Slag splashing method for converter

A technology of slag splashing and slag splashing, which is applied in the manufacture of converters, steel manufacturing processes, climate sustainability, etc., can solve problems such as misoperation and judgment error, reduce nitrogen consumption, stabilize the effect, and improve slag splashing to protect the furnace effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is further described:

[0026] The following examples describe the present invention in detail. These examples are only to describe the best embodiment of the present invention, and do not limit the scope of the present invention.

[0027] A converter slag splashing method, comprising:

[0028] 1) The primary control system presets a variety of slag splash models corresponding to different slag states;

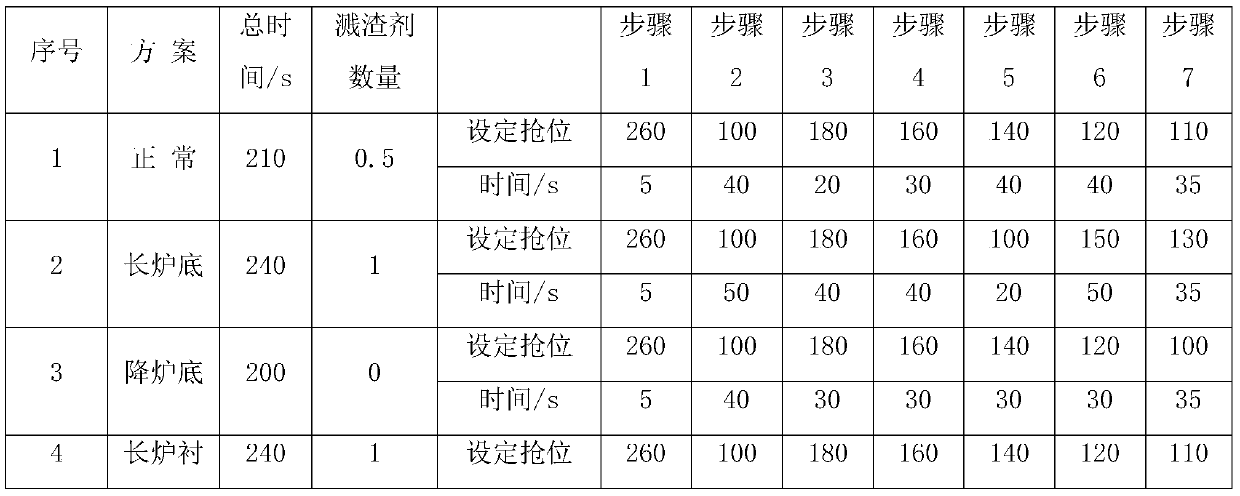

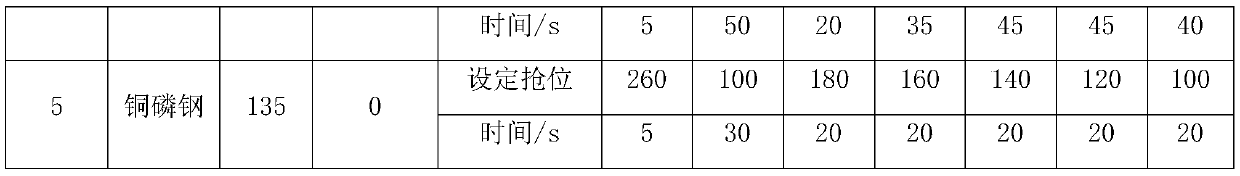

[0029] The converter achieves the purpose of protecting the furnace through nitrogen slag splashing. The slag splashing model includes the total time of slag splashing, the amount of slag splashing agent, the setting of the oxygen lance to grab the position, and the oxygen lance time. The time of slag splashing starts from the time when the oxygen lance is turned on with nitrogen, and the position of the oxygen lance is directly lowered to the gun position set in step 1, and then step 1 is executed to reach th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com