Thimble device capable of threading needle and thread

A technique for thimble and needle thread, which is applied to the field of thimble devices capable of threading needles and threads, can solve the problems of unmoving crochet needles, low work efficiency, time-consuming and the like, and achieves the effects of quick threading, improving work efficiency and reducing operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

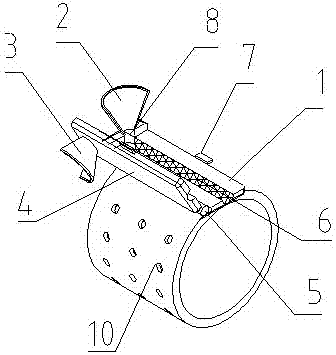

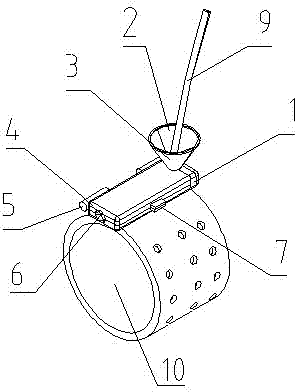

[0015] like figure 1 As shown, a thimble device capable of threading needles and threads includes: a fixed block 1, a right half funnel 2, a left half funnel 3, a movable block 4, a loose leaf 5, a transverse groove 6, a pull button 7, an eyelet 8, and a thimble cover 10 , each component is combined on the thimble sleeve 10, and the thimble sleeve 10 is provided with a plurality of counterbores.

[0016] One side of the fixed block 1 is connected and installed with the movable block 4 through the loose leaf 5, and the other side is provided with a pull button 7 to facilitate the opening and closing of the movable block 4.

[0017] A transverse slot 6 is provided between the fixed block 1 and the movable block 4, and an eyelet 8 is provided at one end of the transverse slot 6 near the port.

[0018] The size of the eyelet 8 can be set according to the needles of different sizes.

[0019] The transverse groove 6 is a long arc-shaped small groove, and an arc-shaped cushion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com