Lining building structure for horizontal converter mouth area

A converter furnace mouth and inner lining technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of difficult masonry, too fast erosion, and low service life, so as to improve the operation rate of converters and prolong maintenance Cycle, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

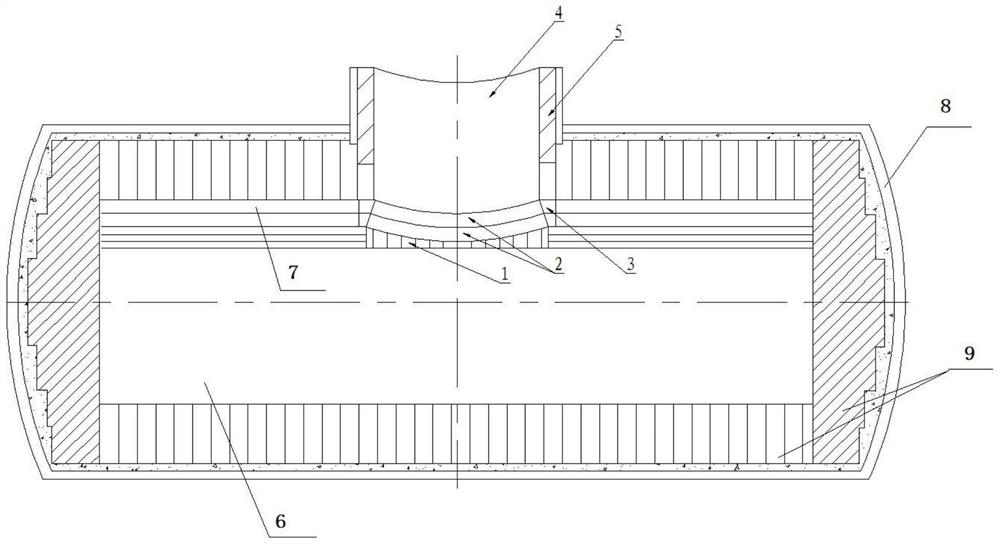

[0012] see figure 1 , a horizontal converter mouth area lining masonry structure of the present invention, comprising a plurality of transition bricks 1, a plurality of arch bricks 2, a plurality of lock bricks 3, a plurality of tongue bricks 4, a plurality of side wall bricks 5, Filling, furnace shell 8, refractory brick masonry 9. A plurality of tongue bricks 4 are built into a tongue brick layer. During the masonry, the tongue brick layer can be divided into two parts to be built separately through the support of the lead screw; the tongue brick layer and the inner surface of the horizontal converter mouth are passed through multiple side walls Bricks 5 are connected by masonry, and the bottom of the tongue brick layer is built with a plurality of arch bricks 2, and the top of the tongue brick layer is the initial position for feeding the horizontal converter. The tongue brick layer and the arch brick layer are closely bonded to realize the joint of the tongue brick of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com