Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "High paint removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green alkaline paint remover for eliminating coating from electronic circuit board and its prepn and usage

InactiveCN1887979AReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideEngineering

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

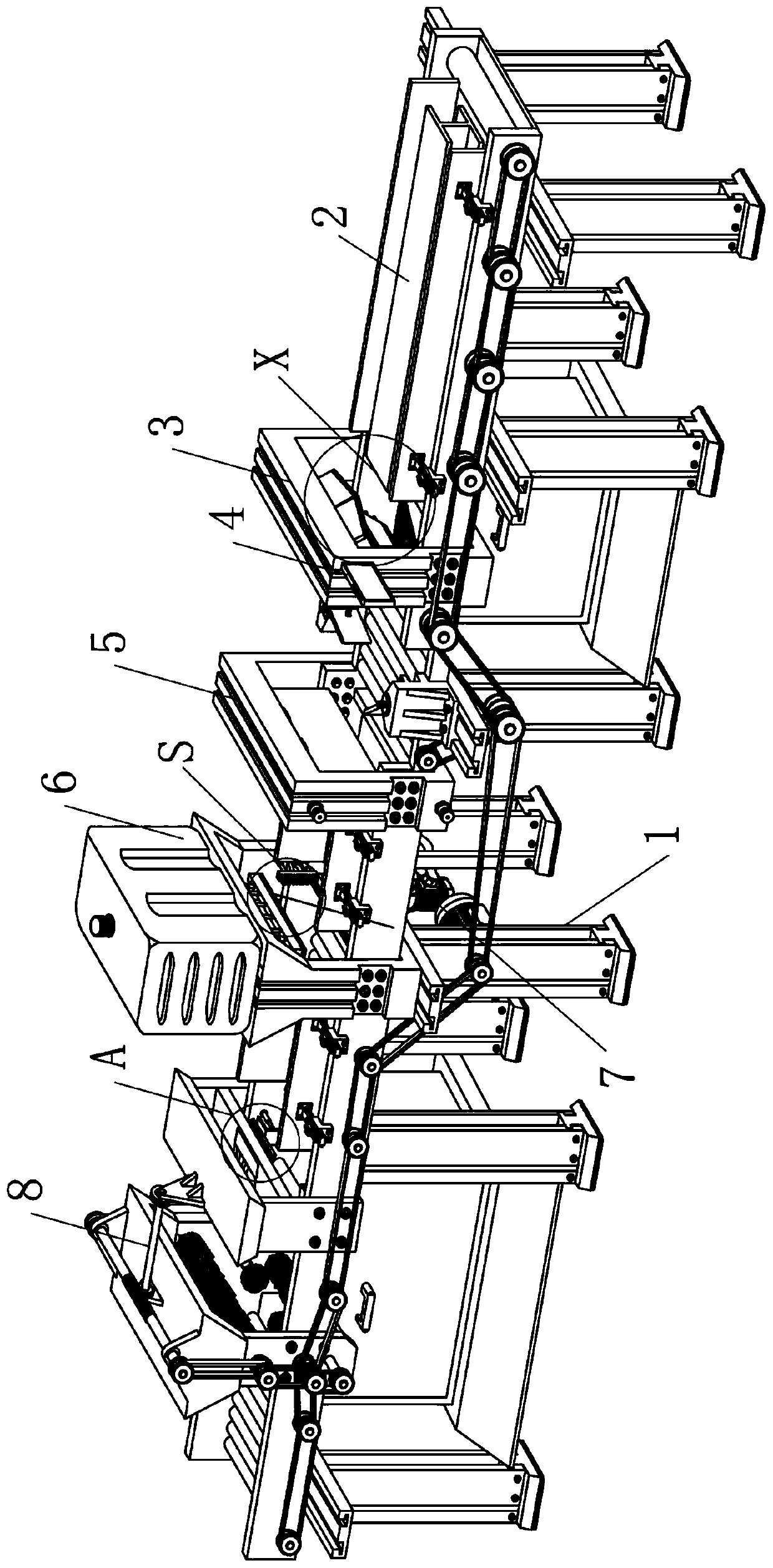

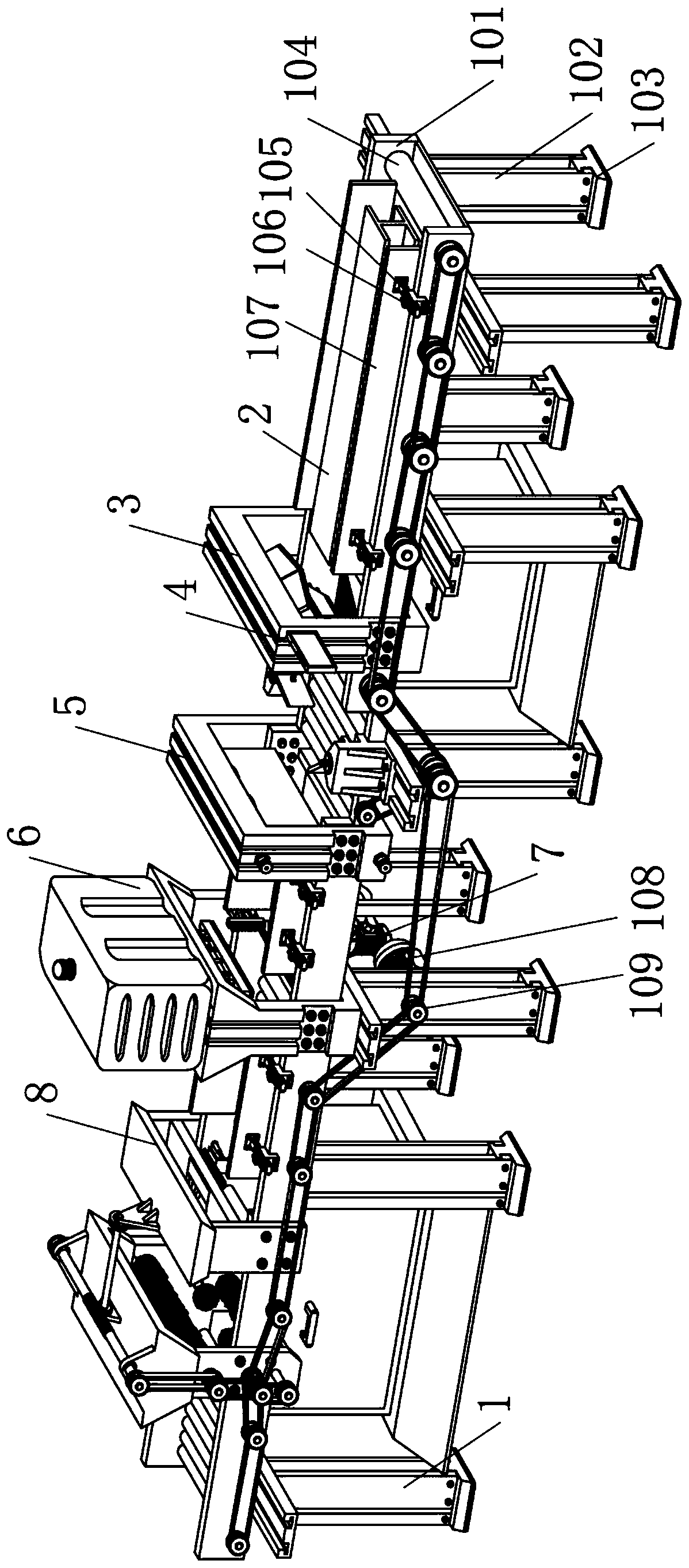

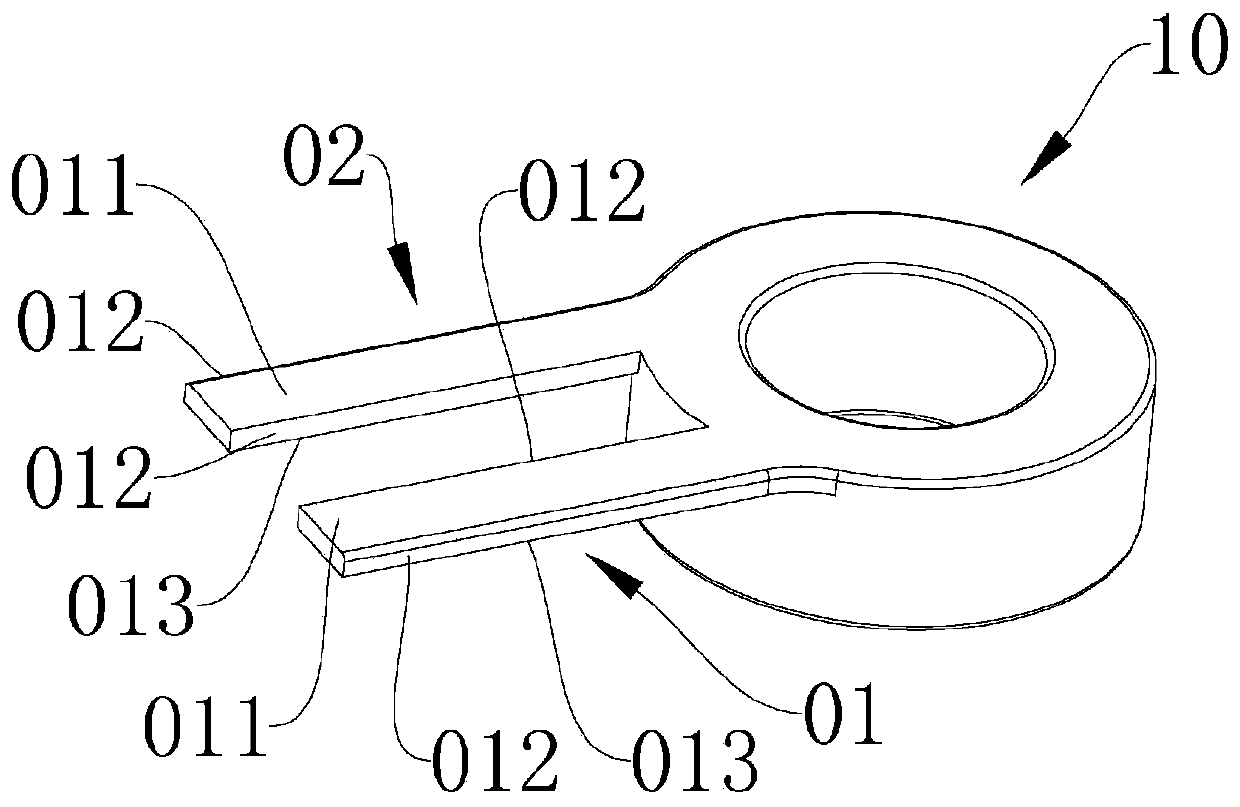

Paint removing method and paint removing equipment for surface of metal hanging rack

ActiveCN106623277AAvoid environmental pollutionImprove the effectCleaning using liquidsChemistryControl system

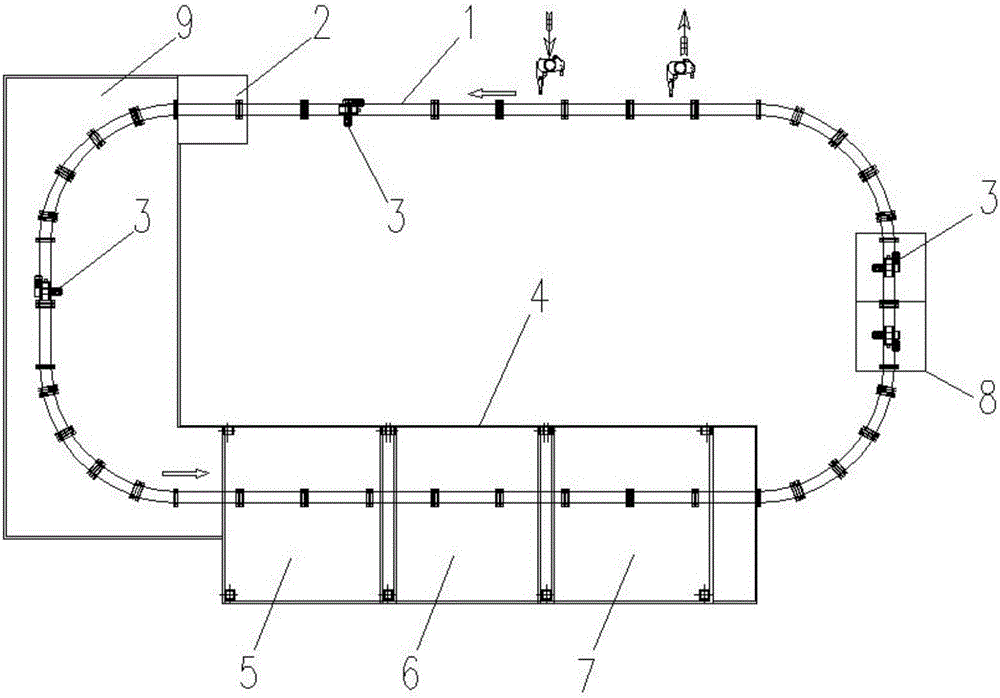

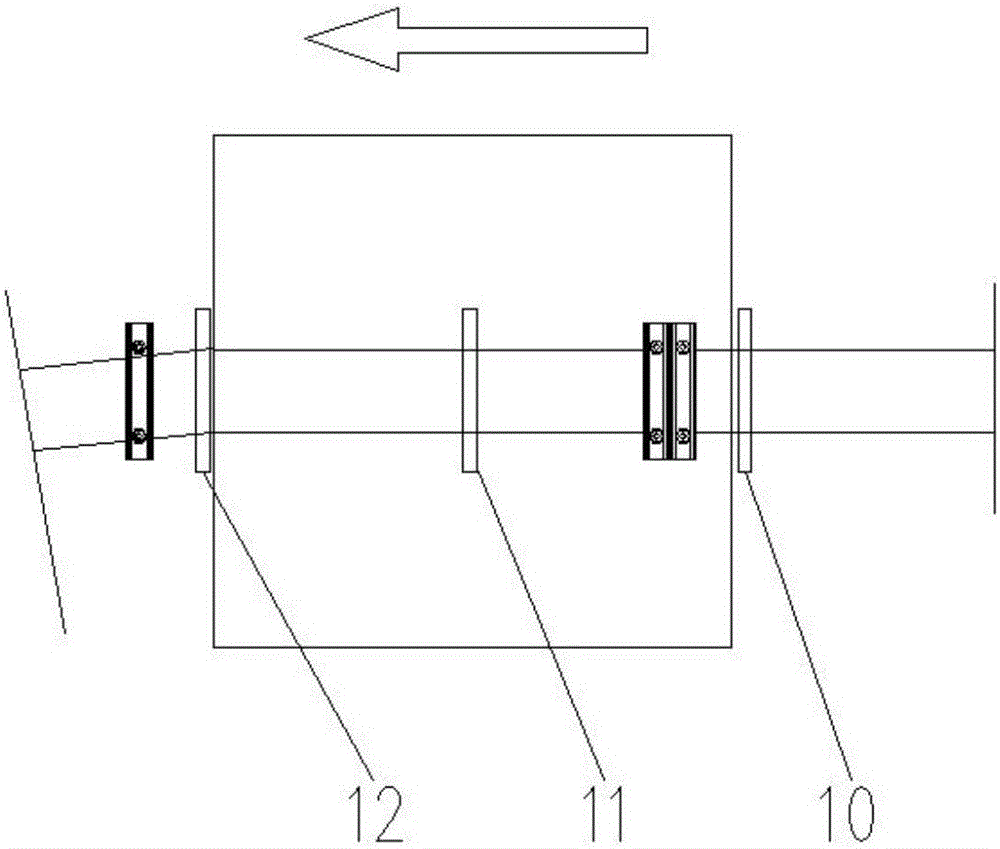

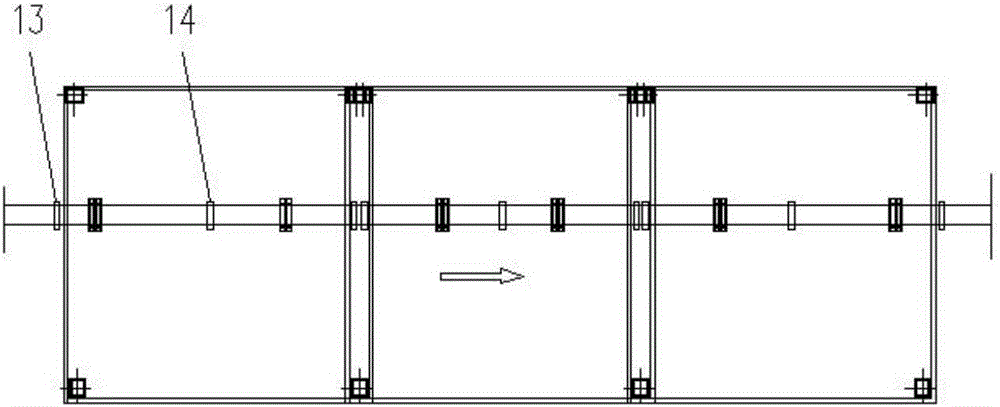

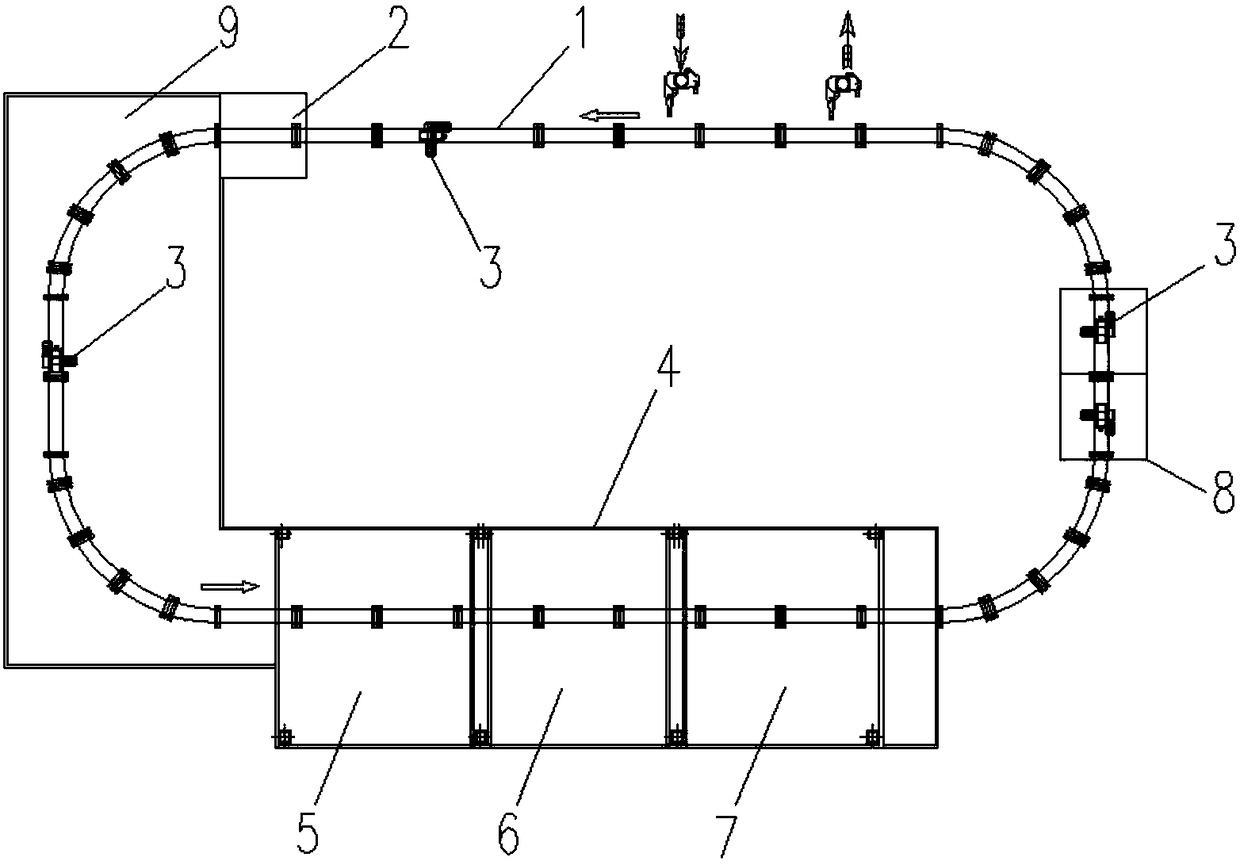

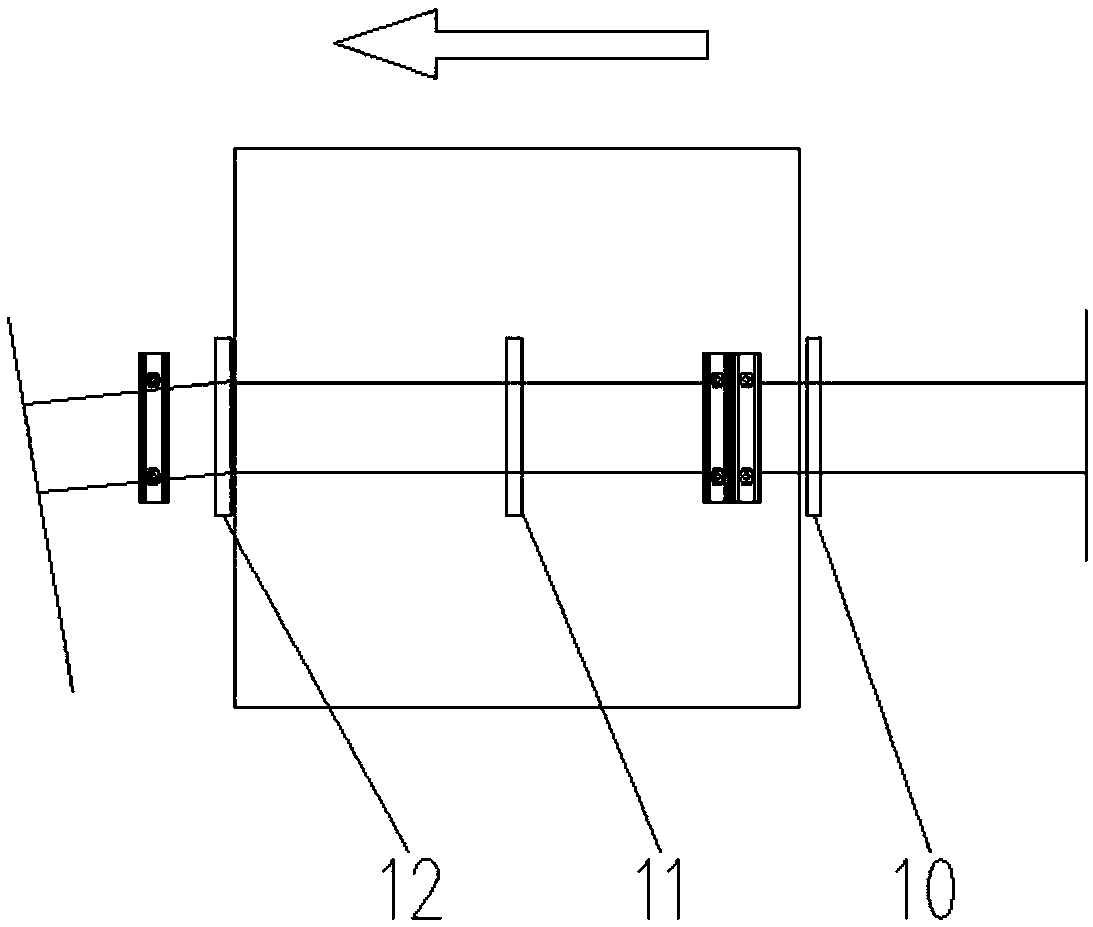

The invention provides a paint removing method and paint removing equipment for a surface of a metal hanging rack. Liquid-nitrogen soaking and metal particles are utilized to perform paint removal treatment on a paint resin coating on the surface of the metal hanging rack, so that the problem that paint removing effect is poor and environmental pollution is caused due to the fact that the metal hanging rack adopts an existing paint removing method is solved. The paint removing method comprises a liquid nitrogen soaking step and a multi-stage variable-frequency particle colliding step; the paint removing equipment comprises a ring-shaped rail, a self-propelling car, a liquid nitrogen slot, a metal particle impact bin and a control system; the ring-shaped rail is horizontally suspended above the liquid nitrogen slot and the metal particle impact bin; liquid nitrogen is contained in the liquid nitrogen slot; the self-propelling car is arranged on the ring-shaped rail, and can move along the ring-shaped rail; and the self-propelling car is equipped with a clamping mechanism used for clamping the metal hanging rack, a hoisting mechanism used for controlling the clamping mechanism to move up and down, and a drive mechanism used for driving the metal hanging rack to rotate along the longitudinal central shaft thereof.

Owner:武汉大润生态环境科技发展有限公司

General efficient paint remover

InactiveCN1743389AFast paint removalHigh paint removal efficiencyChemical paints/ink removersChlorideSURFACTANT BLEND

The invention relates to a general efficient paint remover and its preparing method. The paint remover is prepared by mixing methylene chloride, methanol, formic acid, resordinol, paraffin, surfactant and corrosion inhibitor according to rated proportion and making then react under a certain condition. It has fast depainting speed, good depainting effect, wide application range, and little corrosion to keelson, and non-combustible and hypotoxicity.

Owner:BEIJING UNIV OF CHEM TECH

Preparation and application method of water-based paint remover

InactiveCN103013221ATake off quicklyReduce corrosionChemical paints/ink removersSodium lactateActive agent

The invention discloses a preparation and application method of a water-based paint remover. The water-based paint remover consists of sodium hydroxide, a surface active agent and a composite additive. The mass fraction of sodium hydroxide is 3%-10% that of the surface active agentis 0.5%-2%, that of the composite additive is 1%-6%, and the rest is water. The surface active agent is octadecyl dihydroxy diethyl betaine; and the composite additive is composed of three of sodium lactate, sodium malate, sodium sarcosinate, natrium aceticum and sodium gluconate. The water-based paint remover disclosed by the invention has the characteristics of being efficient, environmentally-friendly, safe, nontoxic, barely corrosive and hard to volatilize, can be used for removing the paint from common metal and plastic base materials, and is simple and easy to prepare and use.

Owner:GUANGDONG UNIV OF TECH

Neutral environment-friendly paint remover

The invention discloses a neutral environment-friendly paint remover. The neutral environment-friendly paint remover is a mixed solution formed by a main solvent, a volatile inhibitor, an activating agent, a cosolvent, an emulsifying agent, a corrosion inhibitor, a penetrating agent, an alkane odor remover and a thickening agent. The main solvent comprises a mixture of two or three of dichloromethane, ethyl acetate and acetone; the volatile inhibitor is liquid paraffin and water; the activating agent is ethanolamine; the cosolvent is ethanol; and the thickening agent is polyethylene glycol. The neutral environment-friendly paint remover comprises, by mass, 70-80% of the main solvent, 0.5-2% of liquid paraffin, 2-5% of water, 4-6% of ethanolamine, 5-10% of ethanol, 3-8% of the emulsifying agent, 0.2-1% of the corrosion inhibitor, 1-3% of the penetrating agent, 0.3-0.7% of the alkane odor remover and 0.5-1.5% of the polyethylene glycol. The neutral environment-friendly paint remover can effectively remove electrophoretic coatings with complex shapes on metal components thoroughly; a paint removal efficiency is higher than or equal to 98%; the neutral environment-friendly paint remover does not corrode metal, wood or cement, and has a wide application scope, no pungent smell, low volatility, and small harm to a human body and an environment. The neutral environment-friendly paint remover has high stability and can be cleaned easily.

Owner:SHANDONG WEIDA MASCH CO LTD

ABS (acrylonitrile butadiene styrene) plastic paint remover

InactiveCN107236353APromote degradationHigh activityChemical paints/ink removersEmulsionLiquid state

The invention discloses an ABS (acrylonitrile butadiene styrene) plastic paint remover and belongs to the technical field of paint removal. A main micromolecule solvent, water and a cosolvent are stirred and mixed, a compound surfactant is added, the mixture is stirred and mixed at a high speed, a mixed emulsion is obtained, an activator, a fermentation product, a corrosion inhibitor, a thickening agent and a defoaming agent are added to the mixed emulsion, dispersed at a high speed and subjected to vacuum defoaming, and the ABS plastic paint remover is obtained. The fermentation product is prepared as follows: a soil suspension obtained by mixing soil at the roots of podocarpus macrophyllus and water is mixed with a liquid-state culture medium and then the mixture is subjected to shake cultivation, filtration and concentration. The ABS plastic paint remover has the benefits as follows: the ABS plastic paint remover has high paint removal efficiency and is small in volatility, large in paint removal amount, short in paint removal time and worth popularization and use.

Owner:杨帮燕

Paint remover for removing paint film on surface of tin-plated steel plate for food can and using method thereof

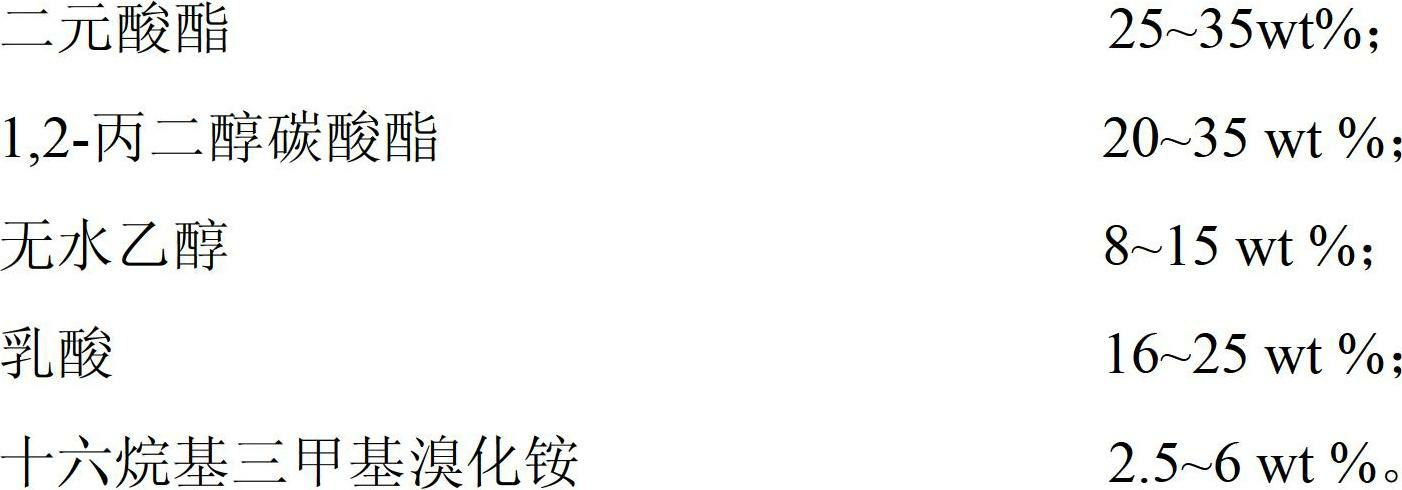

The invention relates to a paint remover for removing a paint film on the surface of a tin-plated steel plate for a food can and a using method thereof, wherein the paint remover is prepared from the following raw materials in percentage by weight: 25-35% of dibasic acid ester, 20-35% of 1, 2-propylene glycol carbonate, 8-15% of absolute ethyl alcohol, 16-25% of lactic acid and 2.5-6% of cetyl trimethyl ammonium bromide. The paint remover is prepared by a method comprising the following steps: firstly, burdening the raw materials of the paint remover according to the content thereof; adding the raw materials according to the sequence from solid to liquid respectively, then stirring for 5-15 minutes at room temperature, and sealing and reserving after mixing uniformly. The using method of the prepared paint remover for removing the paint film on the surface of the tin-plated steel plate for the food can comprises the following step of: immersing objects for removing the paint completely in the paint remover, wherein the using temperature of the paint remover is 25-80 DEG C, the best using temperature is 60-80 DEG C, and the immersing time is 1-15 minutes. The paint remover for removing the paint film on the surface of the tin-plated steel plate for the food can and the using method thereof provided by the invention have the characteristics of good environment-friendly performance, stable solvent components, paint removing efficiency and tiny metal corrosion performance.

Owner:WUHAN UNIV OF SCI & TECH

Environment-friendly metal recycling device

InactiveCN110976362ALow costReduce consumption costLiquid surface applicatorsMeasurement devicesProcess engineeringMetal recycling

The invention relates to the field of metal recycling, particularly relates to an environment-friendly metal recycling device and aims to solve a technical problem of providing the environment-friendly metal recycling device. The device comprises a supporting mechanism, H-shaped steel, a pre-cleaning mechanism, a control screen, a concave-convex surface detection mechanism, a smearing mechanism, awater pump and a scraping and cleaning integrated mechanism, wherein the H-shaped steel is placed on the top right side of the supporting mechanism, and the pre-cleaning mechanism is arranged on theright side of the top of the supporting mechanism. The device is advantaged in that whether the H-shaped steel is collided and generates a concave-convex phenomenon or not is automatically detected, automatic paint scraping and paint removing are achieved, a small amount of paint removing agent is adopted for paint removing in a matched mode, the paint removing agent cost consumption is greatly reduced, moreover, the manual workload is reduced, automatic paint removing detection is achieved, paint removing efficiency is high, and manual post-treatment is not needed.

Owner:臧全文

Laser cleaning device for aircraft skin

PendingCN108421798AAvoid the status quo of movingImprove cleaning efficiencyCleaning processes and apparatusSkin surfaceEngineering

The invention discloses a laser cleaning device for aircraft skin. The laser cleaning device comprises two parallel guide rail racks fixed on the ground, wherein a transverse moving mechanism capableof sliding in a length direction of the guide rail racks is arranged between the two guide rail racks; a longitudinal moving mechanism capable of sliding relative to the transverse moving mechanism isarranged on the transverse moving mechanism; a laser cleaning head is arranged on the longitudinal moving mechanism and connected with a laser generator by virtue of optical fibers; the transverse moving mechanism slides on the guide rail racks and the longitudinal moving mechanism is driven to move on the transverse moving mechanism, so that the laser cleaning head can cover the aircraft skin surface. The problems that the time consumption is high and the efficiency is low in a process of cleaning the aircraft skin by adopting handheld laser are solved.

Owner:彭州启光科技有限公司

Novel environment-friendly nontoxic paint remover and preparation method thereof

ActiveCN104804515AReduce volatilityHigh paint removal efficiencyChemical paints/ink removersEnvironmental resistanceAlcohol

The invention belongs to the technical field of paint removers, particularly to a novel environment-friendly nontoxic paint remover and a preparation method thereof. The paint remover comprises esters, high boiling point alcohol, an additive and the balance of water, wherein the volume fraction of the esters is 20-50%, the volume fraction of high boiling point alcohol is 10-50%, and the volume fractions of the esters and the high boiling point alcohol are not 50% at the same time. The paint remover uses the esters as main solvents, uses the high boiling point alcohol as a cosolvent, is environment-friendly, nontoxic, and high in depainting efficiency, has no corrosion on the base body, makes up the insufficiencies of similar paint removers, is suitable for common metals, curtain walls and part plastic base bodies, and meets requirements of people on environmental protection and requirements of factories on nontoxic product development.

Owner:GUANGDONG UNIV OF TECH

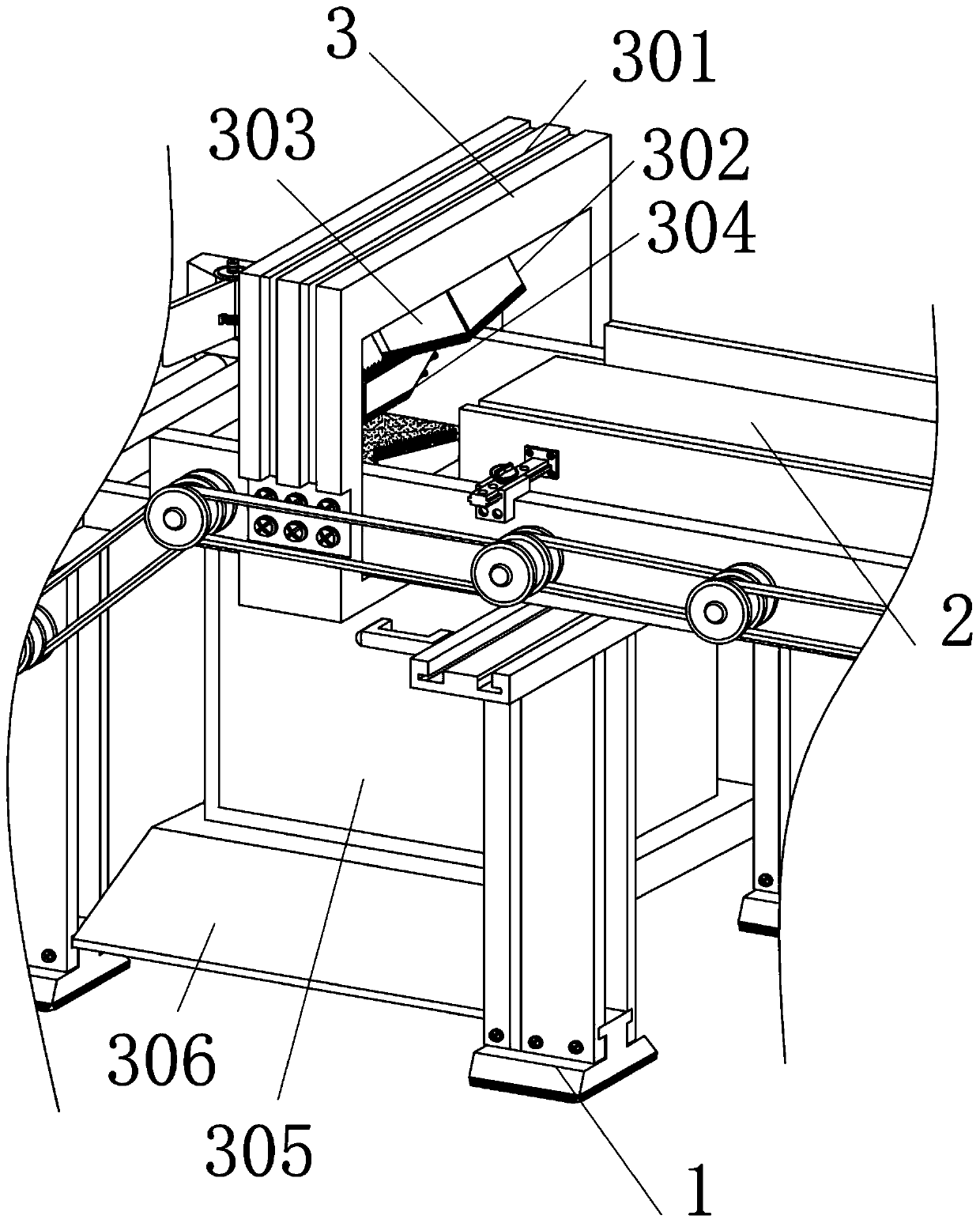

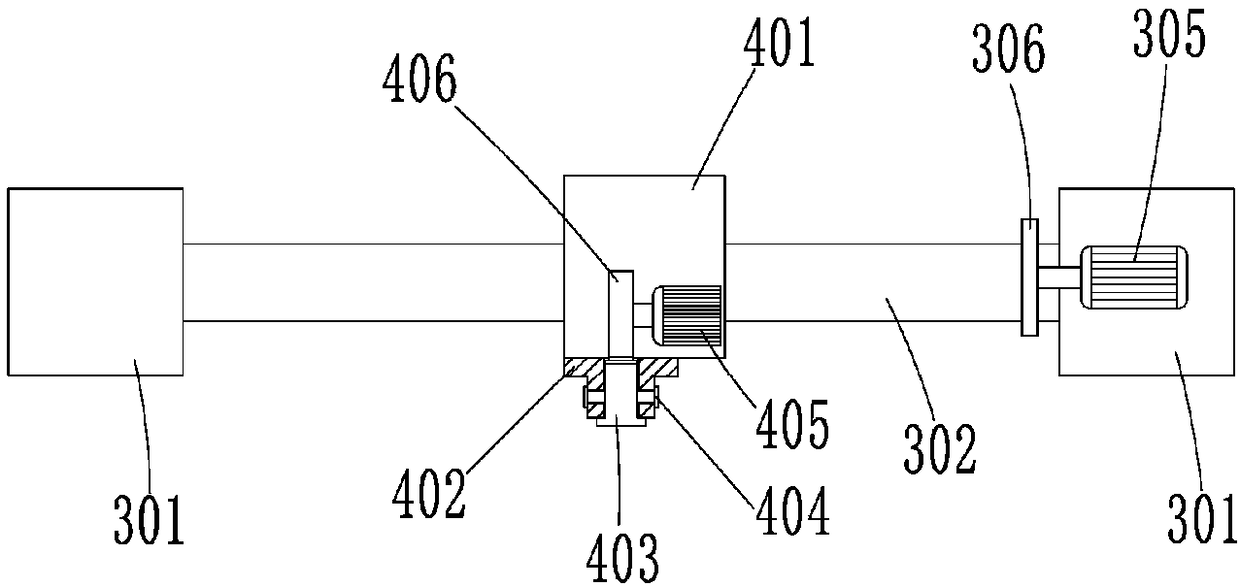

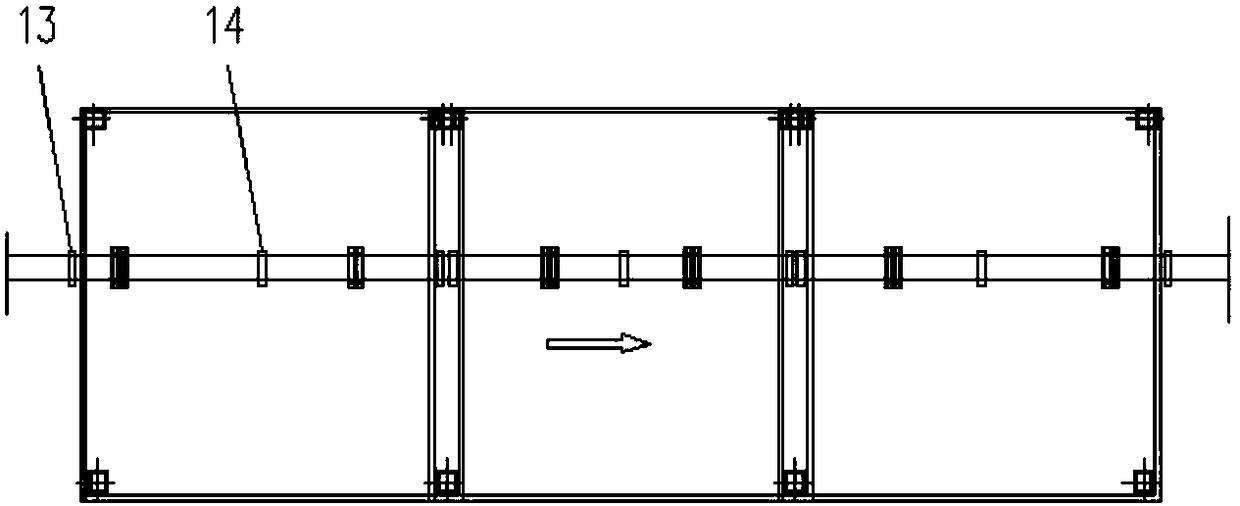

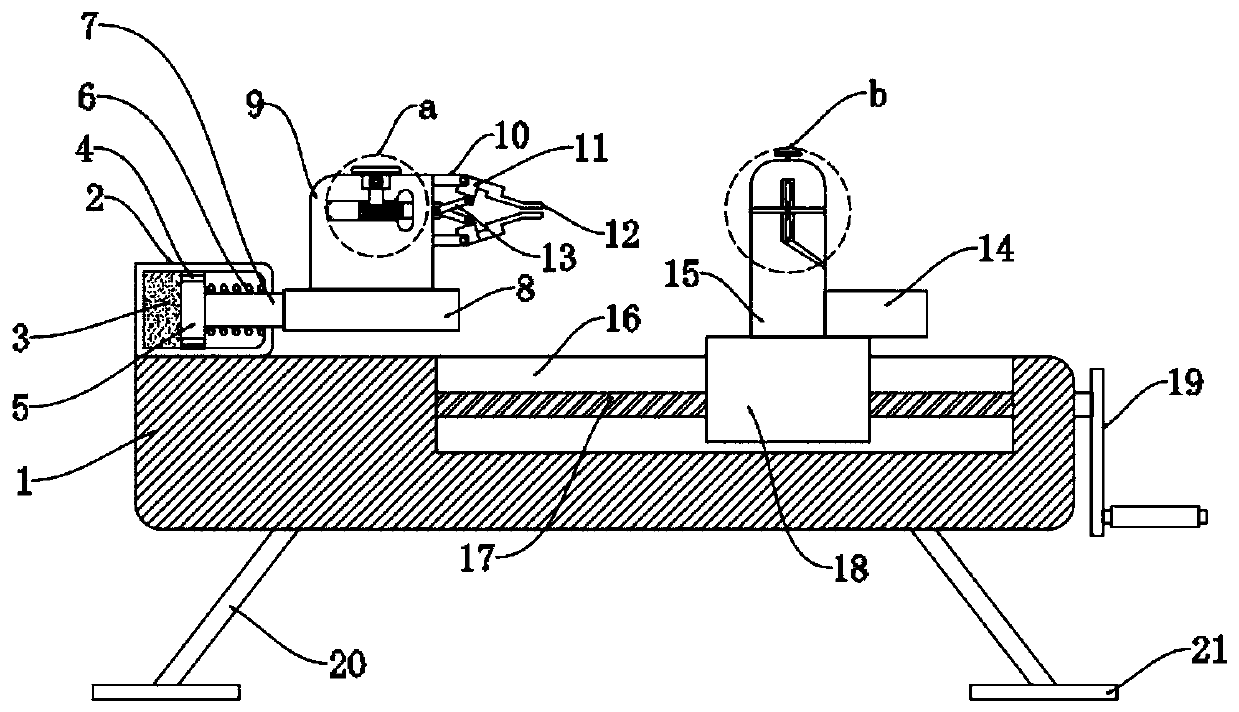

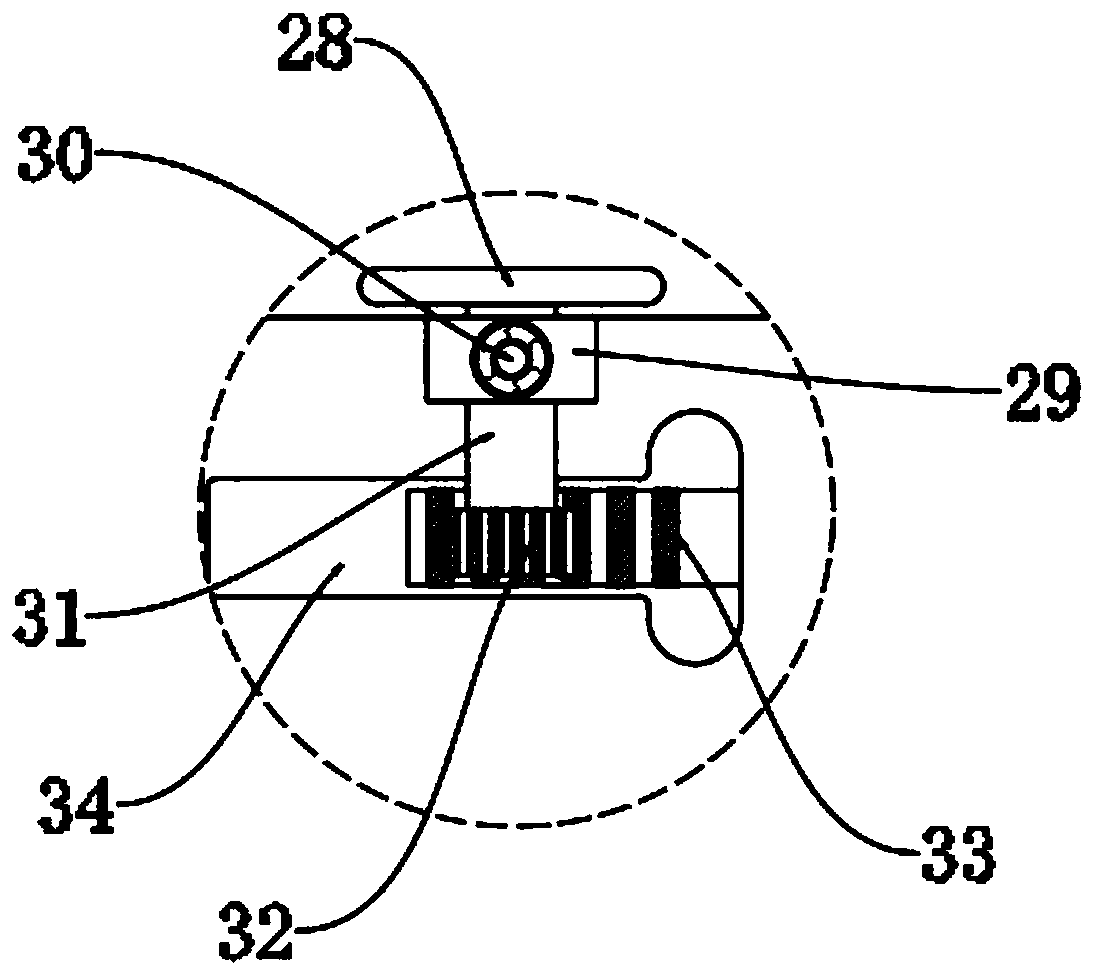

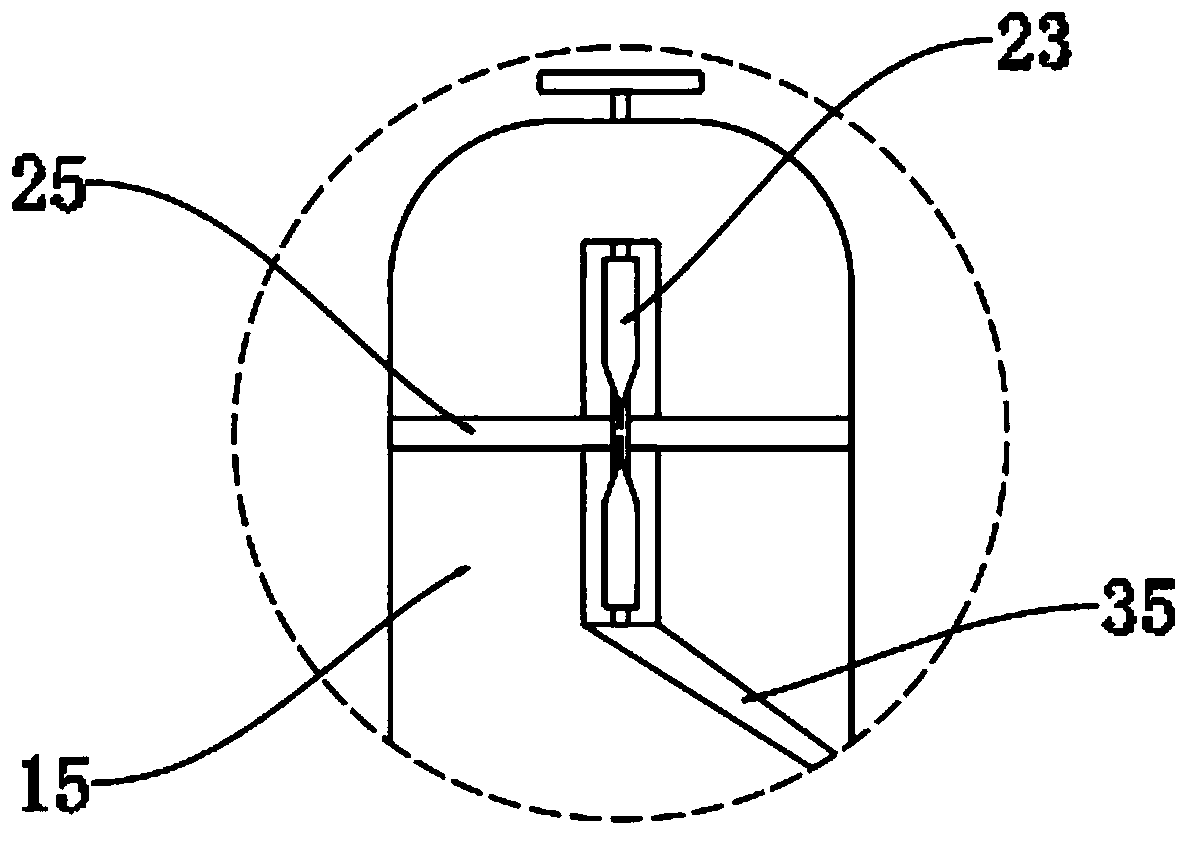

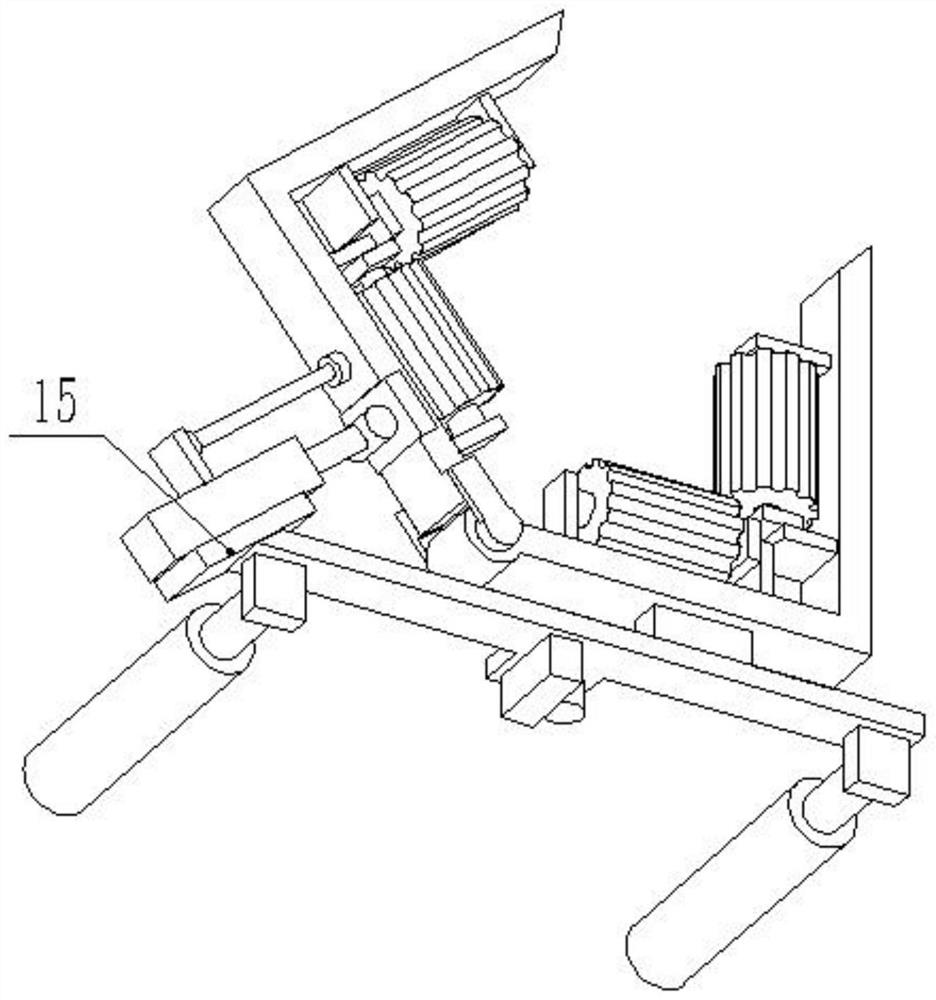

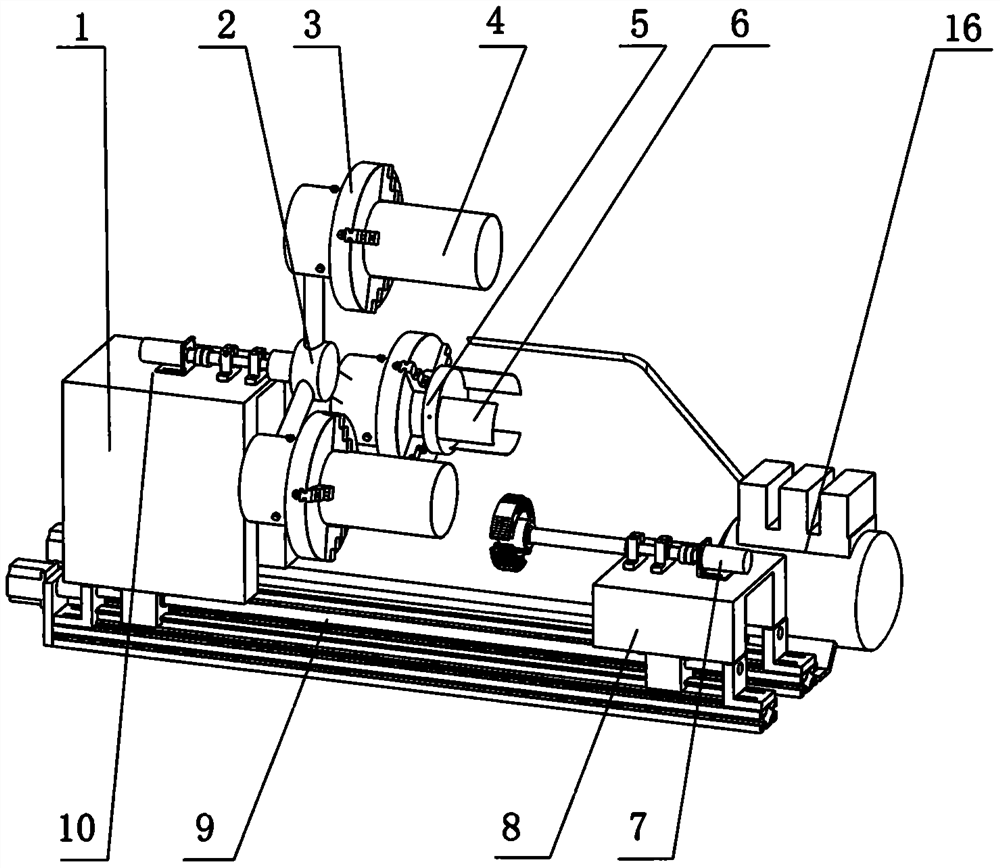

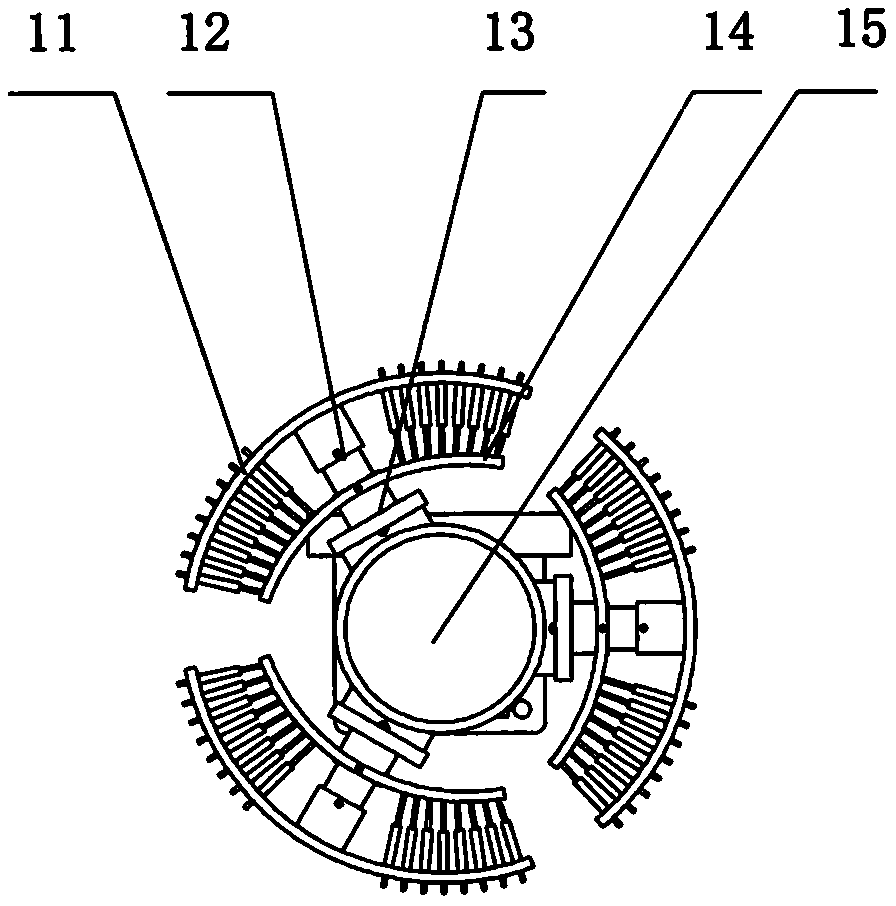

A metal hanger surface paint stripping equipment

ActiveCN106623277BEffective sheddingEliminate toughnessCleaning using liquidsControl systemResin coating

The invention provides a paint removing method and paint removing equipment for a surface of a metal hanging rack. Liquid-nitrogen soaking and metal particles are utilized to perform paint removal treatment on a paint resin coating on the surface of the metal hanging rack, so that the problem that paint removing effect is poor and environmental pollution is caused due to the fact that the metal hanging rack adopts an existing paint removing method is solved. The paint removing method comprises a liquid nitrogen soaking step and a multi-stage variable-frequency particle colliding step; the paint removing equipment comprises a ring-shaped rail, a self-propelling car, a liquid nitrogen slot, a metal particle impact bin and a control system; the ring-shaped rail is horizontally suspended above the liquid nitrogen slot and the metal particle impact bin; liquid nitrogen is contained in the liquid nitrogen slot; the self-propelling car is arranged on the ring-shaped rail, and can move along the ring-shaped rail; and the self-propelling car is equipped with a clamping mechanism used for clamping the metal hanging rack, a hoisting mechanism used for controlling the clamping mechanism to move up and down, and a drive mechanism used for driving the metal hanging rack to rotate along the longitudinal central shaft thereof.

Owner:武汉大润生态环境科技发展有限公司

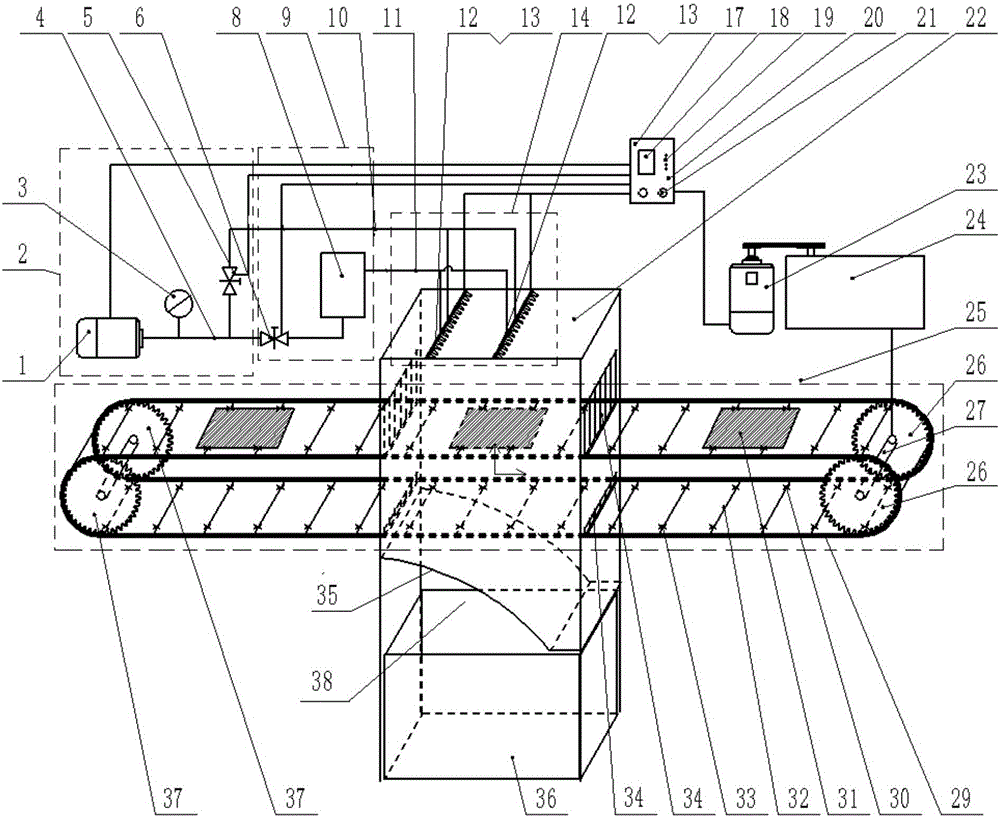

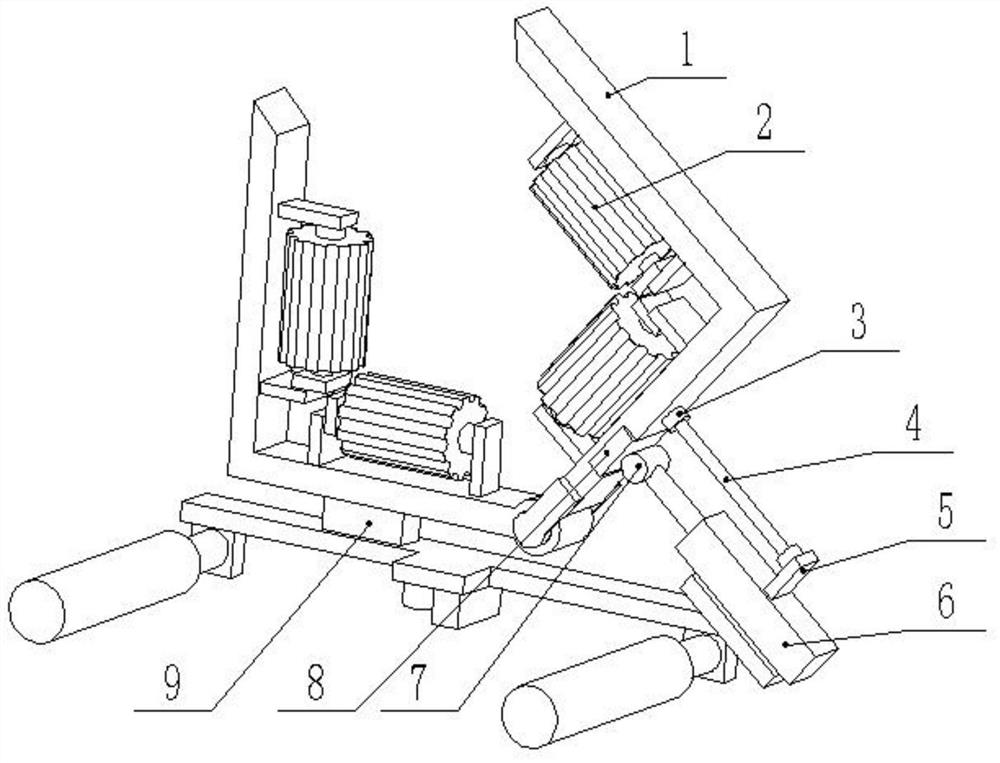

Sand blasting paint removing device for plastic bumper of scraped car

ActiveCN106079155AThe operation process is simpleHigh paint removal efficiencyPlastic recyclingElectrical controlLacquer

The invention discloses a sand blasting paint removing device for a plastic bumper of a scraped car. The sand blasting paint removing device comprises a high pressure air generating module, a sand mixing module, a plastic injection module, a workpiece loading and transmission module and an electric control module, wherein the plastic injection module comprises a hollow main box and a plurality of spray gun groups mounted at the top of the main box; spray gun group swinging mechanisms used for swinging the spray gun groups are arranged on the spray gun groups; the workpiece loading and transmission module horizontally penetrates through the main box, is positioned below the spray gun groups, and comprises at least two groups of chain transmission mechanisms which are parallel and are arranged at the same height; driving sprockets on the same side are connected through a rigid shaft; the rigid shaft drives the driving sprockets to simultaneously rotate under the driving of an external power source; and a plurality of clamping parts used for clamping workpieces are uniformly arranged between adjacent chains. According to the sand blasting paint removing device, the operation process is simple, the paint removing efficiency is high, the effect is good, the labor intensity is relatively low, the environmental pollution is less, and the device is applicable to paint removing of large-batch bumpers and other waste structural parts.

Owner:WUHAN UNIV OF TECH

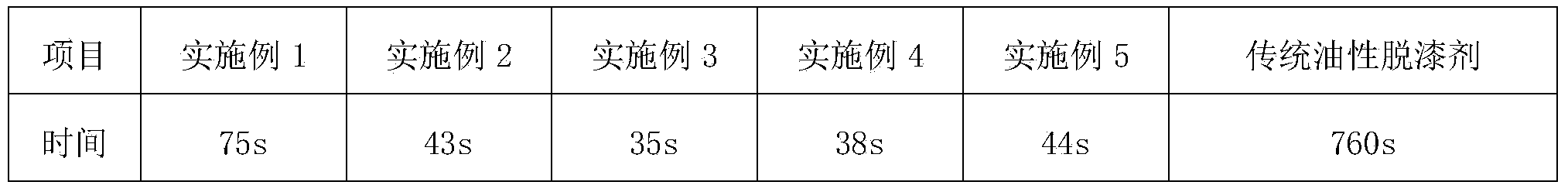

Metal paint remover and preparation method thereof

InactiveCN103450734ANo toxicityHigh paint removal efficiencyChemical paints/ink removersParaffin waxDichloromethane

The invention discloses a metal paint remover and a preparation method thereof. The paint remover comprises the following components in parts by weight: 50-60 parts of formic acid, 10-20 parts of ethyl acetate, 3-8 parts of methanol, 10-20 parts of dichloromethane, 30-50 parts of thinner, 2-6 parts of ethanolamine, 3-8 parts of sodium alkyl benzene sulfonate, 1-5 parts of polyglycerol fatty acid ester, 2-6 parts of butylcellosolve, 1-5 parts of paraffin and 2-7 parts of organic glass powder. The preparation method comprises the following steps: heating to melt paraffin, slowly adding dichloromethane, stirring to completely dissolve the paraffin, adding the other components, and stirring uniformly at the speed of 1500-1800 rpm. The test indicates that the paint removal time of the metal paint remover disclosed by the invention is within 75 seconds, and the paint removal effect can be achieved within 35 seconds at the soonest; and the components of the paint remover are cheap and accessible, and therefore, the metal paint remover has high application value.

Owner:WUJIANG LONGXU METAL PROD

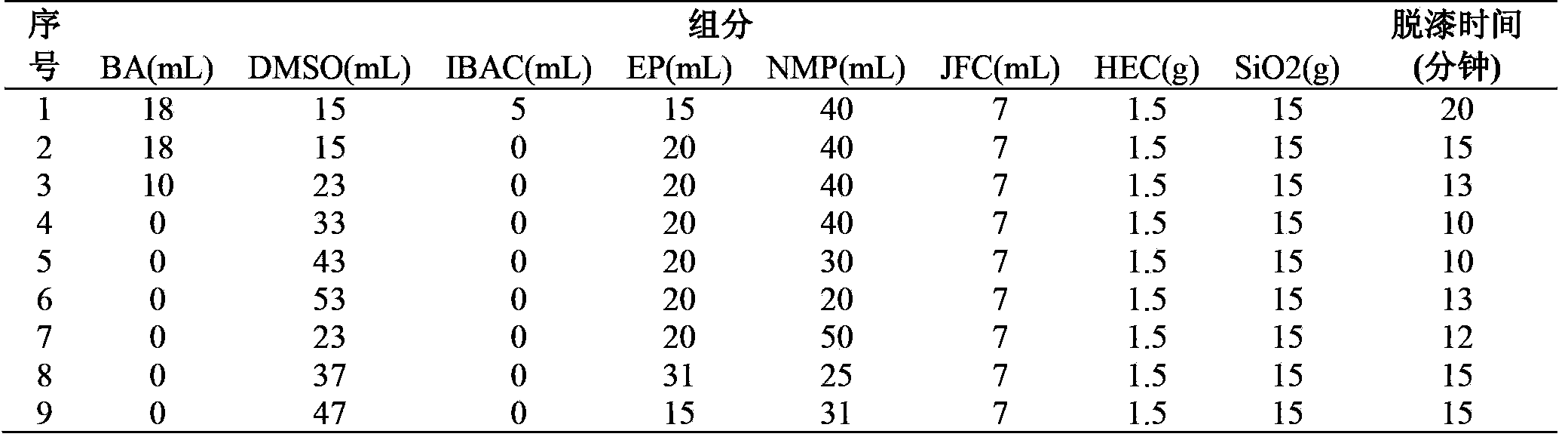

Paint remover and paint removing method thereof

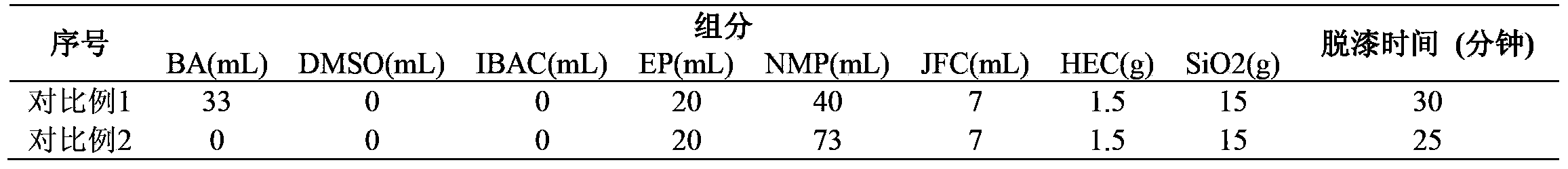

ActiveCN104231713ARemove won'tDoes not affect substrateChemical paints/ink removersLacquerN-Methyl-2-pyrrolidone

The invention provides a paint remover which comprises the following components in percentage by volume: 15-73% of dimethyl sulfoxide, 20-50% of N-methyl pyrrolidone, an organic cosolvent as well as a thickening agent and a thixotropic agent for reducing the flowability of the paint remover. The paint remover can be used for removing conformal paint which is prepared from alkyd resin materials on a PCB without influencing a substrate of the PCB, cannot remove green oil, does not need to be heated and is high in paint removing efficiency and friendly to the environment.

Owner:SIEMENS NUMERICAL CONTROL

Paint remover and preparation method thereof

The invention provides a paint remover. The paint remover is prepared from, by weight, 35%-75% of main solvent, 5%-25% of co-solvent, 5%-15% of an activating agent, 8%-15% of a volatilization inhibitor, 1%-5% of a corrosion inhibitor and 0.1%-1.2% of a surfactant. The invention further provides a preparation method of the paint remover, that is to say, the materials are stirred and mixed to be uniform according to the weight proportion. The paint remover has the advantages of being high in paint removing efficiency, low in volatilization and smell, non-inflammable, little in harm to environment and the like, can be stably stored for a long term and is safe, mild and free of damage to workpieces. The preparation method is very simple, easy to control and operate and convenient to use.

Owner:ZHONGSHAN HUAGUANG CHEM

Paint stripping device for flat or round enameled wire

ActiveCN111416308ASimple structureEasy to operateLine/current collector detailsApparatus for removing/armouring cablesLacquerEngineering

The invention discloses a paint stripping device for a flat or circular enameled wire. The device comprises a base; a fixed table is arranged above the base; the fixed table is fixedly connected withthe base through a buffer mechanism; the upper end of the fixed table is fixedly connected with a mounting plate; the side wall of the mounting plate is fixedly connected with two transverse plates; rectangular blocks are rotationally connected to the ends, away from the mounting plate, of the two transverse plates; the side walls of the rectangular blocks are fixedly connected with clamping plates used for clamping an enameled wire; the side walls of the rectangular blocks are rotatably connected with connecting rods; the side wall of the mounting plate is provided with a pushing device usedfor pushing the connecting rods; a sliding groove is formed in the upper end of the base; and a first threaded rod is arranged on the side wall of the base in a penetrating mode. The device of the invention has the advantages of simple structure, convenience in operation, low cost, adjustable peeling depth, good paint peeling effect and high paint removing efficiency. According to the device, peeled sheathes fall into a storage box through an inclined groove, environmental pollution caused by the splashing of the lacquer sheathes is avoided, and collection is facilitated.

Owner:安徽精隆新材料有限责任公司

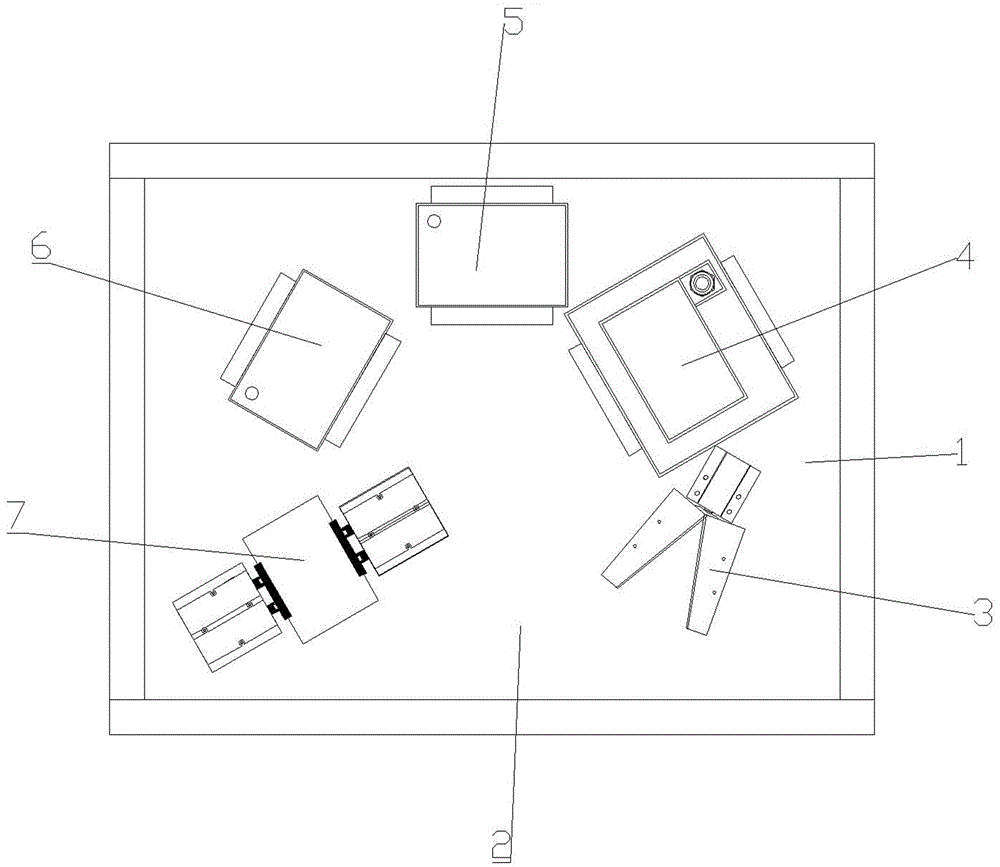

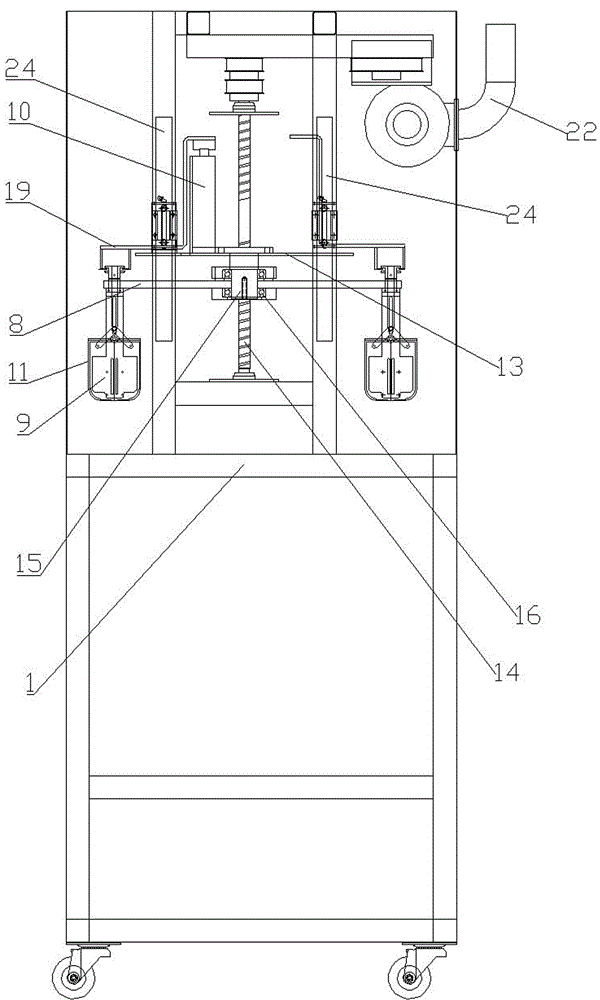

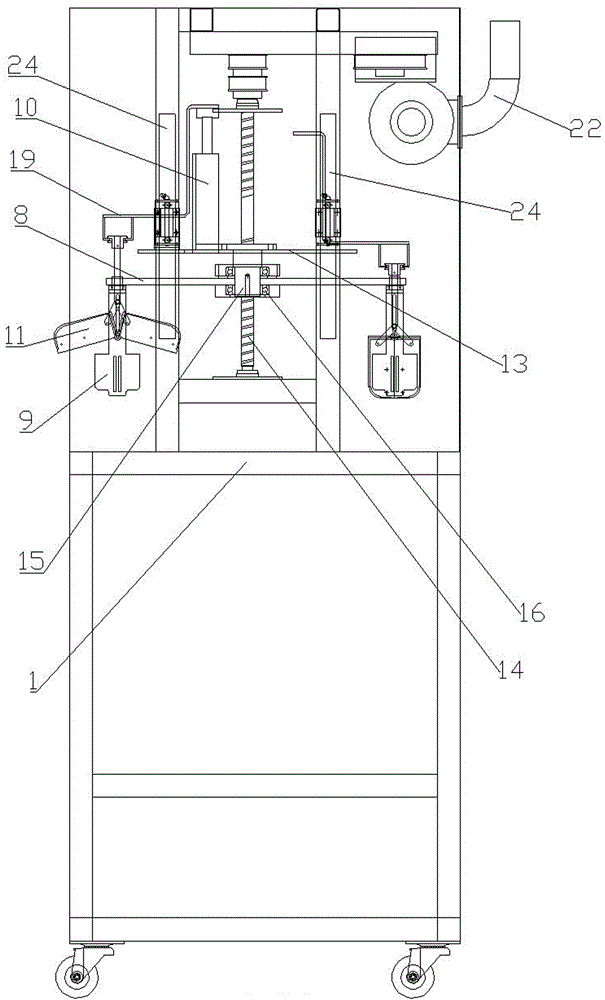

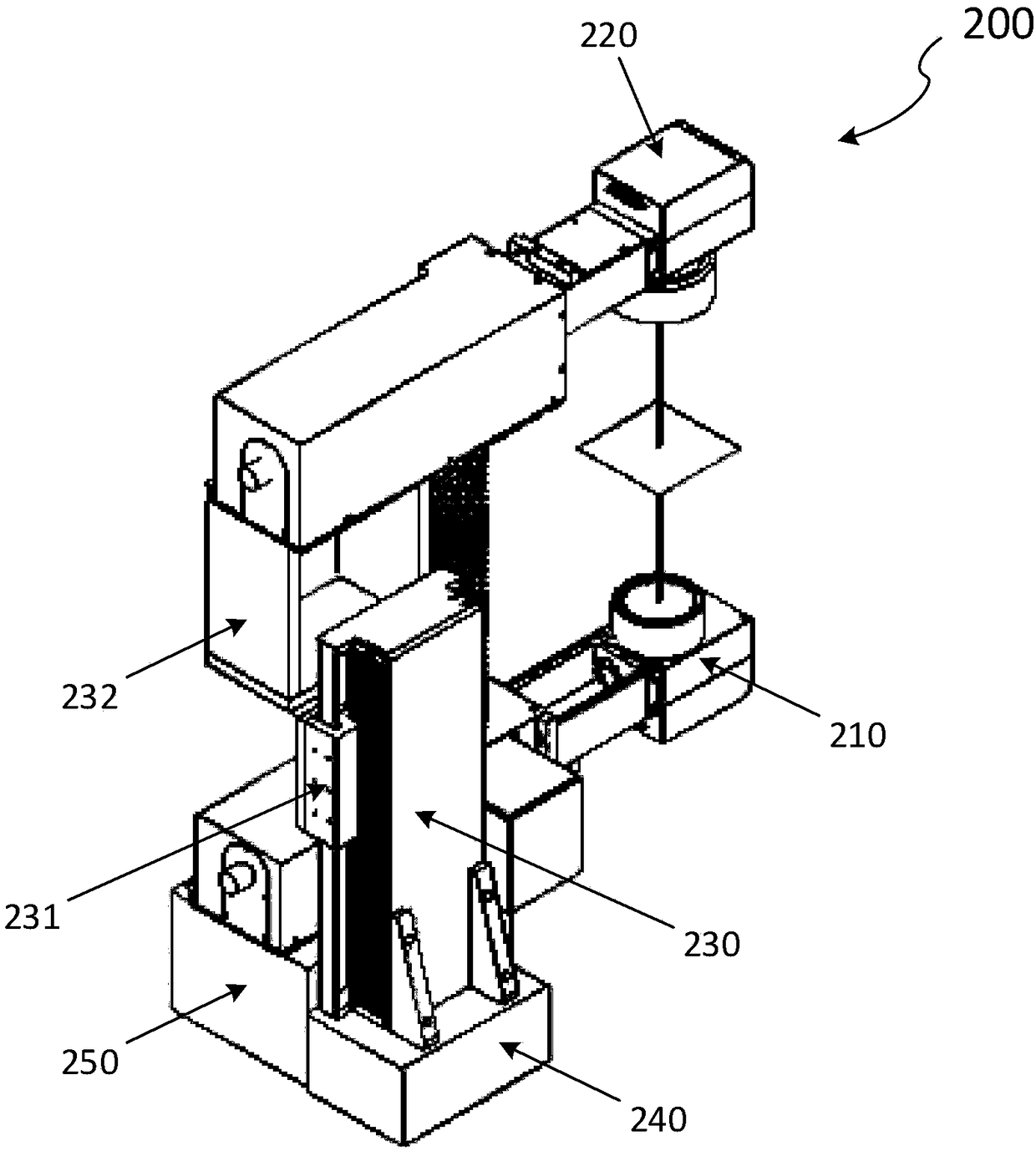

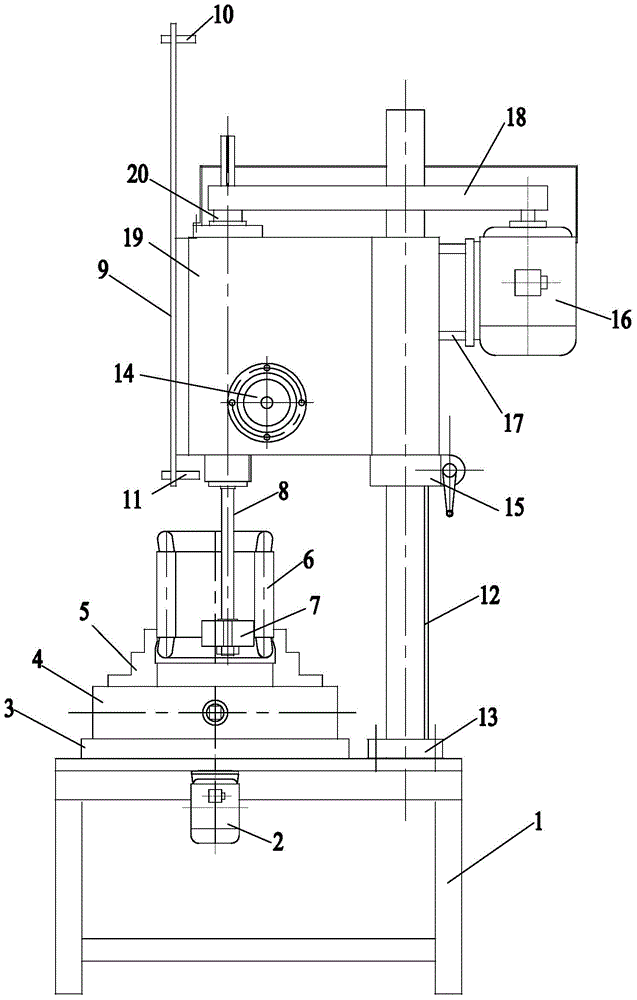

Automatic paint removing machine

InactiveCN106208570ACompact structureReduce volumeManufacturing dynamo-electric machinesCoils manufactureLacquerEngineering

The invention discloses an automatic paint removing machine. The automatic paint removing machine comprises a machine table and an automatic paint removing assembly which is arranged on the machine table, wherein a loading-discharging region is also arranged on the machine table; the mechanisms in the loading-discharging region, and the automatic paint removing assembly are circumferentially arranged around the center of the machine table in sequence; a rotary plate is arranged above the automatic paint removing assembly; at least one suspension frame used for suspending workpieces is arranged on the bottom surface of the rotary plate; the suspension frames are covered with protection boxes; when the suspension frame rotates to a position above one mechanism in the automatic paint removing assembly, a driving assembly pushes the suspension frame to move downwardly until the height of the suspension frame is matched with the mechanism; and when the suspension frame rotates to the loading-discharging region, the corresponding protection box is opened automatically. According to the automatic paint removing machine, the automatic paint removing assembly is circumferentially arranged on the machine table; the workpieces are conveyed to the respective mechanisms in the automatic paint removing assembly in sequence through the rotary plate to be processed; and in addition, the automatic paint removing machine is small in size and high in paint removing efficiency.

Owner:深圳市慈源智能设备有限公司

Nano-aluminium powder modified environment-friendly aqueous paint remover and preparation method thereof

InactiveCN106543796AImprove stabilityImprove antioxidant capacityChemical paints/ink removersBond interfaceMicrocrystalline wax

The invention discloses a nano-aluminium powder modified environment-friendly aqueous paint remover, which is prepared from the following raw materials in parts by weight: 1.2 to 1.4 parts of nano-montmorillonite, 1.5 to 2 parts of penetrating agent T, 42 to 46 parts of benzyl alcohol, 11 to 12 parts of acetone, 10 to 11 parts of hydrogen peroxide, 3 to 3.5 parts of methylcellulose, 2 to 2.4 parts of urotropin, 1.3 to 1.5 parts of dodecyl benzene sulfonate, 1.6 to 1.9 parts of micro-porus starch, 2.2 to 2.5 parts of microcrystalline wax, 0.8 to 1 part of tetrabutyl titanate, a proper amount of ammonium hydroxide, a proper amount of ethyl alcohol, 50 to 55 parts of water, 0.8 to 1 part of sodium sulfite, 0.4 to 0.6 part of nano-aluminium powder and 0.6 to 0.8 part of oxalic acid. Through using the sodium sulfite, the nano-aluminium powder and the oxalic acid, the aqueous paint remover provided by the invention can permeate to a paint film bonding interface, foam, promote paint film stripping and improve paint removing efficiency.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

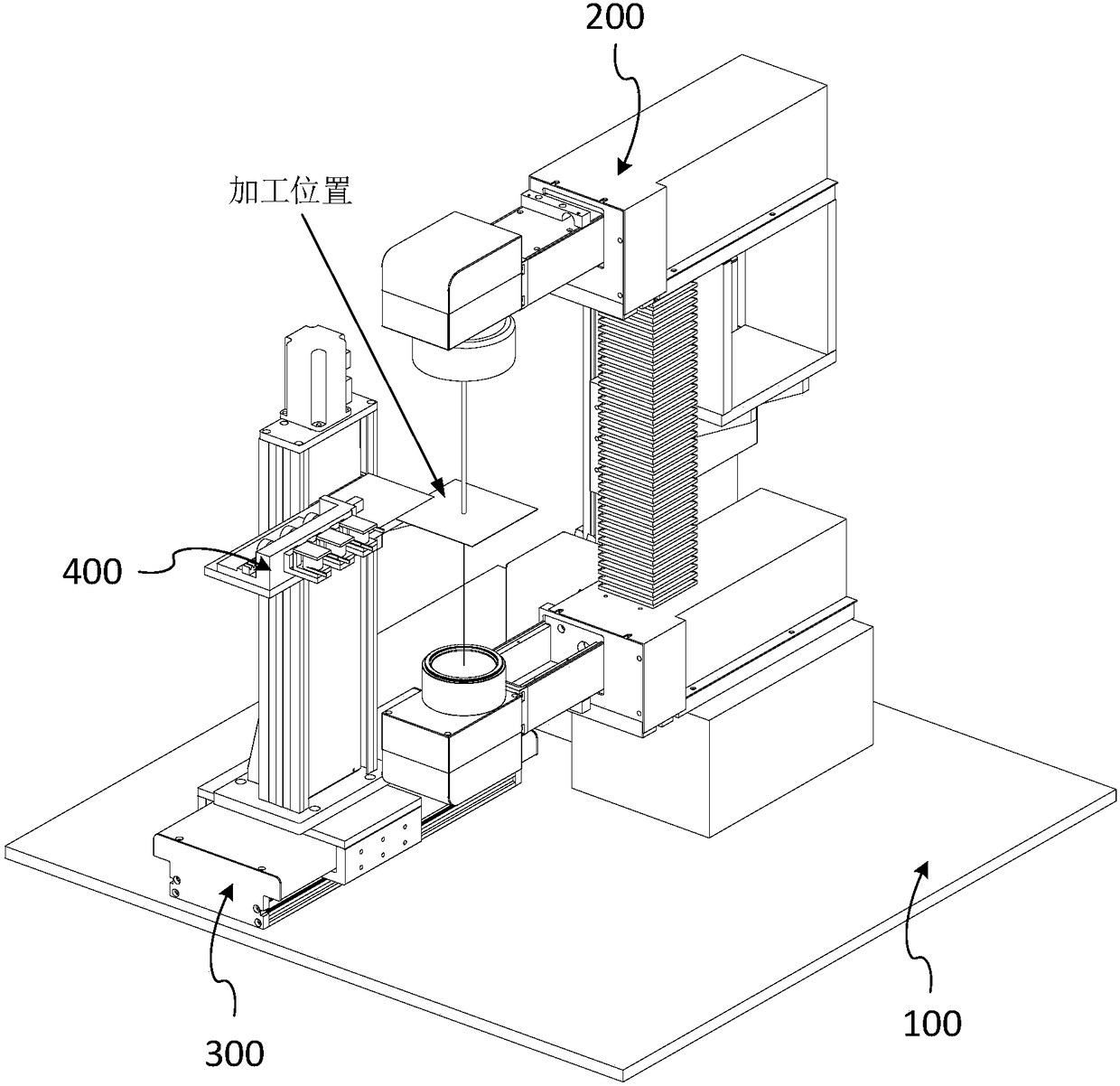

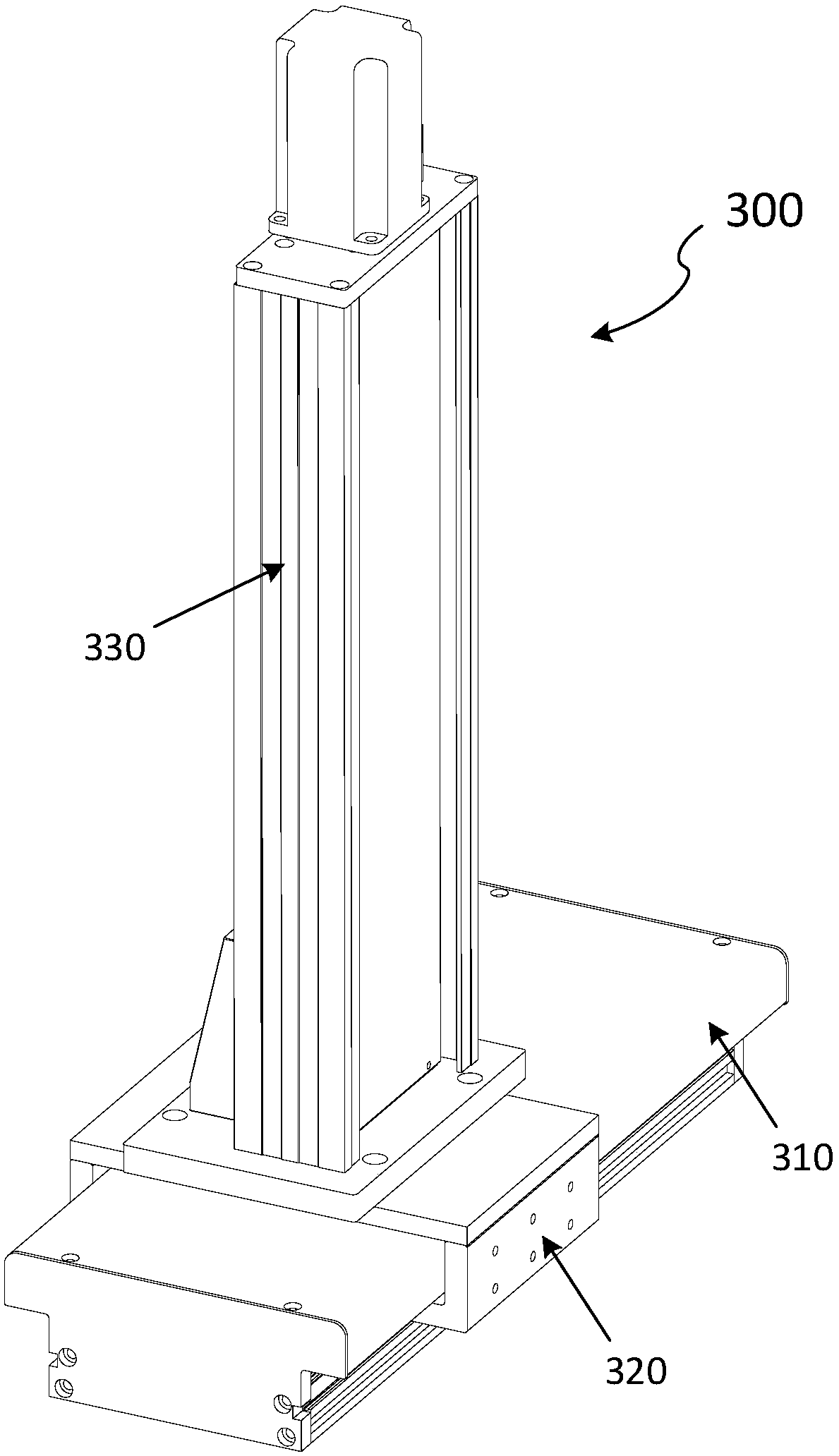

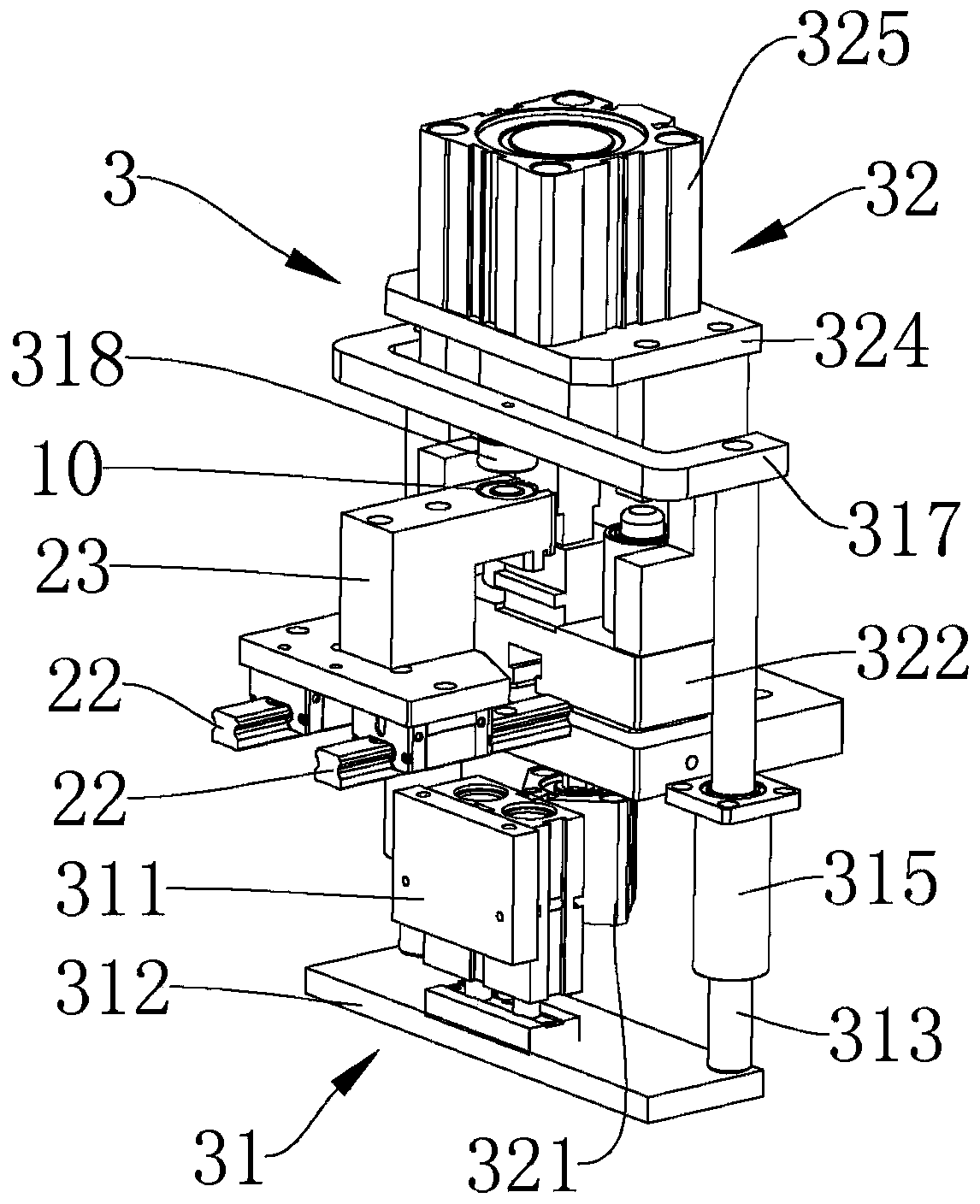

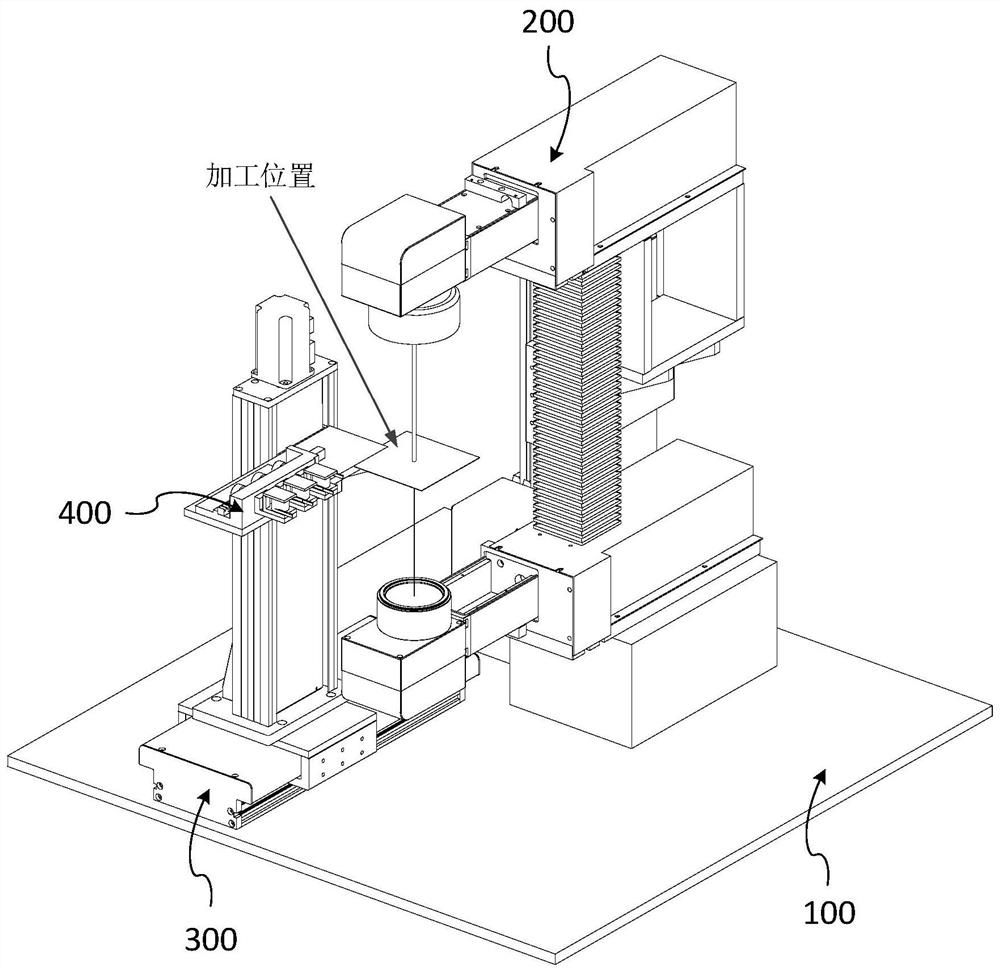

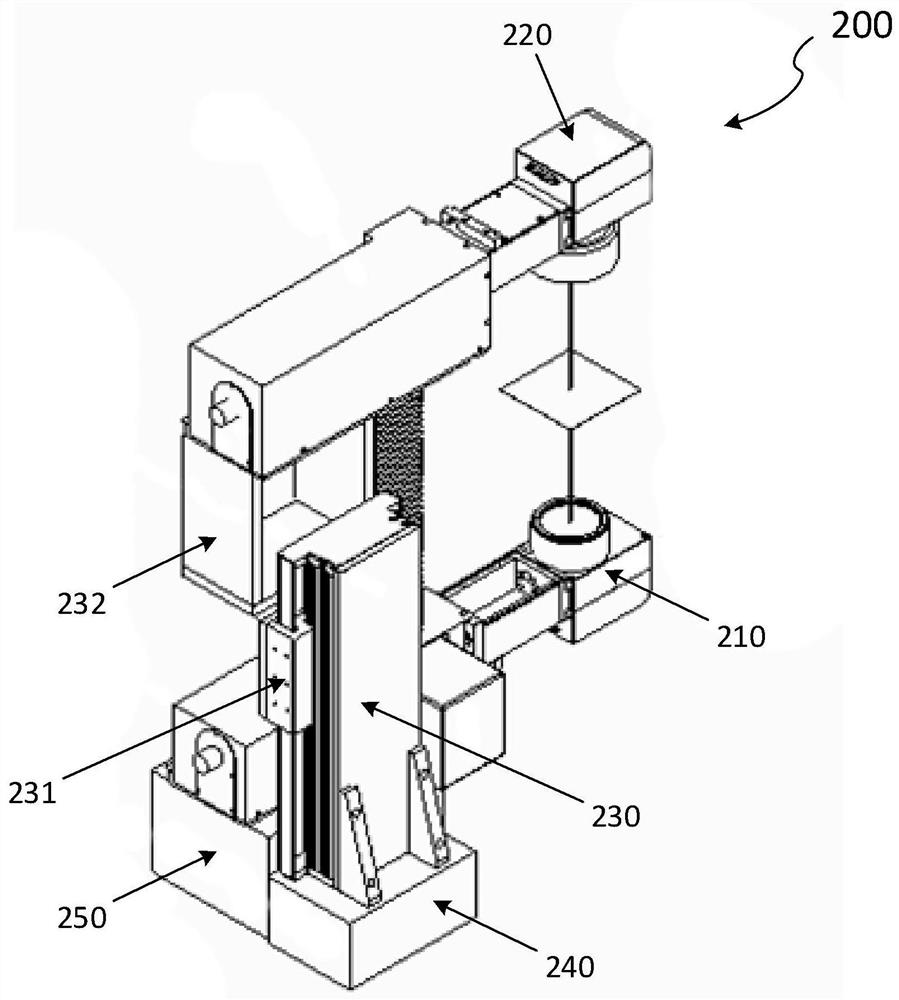

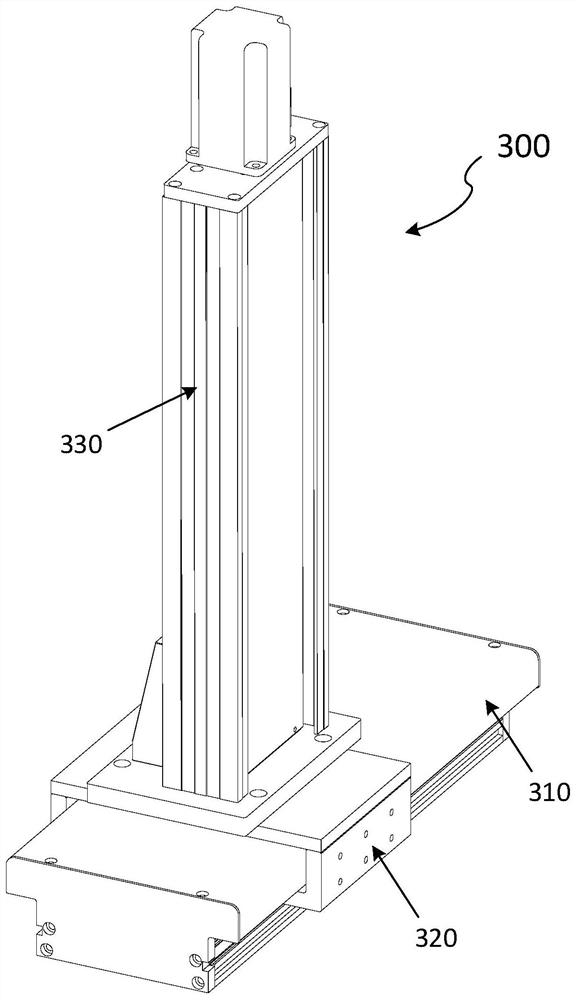

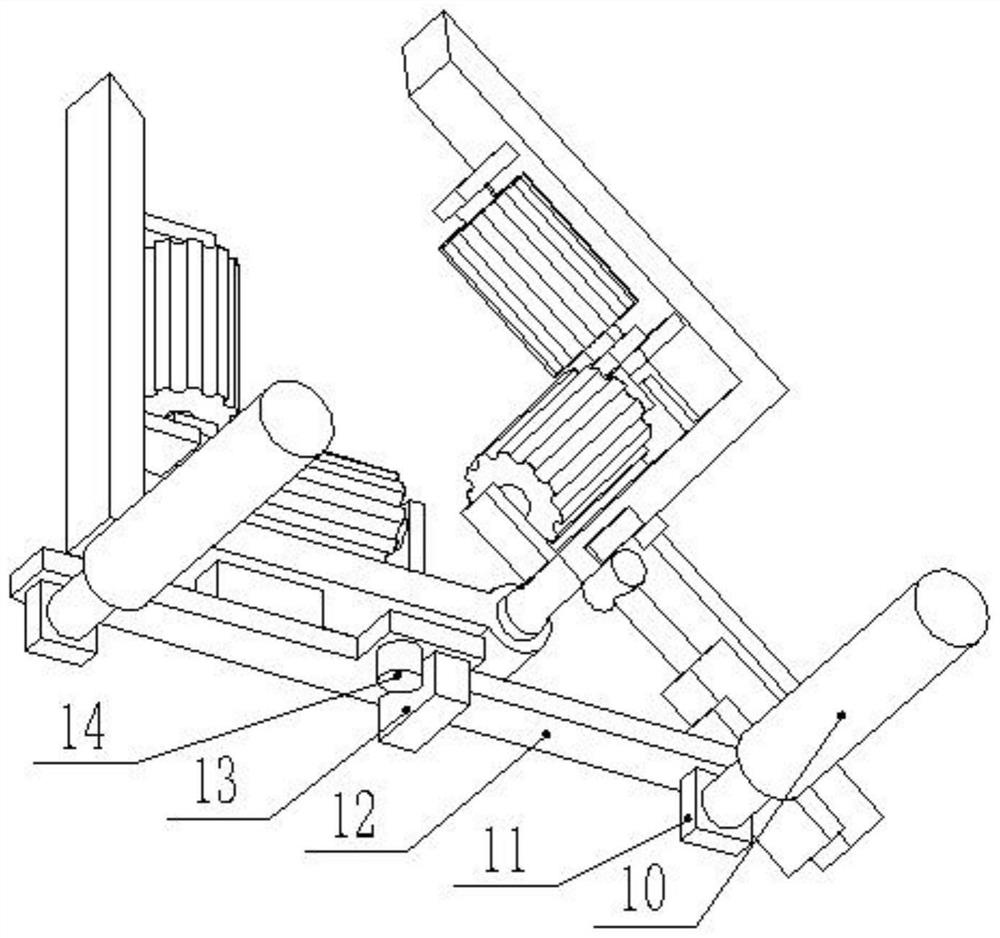

Laser coating removal equipment and laser coating removal method

ActiveCN109420847ARealize automatic paint removalEasy to operateLaser beam welding apparatusLaser processingLaser coating

The invention belongs to the technical field of laser processing, specifically relates to laser coating removal equipment and a laser coating removal method; the laser coating removal equipment comprises an installing base plate, a laser coating removal device, a material transporting mechanism and a clamp assembly, wherein the laser coating removal device and the material transporting mechanism are installed on the installing base plate in parallel; the clamp assembly is connected with the material transporting mechanism by a vertical sliding base on the material transporting mechanism; the clamp assembly is used for clamping inductance to be removed of coating; and the material transporting mechanism is used for driving the clamp assembly to move. The scheme provided by the invention canrealize full-automatic coating removal of an inductance pin; the whole process is automatic; the operation is convenient; and the coating removal efficiency is high.

Owner:HANS LASER TECH IND GRP CO LTD

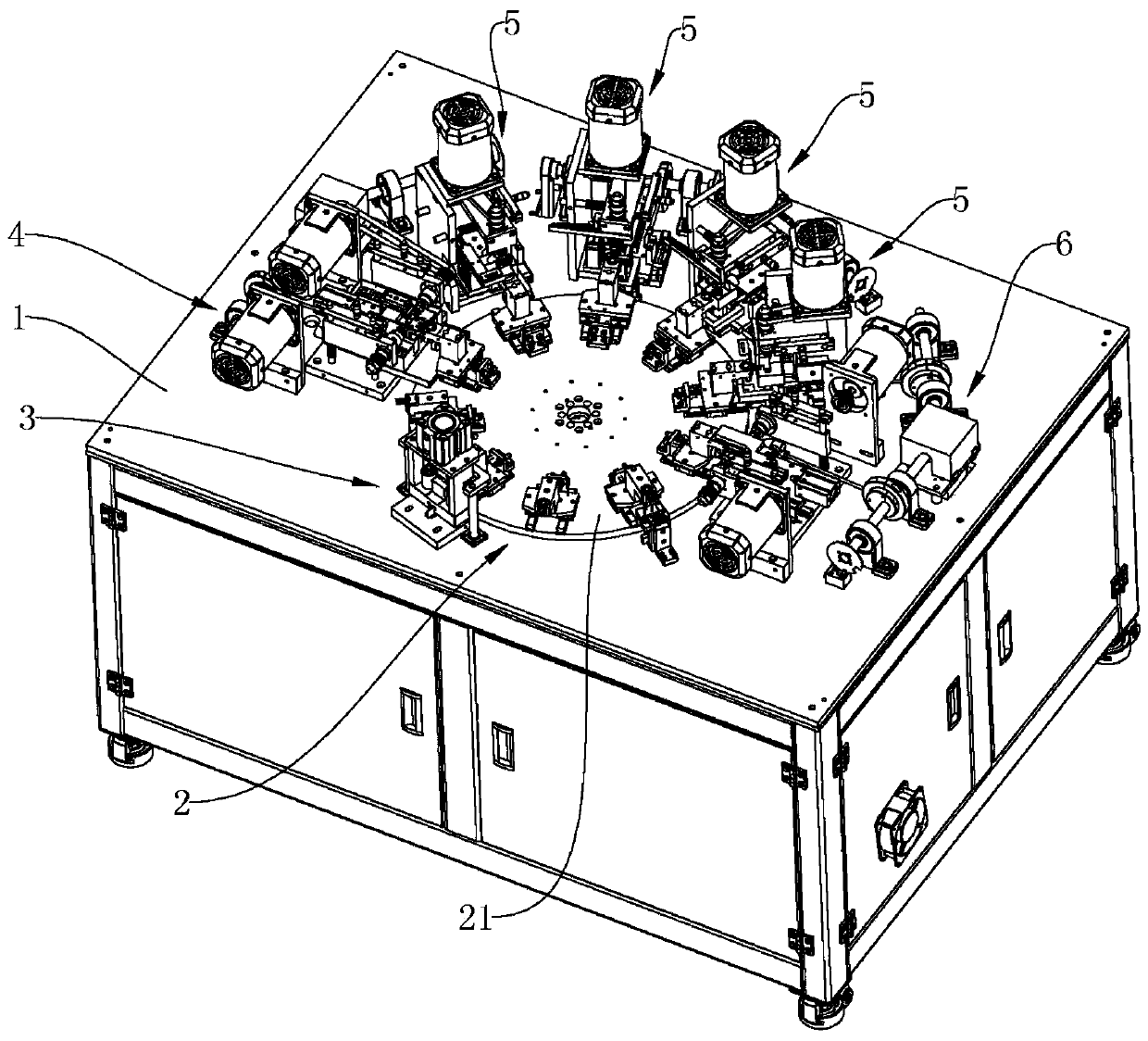

Full-automatic electromagnetic coil terminal paint removing machine

InactiveCN110911154ARealize automatic bendingRealize functionCoils manufactureStructural engineeringMechanical engineering

The invention discloses a full-automatic electromagnetic coil terminal paint removing machine. The full-automatic electromagnetic coil terminal paint removing machine includes a machine frame, a turntable device which is arranged on the rack and is used for transferring the electromagnetic coil, bending devices which are sequentially arranged along the moving direction of the turntable device andare used for bending terminals of the electromagnetic coil, a front surface paint removing device which is used for removing paint on the front surface of the electromagnetic coil terminal, four sidesurface paint removing devices which are used for removing paint on the side surfaces of the electromagnetic coil terminal, and the back surface paint removing device is used for removing paint on theback surface of the electromagnetic coil terminal. The rotary disc device comprises a rotary disc with the axis rotationally connected to the rack. According to the electromagnetic coil terminal paint removing machine, the bending device, the front surface paint removing device, the four side surface paint removing devices and the back surface paint removing device are adopted, so that the functions of automatically bending and depainting terminals of electromagnetic coils are realized, the depainting efficiency is high, and the depainting quality is stable and reliable.

Owner:东莞沛波电子有限公司

Waterborne paint stripper

The invention provides a waterborne paint stripper and belongs to the technical field of paint. The waterborne paint stripper is prepared from the following raw materials in parts by weight: 30-50 parts of propylene carbonate, 5-15 parts of pyrrolidone, 3-8 parts of sodium hydroxide, 2.5-4 parts of potassium permanganate, 0.5-1.5 parts of metasilicate, 0.8-1 part of sodium dodecylbenzenesulfonateand 0.01-0.1 parts of sodium citrate. The paint stripper has high paint stripping efficiency, is corrosion-free to a substrate and low in volatility, can effectively strip various organic coatings, such as epoxy resin coatings, polyurethane resin coatings, organic silicone resin coatings, polyester coatings and the like. The paint stripper reduces use of harmful organic substances and is more environmentally friendly and safer.

Owner:QINGDAO SAIZE NETWORK TECH CO LTD

Regenerated aluminum pre-treatment technique and regenerated aluminum treatment technique

The invention provides a regenerated aluminum pre-treatment technique and a regenerated aluminum treatment technique and relates to the technical field of aluminum alloys. According to the regenerated aluminum pre-treatment technique, discarded zip-top cans are broken into strip-shaped aluminum strips; the aluminum strips are separated sequentially through air separation equipment and magnetic separation equipment, then heated till the temperature is 80-120 DEG C and subjected to curlating; and while being hot, the aluminum strips are added in a first mixing solution of phenylcarbinol, acetic acid and turpentine and stirred for 8-15 min, the volume ratio of the phenylcarbinol to the acetic acid to the turpentine is (3-8):(1-4):(1-3), then the aluminum strips are taken out, placed into a second mixing solution of absolute ethyl alcohol and ethyl acetate and stirred for 5-10 min, the volume ratios of the absolute ethyl alcohol to the ethyl acetate is (4-10):(1-3), and the aluminum strips are dried for 15-20 min under the environment with the temperature being 110-125 DEG C after being washed. Paint layers of the surfaces of the zip-top cans and corrosion prevention thin films of the inner walls of the zip-top cans can be eliminated correspondingly, eliminating efficiency is high, environmental friendliness is achieved, and secondary pollution is avoided. The regenerated aluminum treatment technique comprising the regenerated aluminum pre-treatment technique is simple in technological operation, and the quality of a prepared finished product is high.

Owner:重庆顺博铝合金股份有限公司

Efficient environment-friendly paint remover

InactiveCN103387763AHigh paint removal efficiencyNo pollution in the processChemical paints/ink removersMethyl cellulosePhosphoric acid

The invention relates to an efficient environment-friendly paint remover, and belongs to the technical field of chemical engineering. The paint remover comprises dichloromethane, cyclohexanol ethanolamine, paraffin, methyl cellulose, ethene resin, phosphoric acid and water, which are mixed according to a certain weight percentage. The paint remover of the present invention has advantages of high paint removal efficiency, no toxicity or pollution, little corrosion on a substrate, low volatility, convenience for usage and no trace, and is an ideal paint removal product.

Owner:赵强

Paint removing agent

InactiveCN107245267AImprove performanceReduce playabilityChemical paints/ink removersBenzoic acidFiber

The present invention discloses a paint removing agent, which comprises, by weight, 1-5 parts of dichlorine, 2-6 parts of formic acid, 1-5 parts of carbon tetrachloride, 1-6 parts of ethyl acetate, 5-25 parts of methyl cellulose, 5-11 parts of benzyl alcohol, 3-7 parts of tartaric acid, 3-10 parts of alkylphenol polyoxyethylene ether, 5-11 parts of ethylene glycol anisole, 8-15 parts of methyltriazole, 8-15 parts of mineral oil, 6-12 parts of trichloroacetic acid, 9-18 parts of benzoic acid, 1-8 parts of trichlorotrifluoroethane, 1-7 parts of methyl benzotriazole, 1-5 parts of potassium permanganate, and 1-7 parts of triacetate fiber. According to the present invention, the paint removing agent uses potassium permanganate, such that a certain oxidation effect is provided, and the paint removing efficiency can be improved; carbon tetrachloride, dichloromethane and ethyl acetate are used as the mixed solvent, such that the paint cured on the surface of the substrate can be well dissolved and stripped; and by adding mineral oil, the performance of the paint removing agent can be further improved, the volatility can be reduced, and the paint film on the surface can be well dissolved.

Owner:RUGAO CHANGJIANG SCI & TECHCAL IND CO LTD

Laser paint removal equipment and laser paint removal method

ActiveCN109420847BRealize automatic paint removalEasy to operateLaser beam welding apparatusLaser processingMaterial transport

The embodiment of the present invention belongs to the technical field of laser processing, and relates to a laser paint removal equipment and a laser paint removal method. The paint removal device and the material delivery mechanism are installed side by side on the installation base plate, and the clamp assembly is connected with the material delivery mechanism through a vertical sliding seat on the material delivery mechanism; the clamp assembly is used for clamping For the inductance to be painted, the transport mechanism is used to drive the clamp assembly to move. According to the solution provided by the embodiment of the present invention, it is possible to realize automatic paint removal for the pins of the inductor, the whole process is automatic, the operation is convenient, and the paint removal efficiency is high.

Owner:HANS LASER TECH IND GRP CO LTD

Powder coating paint remover and preparation method thereof

InactiveCN112175442ARemove paint completelyLow costChemical paints/ink removersPhenolic content in teaActive agent

The invention relates to the technical field of paint removal, in particular to a powder paint remover and a preparation method thereof. The invention solves the problem that most paint removers in the prior art are water systems and easily damage base materials after paint removal, and the powder paint remover comprises the following components: a main solvent, a cosolvent, an accelerant, a permeation aid, a surfactant, a thickener and tea polyphenol, wherein dichloromethane is selected as the main solvent, methanol is selected as the cosolvent, inorganic base is selected as the accelerant, OP-10 is selected as the surfactant, AEO-3 emulsifier is selected as the permeation assistant, and magnesium stearate is selected as the thickener. The invention aims at paint removal of the powder coating, the powder coating is dissolved into the paint remover by utilizing a dissolving method, so that isomeric included angles and atomized powder can be fully and completely dissolved, and paint removal of a workpiece is more thorough; the alkaline formula of an anhydrous system is adopted, so that active metals such as aluminum, zinc and the like do not damage a base material after paint removal, the formula cost is low, the paint removal efficiency is high, and the paint remover is safe and convenient.

Owner:厦门斯福泽瑞科技有限公司

Motor stator automatic paint removal machine

InactiveCN105207424AEfficient removalCompact structureManufacturing stator/rotor bodiesLacquerMechanical engineering

The invention relates to paint removal equipment, particularly to a motor stator automatic paint removal machine and belongs to the technical field of motor stator treatment. According to the technical scheme provided by the invention, the motor stator automatic paint removal machine comprises a machine base and a rotary disk, wherein the rotary disk is arranged on the machine base and is used for supporting a motor stator; a vertically arranged main shaft support rod is arranged on the machine base; a main shaft head capable of moving on the main shaft support rod in the vertical direction is arranged on the main shaft support rod; a connecting rod for mounting a steel wire brush is arranged on the main shaft head; a rotary movement driving mechanism for driving the connecting rod to rotate and driving the main shaft head to move on the main shaft support rod is arranged on the main shaft head. The motor stator automatic paint removal machine is compact in structure, convenient to operate, wide in application range, safe and reliable, can effectively remove paint on the motor stator, improves the paint removal efficiency, and reduces the paint removal labor intensity.

Owner:WUXI XISHAN ANDA EXPLOSION PROOF ELECTRIC EQUIP

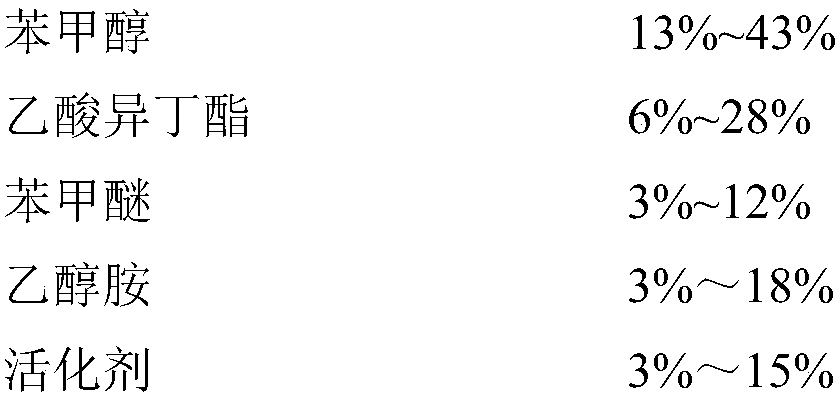

Room-temperature aqueous paint remover and preparation and use methods thereof

InactiveCN109135407AEnvironmentally friendlyNo need for secondary cleaningChemical paints/ink removersRoom temperatureIsobutyl acetate

The invention discloses a room-temperature aqueous paint remover and preparation and use methods thereof. The paint remover comprises, by mass, the following components: 13-43% of benzyl alcohol, 6-28% of isobutyl acetate, 3-12% of anisole, 3-18% of ethanolamine, 3-15% of activator, 1-6% of emulsifier and 15-45% of water, wherein the mass ratio of benzyl alcohol to isobutyl acetate is 3:1-3:2, themass ratio of anisole to ethanolamine is 1:1-1:3. The aqueous paint remover has the advantages of environmental protection, quick paint removal, low energy consumption and room-temperature operation.

Owner:SICHUAN UNIV

A steel pipe paint removal device for construction

ActiveCN111216009BHigh paint removal efficiencySave human effortGrinding feed controlPortable grinding machinesHydraulic cylinderArchitectural engineering

A steel pipe paint removal device for construction, belonging to the field of construction engineering equipment, the support device is installed above the second bracket, the friction device has four movable brackets and static brackets respectively installed on the left and right sides of the support device, the rubber band The base is fixed on the outside of the moving bracket, the rubber band is installed between the rubber band base and the first bracket, the hydraulic cylinder is installed above the fifth bracket, and the friction base is installed on the main shaft of the hydraulic cylinder. The pressure sensor is fixed at the groove of the lower half of the moving support, the hydraulic cylinder driving device is installed at the bottom center of the fourth support, and the controller is installed on the left side of the hydraulic cylinder driving device. The invention pushes the movable support through the hydraulic cylinder to make the flexible grinding wheel press the steel pipe, and under the drive of the motor, it rotates at a high speed to remove the paint on the steel pipe surface, replacing the manual paint removal operation, saving manpower and material resources, and improving efficiency. .

Owner:江西京丰建设工程有限公司

A paint removal device for waste paint buckets

ActiveCN111515205BRealize automatic continuous paint removal functionReduce lossHollow article cleaningElectric machineryStructural engineering

The invention provides a paint removal device for waste paint buckets, the structure of which includes a paint bucket workbench 1, a paint bucket fixing frame 2, a four-claw chuck 3, a paint bucket 4, a paint scraper holder 5, a paint scraper 6, a brush Handle control motor 7, brush workbench 8, linear guide rail screw slide module 9, paint bucket fixing frame control motor 10, brush cover 11, electric push rod 12, electric push rod cover 13, brush 14, brush handle 15, Pressure Washer 16. The telescopic movement of the paint brush is realized through the electric push rod, the feed movement between the paint brush and the paint bucket is realized through the linear guide screw slide module, and the paint removal function is realized through the relative rotation between the paint brush, the paint bucket and the scraper. The paint removal device has the advantages of compact structure, high paint removal efficiency and environmental friendliness, and can be mass-produced and used in industry.

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com