Converting process for converter low-silicon molten iron

A molten iron and converter technology, which is applied in the direction of manufacturing converters and improving process efficiency, can solve the problems of difficult utilization of converter slag, poor dephosphorization effect, and excessive alkalinity of slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (1) Molten iron conditions: [C] 4.6%, [Si] 0.30%, [Mn] 0.45%, [P] 0.12%, [S] 0.020%, molten iron temperature 1345 ℃.

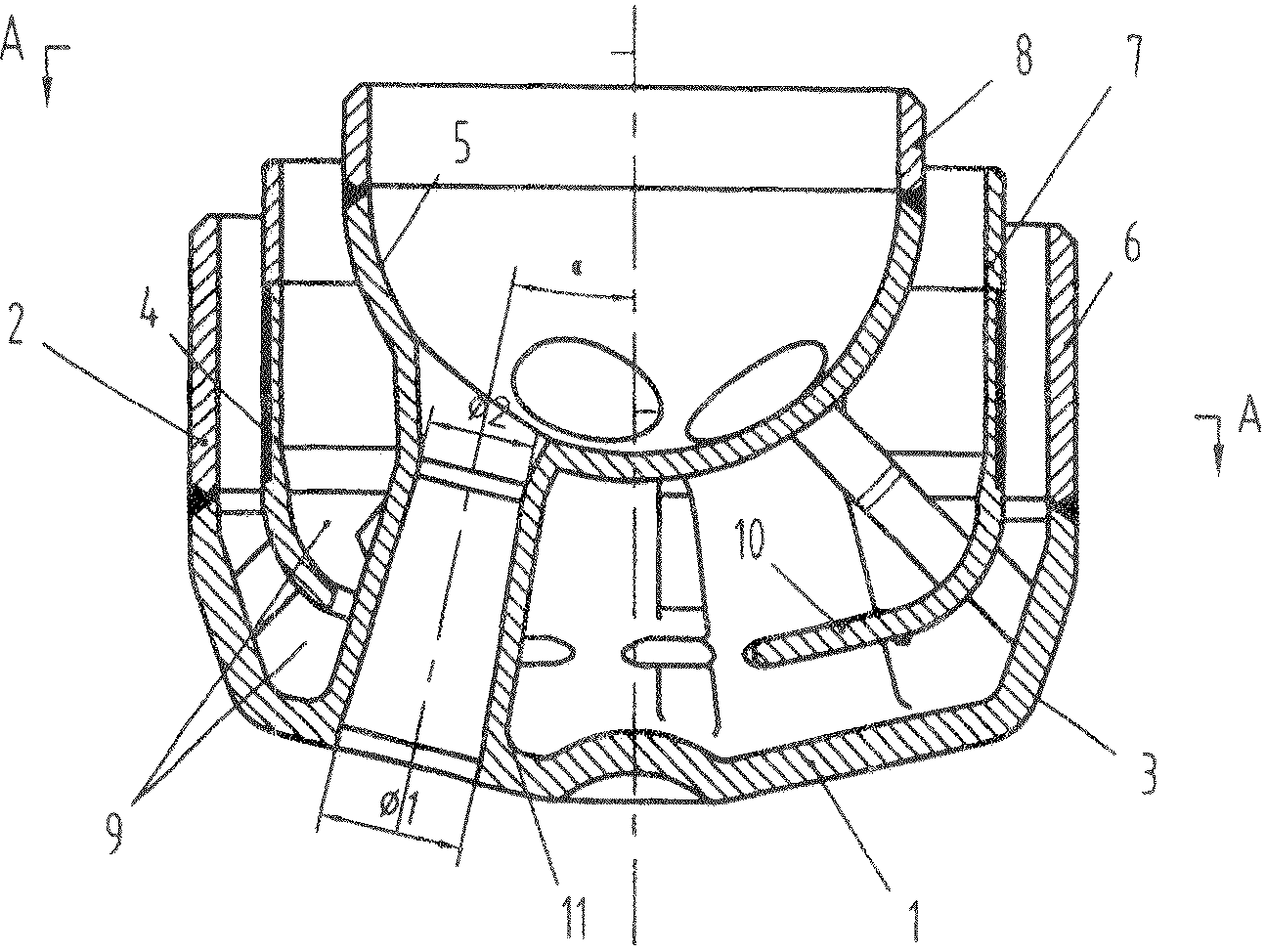

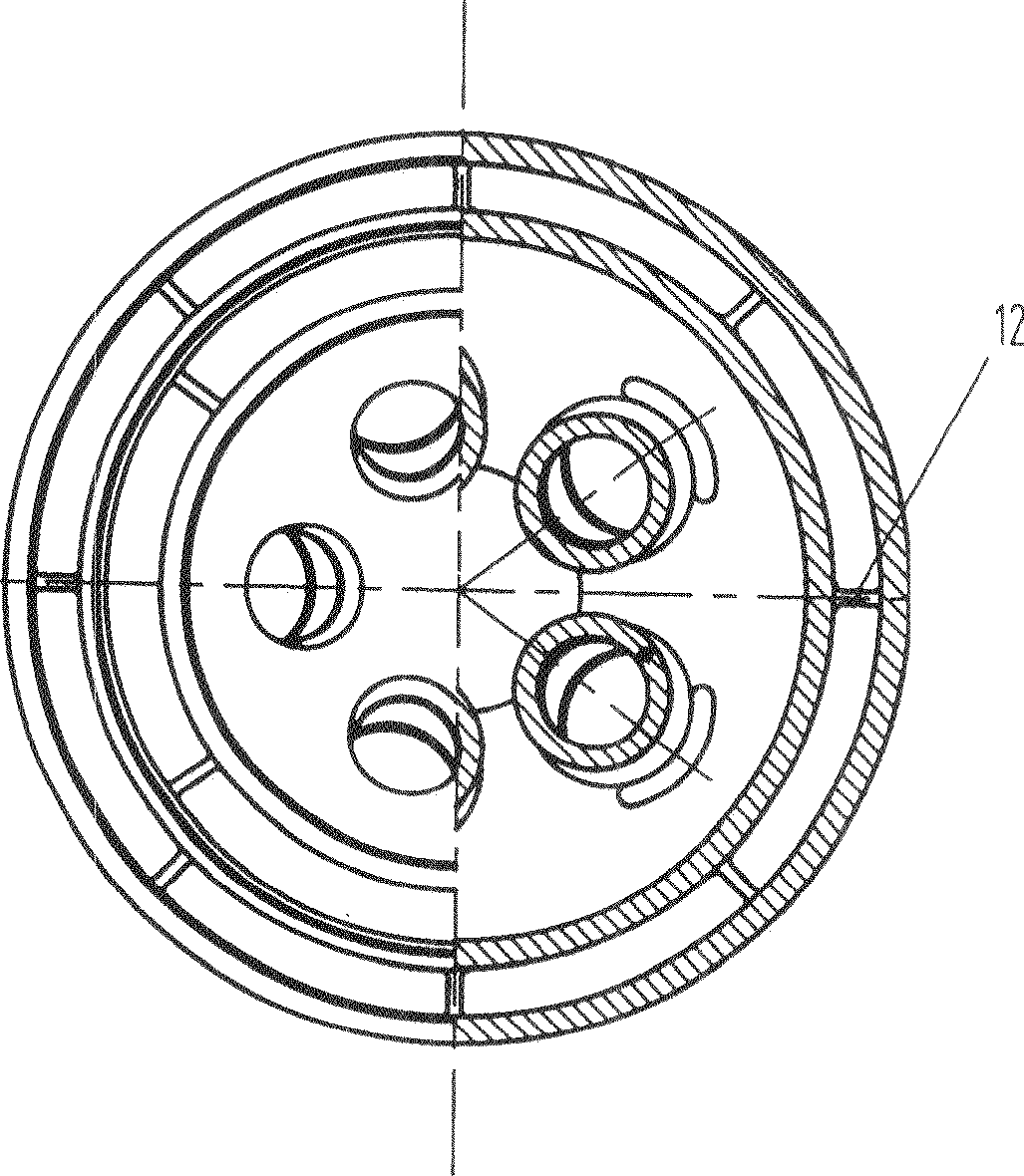

[0082] (2) The oxygen lance spray head adopts the present invention's attached Figure 1-2 Oxygen lance nozzle shown.

[0083] (3) Converter top blowing oxygen flow rate 900Nm 3 / min.

[0084] (4) Oxygen lance position control: 2.3m in the initial stage, 2.8m in the middle stage, and 1.8m in the late stage.

[0085] (5) Fill in the alkalinity 4.5, the amount of slag-making materials per ton of steel: lime 28kg, lightly burned dolomite, iron ore 10kg. The first batch of slagging materials accounted for 60% of the total amount added, and the rest were added in 3 batches. The composition weight mesh ratio of synthetic slag is: Fe 2 o 3 And FeO: 60%, CaO: 12%, MgO: 6.5%, Al 2 o 3 ≤5.0%, SiO 2 ≤8.0%, S≤0.05%, P≤0.05%, H 2 O≤0.5%, the rest is Fe and unavoidable impurities.

[0086] (6) When the amount of oxygen blowing reaches 90% of the total amou...

Embodiment 2

[0090] (1) Molten iron conditions: [C] 43%, [Si] 0.22%, [Mn] 0j0%, [P] 0.08%, [S] 0.010%, molten iron temperature 1330 ℃.

[0091] (2) the oxygen lance nozzle adopts the present invention's attached Figure 1-2 Oxygen lance nozzle shown.

[0092] (3) Oxygen flow rate 950Nm 3 / min.

[0093] (4) Oxygen lance position control: 2.5m in the initial stage, 3.0m in the middle stage, and 2.0m in the late stage.

[0094] (5) Loading alkalinity 5.8, adding amount of slagging material per ton of steel: 24kg of lime, 20kg of lightly burned dolomite, 7kg of iron ore, 4kg of exothermic agent, 3kg of synthetic slag. The first batch of slagging materials accounted for 70% of the total amount added, and the rest were added in 3 batches. The composition weight percent of synthetic slag is; Fe 2 o 3 And FeO: 55%, CaO: 15%, MgO: 8%, Al 2 o 3 ≤5.0%, SiO 2 ≤8.0%, S≤0.05%, P≤0.05%, H 2 O≤0.5%, the rest is Fe and unavoidable impurities.

[0095] (6) When the amount of oxygen blowing reaches ...

Embodiment 3

[0099] (1) Conditions of molten iron: C4.1%, Si0.10%, Mn0.20%, P0.01%, S0.002%, molten iron temperature 1280°C.

[0100] (2) the oxygen lance nozzle adopts the present invention's attached Figure 1-2 Oxygen lance nozzle shown.

[0101] (3) Oxygen flow rate 1050Nm 3 / min.

[0102] (4) Oxygen lance position control: 2.7m in the initial stage, 3.0m in the middle stage, and 1.9m in the late stage.

[0103] (5) Loading alkalinity 5.8, adding amount of slagging material per ton of steel: 18kg of lime, 25kg of lightly burned dolomite, 5kg of iron ore, 7kg of exothermic agent, 6kg of synthetic slag. The first batch of slagging material accounts for 60% of the total amount added, and the rest is added in two batches. The composition weight percent of synthetic slag is; Fe 2 o 3 And O: 65%, CaO: 8%, MgO: 5%, Al 2 o 3 ≤5.0%, SiO 2 ≤8.0%, S≤0.05%, P≤0.05%, H 2 O≤0.5%, the rest is Fe and unavoidable impurities.

[0104] (6) When the amount of oxygen blowing reaches 90% of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com