Balanced pressure-bearing battery pack, preparation method thereof and structural integrated battery box

A battery pack and equalization technology, which is applied to battery pack parts, structural parts, circuits, etc., can solve the undisclosed multi-battery integrated anti-pressure structure and other problems, so as to increase the pressure-bearing and anti-seismic capabilities and avoid battery cycles The effect of reduced lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

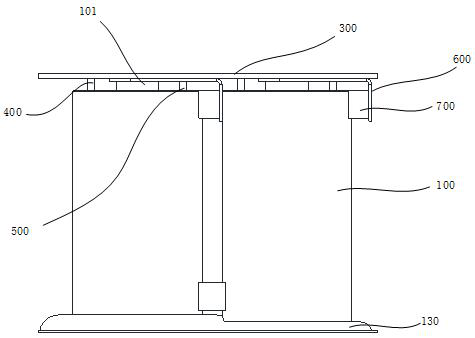

Embodiment 1

[0081] In the application of the power battery CTC group of the new energy vehicle or the energy storage system, the upper cover of the battery pack is used as the structure of the floor of the passenger compartment, and the Z-direction deformation will occur when the load is loaded. There is a tolerance in height. Therefore, when the top of the battery pack is deformed under pressure, the pressure of each single cell 100 will be unbalanced, resulting in different resistance values between different single cells 100, which will affect the battery cycle life and overall performance. The service life of the car will lead to high-voltage leakage or battery leakage, which will trigger thermal runaway and cause fire and explosion, posing a great safety hazard.

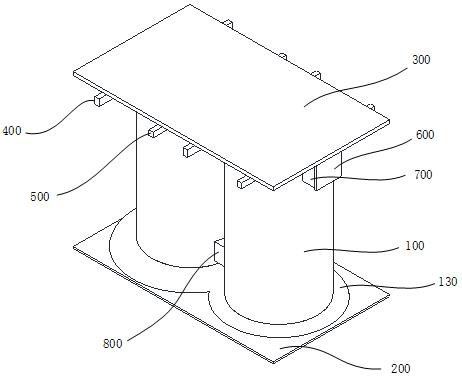

[0082] Based on the above reasons, this embodiment provides a balanced pressure battery pack, the specific structure of which makes it suitable for the application of power battery CTC groups of new energy vehicles or ener...

Embodiment 2

[0109] This embodiment provides a balanced pressure-bearing battery pack, including a support structure unit, a ring beam structure unit, a top plate structure unit, and an external pressure reinforcement unit. The difference from Embodiment 1 is that in this embodiment, in the first A structural adhesive is further provided between the support bar 400 and the top cover 102 .

[0110] Those skilled in the art should understand that the height tolerance between the single cells 100 is not only derived from the height tolerance between the side shells 103 of the single cells 100, but also exists between the pole bodies 101 of different single cells 100, Therefore, in this embodiment, the tolerance between the single cells 100 is adjusted by the structural adhesive provided between the bottom plate 200 and the case bottom 104 and the structural adhesive provided between the first support bar 400 and the top cover 102 .

[0111] Preferably, the thickness of the structural adhesive...

Embodiment 3

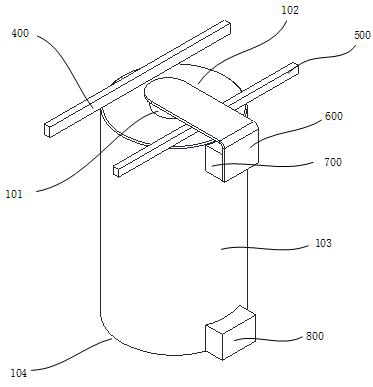

[0113] This embodiment provides a balanced pressure-bearing battery pack, including a support structure unit, a ring beam structure unit, a top plate structure unit, and an external pressure reinforcement unit. The difference from Embodiment 1 is that in this embodiment, the single battery 100 is a single square battery.

[0114] refer to Figure 8 , the pole body 101 is arranged on both sides of the top cover 102 of the single prismatic battery, the pole column body 101 is a polar pole of the single battery 100 respectively, and its side shell 103 is a third pole column body 101.

[0115] In this embodiment, the top plate structural unit includes an insulating flat plate layer 300 and a pad structure. Preferably, the pad structure includes a first support bar 400 and a sheet-like bus bar 600, and the first support bar 400 and the sheet-like bus bar 600 are respectively are arranged on both sides of the top cover 102 . Preferably, in this embodiment, the sheet-shaped bus ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com