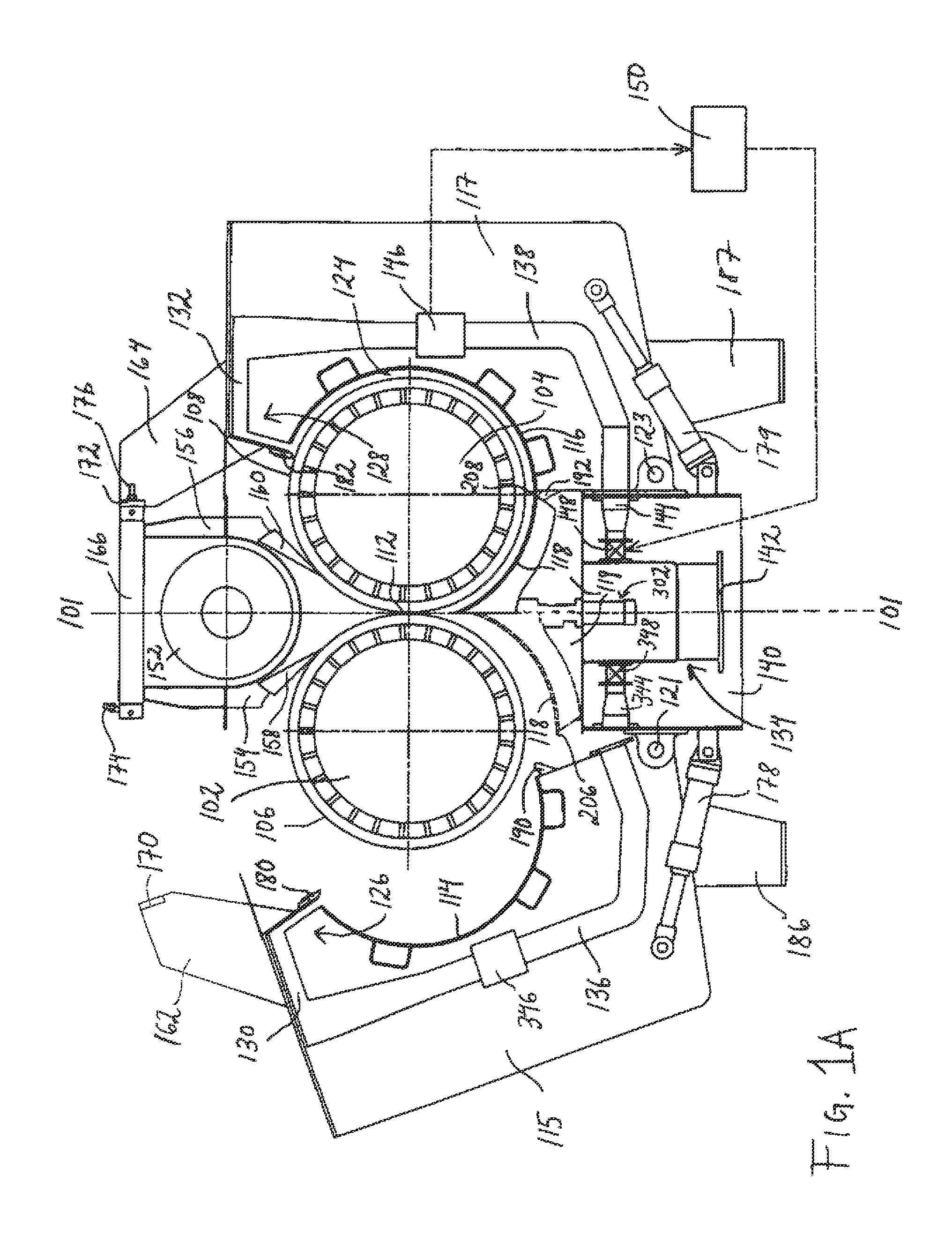

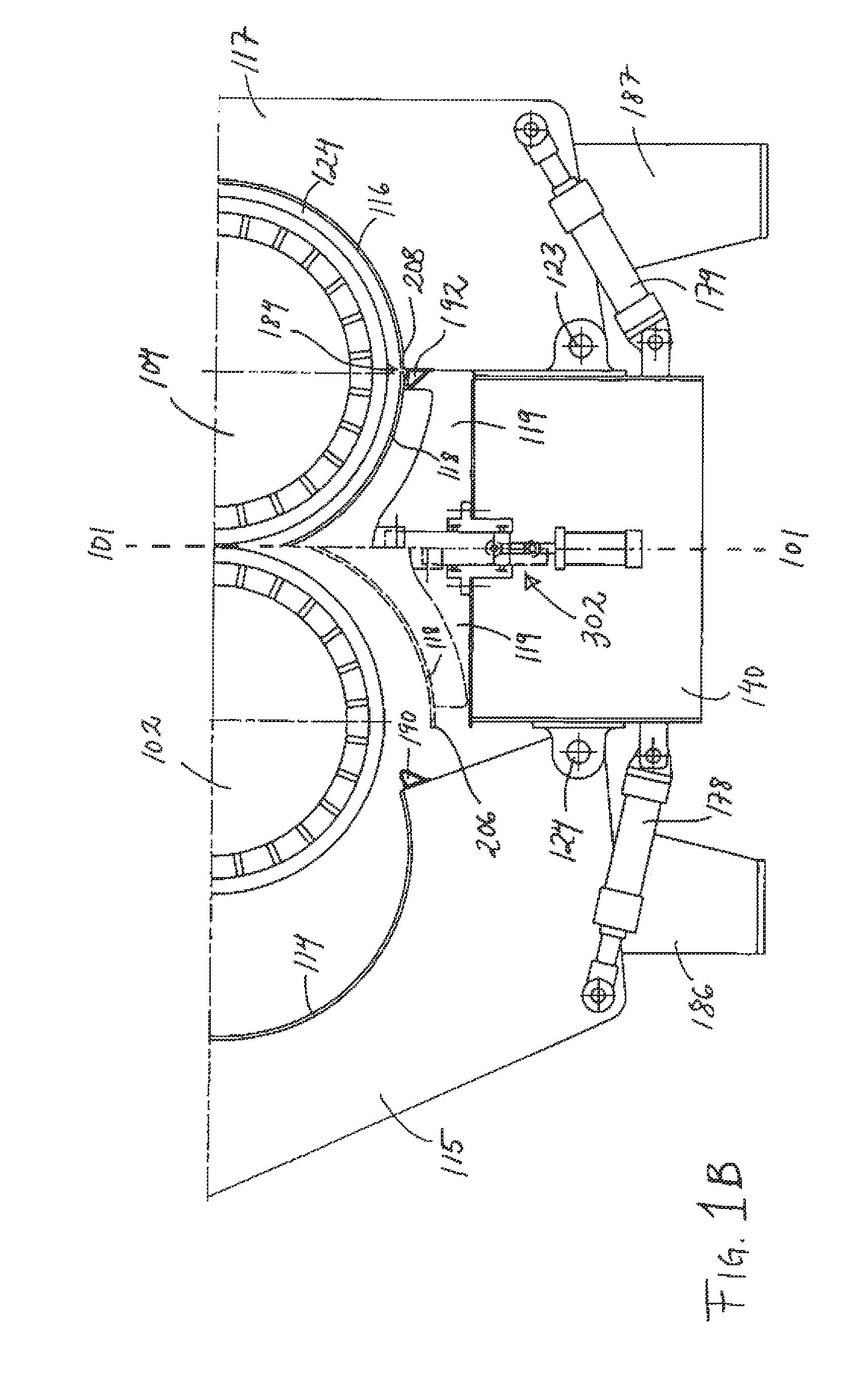

Formation and rotational apparatus for cylindrical workpieces

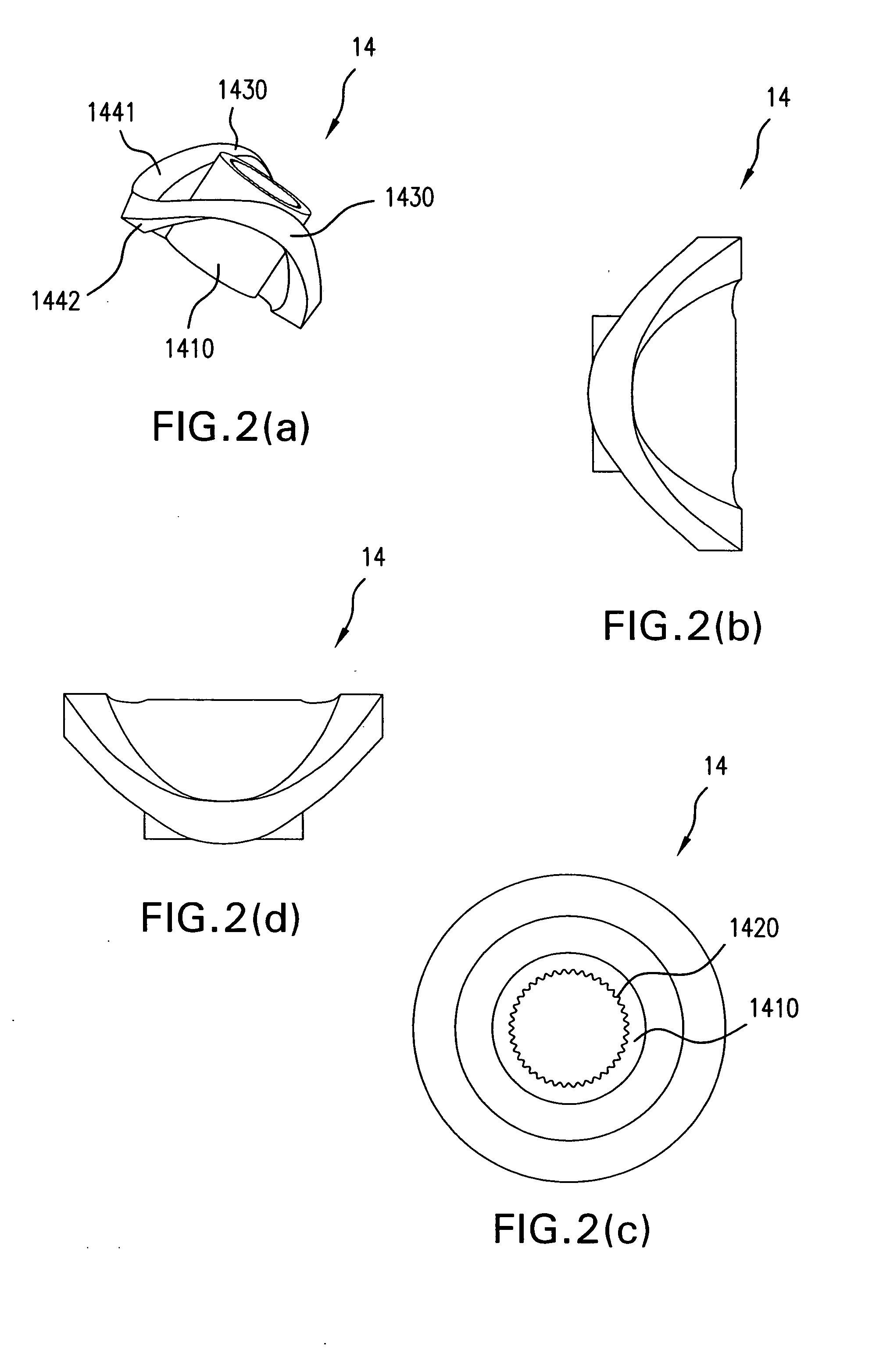

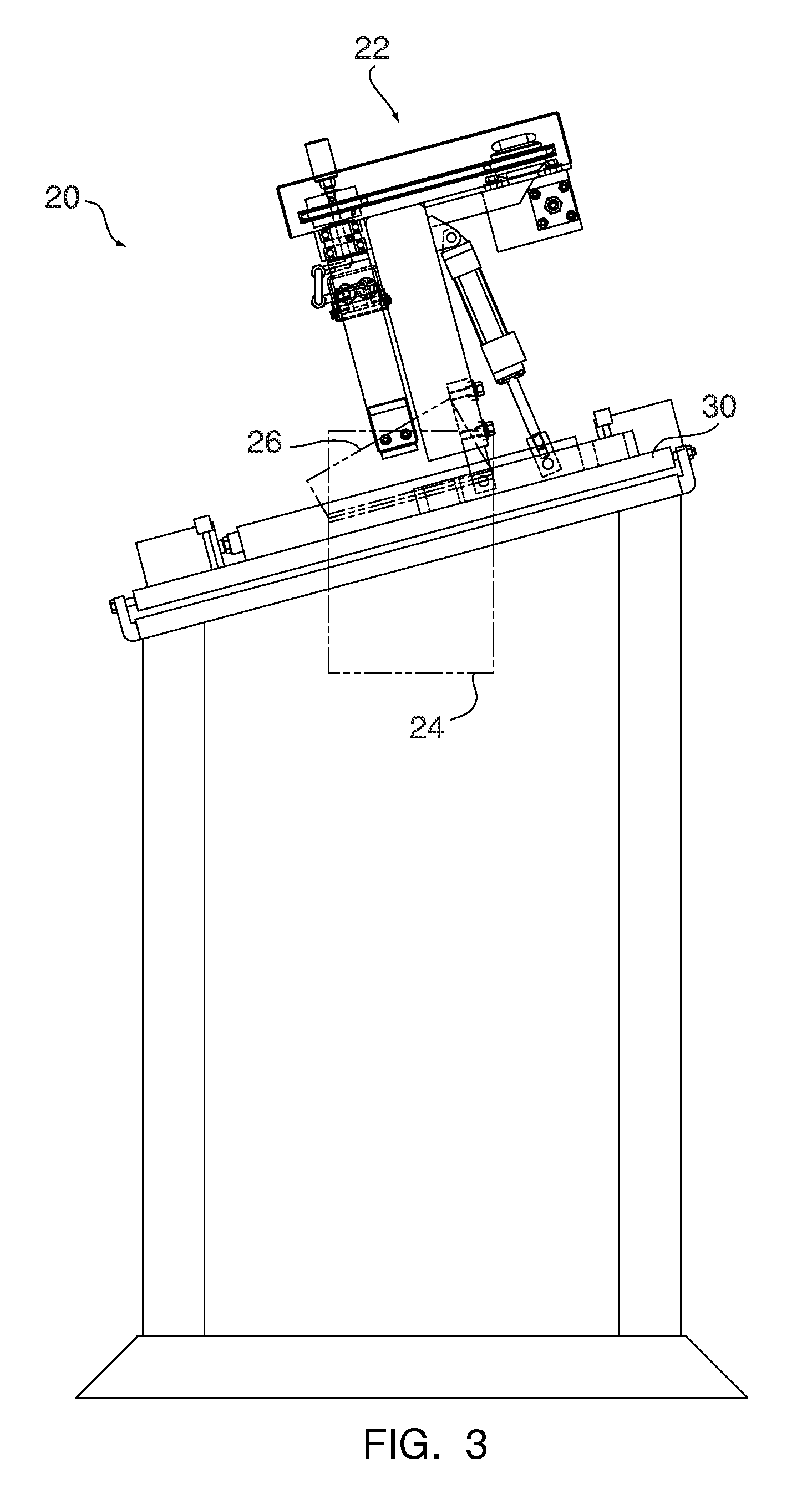

ActiveUS7797805B2Balanced forceAssembly machinesOther manufacturing equipments/toolsEngineeringMechanical engineering

A formation and rotation apparatus for use in forming and rotating interconnected sections of a cylindrical workpiece, including a frame and a head arranged within the frame, the head defining two slots and being operatively rotated via an integral drive assembly. A first slide block is slidably disposed within one of the two slots, and a second slide block is disposed within another of the two slots, each of the first and the second slide blocks include a cutting wheel and a beading wheel for successively forming each of the interconnected sections. An armature having an axis of rotation is also provided, along with a gripping mechanism being operatively connected to the armature. A drive mechanism selectively rotates the armature about the axis of rotation after the gripping means has closed about one of the interconnected sections.

Owner:FORMTEK

Barrel-type internal combustion engine

InactiveUS20080105222A1Minimize engine vibrationForce balanceReciprocating piston enginesLinear motionDrive shaft

An engine, e.g., a cam drive, barrel-type internal combustion engine, that includes: a main drive shaft defining a longitudinal axis; a sinusoidal main drive cam rigidly attached to the main drive shaft; a plurality of cam members that are in contact with the sinusoidal main drive cam and that are configured to follow the sinusoidal main drive cam, wherein rotation of the sinusoidal main drive cam corresponds to reciprocating linear movement of each of the plurality of cam members in a direction parallel to the longitudinal axis; for each cam member, a pair of linear pistons disposed on opposite sides of the cam member for reciprocating linear movement within respective cylinder bores.

Owner:KUBES LARRY +3

A formation and rotational apparatus and method for cylindrical workpieces

ActiveUS20060283010A1Force balanceBalanced forceOther manufacturing equipments/toolsMetal working apparatusEngineeringHead parts

A formation and rotation apparatus for use in forming and rotating interconnected sections of a cylindrical workpiece, including a frame and a head arranged within the frame, the head defining two slots and being operatively rotated via an integral drive assembly. A first slide block is slidably disposed within one of the two slots, and a second slide block is disposed within another of the two slots, each of the first and the second slide blocks include a cutting wheel and a beading wheel for successively forming each of the interconnected sections. An armature having an axis of rotation is also provided, along with a gripping mechanism being operatively connected to the armature. A drive mechanism selectively rotates the armature about the axis of rotation after the gripping means has closed about one of the interconnected sections.

Owner:FORMTEK

Rotary internal combustion engine with adjustable compression stroke

InactiveUS20050161016A1Quickly and efficiently and economically convertLow costInternal combustion piston enginesEngines with oscillating pistonsWork cycleEngineering

Owner:KAMENOV KAMEN GEORGE

Barrel-type internal combustion engine

InactiveUS20080105117A1Minimize engine vibrationForce balanceValve arrangementsMachine framesLinear motionExternal combustion engine

An engine, e.g., a cam drive, barrel-type internal combustion engine, that includes: a main drive shaft defining a longitudinal axis; a sinusoidal main drive cam rigidly attached to the main drive shaft; a plurality of cam members that are in contact with the sinusoidal main drive cam and that are configured to follow the sinusoidal main drive cam, wherein rotation of the sinusoidal main drive cam corresponds to reciprocating linear movement of each of the plurality of cam members in a direction parallel to the longitudinal axis; for each cam member, a pair of linear pistons disposed on opposite sides of the cam member for reciprocating linear movement within respective cylinder bores.

Owner:KUBES LARRY +4

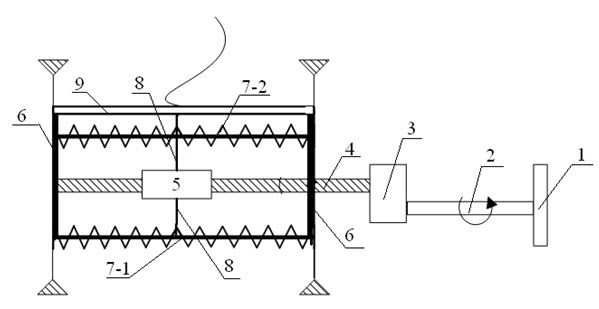

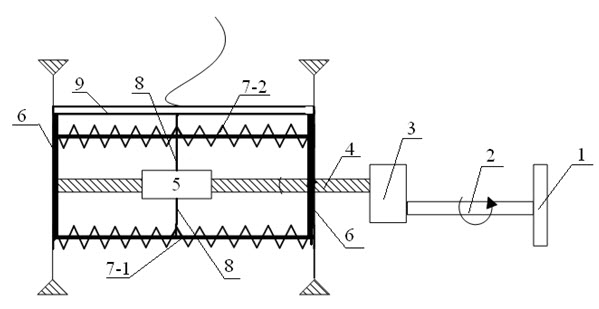

Self-aligning steering wheel simulation device for automobile driving training apparatus

InactiveCN101958064AAbsorb or dampen shock energySoft returnCosmonautic condition simulationsSimulatorsSteering angleSteering wheel

The invention discloses a self-aligning steering wheel simulation device for an automobile driving training apparatus. The simulation device has the structure that: a steering wheel is fixed with a steering shaft; the steering shaft is connected with a screw rod by a reduction gearbox; a screw rod nut and the screw rod form a transmission pair; the screw rod is supported by a frame; two springs are respectively fixed on the inner wall of the frame; the screw rod nut is provided with a connecting rod; two ends of the connecting rod are fixed at a central position of the two springs respectively; one end of the connecting rod is connected with a displacement sensor to transmit a steering angle of the steering wheel to a signal processing system of the automobile driving training apparatus in real time; simultaneously the springs are compressed and stretched to accurately position the steering angle of the steering wheel and a position of a wheel. After steering force is removed, the steering wheel is automatically and steadily aligned without a rebound phenomenon. When a trainee operates the device, the steering wheel generates actual force feeling feedback with the change of a rotation angle. Simultaneously, the device has the advantages of simple installation, convenient maintenance, high environmental protection performance and higher practical value.

Owner:CIVIL AVIATION UNIV OF CHINA

Method for manufacturing elastic woven upper

The invention relates to a process for manufacturing elastic woven upper. The process comprises the following steps: A, selecting warp yarns and weft yarns; B, designing the upper, and inputting upper parameters into a shuttle loom; C, starting the shuttle loom, and weaving an initial product; D, performing laser shaping on the initial product obtained in step C so as to process the upper, wherein the initial product in step C comprises an inner woven layer, an outer woven layer, and connecting yarns used for connecting the inner woven layer and the outer woven layer, a setting process is performed between step C and step D, and the initial product is subjected to setting in the setting process by adopting a scutching and setting machine. Decorative patterns are formed by mixing and interweaving covered spandex yarns and twisted threads / high-elasticity yarns on the outer layer of the upper, the stress is balanced due to equal distribution of the yarn texture, and the inner layer of the upper is woven by taking the high-elasticity yarns as the lining, so that the lining is soft. Therefore, the upper has the advantages of high elasticity and is comfortable to wear. Due to the setting process, the upper is difficult to deform and collapse, and an attractive wearing appearance is guaranteed.

Owner:SINCETECH FUJIAN TECH CO LTD

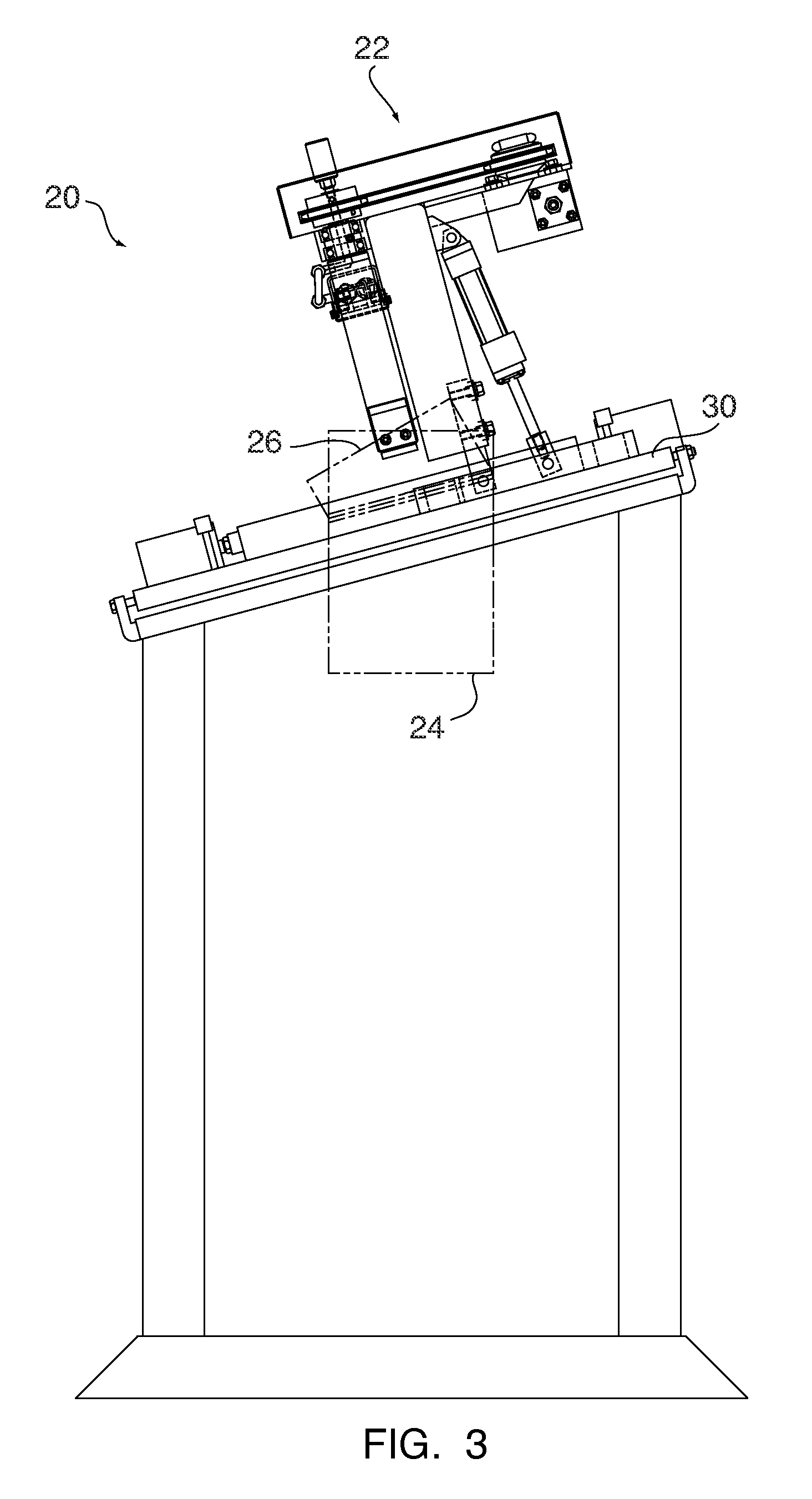

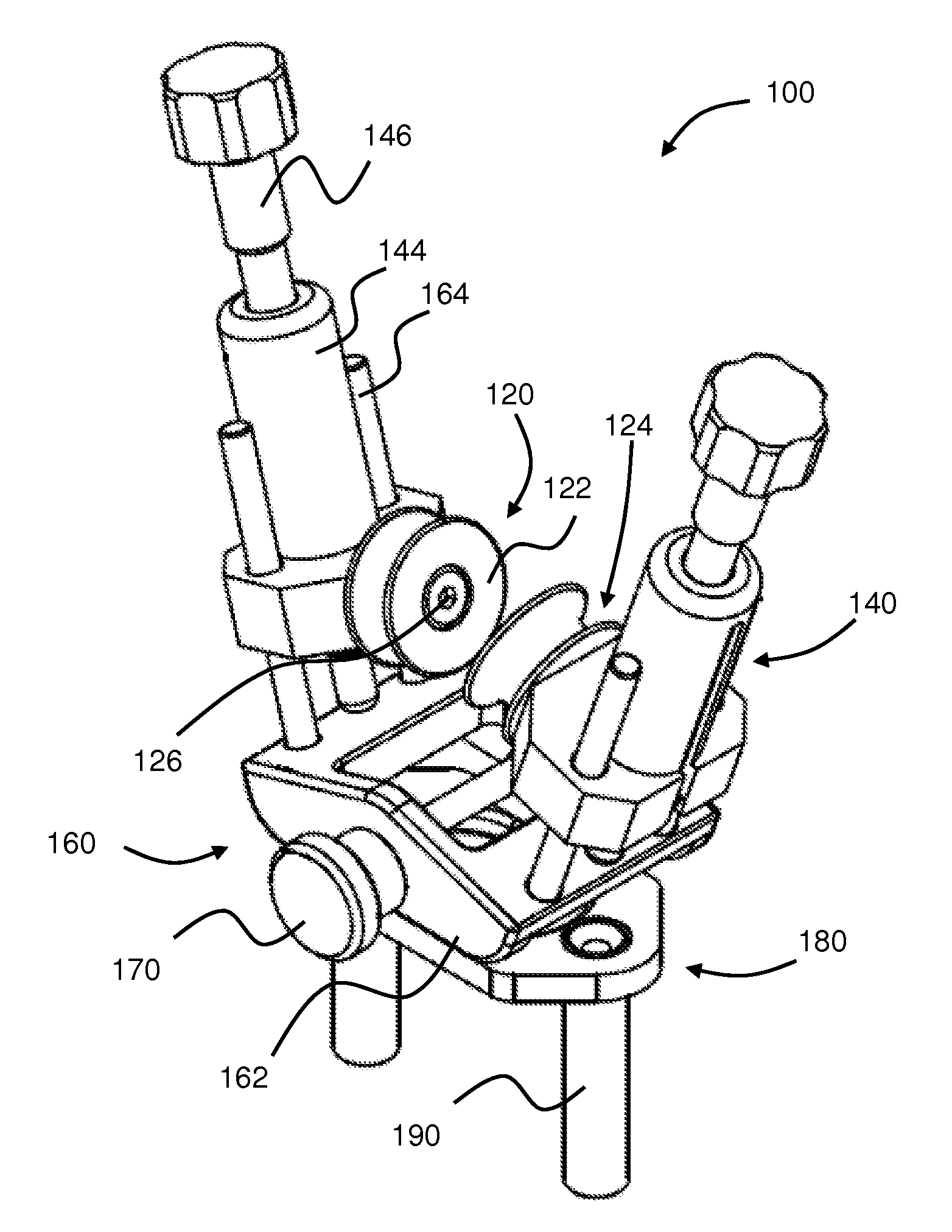

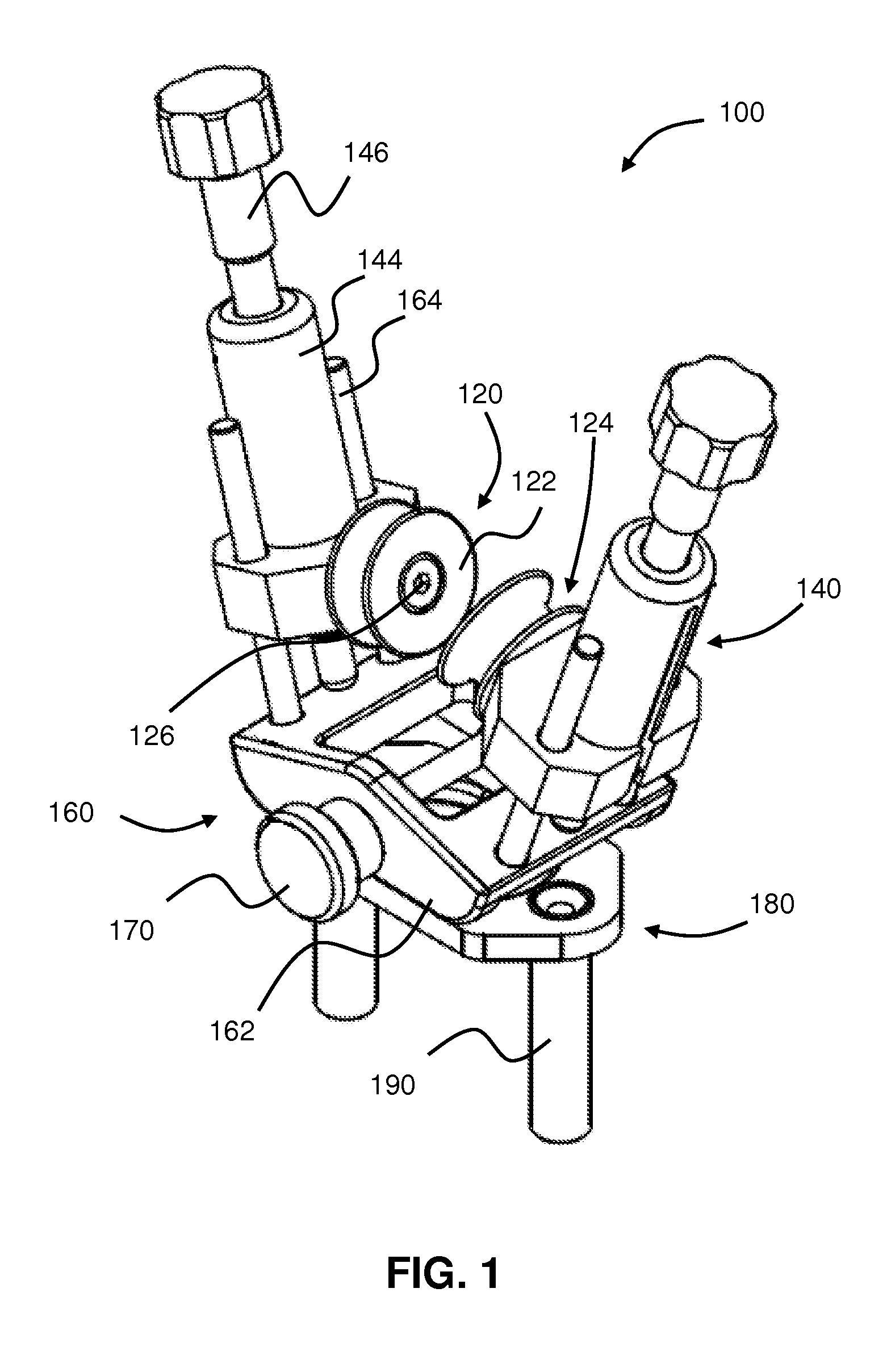

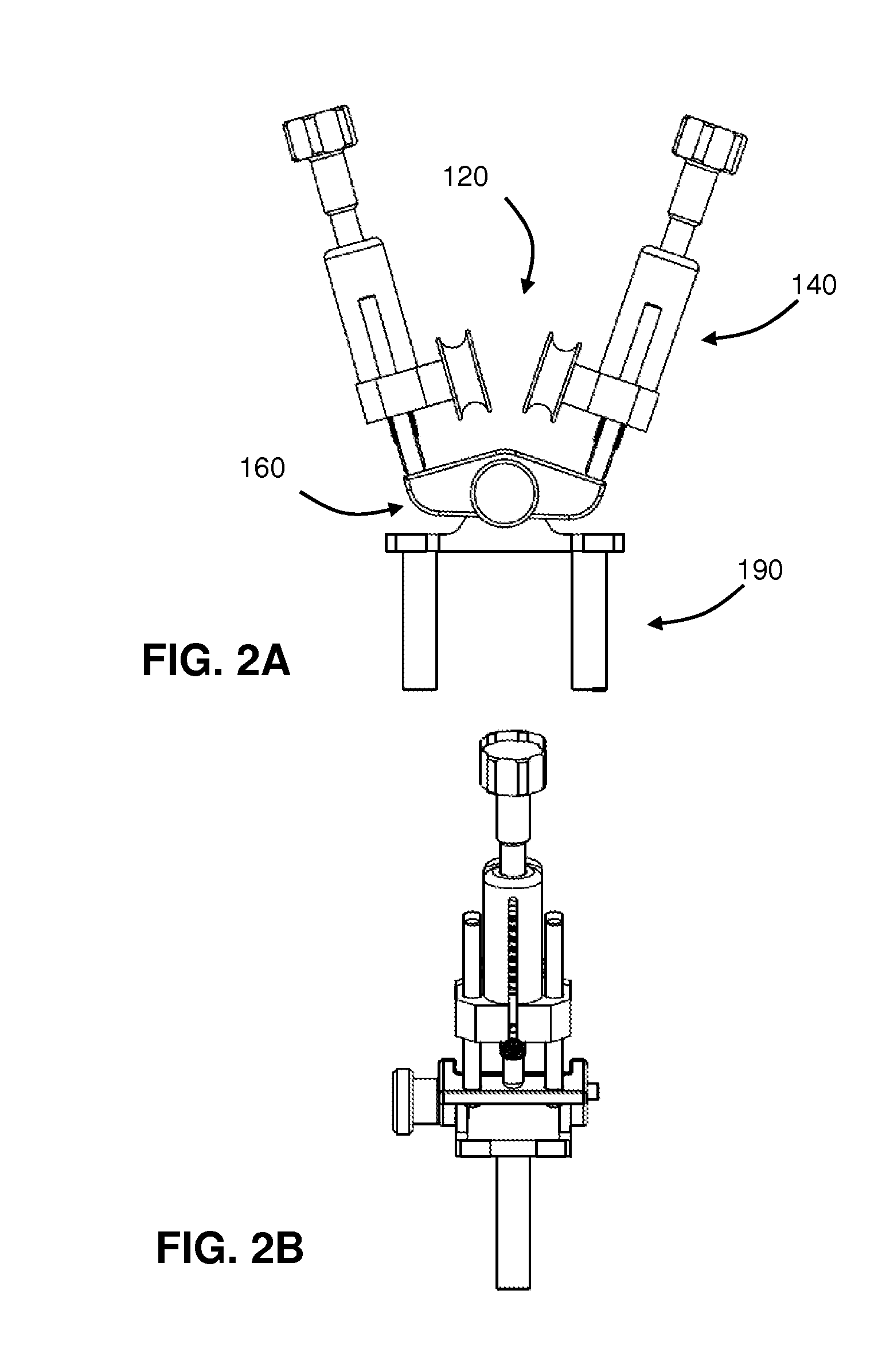

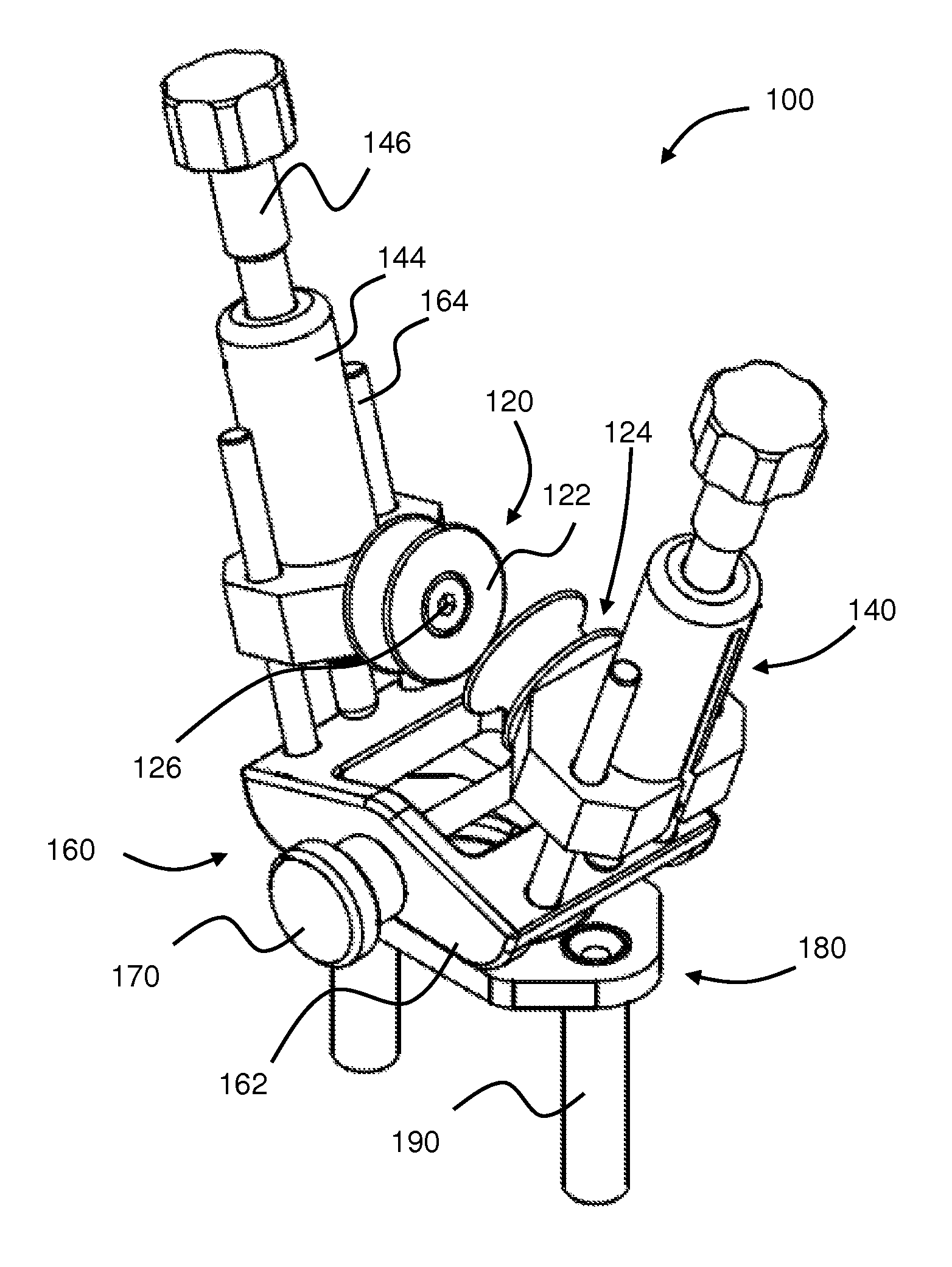

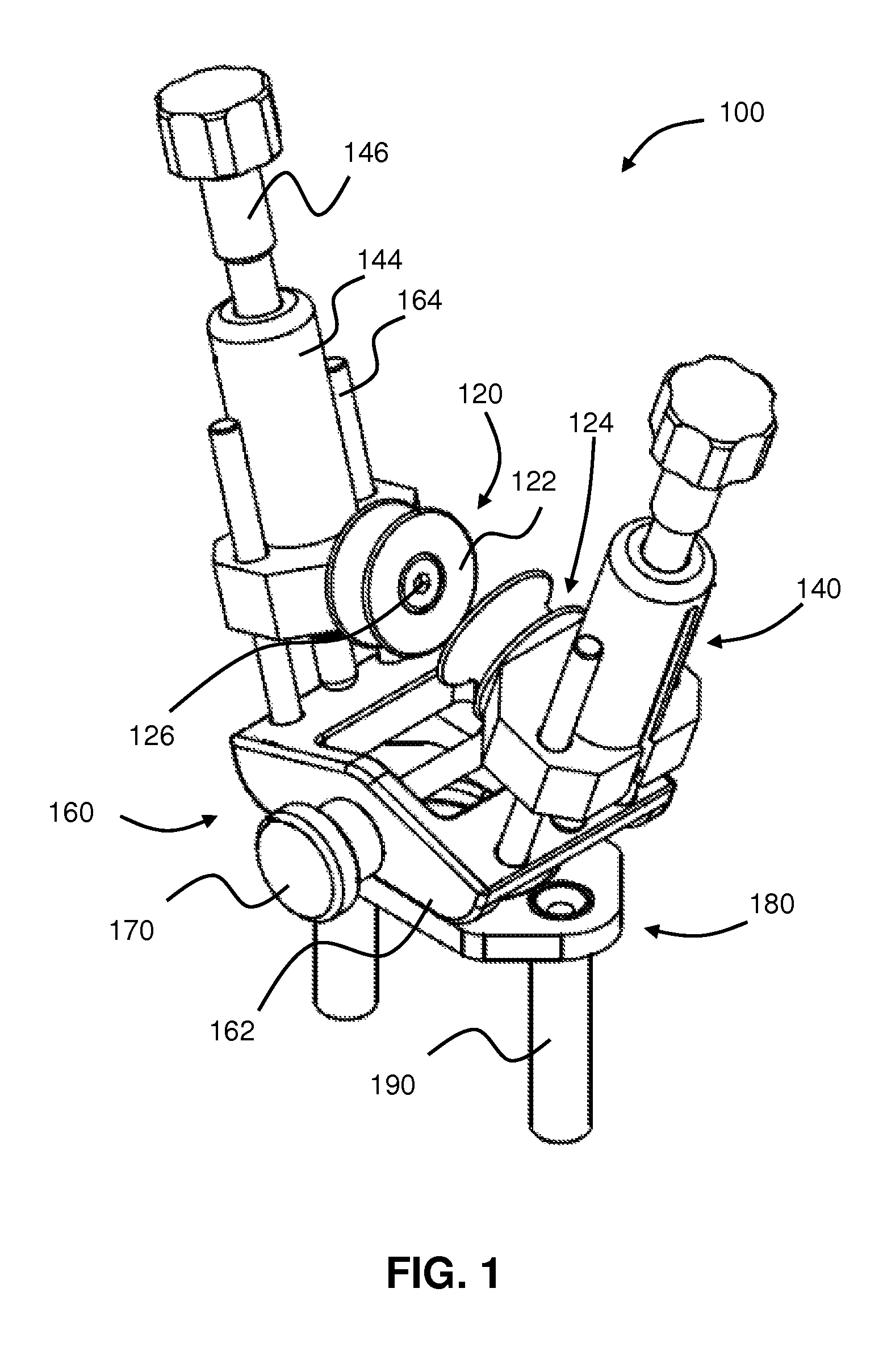

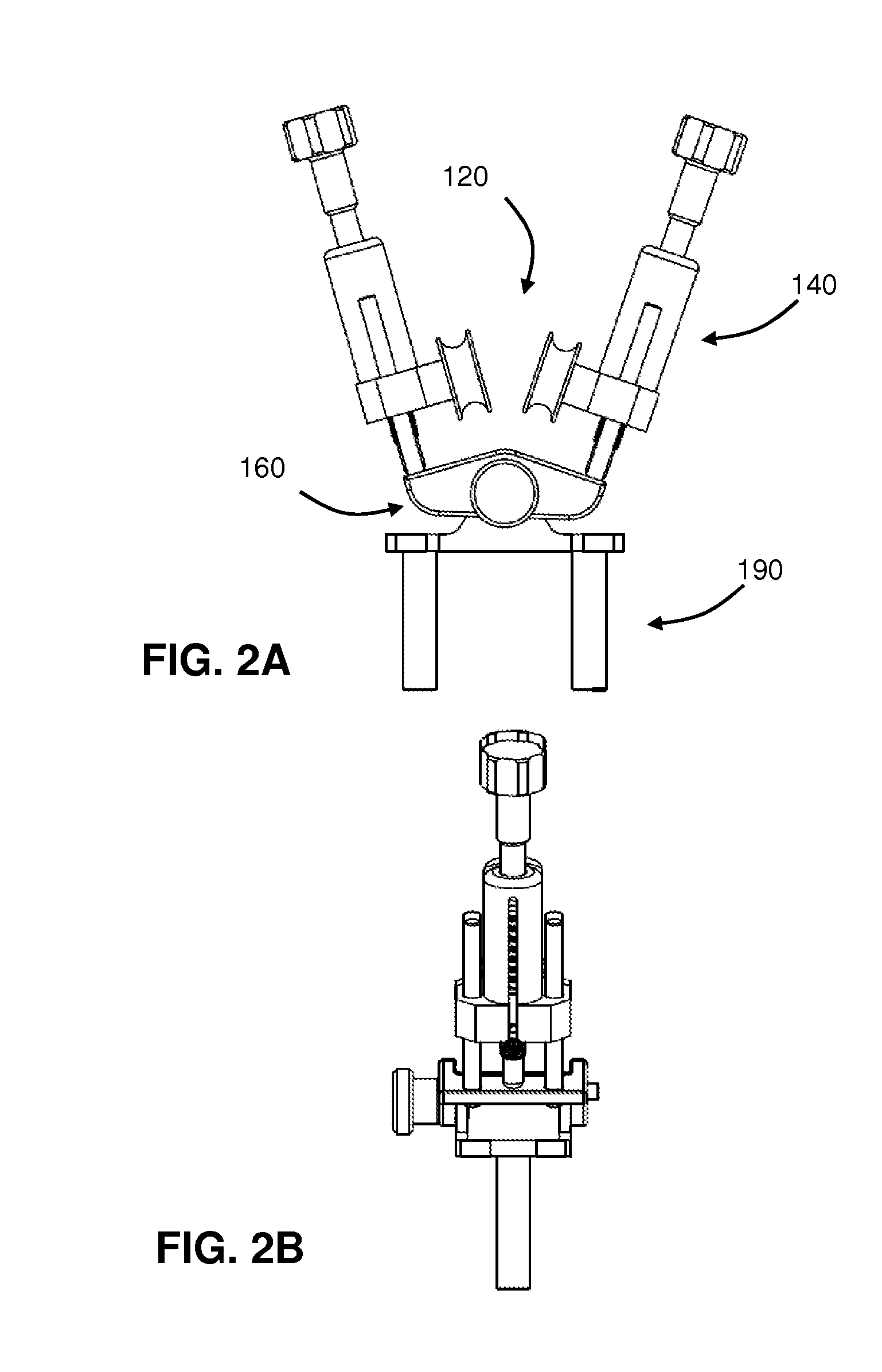

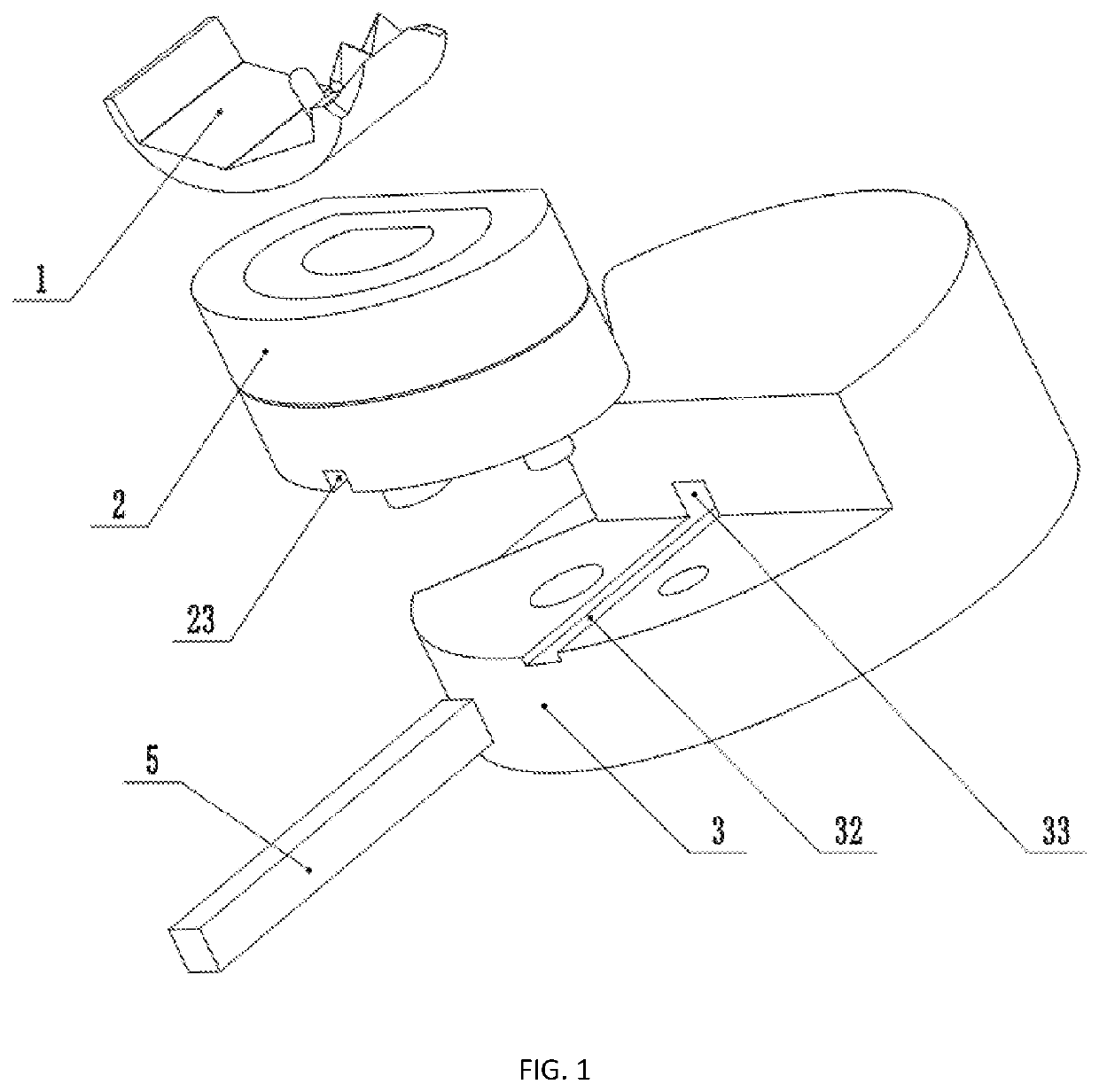

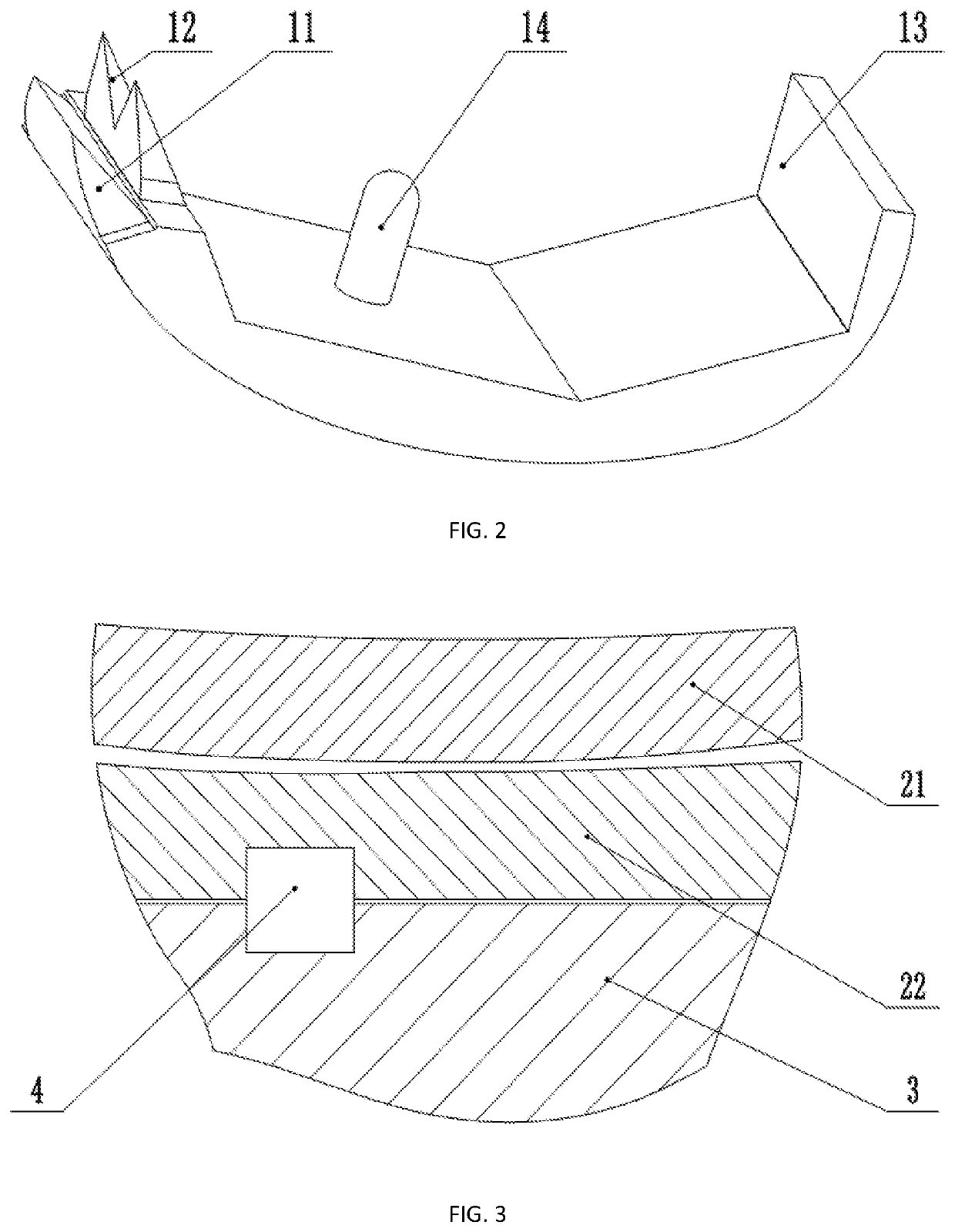

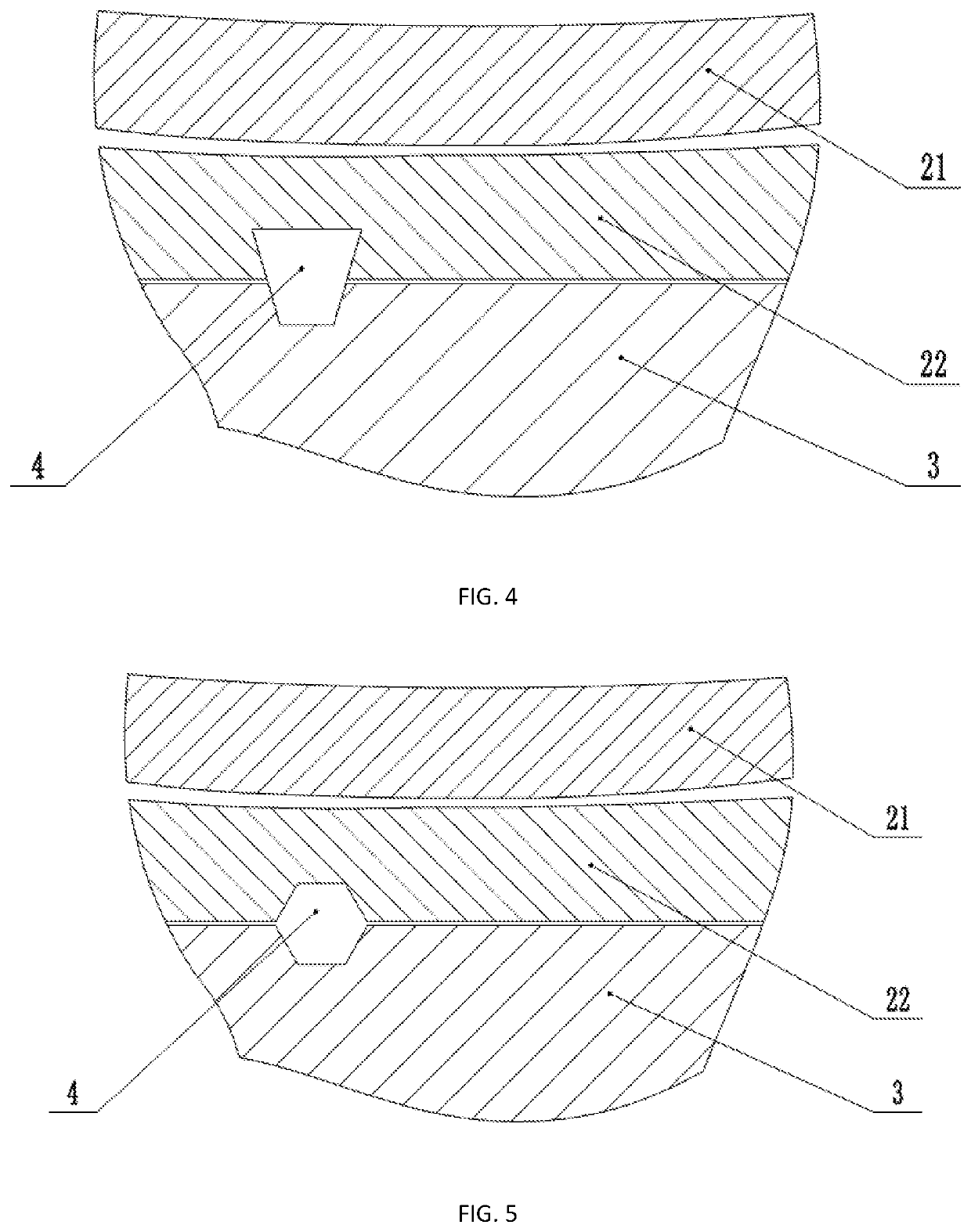

Surgical tensioning assembly and methods of use

InactiveUS20110029079A1Force balanceBalanced forceSuture equipmentsDiagnosticsKnee joint ligamentEngineering

A surgical tensioning assembly providing a means to apply a variable and selective force to tissues, such as replacement ligaments, during a ligament reconstruction surgery. The assembly provides a means to apply a selective, measurable and a generally balanced force on multiple tissues. One embodiment of the tensioning assembly includes a set of subassemblies, namely an engagement subassembly, a variable force subassembly and an equalizing subassembly. These subassemblies are operably connected to each other such that they are able to provide tension on tissues connected to the assembly. In one embodiment the tensioning assembly further includes a mounting subassembly that provides a means to connect the tensioning assembly to a person's body. Methods of use of the surgical tensioning assembly are also disclosed to include novel methods of cycling and conditioning tissue used in a knee ligament replacement surgery.

Owner:THE LONNIE & SHANNON PAULOS TRUST AS AMENDED & RESTATED

Surgical tensioning assembly and methods of use

InactiveUS8657880B2Balanced forceSuture equipmentsDiagnosticsReconstruction surgeryKnee joint ligament

A surgical tensioning assembly providing a means to apply a variable and selective force to tissues, such as replacement ligaments, during a ligament reconstruction surgery. The assembly provides a means to apply a selective, measurable and a generally balanced force on multiple tissues. One embodiment of the tensioning assembly includes a set of subassemblies, namely an engagement subassembly, a variable force subassembly and an equalizing subassembly. These subassemblies are operably connected to each other such that they are able to provide tension on tissues connected to the assembly. In one embodiment the tensioning assembly further includes a mounting subassembly that provides a means to connect the tensioning assembly to a person's body. Methods of use of the surgical tensioning assembly are also disclosed to include novel methods of cycling and conditioning tissue used in a knee ligament replacement surgery.

Owner:THE LONNIE & SHANNON PAULOS TRUST AS AMENDED & RESTATED

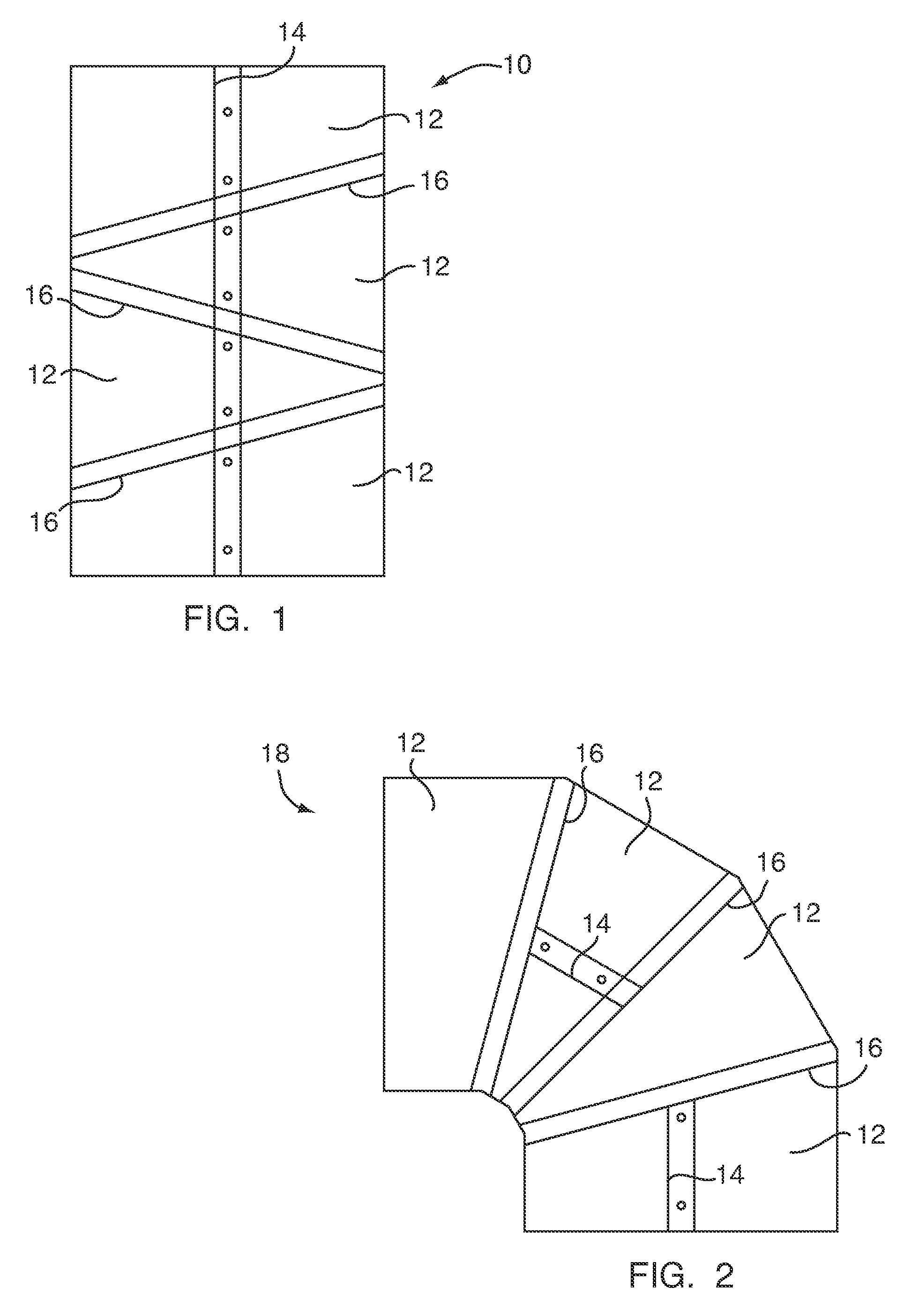

Elbow formation apparatus

An apparatus for forming and rotating interconnected sections of a cylindrical sheet metal workpiece to provide an elbow. The apparatus includes a frame, a head rotatably arranged within the frame and a tool ring mounted to the frame, the head and tool ring being co-operable for sectioning and joining segments of the workpiece. The apparatus also includes a drive drum mounted within the frame for gripping and rotating the segments, and a control module for selectively activating the head, the ring, and the drive drum to form an elbow.

Owner:FORMTEK

Top & bottom mount, heavy load supporting, girder clamp system

InactiveUS20070090242A1Easy to disassembleHigh strengthSecuring devicesFurniture partsEngineeringHeavy load

A clamping system (10 / 110) for holding, supporting or lifting a heavy work piece (200; e.g. a pipe section of pipe line of hundreds of pounds) located below a girder (100) using rigging (210) attached to the clamp at attachment openings (27 / 37, 127 / 137) equally spaced from the center-line web (103) of the girder, which clamping system is attached to opposed, side edges of the top flange member (102) of the girder (vis-a-vis the bottom flange member 101), or in a second embodiment (FIGS. 9+) to either the top or the bottom. In the second embodiment a straight bar (150) with a series of spaced, locking cavities (151a / b) is used in place of the threaded rod, threaded engagement of the first embodiment, with the cavities working with spring-biased pin latches on the side gripping elements. When used on the bottom flange, a slidable, load supporting, centrally located accessory (160) is used.

Owner:GULLEY WILLIAM F

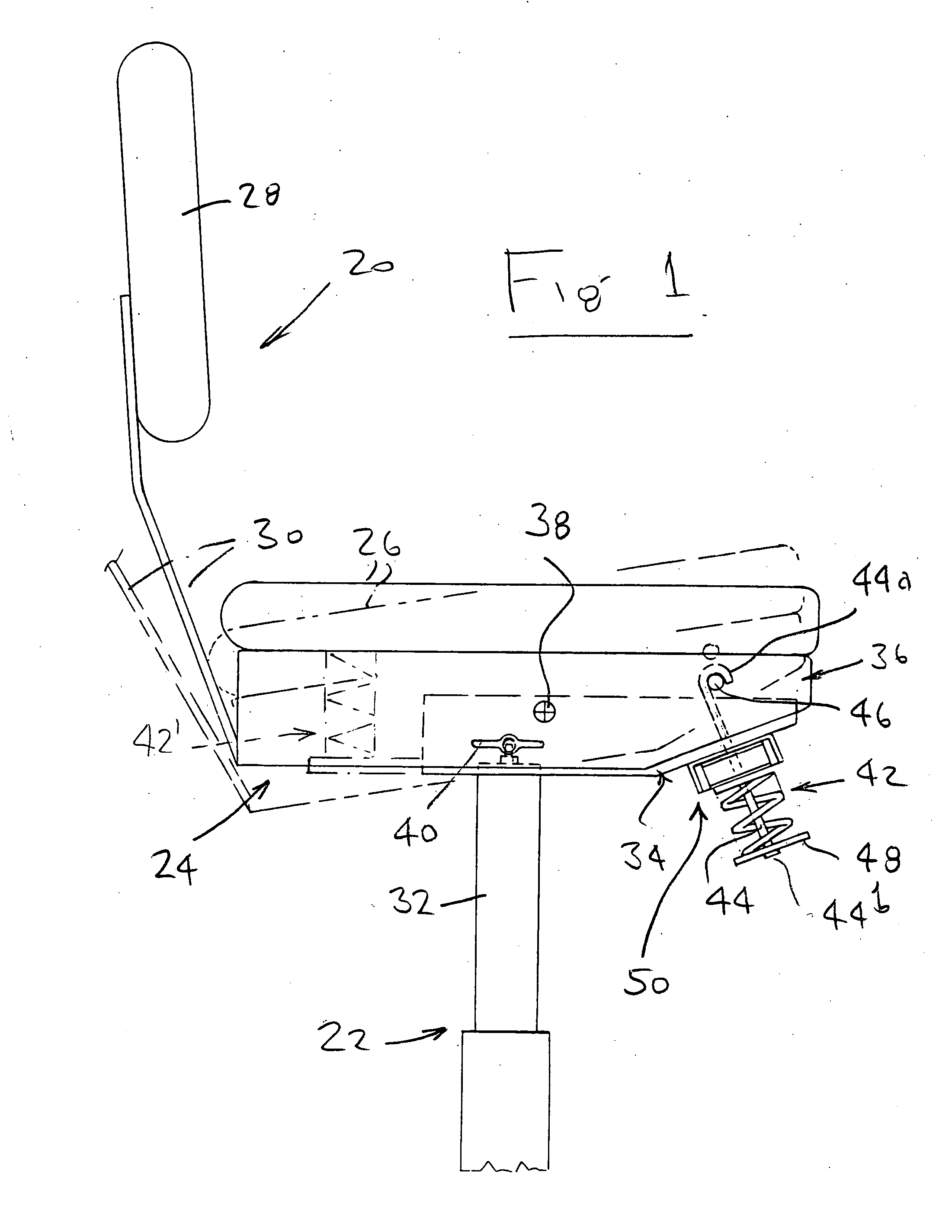

Chair spring tension control

InactiveUS20050104429A1Force balanceGuaranteed uptimeAdjustable chairsMovable seatsOffice chairEngineering

A tilt mechanism for an office chair includes a spring tension control that incorporates a wedge arrangement including a moveable wedge component that is displaceable laterally by turning a control knob below the seat of the chair, to force fixed wedge components apart and increase the spring tension. Turning the knob in the opposite direction reduces spring tension.

Owner:RAM MACHINE 1990

Apparatus for washing and dewatering pulp

InactiveUS8337669B2Less materialReduce weightWashing/displacing pulp-treating liquorsPulp de-wateringEngineeringMechanical engineering

Apparatus for washing and dewatering pulp comprising rotatable press rolls including permeable outer surfaces and a casing comprising a vat in which the rolls are installed are disclosed. A feed for feeding the pulp through the gap between the vat and the outer surfaces of the press rolls is provided and the vat includes a vat segment providing at least one compartment between the vat segment and the casing, the at least one compartment extending along the longitudinal extension of one of the first and second rotatable press rolls and a pressure device to maintain the pressure in the at least one compartment corresponding to the pressure in the gap.

Owner:VALMET TECH INC

Fluidics-balanced fluid bearing

Radial loads and vibrations and axial loads on a rotor are balanced by a fluid bearing controlled by a self-regulating system that supplies fluid flow or pressure to the gap between the rotor and stator in response to signals of imbalance generated in the machinery itself. The resulting balancing force is thus created by fluidics, and in certain embodiments the sensing circuit is fluidics-based as well. This system provides enhanced flexibility and response time relative to conventional fluid bearings.

Owner:AEROJET GENERAL CORP

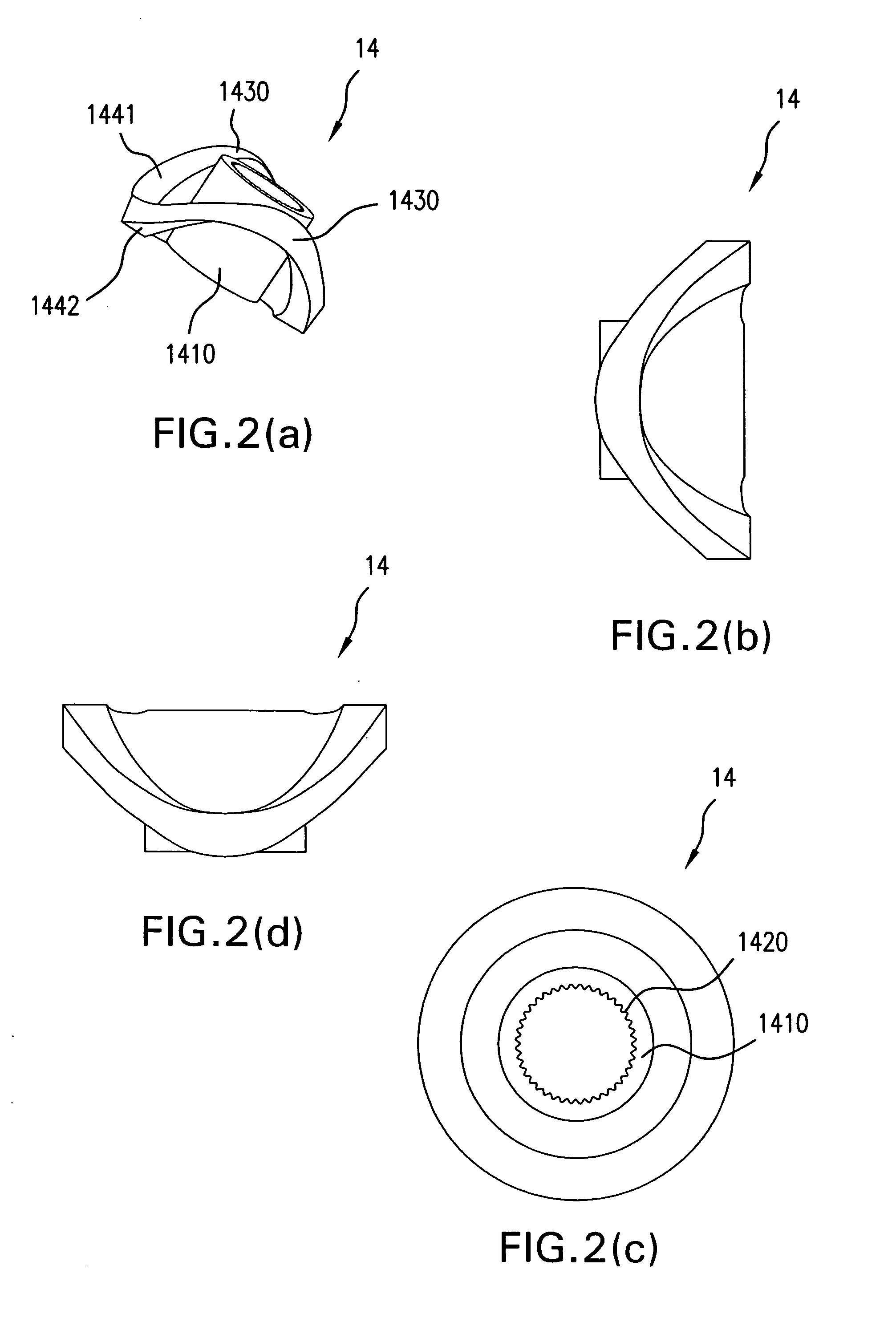

Hemi-condyle type artificial knee joint

ActiveUS20200383794A1Good effectImprove experienceJoint implantsKnee jointsFemoral boneFemoral prosthesis

A semi-condylar artificial knee joint includes a femoral prosthesis and a tibial prosthesis, and the cross-section of said tibial prosthesis is of a kidney-like type. The tibial prosthesis is disposed at one side of the tibial plateau intercondylar eminence and is located below the femoral prosthesis. The artificial knee joint further includes a locating pin for fixing the tibial prosthesis. The bottom surface of said tibial prosthesis is provided with a prosthetic notch, and below said tibial prosthesis is provided with a tibial notch. Said prosthetic notch corresponds to said tibial notch, and together forming a limiting hole for accommodating the locating pin. The cooperation between the locating pin and the limiting hole can ensure relative position stability and balance between the tibial prosthesis and the tibial plateau intercondylar eminence.

Owner:ZHU HONGWEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com