Metal paint remover and preparation method thereof

A paint remover and metal technology, which is applied in the field of metal surface treatment, can solve the problems of demanding use environment, low use efficiency, poor quick-cleaning performance, etc., and achieve good application value and high paint removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

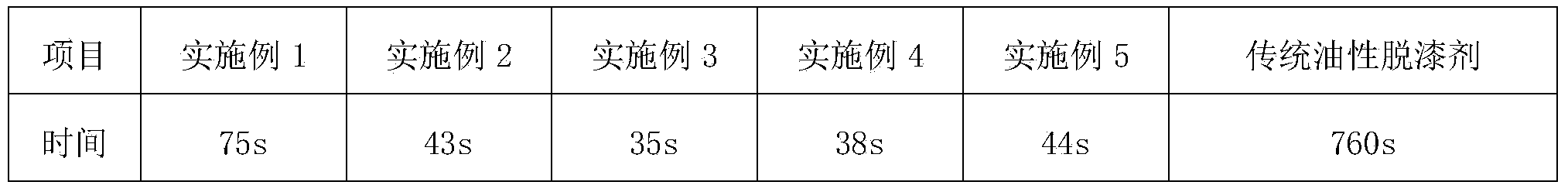

Examples

Embodiment 1

[0012] A metal paint remover, comprising by weight components: 50 parts of formic acid, 10 parts of ethyl acetate, 3 parts of methanol, 10 parts of methylene chloride, 30 parts of thinner, 2 parts of ethanolamine, sodium alkylbenzene sulfonate 3 parts, 1 part of polyglycerol fatty acid ester, 2 parts of butyl cellosolve, 1 part of paraffin, 2 parts of plexiglass powder.

[0013] The preparation method of metal paint stripper described above may further comprise the steps:

[0014] (1) Weigh each component according to parts by weight;

[0015] (2) Heat the paraffin until it melts, slowly add dichloromethane, stir until it is completely dissolved, then add other components, and stir evenly at a speed of 1500 rpm to obtain a metal paint remover.

Embodiment 2

[0017] A metal paint remover, comprising by weight components: 54 parts of formic acid, 15 parts of ethyl acetate, 5 parts of methanol, 13 parts of dichloromethane, 38 parts of thinner, 3 parts of ethanolamine, sodium alkylbenzene sulfonate 6 parts, 2 parts of polyglycerol fatty acid ester, 4 parts of butyl cellosolve, 3 parts of paraffin, 4 parts of plexiglass powder.

[0018] The preparation method of metal paint stripper described above may further comprise the steps:

[0019] (1) Weigh each component according to parts by weight;

[0020] (2) Heat the paraffin to melt, slowly add dichloromethane, stir until it is completely dissolved, then add other components, and stir evenly at a speed of 1600 rpm to obtain a metal paint remover.

Embodiment 3

[0022] A metal paint remover, comprising by weight components: 56 parts of formic acid, 18 parts of ethyl acetate, 6 parts of methanol, 15 parts of dichloromethane, 42 parts of thinner, 4 parts of ethanolamine, sodium alkylbenzenesulfonate 7 parts, 3 parts of polyglycerol fatty acid ester, 5 parts of butyl cellosolve, 4 parts of paraffin, 5 parts of plexiglass powder.

[0023] The preparation method of metal paint stripper described above may further comprise the steps:

[0024] (1) Weigh each component according to parts by weight;

[0025] (2) Heat the paraffin until it melts, slowly add dichloromethane, stir until it is completely dissolved, then add other components, and stir evenly at a speed of 1700 rpm to obtain a metal paint remover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com