Magnetic dry lean iron ore separating machine

A lean iron ore and dry separation machine technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of unclear separation of iron ore and wool, unsuitable separation of lean iron ore, and small magnetic field contact area And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

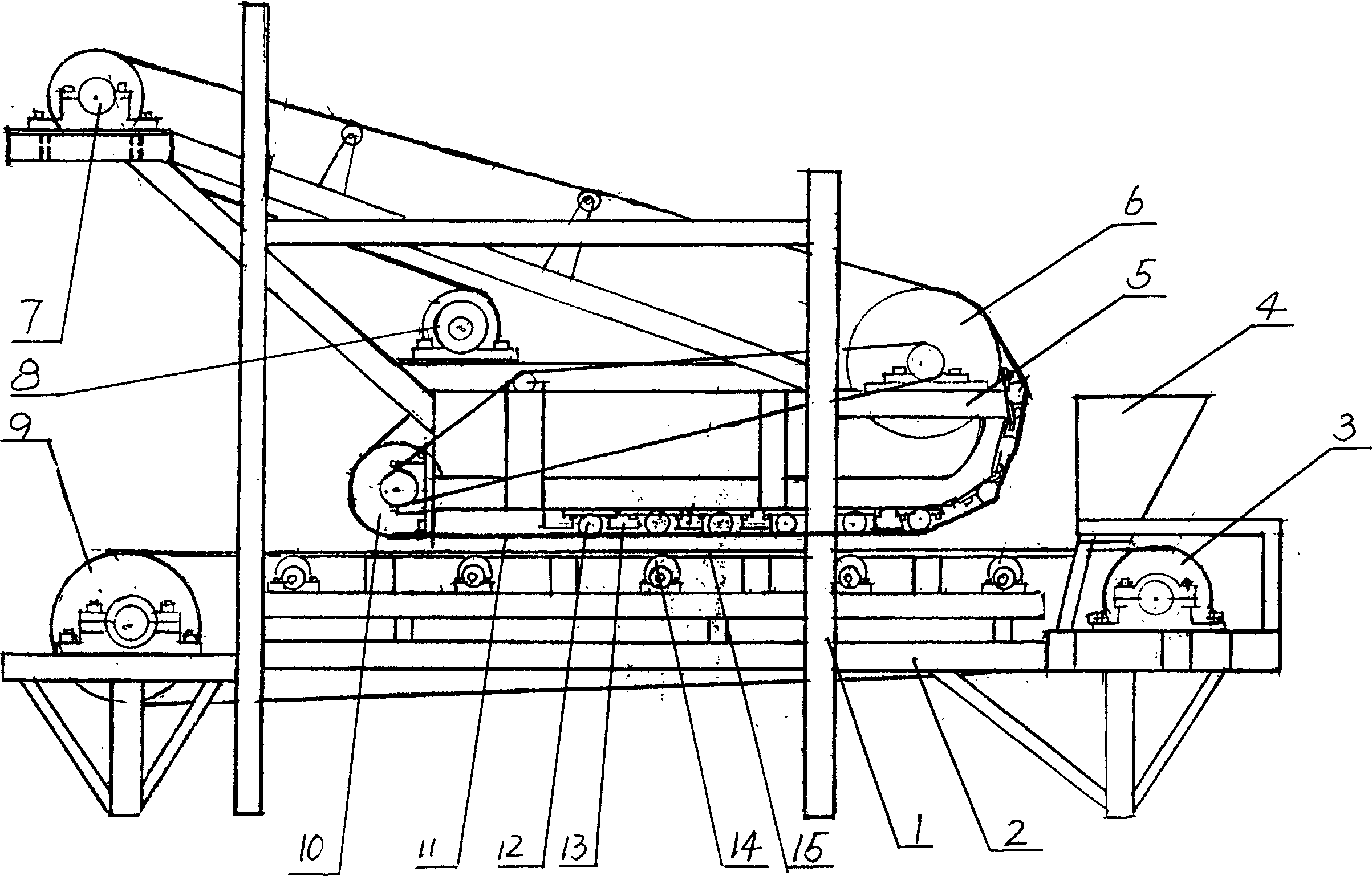

[0008] The lean iron ore magnetic dry separator provided in this embodiment is composed of channel steel frame 1, lower frame 2, driven wheel 3, feed hopper 4, upper frame 5, primary separation magnetic wheel 6, driven wheel 7, tensioner Wheel 8, secondary separation magnetic wheel 9, driving wheel 10, conveyor belt 11, guide roller 12, permanent magnet block 13, guide roller 14, conveyor belt 15, the frame of this machine is a double-layer structure, the upper frame 5 and the lower frame 2 are fixed as a whole through the channel steel frame 1, so that the structure of the whole machine is more compact and stable. The driven wheel 3 is connected between the two by a conveyor belt 15 supported by a guide roller 14, a feed hopper 4 is installed above the driven wheel 3, and a slit-shaped cloth opening corresponding to the conveyor belt 15 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com