Automatic carpet thread-supplying machine

An automatic, thread-feeding technology, applied in carpets, knotting, textiles and papermaking, etc., can solve the problems of low degree of automation, complex weaving process, complex pattern design, etc., and achieve high degree of automation, strong use value and promotion value , The effect of precise and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

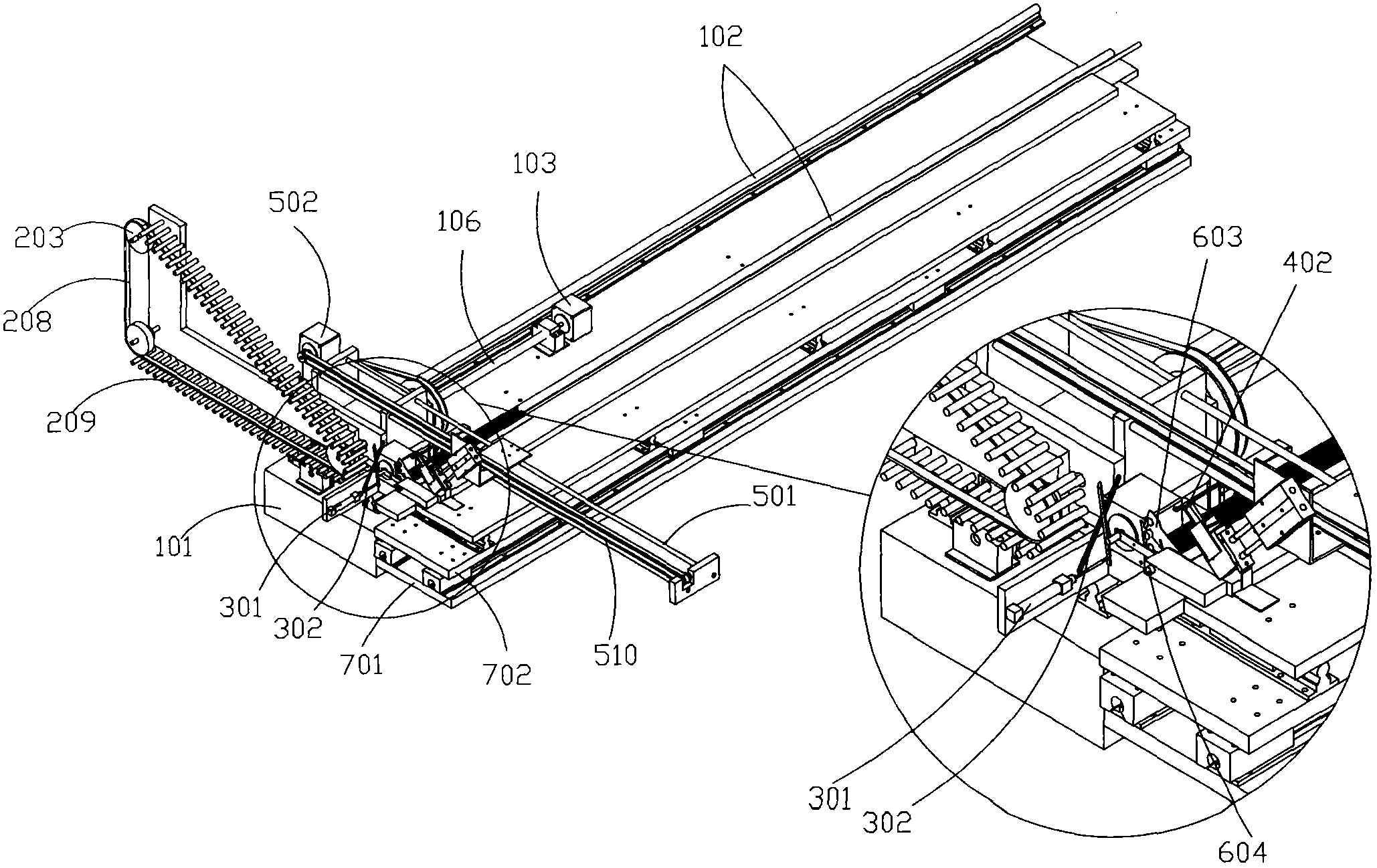

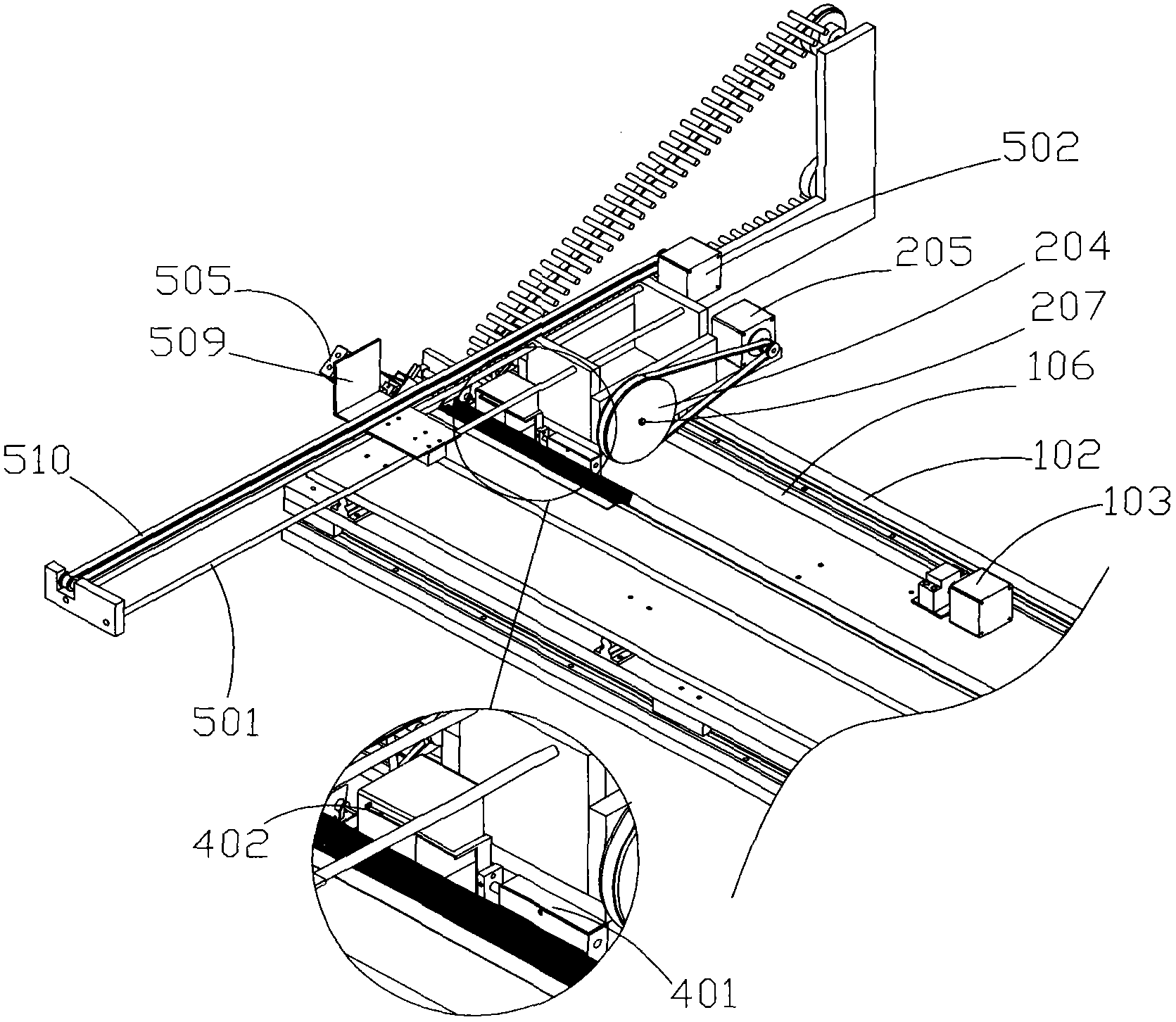

[0049] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0050] Such as Figure 1 to Figure 7 Shown, the automatic carpet wire feeder of the present embodiment, it comprises:

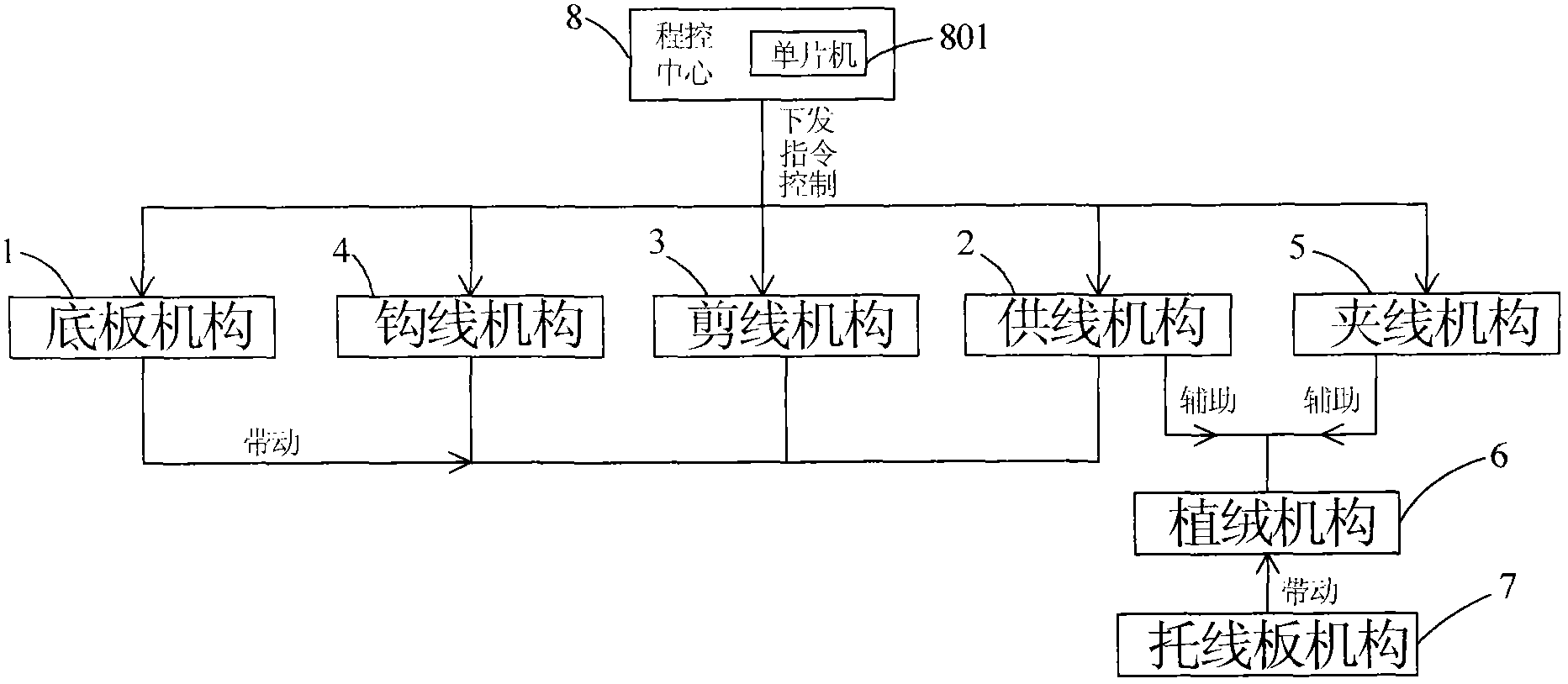

[0051] The program control center 8, the program control center 8 includes a single-chip microcomputer 801, and the pattern file is transmitted to the program control center 8 through the serial port before the carpet weaving, so that the program control center 8 serves as the control center of the entire carpet wire supply machine to the bottom plate mechanism 1, the wire supply mechanism 2, The thread clamping mechanism 5, the thread hooking mechanism 4 and the thread trimming mechanism 3 issue action commands to accurately position each mechanism.

[0052] Bottom plate mechanism 1 provides a supporting platform for thread suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com