Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High gripping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

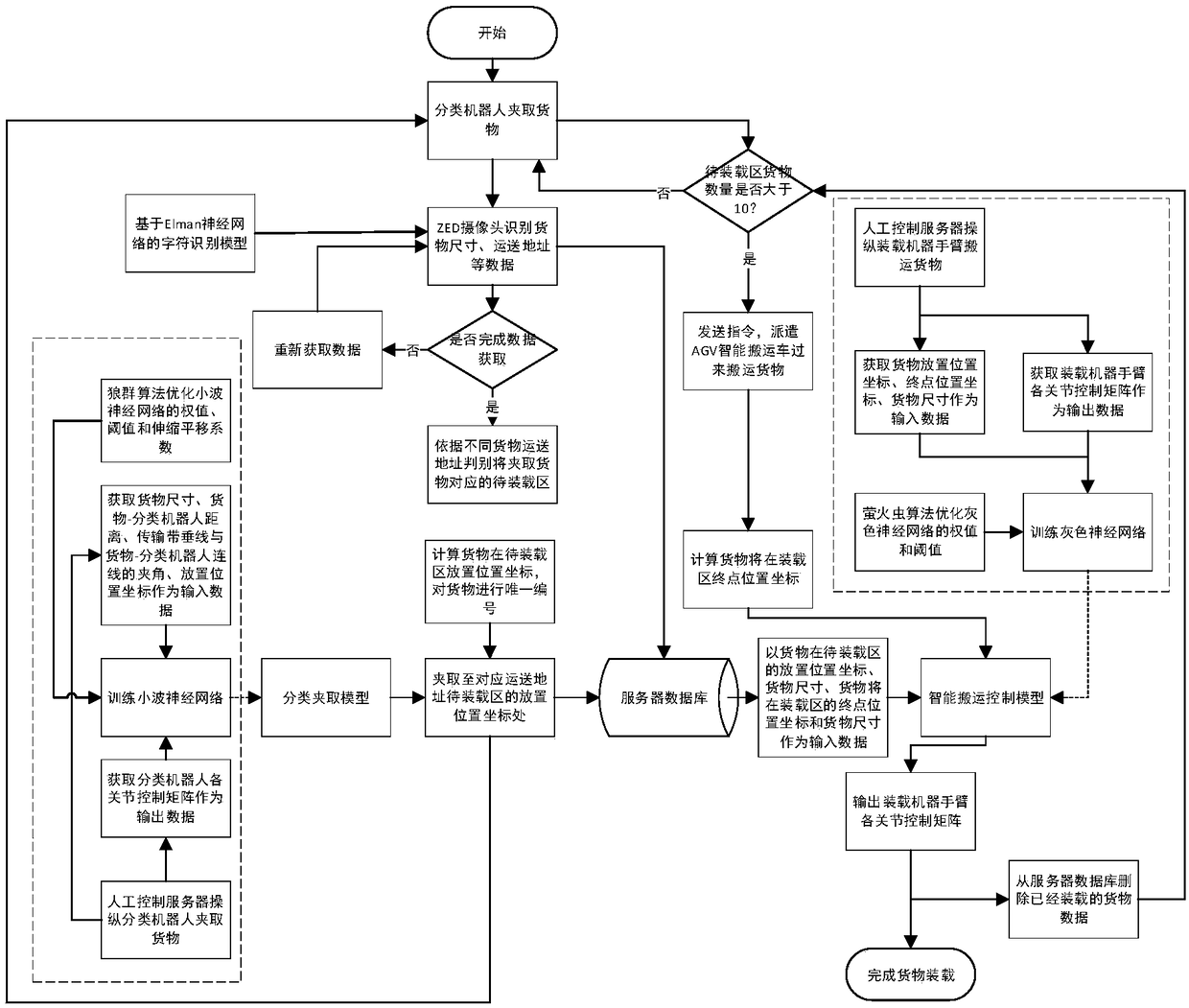

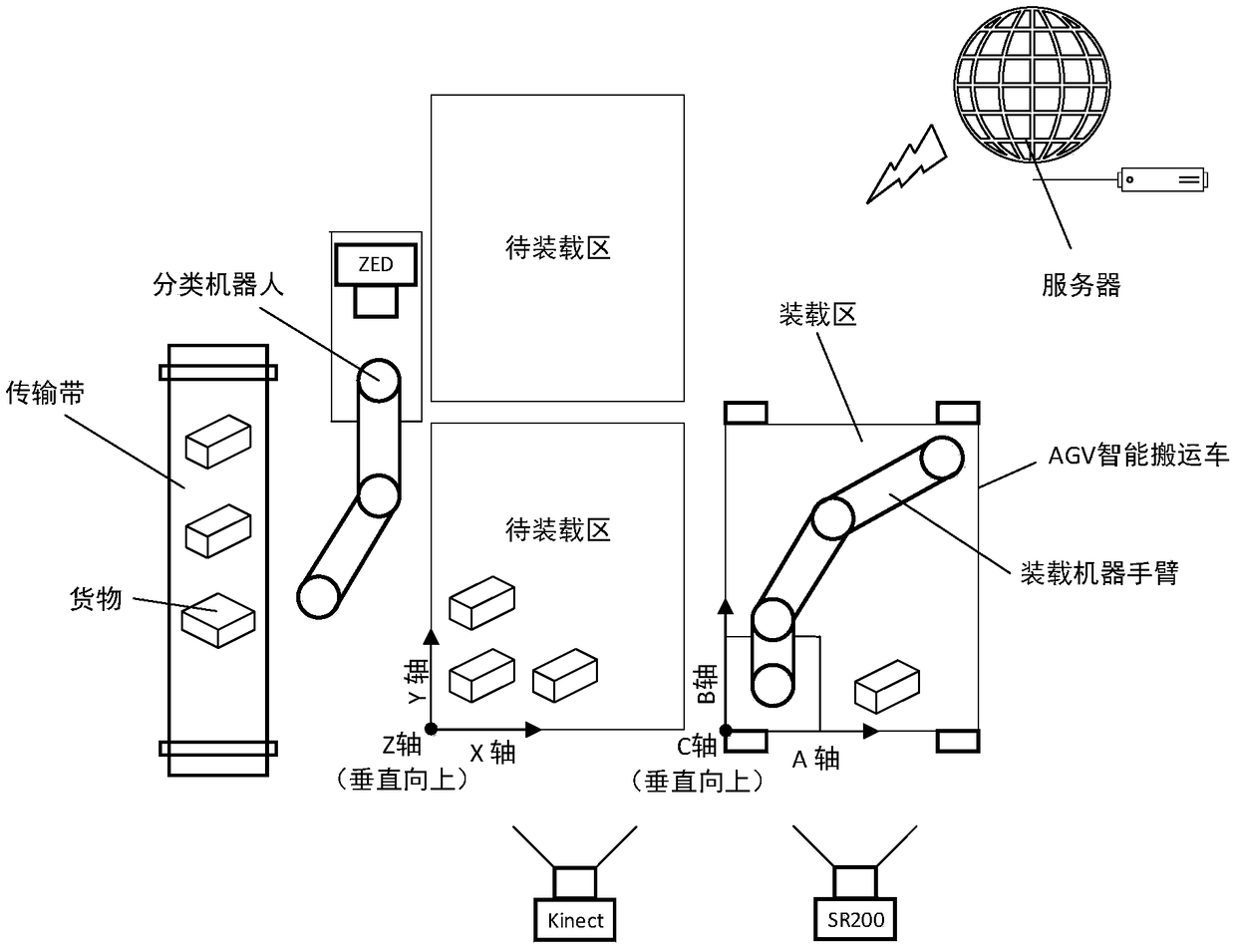

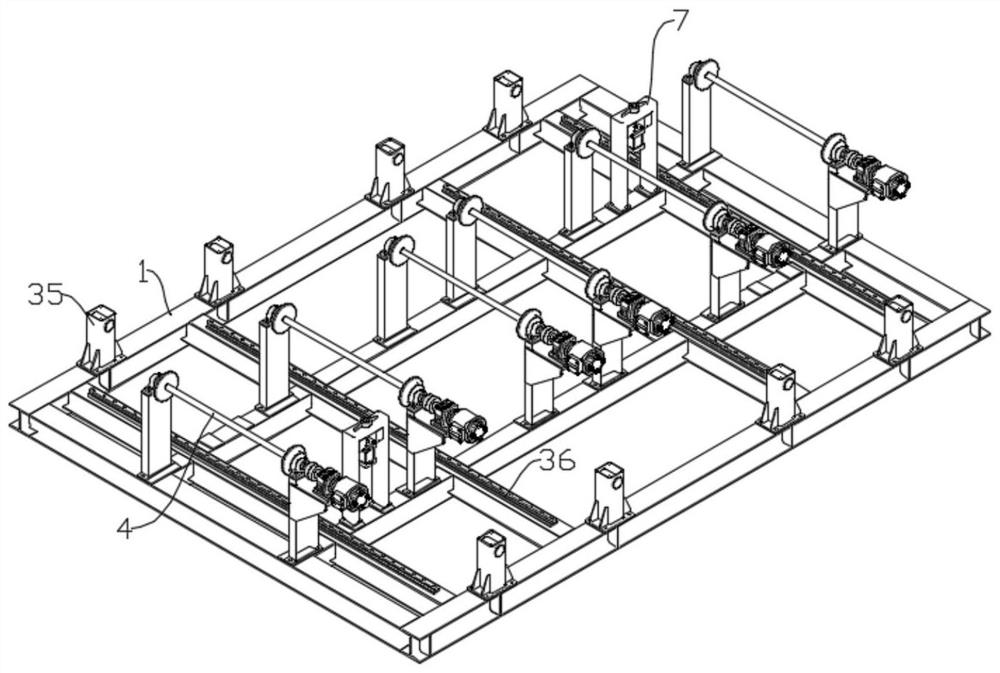

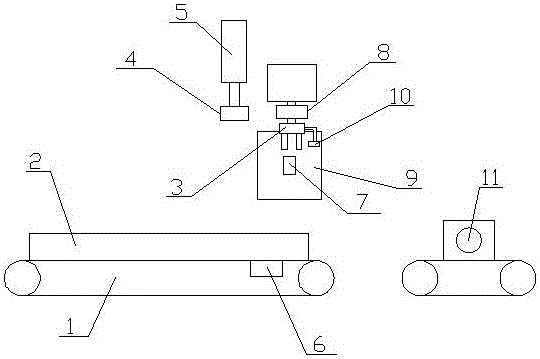

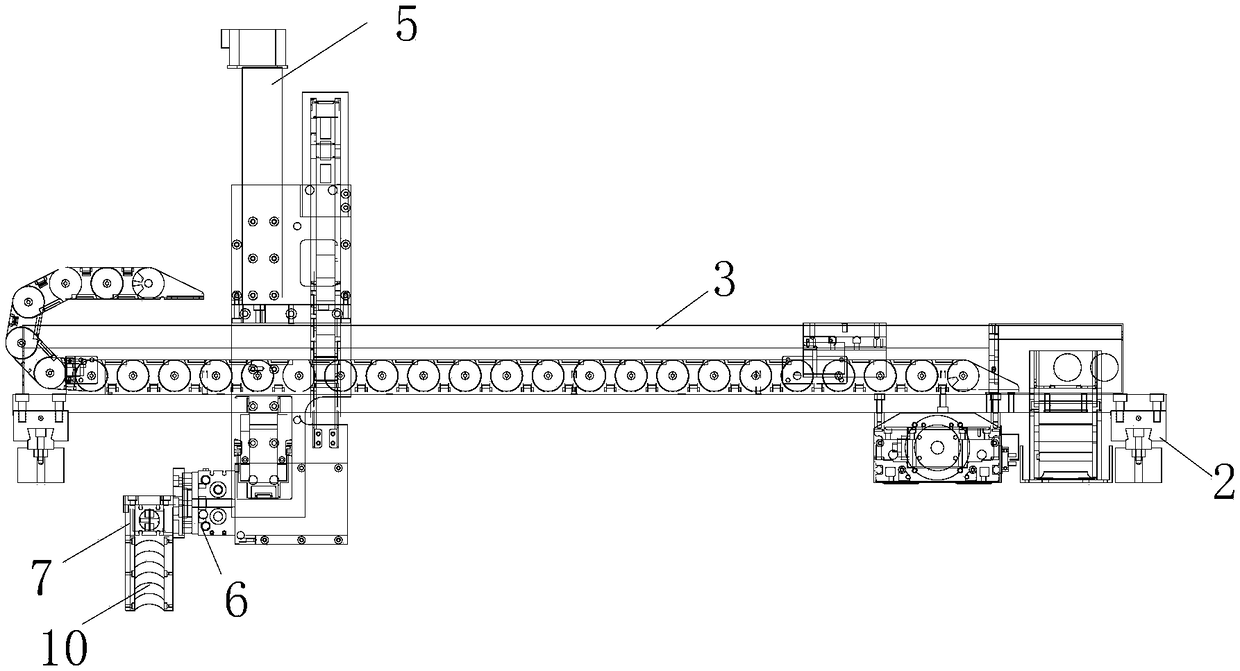

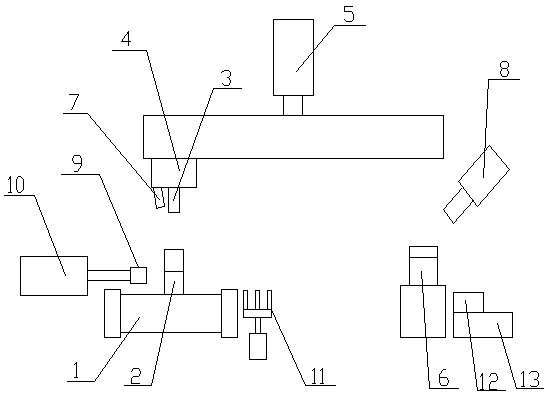

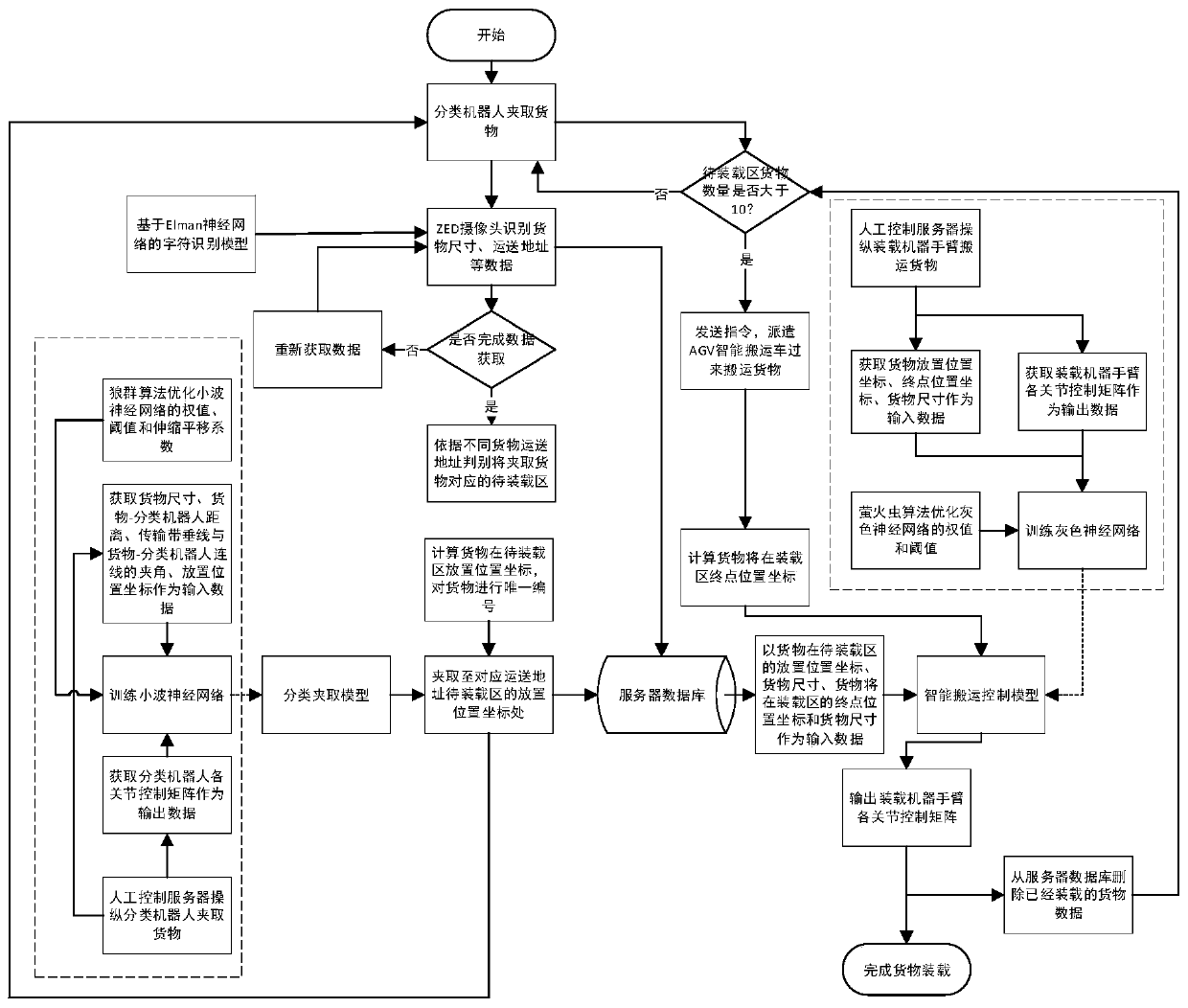

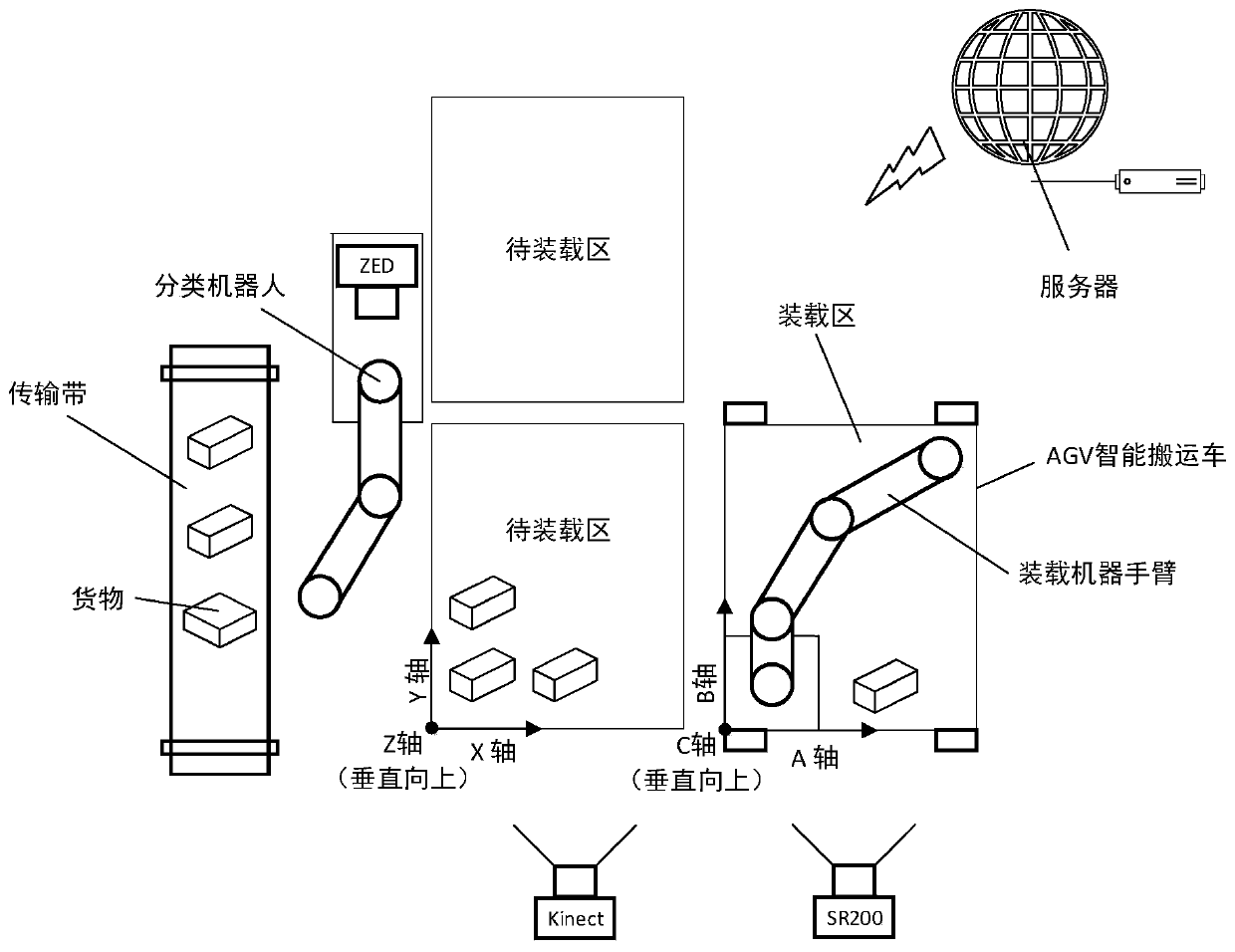

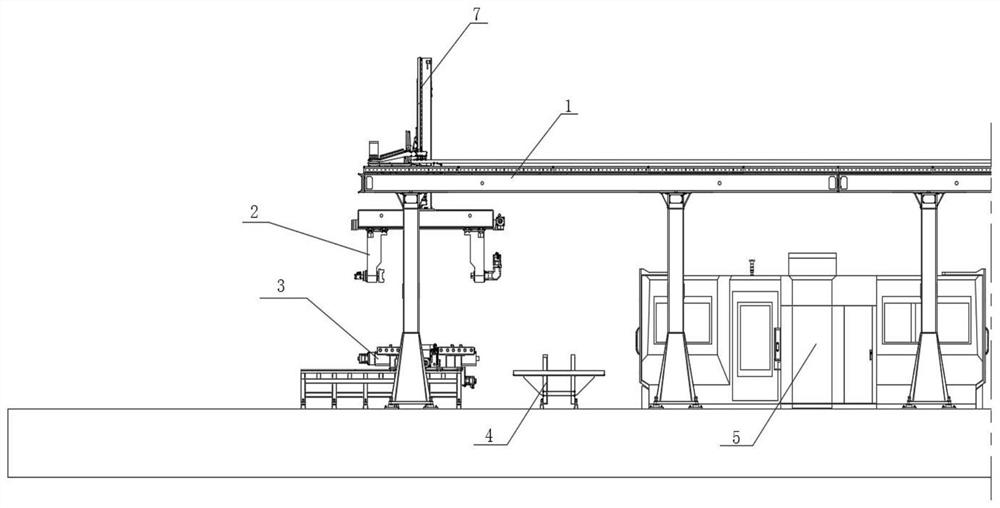

Loading method and device of intelligent logistics environment robot

ActiveCN108942946ASimple structureEasy to operateProgramme-controlled manipulatorMachine visionLogistics management

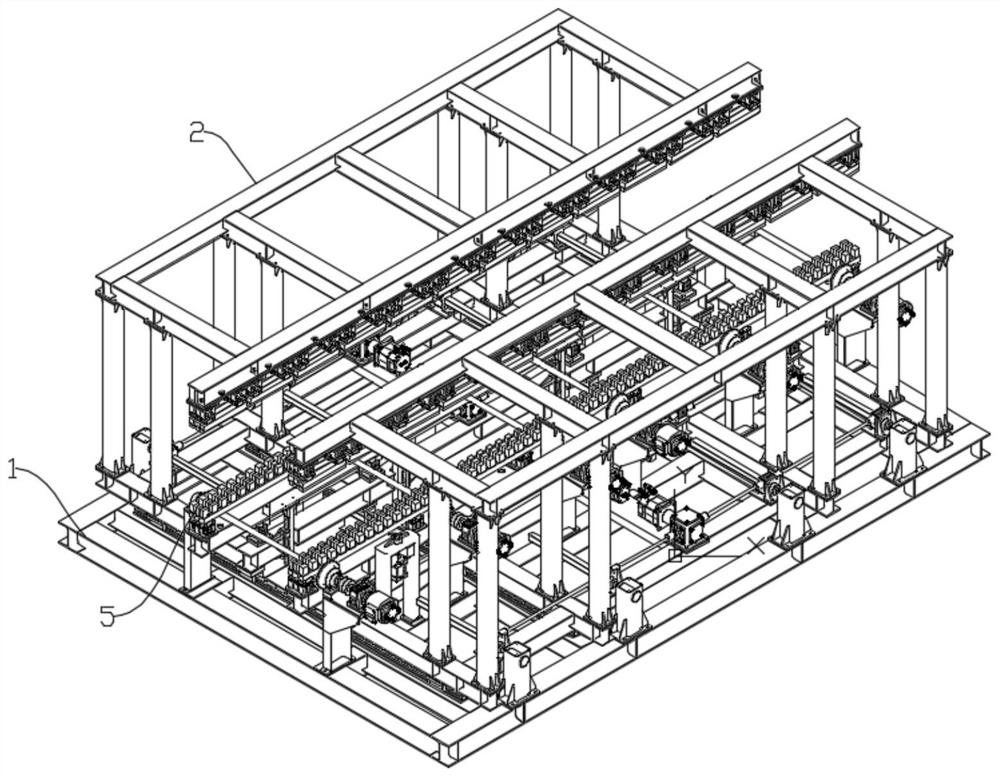

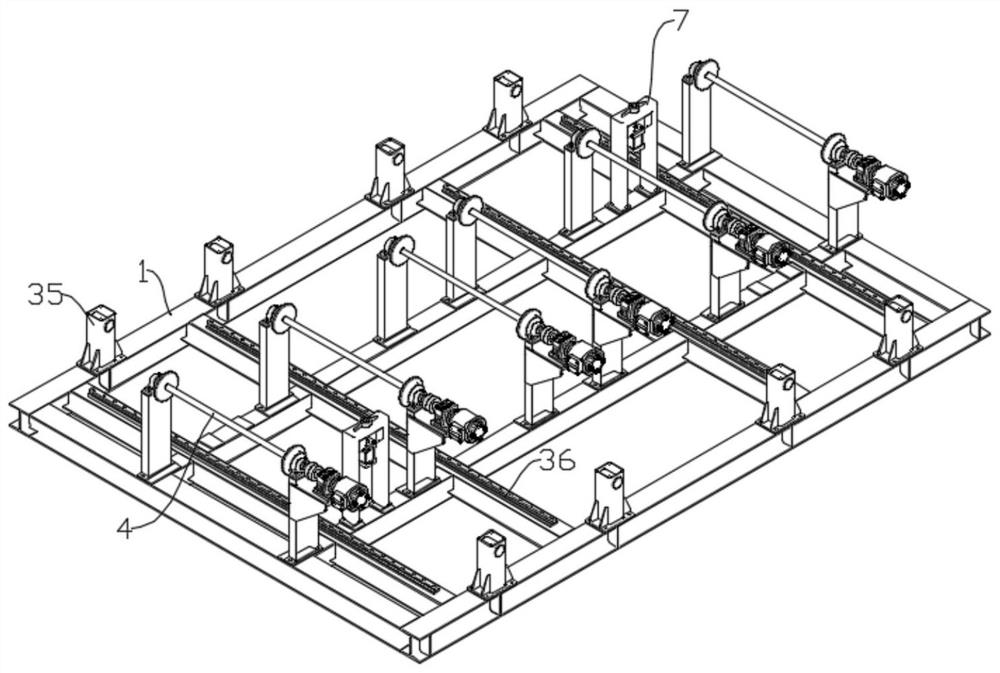

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

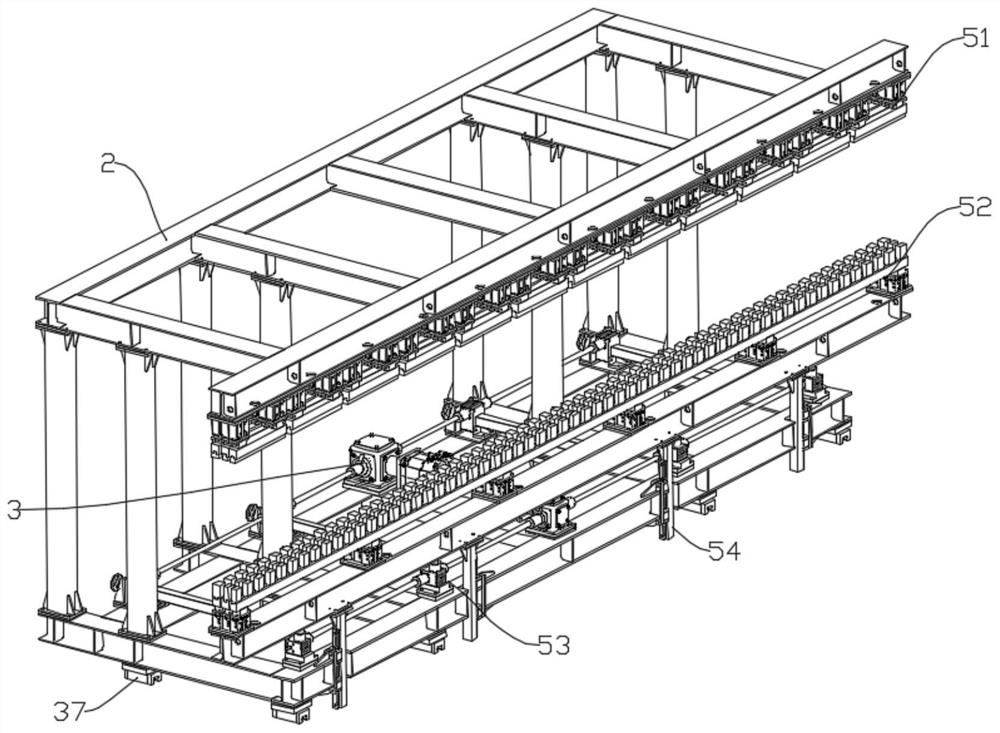

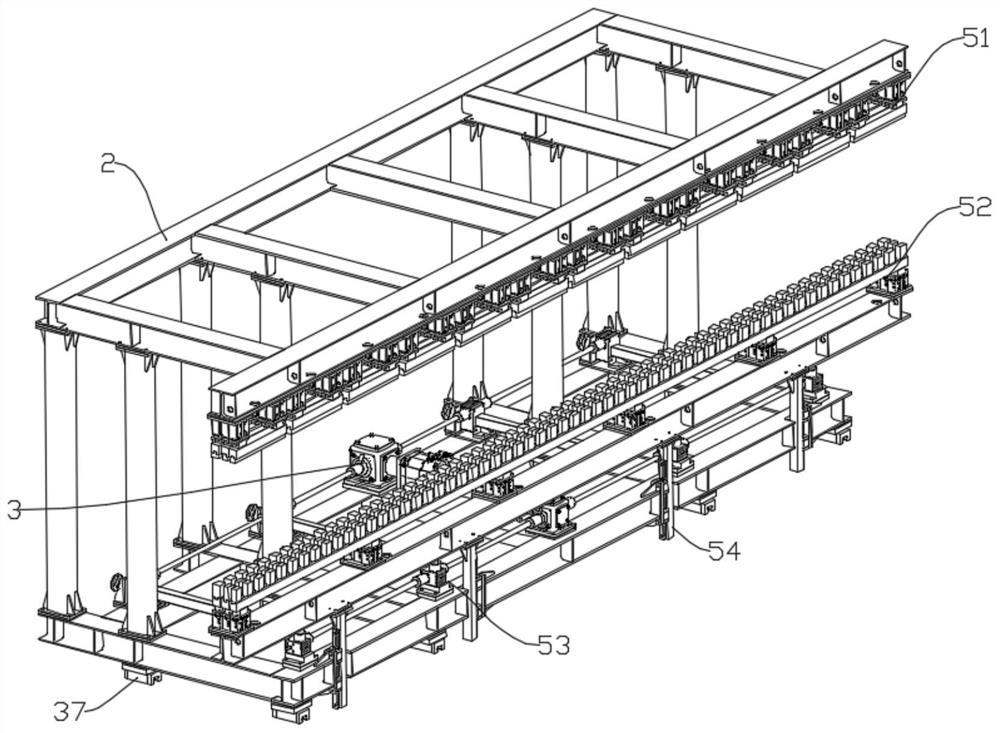

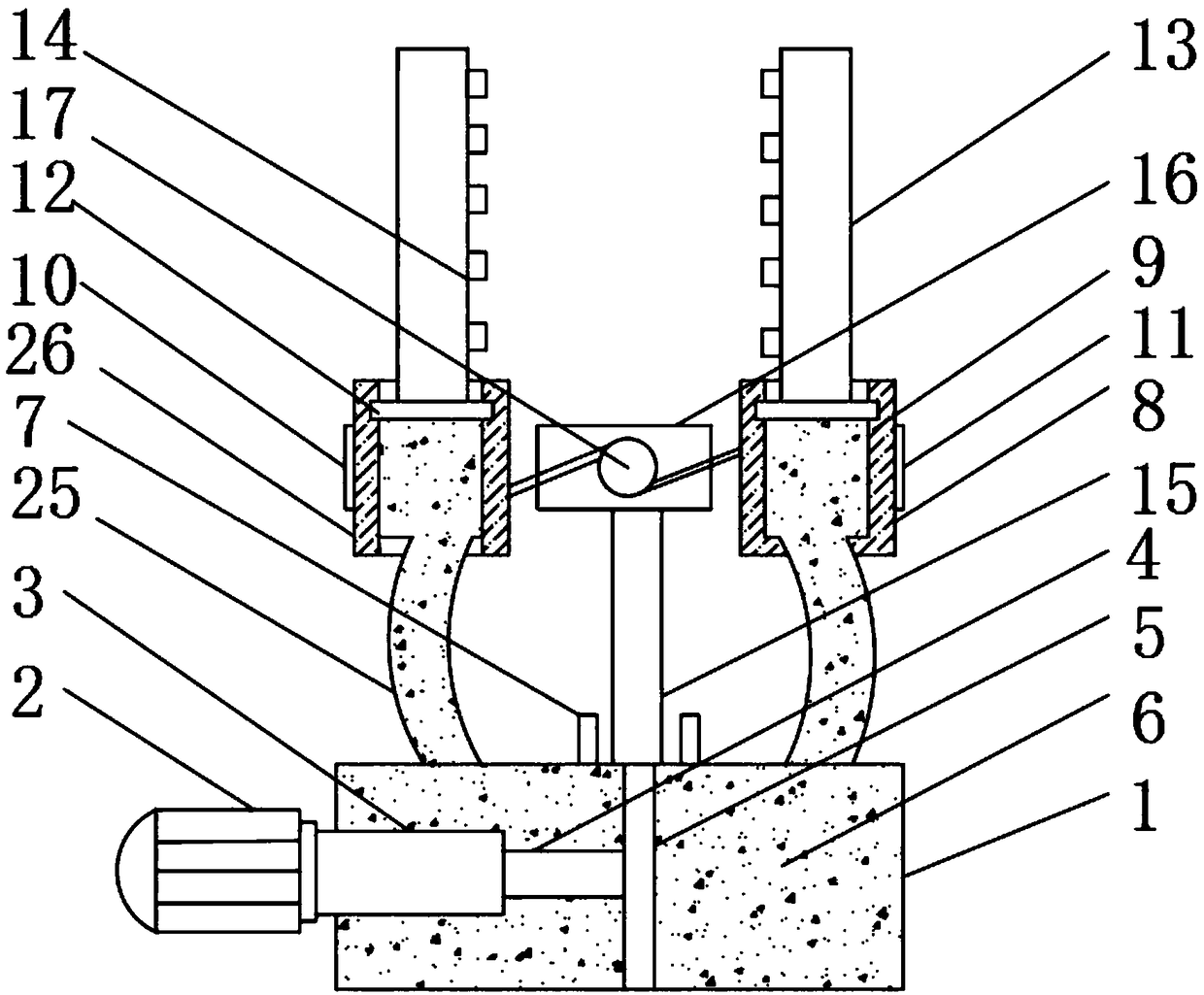

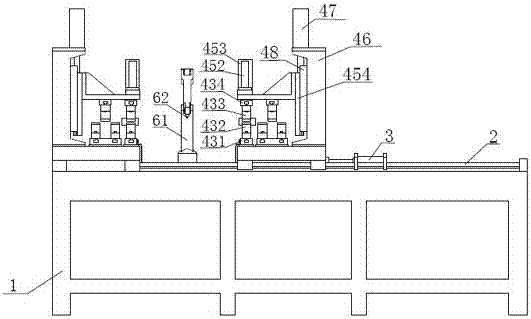

Wet parting method for aerated concrete blocks or plates

PendingCN112589990AImprove yieldAvoid splitting failuresAuxillary shaping apparatusStructural engineeringMaterials processing

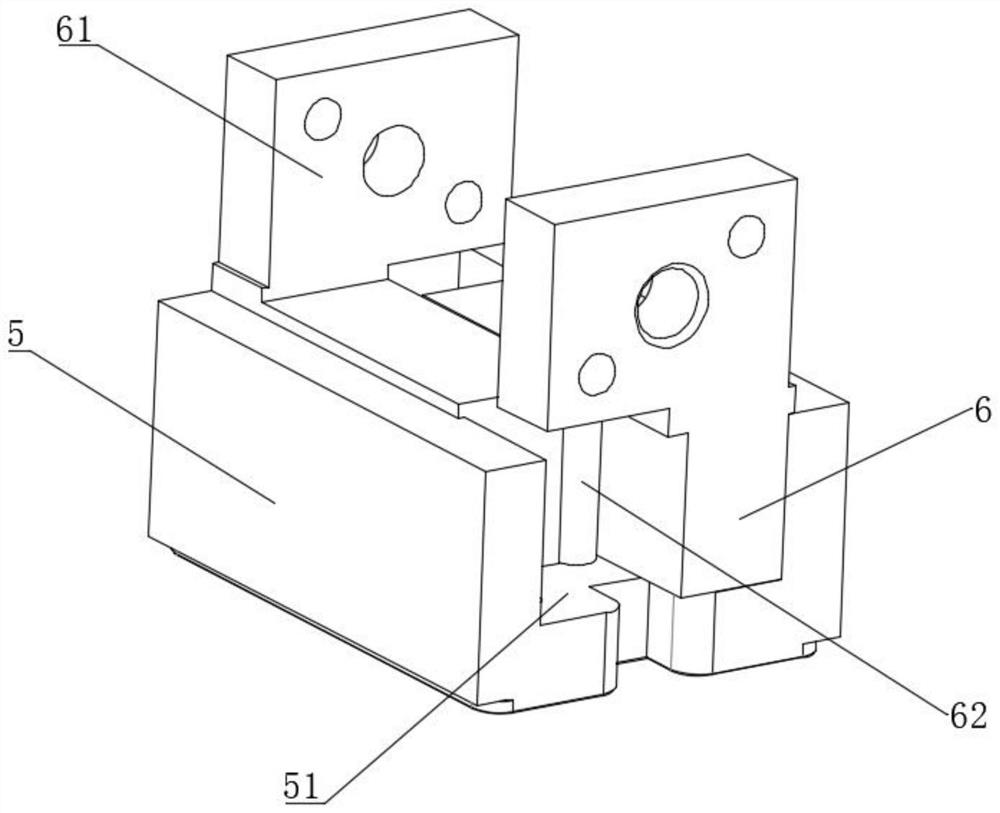

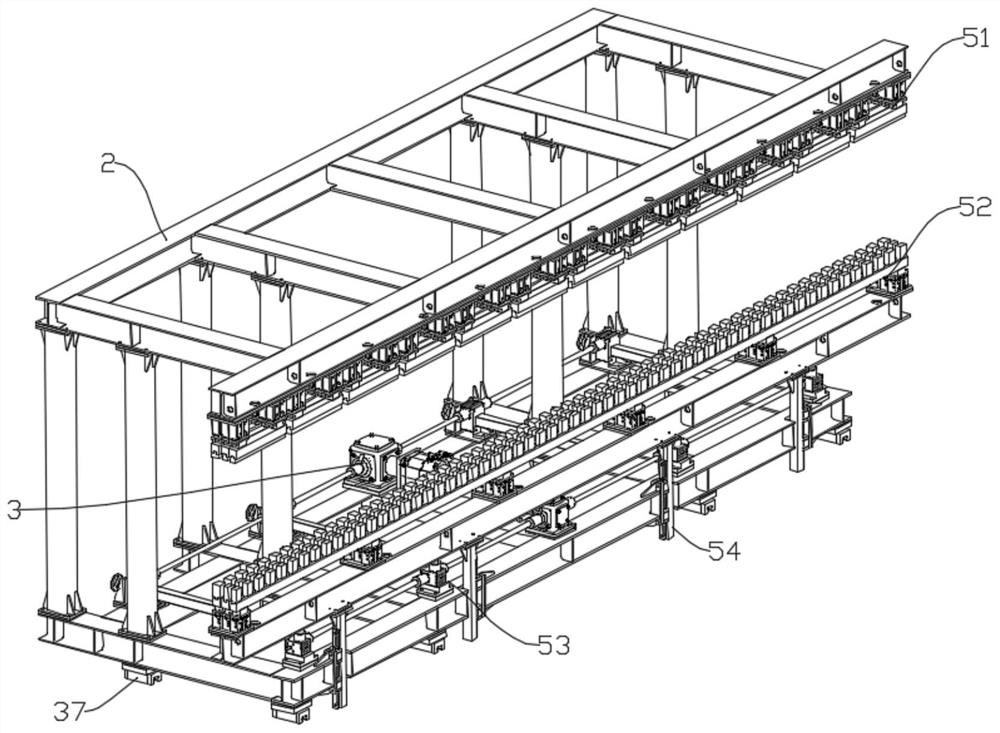

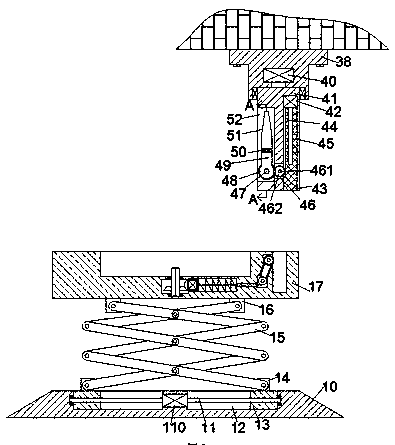

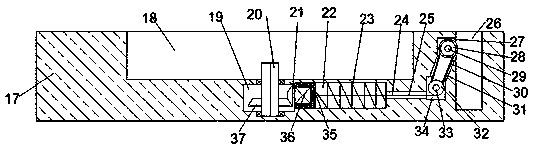

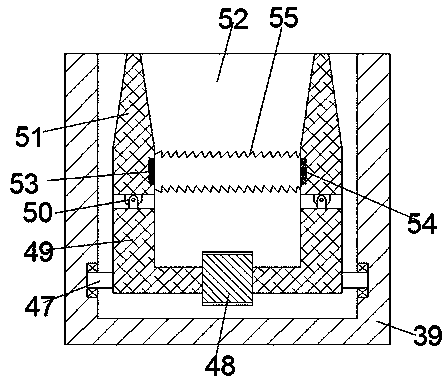

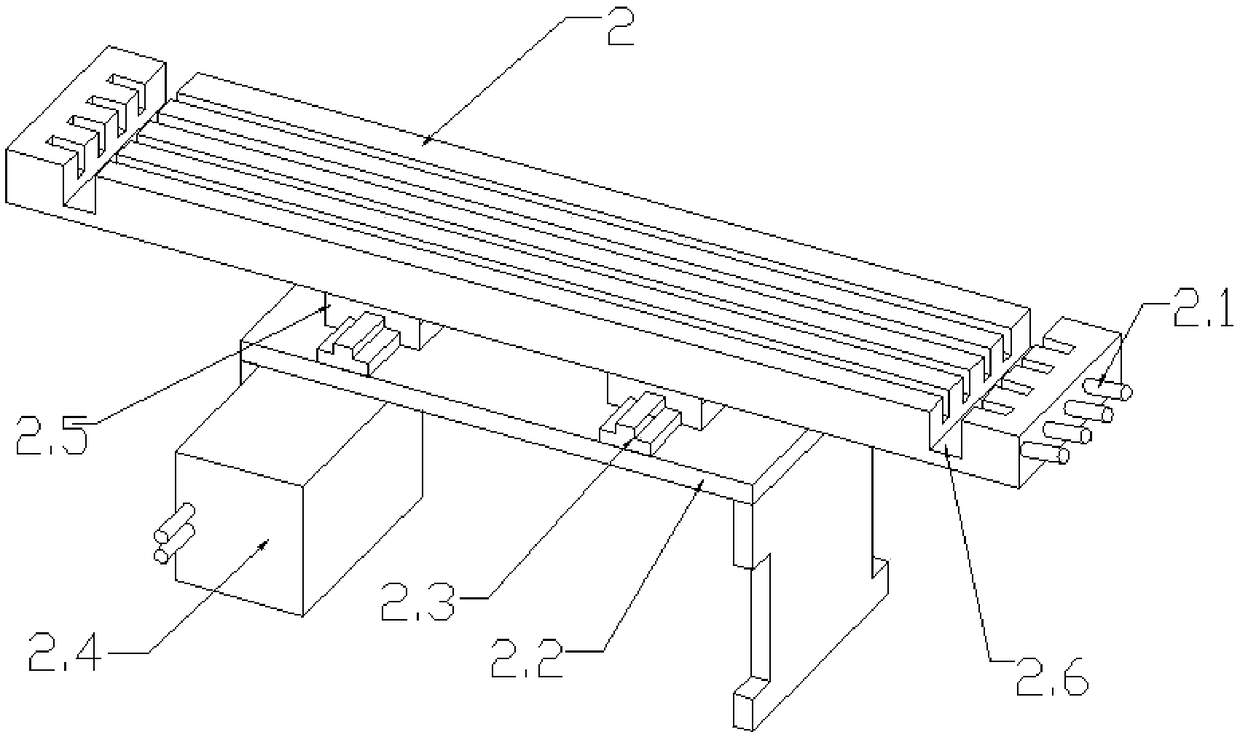

The invention discloses a wet parting method for aerated concrete blocks or plates, and belongs to the field of concrete material processing. The method comprises the following steps that a bottom plate conveying device drives a transversely-placed steam-curing bottom plate to be conveyed to a working position and fixed; then, an upper clamping piece and a lower clamping piece are driven to extendout, so that the upper clamping piece tightly presses the top end of the outermost layer of green body; a lifting device works to eject a lower parting device, so that a upper parting telescopic mechanism is compressed, and the clamped green body is ejected up and forms a height difference with other green bodies; then, a transverse driving device works to drive a rack to move towards the outer side of a base, and after a gap is formed between the outermost layer of green body and the other green bodies, the lifting device resets; and the upper parting telescopic mechanism and the transversedriving device are reset, the operation is repeated, and all the green bodies are parted. According to the wet parting method, the green bodies which are transversely stacked together can be parted, the parting efficiency and accuracy are high, the green bodies are not prone to being damaged, and the finished product rate of the concrete blocks or the plates is increased.

Owner:ANHUI KEDA IND CO LTD

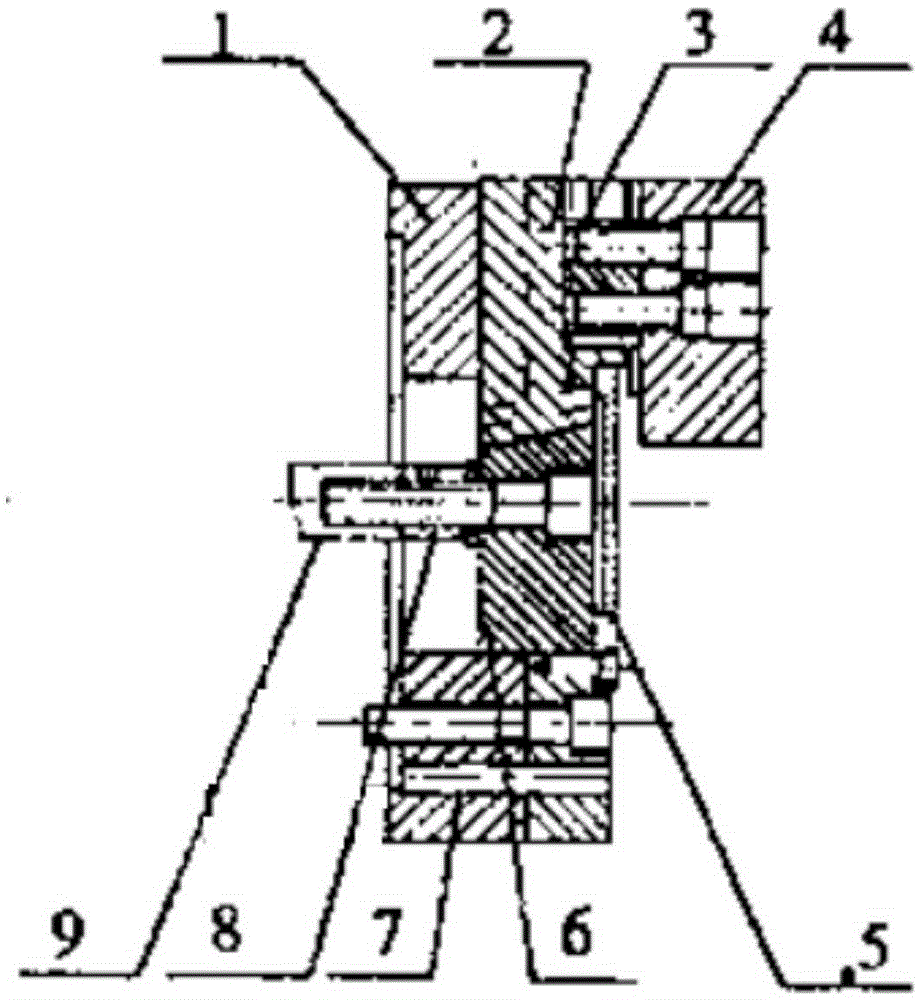

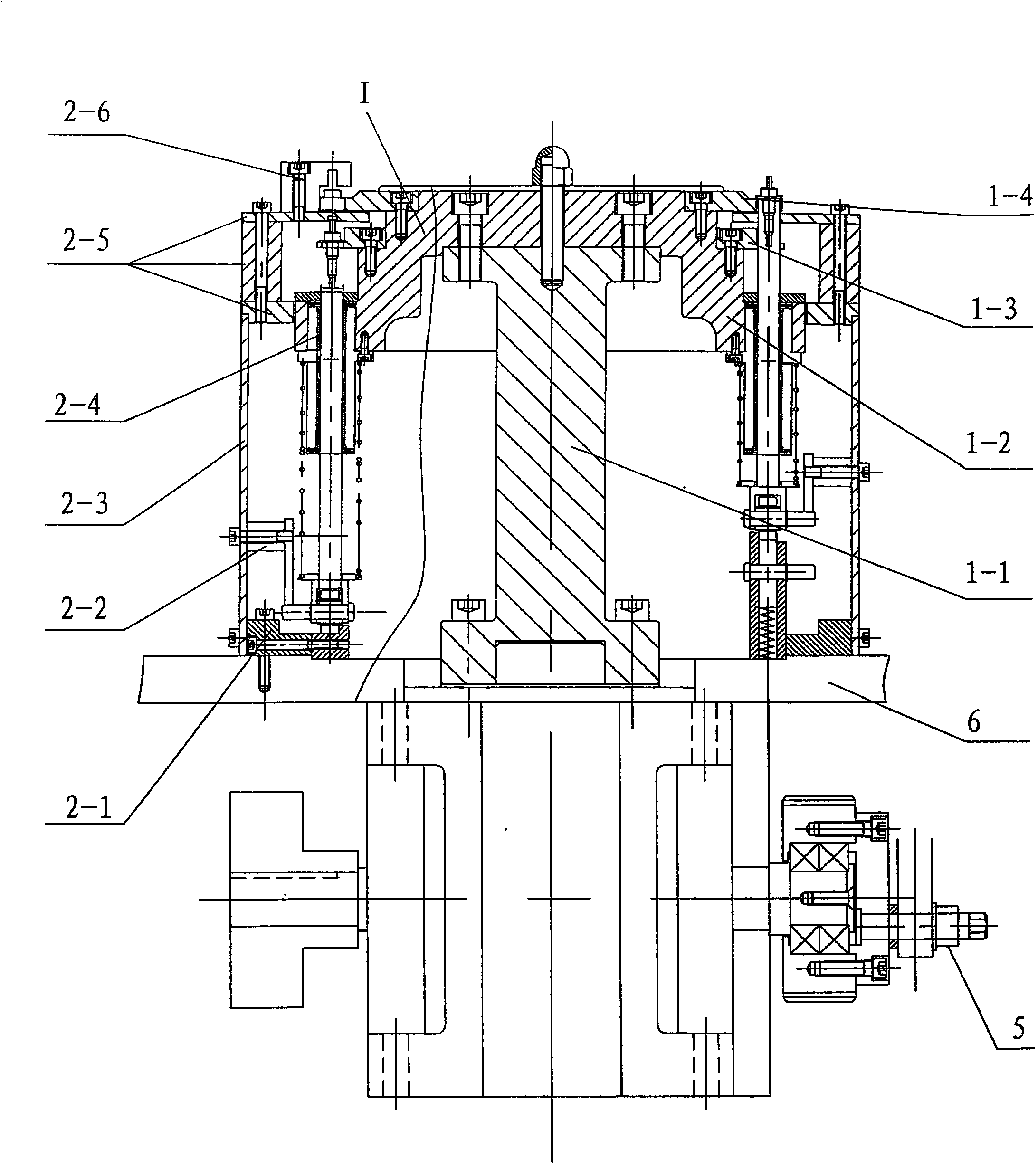

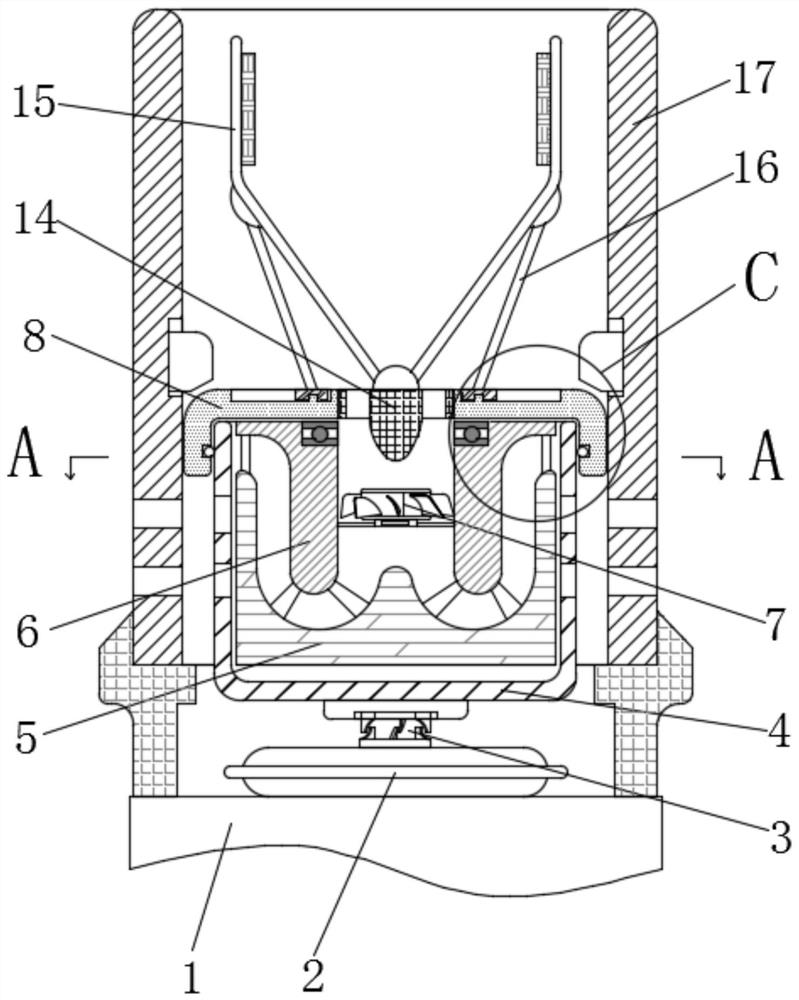

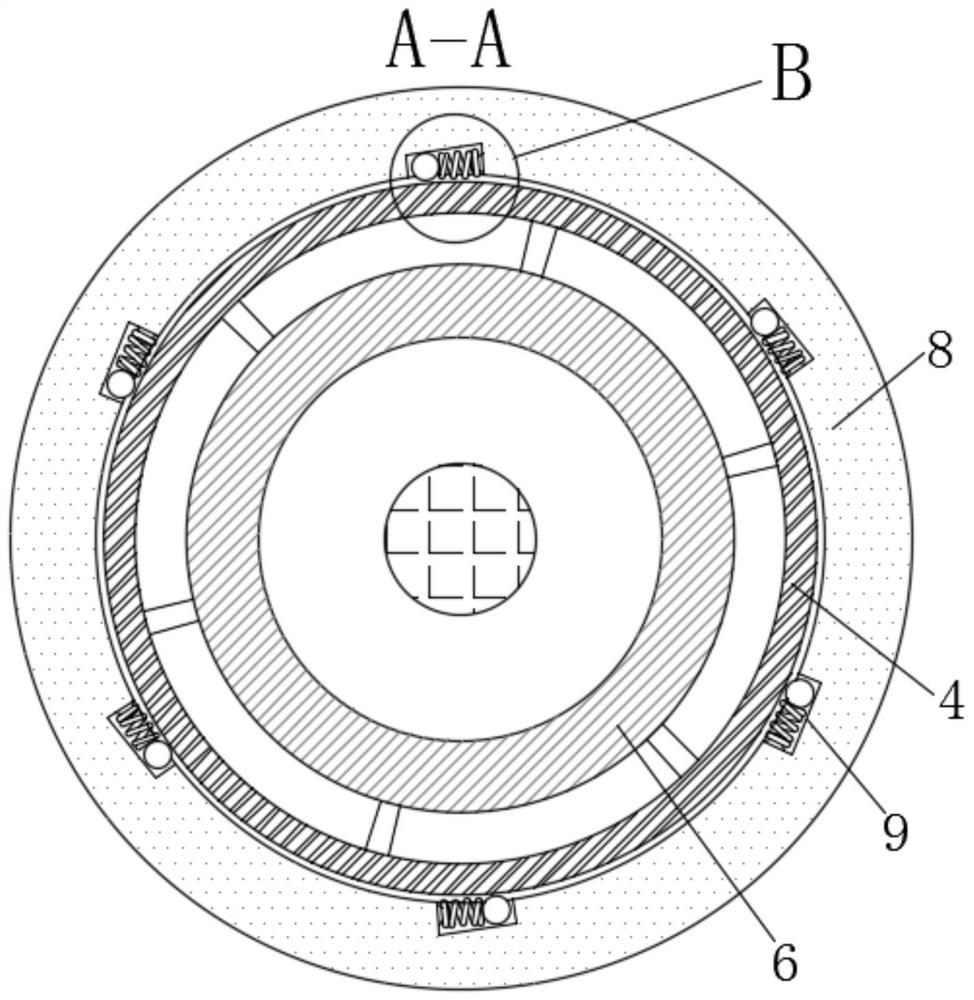

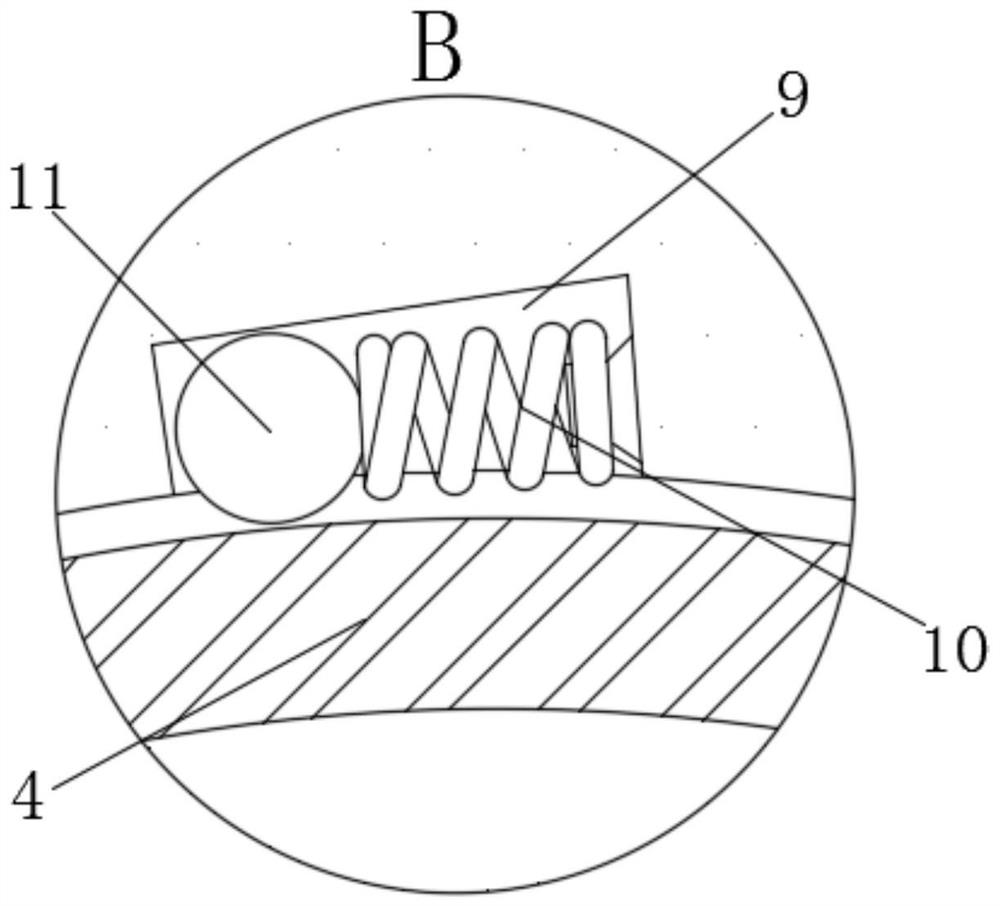

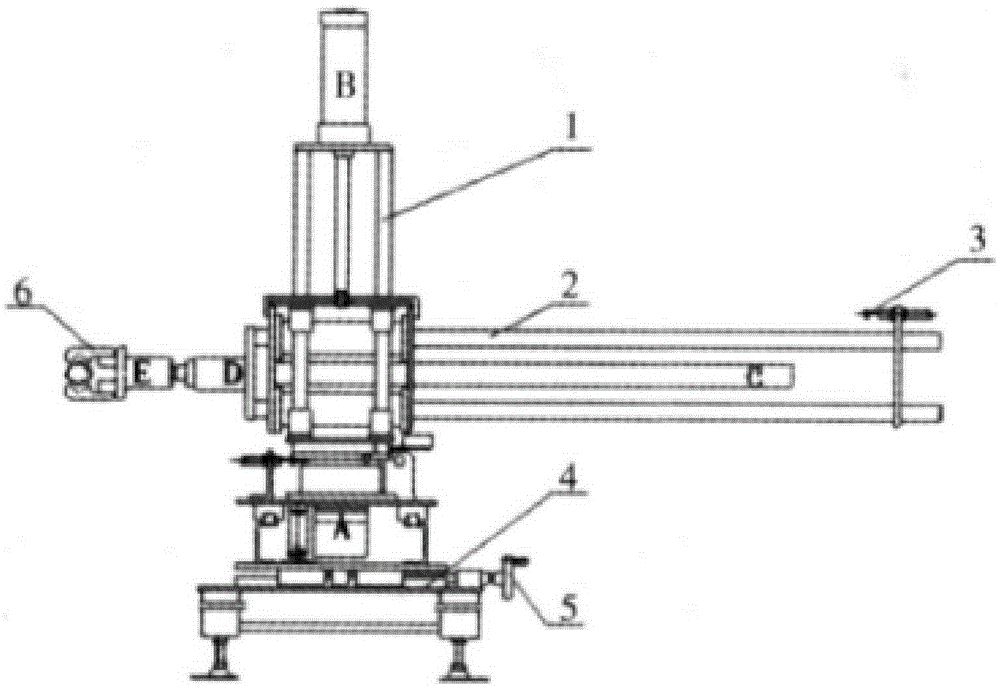

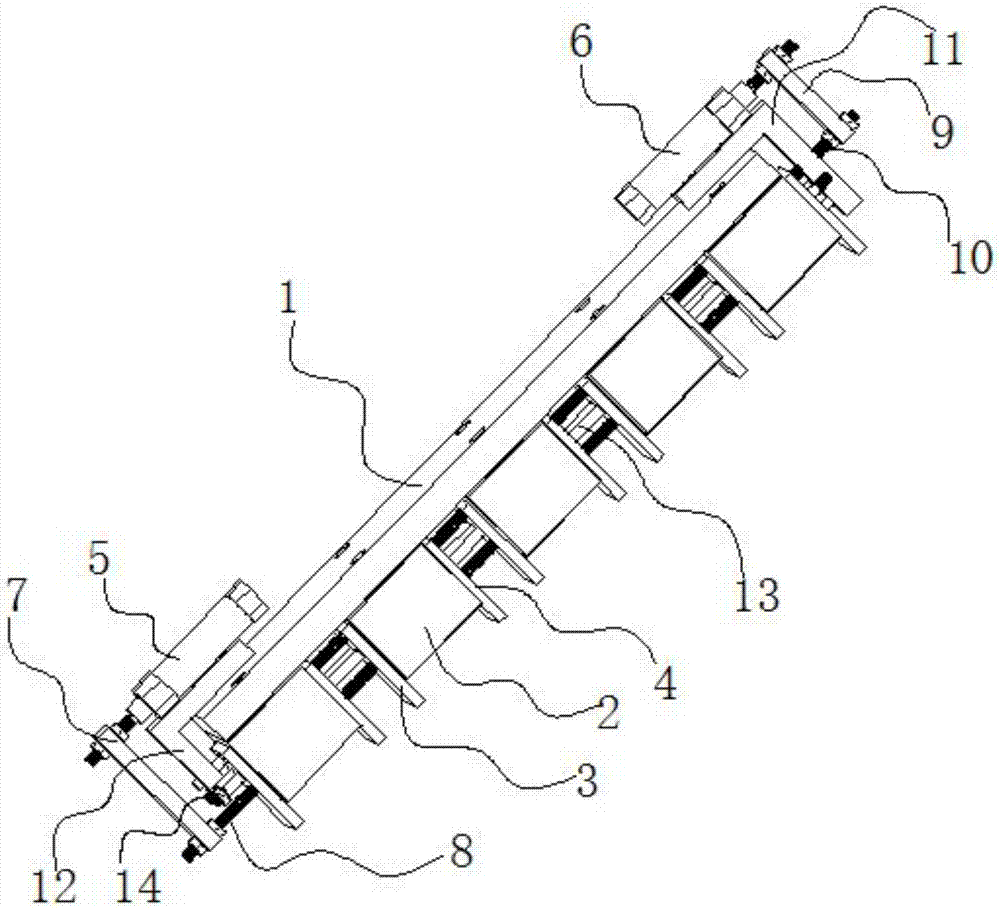

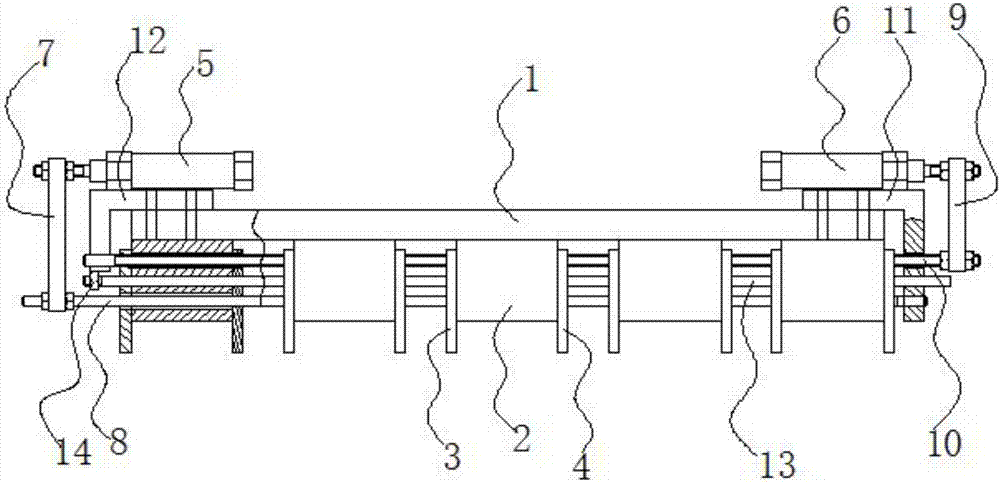

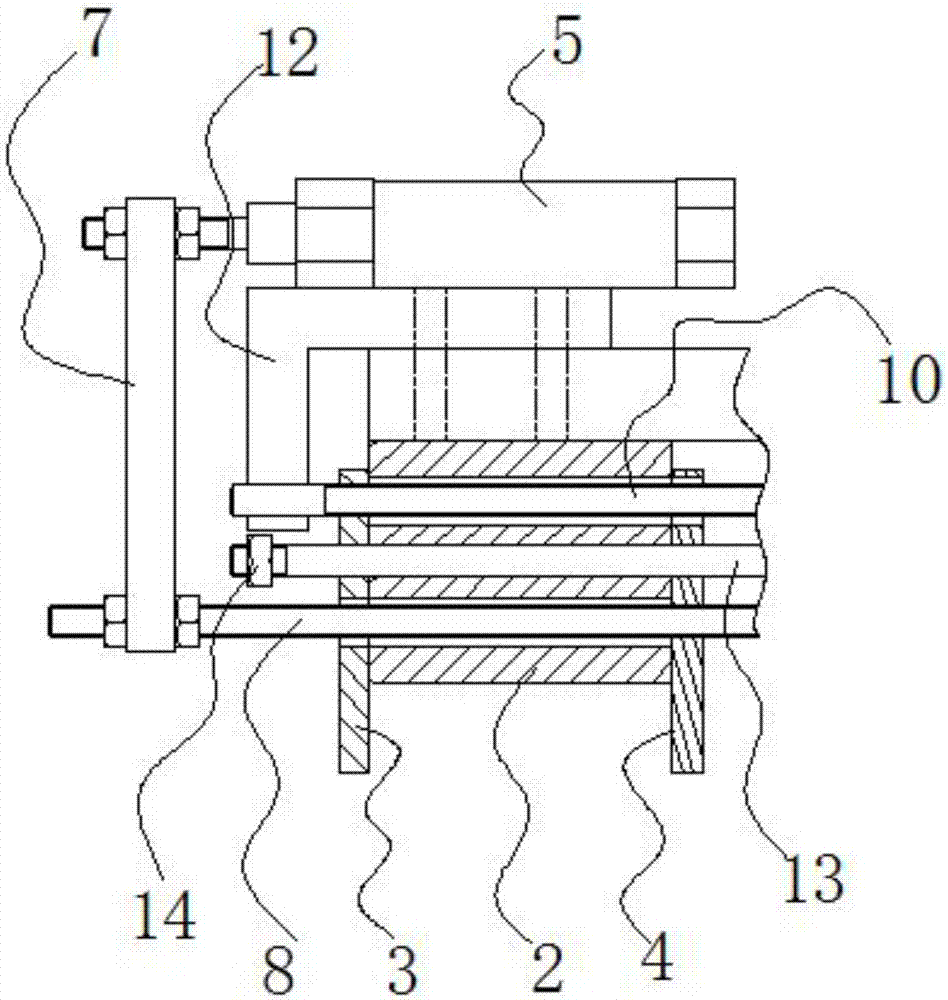

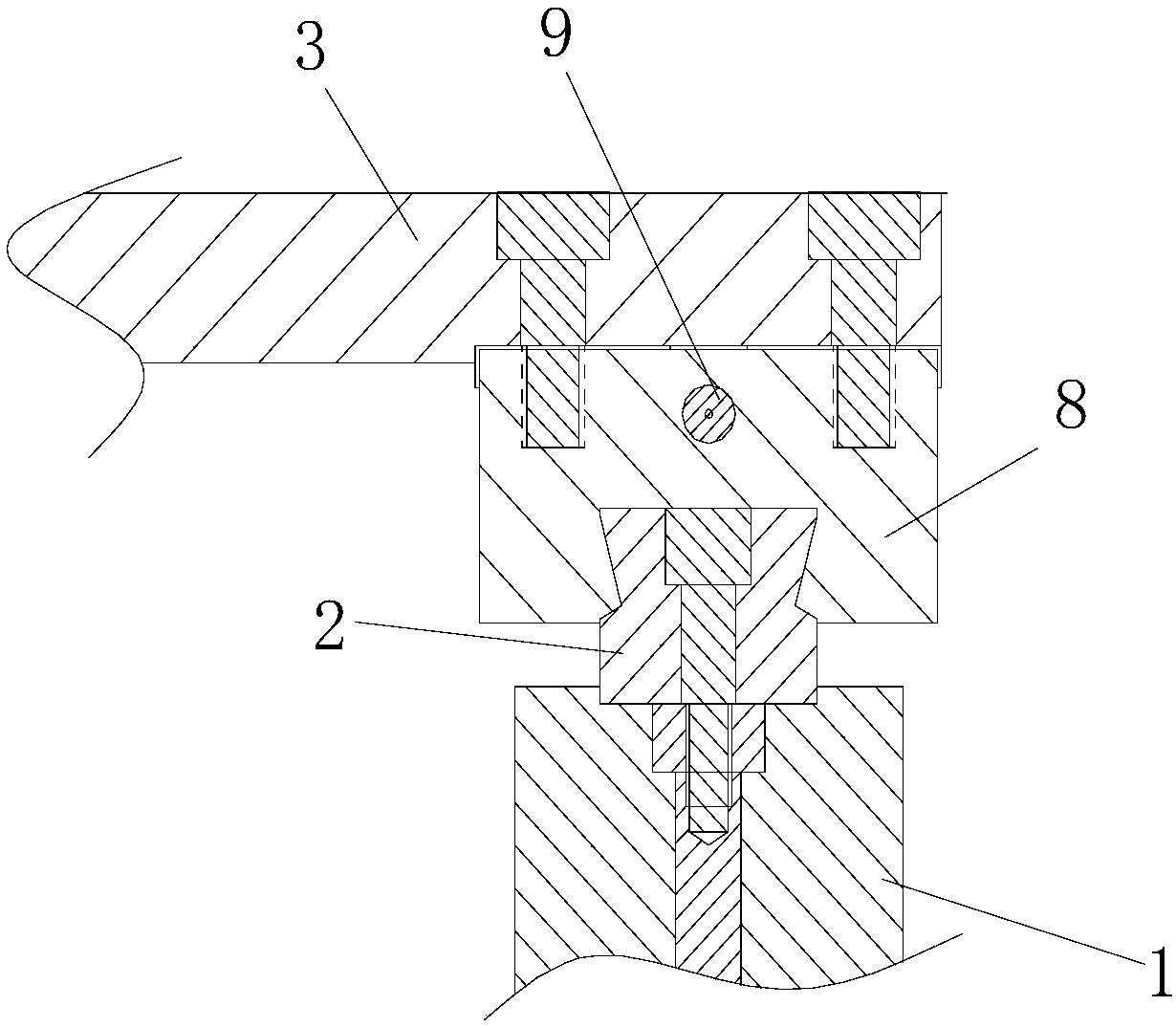

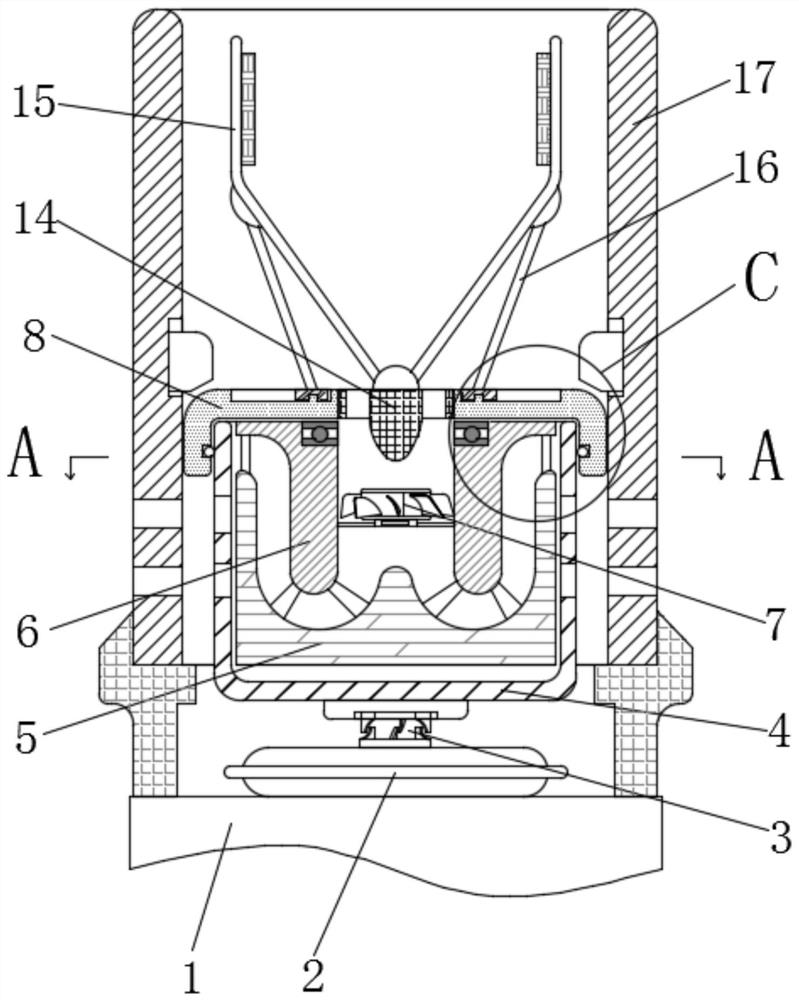

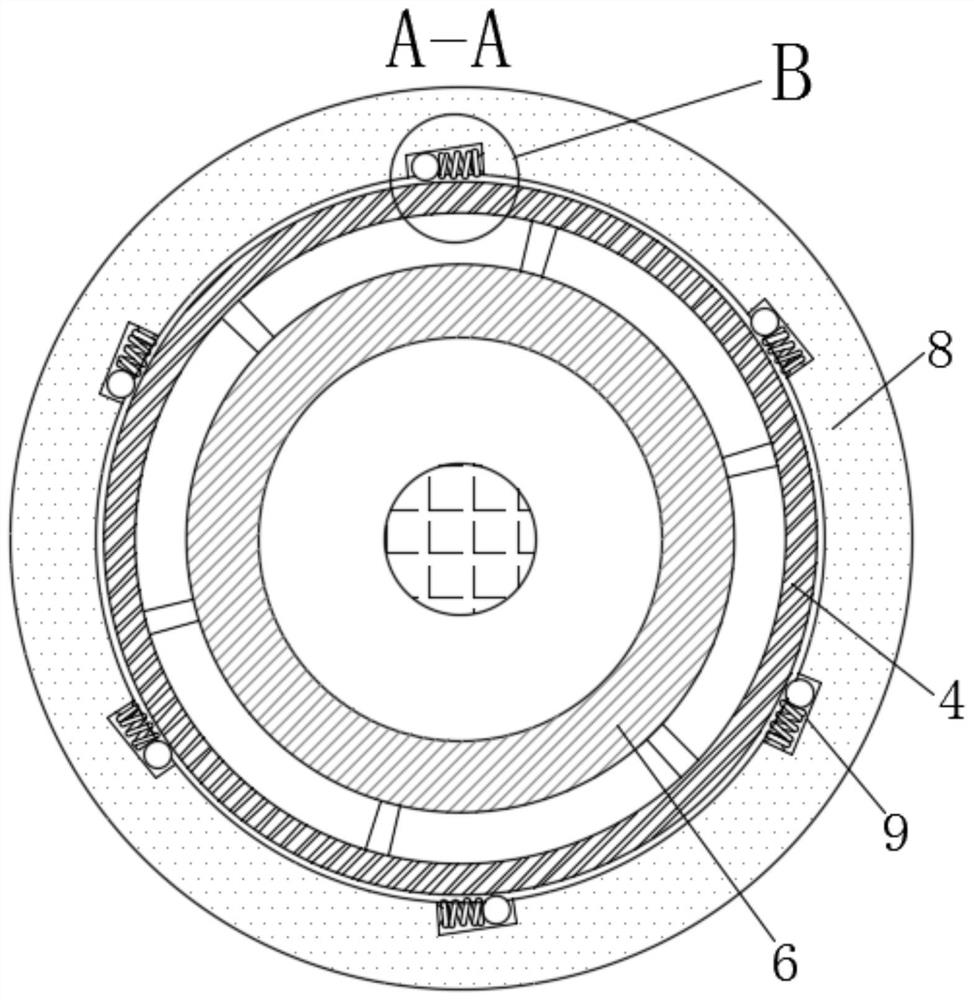

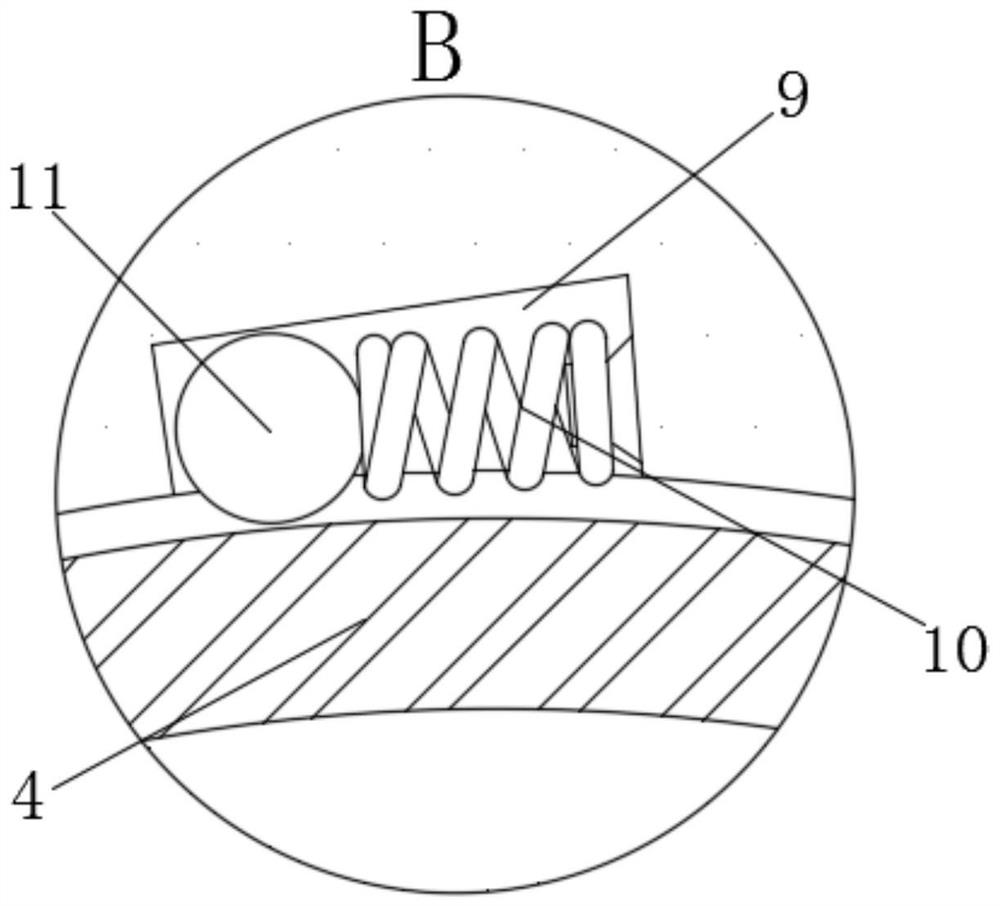

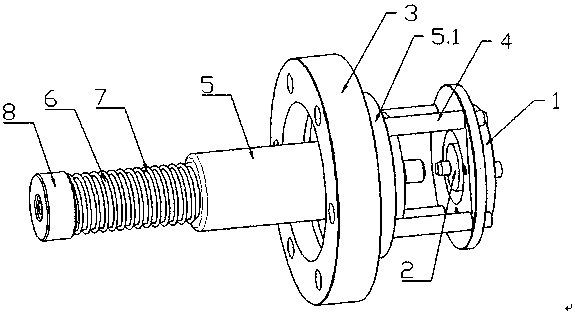

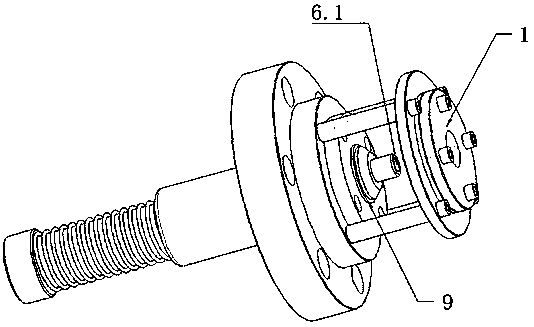

Hydraulic positioning clamping mechanism for shaft machining

InactiveCN105234716AReduce labor intensityHigh gripping accuracyPositioning apparatusMaintainance and safety accessoriesHydraulic cylinderLiquid medium

The invention discloses a hydraulic positioning clamping mechanism for shaft machining. The clamping mechanism comprises three clamping claws; an included angle of 120 degrees is formed between every two adjacent clamping claws; a joint shaft 6 is connected with a hydraulic piston rod 9 through a bolt; a dovetail groove structure which forms a 20-degree included angle with the horizontal axis is designed on the joint shaft 6; the joint shaft 6 is in match connection with a translation base 2; the hydraulic piston rod 9 drives the joint shaft 6 to move left and right through left and right moving; and meanwhile, an inclined angle is formed between the contact surface of the translation base 2 and the joint shaft 6 and the horizontal plane, so that the translation base 2 does centred motion or centrifugal motion along the longitudinal direction. A baffle plate 5 is connected with a cylindrical disc 1 through bolts, so that dust is prevented from falling into the joint shaft 6; and the hydraulic piston rod 9 is provided with a sealing ring 8, so that a liquid medium in a hydraulic cylinder is isolated. A clamping claw base 4 is connected with the translation base 2 through bolts 3, so that the clamping claw 4 moves along with the movement of the translation base 2; and connection threaded holes are formed in the clamping claw base 4, so that different clamping claws can be changed according to different workpieces.

Owner:WUXI QINGYANG MACHINERY MFG

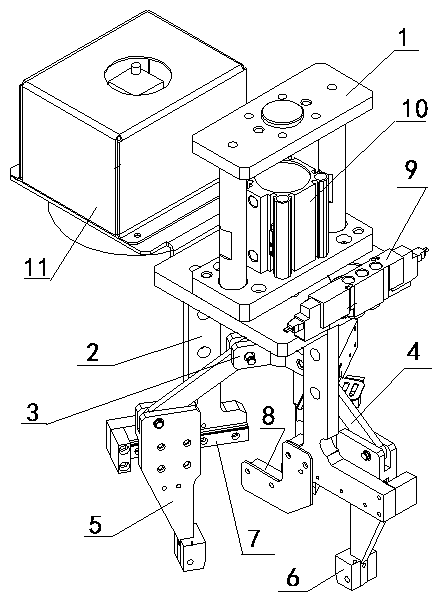

Automatic clamp, automatic grabbing device, mechanical arm and robot

PendingCN111070197AHigh gripping accuracyImprove general performanceProgramme-controlled manipulatorGripping headsSensing dataControl engineering

The invention discloses an automatic clamp, an automatic grabbing device using the automatic clamp, a mechanical arm and a robot. The automatic clamp comprises a driving module, a clamping jaw module,a transmission module, a sensing module and a processing module, wherein the driving module is used for driving the clamping jaw module to clamp a workpiece; the clamping jaw module is used for clamping the workpiece; the transmission module is connected with the driving module and the clamping jaw module and used for transmitting driving force to the clamping jaw module for the driving module; the sensing module is used for sensing the position of the workpiece and whether the workpiece is clamped or not; and the processing module is used for acquiring and processing the sensing data of thesensing module and then issuing an action instruction to the driving module. According to the automatic clamp, the automatic grabbing device, the mechanical arm and the robot, coordinates of a clamping station do not need to be input in advance, the clamping precision is high, the universality is high, the cost is greatly saved, and the production efficiency is greatly improved.

Owner:上海甲佳智能科技有限公司

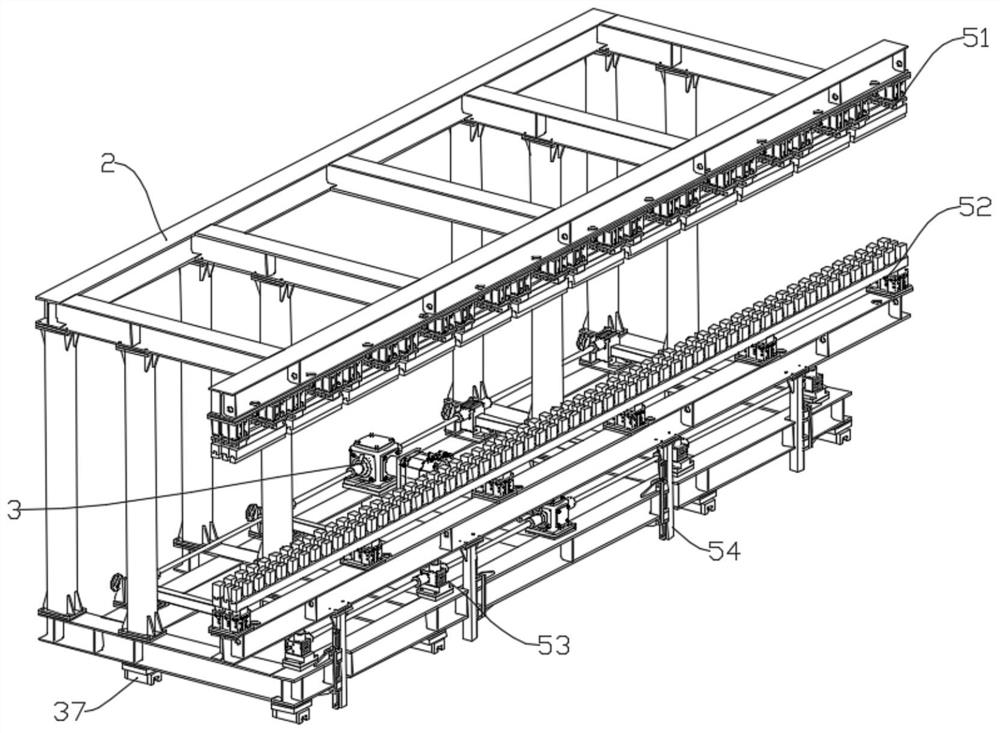

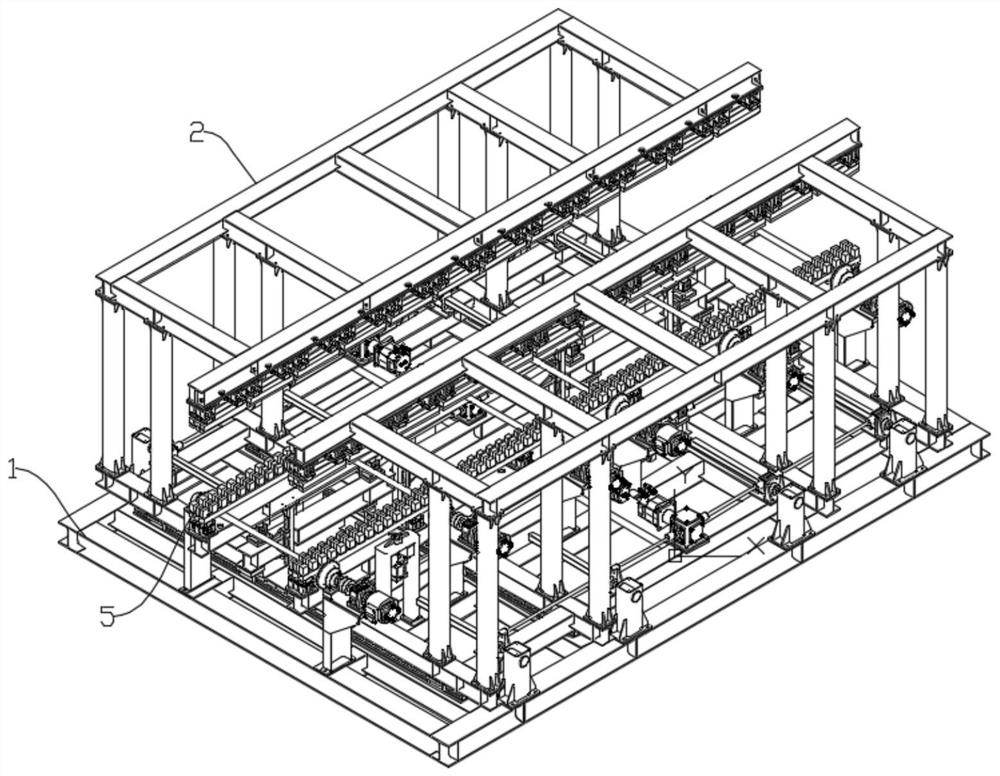

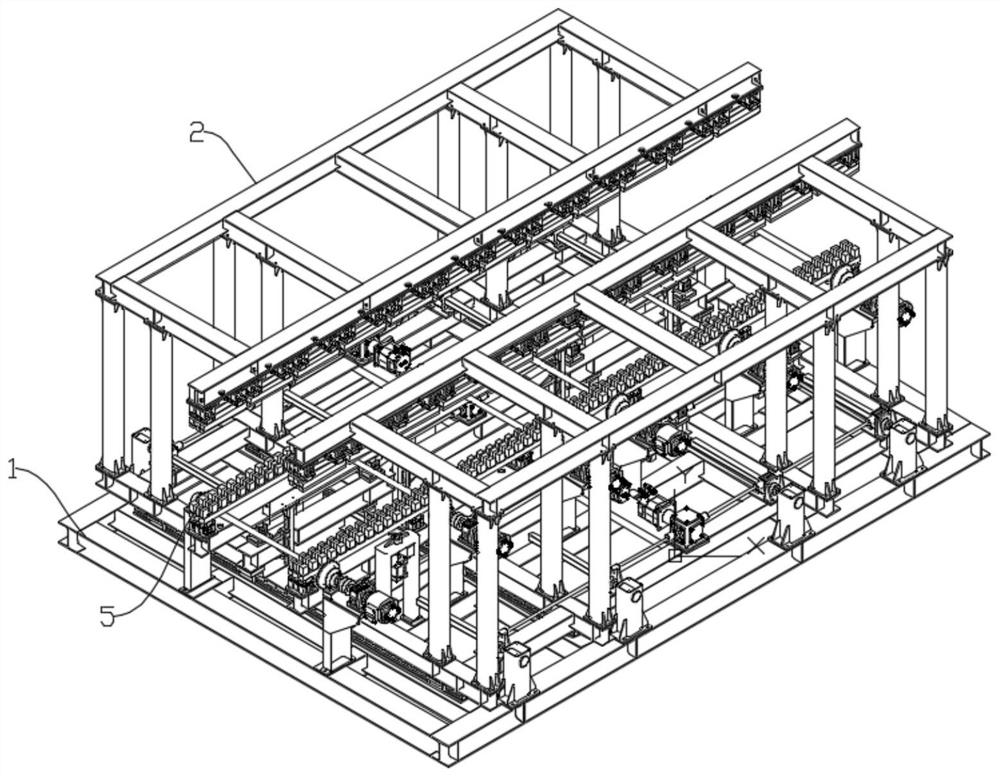

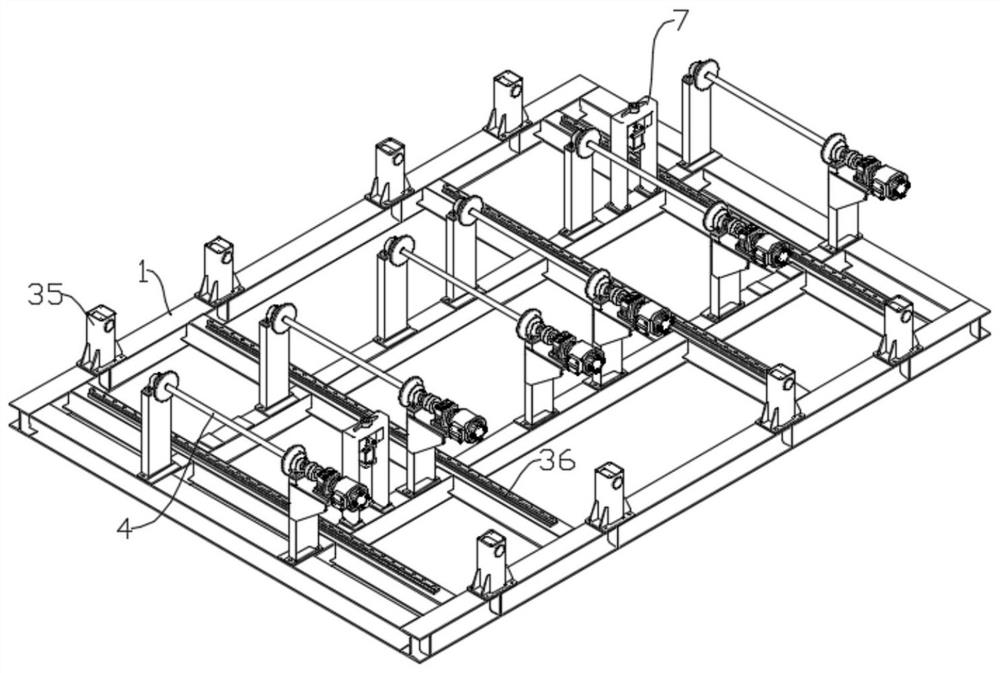

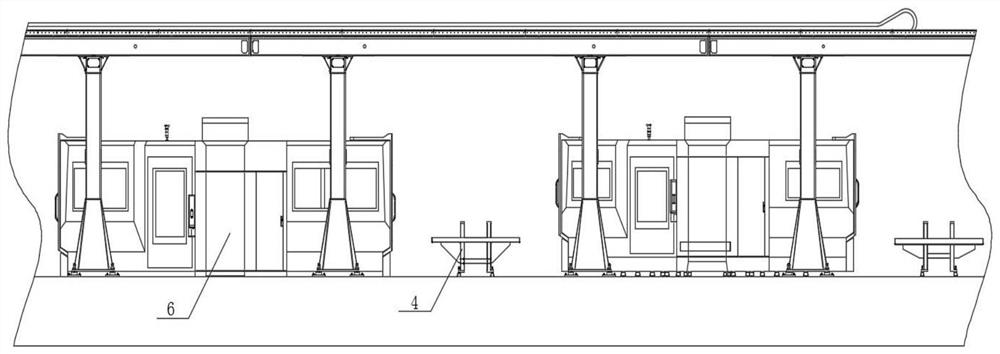

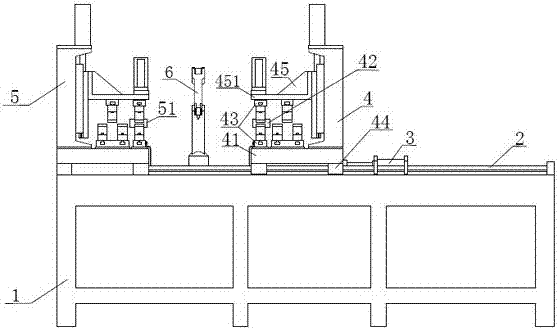

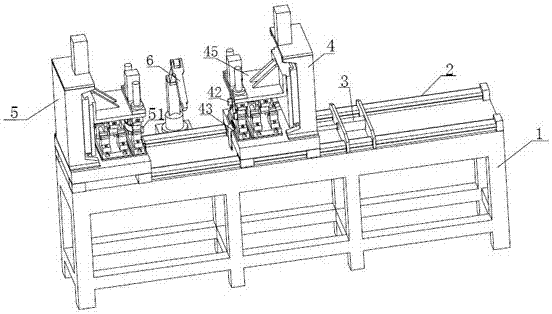

Wet breaking system for concrete blocks or plates

The invention discloses a wet breaking system for concrete blocks or plates, and belongs to the field of concrete material production equipment. The system comprises a vertical steam-curing bottom plate, a semi-finished product crane, an overturning machine, a transverse steam-curing bottom plate and a wet breaking machine. A cutting conveying rail is arranged on a vertical steam-curing rail, andthe transverse steam-curing bottom plate is arranged on a transverse steam-curing rail. The cutting conveying rail and the transverse steam-curing rail are arranged on the two sides of the overturningmachine correspondingly. The semi-finished product crane is located above the overturning machine, and the wet breaking machine is located on the transverse steam-curing rail. The overturning machinecomprises an overturning base, an overturning shaft and an overturning table. The overturning shaft is installed on the overturning base in a rotating manner and fixedly connected with the overturning table. The overturning table is of an L-shaped structure. Fixing devices used for fixing the steam-curing bottom plate are installed on the inner side faces of the two sides of the overturning table. According to the system, blanks stacked vertically can be changed to be stacked transversely, breaking operation is carried out on the blanks stacked transversely, the damage probability in the breaking process of the blanks is reduced, and the yield of the blocks or the plates is increased.

Owner:ANHUI KEDA IND CO LTD

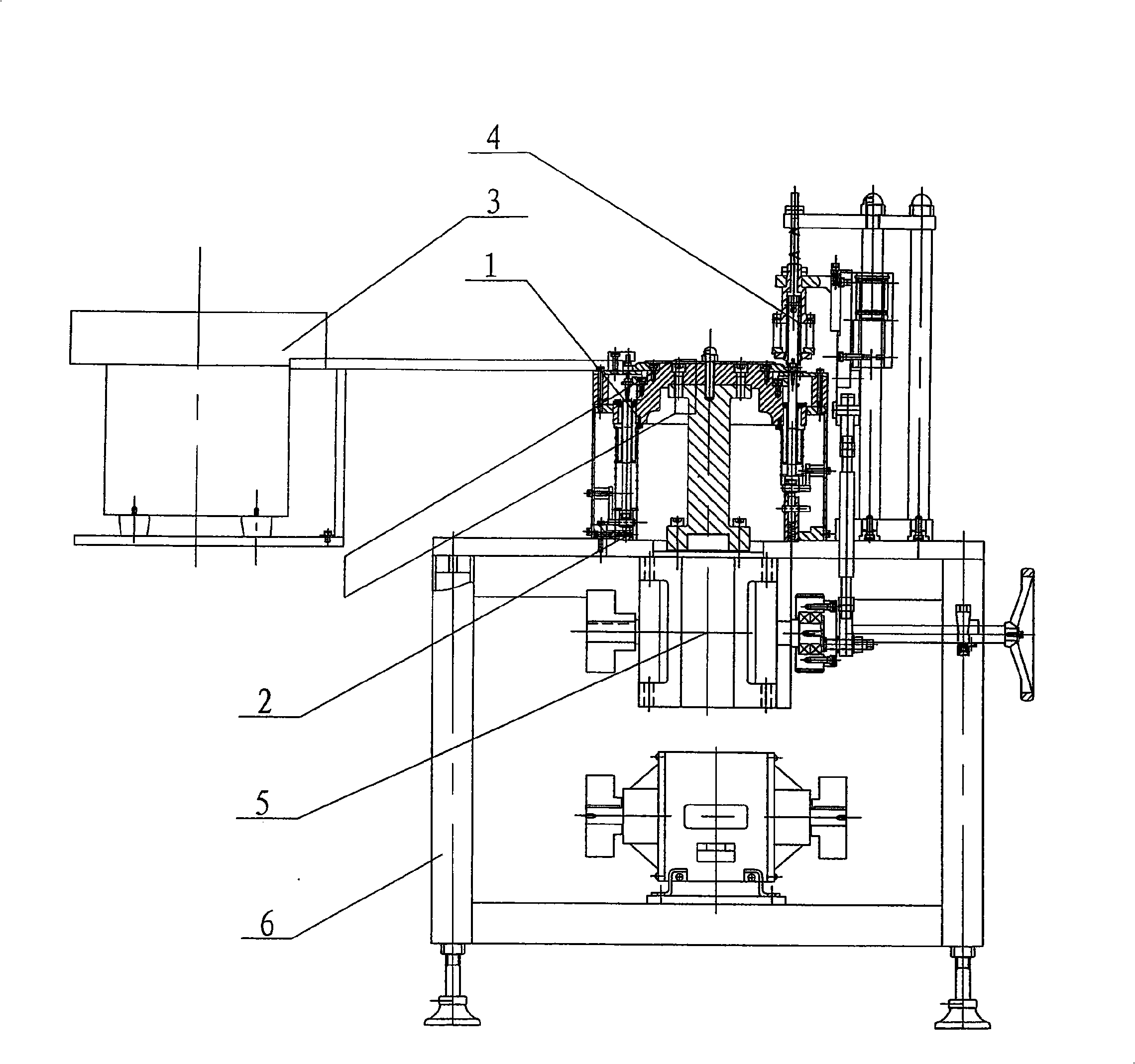

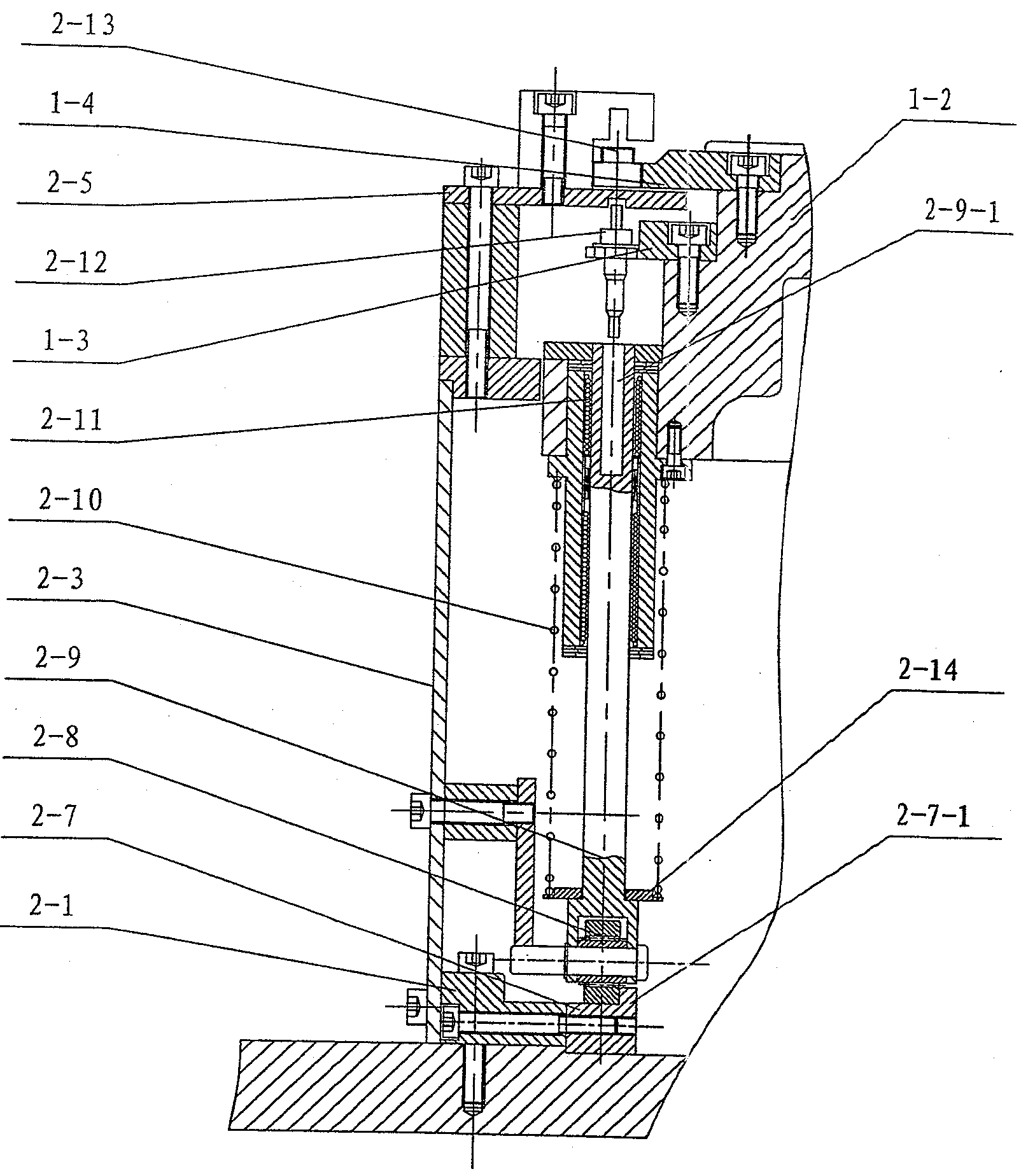

Novel belt-edge convex rail dial type atomizing pump electrified aluminum shell sealing assembly machine

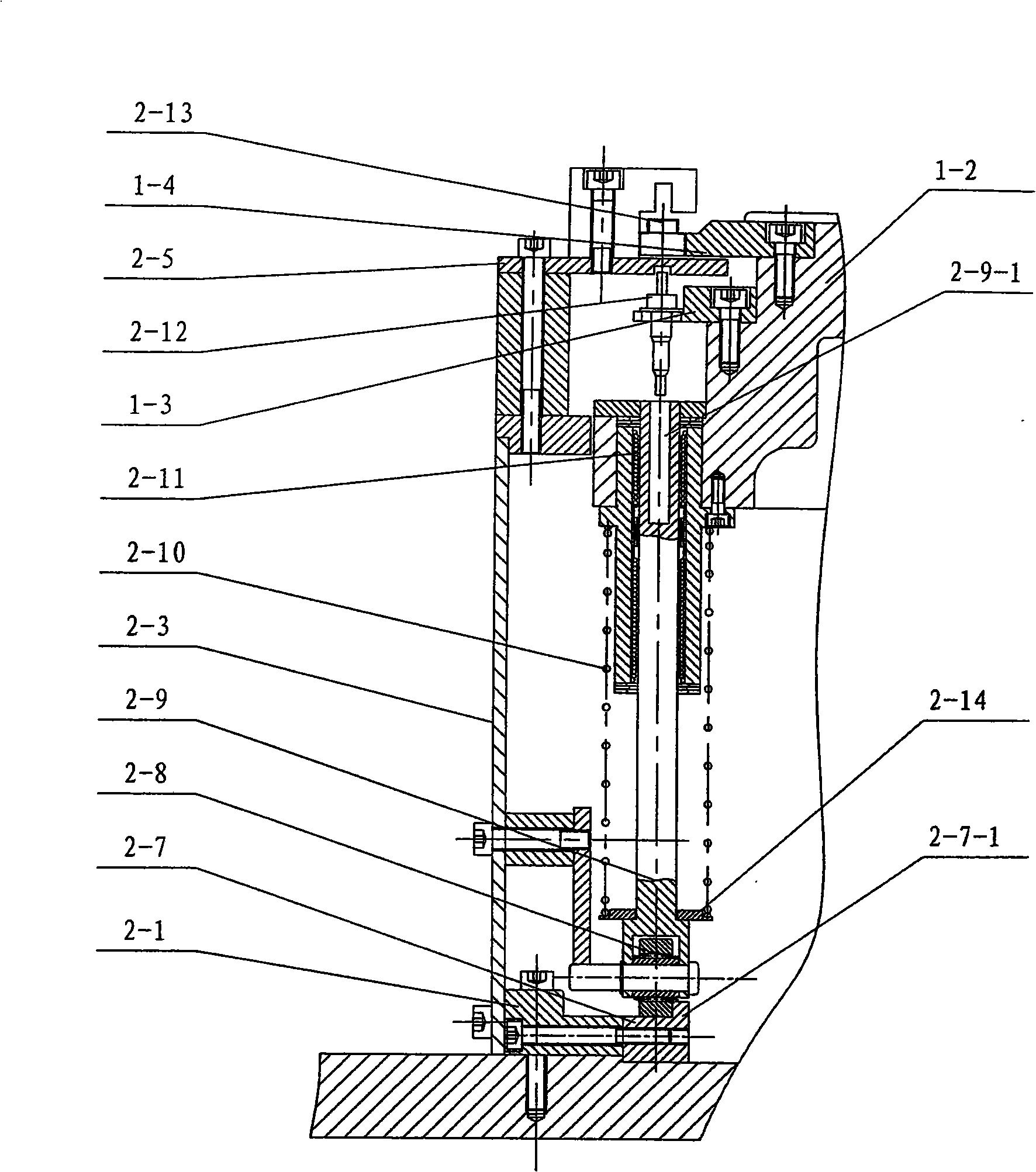

InactiveCN101337322AGood gripping accuracyIncrease the pilot positionMetal working apparatusAluminiumCam

The invention relates to a novel opening grabbing assembly machine for an electric aluminum shell of a rotating-disk spray pump with a bump provided with edges, which is mainly used for automatically assembling the electric aluminum shell of the rotating-disk spray pump and a pump body. The assembly machine comprises a machine seat (6), a rotating disk mechanism (1) and a bump elevating mechanism (2), wherein the rotating disk mechanism (1) is arranged on the machine seat (6) and comprises a main shaft (1-1), a rotating disk seat (1-2), a pump body rotating disk (1-3) and an electric aluminum shell rotating disk (1-4); the bump elevating mechanism (2) comprises a bump fixed seat (2-1), a bump (2-7), a safety block device (2-2), a cam bearing follower (2-8), an elevating shaft (2-9), a linear bearing (2-4), a linear bearing seat (2-11), a first spring(2-10), a spring seat (2-14), a protective cover (2-3), a fixed seat (2-5), a guide positioning block (2-6), a spring cam (2-17) and a second spring (2-18). The assembly machine has the advantages of high opening grabbing precision of the electric aluminum shell and high production efficiency.

Owner:WUXI SUNMART TECH

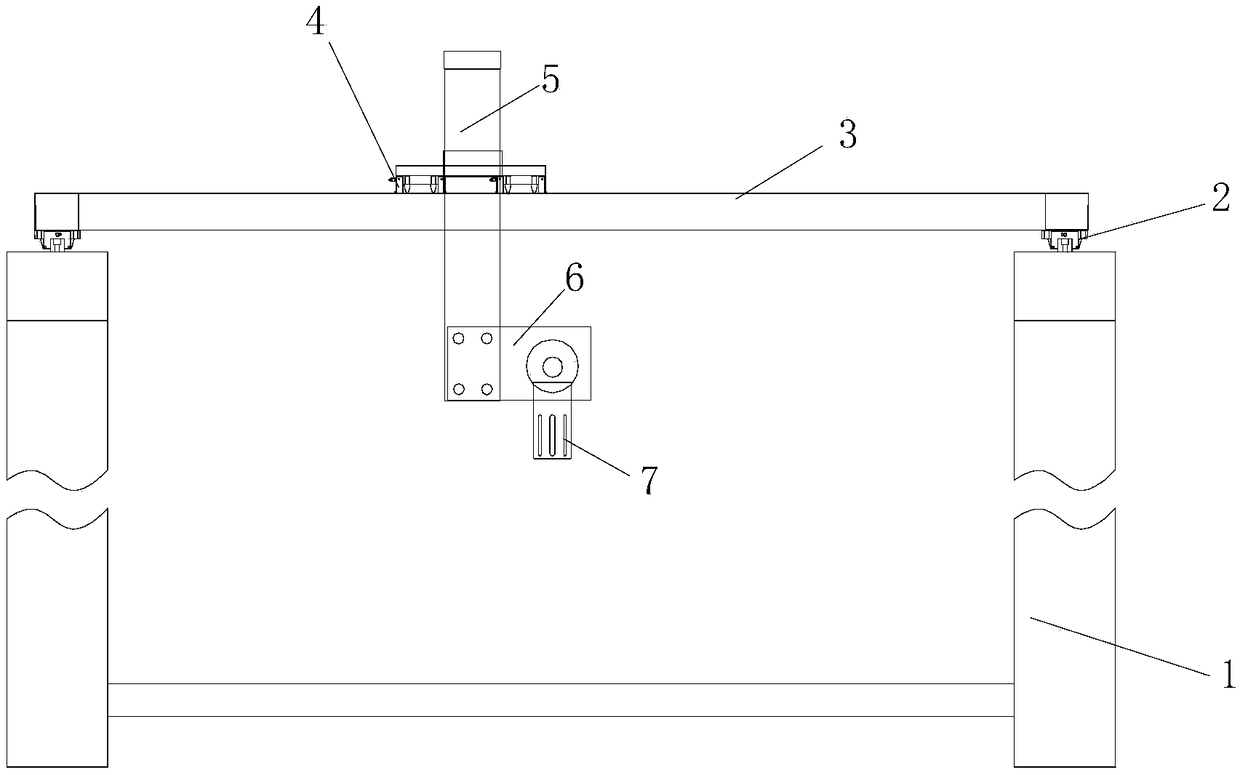

Feeding and discharging temperature detection device of outer ring composite grinding machine

InactiveCN106217150AHigh gripping accuracyImprove working precisionRevolution surface grinding machinesGrinding feed controlEngineeringManipulator

The invention provides a feeding and discharging temperature detection device of an outer ring composite grinding machine. The feeding and discharging temperature detection device comprises a feeding and discharging track. Protection plates are arranged on the two sides of the feeding and discharging track. A material clamping mechanical arm is arranged on one side of the feeding and discharging track. A temperature sensor is arranged above the feeding and discharging track. The temperature sensor is driven by a lifting device arranged at the upper portion to move up and down. The feeding and discharging track is provided with a material detecting device. The material detecting device is correlated to the material clamping mechanical arm and the lifting device. Outer rings are fed and discharged through the feeding and discharging track, the temperature of the outer rings is detected through the temperature sensor, and the too high temperature of the outer rings is avoided. The material clamping mechanical arm and a channel detection device are used for detecting outer ring channels, the work efficiency is improved, the clamping precision of the material clamping mechanical arm is improved through a position detecting device, a discharging pushing air cylinder is arranged for auxiliary discharging, and the work efficiency is improved.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

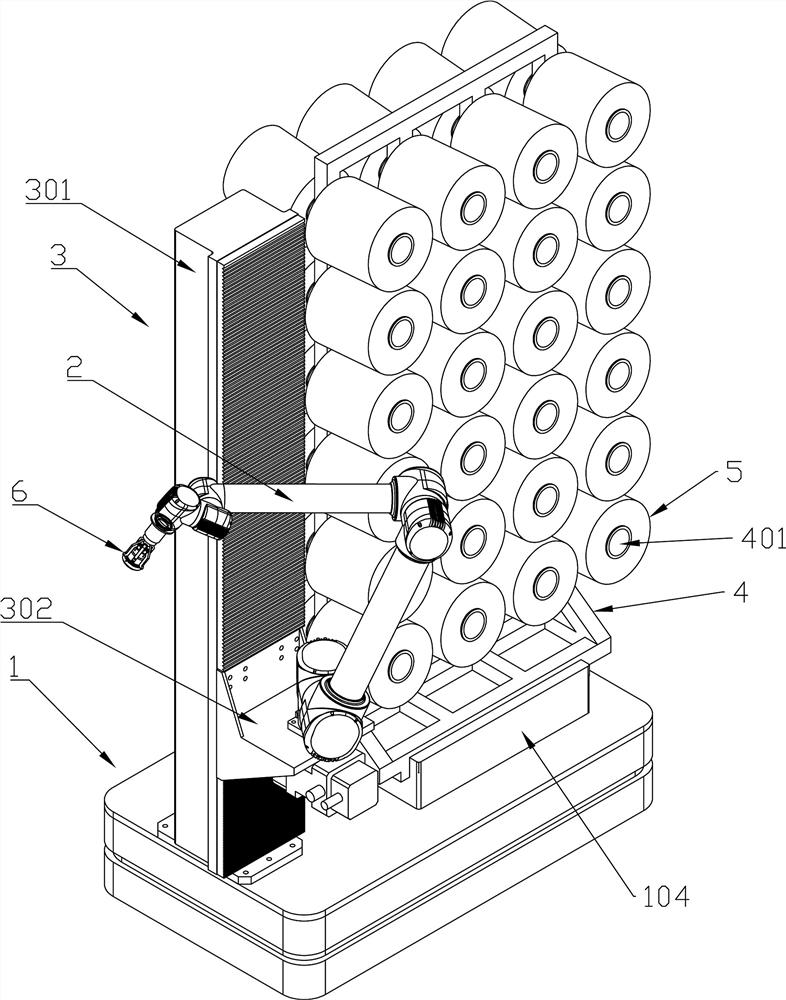

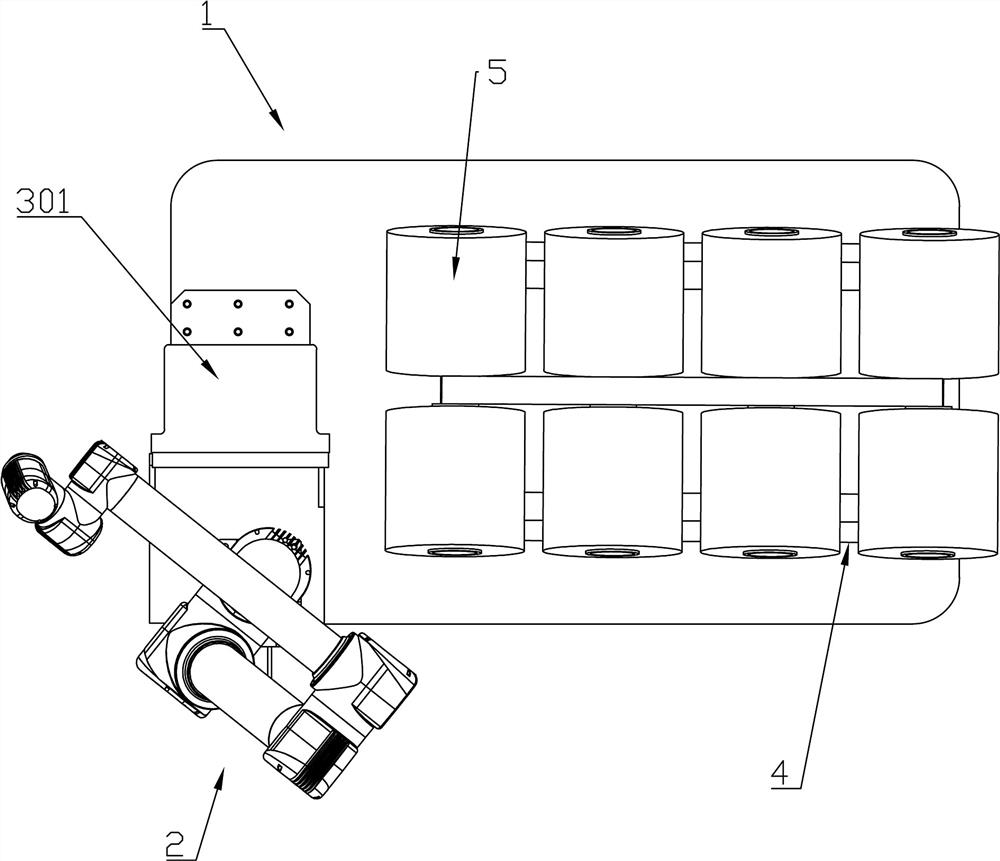

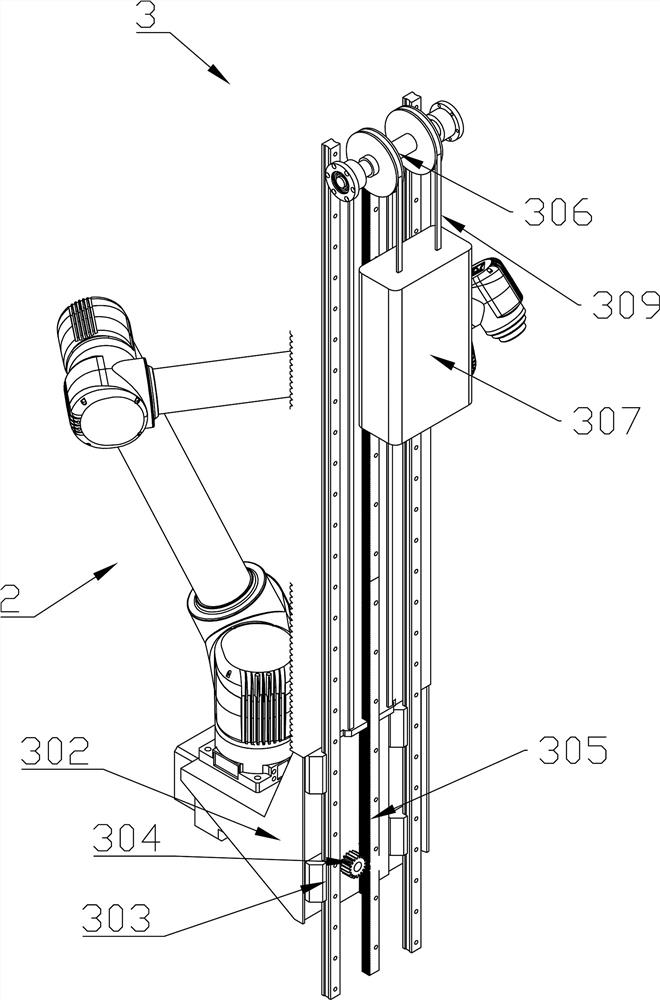

Intelligent wire feeding robot and wire feeding method thereof

PendingCN114380008AIncrease the upper wire rangeAccurate threadingMechanical conveyorsYarnControl engineering

The invention provides an intelligent silk feeding robot which is characterized by comprising an AGV main body device, a linear sliding device is arranged on the AGV main body device, a sliding frame capable of sliding up and down is arranged on the linear sliding device, a multi-axis robot with a clamp device is arranged on the sliding frame, and a creel is arranged on one side of the linear sliding device on the AGV main body device. A plurality of grey yarn supporting rods are arranged on the two sides of the creel, each grey yarn supporting rod is approximately horizontally arranged, the grey yarn supporting rods are used for containing grey yarn rolls, the clamp device is provided with a plurality of clamping jaws capable of being opened in the axial direction, and a camera is arranged at the front end of the clamp device. Therefore, the purposes of reducing the working intensity and improving the working efficiency are achieved.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

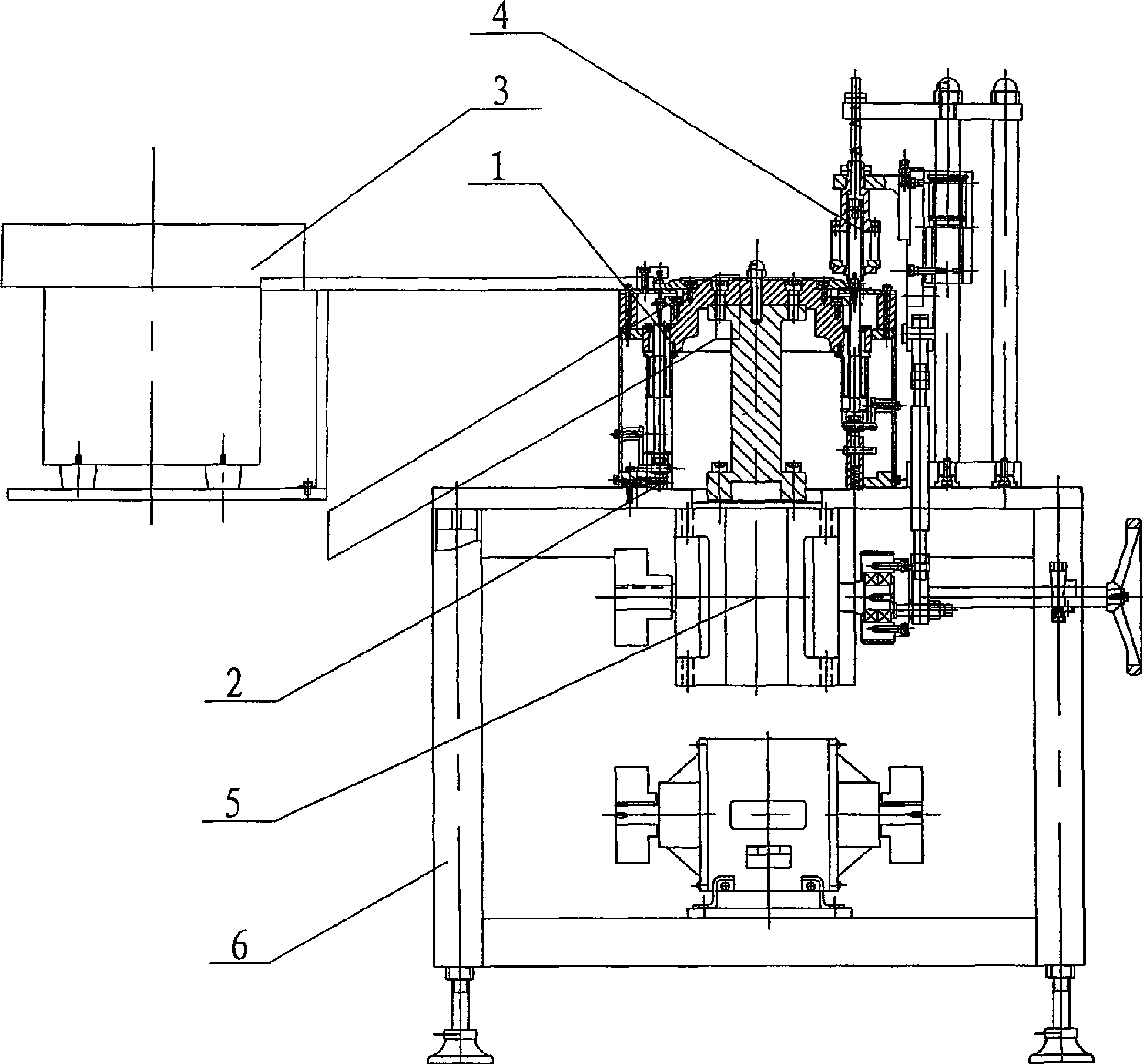

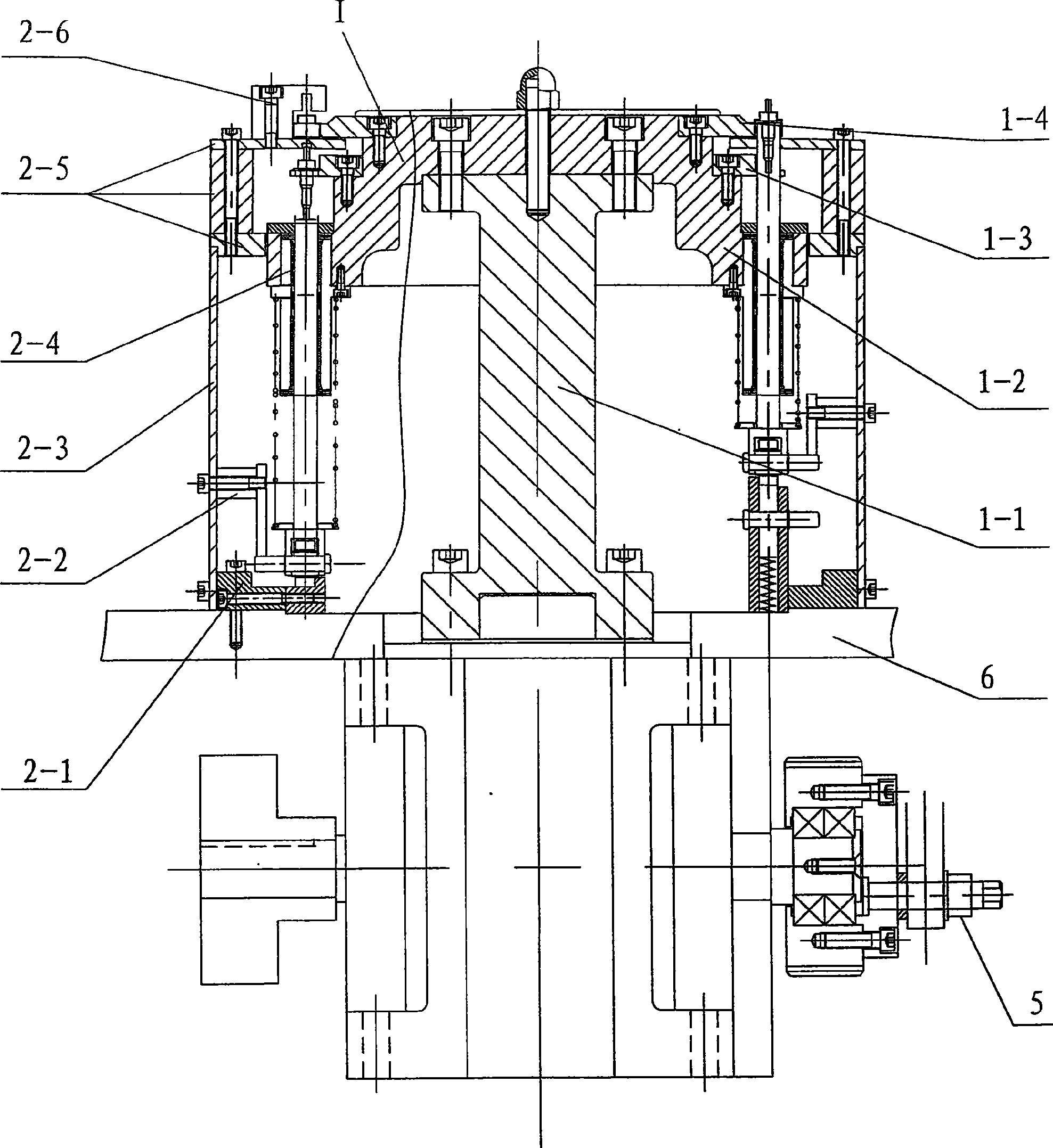

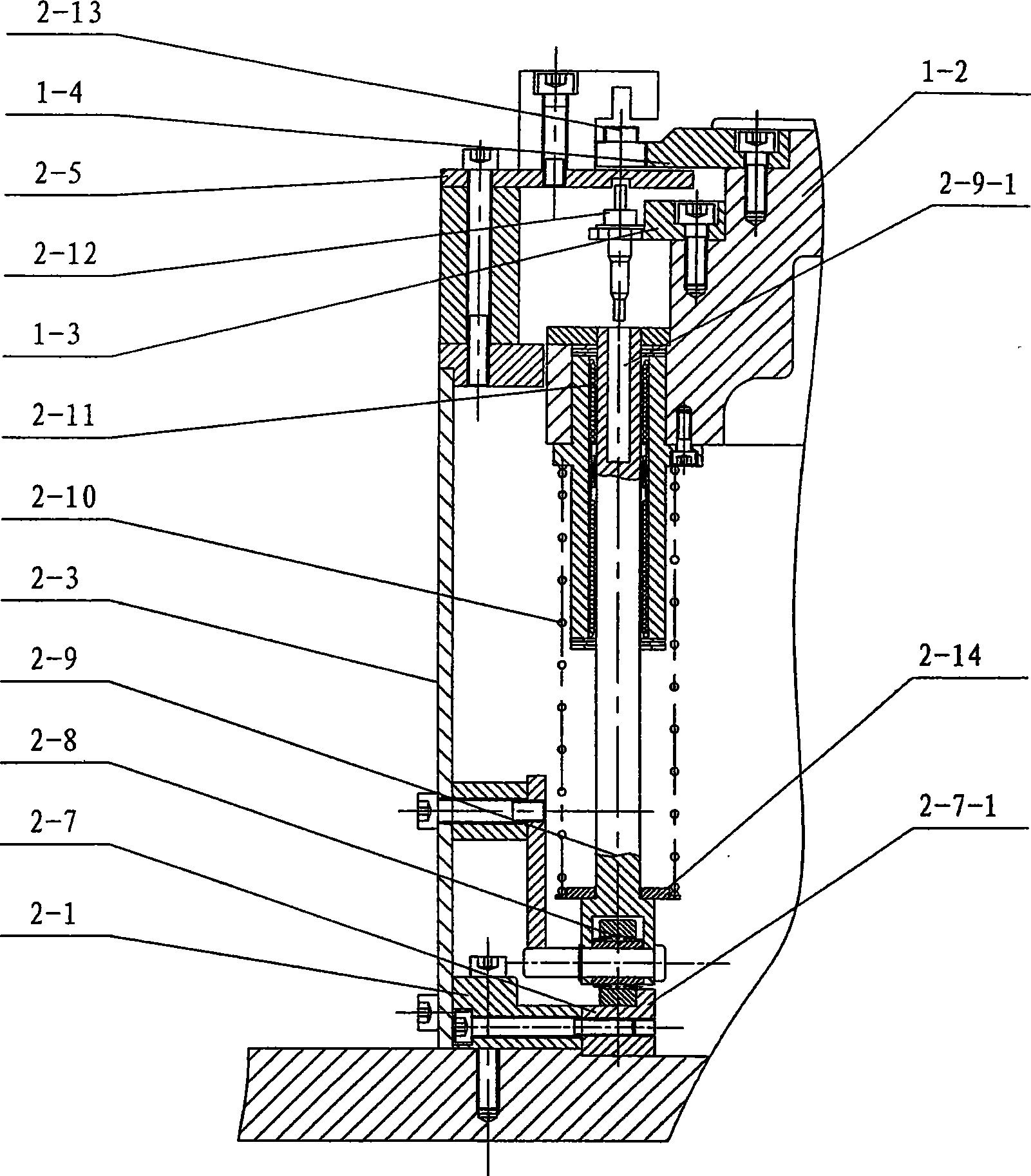

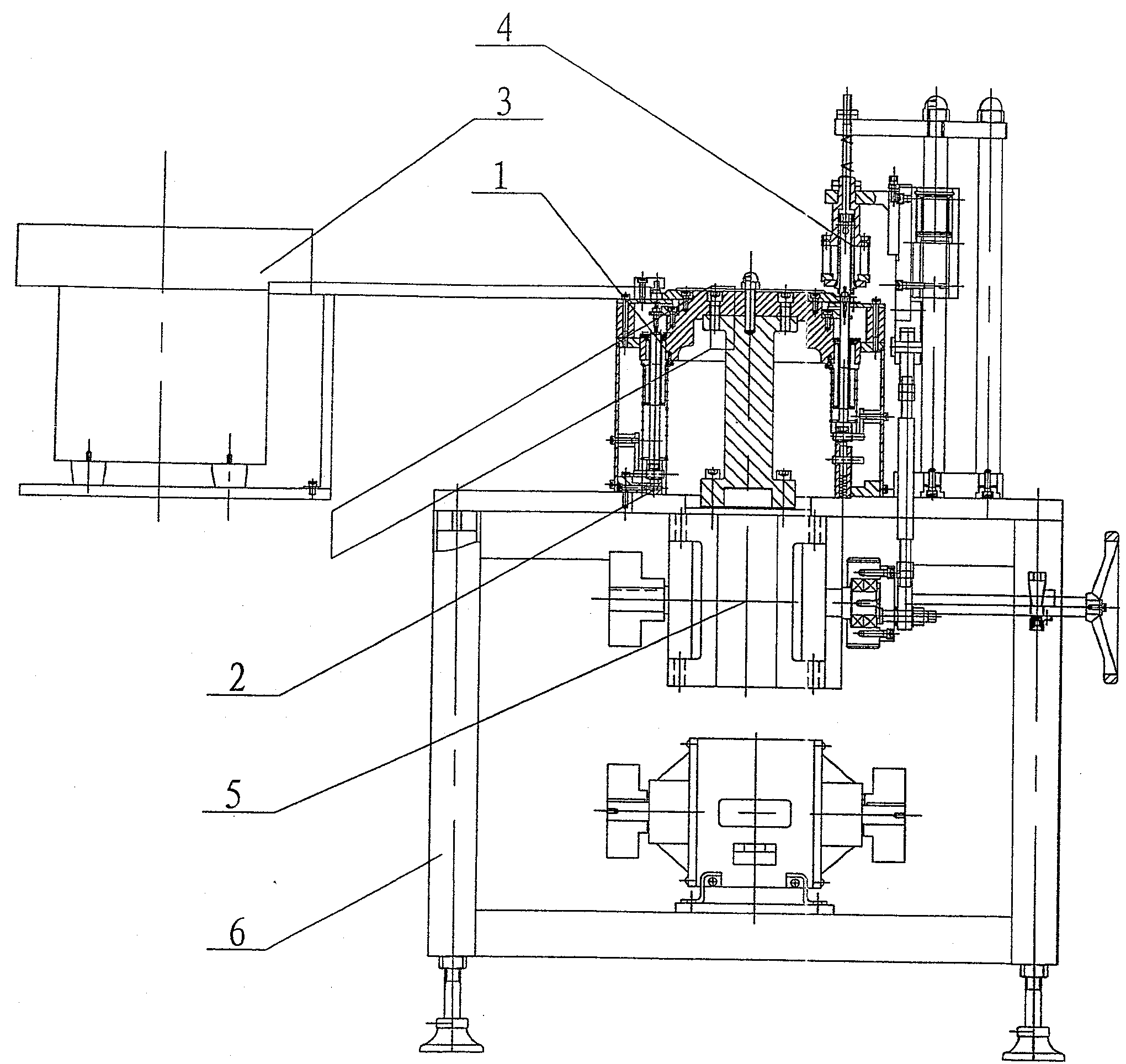

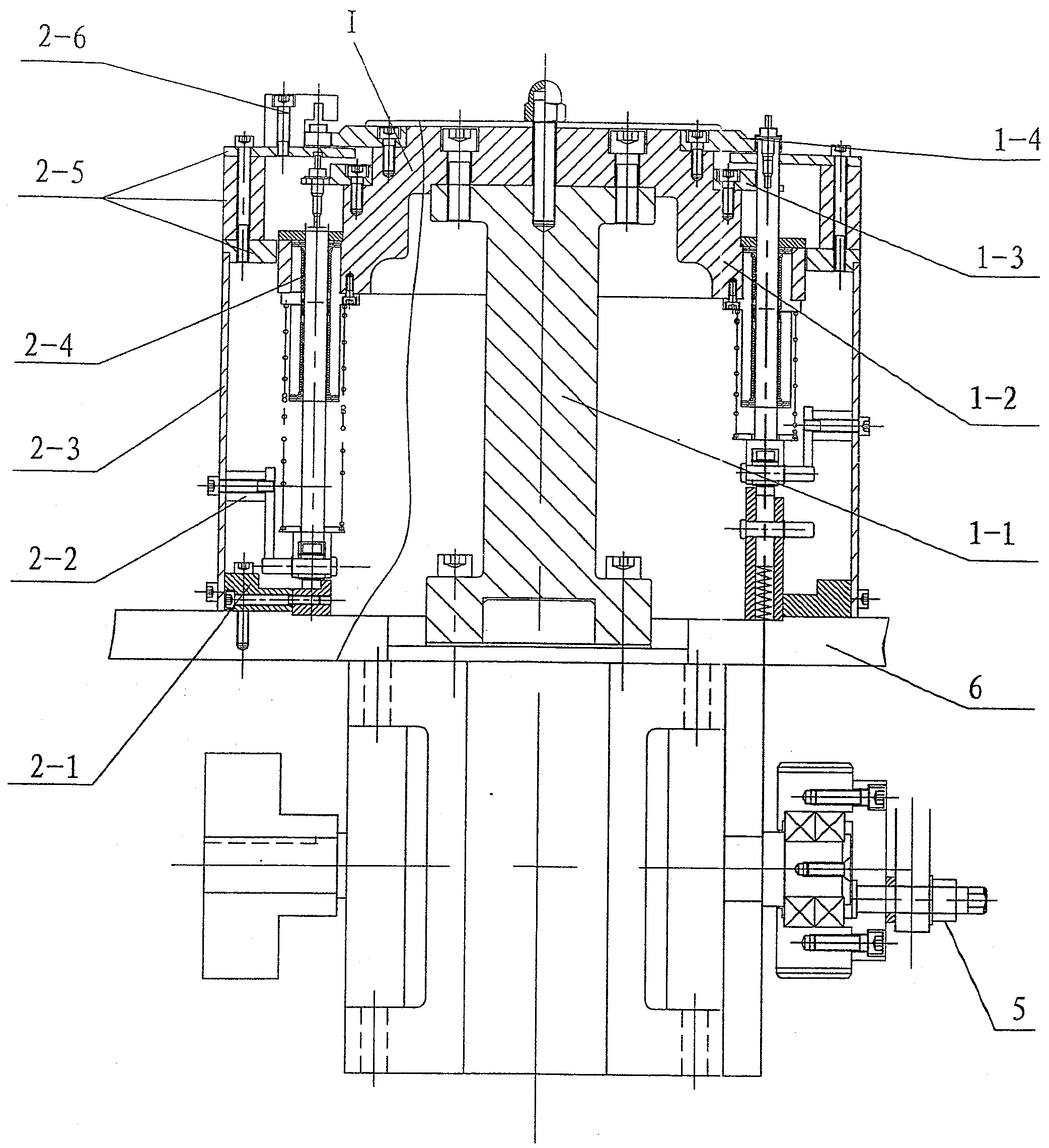

Novel atomizing pump electrified aluminum-shell sealing assembly machine

The invention relates to a novel mouth seizing assembly machine for a spray pump electrical aluminum shell, which is used for automatic assembly of a spray pump electrical aluminum shell and a pump body. The assembly machine comprises a machine seat(6), a rotary table mechanism(1), a convex rail lifting mechanism(2), a vibration tray material-feeding mechanism(3), a mouth seizing mechanism(4) and a divider mechanism(5). The rotary table mechanism (1) includes a main shaft(1-1), a rotary table seat(1-2), a pump body rotary table(1-3) and an electrical aluminum shell rotary table(1-4). The convex rail lifting mechanism (2) includes a convex rail fixing seat(2-1), a convex rail(2-7), a safety block device(2-2), a cam bearing follower(2-8), a lifting shaft(2-9), a linear bearing(2-4), a linear bearing seat(2-11), a first spring(2-10), a spring seat(2-14), a fixed seat(2-5), a guide positioning block(2-6), a marble cam(2-17) and a second spring(2-18). The mouth seizing mechanism (4) includes a guide shaft(4-1), a linear bearing(4-2), a guide seat(4-3), a joint bearing(4-3), a bottom seat plate(4-5), a handle(4-6), an eccentric wheel(4-7), a connecting bar(4-8), a seizing claw(4-9) and an upper seat plate(4-10). The machine has a high precise in assembling the pump body and the electrical aluminum shell.

Owner:WUXI SUNMART TECH

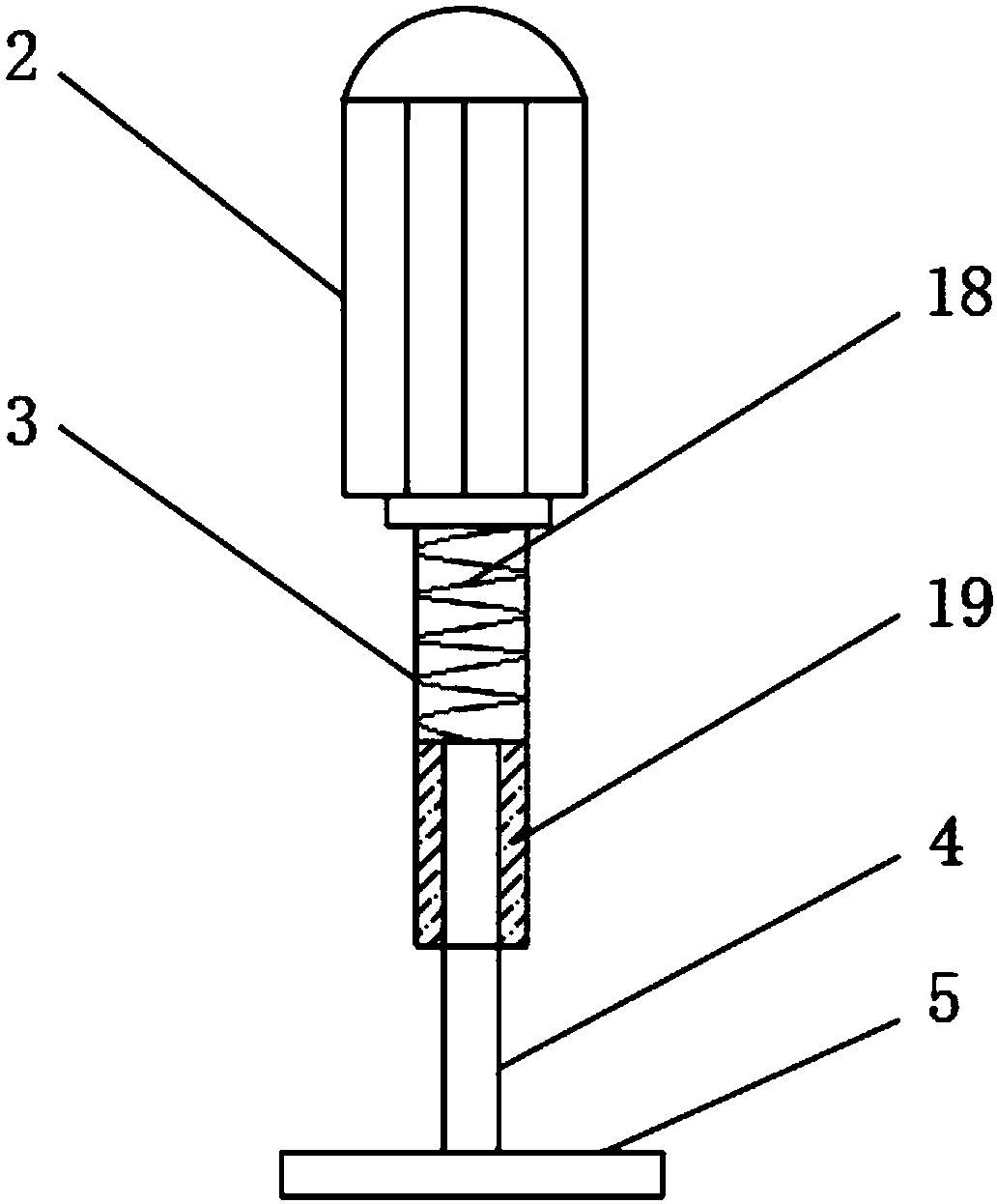

Fruit mechanical picker for artificial intelligence planting

ActiveCN113057022AHigh gripping accuracyAvoid misclamps or empty clampsPicking devicesHorticultureElectric machinery

The invention relates to the technical field of artificial intelligence hardware and discloses a fruit mechanical picker for artificial intelligence planting. The fruit mechanical picker for artificial intelligence planting comprises a connecting base, a control motor is arranged above a center of the connecting base, a transmission buckle is arranged above the control motor, a flexible sleeve is arranged at an upper end of the transmission buckle, a flow guide bowl is arranged in the flexible sleeve, a lining is arranged on an upper side of an interior of the flow guide bowl, a wind wheel is arranged in a center of an interior of the lining, a center piece is movably connected to an upper side of the lining, and a plurality of clamping grooves are formed in an inner wall of an outer ring of the center piece. In the fruit mechanical picker for artificial intelligence planting, the wind wheel rotate, negative pressure is formed in an upper section of a protection barrel, fruits are sucked and picked, a clamping jaw is ensured to grab the fruits, positive pressure is provided at an annular outlet in a top part of the flow guide bowl, the flexible sleeve is driven to drive the center piece to rotate to achieve a clamping action, the suction clamping action is completed in the protection barrel, clamping precision is improved, and mistaken clamping or empty clamping is effectively avoided.

Owner:聊城市飓风工业设计有限公司

Crystal grain moving clamp

InactiveCN106024694AFlexible grabReduce areaSemiconductor/solid-state device manufacturingEngineeringMotor control

The invention discloses a crystal grain moving clamp, which comprises a motor control rod. The lower end of the motor control rod is fixed with a disc-shaped clamp fixing disc; and multiple equidistant mounting grooves are arranged at edges of the lower surface of the clamp fixing disc. The crystal grain moving clamp also comprises clamp claws. Each clamp claw comprises a first arm rod fixed above the mounting groove; the tail end of the first arm rod is provided with a second arm rod and the second arm rod can rotate around the tail end of the first arm rod relative to a first axis; the tail end of the second arm rod is provided with a third arm rod and the third arm rod can rotate around the tail end of the second arm rod relative to a second axis; and the tail end of the third arm rod has a flat structure, and the tail end of the flat structure is a sharp end. According to the crystal grain moving clamp disclosed by the invention, through a matched motor group, the clamp can flexibly grasp a crystal grain with a small area and thin thickness, the grasping accuracy is high, the crystal grain is firmly fixed after being grasped, and the crystal grain is likely to fall.

Owner:WUXI HI NANO TECH

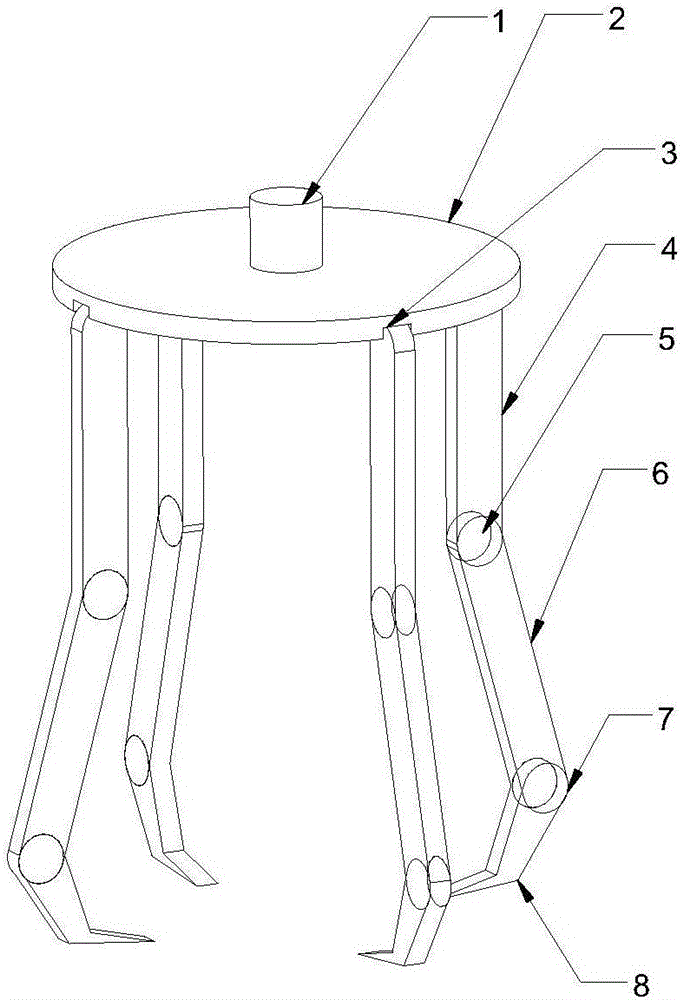

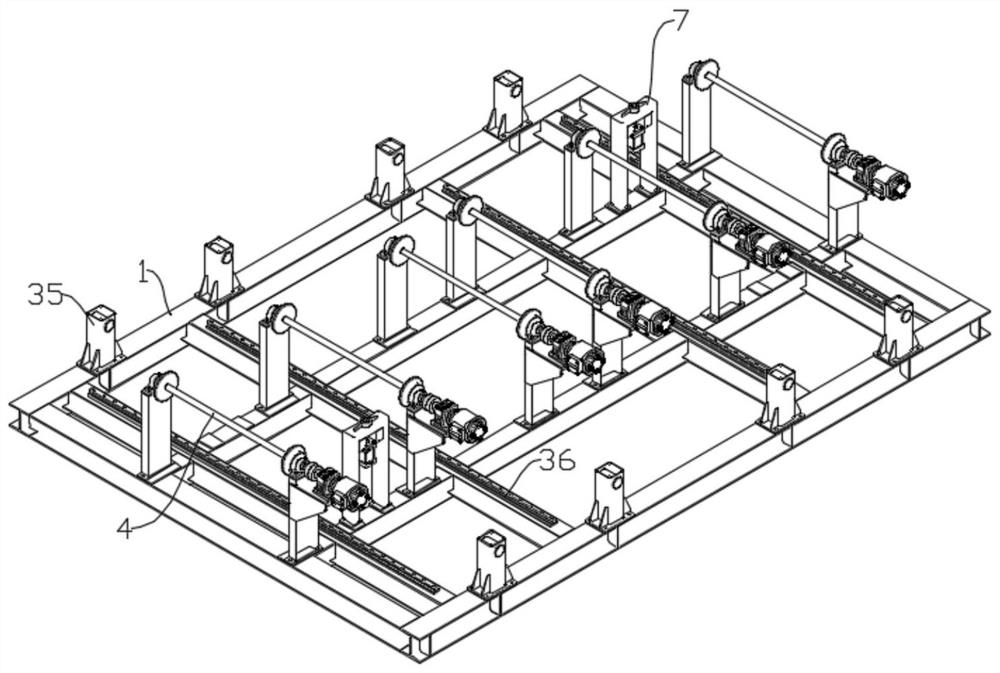

Hydraulic feeding device

InactiveCN105290303AHigh gripping accuracyExpand the scope of activitiesHandling devicesHydraulic cylinderLiquid medium

The invention discloses a hydraulic feeding device. The hydraulic feeding device is fixed to the ground through four cylindrical legs. After a base is fixed to the ground, a rotating hydraulic table is fixed to the base, the rotating angle of the rotating hydraulic table is controlled hydraulically, the rotating range is 0-24 degrees, and a liquid inlet controls entering and exiting of liquid media. Then, a screw device is installed on the rotating hydraulic table and is connected and fixed through a bolt, and three screw pillars are arranged and are shown in the drawing. Afterwards, a corresponding hydraulic cylinder is installed on a square positioning box, the square positioning box is provided with three threaded holes matched with the screw pillars, the positioning box is arranged on a screw in a sleeving manner, and the height adjusting range of the positioning box is 200-800 mm. A feeding jaw is connected with the top of the hydraulic cylinder, and therefore the running length of the feeding jaw can be adjusted along with stretching and contracting of the hydraulic cylinder, wherein the length adjusting range of the feeding jaw is 160 mm-960 mm.

Owner:WUXI QINGYANG MACHINERY MFG

Wet parting process for concrete blocks or plates

ActiveCN112589981AFix damageImprove yieldAuxillary shaping apparatusArchitectural engineeringEngineering

The invention discloses a wet parting process for concrete blocks or plates, and belongs to the field of concrete material production. The process comprises the following steps of turnover preparation, green body turnover, green body steam curing and the like, vertically stacked green bodies can be changed into transversely stacked green bodies, the transversely stacked green bodies are parted, the damage probability of the green bodies during parting is reduced, and the yield of building blocks or the plates is increased.

Owner:ANHUI KEDA IND CO LTD

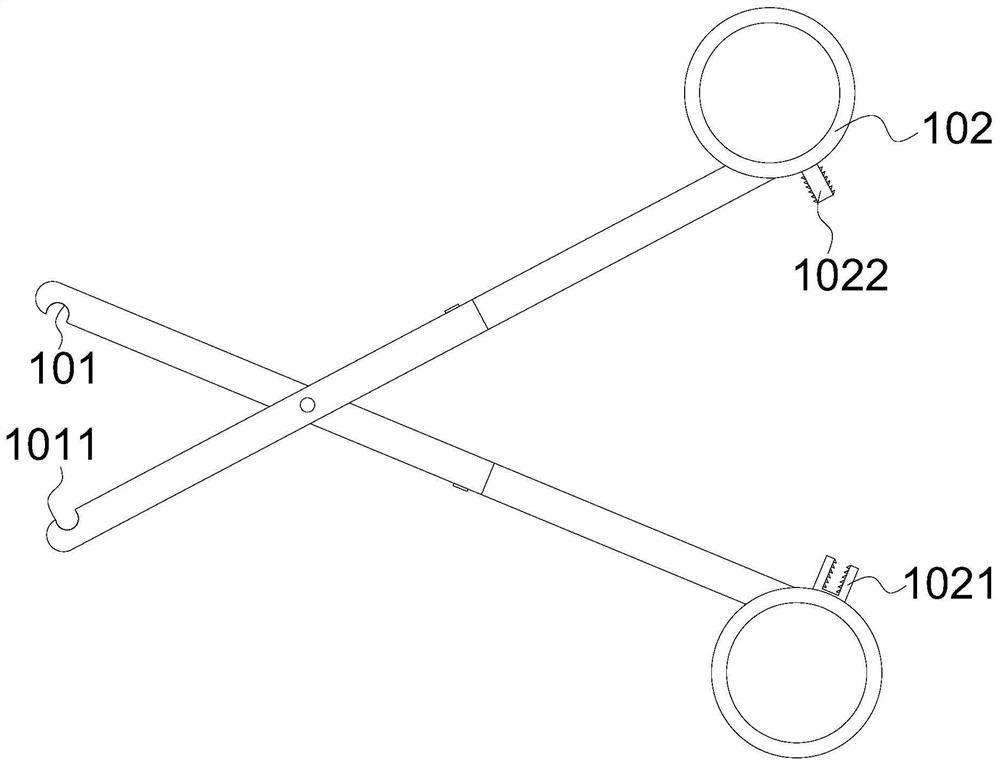

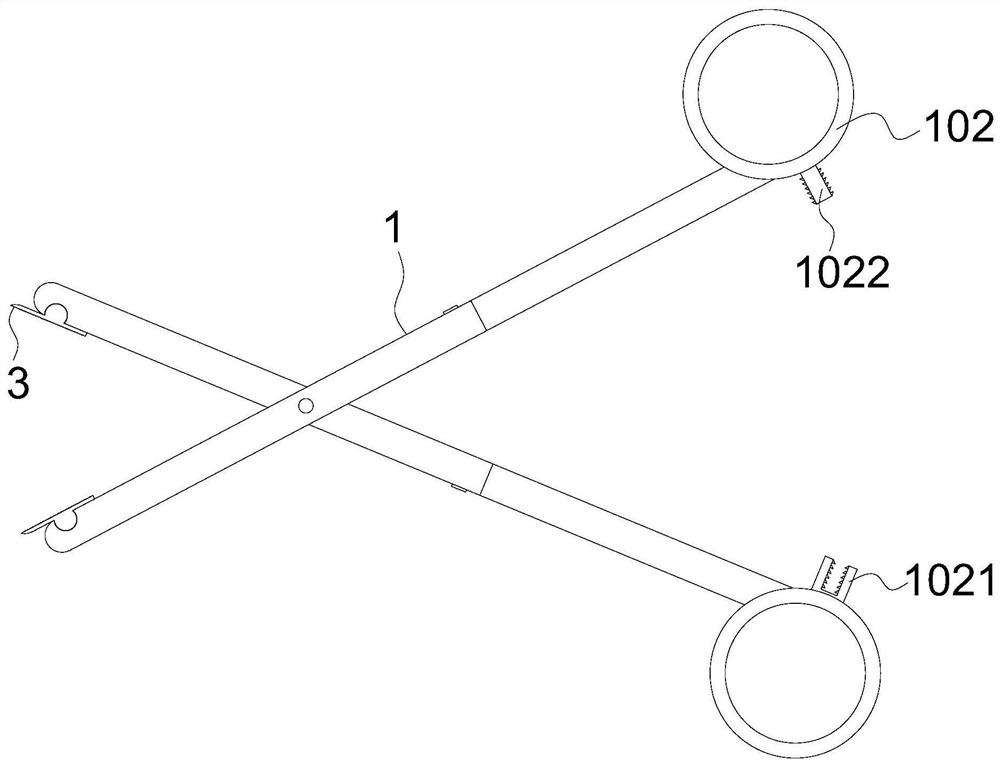

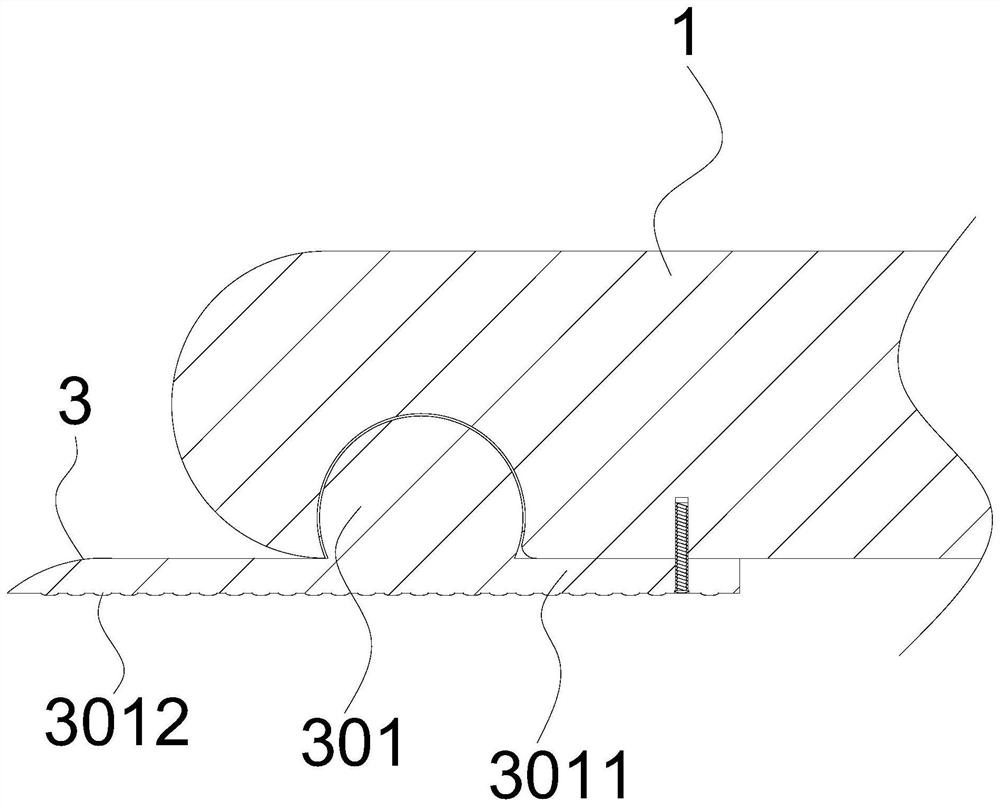

Operating forceps for obstetrics and gynecology department

ActiveCN112914623AIncrease capacitySave energyVaccination/ovulation diagnosticsObstetrical instrumentsForcepsEngineering

The invention provides operating forceps for obstetrics and gynecology department, and relates to the technical field of medical instruments. The operating forceps for obstetrics and gynecology department comprise a pair of forceps bodies which are hinged to each other, wherein notches are formed in two opposite side walls of one ends of the two forceps bodies, the notches are in concave arc shapes, finger rings are arranged at the other ends of the forceps bodies, and the corners of the ends, away from the finger rings, of the notches are in blade shapes. The corners of the sides, close to the ends, of the notches are arranged to be in the blade shapes, when the forceps bodies are folded, the two notches form a clamping shape, two blade parts generate shearing force, clamping and cutting-off of a material taking assembly are achieved, it can be guaranteed that medical workers can cut off and sample tissue at a time through the design, secondary sampling operation is avoided, and the sampling risk is reduced. The operating forceps are convenient to use and simple in structure, the notches are formed in the ends of the forceps bodies, tissue cutting sampling is performed through the blade parts at the corners of the notches, the pain of a patient during sampling can be reduced, the sampling efficiency is improved, and the operating forceps have high practical value and are convenient to popularize in a large range.

Owner:朱新晶

Light arrangement fixture

PendingCN107053227AAchieve grippingPrevent disengagementGripping headsStructural engineeringMechanical engineering

Owner:DONGGUAN POLYTECHNIC

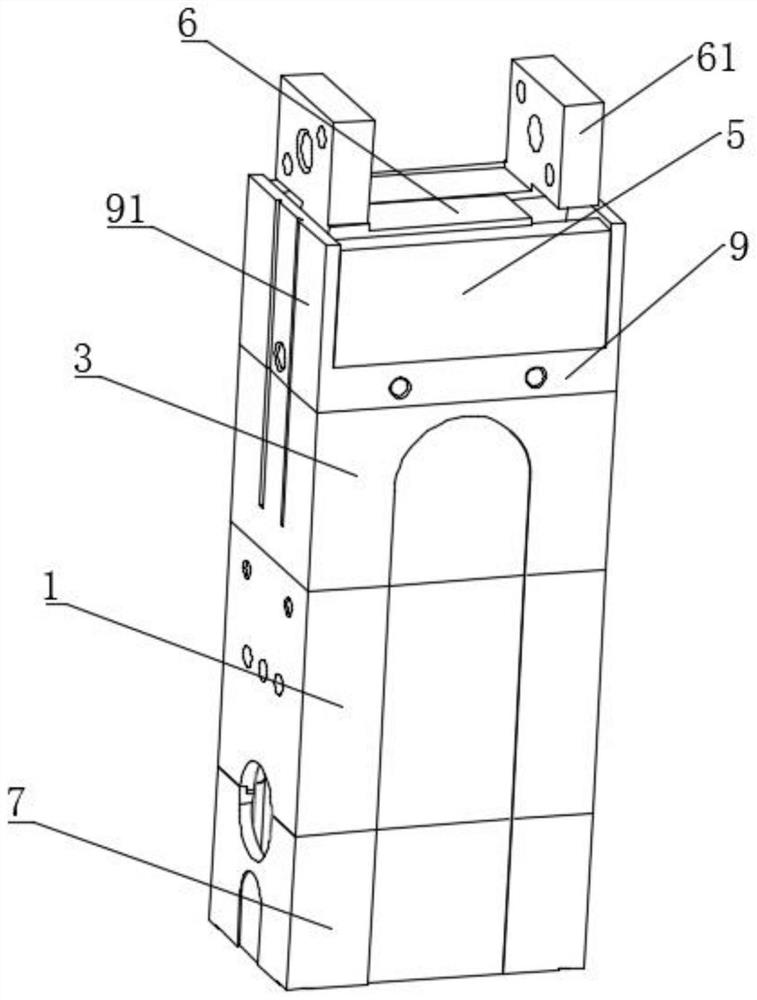

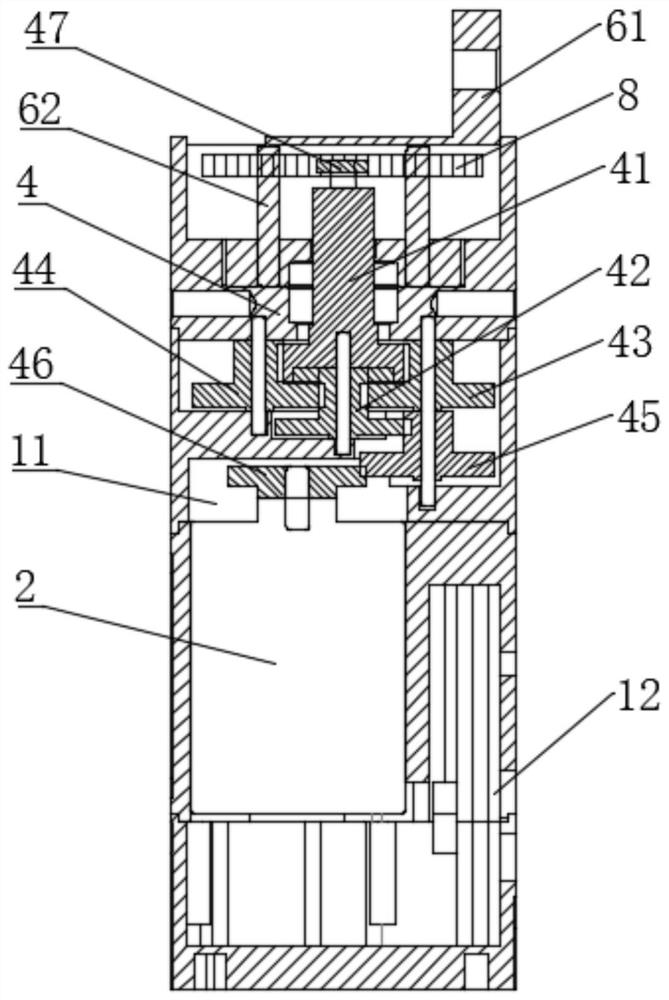

High-precision double-finger clamping jaw

The high-precision miniature double-finger clamping jaw comprises a main body and a main driving piece installed in the main body, an installation base is installed on the main body, a gear set is arranged in the installation base, and a driving shaft of the main driving piece is in transmission connection with the gear set; a clamping jaw seat is fixedly mounted above the mounting seat, two clamping jaws which are arranged in a central symmetry mode are slidably mounted in the clamping jaw seat, the two clamping jaws are arranged in a central symmetry mode and are both in transmission connection with the gear set, the two clamping jaws synchronously and relatively move in the clamping jaw seat through the gear set, each clamping jaw comprises a clamping part, and the clamping parts are arranged on the clamping jaw seat. And the clamping parts of the two clamping jaws are correspondingly arranged. The clamping device is convenient to operate, simple in structure, compact in structural design, small in overall size, stable in operation and high in clamping precision.

Owner:苏州触点机器人科技有限公司

A wet breaking process of concrete block or plate

ActiveCN112589981BFix damageImprove yieldAuxillary shaping apparatusConstruction engineeringStructural engineering

The invention discloses a wet breaking process of concrete blocks or plates, which belongs to the field of concrete material production. It includes the steps of overturning preparation, overturning green bodies, and green body steaming, which can make the vertically stacked green bodies become horizontal stacks, and perform splitting operations on the horizontally stacked green bodies to reduce the impact of the green bodies during splitting. Damage probability, improve the yield of blocks or plates.

Owner:ANHUI KEDA IND CO LTD

Permanent magnetic ferrite wet forming magnetic shoe carrying device

PendingCN108724444AHigh precisionRun smoothlyConveyorsDischarging arrangementEngineeringMechanical engineering

Owner:德昌电机(南京)有限公司

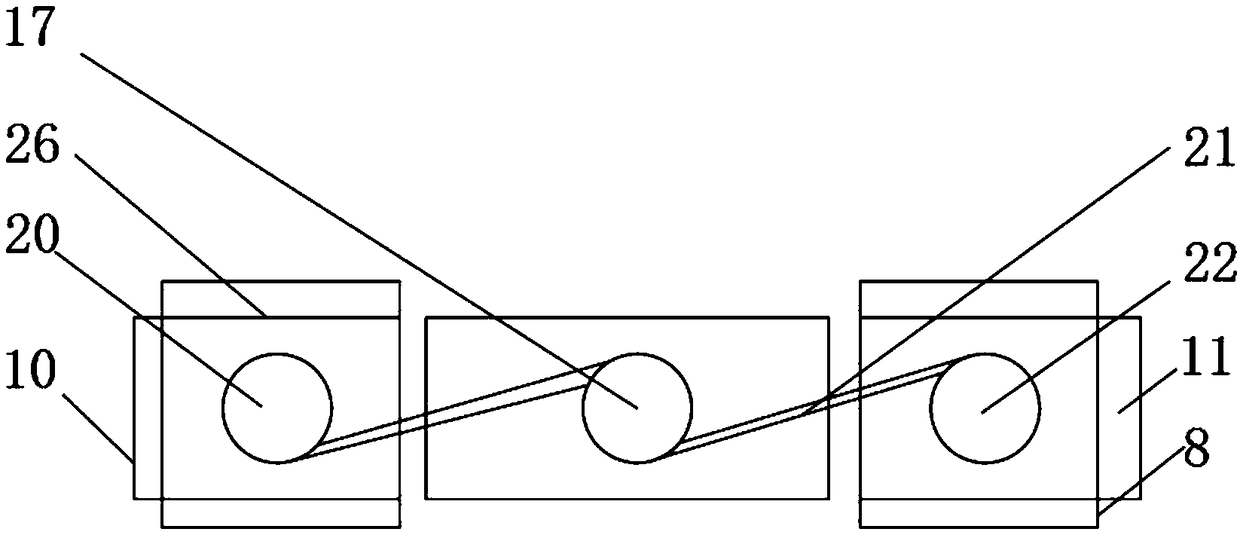

Robot clamp for industrial processing

The invention provides a robot clamp for industrial processing, and relates to the technical field of the robot clamp. The robot clamp comprises a hydraulic tank, and a motor I is fixedly arranged onthe left side of the hydraulic tank. By the matching of the hydraulic tank, the motor I, a spring shell, a push rod, a push disc I, a push disc II, an oil groove, a clamping plate, a hydraulic pipe, aspring, a metal shell I, a metal shell II, a sliding chute I and a sliding chute II, the clamping plate can do scalable motion, electric power is saved, abrasion of all moving parts is avoided, and the robot clamp maintains good clamping precision. By the matching of a clamping device I, a clamping device II, a support pillar, a tensioner shell, a transmission drum I, a transmission drum II, a transmission drum III, a transmission belt, a motor II and a transmission shaft, the robot clamp prevents a workpiece from dropping and reduces noise during clamping, and the transmission process is stable.

Owner:宗芳

Novel atomizing pump electrified aluminum-shell sealing assembly machine

The invention relates to a novel mouth seizing assembly machine for a spray pump electrical aluminum shell, which is used for automatic assembly of a spray pump electrical aluminum shell and a pump body. The assembly machine comprises a machine seat(6), a rotary table mechanism(1), a convex rail lifting mechanism(2), a vibration tray material-feeding mechanism(3), a mouth seizing mechanism(4) and a divider mechanism(5). The rotary table mechanism (1) includes a main shaft(1-1), a rotary table seat(1-2), a pump body rotary table(1-3) and an electrical aluminum shell rotary table(1-4). The convex rail lifting mechanism (2) includes a convex rail fixing seat(2-1), a convex rail(2-7), a safety block device(2-2), a cam bearing follower(2-8), a lifting shaft(2-9), a linear bearing(2-4), a linear bearing seat(2-11), a first spring(2-10), a spring seat(2-14), a fixed seat(2-5), a guide positioning block(2-6), a marble cam(2-17) and a second spring(2-18). The mouth seizing mechanism (4) includes a guide shaft(4-1), a linear bearing(4-2), a guide seat(4-3), a joint bearing(4-3), a bottom seat plate(4-5), a handle(4-6), an eccentric wheel(4-7), a connecting bar(4-8), a seizing claw(4-9) and an upper seat plate(4-10). The machine has a high precise in assembling the pump body and the electrical aluminum shell.

Owner:WUXI SUNMART TECH

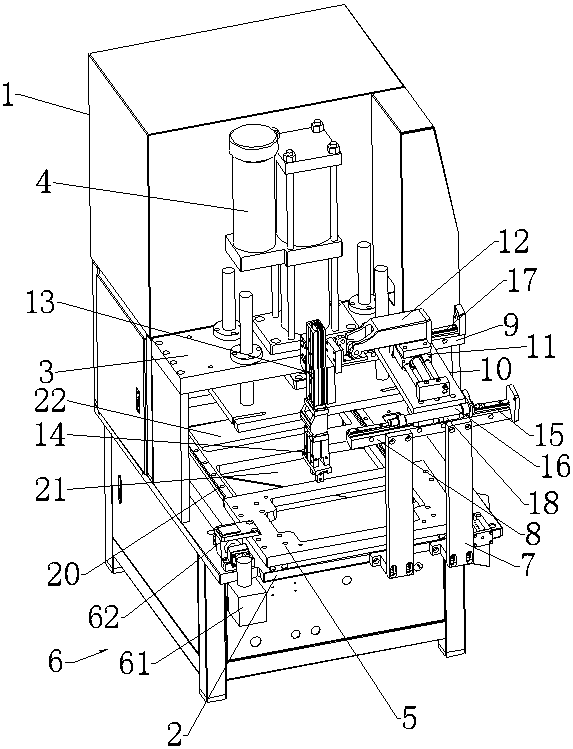

Automatic water gap classifying machine

PendingCN108058344AImprove gripping accuracyImprove work efficiencyMetal-working feeding devicesPositioning devicesManipulatorWater gap

The invention discloses an automatic water gap classifying machine. The automatic water gap classifying machine comprises a rack, a table plate and a worktable are arranged on the rack, a punching mold is arranged at the position, above the table plate, of the worktable, a discharging frame capable of sliding front and back is arranged on the table plate in a sliding manner, a driving device usedfor driving the discharging frame to move front and back is arranged on one side of the front end of the table plate, a support is arranged at the front end of the table plate, a first fixed table isarranged on the top of the support, a second fixed table is arranged on the top of the worktable, a sliding plate capable of sliding left and right is arranged between the first fixed table and the second fixed table, a rotating air cylinder is arranged on the top of the sliding plate, a support arm is connected to the rotating air cylinder, the end of the support arm is connected with a lifting air cylinder, and the bottom end of the lifting air cylinder is provided with a mechanical arm located above the discharging frame. The mechanical arm can move left and right and up and down, rotationis achieved, in cooperation with the discharging frame which can move front and back, the mechanical arm can flexibly clamp a workpiece, clamping accuracy is improved, and work efficiency is improved.

Owner:宁波振锐智能机器科技有限公司

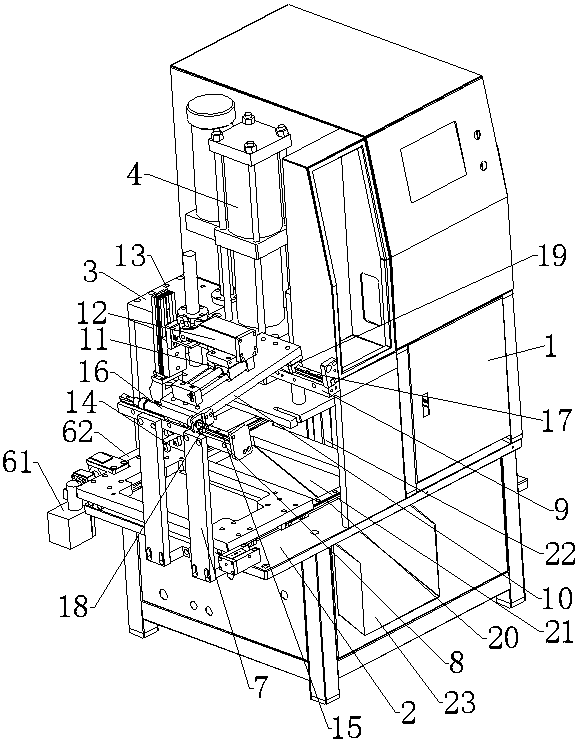

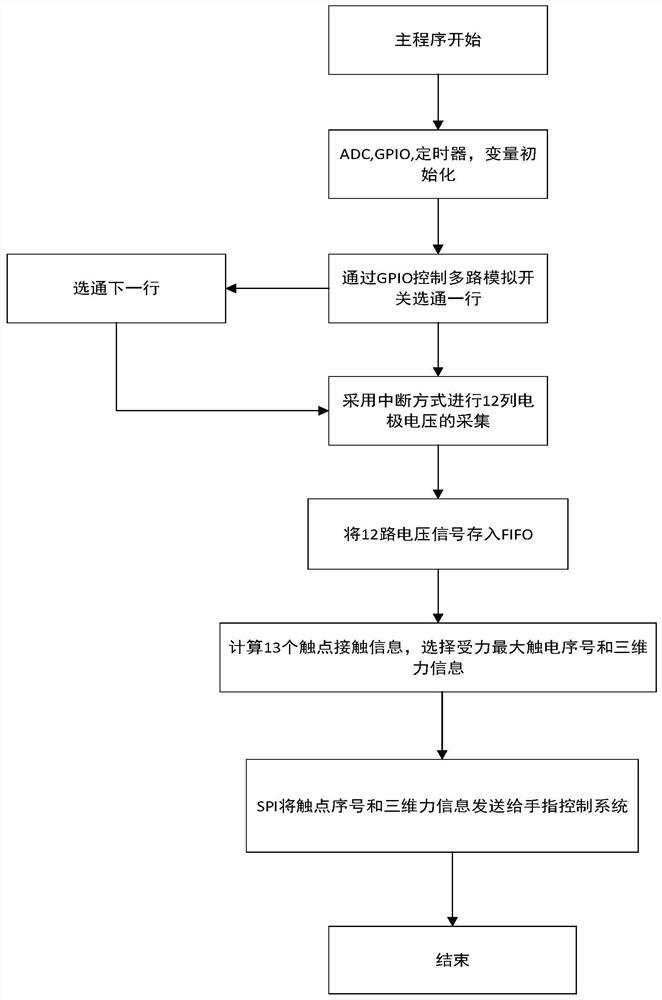

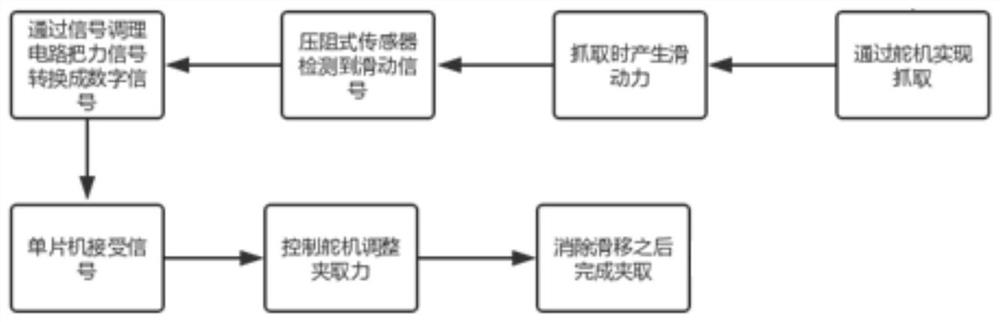

Anti-skid control system and method for grabbing manipulator

InactiveCN113664827AHigh gripping accuracyReduce slippageProgramme-controlled manipulatorSignal conditioning circuitsMicrocomputer system

The invention discloses an anti-skid control system for a grabbing manipulator. The anti-skid control system comprises a slip sensor mounted on the manipulator, a signal conditioning circuit connected with the slip sensor, an upper computer PC connected with the signal conditioning circuit, a single-chip microcomputer system connected with the upper computer PC, and a driving motor connected with the single-chip microcomputer system and mounted on a manipulator steering engine. By means of the anti-skid control system, the grabbing precision of the manipulator is effectively improved, and meanwhile the slippage condition of the manipulator in the grabbing operation process is relieved.

Owner:YANCHENG INST OF TECH

A mechanical fruit picker for artificial intelligence planting

ActiveCN113057022BWon't catch shortHigh gripping accuracyPicking devicesAgricultural engineeringElectric machinery

The invention relates to the technical field of artificial intelligence hardware, and discloses a mechanical fruit picker for artificial intelligence planting, including a connecting seat, a control motor is arranged above the center of the connecting seat, and a transmission buckle is arranged above the control motor. The upper end of the transmission buckle is provided with a flexible sleeve, and the inside of the flexible sleeve is provided with a diversion bowl, and a bush is arranged above the interior of the diversion bowl, and a wind wheel is arranged at the inner center of the bush. A central piece is movably connected above the bush, and the inner wall of the outer ring of the central piece is provided with a plurality of card slots. The mechanical fruit picker for artificial intelligence planting, through the rotation of the wind wheel, forms a negative pressure inside the upper part of the protection tube to attract the picked fruits, ensuring that the claws will not catch empty, and at the same time provides positive pressure at the annular outlet on the top of the diversion bowl to drive The flexible sleeve drives the center piece to rotate to realize the clamping action, and its adsorption and clamping actions are all completed in the protective tube, which improves the clamping accuracy and effectively avoids wrong clamping or empty clamping.

Owner:聊城市飓风工业设计有限公司

Automatic moving device of wire plug cord

InactiveCN107768960AHigh gripping accuracyImprove accuracyContact member assembly/disassemblyEngineeringElectric wire

The invention provides an automatic moving device of a wire plug cord. The automatic moving device comprises a transmission rail, wherein a wire clamp is arranged on the transmission rail and is distributed on the transmission rail, a movable wire clamp is arranged above the transmission rail, a transverse telescopic air cylinder is arranged at an upper end of the movable wire clamp, a lifting aircylinder is arranged at an upper end of the transverse telescopic air cylinder, a wire head placement rack is arranged aside the transmission rail, an infrared detector is arranged on the movable wire clamp, a wire position detector is arranged aside the wire head placement rack, and the infrared detector and the wire position detector are respectively correlated to the movable wire clamp, the transverse telescopic air cylinder and the lifting air cylinder. A wire is transmitted by the wire clamp, the wire is discharged and displaced by the movable wire clamp and is moved onto the wire head placement rack, the clamping accuracy is improved by the infrared detector and the wire position detector, a stop position of the wire clamp is limited by a position limitation baffle head, the accuracy is improved, and the counting operation is automatically completed by a counter, and the working efficiency is improved.

Owner:WUHU SHUNCHENG ELECTRONICS

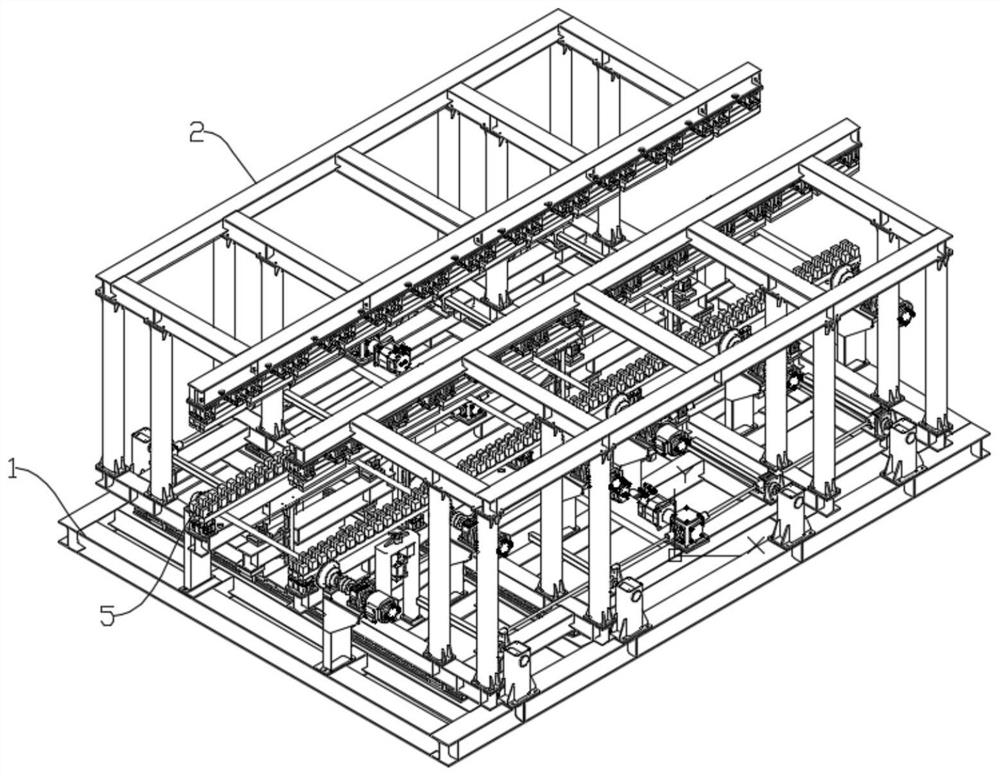

A smart logistics environment robot loading method and device

ActiveCN108942946BSimple structureEasy to operateProgramme-controlled manipulatorNerve networkMachine vision

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

Multi-arrangement label supporting table lifting feeding and label conveying mechanical arm

The invention discloses a multi-arrangement label supporting table lifting feeding and label conveying mechanical arm. The multi-arrangement label supporting table lifting feeding and label conveyingmechanical arm comprises a label table, a base, a supporting table and a mechanical arm device, wherein the supporting table is arranged on the base through a lifting device, and the mechanical arm device is arranged above the supporting table. The supporting table is internally provided with an installation groove with an upward opening. The inner bottom wall of the installation groove is provided with a first rotating cavity. The inner bottom wall of the first rotating cavity is rotatably and cooperatively provided with a spline shaft extending into the installation groove. A first bevel gear is fixedly arranged on the spline shaft in the first rotating cavity. The right inner wall of the first rotating cavity is provided with a first sliding groove extending rightwards. A first slidingblock is slidably installed in the first sliding groove. A first motor is fixedly arranged in the left end surface of the first sliding block. A second bevel gear is in power connection with the leftside of the first motor. A slot with an upward opening is formed in the position, on the right side of the mounting groove, of the top end surface of the supporting table.

Owner:周利东

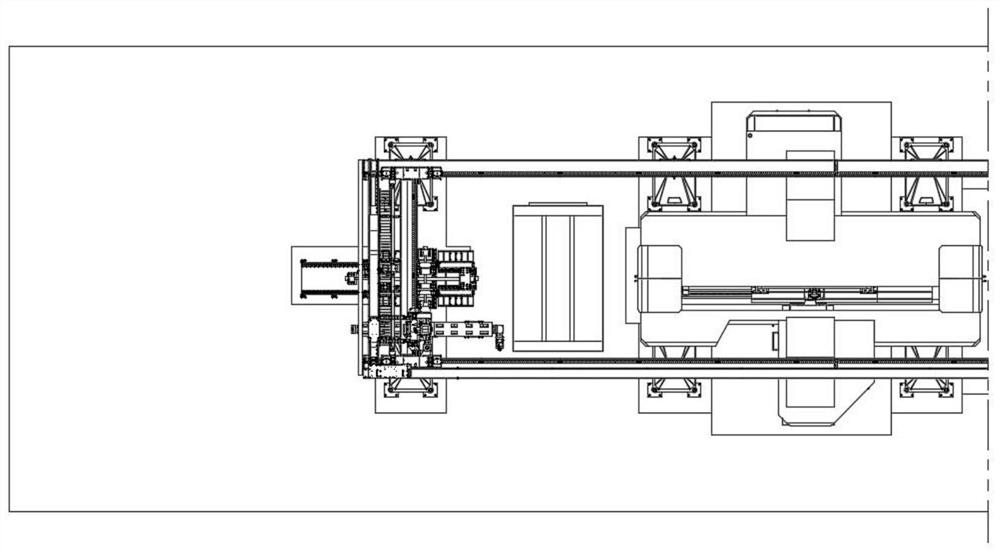

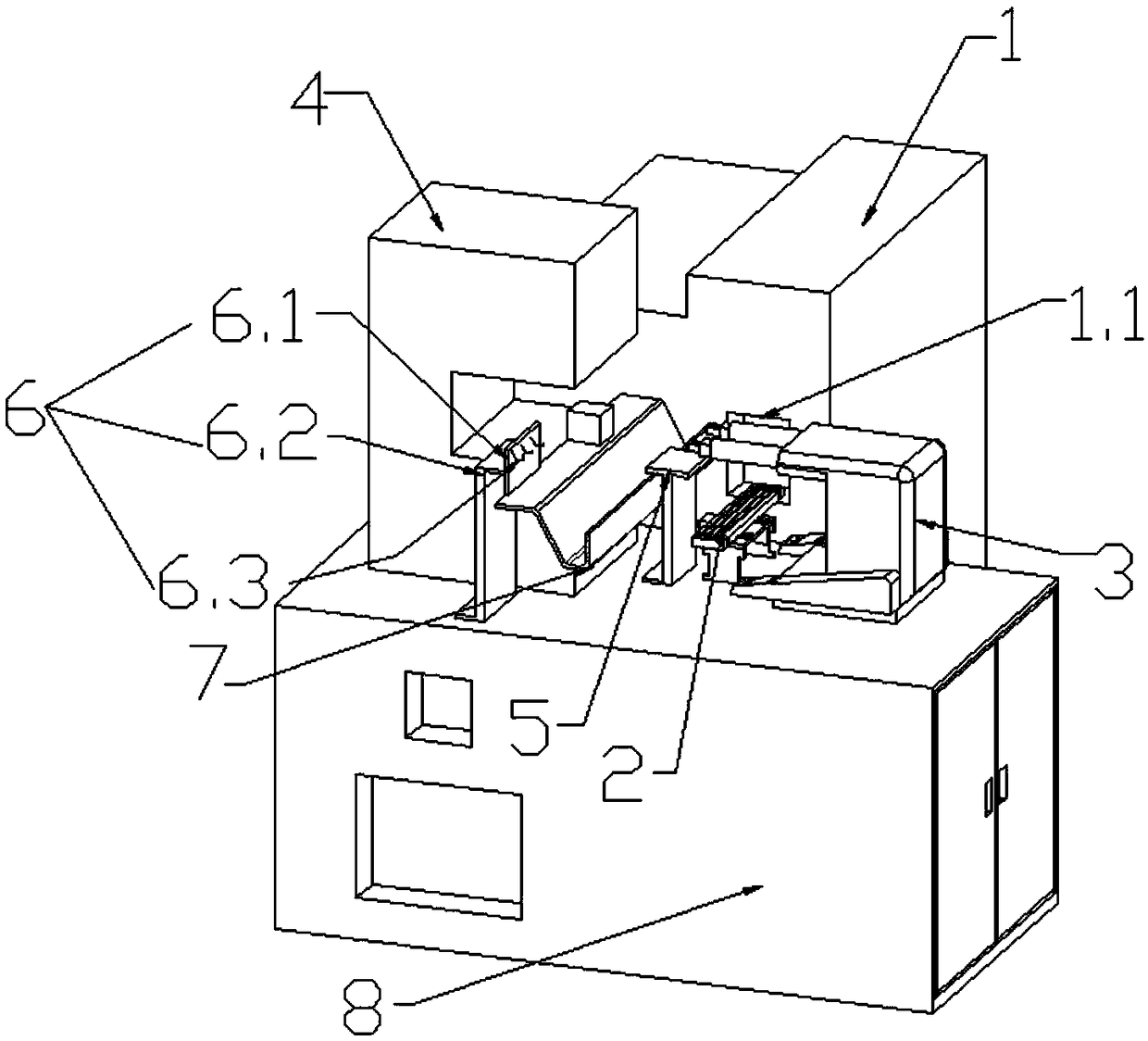

An intelligent and automatic sand box production line

ActiveCN110640551BImprove intelligenceHigh degree of automationMeasurement/indication equipmentsMetal working apparatusProduction lineRobot hand

The invention discloses an intelligent and automatic sand box production line, which is characterized in that it includes a truss, and is sequentially provided with a reversible servo manipulator, a bidirectional self-centering mechanism and several cutting machine tools along the straight line of the truss. This production line is intelligent and highly automated. Through the servo manipulator, it can grasp and rotate the workpiece of the sand box, and can easily handle a variety of sand box workpieces of different sizes, and the centering accuracy of the workpiece is high. The cutting machine tool can also meet the vertical and horizontal double-sided processing, which greatly improves the production efficiency.

Owner:国机铸锻机械有限公司 +1

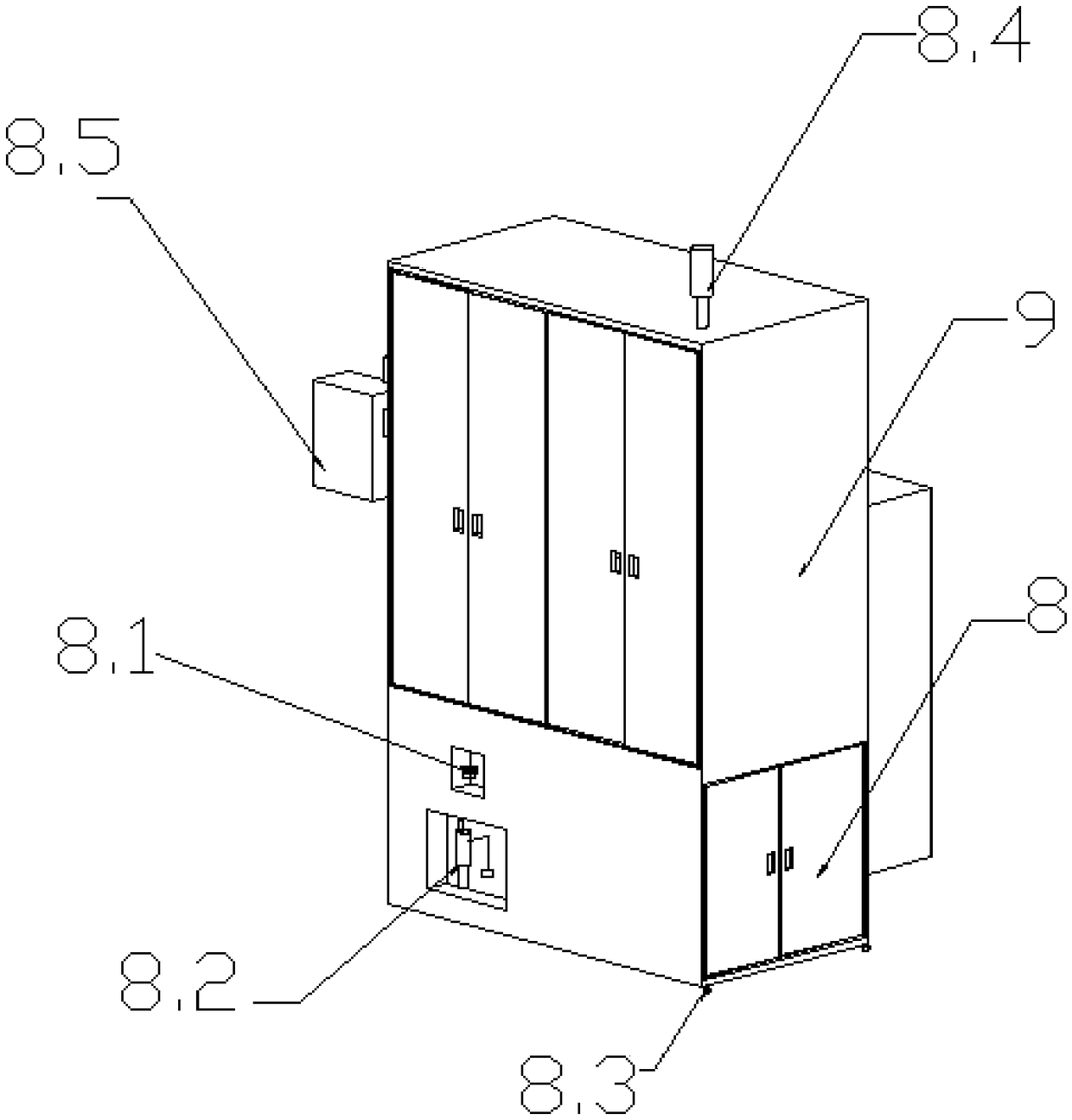

Automatic bonding equipment for rubber strip

The invention relates to automatic bonding equipment for a rubber strip. The automatic bonding equipment comprises a control base and an operation cabinet, wherein the control base is arranged at thebottom of the operation cabinet; a rubber strip bonding assembly is arranged in the operation cabinet; a drive control device is arranged in the control base; the rubber strip bonding assembly comprises rubber strip cutting equipment, a rubber strip positioning groove plate, a mechanical arm component, rubber strip hot pressing equipment, an adhesive platform, a wire hanging frame and a wire supporting plate; the rubber strip hot pressing equipment comprises a press fit head and a press fit platform, and a pressure welding jig is arranged under the press fit head and located in the center of the press fit platform; the wire supporting plate is arranged on the upper surface of the press fit platform and comprises a platform and a bearing trough, and the bearing trough has a slope structure;workpieces hung on hooks falls on the slope structure of the bearing trough accordingly and are borne by the bottom of the bearing trough; a hole accommodating extension of the pressure welding jig is formed in the platform; and the adhesive platform is located between the wire supporting plate and the mechanical arm component. An automatic machine is utilized to replace manual work, the efficiency is improved, and the yield stability is improved.

Owner:WUXI JONES TECH +1

Impeller production clamp for passenger car turbocharger

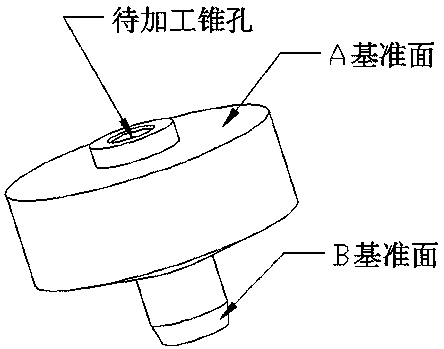

PendingCN108274284ALow production costHigh gripping accuracyPositioning apparatusMetal-working holdersImpellerTurbocharger

The invention discloses an impeller production clamp for a passenger car turbocharger. The impeller production clamp comprises a linear optical shaft and a linear bearing arranged at the front end ofthe linear optical shaft in a sleeving mode. A compression spring and a spring check ring are further arranged on the linear optical shaft and at the rear end of the linear bearing; a circle of boss is further arranged at the front end of the linear bearing; a flange plate is arranged outside the linear bearing in a sleeving mode and clamped to the boss; an A datum plane positioning plate locatedat the front end of the linear optical shaft and perpendicular to the axis direction of the linear optical shaft is further supported on the boss through supports; and a conical positioning hole is further formed in the front end of the linear optical shaft, and the conicity of the conical positioning hole is matched with the conicity of a B datum plane. The parallel deviation is controlled through a front positioning mode, and the bounce mode is controlled through the linear optical shaft with the rear conical hole; the clamp manufacturing cost is reduced, clamping precision is high, and machined products are stable in quality and good in consistency; and full inspection is not needed, the spot check period is prolonged, and the production period is greatly shortened.

Owner:JIANGSU LIANCHENG PRECISION ALLOY TECH CO LTD

Full-automatic automobile hub welding equipment

InactiveCN106975873AEnable multi-location targetingHigh gripping accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFully automatic

The invention belongs to the field of automobile wheel hub processing, and relates to a fully automatic automobile wheel hub welding equipment, which includes a frame, a guide rail is fixed on the upper end of the frame, and a first cylinder is fixed on the inner side of the guide rail through a mounting plate on the frame. The telescopic rod of the first cylinder is connected to the side of the movable clamping mechanism, and a fixed clamping mechanism is fixed on the upper part of one end of the frame, and a welding mechanism is provided on the side of the frame, and the welding mechanism is arranged between the movable clamping mechanism and the Between the fixed clamping mechanisms, the movable clamping mechanism is slidingly connected with the guide rail through the guide rail cover; when working, the movable clamping mechanism moves to the vicinity of the fixed clamping mechanism through the push of the first cylinder, and then realizes the welding of the hub through the welding mechanism; The invention has the advantages of simple and compact structure, high welding efficiency and simple operation, and can save more manpower costs and is worthy of popularization.

Owner:SUZHOU HIGH & SPECIALITY INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com