Wet parting method for aerated concrete blocks or plates

A technology for aerated concrete and blocks, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as failure of breaking and damage to green bodies, so as to increase the adaptability, improve yield, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

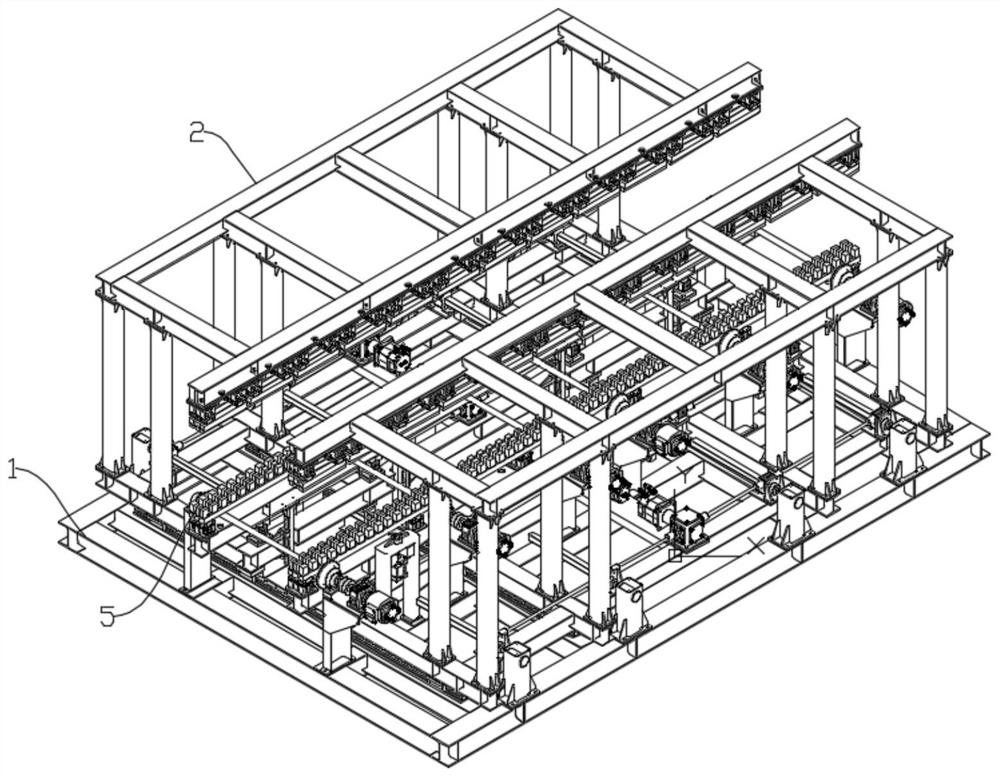

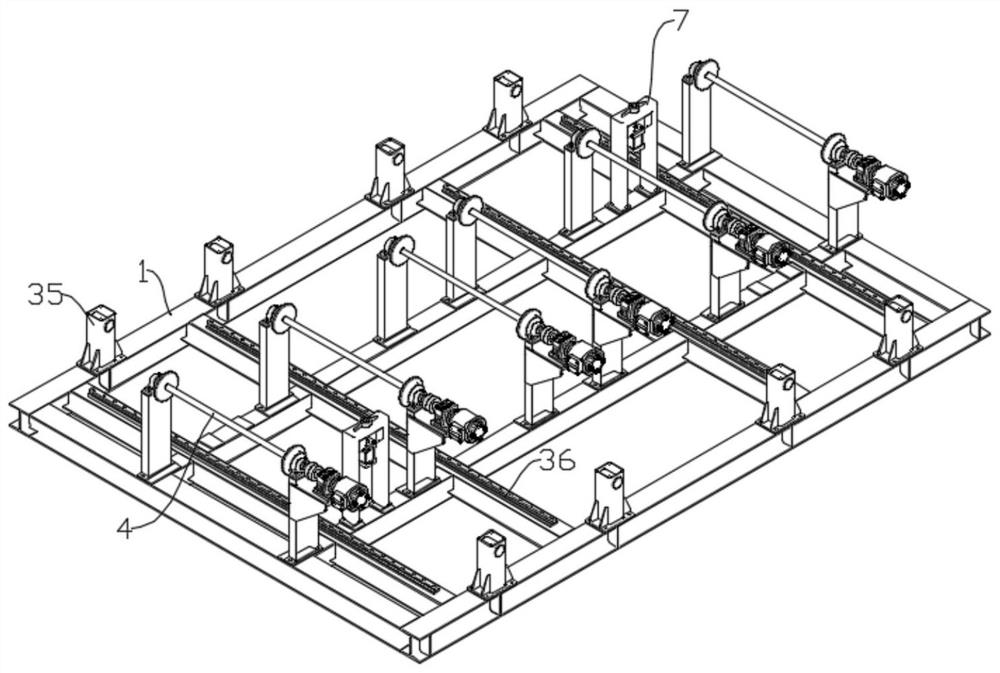

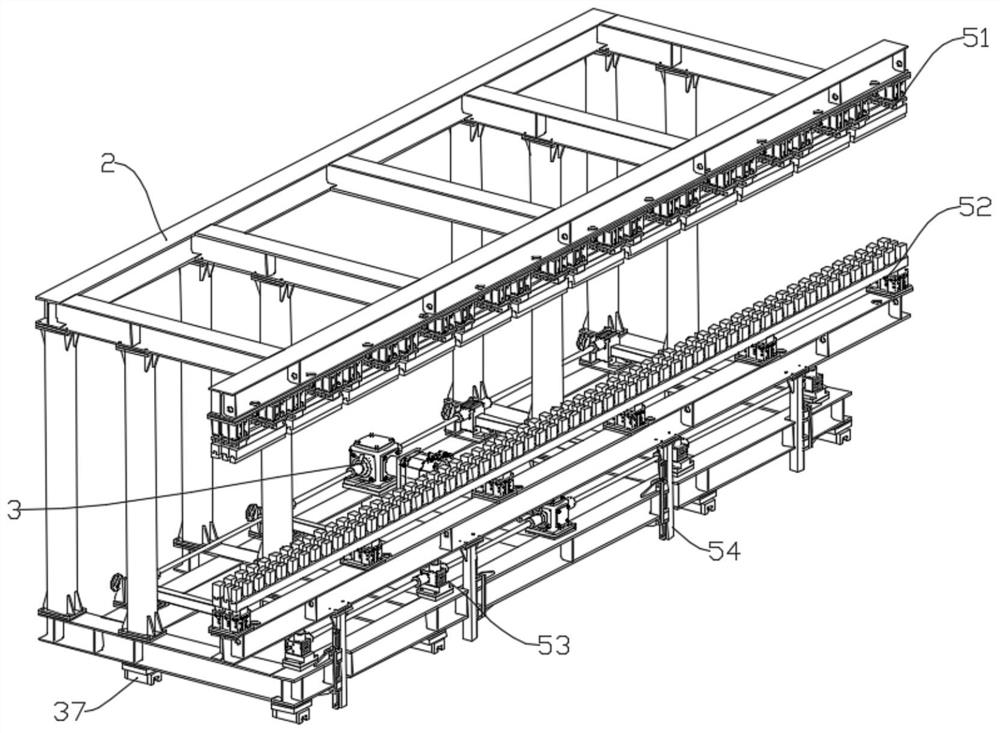

[0057] A wet splitting machine for aerated concrete blocks or plates, used for splitting horizontally stacked blanks, which mainly includes a base 1, a frame 2, a lateral driving device 3, a bottom plate transportation device 4, and a splitting machine. Component 5, horizontally placed steam curing bottom plate 6 and bottom plate positioning device 7, the specific structure and working principle of the wet breaking machine will be described in detail below.

[0058] Such as figure 1 As shown, the base 1 and the frame 2 are the installation bases of the various devices of the wet breaking machine, wherein the frame 2 has a pair and is symmetrically installed on both sides of the base 1 . It should be noted that the structures of the two racks 1 and the components installed on them are consistent, and they are all arranged symmetrically on the base 1. In this embodiment, only a single rack 2 and its mounting components are described for convenience. describe.

[0059] Such as ...

Embodiment 2

[0072] A method for wet breaking of aerated concrete blocks or plates, using a wet breaking machine for aerated concrete blocks or plates in Example 1 to break apart the body before steam curing, the specific process is as follows:

[0073] 1. Floor conveying and positioning

[0074] Such as Figure 12 As shown, each device of the wet breaking machine is in the initial state, and the conveying motor 42 in the floor conveying device 4 works, driving the conveying shaft 43 and the wheel 44 to rotate, and driving the horizontal steam-cured floor 6 carrying the concrete body to be transported to the working position , a plurality of concrete blanks are bonded together along the horizontal direction on the steam-cured bottom plate 6 placed horizontally. Then, the bottom plate positioning device 7 works, and the piston rod of the positioning cylinder 72 stretches out and passes through the positioning hole 63 on the horizontally placed steam-cured bottom plate 6 to complete the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com