Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve converter operating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Converting process for converter low-silicon molten iron

ActiveCN101117651AOxygen blowing time shortenedGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

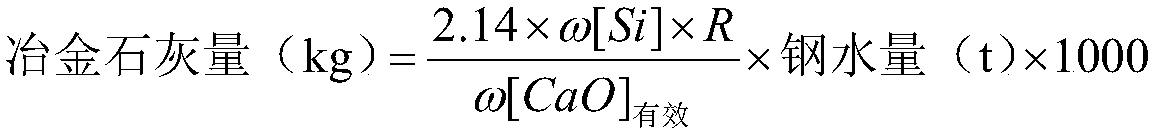

The present invention provides a siliconeisen iron melt blowing and refining method in a converter, and the method includes the steps as follows: (1) waste steel and iron melt are loaded into the converter, and oxygen blowing and steel making begin, the oxygen flux is 900Nm3 / min to 1050Nm3 / min, the height that the oxygen gun spraying head departs the metal liquid surface in the melt pond is 1.8-3.0m; (2) a first batch of slag charge is added after oxygen is blown in the first batch of the slag charge is 60-80 percent of the total slag charge, and the rest slag charge can be charged in 2-3 batches after the first batch of the slag charge is melted. The consumption of the slag charge: the lime 18-28kg / t steel, the light calcined dolomite 15-25kg / t steel, the ironstone 5-10kg / t steel, the carbonaceous heat generating agent 0-7kg / t steel, the compound slag 0-6kg / t steel; and the rest process are same as the prior art. The oxygen blowing duration of the present invention decreases 1.8min per furnace averagely, and the problem that the heat quantity is short and the slag forming is difficult can be solved simultaneously, and the present invention can make the converter steel-making to produce efficiently.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for rapidly maintaining converter lining

InactiveCN104673966AEasy to obtainEasy to burn throughManufacturing convertersProcess efficiency improvementBrickSlag

The invention discloses a method for rapidly maintaining a converter lining. The method comprises the following steps of: remaining slag after tapping of converter, pouring magnesia-carbon refractory brick blocks in the converter, shaking the converter till the magnesia-carbon refractory brick blocks and remained slag in the converter are flatly spread at a repaired part of the converter lining, and standing so that the mixture of the magnesia-carbon refractory brick blocks and the remained slag are stuck to the repaired part of the converter lining. According to the method disclosed by the invention, the converter repairing time is effectively shortened; the disadvantage that the time for pouring materials to repair the converter and sintering is long is changed; the operability of the converter is increased; high-temperature converter slag is easy to burn thoroughly; furthermore, a part of clearances can be filled by the molten part of converter repairing bricks; the erosion resistance and the scouring resistance are increased; the material collapse phenomenon due to non-thorough burning and half-baking of a part of positions in the event of traditionally repairing can be effectively avoided; the labour safety coefficient of workers is increased; a part of converter repairing materials and the labour cost are saved; the converter repairing cost is effectively reduced; compared with the original depletion speed, the depletion speed of the converter lining after the method is implemented is reduced; and therefore, the method has the characteristics of being rapid in maintenance speed, high in efficiency and safety and low in cost.

Owner:HEBEI IRON AND STEEL

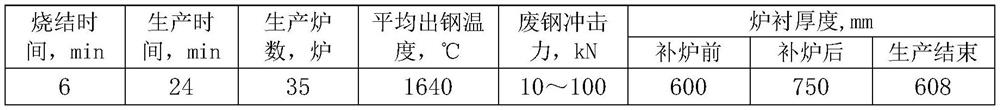

Fast maintenance method for furnace lining of deslagging surface of converter

InactiveCN108660282AImproves washout propertiesEasy dischargeManufacturing convertersProcess efficiency improvementSmelting processTemperature difference

The invention provides a fast maintenance method for a furnace lining of a deslagging surface of a converter. The fast maintenance method for the furnace lining of the deslagging surface of the converter is applied to the technical field of iron and steel smelting processes, and comprises the maintenance steps of deslagging the converter, and remaining high-temperature residual furnace slags in the converter; adding bar steel scraps having temperature difference with the residual furnace slags into the converter, precipitating and condensing high-melting-point mineral substances in the furnaceslags under the action of the temperature difference of the bar steel scraps and the residual furnace slags, and adhering to the deslagging surface of the converter so as to replace a fettling material; and statically cooling the converter, and after finishing cooling, accomplishing the fast maintenance operation for the furnace lining of the deslagging surface of the converter. According to thefast maintenance method for the furnace lining of the deslagging surface of the converter provided by the invention, no cost input of the fettling material is required, the problems of the adverse effect on fettling and the environment pollution due to too long or too short sintering time are avoided, the molten steel end point components are ensured, the fettling time is effectively shortened, the converter operability is improved, and meanwhile, the fast maintenance method for the furnace lining of the deslagging surface of the converter has the characteristics of fast maintenance speed, good fettling effect, low fettling cost, safety, environment protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

Maintenance method for converter lining

InactiveCN102851430AIncrease the content of MgOHigh viscosityLinings repairManufacturing convertersSlagRepair material

The invention involves a maintenance method for the converter lining. The method is characterized in that: during the process of converter turndown for sampling, standing for tapping or taping, spray repair operation and / or manual feed repair operation is performed to the part of the furnace lining not covered by steel slag, and modification to the slag is not required to be performed during the slag splashing furnace maintenance process performed after tapping is finished. Compared with the prior art, the method has the advantageous effects that: a part of spray repair material or feed repair material adheres on the furnace lining, increases the thickness of the slag splashing layer, and has effect on furnace lining protection, and the rest spray repair material or feed repair material enters into the slag, is molten under the high temperature action of the slag; and since the spray repair material or feed repair material has higher MgO content, the slag viscosity can be remarkably increased, so that slag modification is not required to be performed during the slag splashing furnace maintenance process after the following tapping is finished, and under the condition that slag splashing furnace maintenance time is remarkably shortened, the slag splashing effect is still superior to that the modified slag not adopting the process, in addition, adoption of the process has no need of shutdown of the furnace, so that the converter operating rate can be remarkably improved.

Owner:ANGANG STEEL CO LTD

Low-cost and high-efficiency converter fettling process

InactiveCN106995866AShort sintering timeImprove converter operating rateManufacturing convertersSmall amplitudeBrick

The invention relates to a low-cost and high-efficiency converter fettling process, and belongs to a smelting production technology of a converter. The method comprises the following steps: adding a magnesian slagging material when a converter starts for blowing by 2 minutes according to the adding amount of 30 kg / t, and stopping adding iron-containing slag materials 3 minutes before a final blowing point; and wagging the converter till the inclination angle is 60 to 70 degrees according to a slag supplementing large-area part, adding prepared fettling bricks into the converter according to a proportion of 200 to 300 pieces of fettling bricks in 80 tonnage of the converter, rotating the converter along small amplitude when the fettling bricks are added, backwards slowly wagging the converter to enable the fettling bricks to be fully mixed with furnace slag after a waste steel pipe is extracted out of the converter, then wagging the converter till the inclination angle is 85 to 95 degrees, standing for 35 to 45 minutes to enable the viscosity of the furnace slag to be increased, wrapping the fettling bricks, and attaching the fettling bricks to a furnace lining. According to the low-cost and high-efficiency converter fettling process, the after-fettling sintering time is shortened by 20 minutes, and the converter working efficiency is improved; the fettling bricks can prolong the use time by 8 hours, and no phenomenon of falling of the fettling bricks is caused; the use amounts of the fettling bricks, large-area fabrics and gunning mixes is reduced; and safety accidents caused by falling of the fettling bricks are reduced.

Owner:TANGSHAN GUOFENG IRON & STEEL

Method for repairing converter through waste magnesia carbon bricks

ActiveCN109593909AImprove liquidityEffective bondingManufacturing convertersProcess efficiency improvementBrickSlag

The invention relates to a method for repairing a converter through waste magnesia carbon bricks. The method comprises the following steps that the to-be-repaired converter is tapped; terminal slag after tapping is directly poured without slag splashing until to-be-used brick fillers are covered with the terminal slag; a pre-calculated amount of brick fillers are added into the to-be-repaired converter, and forms a molten material together with the terminal slag; according to the converter repairing position, the converter is shaken, and thus the molten material can cover the to-be-repaired position; the to-be-repaired converter is sintered for 30 minutes or longer until the terminal slag is solidified; and iron is fed, and next batch of smelting is conducted. According to the method for repairing the converter, the problems of long sintering time, poor converter repairing effect, high converter repairing cost, serious environmental pollution and the like can be effectively solved, byreasonably controlling converter terminal slag, the effect that a mixture of the converter terminal slag remaining in the converter and the waste magnesia carbon bricks is effectively bonded to the repairing position of a converter lining is achieved, and finally the broken converter is repaired.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method of converter smelted low-sulphur steel

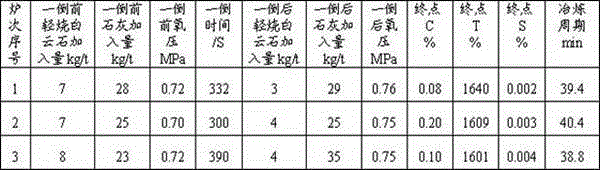

InactiveCN106566908AReduce sulfur contentAverage smelting cycle shortenedManufacturing convertersSulfurSlag

The invention relates to a production method of converter smelted low-sulphur steel. The production method comprises following steps: 1, molten iron KR stirring desulfurized lime powder, fluorite, and aluminium slag are mixed at a ratio of 10:1:1, wherein ladle slagging-off rate is controlled to be 90% or higher, and the S content of molten iron put into a furnace is controlled to be 0.003% or lower; 2, reactor washing after smelting of a former batch of non low sulphur steel and before smelting of a first batch of low-sulphur steel is carried out; 3, remaining slag and double slag operation is adopted in smelting of low-sulphur steel. According to the production method, reactor washing, remaining slag, and double slag treatment are combined for smelting in a converter, and reactor washing after smelting of a former batch of non low sulphur steel and before smelting of a first batch of low-sulphur steel is carried out, so that the sulphur introduced by remaining slag operation of the first batch of low-sulphur steel smelting is reduced, combination of remaining slag and double slag is beneficial for stable control of end point low sulphur content, converter end point sulphur content is controlled to be 0.005% or lower stably, the lowest sulphur content is 0.001%, technical guarantee is provided for development of low-sulphur novel steel; and at the same time, converter average smelting period is shortened by 4min or longer, converter operation efficiency is increased, and production capacity is increased.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Method for repairing converter lining

The invention relates to the field of ferrous metallurgy, in particular to a method for repairing a converter lining. The method is characterized by comprising the steps of reserving a defined amount of furnace slags according to the mass ratio between the furnace slags and magnesia carbon bricks to be added after tapping of a converter is finished, then conducting hardening and tempering on the furnace slags by adding MgO particles and dolomite, jetting and shaking up the furnace slags through nitrogen, and then adding the magnesia carbon bricks for sintering. By means of the method, the lining repairing effect is improved remarkably, the time for repairing a furnace is shortened, and the converter operation rate is improved; the labor intensity of workers is reduced remarkably, and the implementation safety is high.

Owner:NORTHEASTERN UNIV

Furnace protection process combining high flow bottom blowing slag splashing with top blowing slag splashing

The invention discloses a furnace protection process combining high flow bottom blowing slag splashing with top blowing slag splashing, and belongs to the technical field of metallurgy. The process includes a converter cap and a trunnion for slagging operation and bottom blowing slag splashing maintenance and a converter bottom and a batch for top gun slag splashing as the main maintenance. On onehand, the high flow bottom blowing slag splashing process is adopted to make up for the blank of the current high flow bottom blowing slag splashing process; on the other hand, the high flow bottom blowing slag splashing is combined with the top blowing slag splashing process. The high flow bottom blowing slag splashing solves the problem of difficult maintenance of the converter cap portion of the top gun slag splashing furnace protection process by compensation, and the top gun slag splashing process solves the problem of difficult maintenance of the bottom of the high flow bottom blowing slag splashing furnace protection process, the two processes are complementary, the furnace protection quality is improved, and conditions are created for achieving long furnace life of a converter. The process improves the slag splashing furnace protection effect of the converter, reduces the static maintenance frequency of the converter cap portion, shortens the slag splashing furnace protectiontime, improves the converter operation rate, achieves the long furnace life of the converter, prevents the converter bottom from rising, and prevents a bottom blowing spray gun from being blocked.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

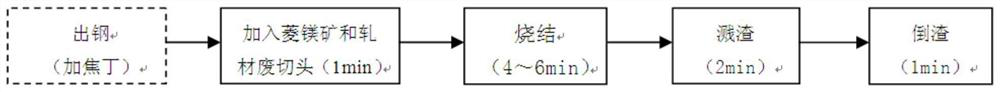

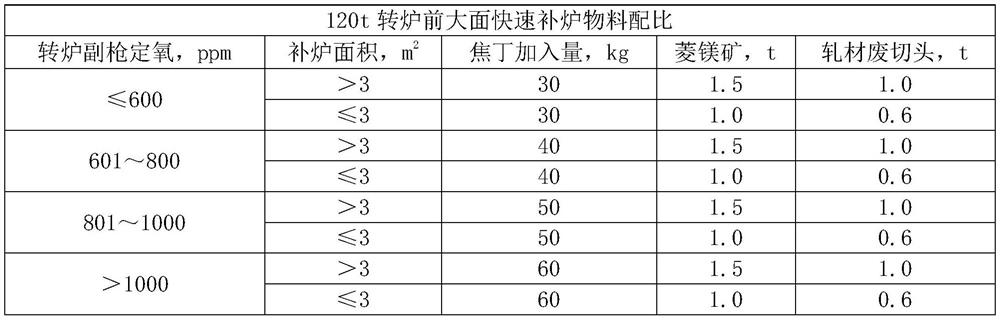

Rapid converter protection method for front large surface of converter

The invention belongs to the field of metallurgy, and particularly relates to a rapid converter protection method for a front large surface of a converter. The method comprises the steps that nut coke is added to deoxidize and adjust final slag according to a converter end point oxygen determination and oxygen activity value at the tapping time, the oxidability of the slag is reduced, the final slag FeO is adjusted to 7-10%, then raw magnesite and waste bar cutting heads are poured into the converter from the front of the converter by using a waste steel hopper, the raw magnesite is rapidly decomposed into a high-melting-point substance MgO in a high-temperature environment in the converter, and a large amount of heat is absorbed, so that high-melting-point substances such as MgO, C2S and C3S in the slag are rapidly separated out and condensed and are adhered to the waste cutting heads of the bars, and a structure similar to reinforced concrete is formed and is firmly combined on the converter lining. The method is easy to implement, low in cost, short in sintering time, long in converter protection period, beneficial for improving the converter operation rate and capable of helping enterprises to increase the yield and the benefits.

Owner:ZENITH STEEL GROUP CORP +1

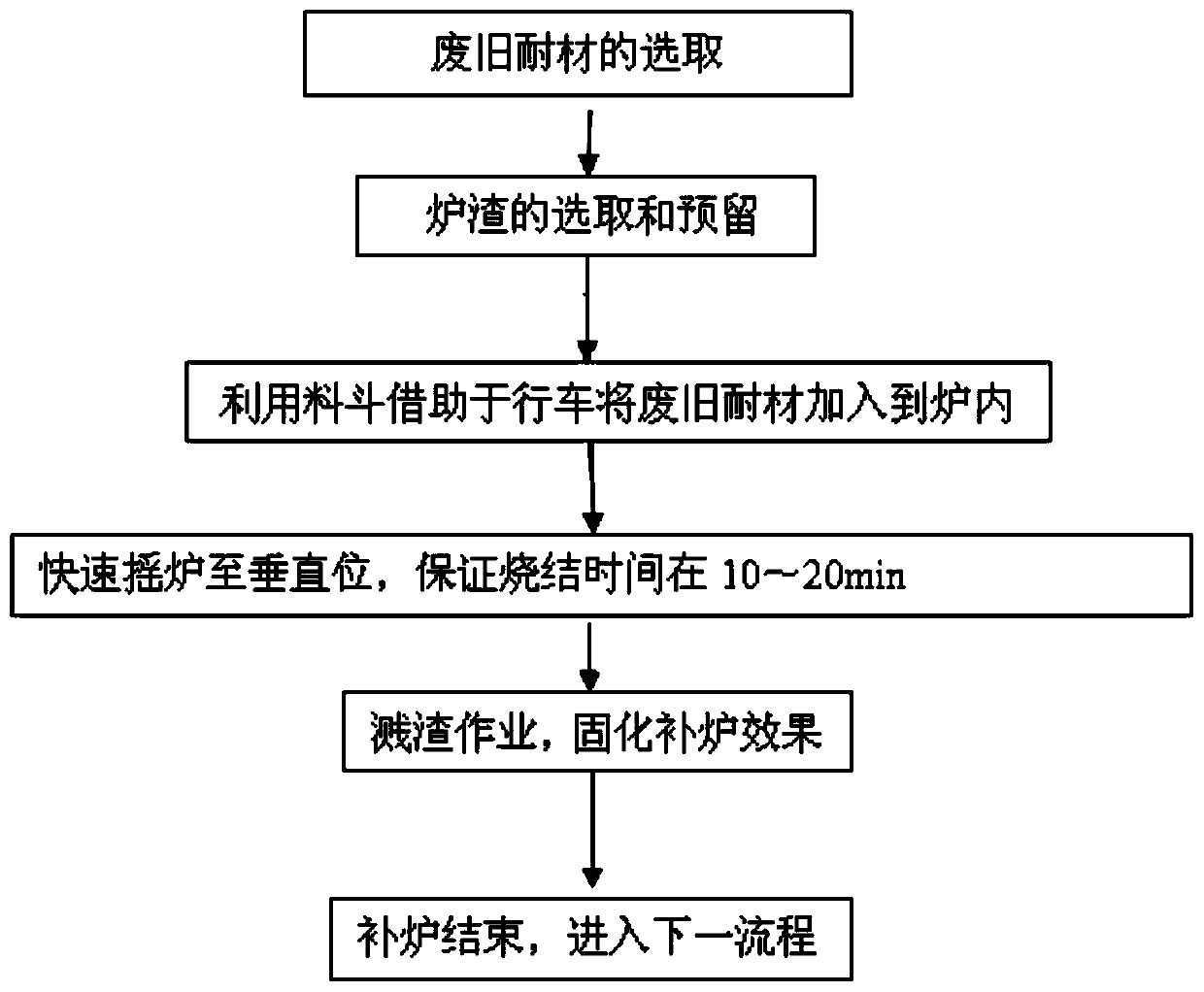

Shaping refractory material converter protection method for converter

InactiveCN110042196AExtended service lifeImprove corrosion resistanceManufacturing convertersBrickErosion rate

The invention discloses a shaping refractory material converter protection method for a converter. The method specifically comprises the following steps of: (1), selecting waste shaping refractory materials; (2), selecting slag and determining the allowance of the slag; and (3), fettling by using the shaping refractory materials. The converter protection method is simple and easy to implement; after the tapping of the converter is finished, how much of the slag to be reserved in the converter is determined according to the size of the slag and the required amount of the shaping refractory materials, the slag is quickly cooled and bonded together after a waste magnesia carbon brick or magnesite is added in, and the slag is integrated with converter lining by utilizing the temperature difference of the slag and the interface of the converter lining and through mutual diffusion among minerals, so that the fettling effect is achieved, the erosion rate of a working layer of the converter lining is slowed down, smoothness of a bottom blowing pipeline is protected, and long-acting visual operation of bottom blowing is achieved

Owner:NANJING IRON & STEEL CO LTD

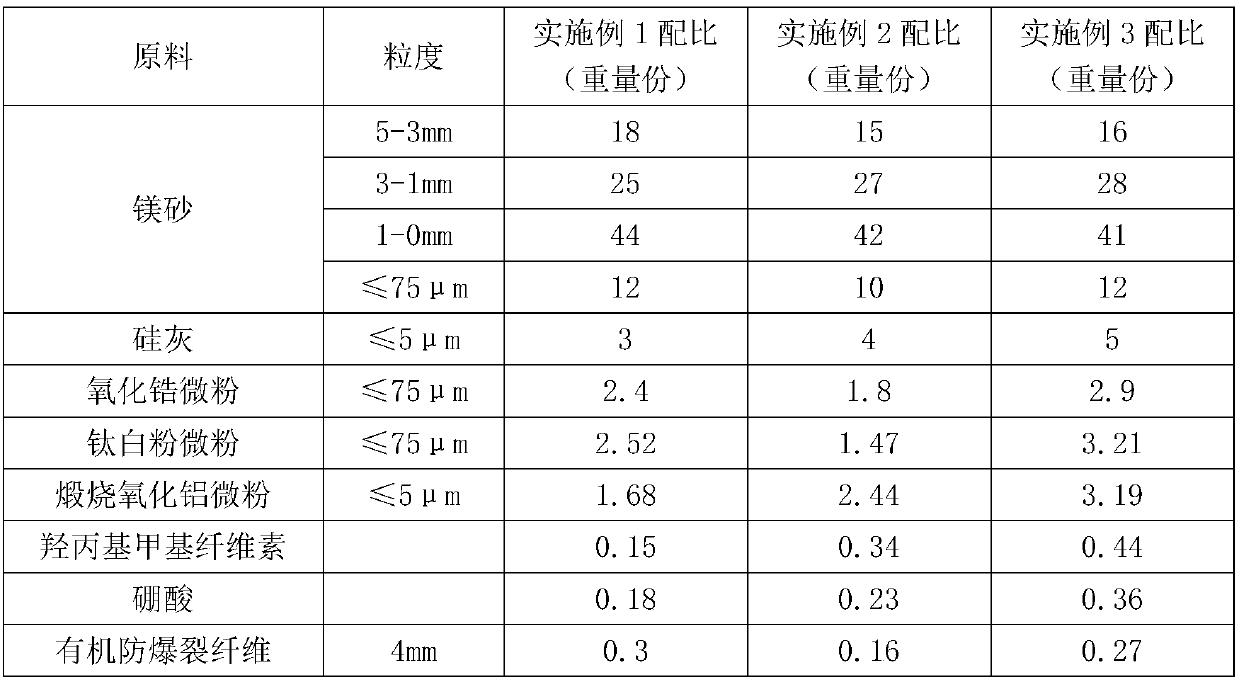

Magnesia material for repairing converter lining, and preparation method and using method thereof

InactiveCN109678470AImprove high temperature performanceNo pollution in the processManufacturing convertersFiberPollution

The invention relates to a magnesia material for repairing a converter lining, and a preparation method and a using method thereof. According to the magnesia material, magnesia is taken as a main rawmaterial, silica fume is taken as a binding agent, at least one magnesium oxide micro powder, calcined alumina micro powder, silicon carbide micro powder, zirconium oxide micro powder and titanium dioxide micro powder is taken as an additive, at least one of hydroxypropyl methyl cellulose and carboxymethylcellulose is taken as a bleeding prevention agent, at least one of boric acid, citric acid, tartaric acid and oxalic acid is taken as a retarder, at least one of metal aluminum powder and organic anti-explosion fiber is taken as an anti-burst agent, water is taken as a medium, and the magnesia material is prepared after uniform mixing. The magnesia material is an environmentally-friendly magnesia material which is rapid in sintering and long in service life, and has the advantages of environmental protection, no pollution, high mobility, short sintering time and the like.

Owner:辽宁利尔镁质合成材料股份有限公司 +1

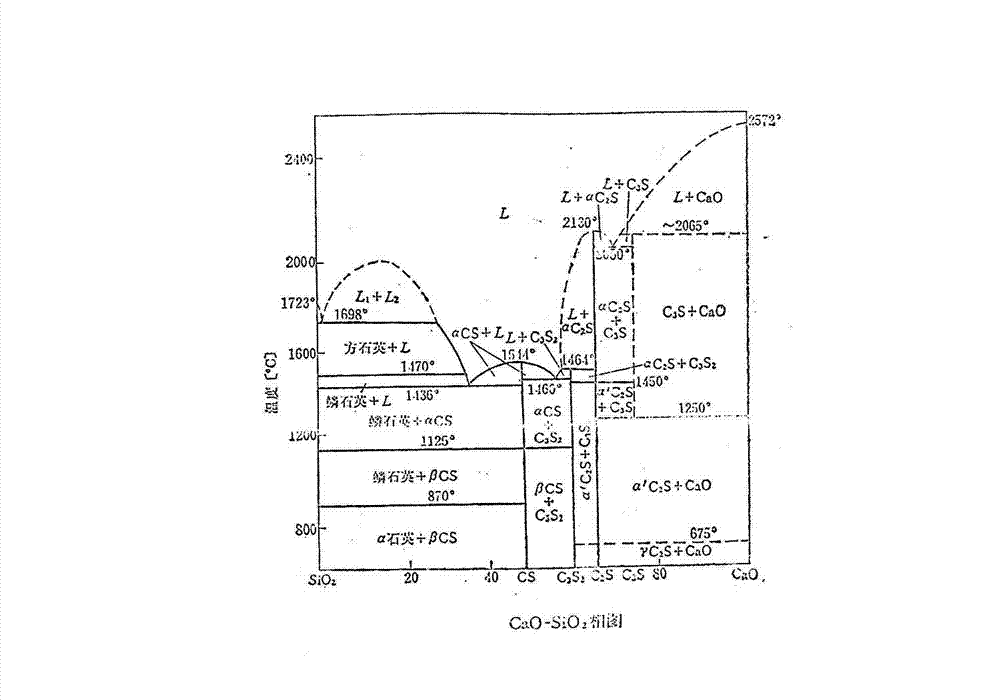

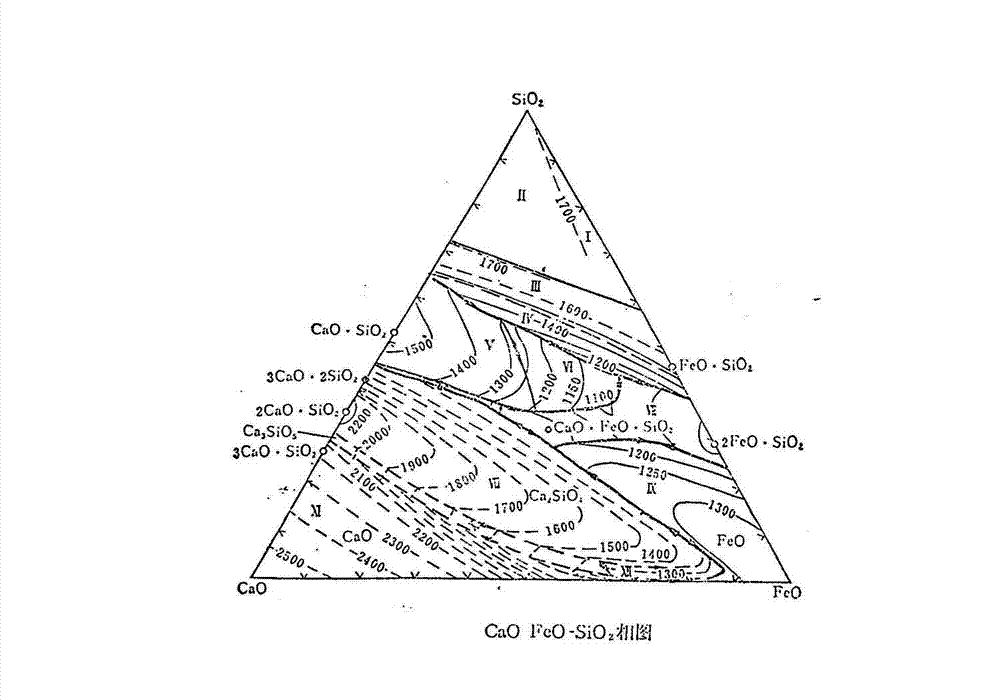

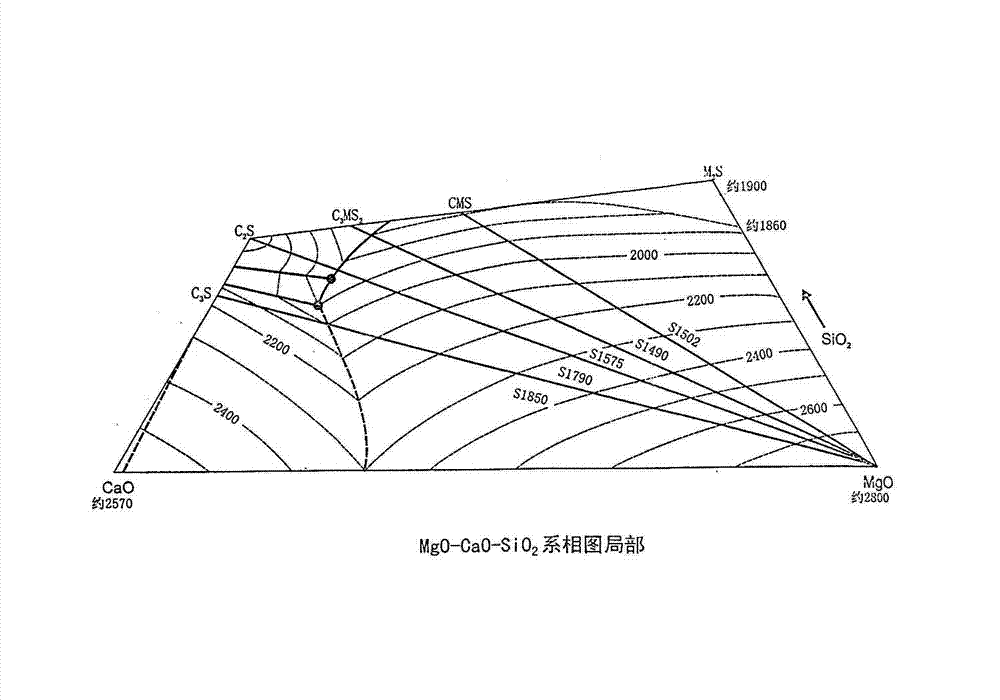

Converter slag mending material

The invention discloses a converter slag mending material which is mainly characterized in that: in the converter smelting process, the sigma FeO in the converter slag is controlled to 8%-12%; a reductant active metal or alloy thereof is added in the slag after tapping, so that all of FeO in the slag is reduced, and a slag system material is turned into a CaO-SiO2 binary system or CaO-MgO-SiO2 ternary system refractory material; and the refractory material is adhered on a furnace wall through rocking a furnace or N2 splashing, thereby achieving the fettling purpose. Because the technical scheme is adopted in the invention, compared with the prior art, the converter slag mending material has the advantages that operation is simple, practicable and rapid and the effect is good.

Owner:河南新锦新材料有限公司

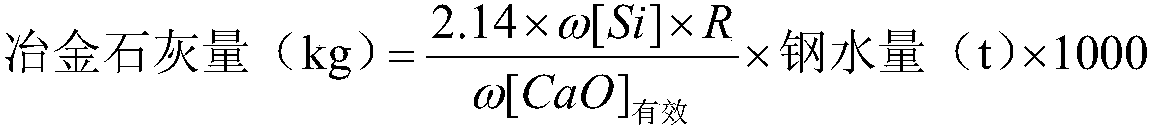

Method for repairing steel tapping face furnace lining through final slag of rotating furnace

InactiveCN109182643AReduce the frequency of refurbishmentImprove converter operating rateManufacturing convertersSlagDolomite

The invention discloses a method for repairing a steel tapping face furnace lining through final slag of a rotating furnace. According to the method, in the furnace repairing process, at first, when smelting and slagging are carried out, metallurgy lime and light burnt dolomite are added to molten steel according to the weight proportion of 3:2; when slag is poured, the left slag amount is controlled to account for 7%-8% of the total charge weight of the rotating furnace; after the molten steel is discharged completely, the residual slag is treated for 1-2 min, the temperature of the furnace slag is reduced properly, viscosity of the furnace slag is increased, then the rotating furnace inclines, the final slag of the rotating furnace is flatly laid to cover the corrosion portion of the steel tapping face furnace lining, power of the rotating furnace is off, and the final slag is cooled statically for over 8 h. According to the method, the corrosion portion of the steel tapping face furnace lining is directly repaired through the slag of the rotating furnace, the high-temperature furnace slag has good mobility and can be laid on the corrosion portion of the furnace lining flatly, high-melting-point substances such as 2CaO, SiO2, MgO, 3CaO and SiO2 in the furnace slag are mutually dispersed, mineral of the same kind is recrystallized, the high-temperature furnace slag is cooled and solidified on the corrosion portion of the furnace lining, the effect of maintaining the furnace lining is achieved, the cost investment of repairing mass is not needed, the frequency of furnace repairing is effectively reduced, the operation rate of the rotating furnace is increased, the furnace repairing effect is good, the furnace repairing cost is low, and use is safe and environmentally friendly.

Owner:MAANSHAN IRON & STEEL CO LTD

Slag stopping material, slag stopping method and combined technology method of slag stopping and slag splashing protection

InactiveCN102943143ASolve the problem of slaggingReduce thicknessManufacturing convertersMaterial consumptionSlag

The invention relates to a slag stopping material, a slag stopping method and a combined technology method of slag stopping and slag splashing protection. The sum of mass percentages of CaO, MgO and C in the slag stopping material accounts for over 40% of the total mass of the slag stopping material, igloss is smaller than 47% of the total mass of the slag stopping material, and the mass percent of C is not more than 25% of the total mass of the slag stopping material. The slag stopping method comprises the step of putting a certain amount of slag stopping material on the liquid level area over a steel tapping hole in a converter. The slag stopping material, the slag stopping method and the combined technology method of slag stopping and slag splashing protection have the following beneficial effects: roughing slag amount is reduced, the thickness of the slag blanket in a ladle is thinned obviously, the tasks of deoxidation of molten steel in the ladle and modification of top slag are relieved, the consumption of deoxidizer is lessened, the phenomena of rephosphorization and silicon pick up in the refining process of the molten steel are reduced, the consumption of slag regulating materials is lowered, the time of molten steel refining is shortened and the smelting cost is decreased; and after steel tapping is finished, the slag stopping material can be directly used as a slag splashing protection material, the use amount of the slag splashing protection material is reduced, the time of slag splashing protection is shortened and the working efficiency of the converter is enhanced.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

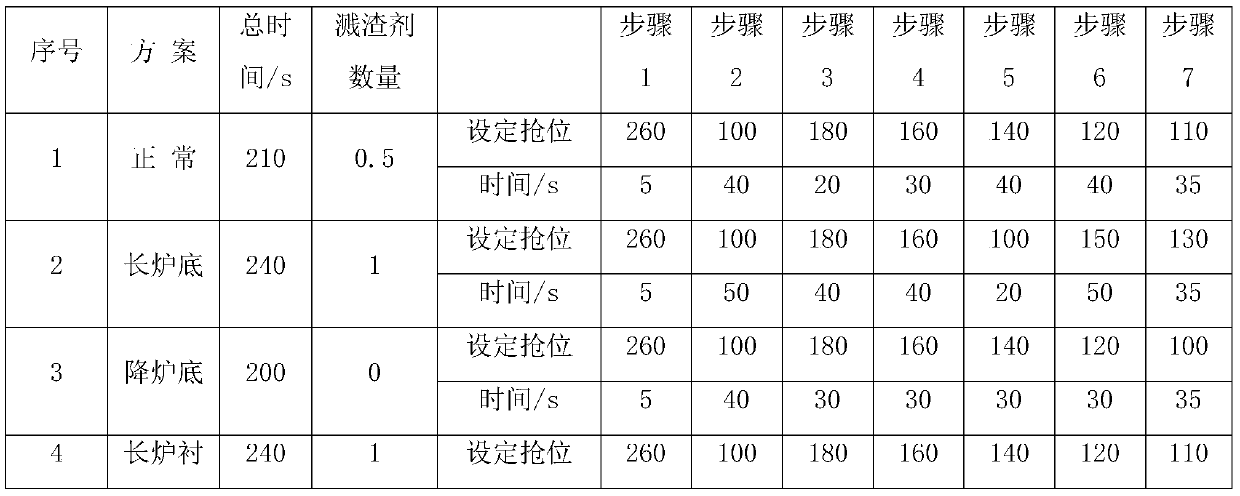

Slag splashing method for converter

InactiveCN111321269AReduce workloadReduce slag splash timeSteel manufacturing process aspectsIncreasing energy efficiencyThermodynamicsControl system

The invention relates to a slag splashing method for a converter. The slag splashing method for the converter comprises the steps that step (1). a primary control system is used for preseting slag splashing models corresponding to different slag states, wherein each slag splashing model comprises the total slag splashing time, the amount of a slag splashing agent, and the setting of the oxygen lance position and the oxygen lance time; and step (2). a secondary control system is used for judging the slag state according to the converter age, the TSO test temperature of a sublance, the oxygen value, the point blowing condition of the converter, the BL value and the drawing-up carbon-oxygen equilibrium at the time of each tapping from the converter, and the primary control system is used forselecting the corresponding slag splashing model according to the slag state. The slag splashing method for the converter reduces the workload of operators, shortens the slag splashing time, increasesthe operation rate of the converter, improves the effect of protecting the converter by slag splashing, ensures the safe, stabile and long-period direct motion of the whole furnace campaign, stabilizes the bottom blowing effect of the converter under the premise of guaranteeing a furnace lining, and reduces the nitrogen consumption.

Owner:ANGANG STEEL CO LTD

Control method for preventing earlier-stage explosion venting of converter dry dedusting

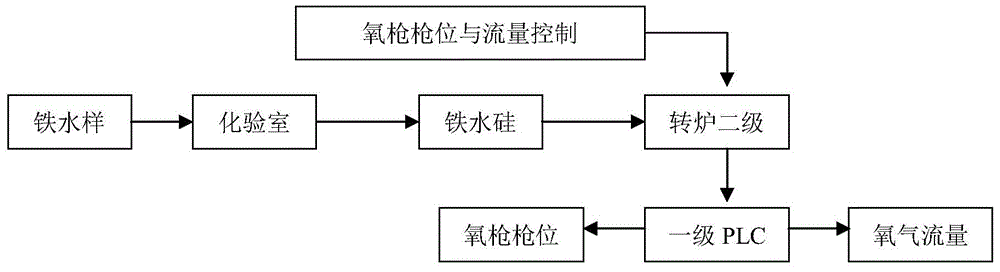

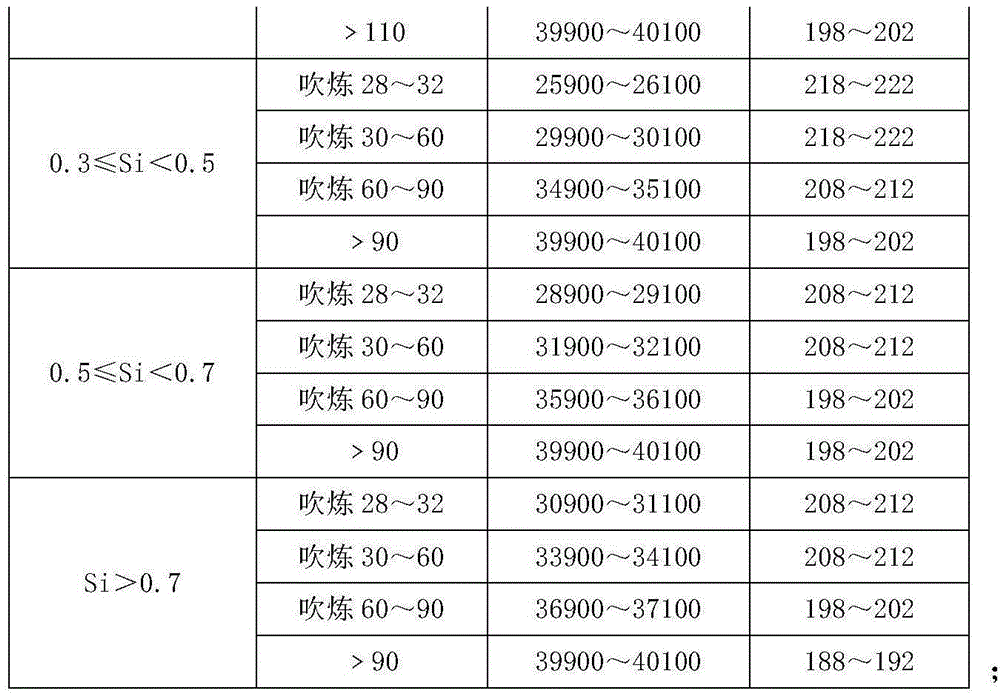

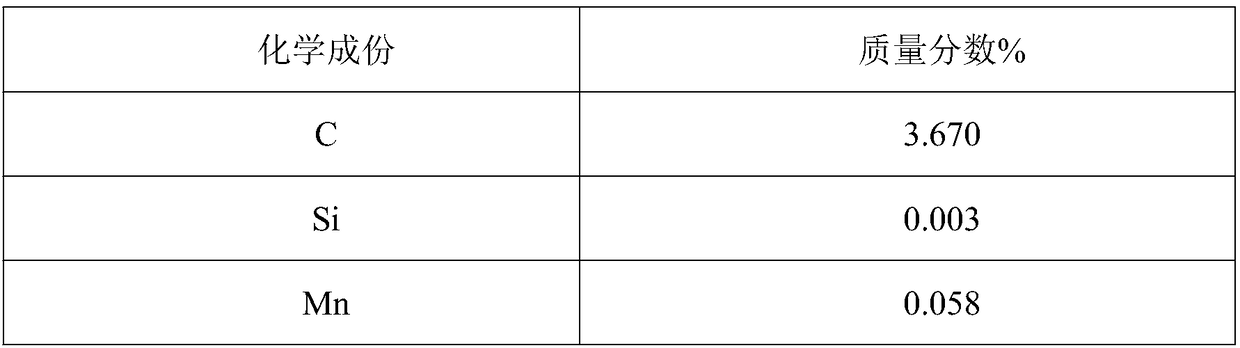

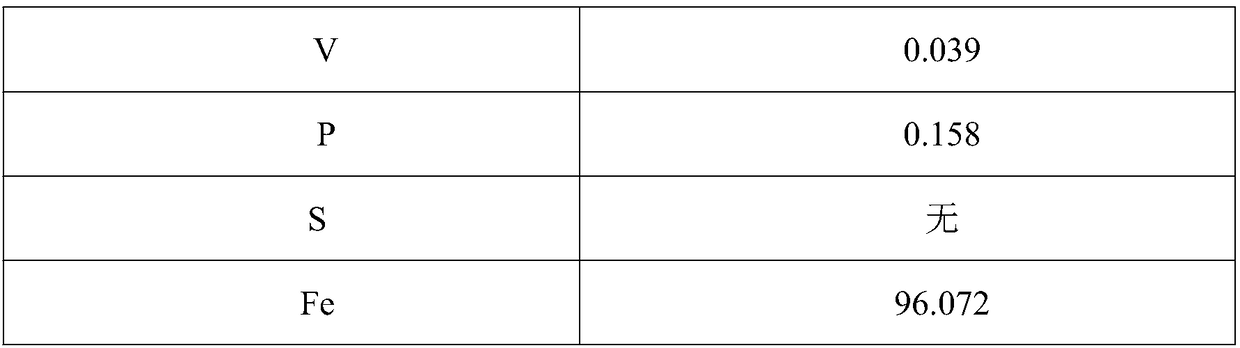

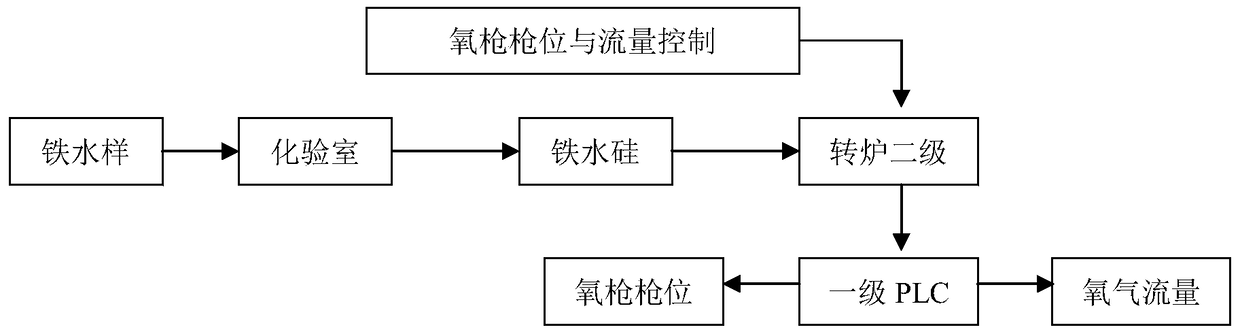

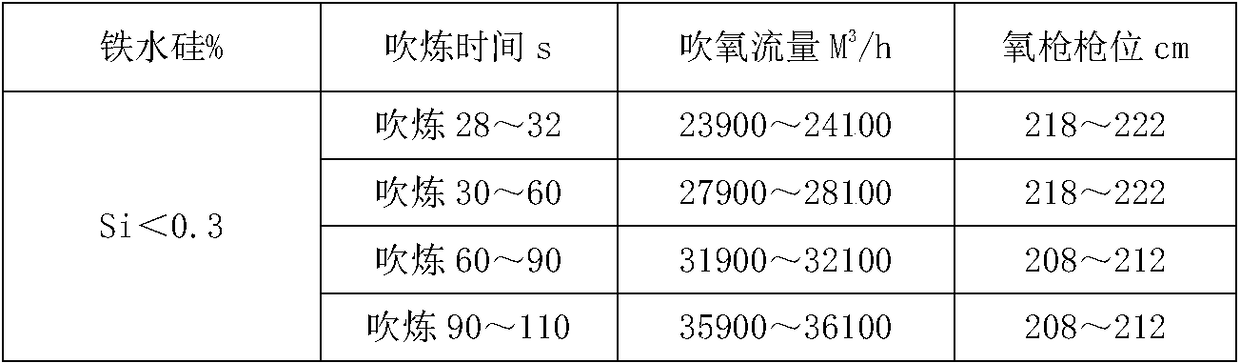

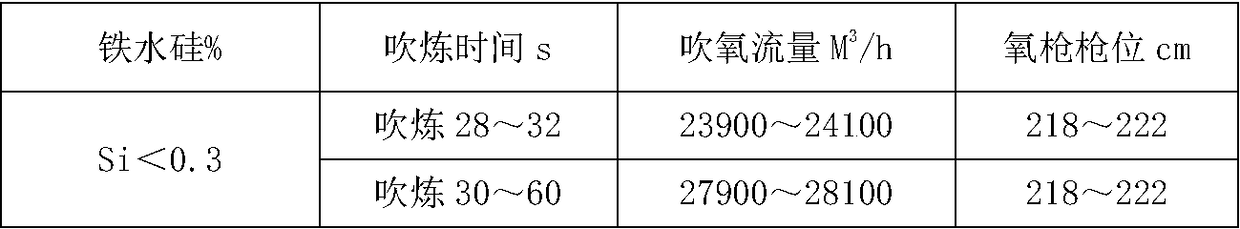

ActiveCN106544465AStable Smelting ControlImprove converter operating rateManufacturing convertersTime scheduleEngineering

The invention relates to a control method for preventing earlier-stage explosion venting of converter dry dedusting, and the earlier-stage control of converting is reinforced. The control method for preventing earlier-stage explosion venting of converter dry dedusting comprises the following steps that (1) a molten iron sample is obtained in a desulphurization station and sent to a test cabinet for a chemical examination as soon as possible, and chemical examination components of the molten iron sample in the test cabinet are sent to a converter second stage; (2) the lance position of an oxygen lance and the blowing oxygen flow are confirmed according to the content of molten iron silicon before converting of the converter second stage is started, and a control corresponding table of the lance position of the oxygen lance and the flow is sent to a converter first stage PLC; and (3) after converting is started, the converter first stage PLC controls the blowing oxygen flow and the oxygen lance lance position according to the converting time schedule. The control method for preventing earlier-stage explosion venting of converter dry dedusting has the advantages that the reasonable converting flow and lance position are confirmed according to a different molten iron silicon quantity, the silicon manganese oxidizing period of converting is stably spent, the phenomenon that the reaction in a furnace is too intense is avoided, and the CO generating speed is slowly increased, so that the explosion venting limitation of CO and O2 in smoke gas is missed. According to the control method for preventing earlier-stage explosion venting of converter dry dedusting, the oxygen flow and lance position in the earlier stage of converting are reasonably controlled, and zero explosion venting of earlier-stage converting dry dedusting is achieved.

Owner:ANGANG STEEL CO LTD

Technology for processing vanadium extraction semi-steel

InactiveCN109136445AGood slag effectSignificant comprehensive benefitsManufacturing convertersCoolantSemi-steel

The invention discloses a technology for processing vanadium extraction semi-steel. The technology includes technological processes of (1), feeding pig iron; (2), carrying out iron charging; (3), carrying out blowing; (4), adding coolants; (5), terminating blowing. Molten pig iron added during production according to the technology comprises chemical components including, by weight, 4%-5% of C, 0.08%-0.3% of Si, 0.2%-0.5% of Mn, 0.25%-0.3% of V, less then or equal to 0.25% of P, less than or equal to 0.07% of S and 93.58%-95.47% of Fe. The technology has the advantages that the original double-slag vanadium extraction smelting is replaced with semi-steel vanadium extraction, the yield of double-slag vanadium slag is approximately 30 Kg / t steel, the comprehensive grade is higher than 13%, and good benefits can be created for companies; slag splashing effects of semi-steel smelting converters can be obviously improved after semi-steel vanadium extraction is adopted, the fettling frequencies can be lowered, the operation rate of the converters can be increased, accordingly, the production efficiency can be improved, and the enterprise benefits can be increased.

Owner:YUNNAN DESHENG STEEL CO LTD

Method for producing converter coolant by Bayer red mud

ActiveCN103352099BImprove cooling efficiencyIncrease total iron contentManufacturing convertersSteelmakingRed mud

The invention discloses a method for producing converter coolant by Bayer red mud, and relates to the field of converter steelmaking. The method comprises steps of preparing Bayer red mud by using 30-40% of Fe2O3, 25-30% of SiO, 10-20% of Al2O3, 1-7% of CaO, 5-10% of Na2O and 2-5% of TiO in percentage by weight; carrying out wet magnetic separation on the Bayer red mud, to obtain 45-75% of Fe2O3, 5-15% of SiO2, 6-16% of Al2O3, 0.2-5% of CaO, 3-10% of Na2O and 1-3% of TiO2; filter-pressing the red mud after the magnetic separation to obtain 5-8% of water, adding 4-6% of water glass and 0.5-1% of sodium fluosilicate, mixing and shaping in a ball press machine, and drying until water content is 2-4%, thus obtaining the converter coolant. The converter coolant prepared by the method is high in cooling efficiency, free from smelting time occupation, convenient to regulate temperature, low in production cost, uniform in granularity, good in ball press effect, high in strength and small in dust; the converter coolant protects environment and saves resource.

Owner:武汉振海科技有限公司

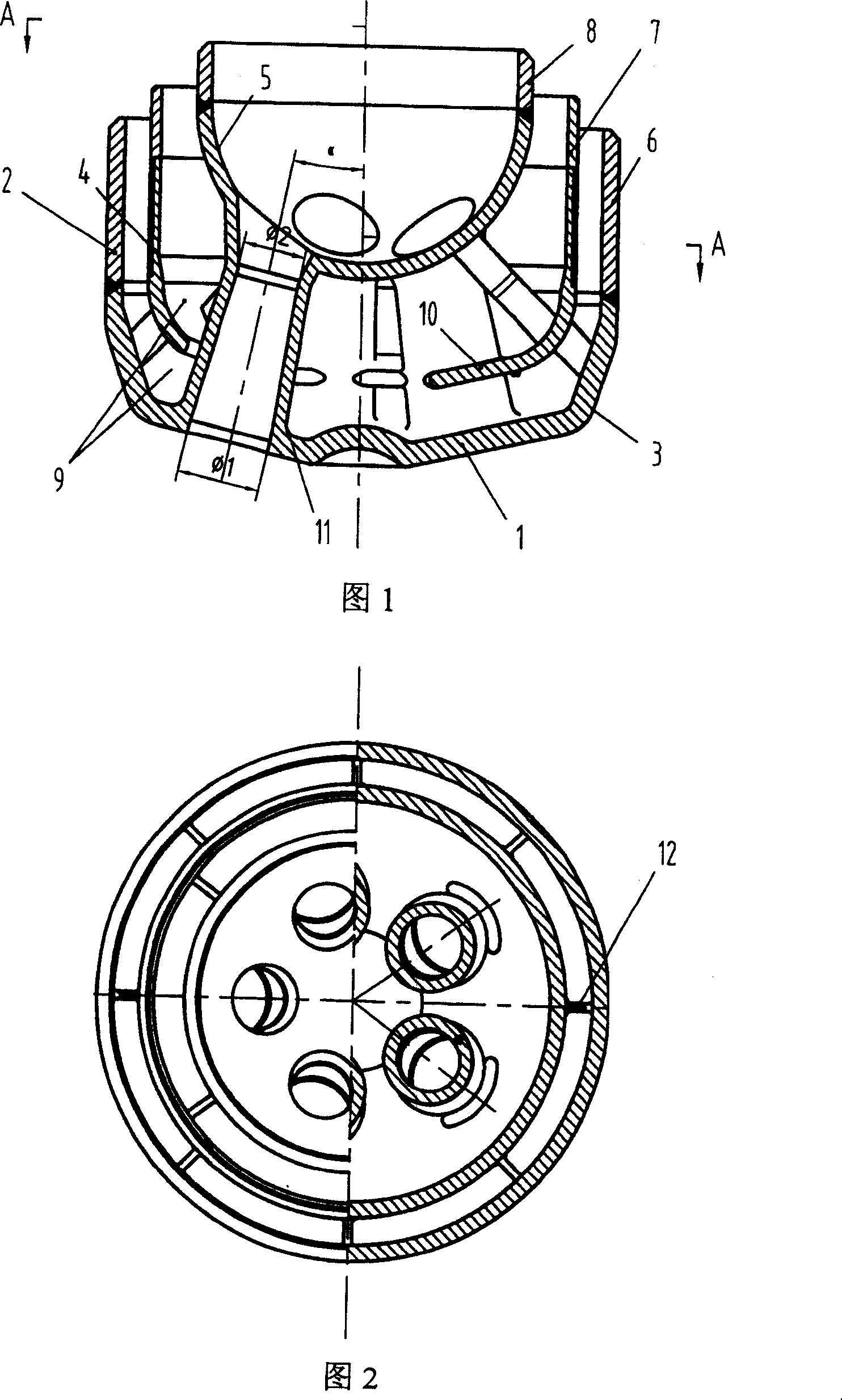

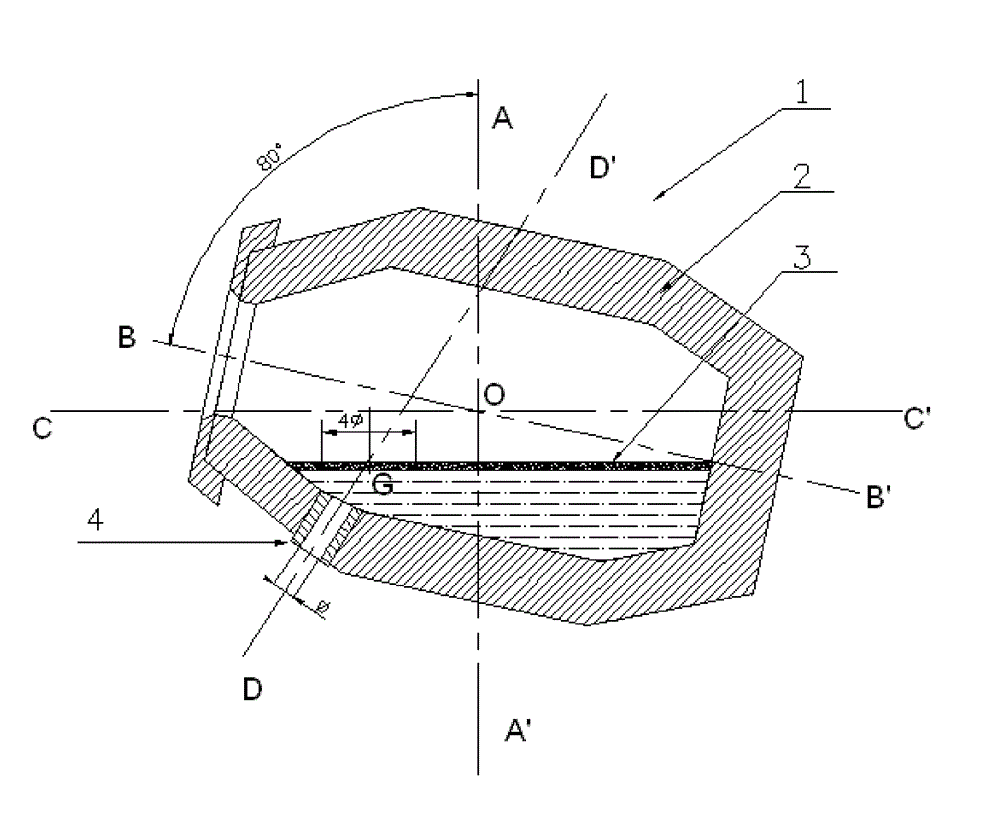

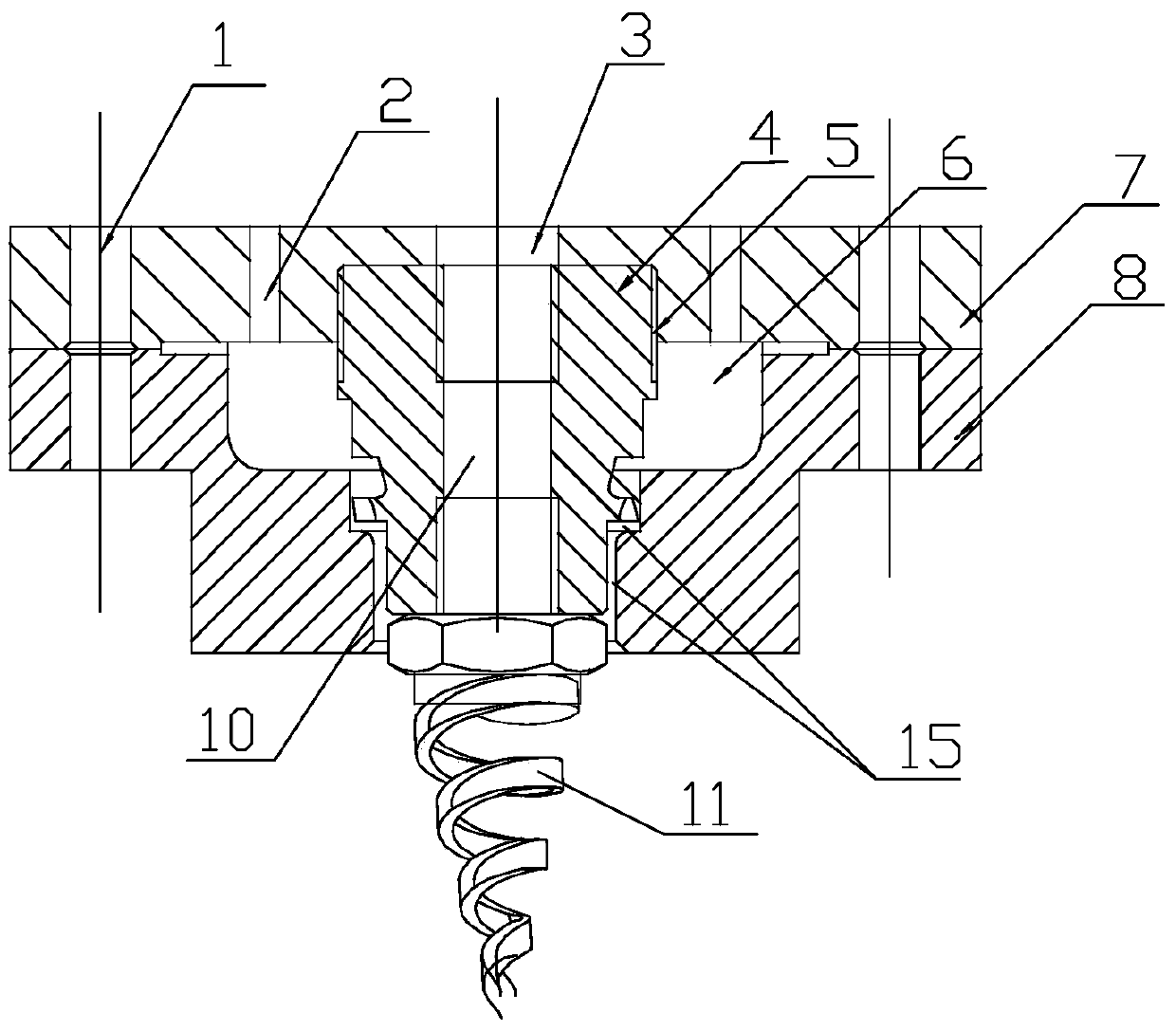

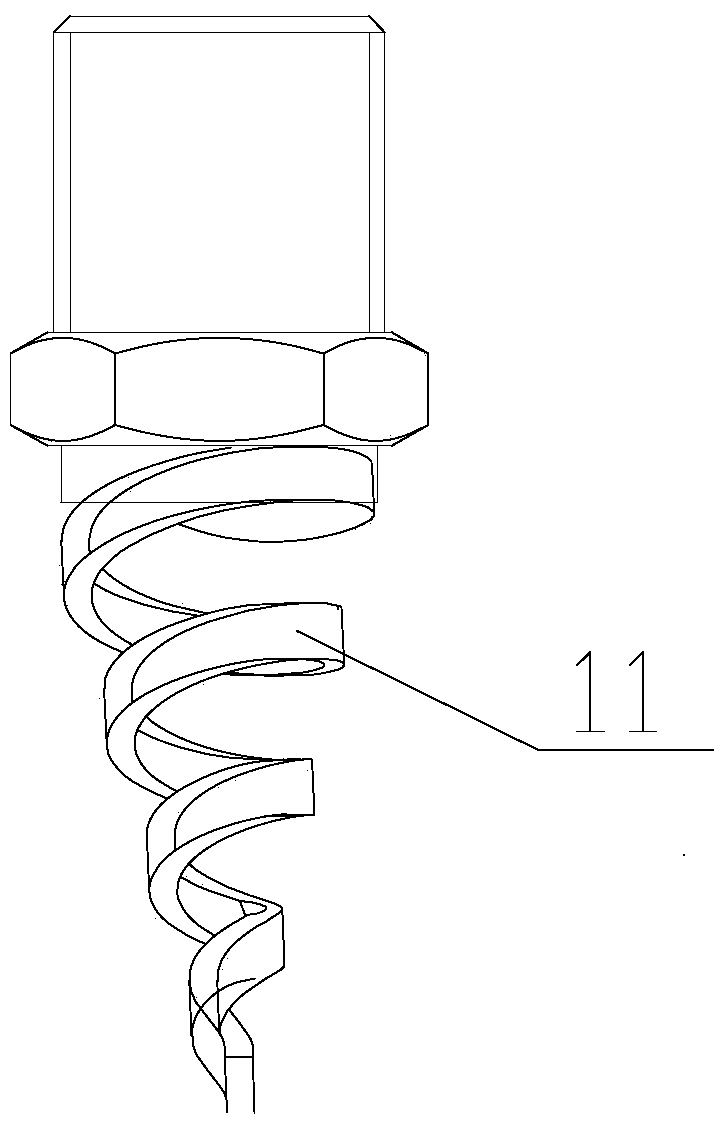

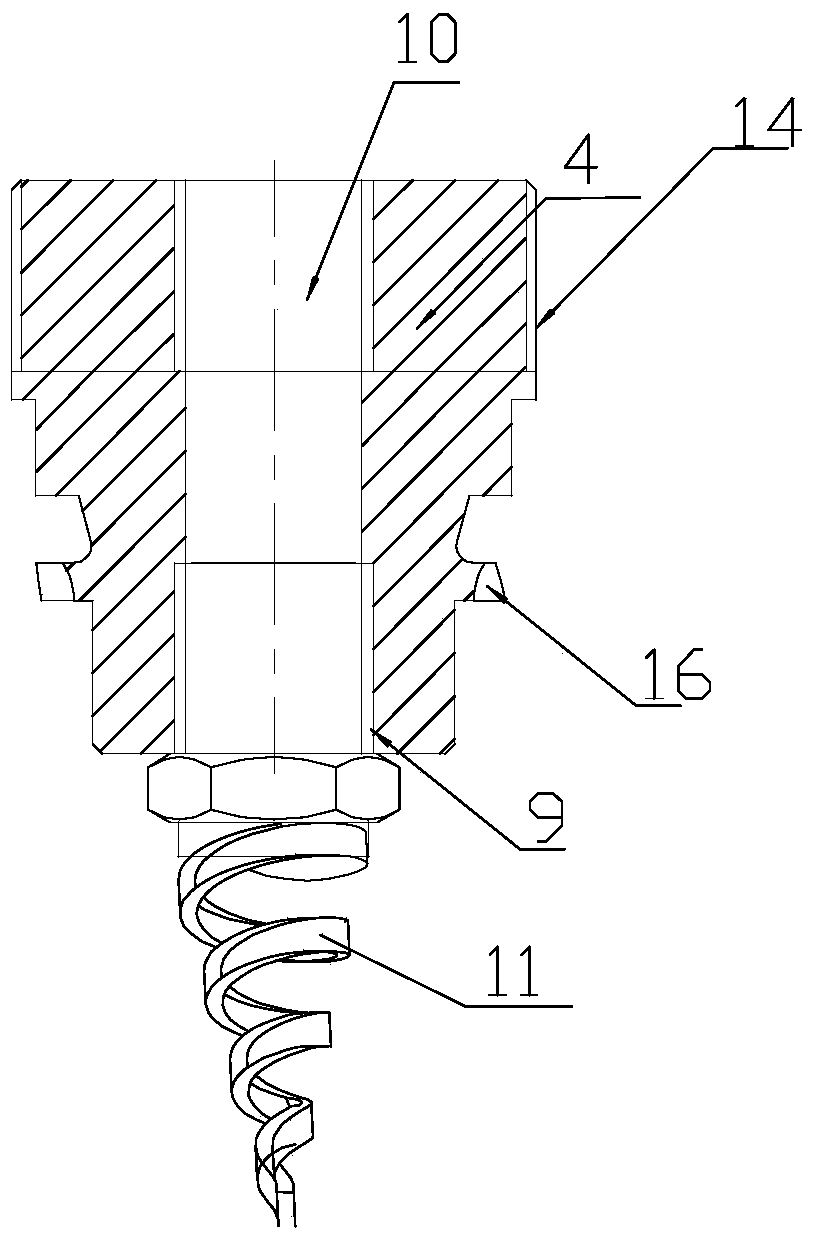

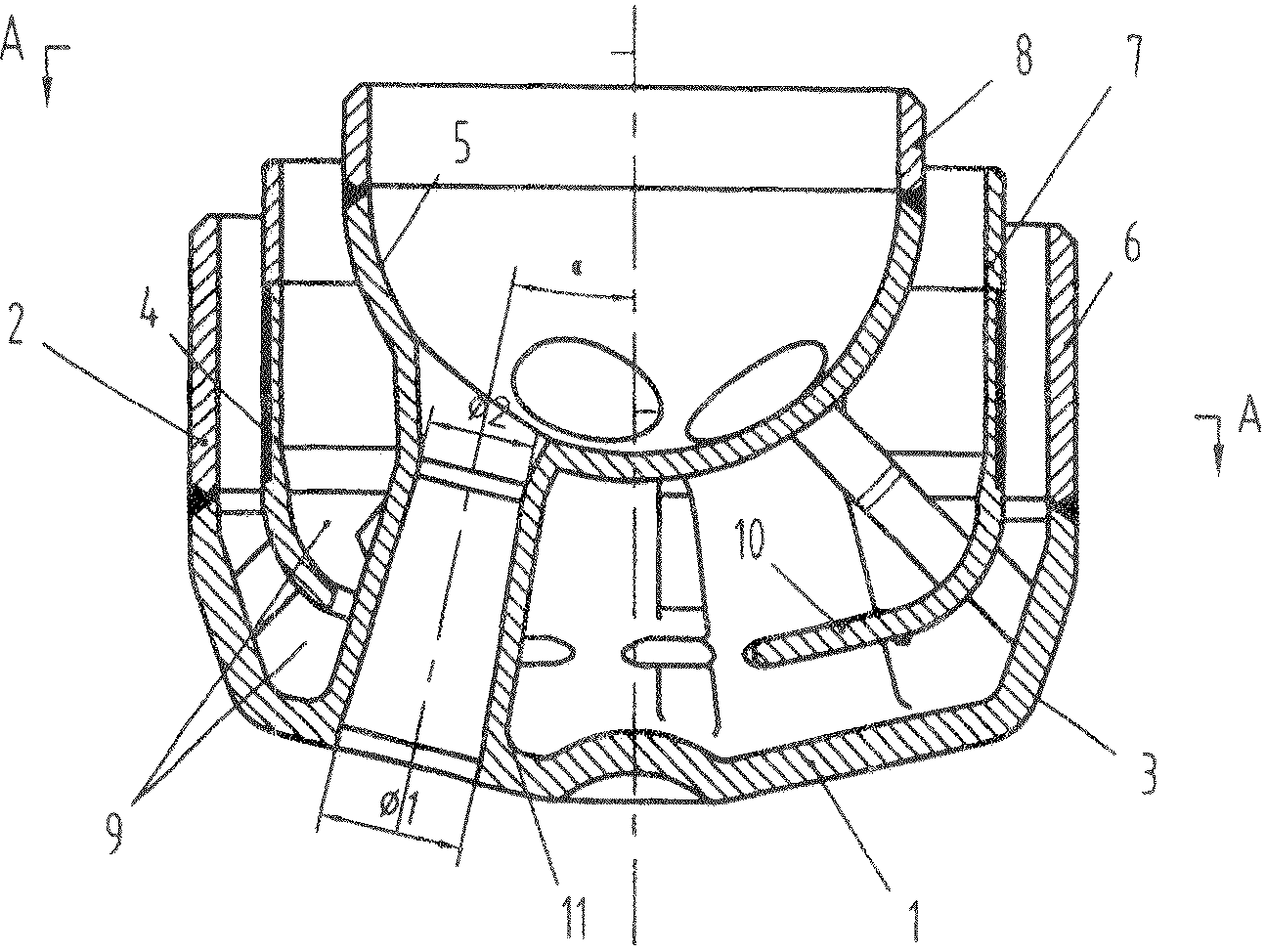

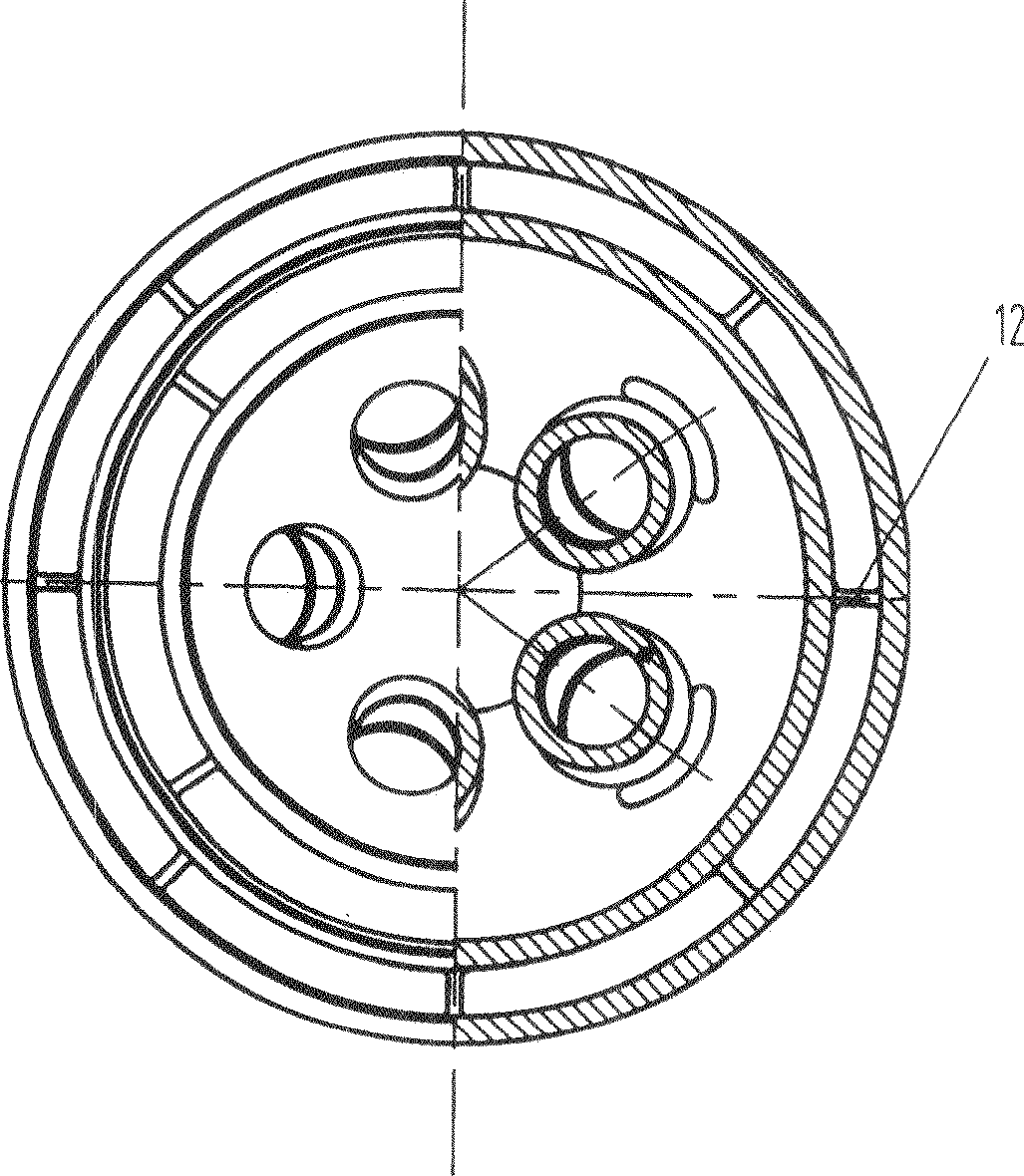

spiral nozzle device

The invention provides a spiral nozzle device. The spiral nozzle device comprises an outer flow atomizing nozzle, a fixing flange, an inner flow atomizing nozzle and a spiral nozzle, wherein the lower end of the fixing flange is connected with the upper end of the outer flow atomizing nozzle, a cooling water hole is formed in the central part of the upper section of the fixing flange, a threaded hole is formed in the central part of the lower section of the fixing flange, and a through hole is formed in the central part of the outer flow atomizing nozzle; the threaded hole communicates with the through hole; the upper section of the inner flow atomizing nozzle is arranged in the threaded hole, the lower section of the inner flow atomizing nozzle is arranged in the through hole, a guide hole is formed in the central part of the inner flow atomizing nozzle, and the guide hole penetrates through the top end and the bottom end of the inner flow atomizing nozzle; the cooling water hole communicates with the guide hole; and the spiral nozzle is connected at the bottom end of the inner flow atomizing nozzle. The water atomizing effect of the spiral nozzle device provided by the invention is great.

Owner:SHANDONG IRON & STEEL CO LTD

A Control Method for Preventing Explosion Venting in the Early Stage of Converter Dry Dust Removal

ActiveCN106544465BRealize dust removal and zero explosion ventingPerfect operationManufacturing convertersTime scheduleManganese

The invention relates to a control method for preventing earlier-stage explosion venting of converter dry dedusting, and the earlier-stage control of converting is reinforced. The control method for preventing earlier-stage explosion venting of converter dry dedusting comprises the following steps that (1) a molten iron sample is obtained in a desulphurization station and sent to a test cabinet for a chemical examination as soon as possible, and chemical examination components of the molten iron sample in the test cabinet are sent to a converter second stage; (2) the lance position of an oxygen lance and the blowing oxygen flow are confirmed according to the content of molten iron silicon before converting of the converter second stage is started, and a control corresponding table of the lance position of the oxygen lance and the flow is sent to a converter first stage PLC; and (3) after converting is started, the converter first stage PLC controls the blowing oxygen flow and the oxygen lance lance position according to the converting time schedule. The control method for preventing earlier-stage explosion venting of converter dry dedusting has the advantages that the reasonable converting flow and lance position are confirmed according to a different molten iron silicon quantity, the silicon manganese oxidizing period of converting is stably spent, the phenomenon that the reaction in a furnace is too intense is avoided, and the CO generating speed is slowly increased, so that the explosion venting limitation of CO and O2 in smoke gas is missed. According to the control method for preventing earlier-stage explosion venting of converter dry dedusting, the oxygen flow and lance position in the earlier stage of converting are reasonably controlled, and zero explosion venting of earlier-stage converting dry dedusting is achieved.

Owner:ANGANG STEEL CO LTD

Method for repairing converter by using waste magnesia carbon bricks

ActiveCN109593909BEffective bondingEffective solution to converter stickingManufacturing convertersProcess efficiency improvementBrickSlag

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

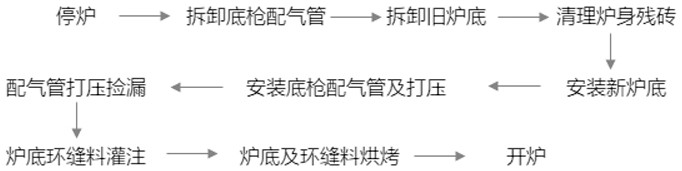

Method for thermally replacing furnace bottom of high-flow top-bottom combined blown converter

InactiveCN114196796AReduce consumptionReduce manufacturing costManufacturing convertersSteelmakingMaterial consumption

The invention discloses a method for thermally replacing a furnace bottom of a high-flow top-bottom combined blown converter, belongs to the technical field of converter steelmaking, and solves the technical problems of bottom blowing closing and combined blowing effect loss caused by erosion of a bottom gun at the furnace bottom of a carbon steel smelting top-bottom combined blown converter. Comprising the following steps: blowing down a furnace; dismounting a gas distribution pipe connected with a bottom gun of an old furnace bottom; dismounting the old furnace bottom; cleaning a residual furnace lining at the combined part of a furnace body and the furnace bottom; filling a repairing material into a circular seam at the connecting part of the new furnace bottom and the furnace body; baking the furnace bottom and the circular seam material; finishing hot replacement of the new furnace bottom, and recovering smelting of the converter. Full-furnace-service large-flow bottom blowing smelting can be achieved, steel material consumption of the converter is remarkably reduced, production cost is reduced, one set of furnace body is matched with 2-3 sets of furnace bottoms, the service life of the converter can reach the high level of 8000-10000 times, refractory materials of the furnace body can be fully utilized, the turnover occupation time of the converter is shortened, and the converter operation rate can be improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Converting process for converter low-silicon molten iron

ActiveCN101117651BPrevent re-dryingGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

Owner:BAOSHAN IRON & STEEL CO LTD +1

Slag stopping material, slag stopping method and combined technology method of slag stopping and slag splashing protection

InactiveCN102943143BSolve the problem of slaggingReduce thicknessManufacturing convertersSlagMolten steel

The invention relates to a slag stopping material, a slag stopping method and a combined technology method of slag stopping and slag splashing protection. The sum of mass percentages of CaO, MgO and C in the slag stopping material accounts for over 40% of the total mass of the slag stopping material, igloss is smaller than 47% of the total mass of the slag stopping material, and the mass percent of C is not more than 25% of the total mass of the slag stopping material. The slag stopping method comprises the step of putting a certain amount of slag stopping material on the liquid level area over a steel tapping hole in a converter. The slag stopping material, the slag stopping method and the combined technology method of slag stopping and slag splashing protection have the following beneficial effects: roughing slag amount is reduced, the thickness of the slag blanket in a ladle is thinned obviously, the tasks of deoxidation of molten steel in the ladle and modification of top slag are relieved, the consumption of deoxidizer is lessened, the phenomena of rephosphorization and silicon pick up in the refining process of the molten steel are reduced, the consumption of slag regulating materials is lowered, the time of molten steel refining is shortened and the smelting cost is decreased; and after steel tapping is finished, the slag stopping material can be directly used as a slag splashing protection material, the use amount of the slag splashing protection material is reduced, the time of slag splashing protection is shortened and the working efficiency of the converter is enhanced.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

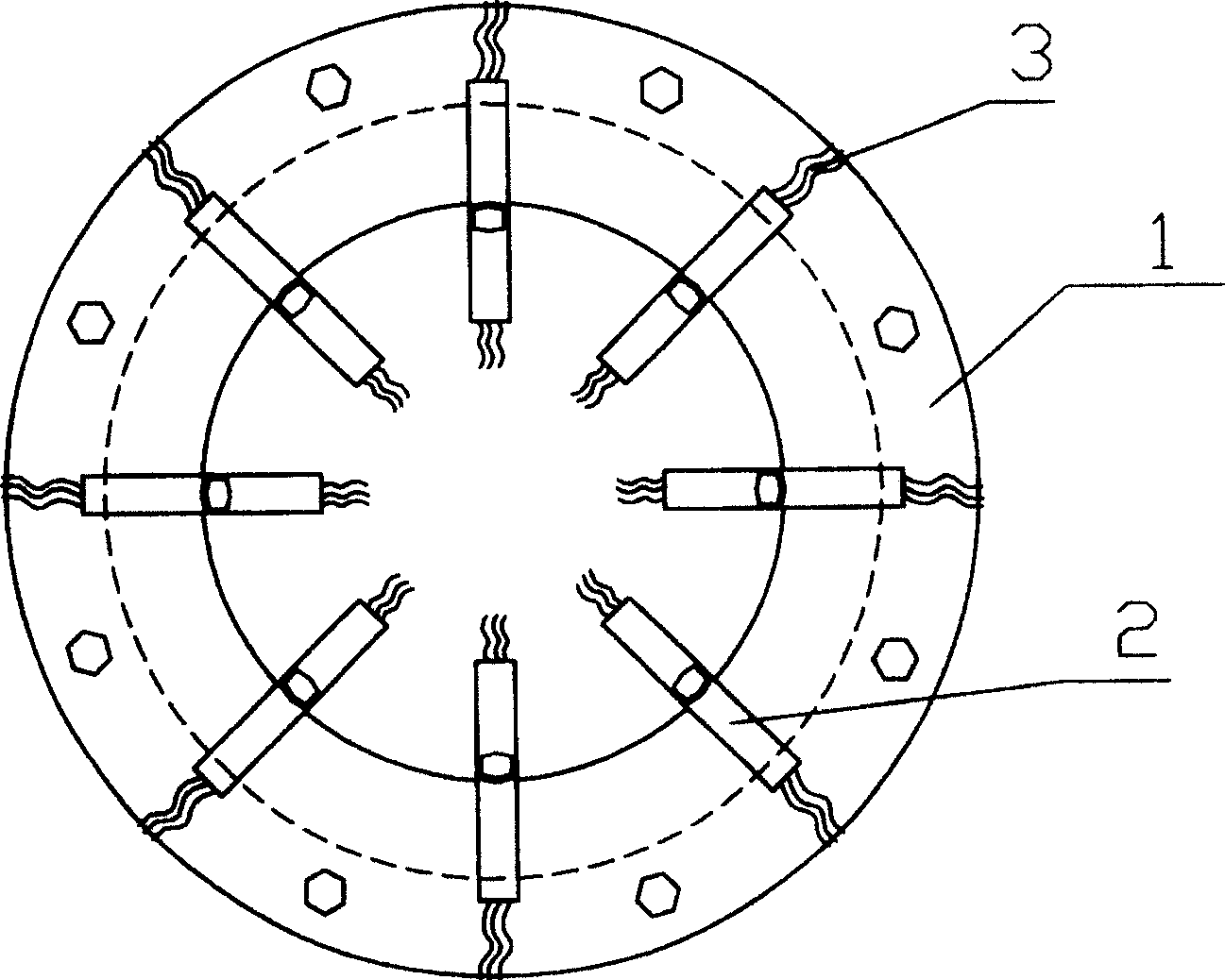

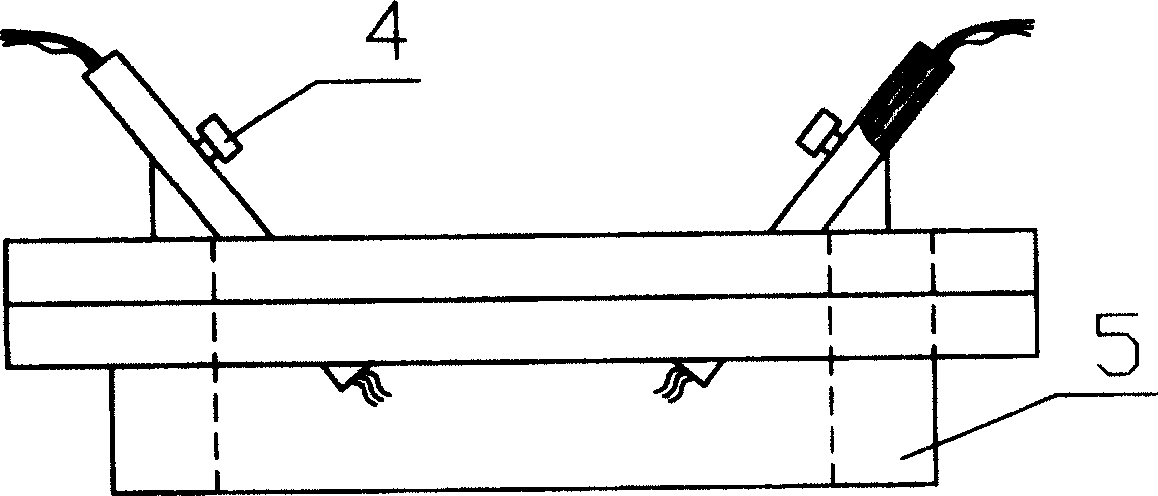

Maintenance and clinker removal method of sub lance for converter dual blown from top and bottom, and equipment

This invention discloses method and apparatus for maintaining and removing slag from sublance of steelmaking top-bottom composite blown converter. The method solves the problems of adverse effects and many malfunctions caused by slag adhered to sublance. The method comprises: brushing slag, maintaining sublance and removing slag on the probe end during sublance lifting process after testing in converter. Therefore, the sublance can receive maintenance in time, and the method has such advantages as simple process, good slag removing effect, and few malfunctions. The brushing apparatus is easy to adjust, use and maintain. The converter with cleaned sublance has such advantages as high productivity, and short smelting period.

Owner:ANGANG STEEL CO LTD

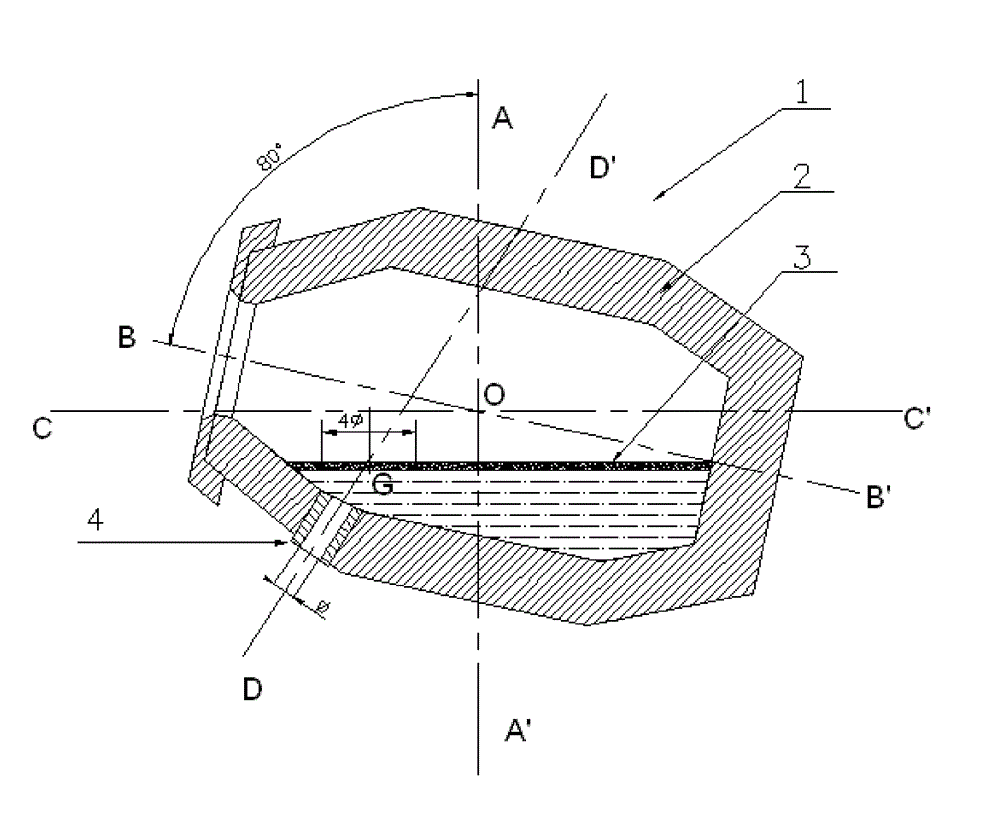

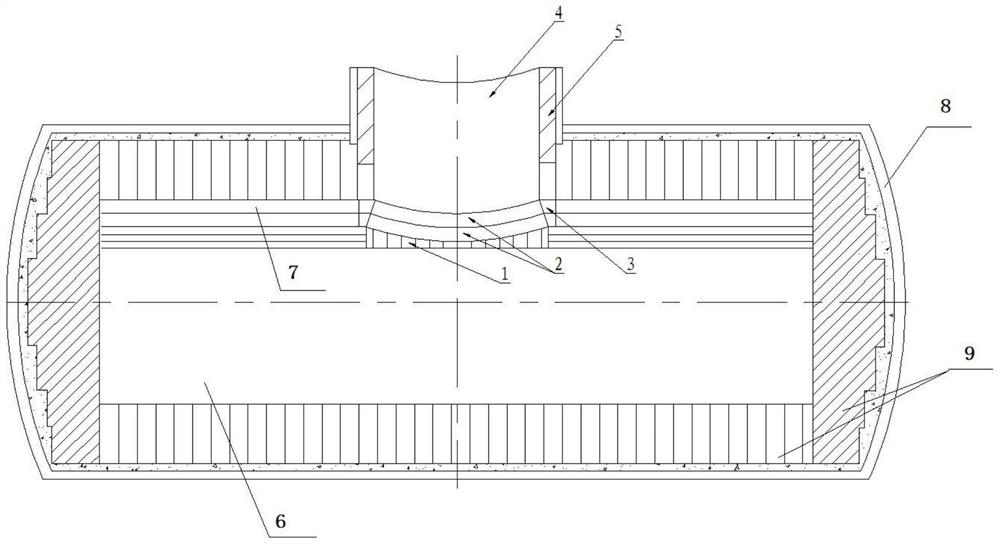

Lining building structure for horizontal converter mouth area

PendingCN112082383AImprove securityStrong pressing forceFurnace componentsBrickArchitectural engineering

The invention discloses a lining building structure for a horizontal converter mouth area. The lining building structure for the horizontal converter mouth area comprises multiple transition bricks (1), multiple arch bricks (2), multiple locking bricks (3), multiple tongue bricks (4) and multiple side wall bricks (5). The multiple tongue bricks (4) are built into a tongue brick layer, and the tongue brick layer is in building connection with the inner side face of a horizontal converter mouth through the multiple side wall bricks (5). An arch brick layer is built at the bottom of the tongue brick layer through the multiple arch bricks (2). A cylinder brick layer is built on the inner side of a horizontal converter body (6) through multiple cylinder bricks (7). The arch brick layer is connected with the cylinder brick layer through the multiple locking bricks (3). A transition brick layer is built at the bottom of the arch brick layer through the multiple transition bricks (1) and is inbuilding connection with the cylinder brick layer. By means of the lining building structure for the horizontal converter mouth area. The problems that in the prior art, a lining of the horizontal converter mouth area is large in building difficulty, too fast in erosion and short in service life can be solved.

Owner:JINCHUAN GROUP LIMITED

A maintenance method for converter lining

Owner:QIANAN CITY JIUJIANG WIRE

Composite cooling agent for steel-smelting and production technique thereof

The invention discloses a composite cooling agent for steelmaking and a production process, which consists of 50-70% of steelmaking discharge sludge, 15-30% of continuous casting scale, 2-6% of magnesium chloride, 1-3% of It is composed of humic acid, 2-7% bentonite, and 10-20% dust return material. After removing impurities, the sludge recovered from the sewage discharged from steelmaking and the iron oxide scale of continuous casting are respectively placed on the hollow iron plate. Wet sludge is heated and dried to make slag-like granular raw materials, then dried again to 6-8% water content, mixed according to the raw material ratio, and then pressed to form a spherical billet, and the billet is put into the rotary kiln , preheated for 20-30 minutes, then heated to 900-1000 degrees, and calcined into products at high temperature for 40-60 minutes. The composite cooling agent for steelmaking in the present invention can flexibly and effectively adjust the steelmaking temperature, reduce the difficulty of temperature control, shorten the smelting time, increase the steel output, save the steelmaking cost, optimize the carbon-oxygen reaction in the steelmaking furnace, and increase the metal yield. Efficiency, reducing the discharge of pollutants, improving the effect of energy saving and emission reduction, has good economic and social benefits.

Owner:彭海圣

Converter slag mending material

The invention discloses a converter slag repair charge, which is mainly characterized in that during the converter smelting process, the ΣFeO in the converter slag is controlled at 8% to 12%, and a reducing agent active metal or its alloy is added to the slag after tapping to make the FeO in the slag is all reduced, so that the slag system becomes a CaO-SiO2 binary system or CaO-MgO-SiO2 ternary system refractory material, and it is attached to the furnace wall by shaking the furnace or blowing with N2 to achieve refractory purpose of the furnace. Because the present invention adopts the above scheme, compared with the prior art, the present invention has the advantages of simple, easy, quick and effective furnace repairing operation.

Owner:河南新锦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com