Intelligent wire feeding robot and wire feeding method thereof

A robot, multi-axis robot technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of affecting the control rhythm, high practical cost, affecting the efficiency of the assembly line, etc., to reduce the work intensity and workload, clamping The effect of taking high accuracy and saving redundant labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

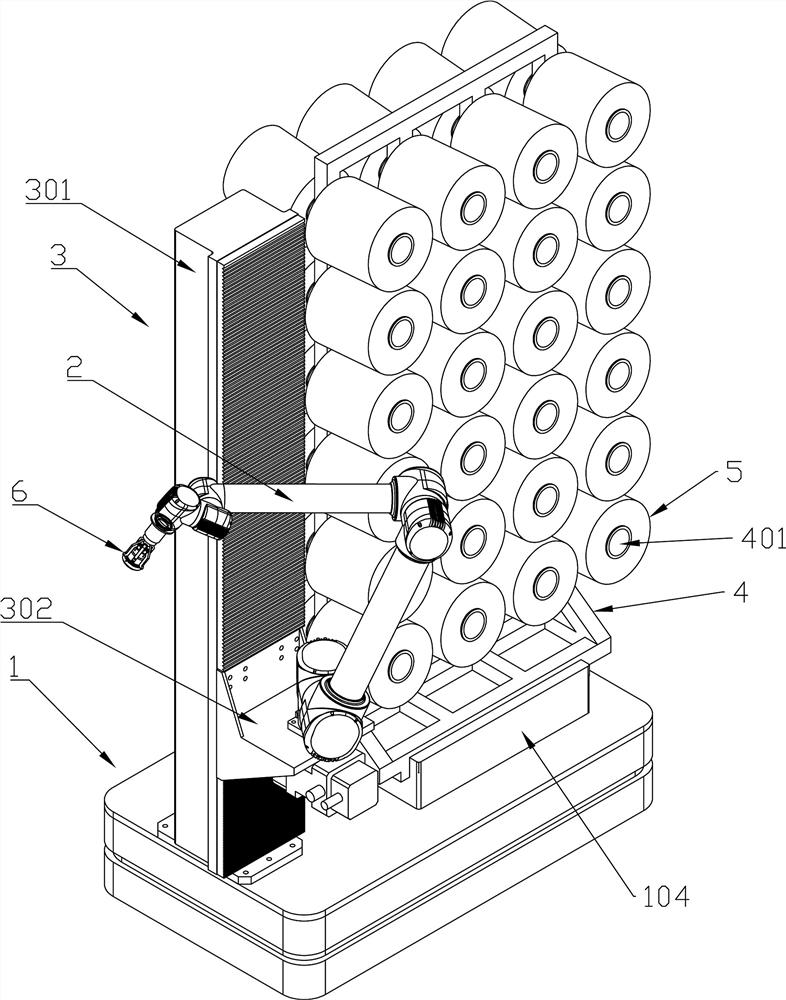

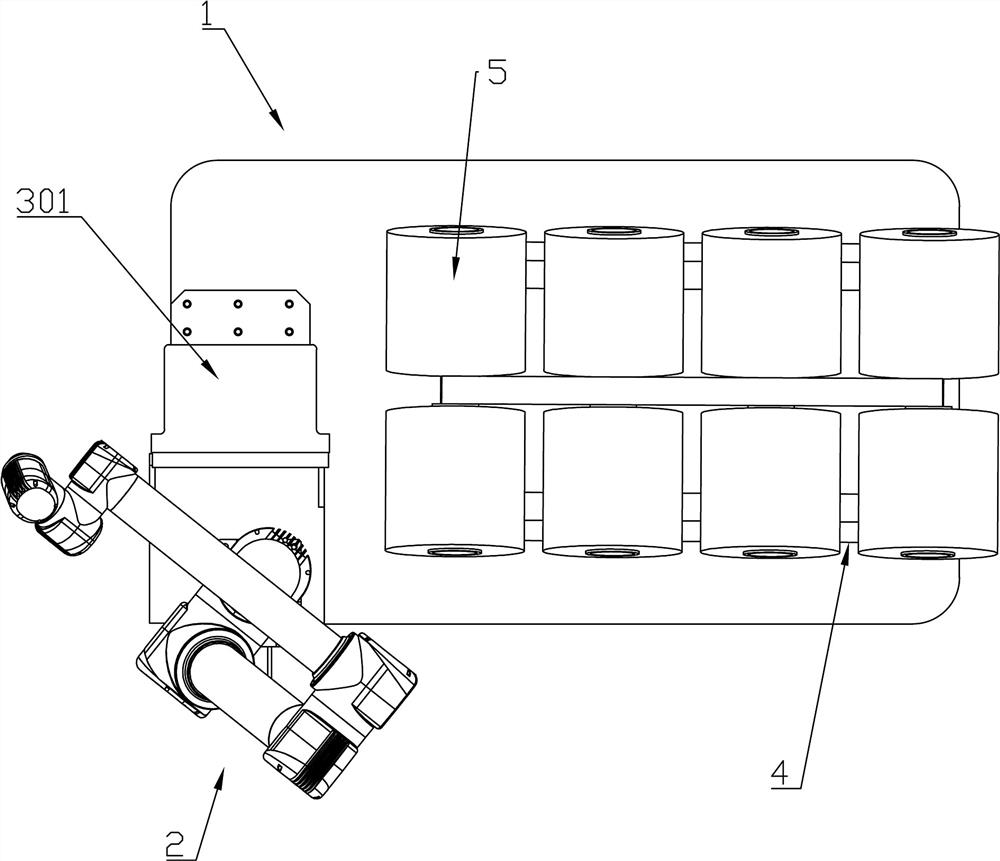

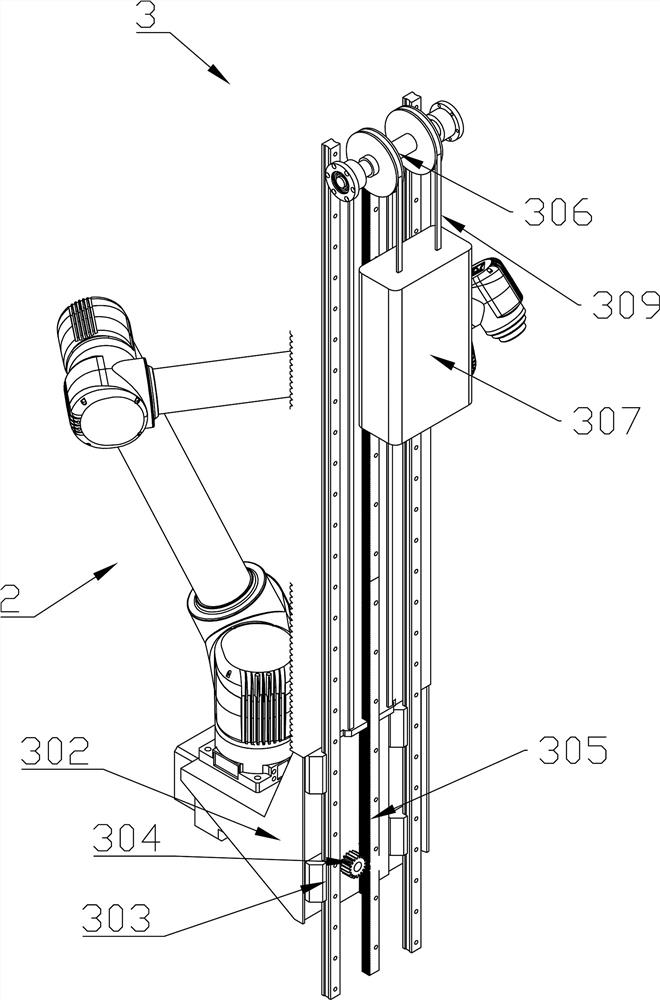

[0049] Such as Figure 1-10Among them, an intelligent threading robot includes an AGV main device 1. AGV main device 1 is provided with a linear sliding device 3. The linear sliding device 3 is provided with a sliding frame 302 that can slide up and down. The sliding frame 302 is provided with a belt clamp device. 6 multi-axis robot 2, one side of the linear sliding device 3 on the AGV main device 1 is provided with a creel 4, and a plurality of raw yarn support rods 401 are arranged on both sides of the creel 4, and the raw yarn support rods 401 are used to place the raw yarn Roll 5, clamping device 6 is provided with a plurality of clamping jaws 604 that can be expanded along the axial direction, and the front end of clamping device 6 is provided with camera 7 .

[0050] The connection position between the sliding frame 302 and the multi-axis robot 2 faces the direction of the AGV main device 1 side, and the AGV main device 1 side refers to figure 2 The direction of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com