Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Slip sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

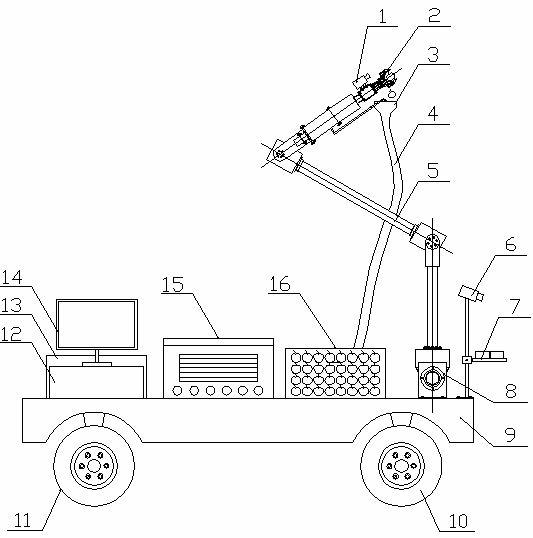

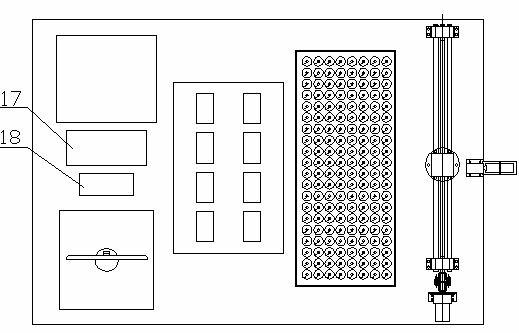

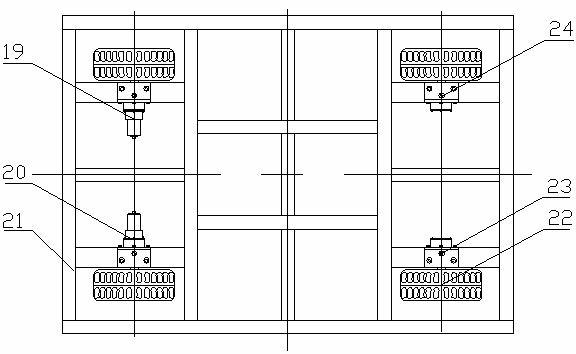

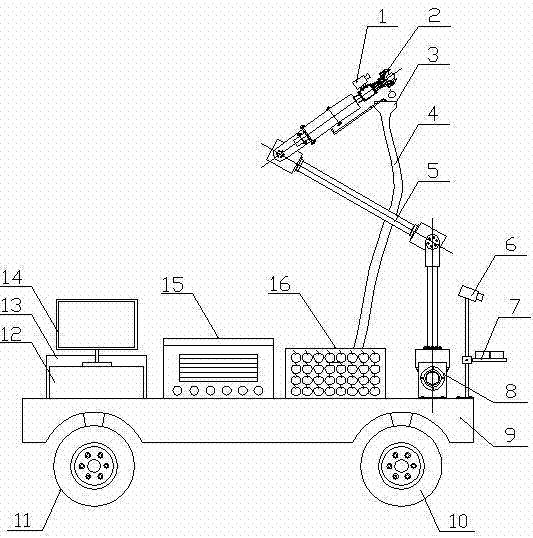

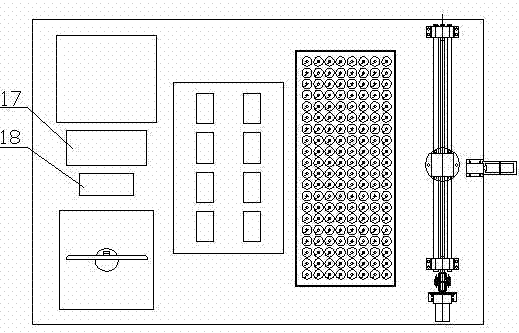

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

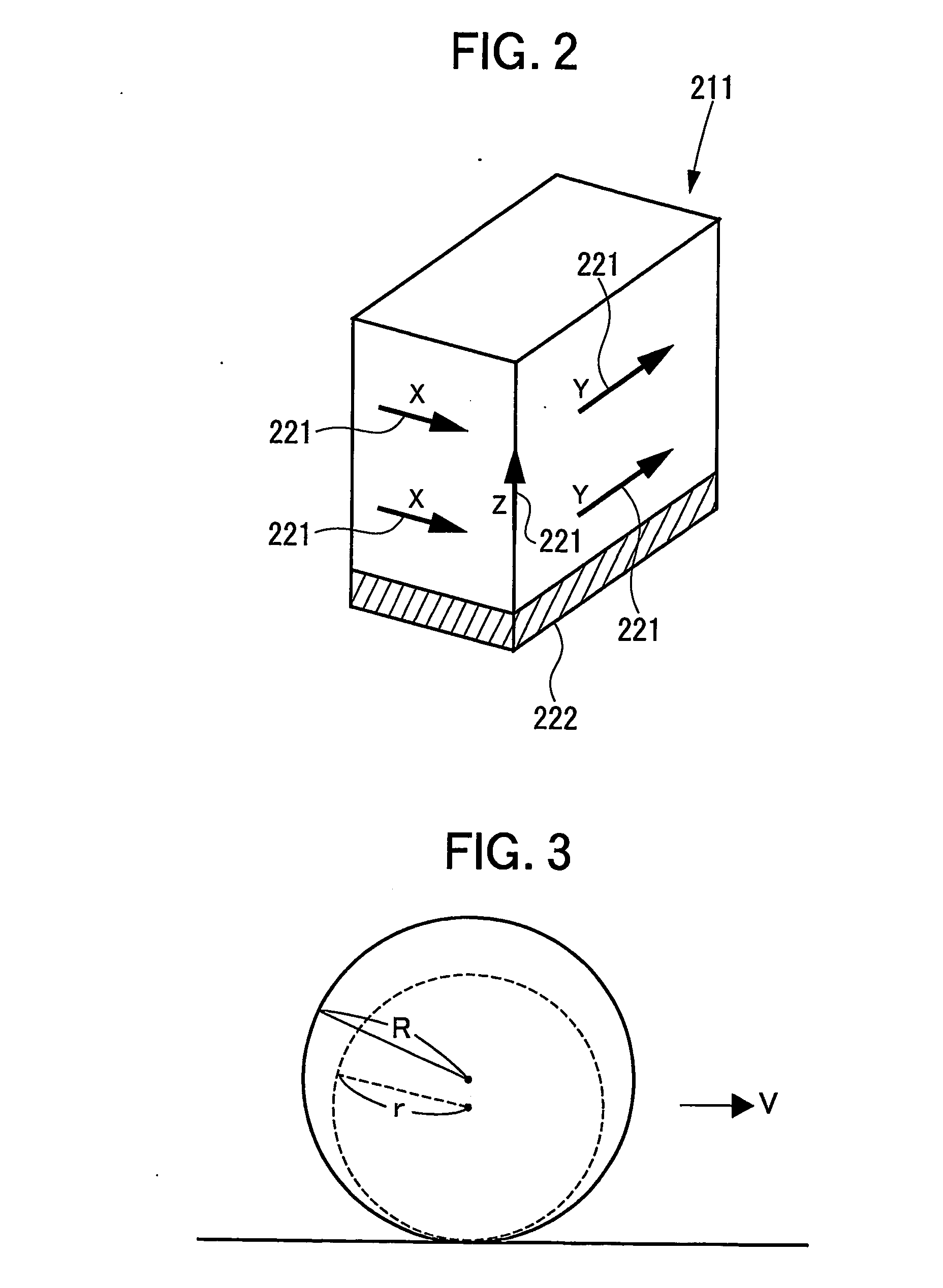

Axle unit with slip sensor and slip meansurement method

InactiveUS20060108170A1Improve accuracyStable controlBearing assemblyPedestrian/occupant safety arrangementRolling-element bearingRunning time

An axle unit 210 including a rolling bearing unit attached to a knuckle of a wheel support member has a slip sensor (211) including acceleration sensors and a rotation sensor in one piece. The slip sensor (211) has the rotation sensor placed on the base face, and the rotation sensor is placed facing an encoder (213) attached to a rotation member (212). At the vehicle running time, the traveling acceleration in the traveling direction of the wheel and the rotation angular speed are detected and at the vehicle running time, the ground speed of each wheel, the tire radius of each wheel, and the slip ratio of each wheel are found.

Owner:NSK LTD

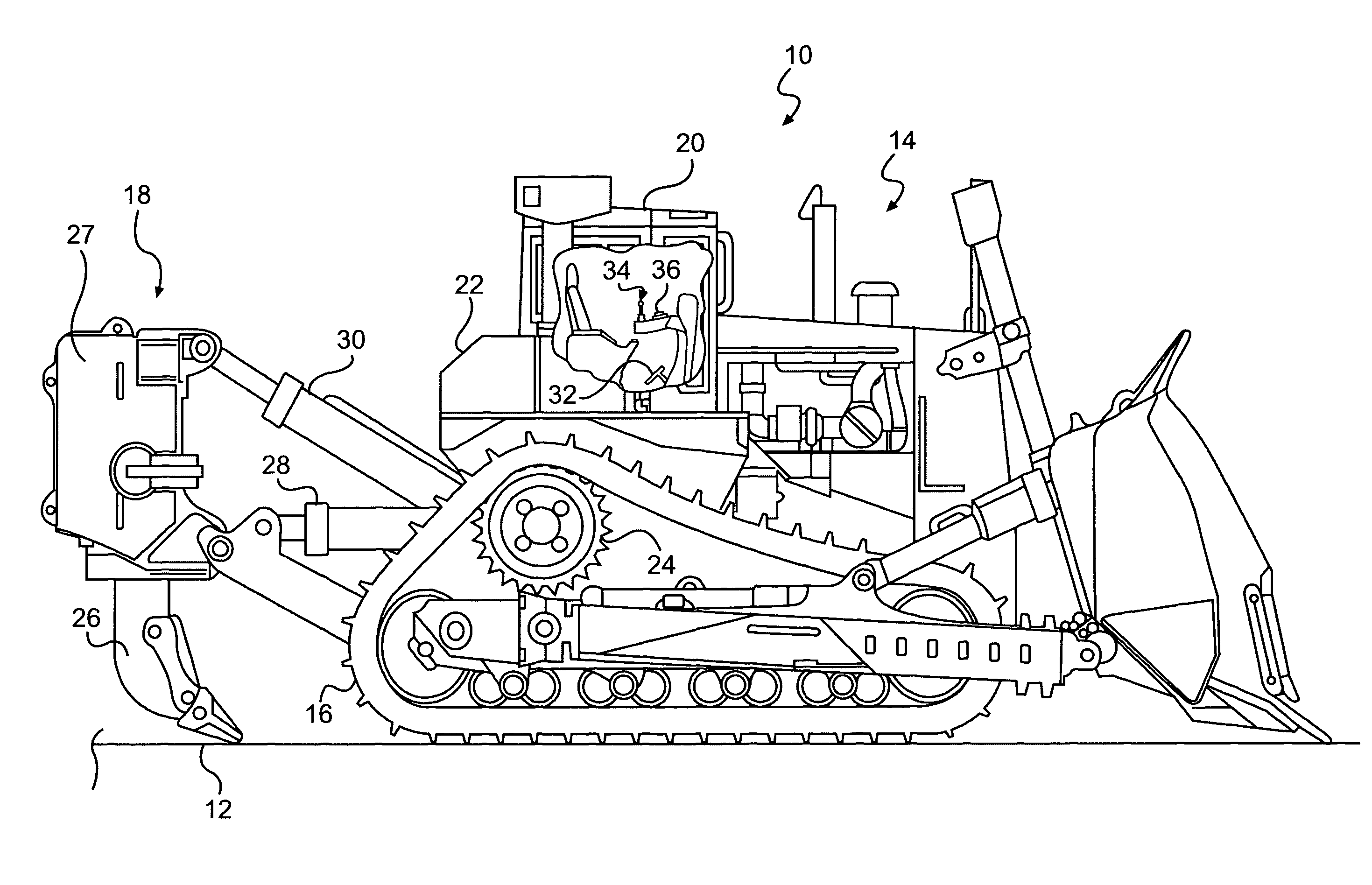

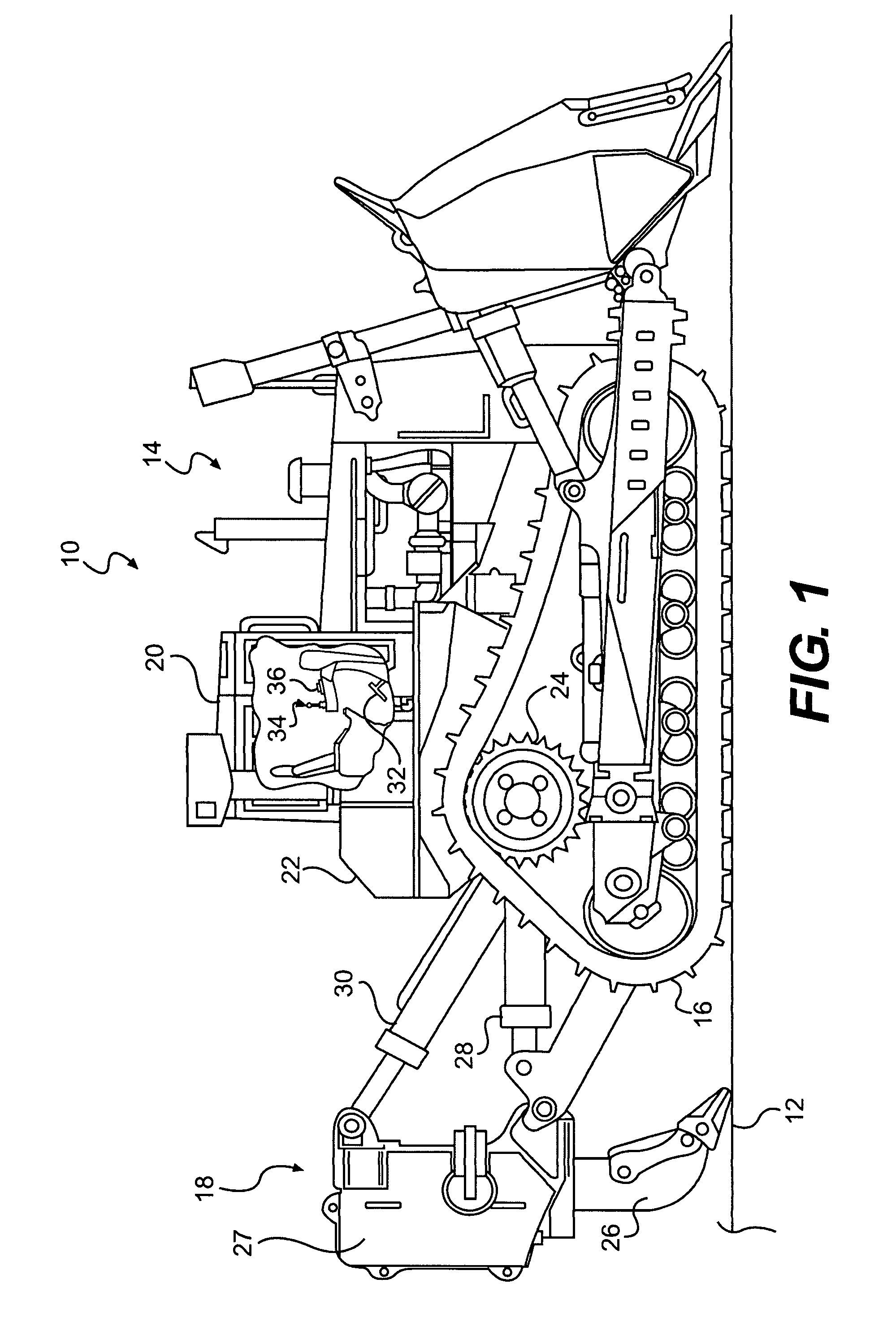

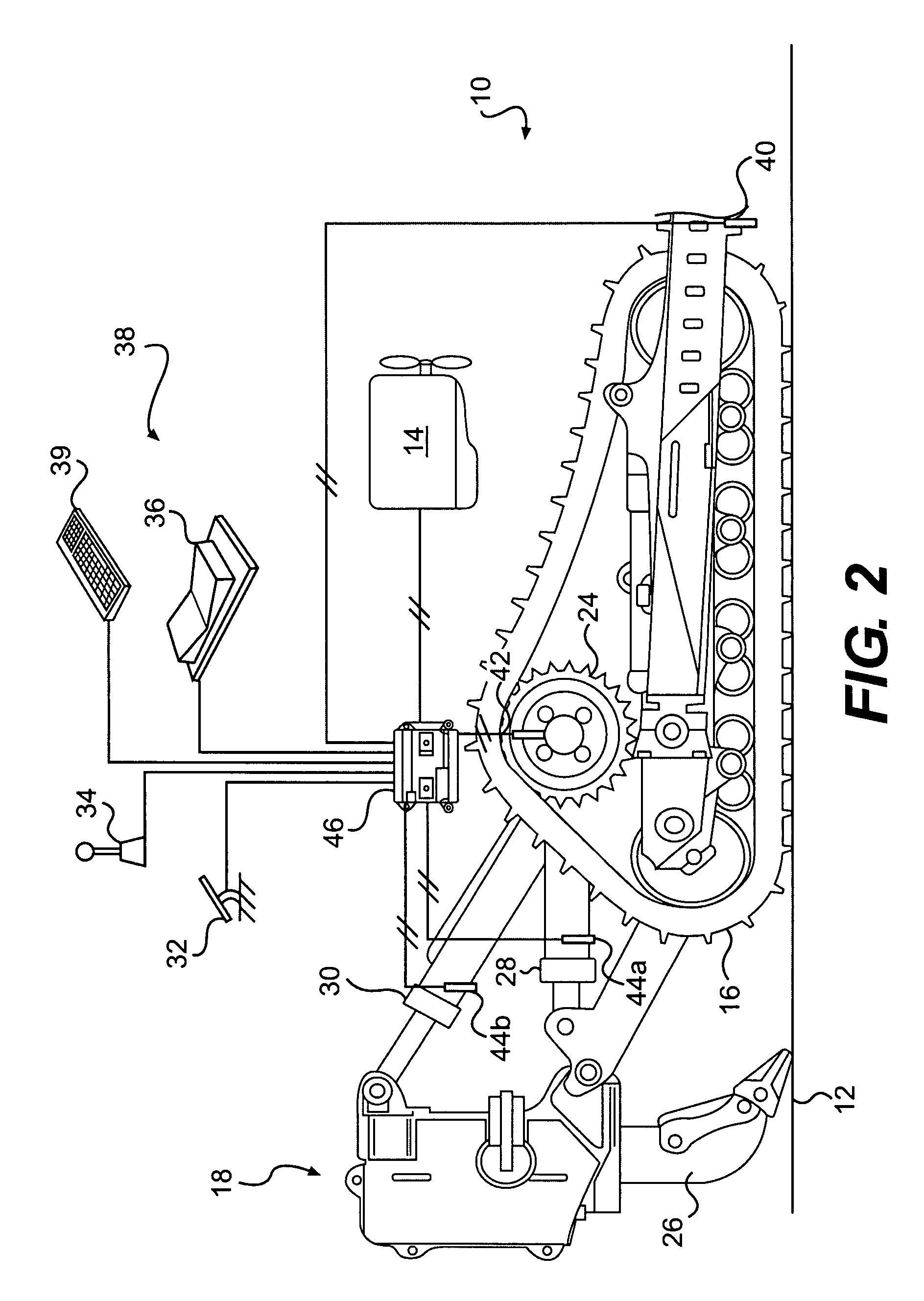

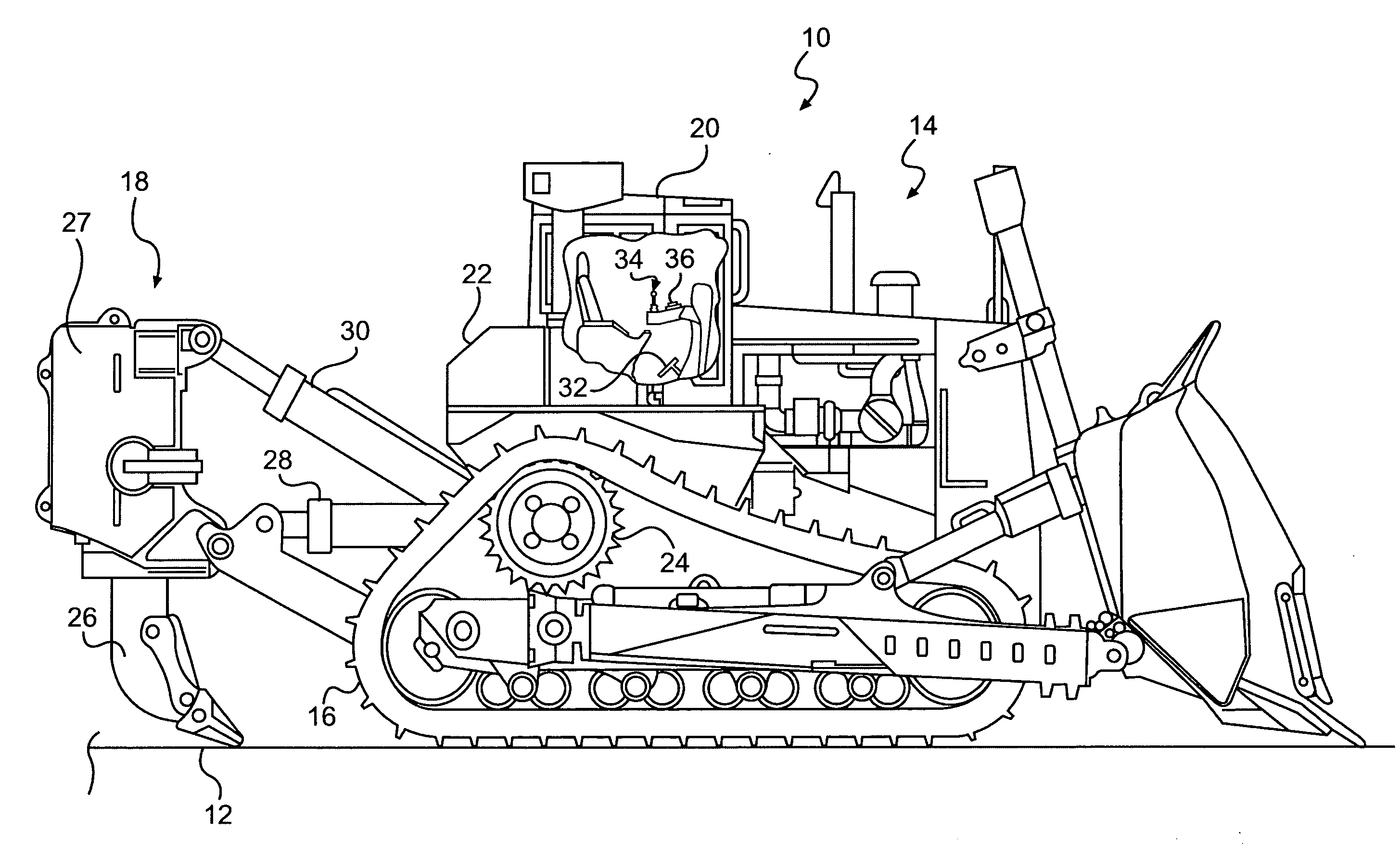

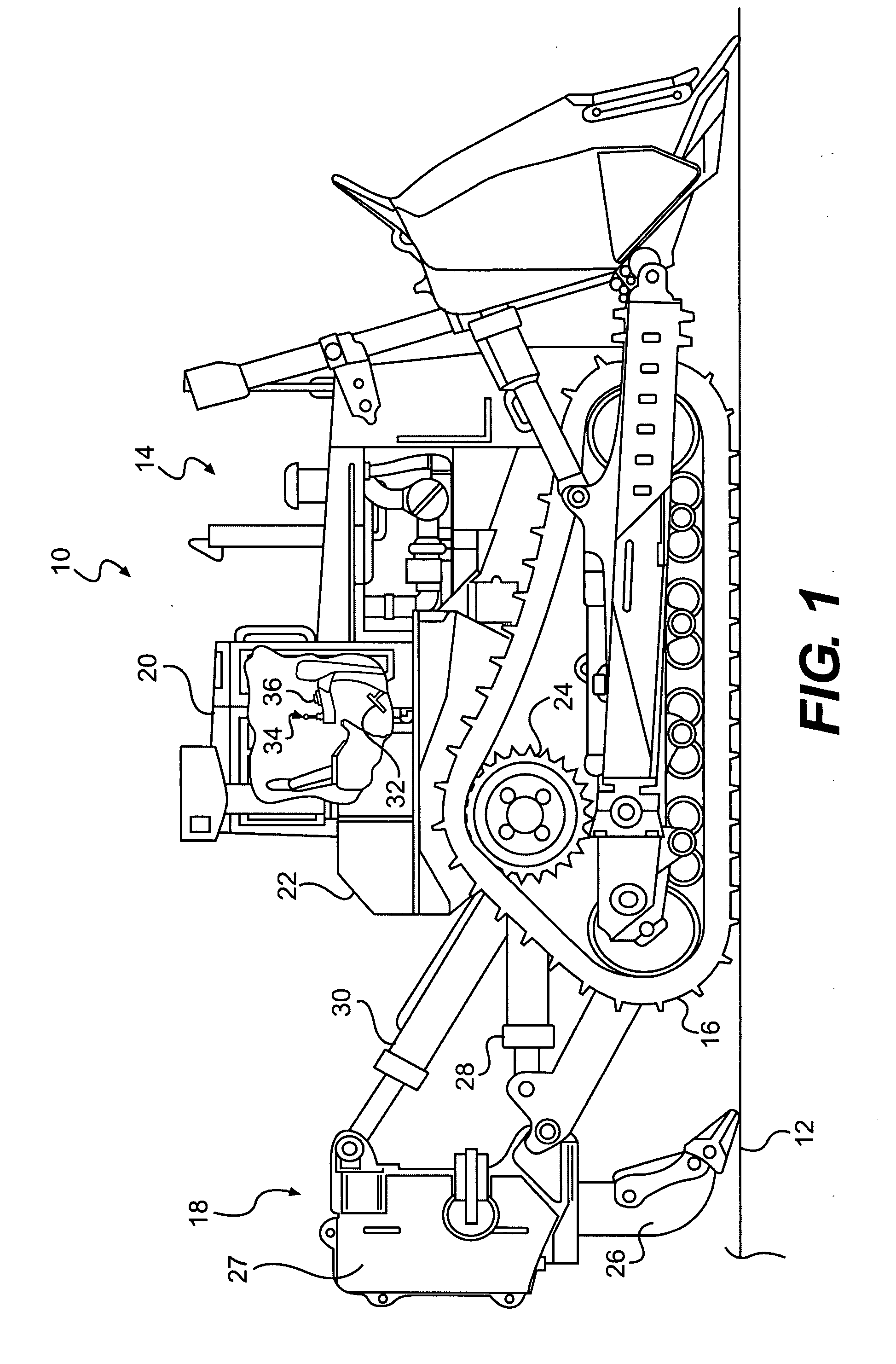

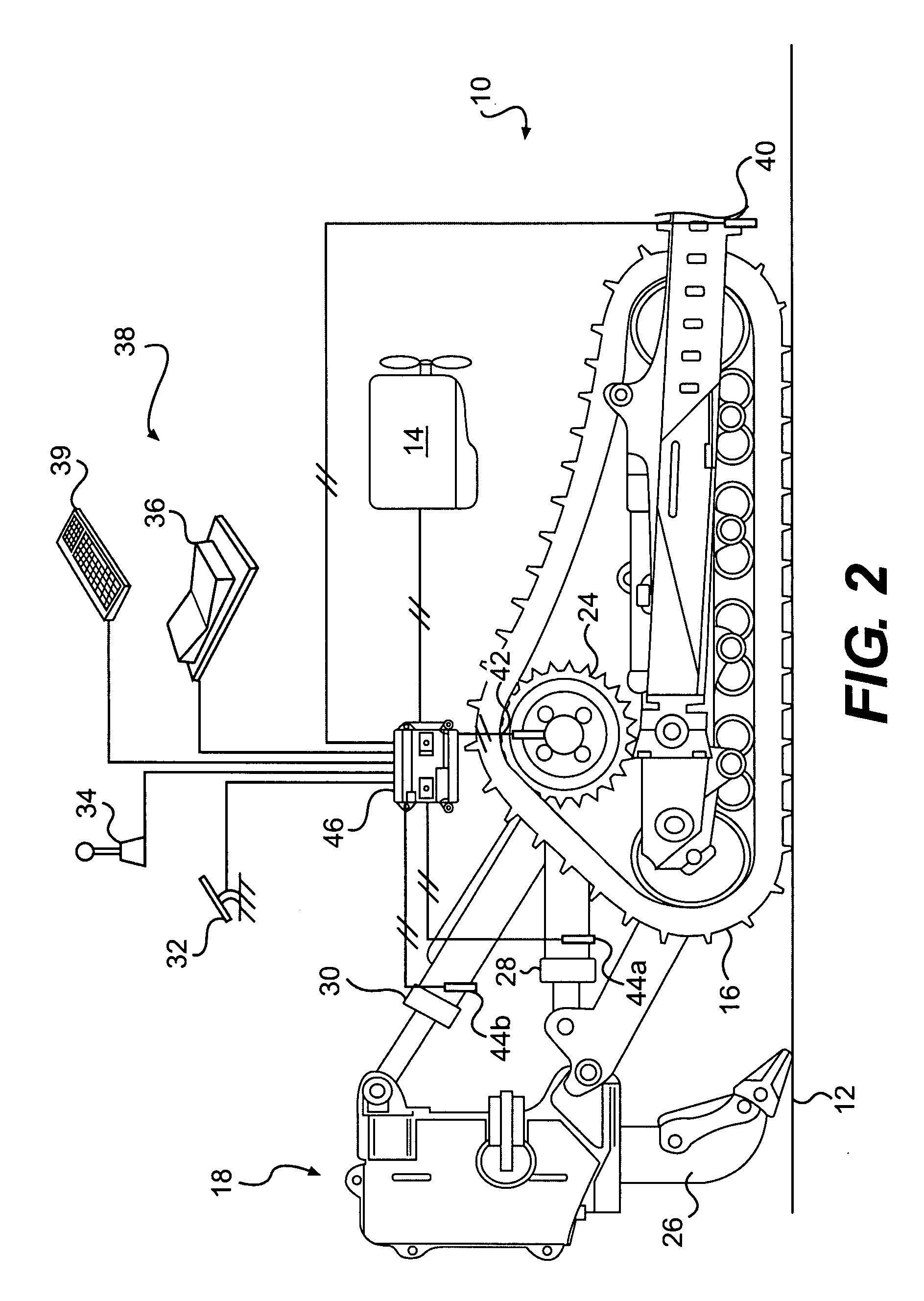

Ripper autodig system implementing machine acceleration control

A control system for a machine having a power source, a traction device, and a ripping tool is disclosed. The control system may have a slip sensor configured to generate at least one signal indicative of machine slippage, and at least one actuator operable to position the ripping tool. The control system may also have a controller in communication with the slip sensor, the at least one actuator, and the power source. The controller may be configured to receive at least one operator input indicative of an acceptable slip value, and determine actual machine slippage based on the at least one signal. The controller may also be configured to directly and separately regulate a speed of the machine and a position of the ripping tool during an excavation process based on the acceptable slip value and actual machine slippage.

Owner:CATERPILLAR INC

Ripper autodig system implementing machine acceleration control

A control system for a machine having a power source, a traction device, and a ripping tool is disclosed. The control system may have a slip sensor configured to generate at least one signal indicative of machine slippage, and at least one actuator operable to position the ripping tool. The control system may also have a controller in communication with the slip sensor, the at least one actuator, and the power source. The controller may be configured to receive at least one operator input indicative of an acceptable slip value, and determine actual machine slippage based on the at least one signal. The controller may also be configured to directly and separately regulate a speed of the machine and a position of the ripping tool during an excavation process based on the acceptable slip value and actual machine slippage.

Owner:CATERPILLAR INC

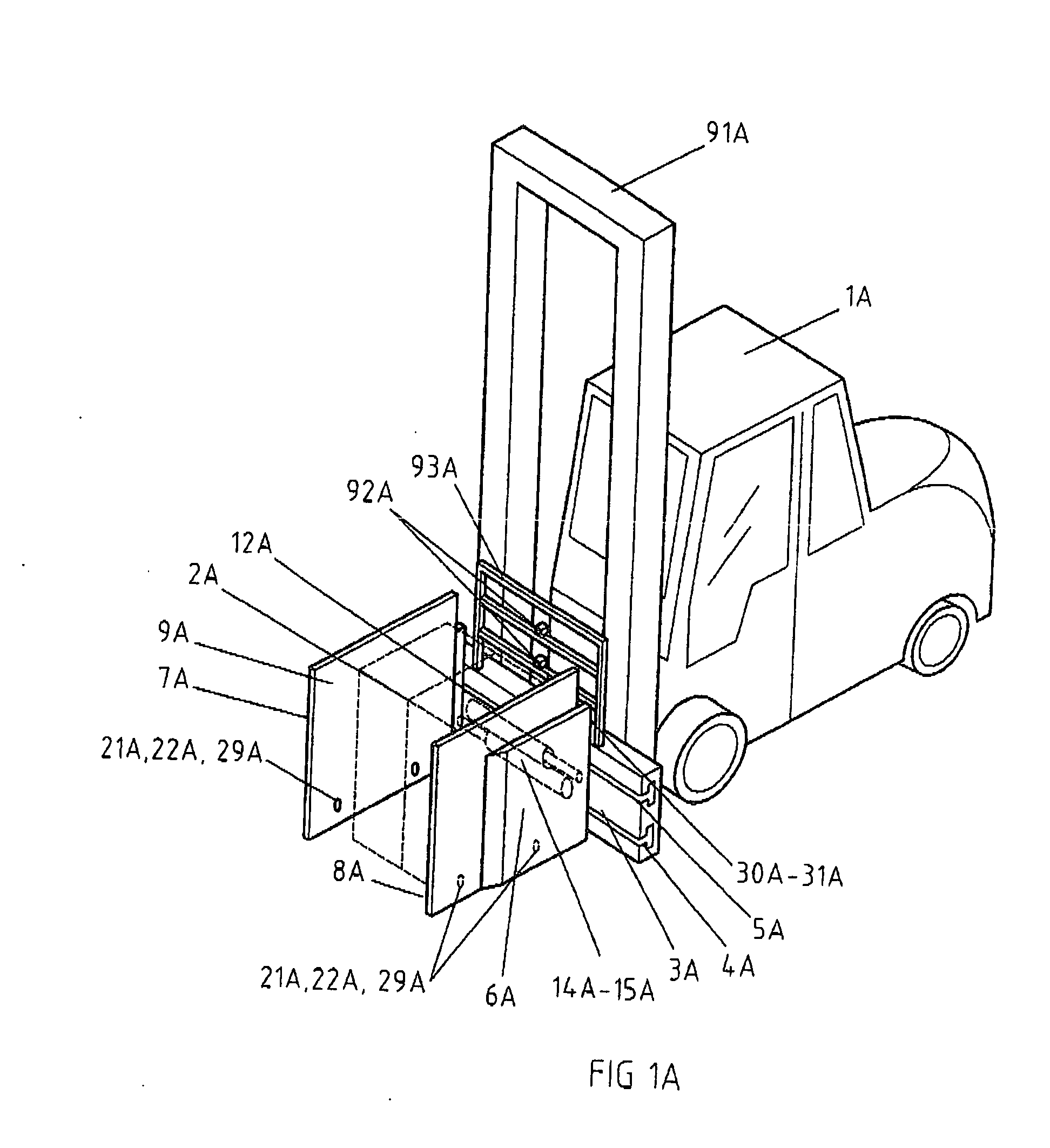

Method and apparatus for handling a load

InactiveUS20060104781A1Rapid and easy identificationEliminate riskLifting devicesManipulatorContact padEngineering

Owner:AURAMO

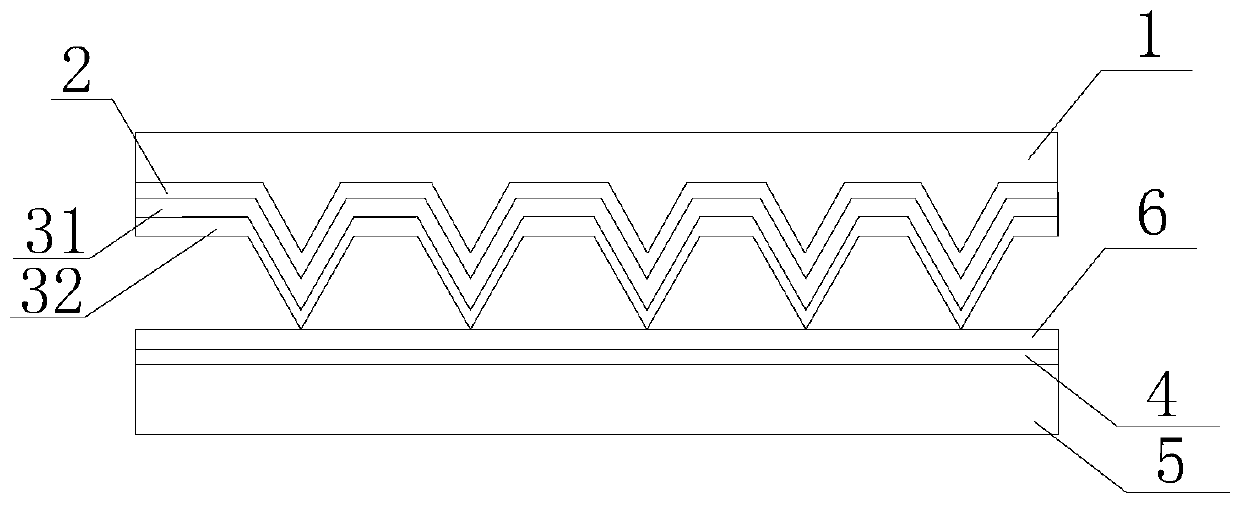

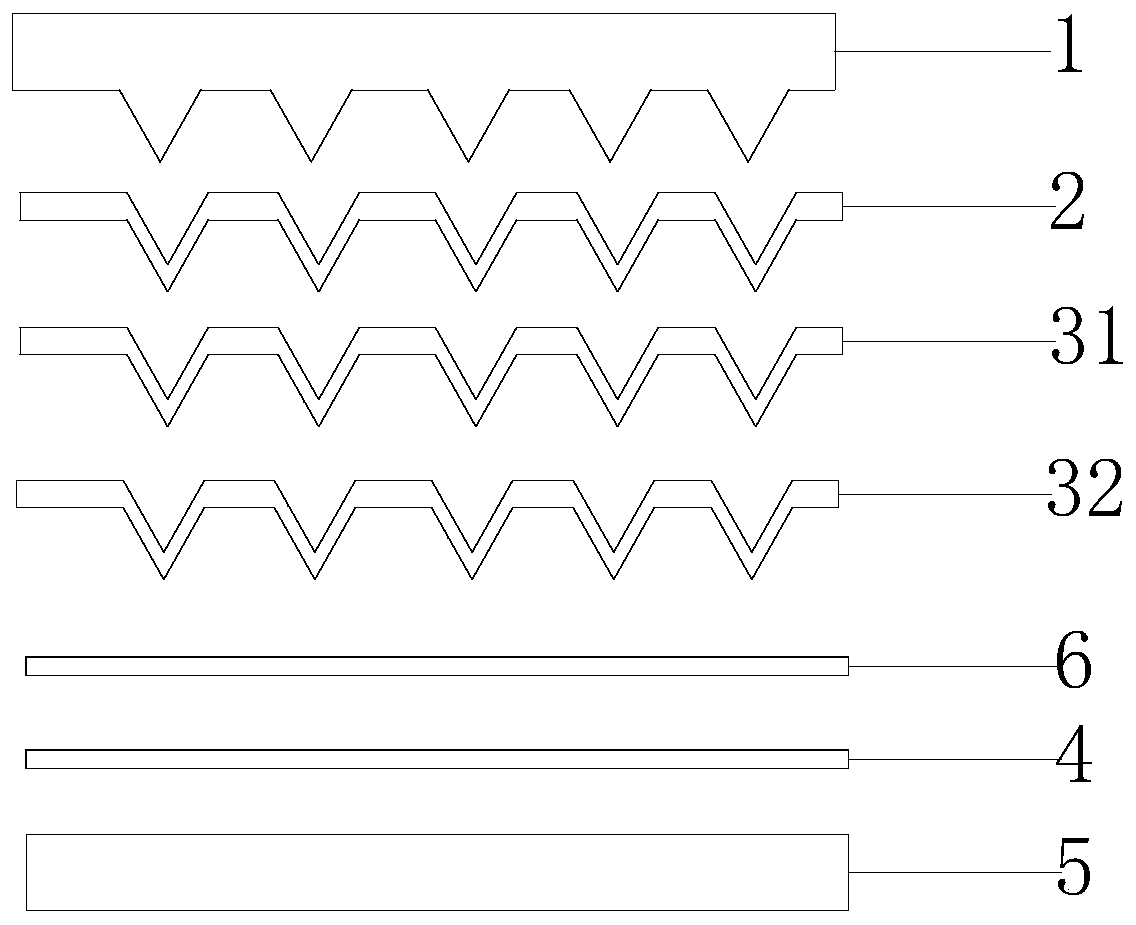

Touch/slip sensor and preparation method thereof, electronic equipment, braille identification equipment and robot

ActiveCN110031135AHighly integratedImprove stabilityMaterial nanotechnologyForce measurement using piezo-electric devicesMicro nanoEngineering

The invention discloses a capacitive touch / slip sensor. The capacitive touch / slip sensor comprises two electrode layers arranged oppositely, and a dielectric layer located between the two electrode layers; a micro-nano structure is arranged on at least one electrode layer corresponding to one side of the dielectric layer, and the dielectric layer and the electrode layer with the micro-nano structure are conformally integrated to form a dielectric layer / electrode conformal integrated structure, so that the integration level and the stability during the period are improved; and a graphene nanowall with the micro-nano structure is adopted on the electrode layer, so that the sensitivity and the measuring range of the sensor are improved. Correspondingly, the invention further provides a preparation method of the capacitive touch / slip sensor, electronic equipment with the capacitive touch / slip sensor, braille identification equipment and a robot.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

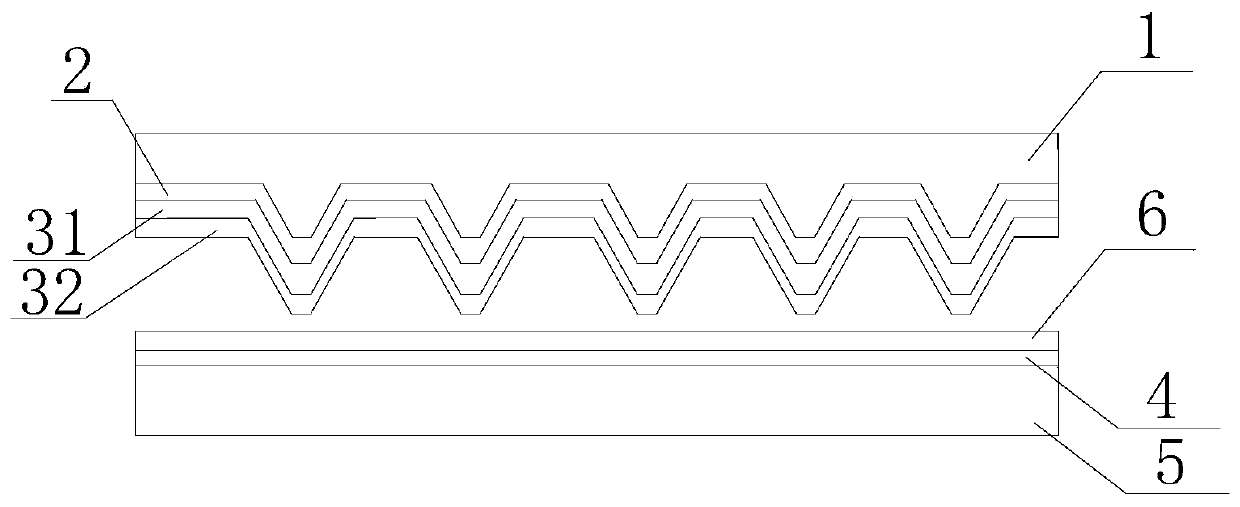

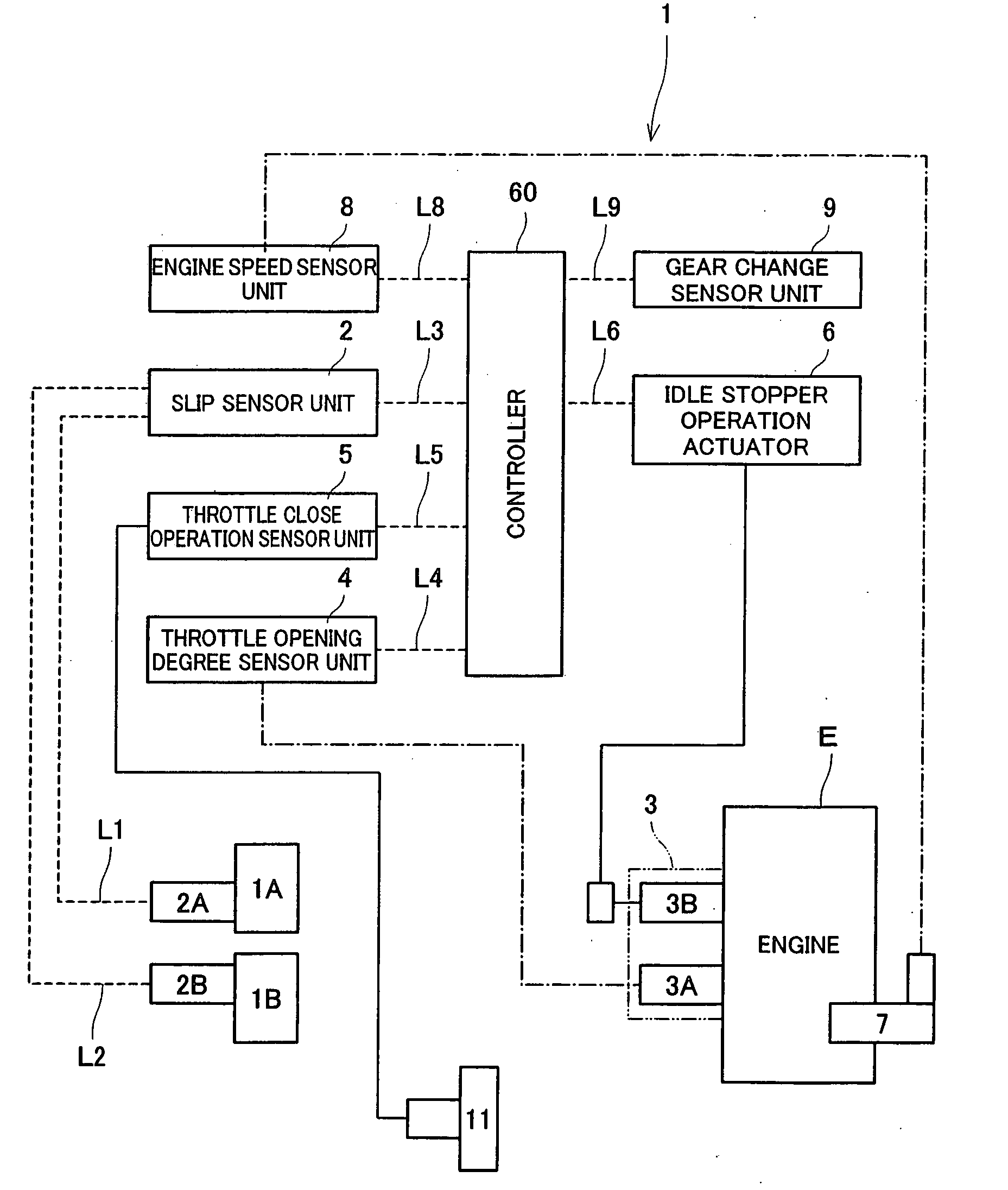

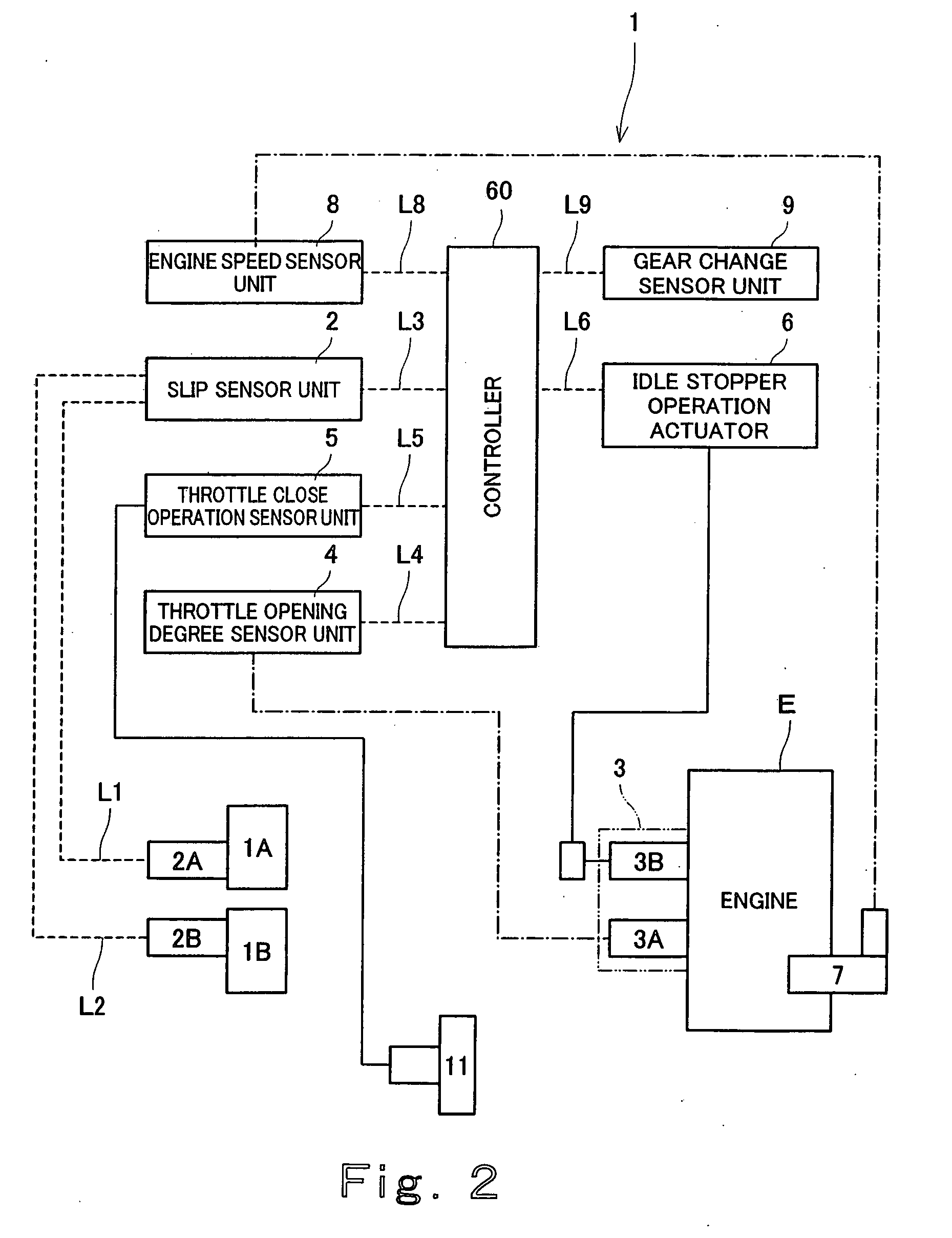

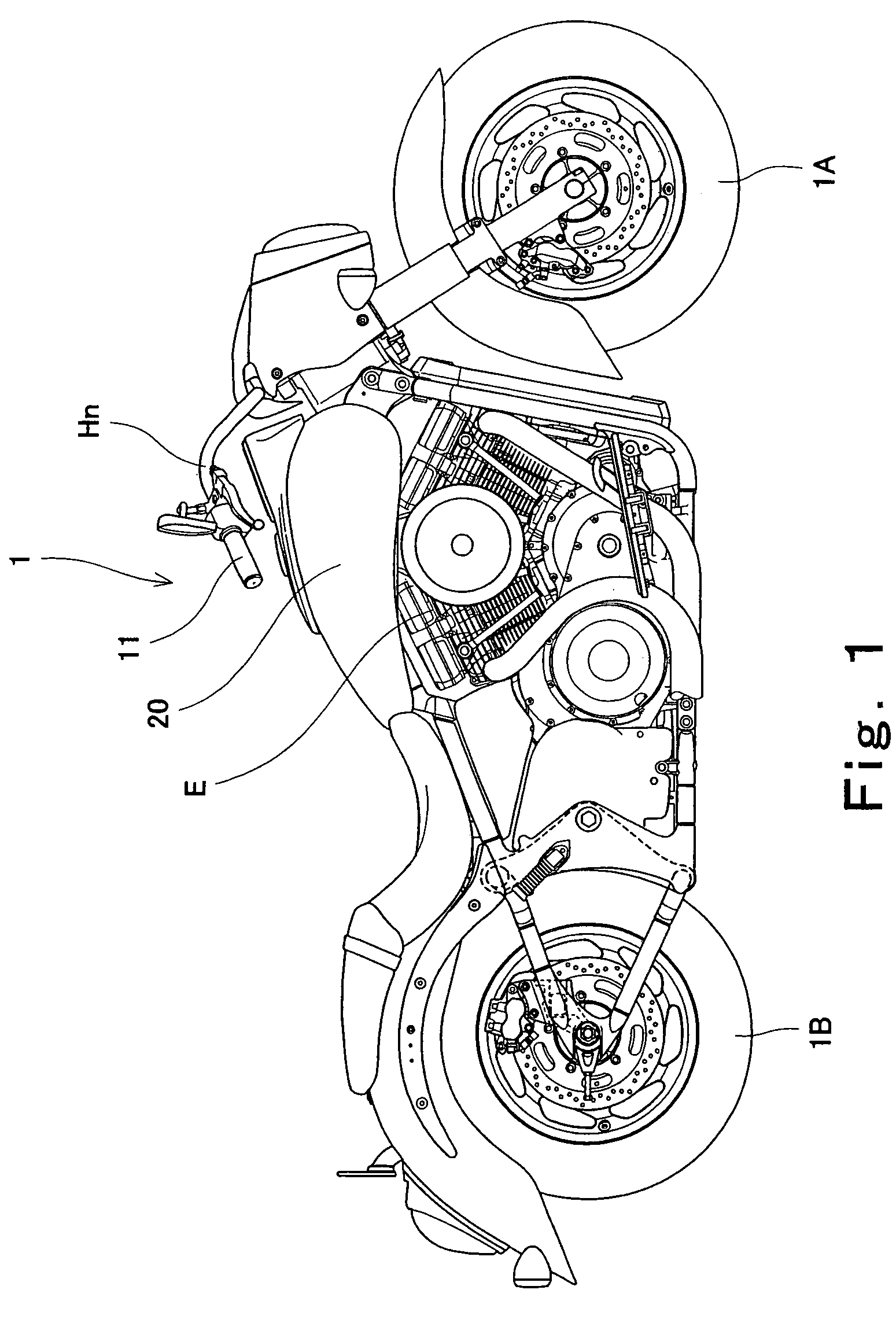

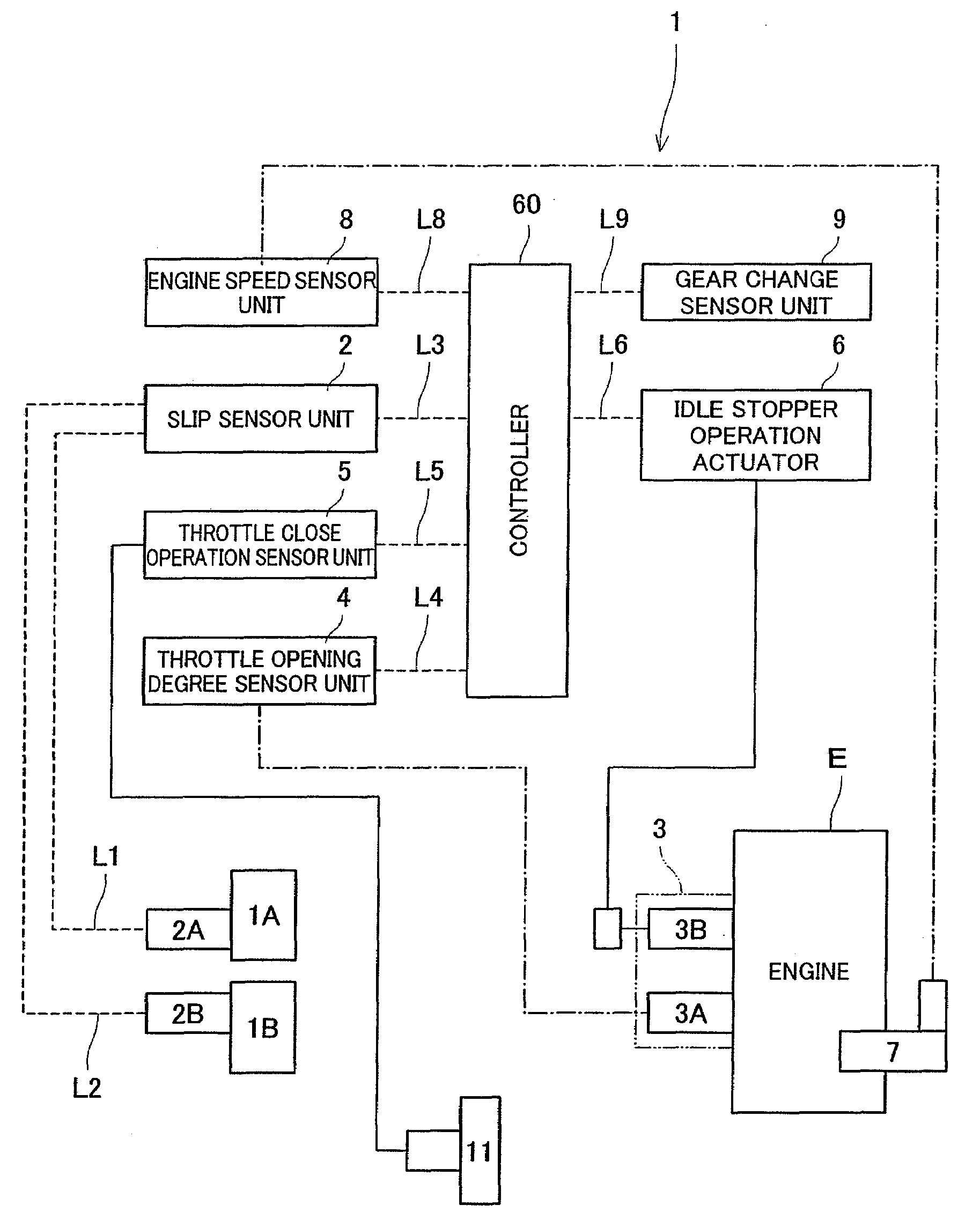

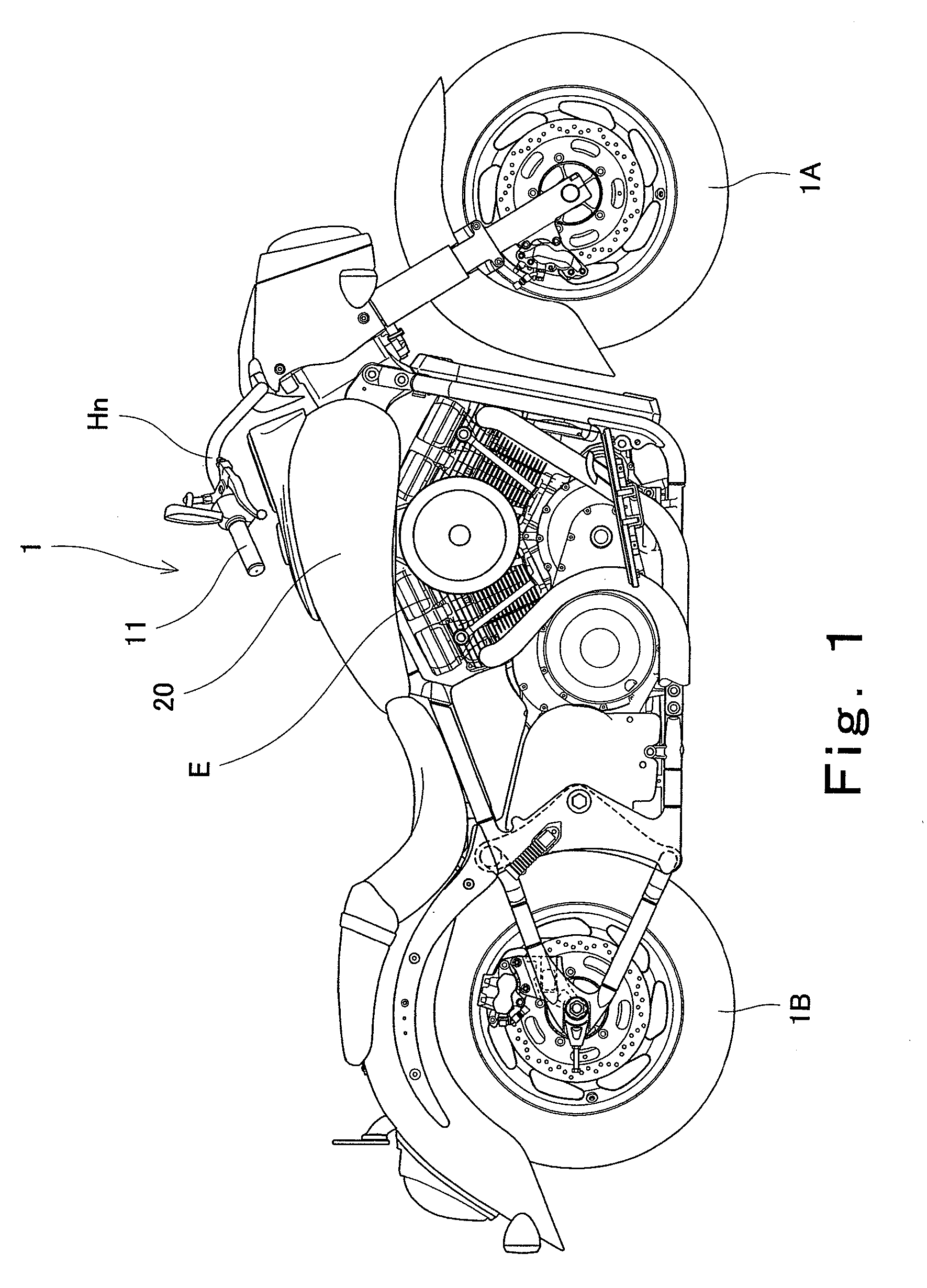

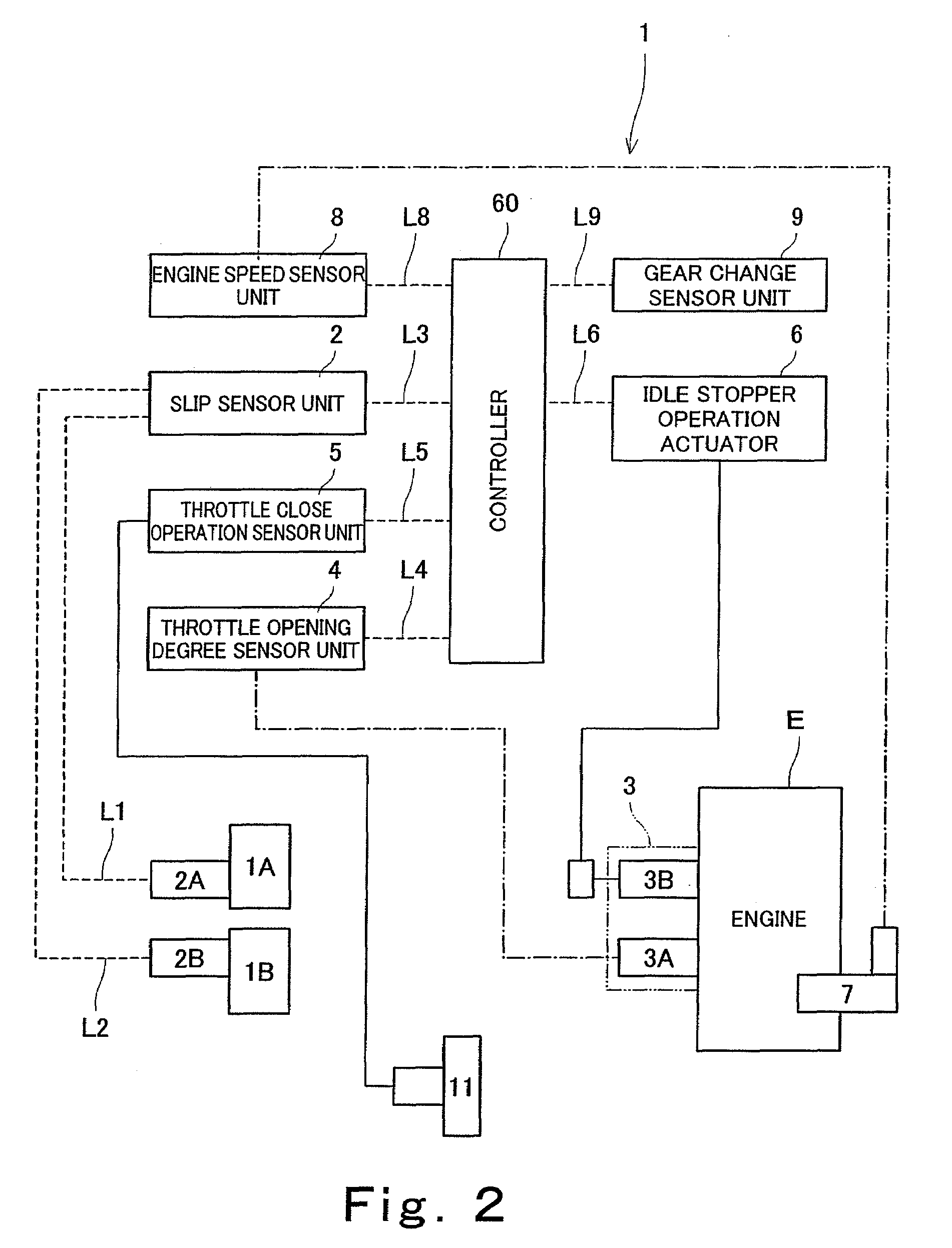

Leisure vehicle

ActiveUS20060241843A1Shorten speedSmall braking forceElectrical controlInternal combustion piston enginesDrive wheelInternal combustion engine

A leisure vehicle equipped with an internal combustion engine as a power unit to drive the leisure vehicle, including a drive wheel, a slip sensor unit configured to detect a slip of the drive wheel, a throttle device mounted to the internal combustion engine, a throttle valve position changing device configured to change a position of a throttle valve of the throttle device, a throttle close operation sensor unit configured to detect that a rider has performed a throttle close operation to close a throttle of the throttle device, and a controller configured to control an operation of the throttle valve position changing device.

Owner:KAWASAKI MOTORS LTD

Leisure vehicle

ActiveUS7458915B2Increase engine speedSmall braking forceElectrical controlInternal combustion piston enginesDrive wheelEngineering

A leisure vehicle equipped with an internal combustion engine as a power unit to drive the leisure vehicle, including a drive wheel, a slip sensor unit configured to detect a slip of the drive wheel, a throttle device mounted to the internal combustion engine, a throttle valve position changing device configured to change a position of a throttle valve of the throttle device, a throttle close operation sensor unit configured to detect that a rider has performed a throttle close operation to close a throttle of the throttle device, and a controller configured to control an operation of the throttle valve position changing device.

Owner:KAWASAKI MOTORS LTD

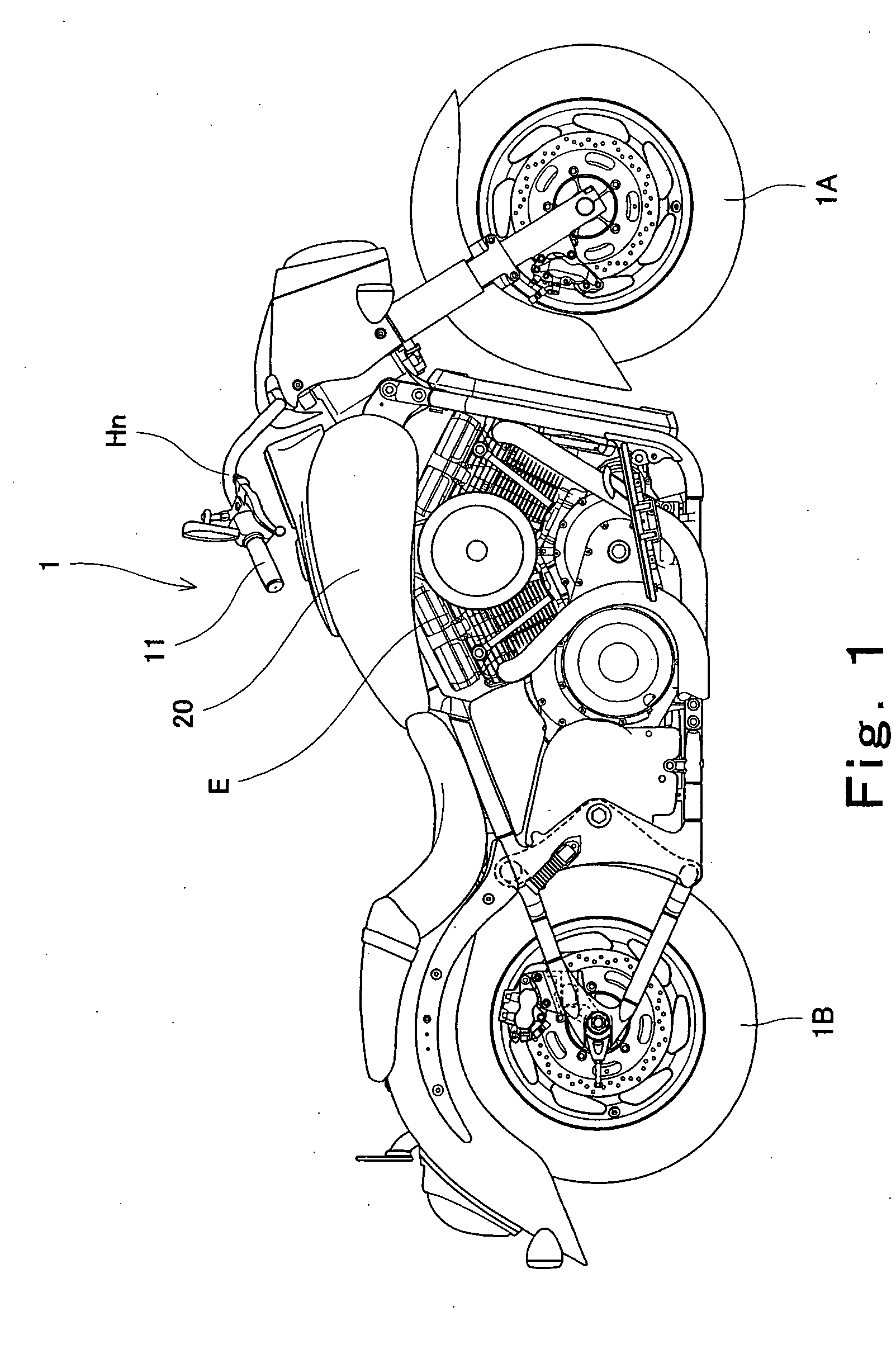

Manipulator touch-slip sensor based on fiber bragg grating

InactiveCN110779639AStrong normal work impactReduce work impactForce measurement by measuring optical property variationMeasurement of force componentsGratingEngineering

The invention relates to the technical field of fiber bragg grating sensing, and particularly discloses a manipulator touch-slip sensor based on a fiber bragg grating. The manipulator touch-slip sensor comprises a sensing layer, a first cascade grating string and a second cascade grating string are arranged in the sensing layer, and a temperature compensation grating is arranged outside the sensing layer; the first cascade grating string comprises N first fiber grating sensing elements which are positioned on the same straight line and are sequentially connected in series; the second cascade grating string comprises N second fiber grating sensing elements which are arranged in parallel and are sequentially connected in series, and a first plane where each first fiber grating sensing element is located is parallel to a second plane where each second fiber grating sensing element is located; and the temperature compensation grating is connected with the first cascade grating string. Themanipulator touch-slip sensor is surface-mounted or buried in a mechanical finger, can detect tactile-slip sense information such as forward pressure, shearing force, sliding and the like, and can compensate interference of environment temperature on measurement information.

Owner:CHONGQING JIAOTONG UNIVERSITY

Robot arm used for handling LCD screens

InactiveCN104786220AAvoid damageFlexible useProgramme-controlled manipulatorGripping headsProximity sensorEngineering

The invention discloses a robot arm used for handling LCD screens. The robot arm comprises a large arm connected with a stand column of a robot. The tail end of the large arm is provided with a small arm and a small arm motor which are connected. The tail end of the small arm is provided with a claw used for handling the LCD screens. The robot arm is characterized in that the claw comprises a claw motor, a first finger and a second finger. A first sensor set is arranged at the bottom of the first finger. The first sensor set comprises a slip sensor, a touch sensor and a proximity sensor. A second sensor set is arranged at the bottom of the second finger. The second sensor set comprises a temperature sensor and a thermal sensor. Preferably, the first sensor set and the second sensor set are each provided with a force sensor. As the multiple types of sensors are arranged, the robot arm is more flexible to use. Furthermore, the force sensors and a warning device are arranged, so the LCD screens can be prevented from being damaged in the handling process.

Owner:SFAM SCI & TECH JIANGSU

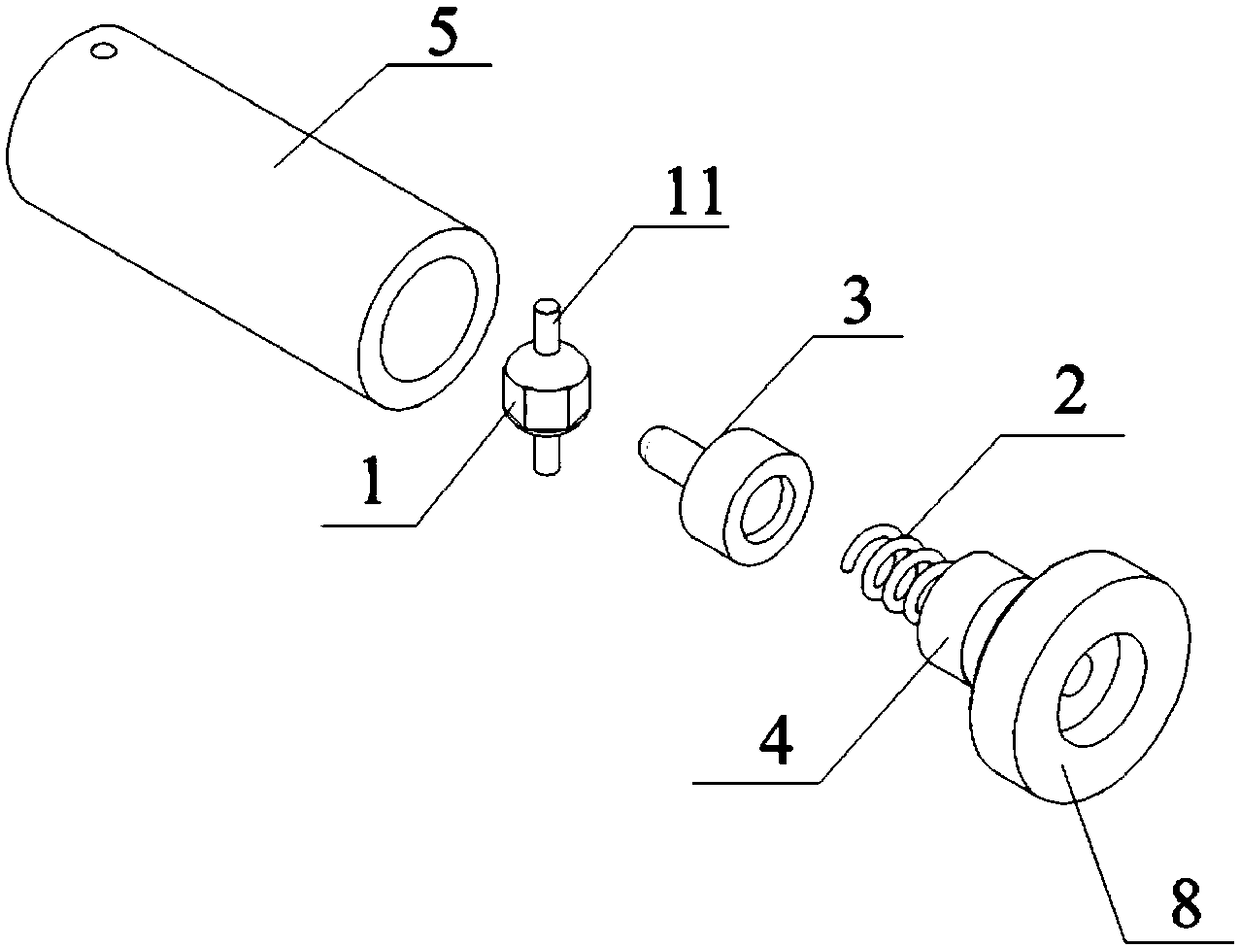

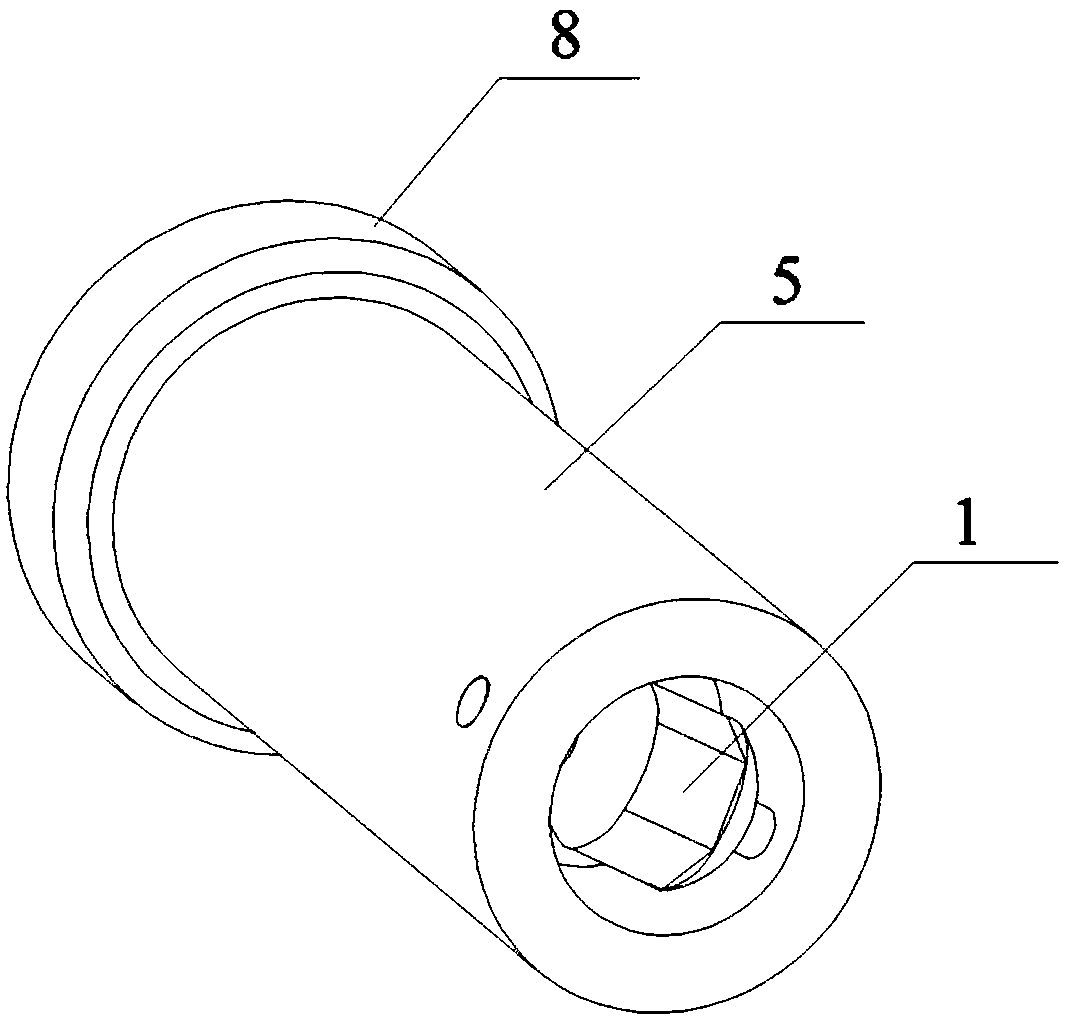

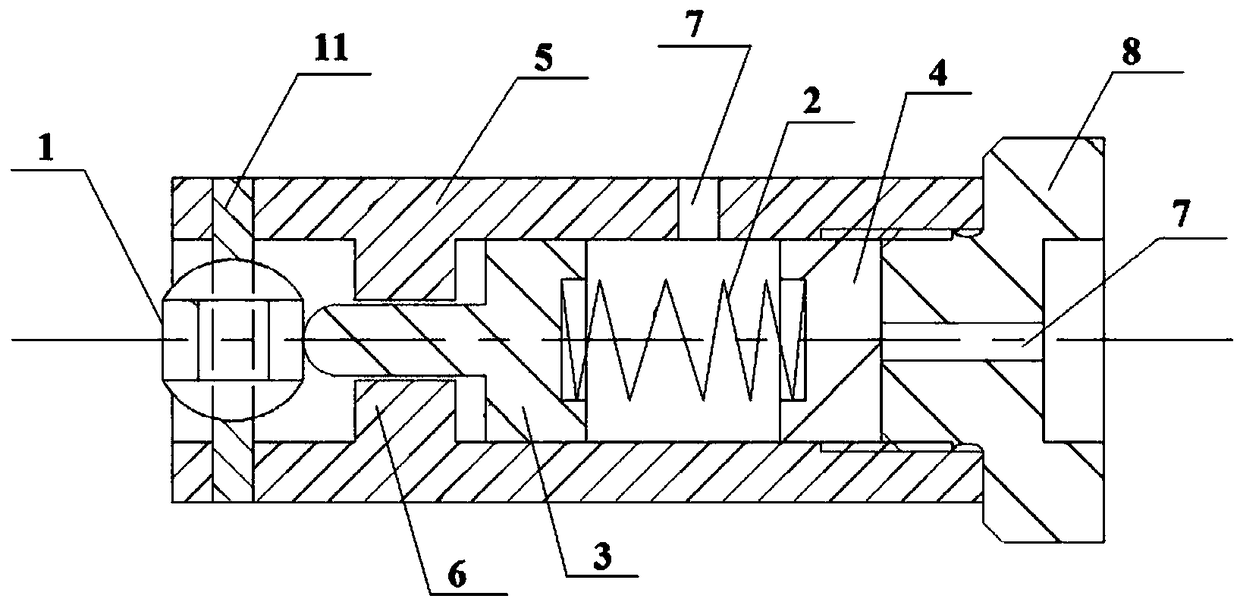

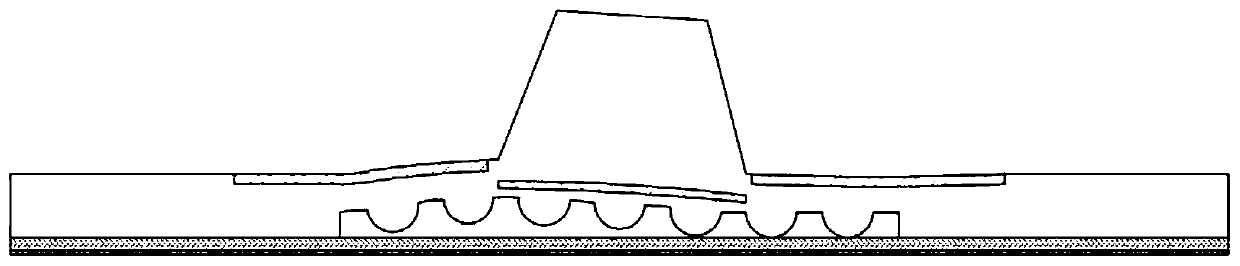

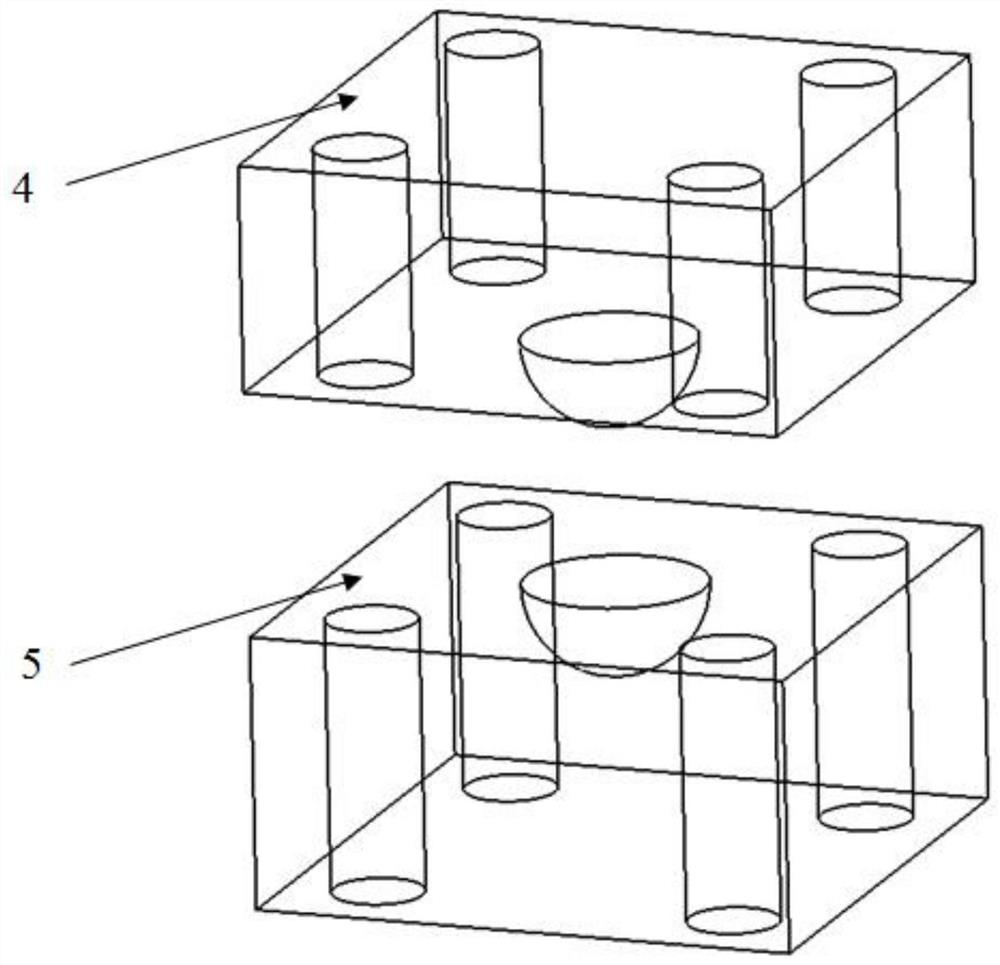

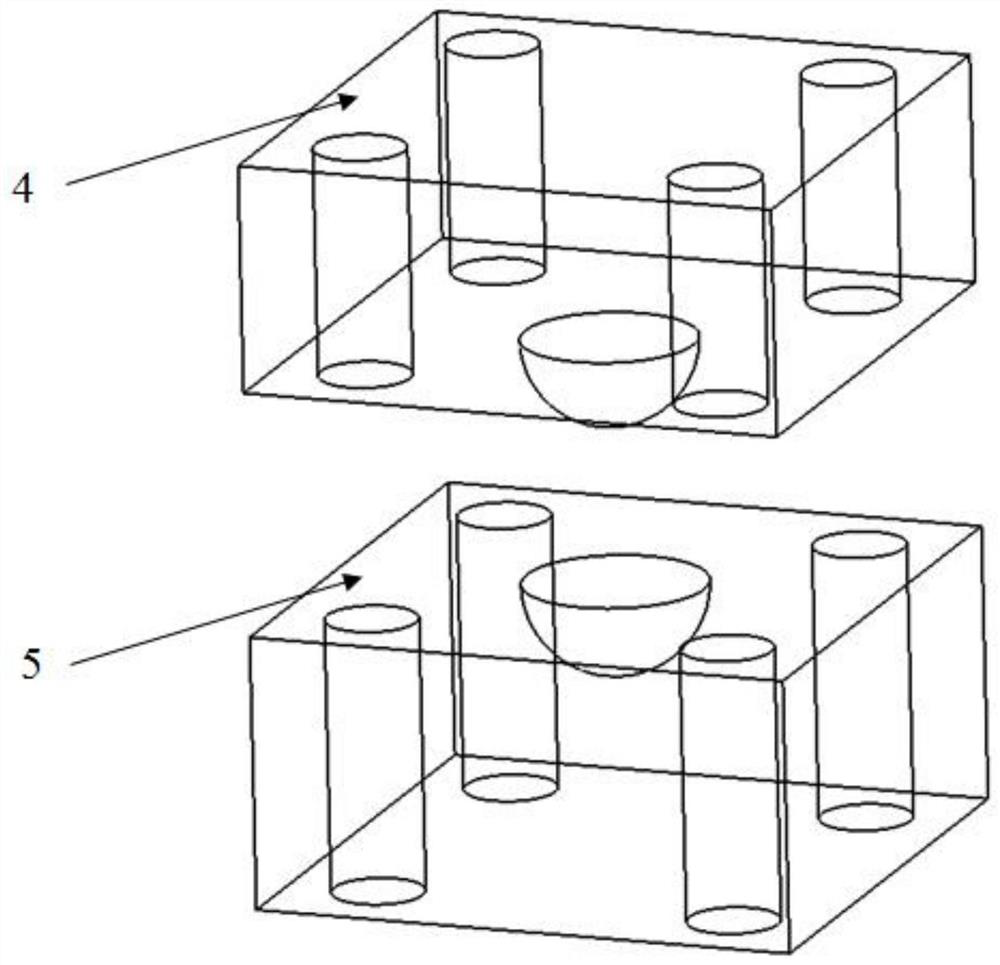

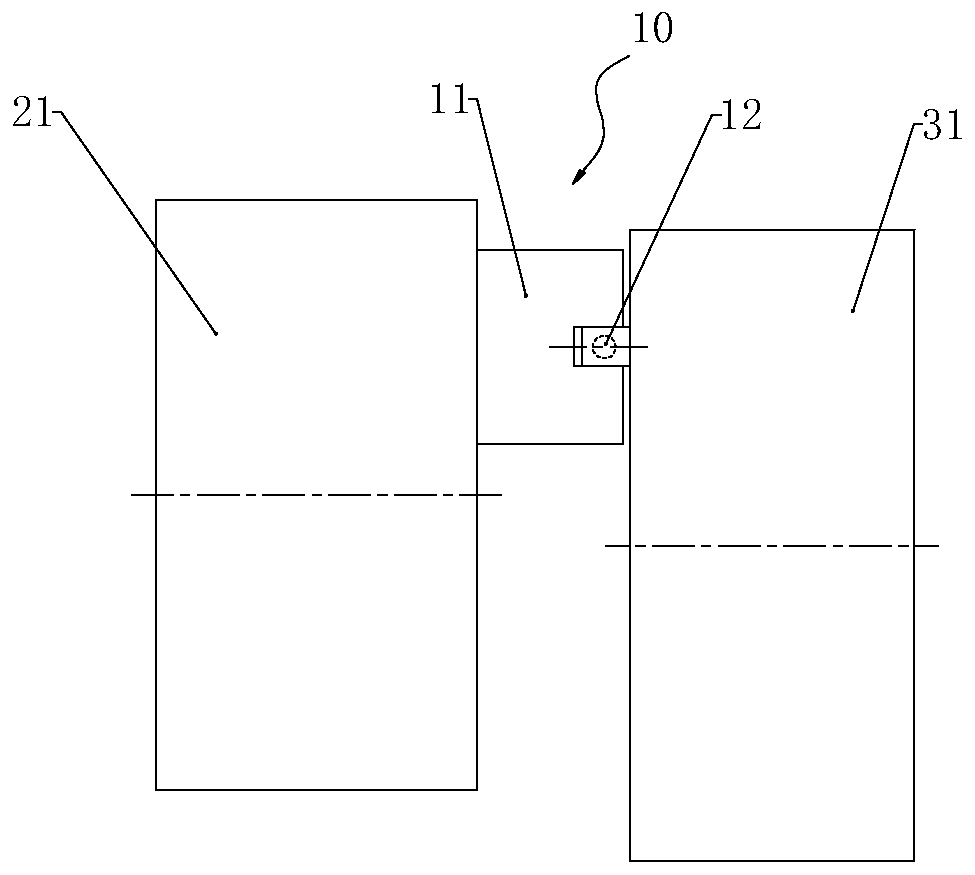

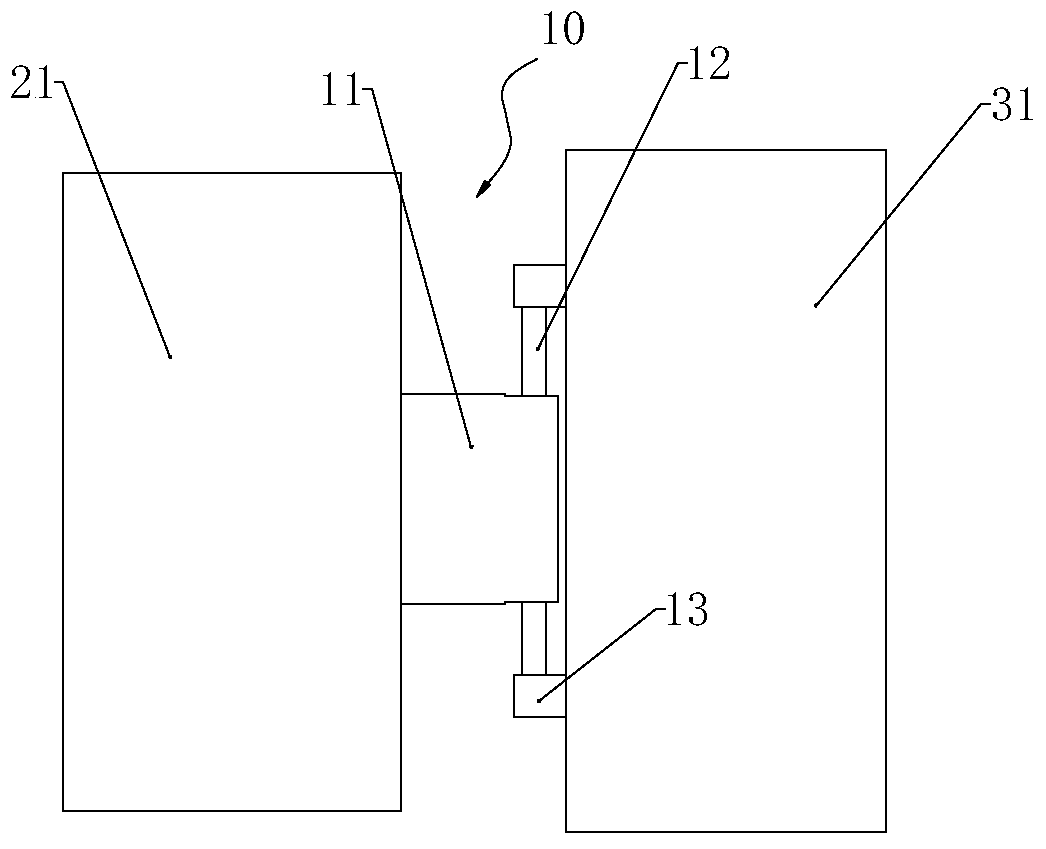

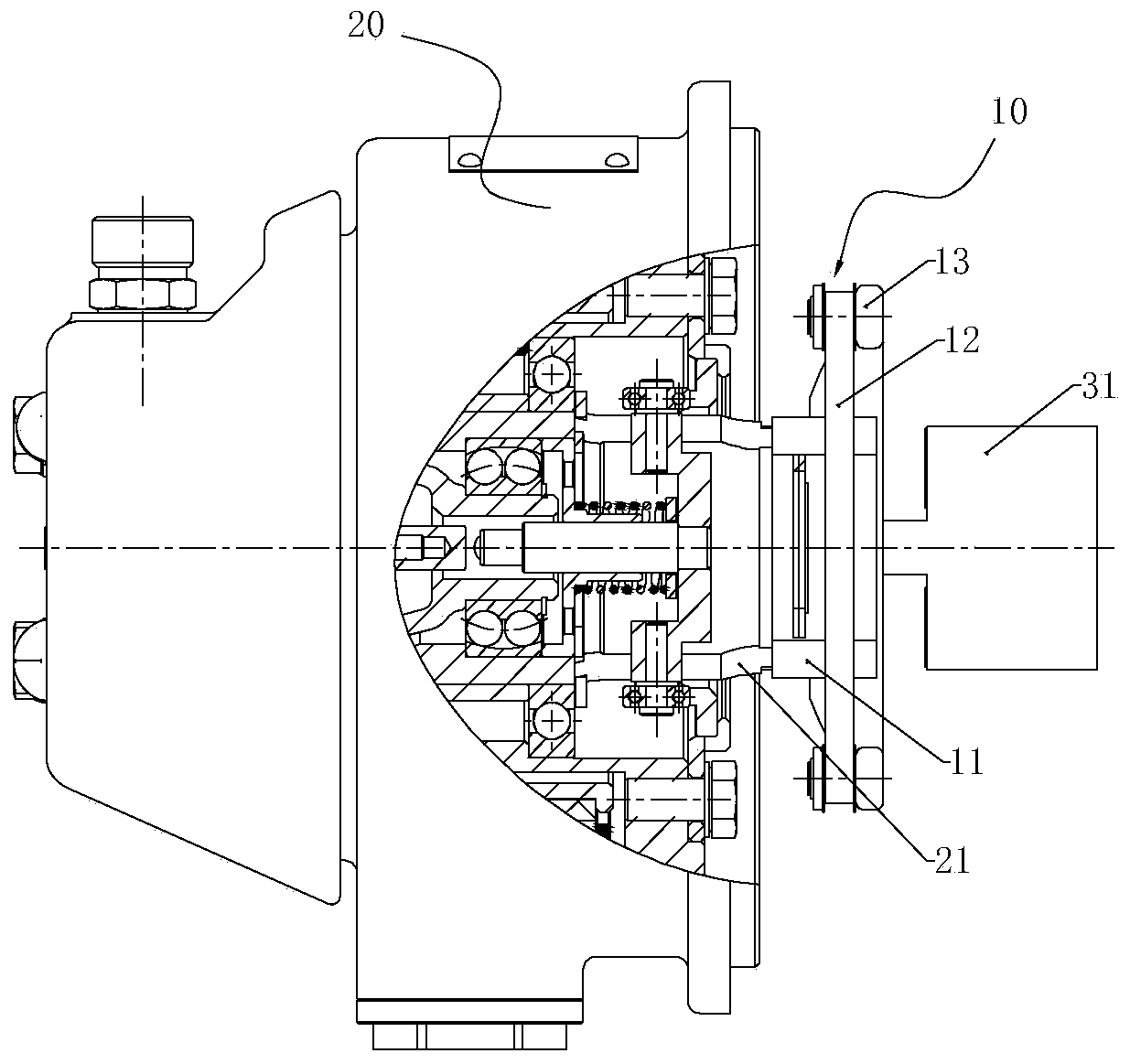

Slip sensor and clamping device including same

PendingCN109406018AHigh sensitivityImprove flexibilityForce measurement by measuring optical property variationManipulatorFiberInterference resistance

The invention discloses a slip sensor and a clamping device including same. The slip sensor comprises the components of a roller, an outer peripheral surface is used for contacting with an object, furthermore the roller can roll around the central axis of the roller along with relative sliding of the object to the outer peripheral surface, and the outer peripheral surface has a projection structure; an elastic assembly of which one end functions on the outer peripheral surface; and a fiber grating which can sense the stress change, wherein the other end of the elastic assembly functions on thefiber grating. Furthermore the distance between the central axis of the roller and the fiber grating is fixed. The fiber grating detects object sliding according to the pressure change of the elasticassembly. According to the structure, because the fiber grating has advantages of relatively high interference resistance, relatively high sensitivity, relatively high flexibility and relatively highpracticability for an application scene with a relatively small mounting space, the slip sensor settles problems of relatively low electromagnetic interference resistance, relatively low sensitivityand low flexibility in the slip sensor in prior art.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

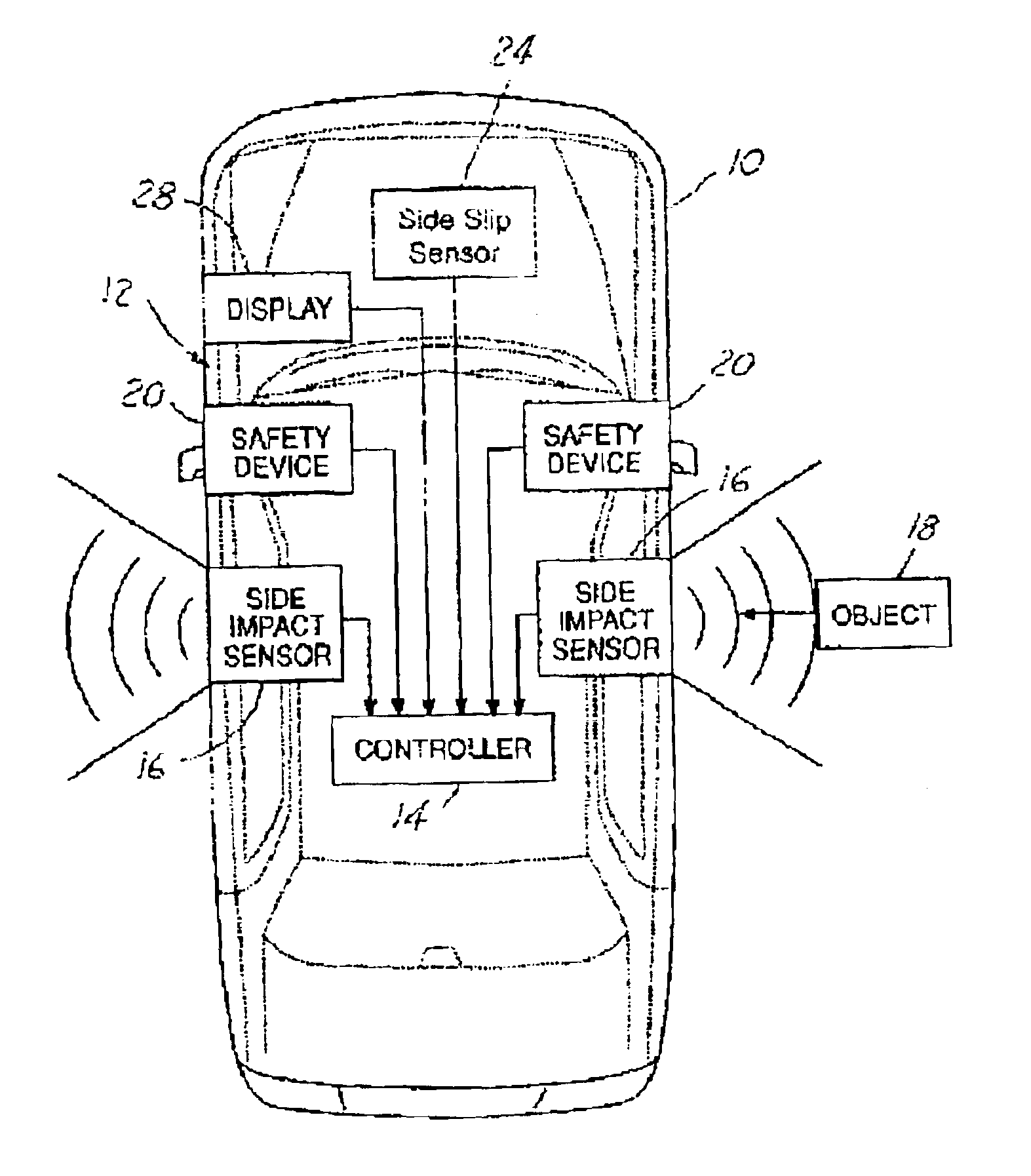

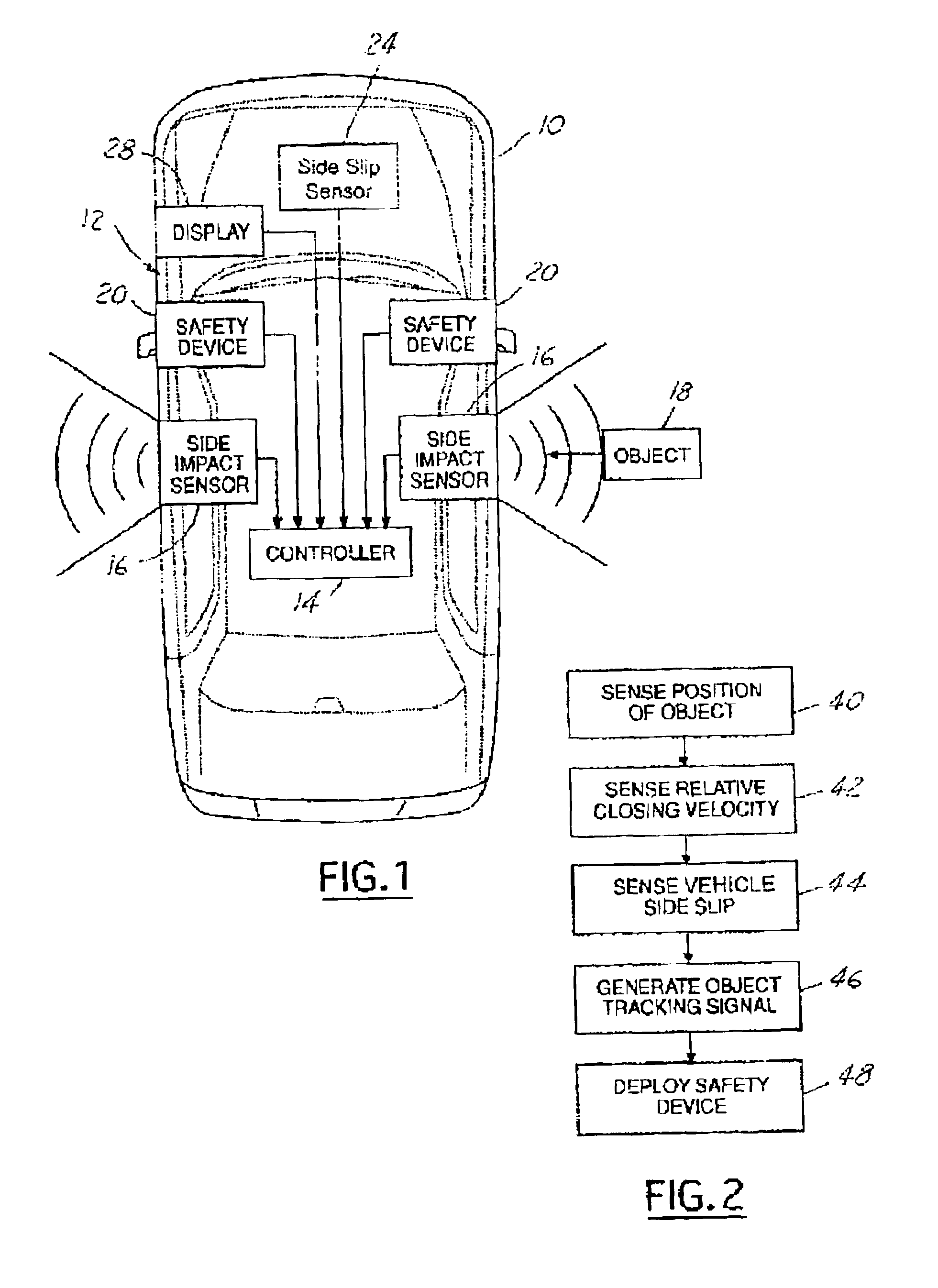

Side impact automotive crash sensor system

ActiveUS6863302B2Reduce in quantityReduce processing timePedestrian/occupant safety arrangementAnti-collision systemsMobile vehicleEngineering

A side impact crash detection system (12) for an automotive vehicle (10) is provided that has a side impact sensor (16) that generates a relative closing velocity signal of an object (18). A side slip sensor (24) is positioned within the vehicle and generates a side slip signal corresponding to the side slip of the vehicle (10). A controller (14) is coupled to the side impact sensor and the side slip sensor. The controller (14) generates an object tracking signal in response to the relative closing velocity signal and the side slip signal of the vehicle.

Owner:FORD MOTOR CO +1

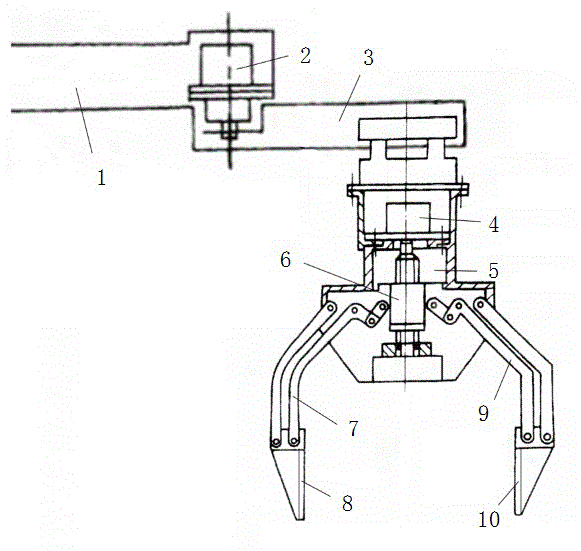

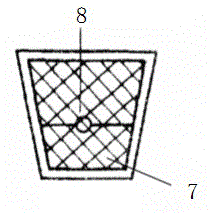

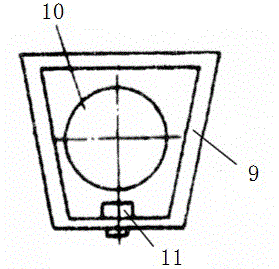

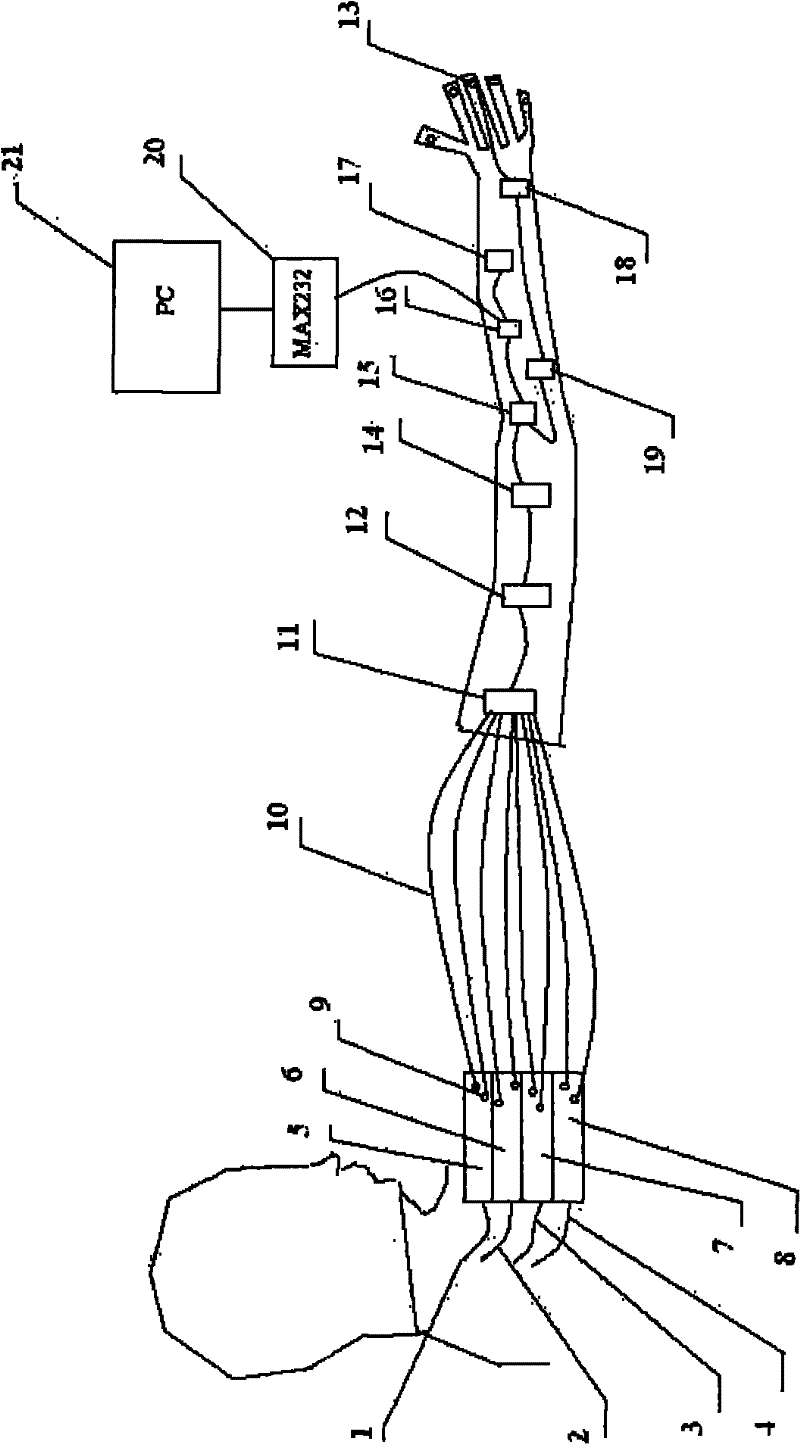

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866BReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

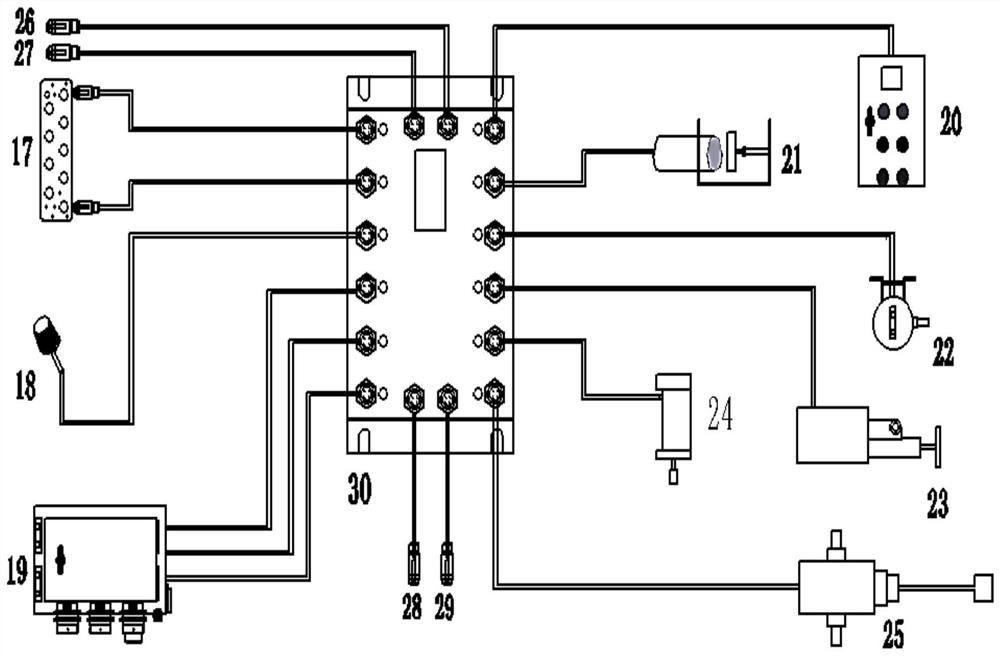

The invention discloses a picking method and picking robot device aiming at fruits which are in size of an apple and is similar to a sphere. The picking robot device comprises a mechanical actuating device, control system hardware and control system software. The mechanical actuating device comprises a picking mechanical arm, an underactuated manipulator, an electric sliding table and an intelligent mobile platform, wherein the control system hardware comprises an IPC (industrial personal computer), a motion control card, a data acquisition card, an AHRS (attitude and heading reference system), a coder, a monocular camera, a binocular camera, a force sensor, a slipping sensor and the like. During operation, the IPC fuses information of the coder, the AHRS, monocular camera components and an ultrasonic sensor to enable the mobile platform to independently navigate and avoid obstacles. A binocular vision system collects images of mature fruits and obstacles and extracts the characteristics of the images so as to realize obstacle avoidance of the mechanical arm and fruit positioning. Finally, the IPC fuses the information of the force sensor, the slipping sensor and the position sensor, thereby further reliably gripping the mature fruits and separating the fruits from fruit branches.

Owner:NANJING AGRICULTURAL UNIVERSITY

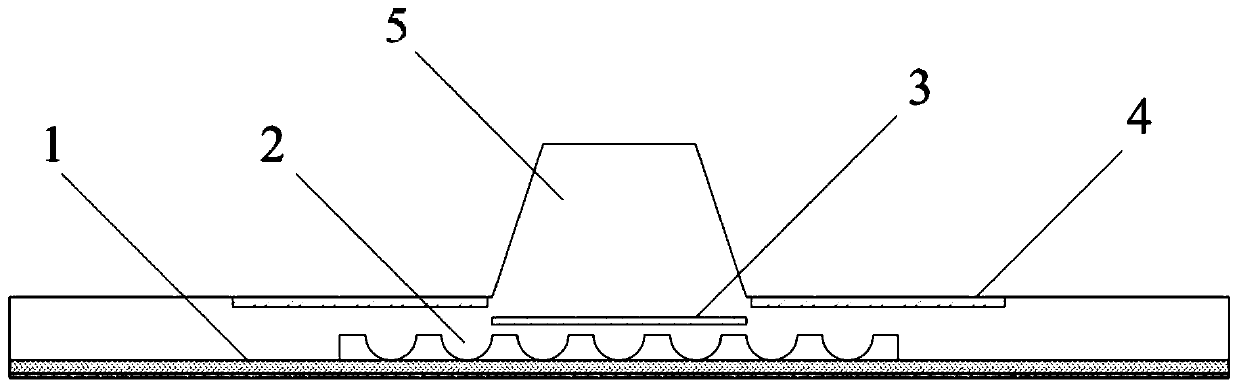

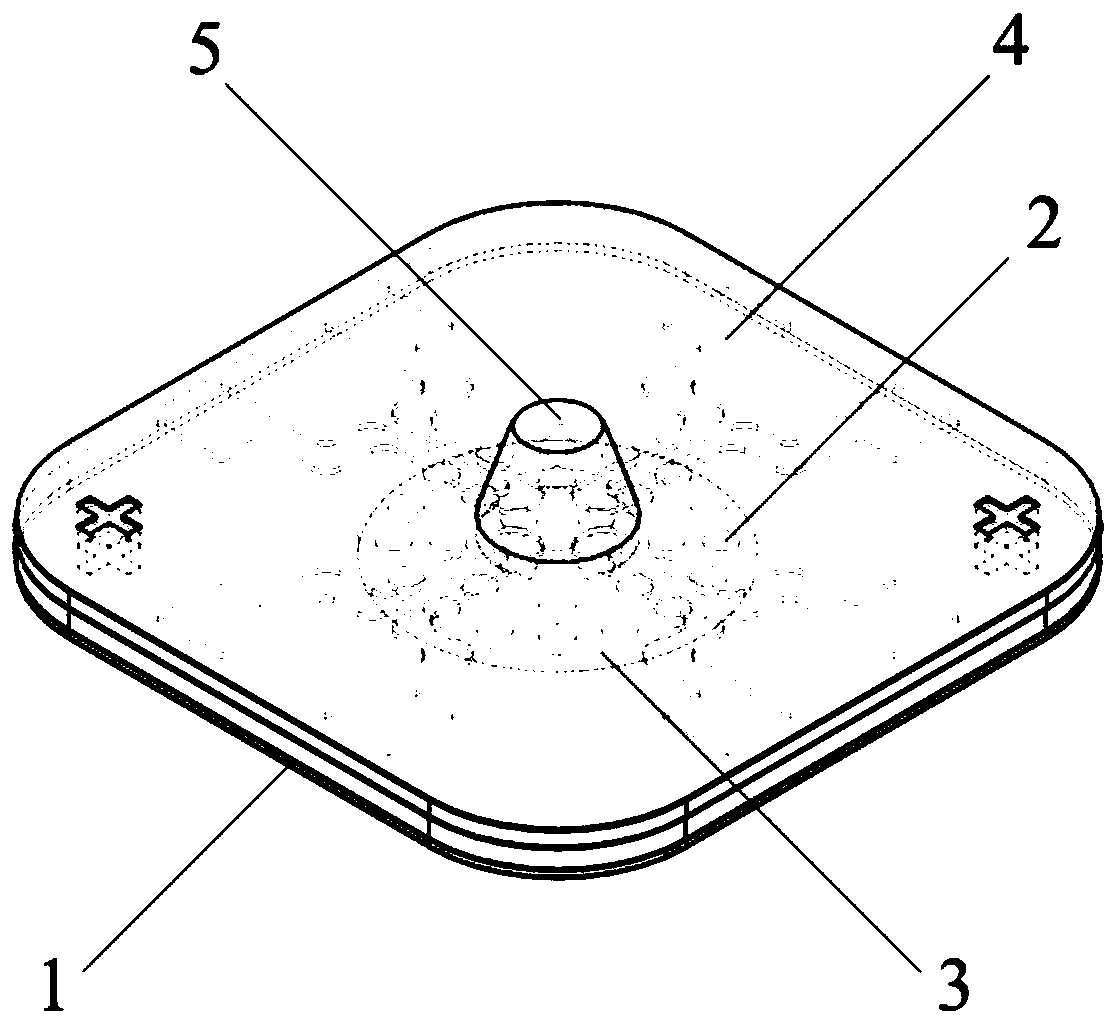

Touch and slip sensor for acquiring resonance signal based on active excitation signal

ActiveCN110243400ASimple structureLow costConverting sensor ouput using wave/particle radiationConverting sensor output electrically/magneticallyElectricityEngineering

The invention discloses a touch and slip sensor for acquiring resonance signal based on an active excitation signal. The sensor is applied to a manipulator, the manipulator is used for capturing an object, the touch and slip sensor comprises a slip touch panel arranged on the manipulator; an electret microphone arranged on the slip touch panel; a piezoelectric ceramic piece arranged on the slip touch panel; and a signal generator for acting the produced excitation signal on the piezoelectric ceramic piece, thereby enabling the piezoelectric ceramic piece to produce vibration; the piezoelectric ceramic piece acts the produced vibration on the slip touch panel, and the electret microphone outputs a response signal according to the vibration signal produced when the piezoelectric ceramic piece and the manipulator capture an object. The resonance frequencies of the manipulator under no-load, sliding, clamping and like different states in the capturing process are measured by utilizing an acoustic resonance spectrum method, and the resonance frequency is used as the evidence for judging the accomplishment of the capturing the manipulator, and the sensor has the advantages of being simple in structure and low in cost.

Owner:GUIZHOU UNIV

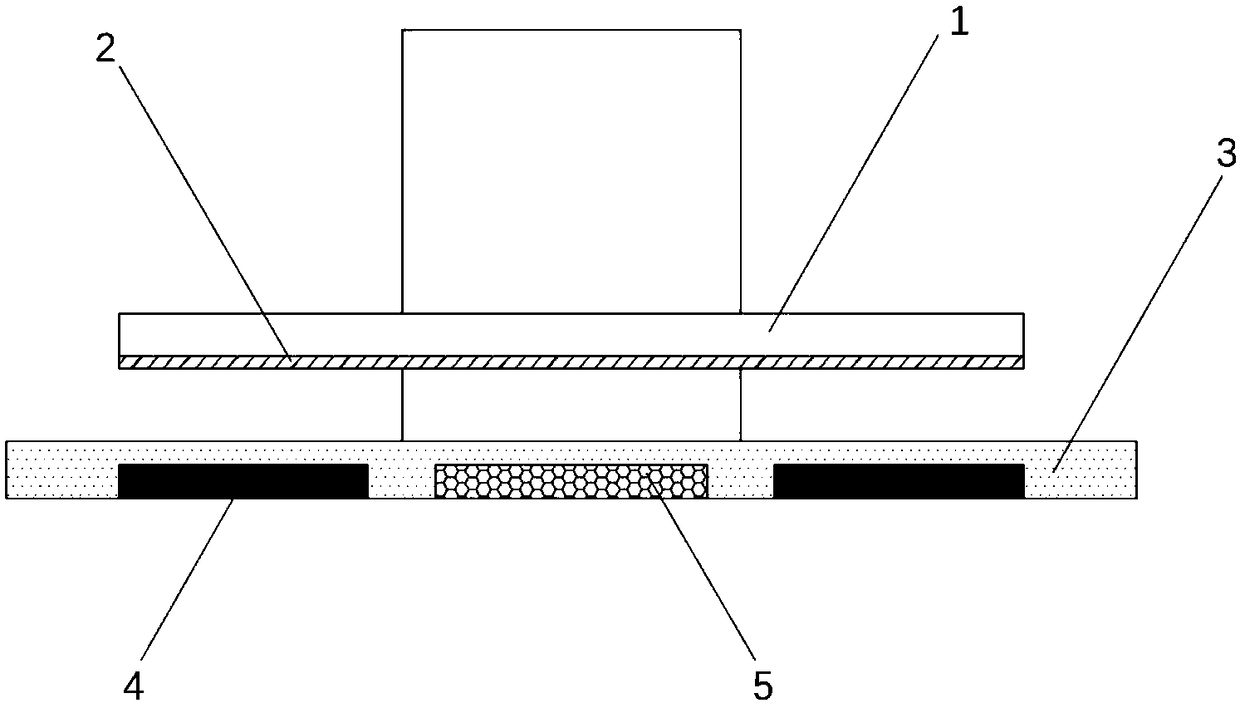

Touch and slip sensor and preparation method thereof

PendingCN110108395ASimple preparation processFeedback latency is lowSynthetic resin layered productsForce measurement using piezo-resistive materialsSlip sensorAnnular array

The invention discloses a touch and slip sensor and a preparation method thereof. The touch and slip sensor comprises five layers of structures including an organic polymer film, organic materials, acircular organic polymer film, an insulation film and a circular truncated cone structure in sequence from bottom to top, wherein the bottom surface of the organic polymer film is covered with conducting materials, circular grooves are formed in centers of the organic materials, hemispherical raised ring arrays with radiuses being equal to the depth of the grooves are uniformly distributed in thegrooves, and a plurality of piezoresistance films are distributed on the upper surface of the insulation film. According to the touch and slip sensor, on the basis of capable of recognizing whether slip occurs or not, the direction of the slip and the speed of the slip can be measured, in addition, the space force acting on the sensor can be measured, complex post-processing to obtained data is not needed, and the information feedback delayed performance is low.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

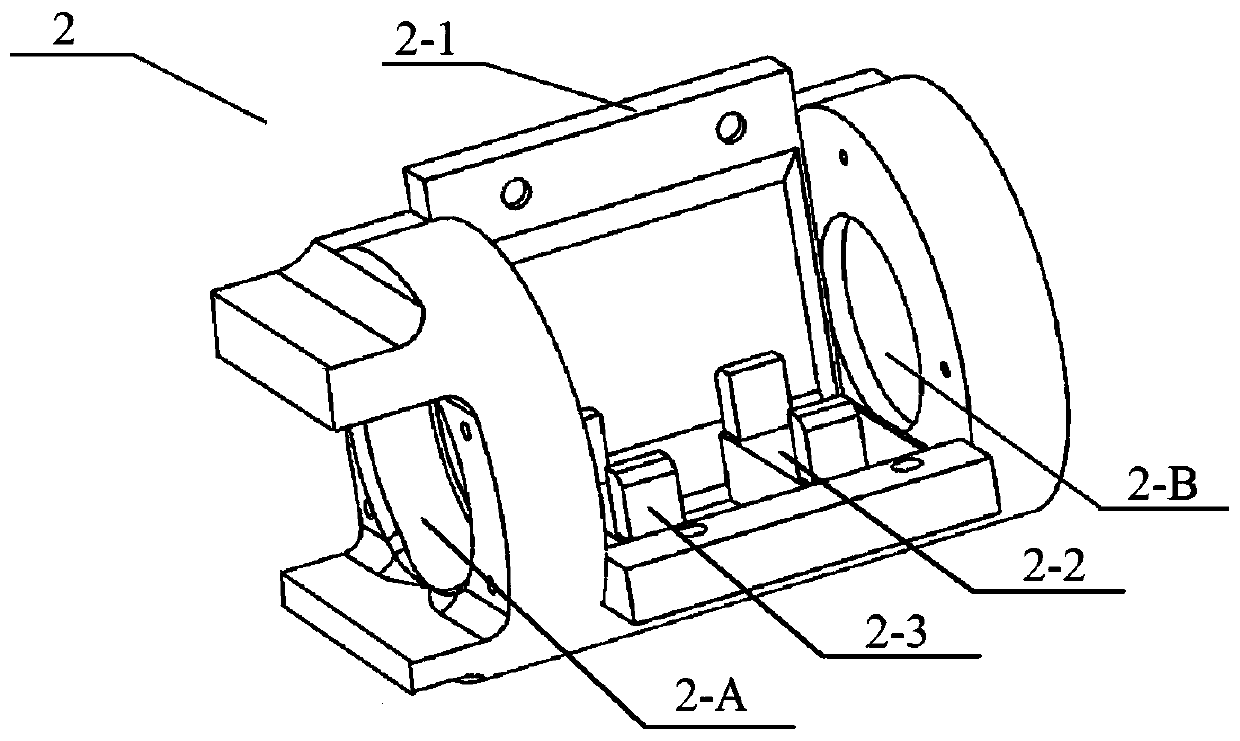

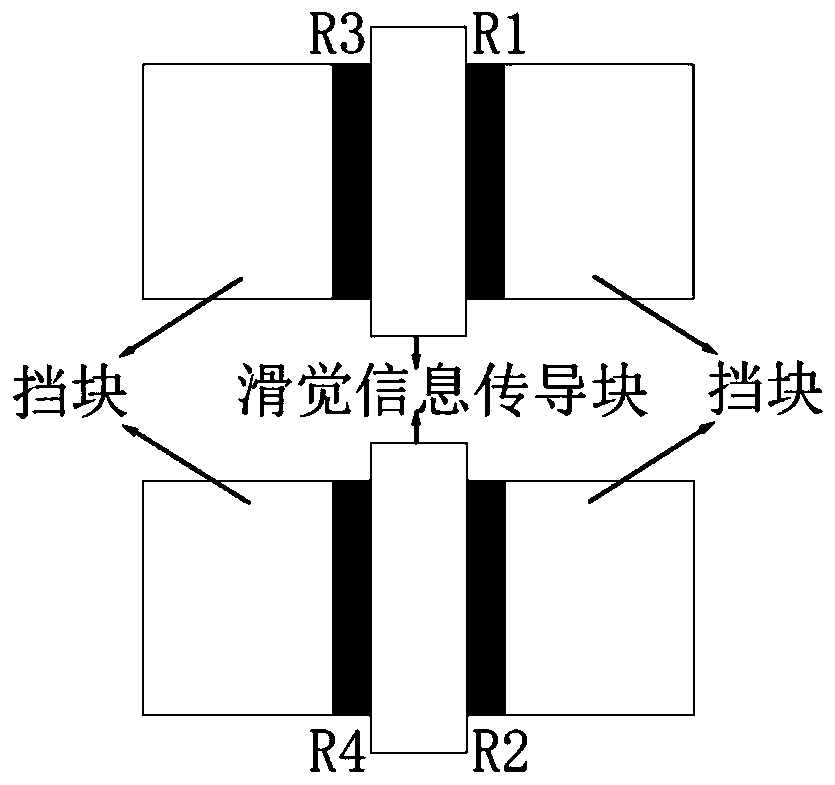

Tactile and slip sensor, flexible finger grabbing system and grabbing method thereof

ActiveCN111015740ASimple structureSimple decoupling calculation principleProgramme-controlled manipulatorGripping headsControl engineeringHemt circuits

The invention provides a tactile and split sensor, a flexible finger grabbing system and a grabbing method thereof. Through a magnetorheological elastomer induction surface and an induction surface voltage acquisition circuit in a tactile and slip sensing unit, pressure applied on the magnetorheological elastomer induction surface by an object can be converted into a voltage signal, a relationshipbetween the voltage signal and pressure information is established, and the acquired voltage signal can be converted to obtain grabbing force information of the object; through a rotatable transmission integrated rotation shaft, a stop dog and an induction block bridge circuit, slip information of the object can be converted into a voltage signal, a relationship between the voltage signal and theslip information is established, the acquired voltage signal can be converted to obtain the slip information of the object, and by combining a time, slip speed information can be obtained; a tactileand slip decoupling calculation principle is simple and the calculated amount is relatively small; and memory storage is carried out by combining a texture perception neural network model, so that corresponding pressure can be directly applied when objects of the same type come out, thereby ensuring the timeliness, rapidity and stability of the grabbing.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

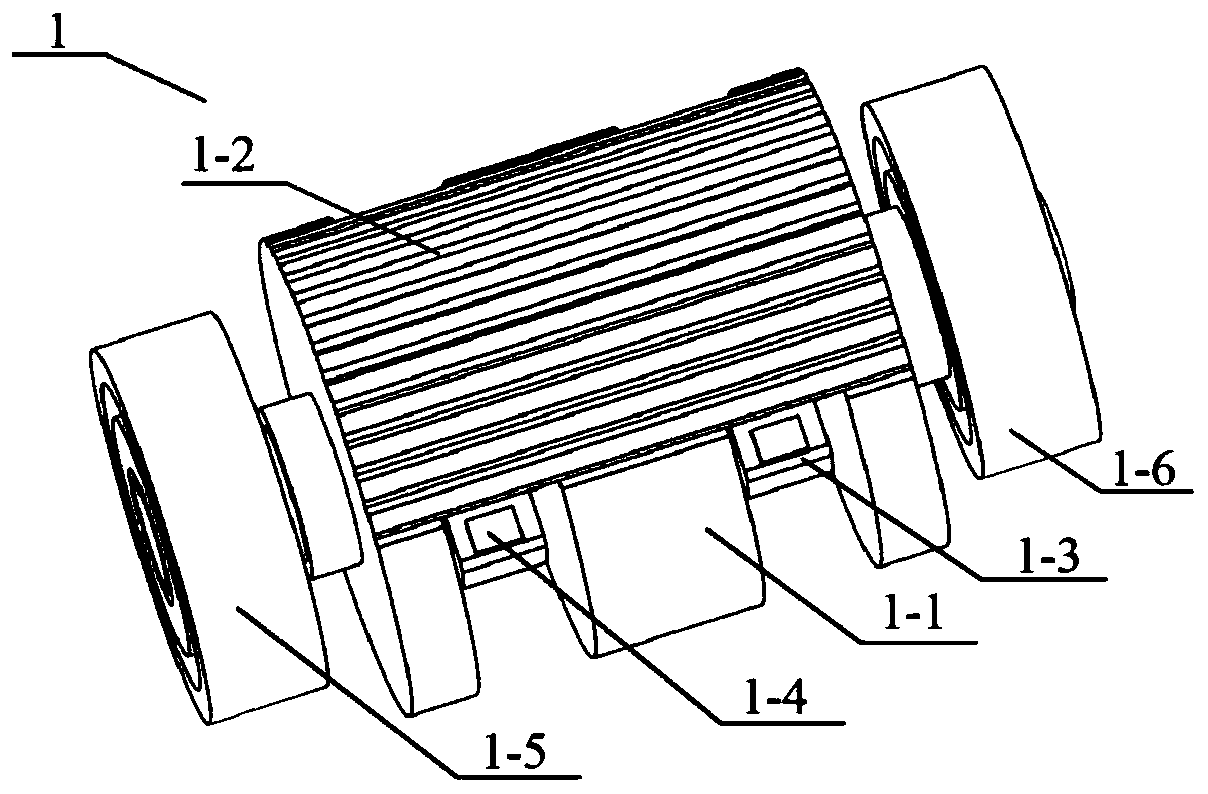

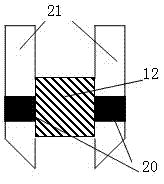

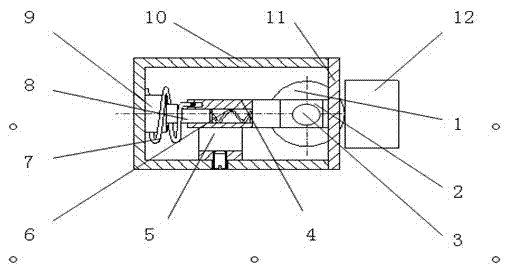

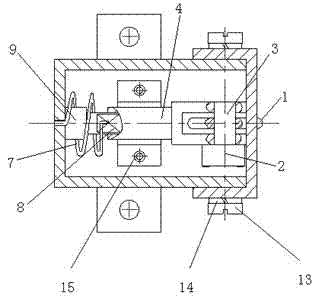

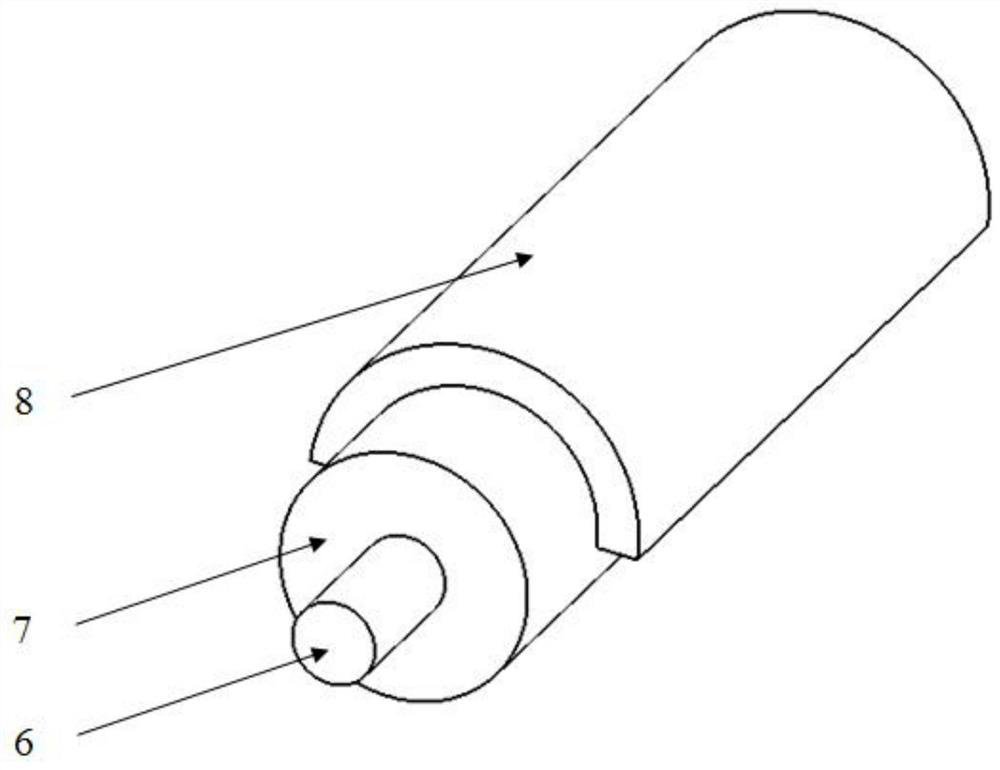

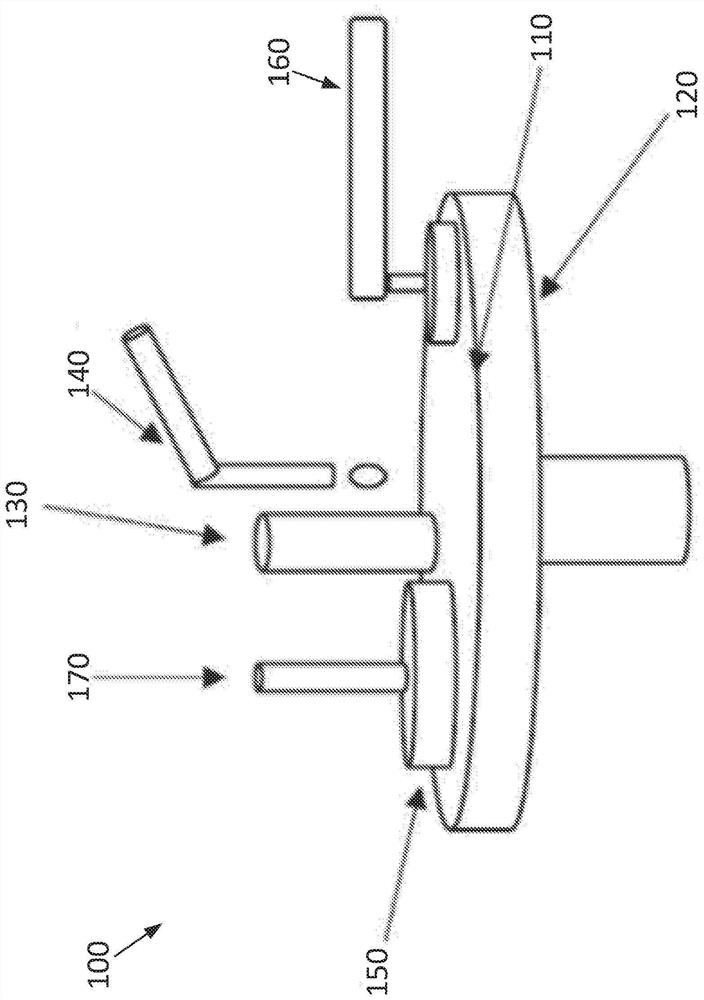

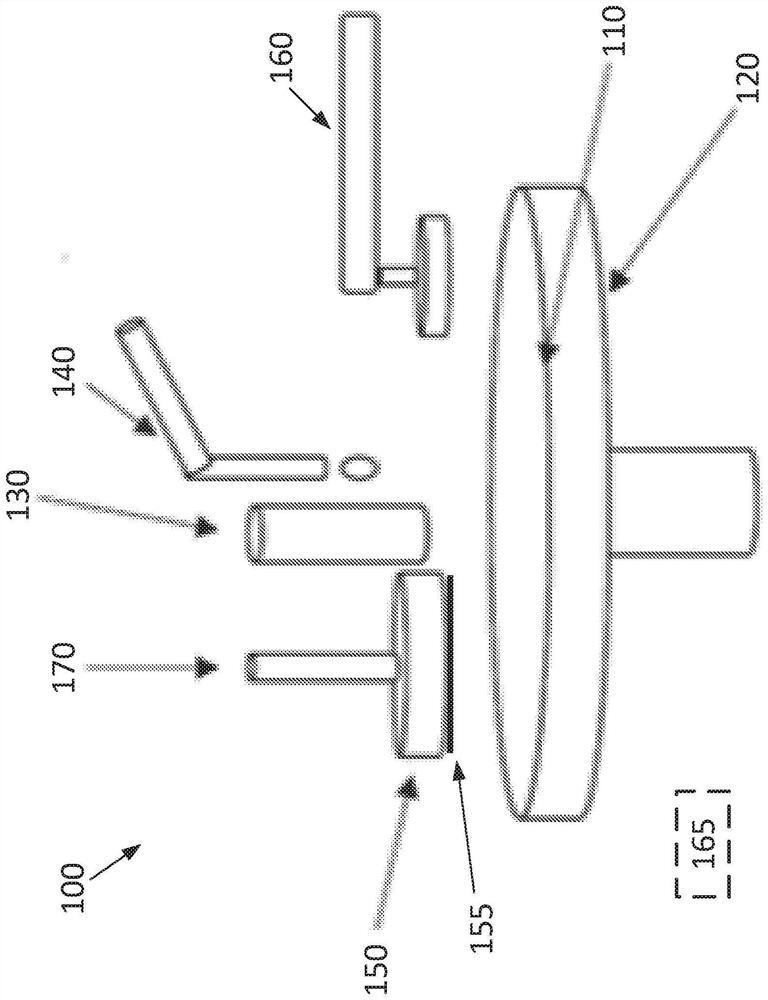

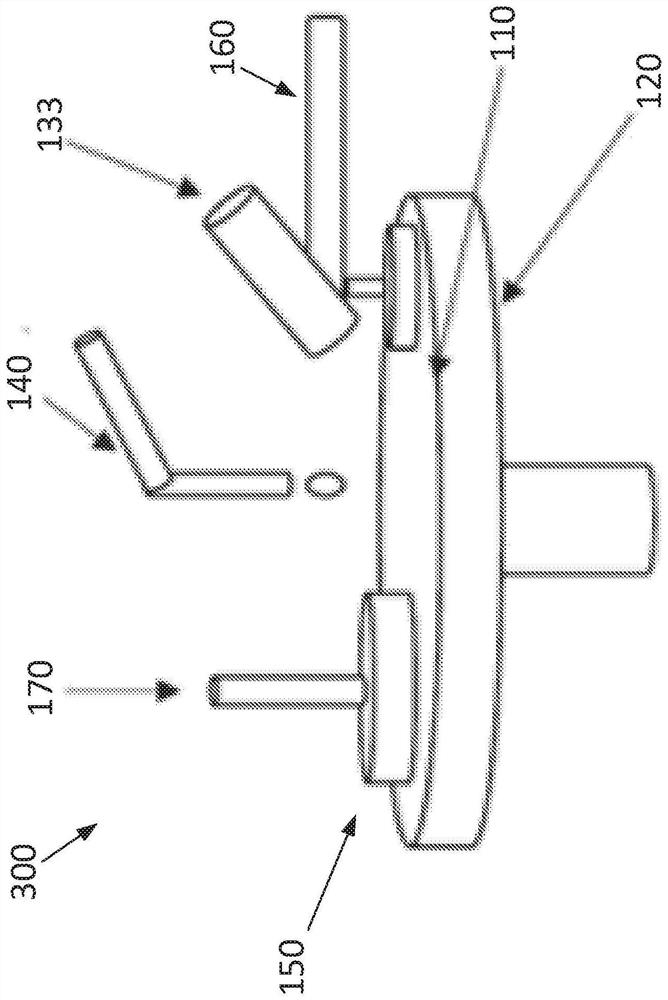

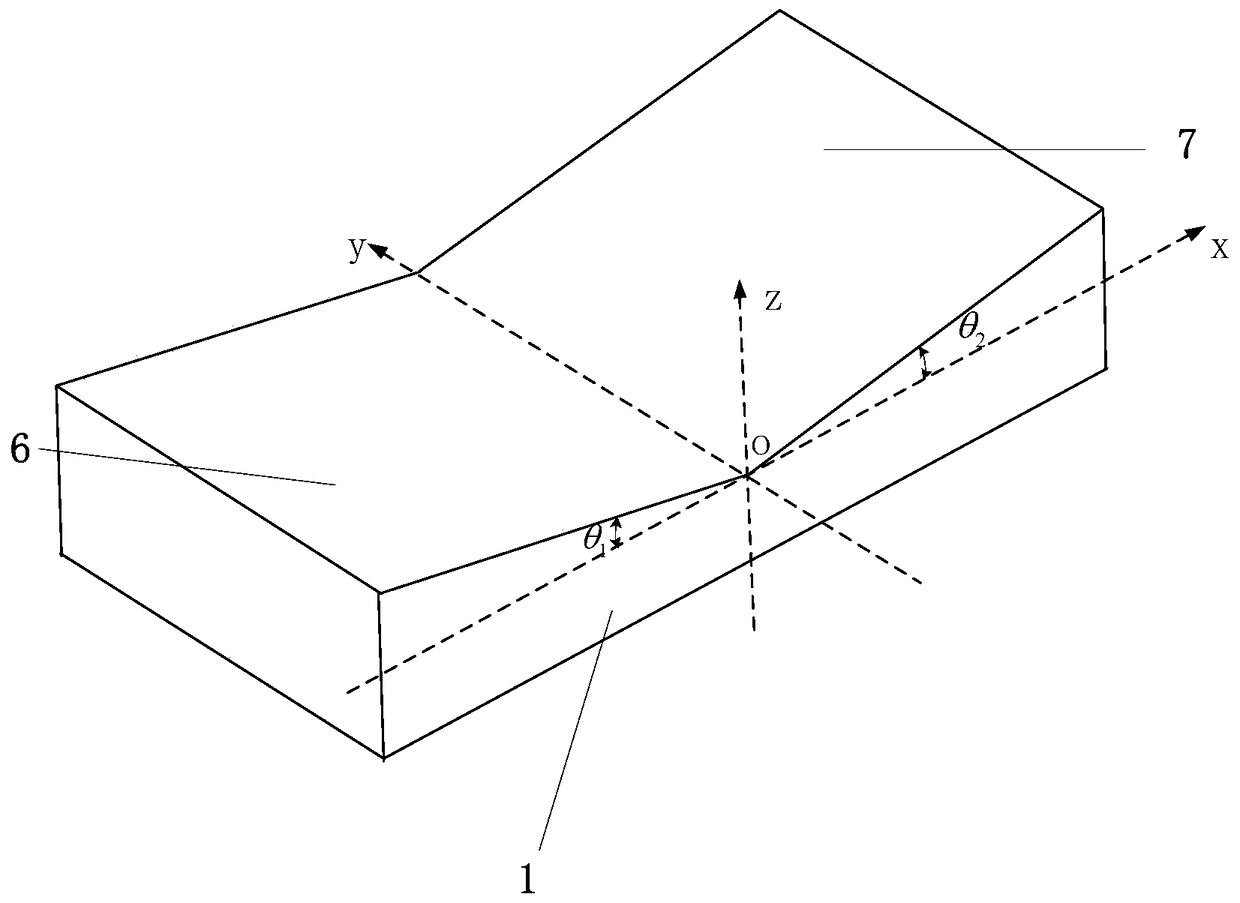

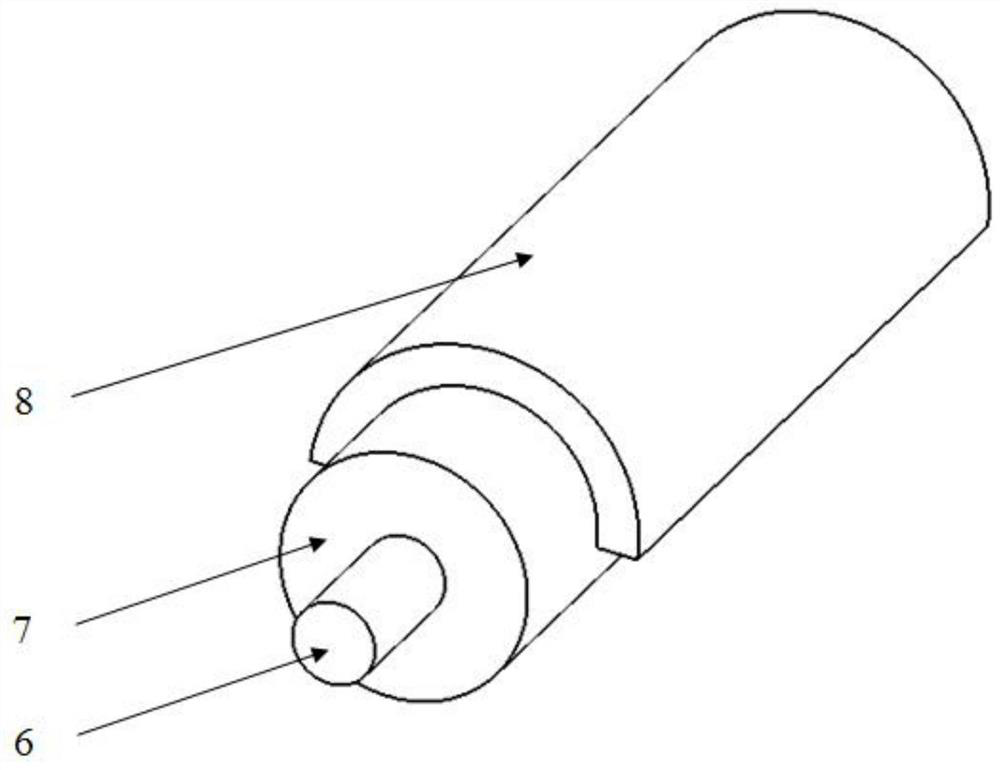

Multi-directional slip sensor

InactiveCN102501257ASolve the problem that the sliding direction cannot be automatically detected, that is, the sliding deflection angleCompact structureManipulatorDrift angleEngineering

The invention relates to a multi-directional slip sensor. A slip wheel is mounted in a box body and is rotatably connected with a fork-shaped structure at the front end of a bracket by a mandrel. The outer end of a precision potentiometer a is fixed on the end face of the fork-shaped structure of the bracket, and the inner end of the precision potentiometer a rotates with the mandrel. The back end of the bracket is supported on a shaft support, the shaft support is fixed in the box body, and a rotating shaft is movably matched and connected in the back end of the bracket. And a compression spring is mounted between the rotating shaft and the bracket. The back end of the rotating shaft is rotatably connected with a precision potentiometer b. The outer end of the precision potentiometer b is fixed on the box body and the inner end of the precision potentiometer b rotates with the rotating shaft. A tension spring is sleeved outside the rotating shaft and the precision potentiometer b. And one end of the tension spring is fixed on the bracket and the other end of the tension spring is fixed on the box body. Through adoption of the multi-directional slip sensor, whether relative slip and a slip drift angle exist or not between a mechanical arm and a grabbed object can be detected. The multi-directional slip sensor is compact in structure and reliable, and can automatically follow the slip direction of the object, thereby solving the problem that some slip sensors cannot automatically detect a slip direction, namely the slip drift angle.

Owner:SHANGHAI INST OF TECH

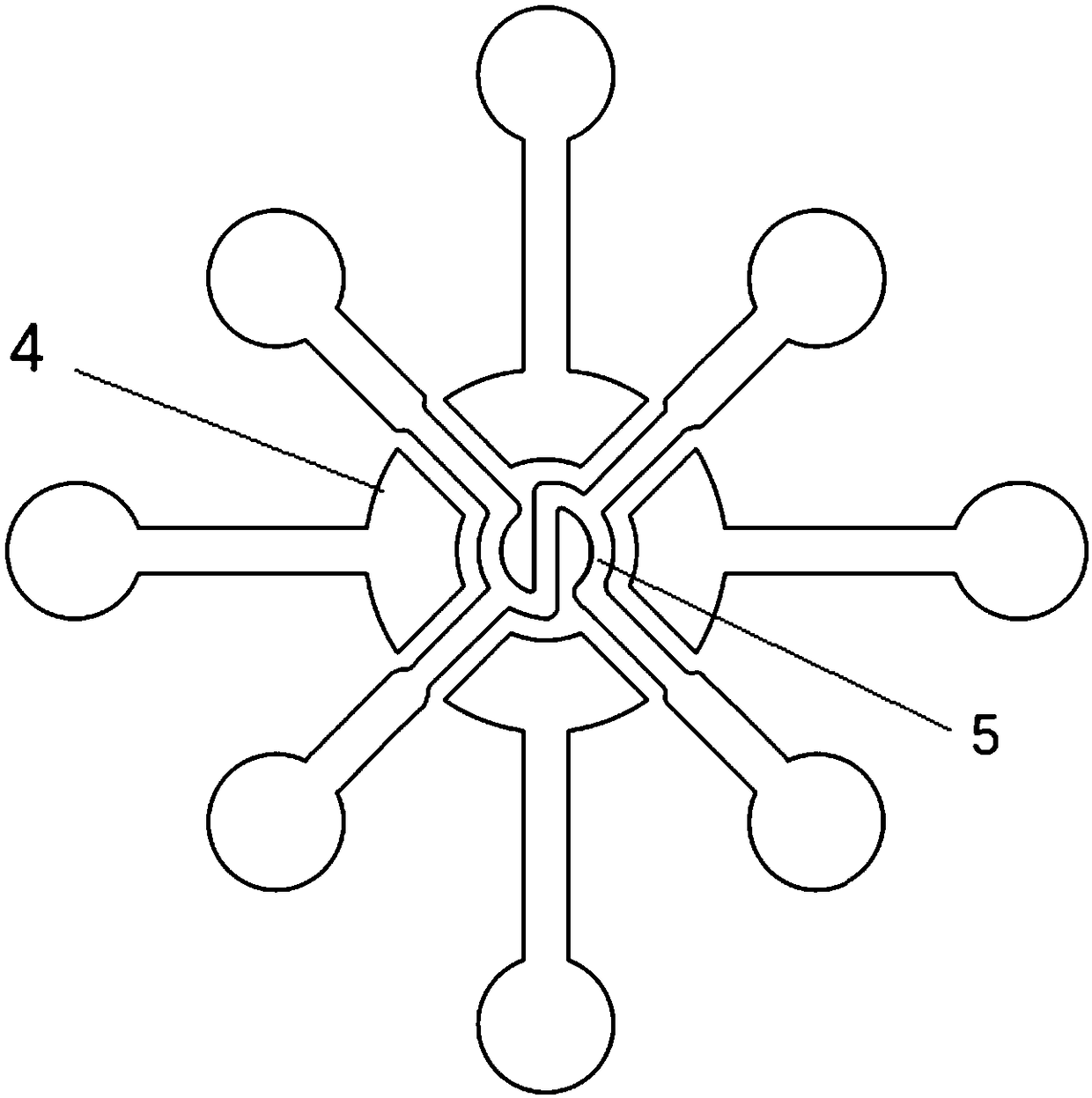

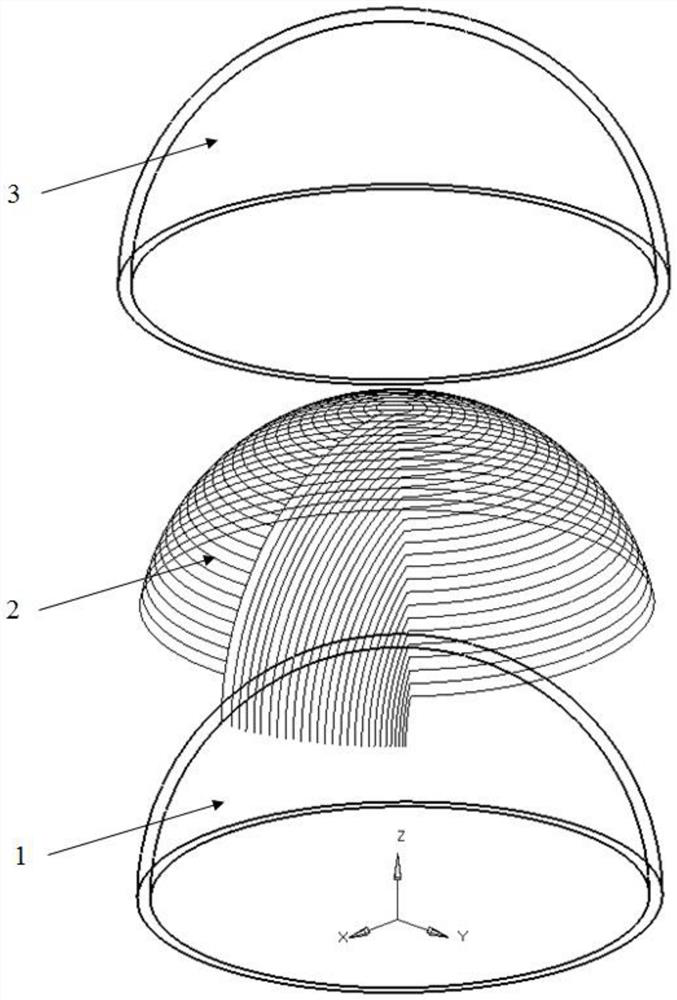

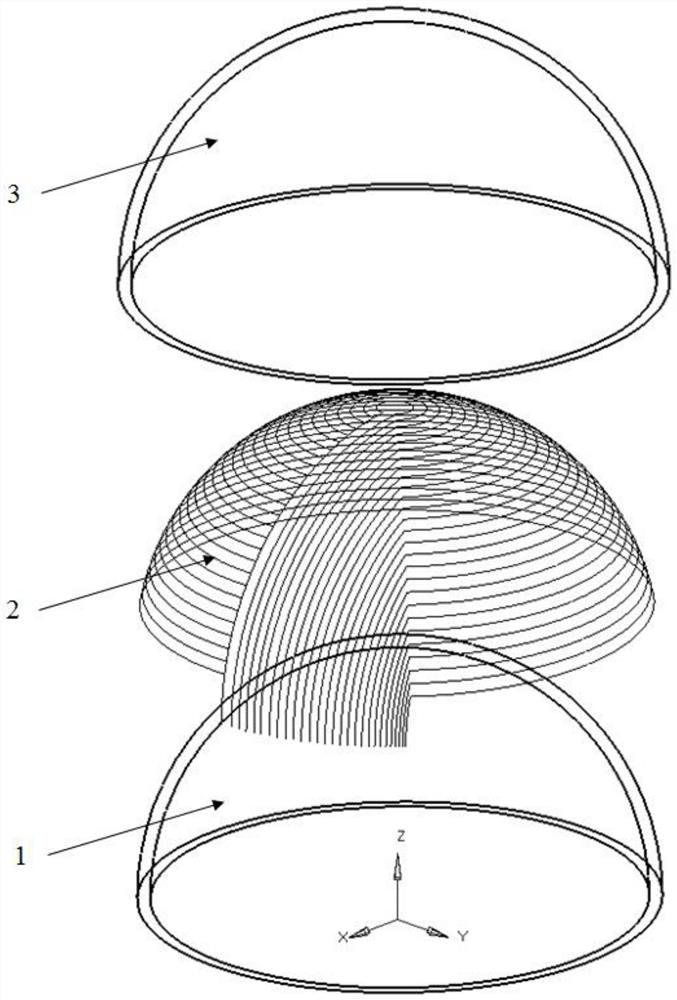

Omnidirectional slip sensor

PendingCN108827349AHigh sensitivityFast preparationConverting sensor output electrically/magneticallyElectrical resistance and conductanceEngineering

Provided is an omnidirectional slip sensor. The omnidirectional slip sensor comprises an upper structure and a lower structure, the upper structure is a cylindrical structure with a circular skirt edge, the material of the upper structure is a flexible material, the lower surface of the skirt edge is provided with an upper electrode, the lower structure comprises a piezoresistive film, a pluralityof lower electrodes, and an insulation film covering the piezoresistive film and the plurality of lower electrodes, the plurality of lower electrodes are distributed at intervals around the outside of the piezoresistive film, the piezoresistive film is located at the center surrounded by the plurality of lower electrodes, the lower surface of the cylindrical structure is aligned with the piezoresistive film, when a shearing force is applied to the sensor, the upper structure inclines towards the direction of the force to enable the upper electrode to make contact with the insulation film below, electric signals are inducted between the upper electrode and the lower electrodes under the insulation film, and when a normal pressure is applied to the sensor, the piezoresistive film is normally deformed, and a resistance thereof is changed. According to the omnidirectional slip sensor, sliding in any direction can be identified, and the sliding speed and the shearing force can also be measured.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Leisure Vehicle

InactiveUS20090064965A1Increase engine speedSmall braking forceValve arrangementsElectrical controlDrive wheelInternal combustion engine

A leisure vehicle equipped with an internal combustion engine as a power unit to drive the leisure vehicle, including a drive wheel, a slip sensor unit configured to detect a slip of the drive wheel, a throttle device mounted to the internal combustion engine, a throttle valve position changing device configured to change a position of a throttle valve of the throttle device, a throttle close operation sensor unit configured to detect that a rider has performed a throttle close operation to close a throttle of the throttle device, and a controller configured to control an operation of the throttle valve position changing device.

Owner:KAWASAKI JUKOGYO KK

Piezoelectric flexible slip sensor and preparation method thereof

ActiveCN112665764AIncrease distribution densitySuitable for surface loadingForce measurement using piezo-electric devicesMeasurement of force applied to control membersCapacitanceConductive coating

The invention belongs to the field of flexible slip sensors, and particularly relates to a piezoelectric type flexible slip sensor and a preparation method thereof, and the flexible slip sensor is composed of a flexible substrate layer, a piezoelectric type force sensitive layer and a surface packaging layer in sequence from bottom to top; the piezoelectric force sensitive layer is composed of piezoelectric capacitance sensing units and electrode leads, the n piezoelectric capacitance sensing units are arranged in a concentric circle to form a piezoelectric capacitance sensing array, and each piezoelectric capacitance sensing unit is composed of core-shell structure nanofibers and a semi-wrapped conductive coating; and each core-shell structure nanofiber sequentially comprises a conductive core and a piezoelectric shell from inside to outside, the piezoelectric shell is embedded between the conductive core and the semi-wrapped conductive coating to form a piezoelectric capacitance sensing unit, and under the action of external force, the piezoelectric shell generates polarization to generate charges on the conductive core and the semi-wrapped conductive coating. The sensor has the advantages of being flexible, suitable for curved surface loading, high in response speed, large in sensing unit distribution density and capable of achieving slip prediction.

Owner:WENZHOU UNIVERSITY

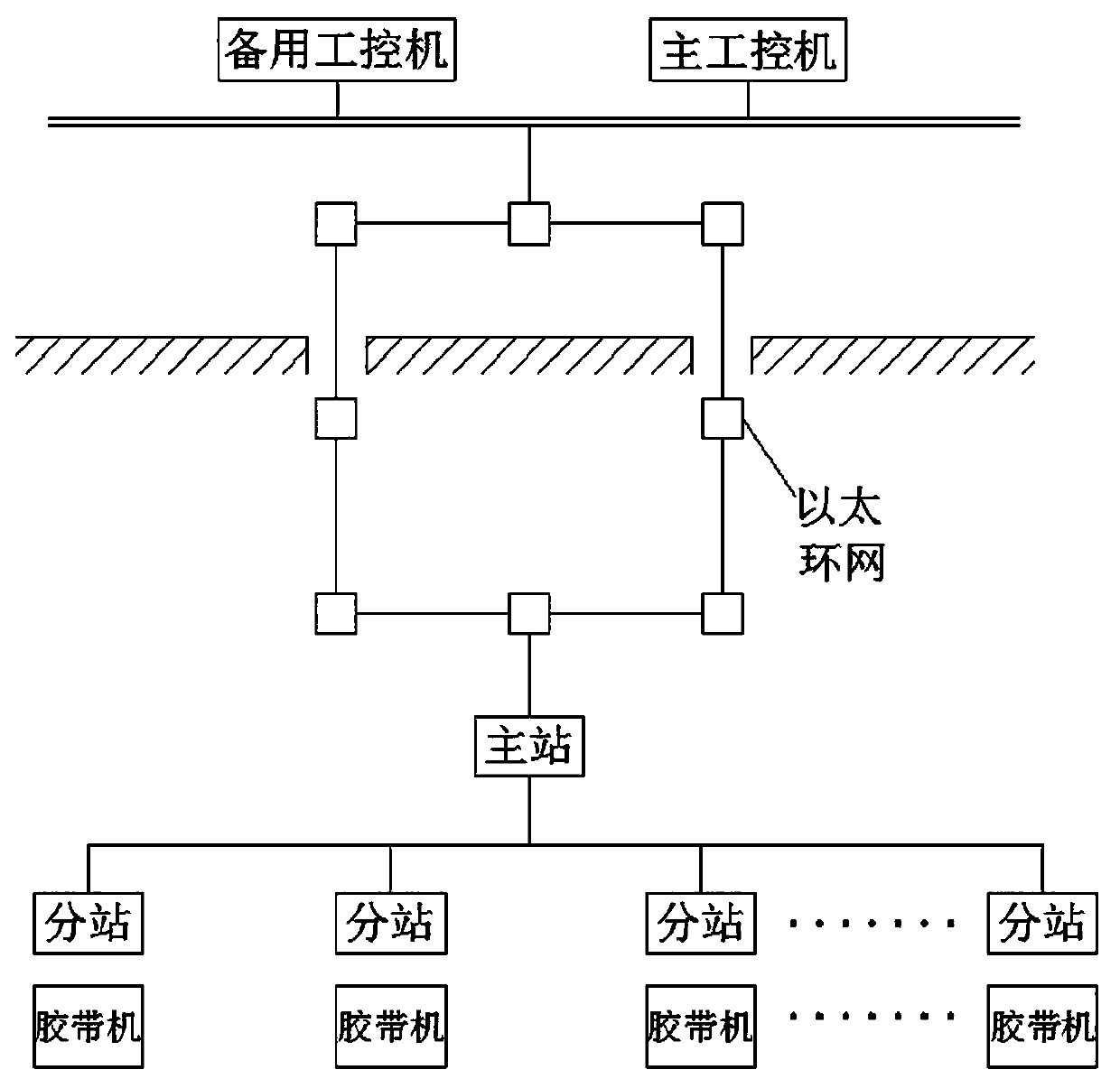

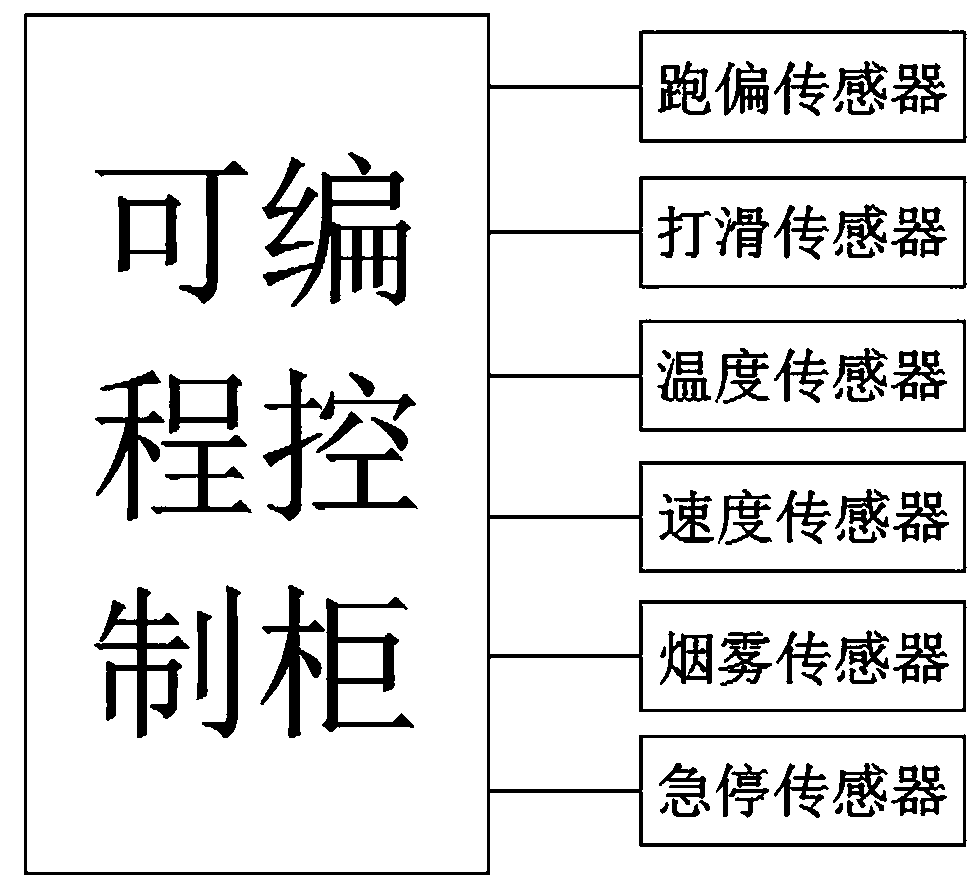

Centralized control system of adhesive tape machines

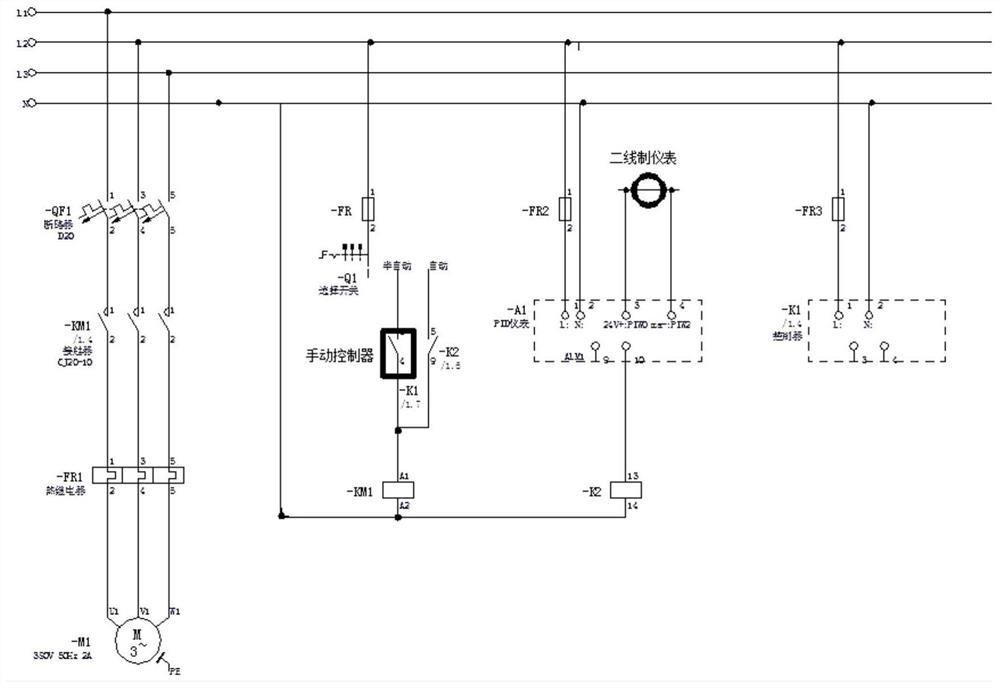

PendingCN110077803AComplete protection functionsPowerfulControl devices for conveyorsControl systemEconomic benefits

The invention provides a centralized control system of adhesive tape machines, and belongs to the technical field of control over the adhesive tape machines. The system comprises a central control room on the ground, and the multiple adhesive tape machines mounted under a mine. A main industrial personal computer and a standby industrial personal computer are mounted in the central control room and connected with a downhole main station through the Ethernet, the main station is connected with substations distributed beside the adhesive tape machines, a programmable control cabinet for locallycontrolling the corresponding adhesive tape machine is mounted in each substation, an off tracking sensor, a slipping sensor, a temperature sensor, a speed sensor, a smoke sensor and a scram sensor are mounted on each adhesive tape machine, and the sensors on each adhesive tape machine are connected to the corresponding programmable control cabinet. According to the system, a distributed control structure is adopted, and multiple complete detection and protection functions are achieved; and the scene programmable function and the scene networking function are strong, the system is controlled and monitored, the production efficiency can be improved, the accident rate can be reduced, the fault treatment time can be shortened, the economic benefits are high, and good stability and high reliability are achieved.

Owner:SHANDONG SHANKUANG MACHINERY

Method and apparatus for in-situ adjustment of wafer slip detection during workpiece polishing

PendingCN114206551AImage analysisSemiconductor/solid-state device testing/measurementThermodynamicsWafering

A method and apparatus for in-situ adjustment of wafer slip detection during workpiece polishing is disclosed. In one aspect, a chemical mechanical planarization (CMP) system includes a carrier configured to hold a substrate, a platen supporting a polishing pad, and a slip sensor configured to generate a signal indicative of a surface characteristic of the polishing pad. The system further includes a processor configured to receive the signal from the slip sensor, calibrate a steady-state value of the signal when the CMP system is in a steady-state condition, compare the signal received from the slip sensor to the calibrated steady-state value during CMP polishing, and determine whether the CMP system is in the steady-state condition. And detecting wafer slip in response to a difference between a signal received from the slip sensor and the calibrated steady-state value exceeding a threshold value during CMP polishing.

Owner:AXUS TECH

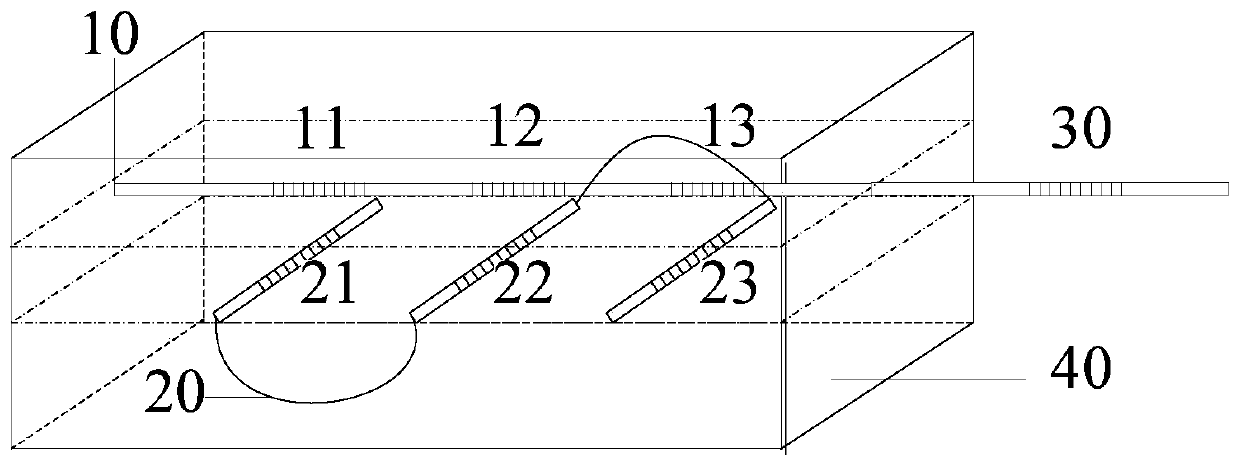

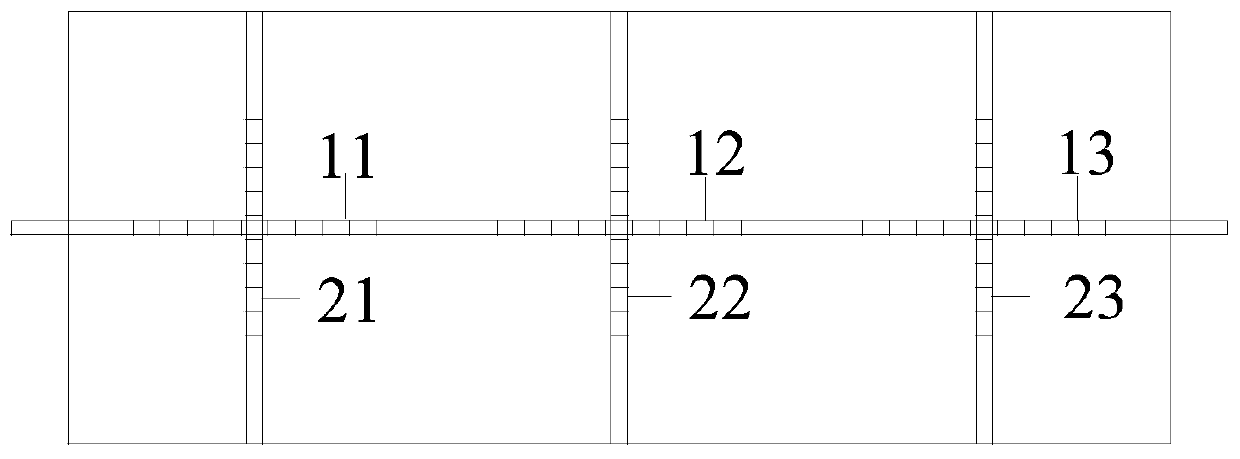

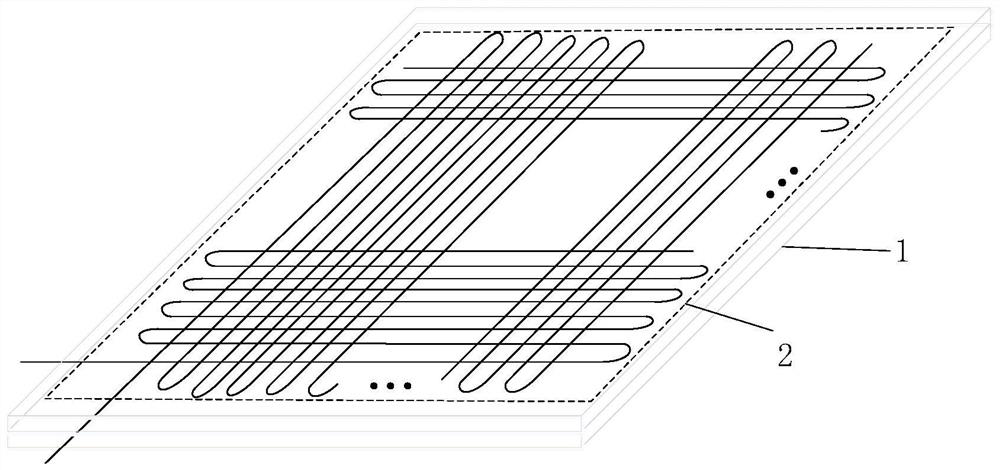

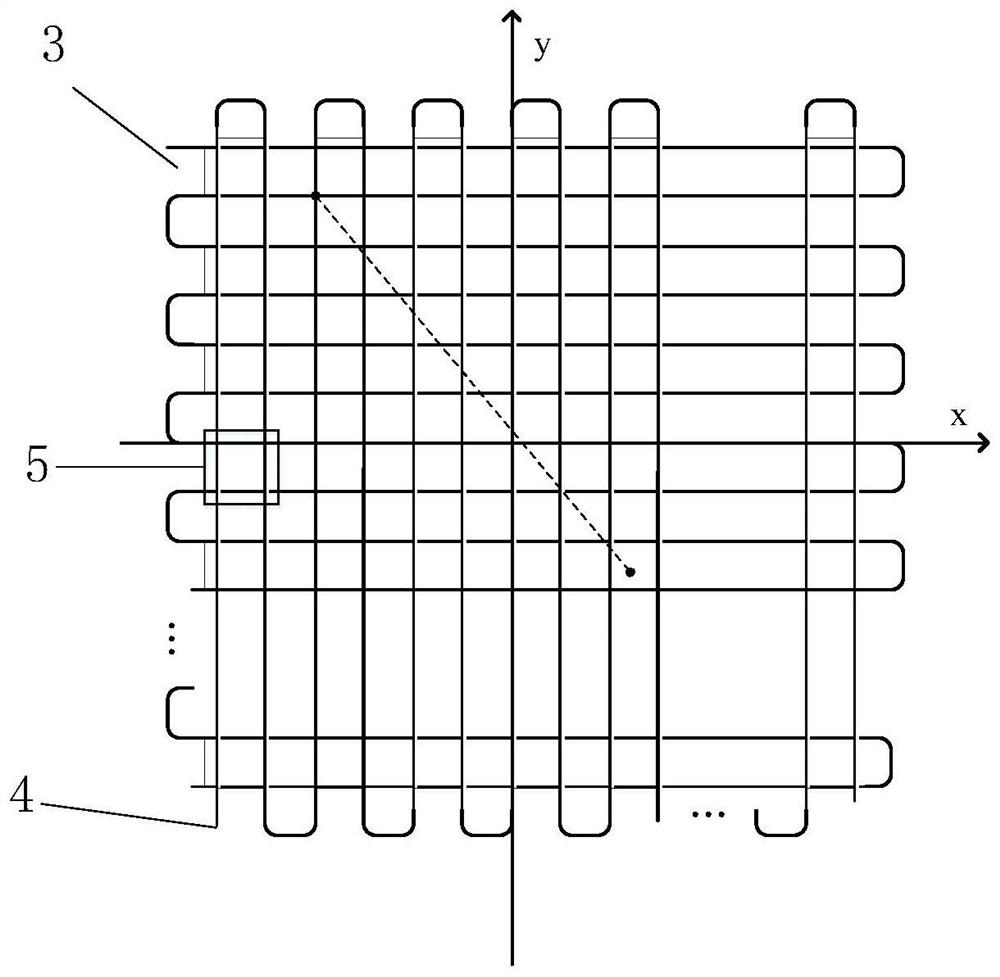

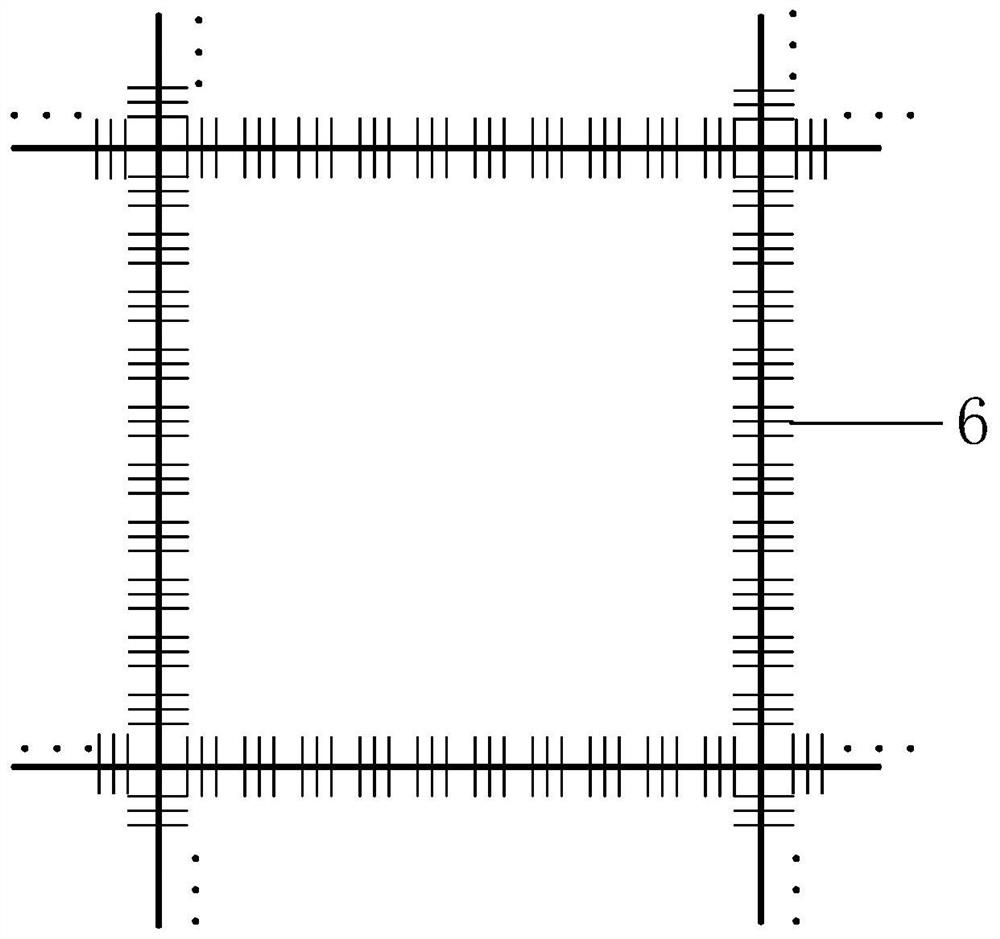

Large-area flexible electronic skin slip sensor based on DUS-FBG

ActiveCN113465798ASimple structureIngenious structureForce measurement by measuring optical property variationGratingEngineering

The invention discloses a large-area flexible electronic skin slip sensor based on DUS-FBG, and relates to the technical field of flexible electronics. The large-area flexible electronic skin slip sensor comprises an optical fiber flexible skin structure which is formed by packaging a slip sensing array through a flexible packaging material, wherein the slip sense sensing array is formed by grid arrangement and distribution of first DUS-FBGs which are transversely arranged and second DUS-FBGs which are longitudinally arranged, the first DUS-FBGs and the second DUS-FBGs are two grating optical fibers with different central wavelengths, and the array arrangement is that DUS-FBGs with a preset length are arranged at intervals of a preset distance; a tunable laser module used for providing an incident light source for the slip sense sensing array; and a slip sensation sensing module which is used for determining slip sensation generation and ending positions and moments according to the central wavelength shift of the two DUS-FBGs of the slip sensation sensing array and a threshold value so as to realize slip sensation measurement. The two fiber bragg gratings with different central wavelengths are used, so that the sensitivity is improved, and large-area flexible electronic skin slip sensor has the advantages of high sensitivity and large-area measurement.

Owner:YANSHAN UNIV

Intelligent ore drawing device of ore leakage trolley

ActiveCN114590552APrevent large area accumulationAvoid secondary failureConveyorsControl devices for conveyorsProduction lineMining engineering

The invention relates to an intelligent ore drawing device of an ore leaking trolley. The ore drawing device is mainly composed of an intelligent ore drawing device module input control contactor of the ore leaking trolley, a belt ore overflowing sensor device, a belt slipping sensor device and a belt hopper ore overflowing sensor device 25. According to the belt hopper ore overflowing sensor device, when the hopper ore reaches the maximum limiting capacity, the module receives data, the vibration machine vibrates, ore loosening is conducted, and the hopper ore overflowing phenomenon is prevented. The stock bin liquid level sensor monitors and sets the operation time and the interval time of the vibration motor according to the actual condition of the moisture content of the iron ore concentrate powder, and indirect ore loosening can be achieved to avoid large-area ore accumulation. The belt deviation sensor device monitors the running condition of the conveying belt in real time, the function of automatic alarming and line stopping is achieved when deviation occurs, and maintainers are prompted that the conveying belt production line is abnormal and needs to be repaired, maintained and corrected. The belt ore overflowing sensor device monitors the operation condition of ores above the belt all the time, and automatically alarms and stops the line when the ores are accumulated, so that large-area accumulation of the ores is avoided, and the secondary fault that electrical elements are damaged due to overload operation of a motor is avoided.

Owner:NANJING MEISHAN METALLURGY DEV +1

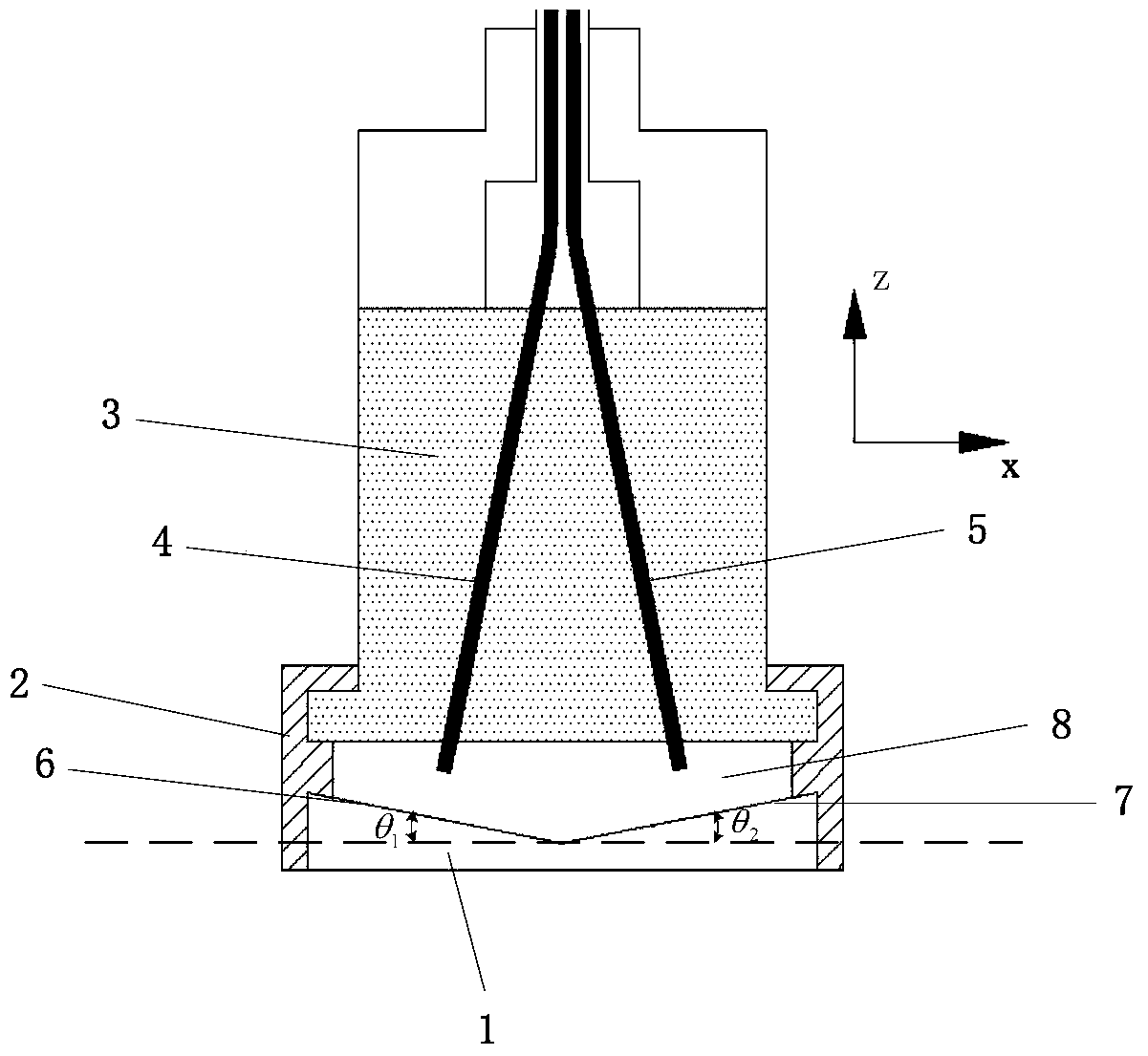

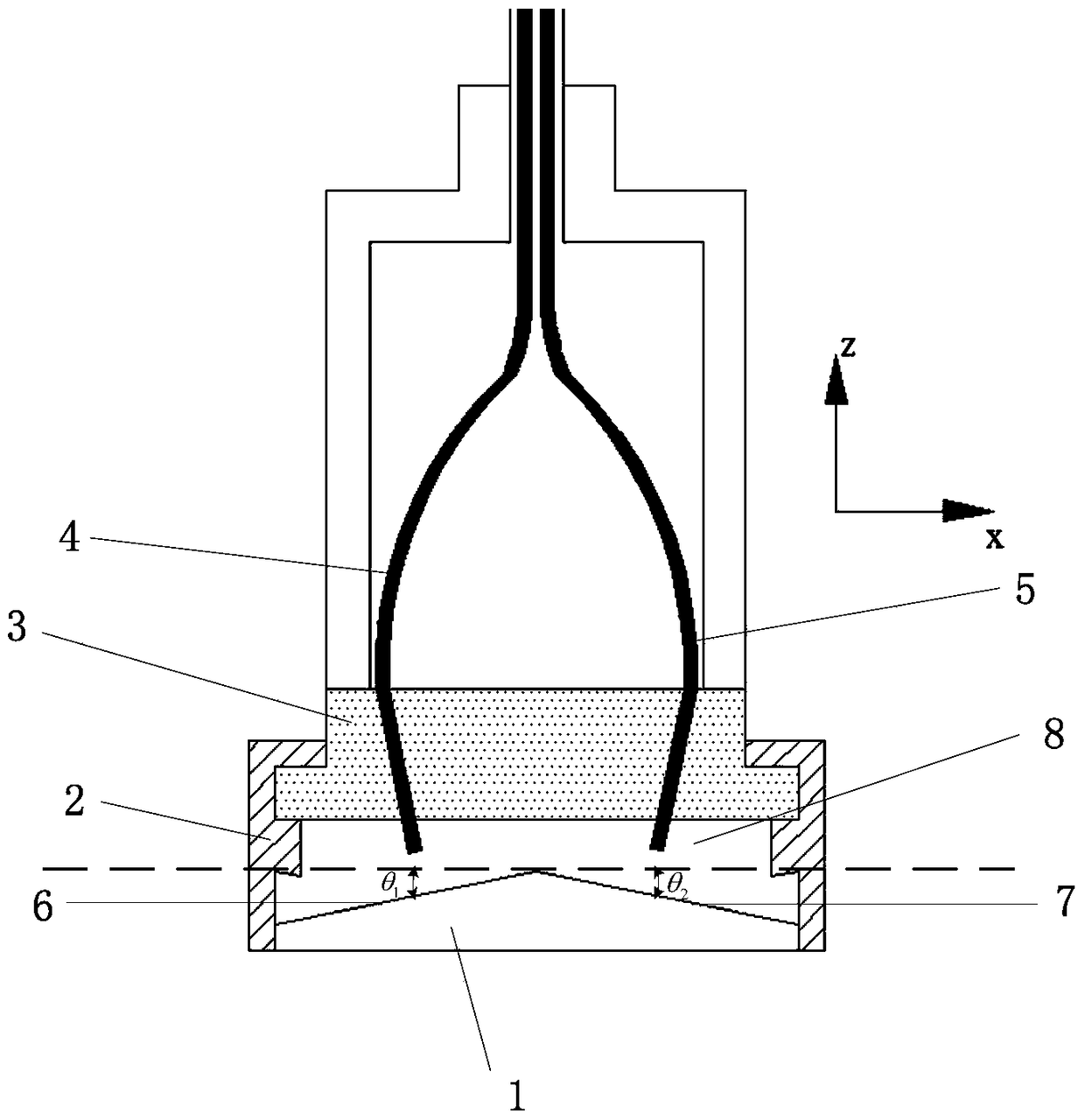

An Inner-Cavity Optical Fiber Fabry-Perot Sensor for Slip Measurement

ActiveCN106885590BPrecise SlipLong-term monitoringUsing optical meansConverting sensor output opticallyFiberThree-dimensional space

Owner:陈艺征

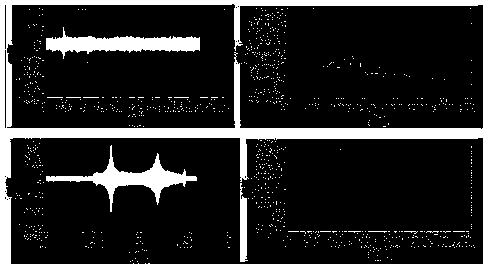

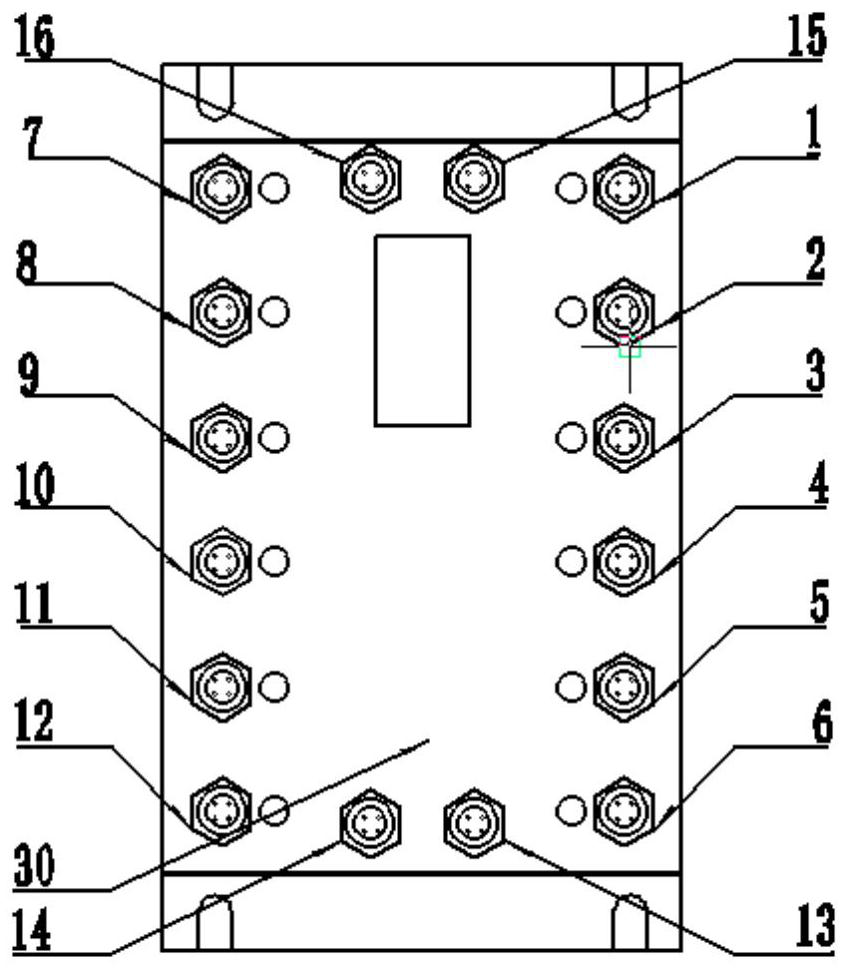

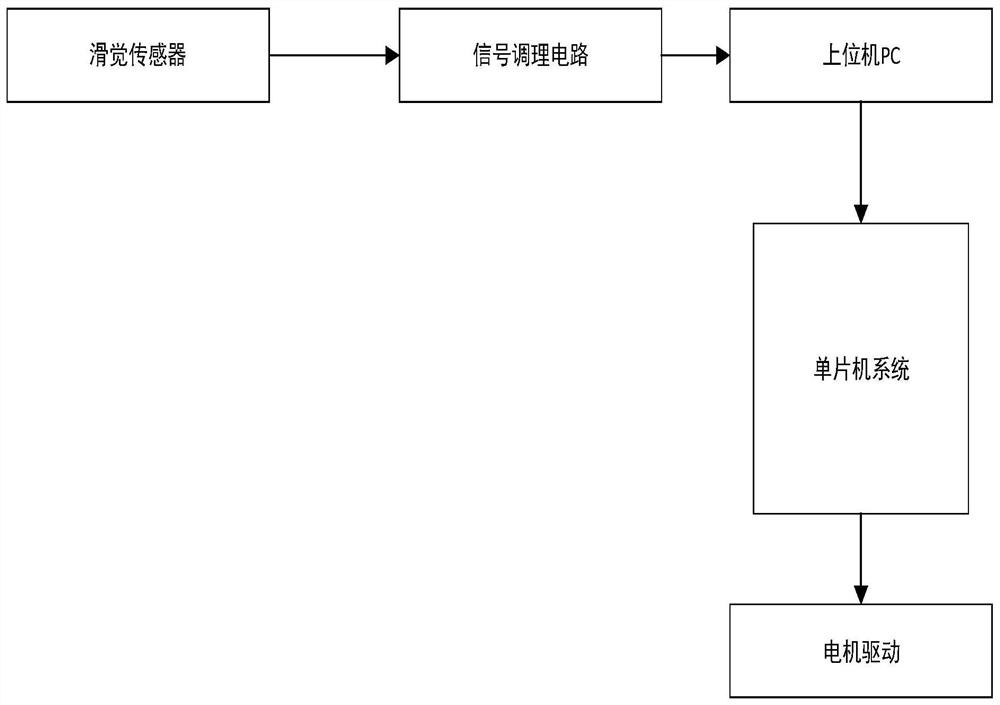

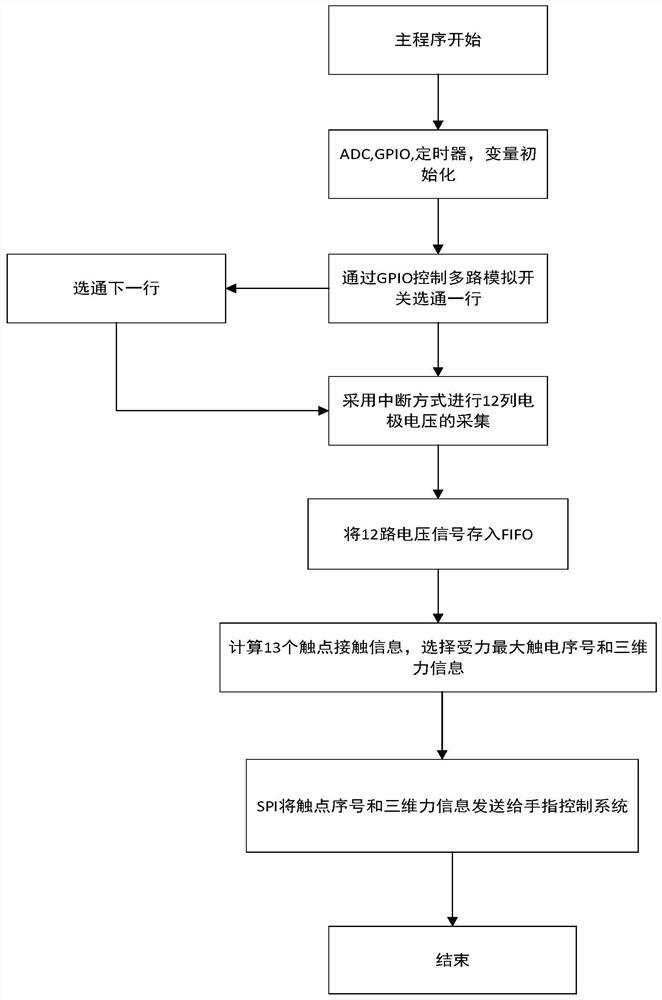

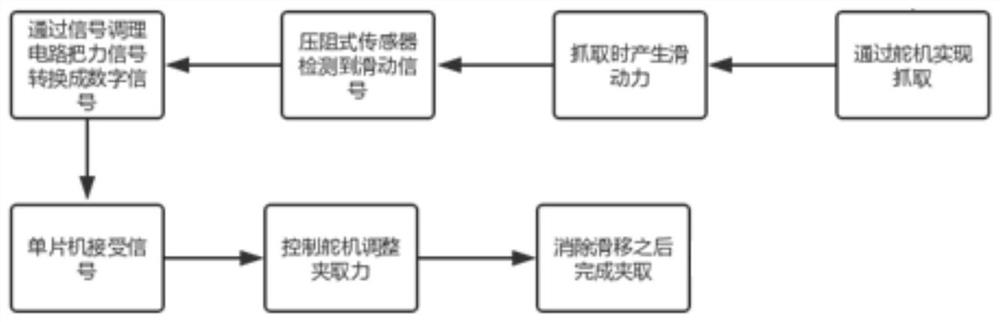

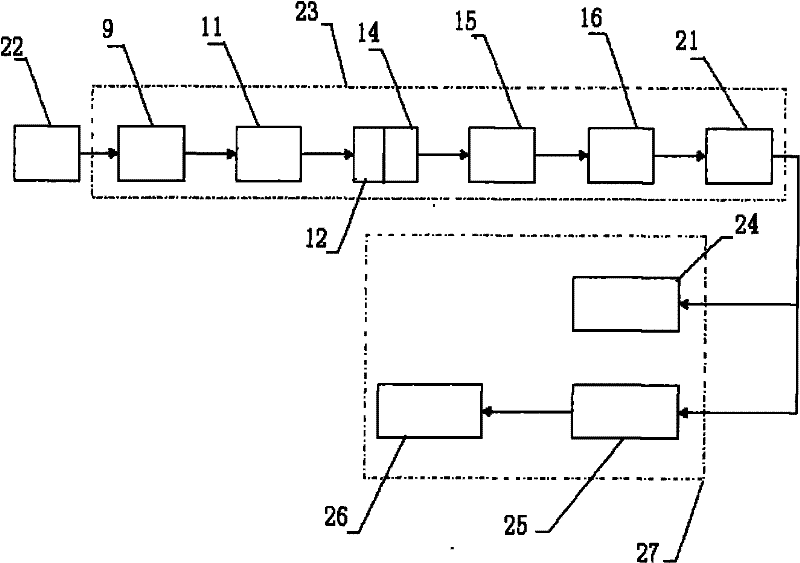

Anti-skid control system and method for grabbing manipulator

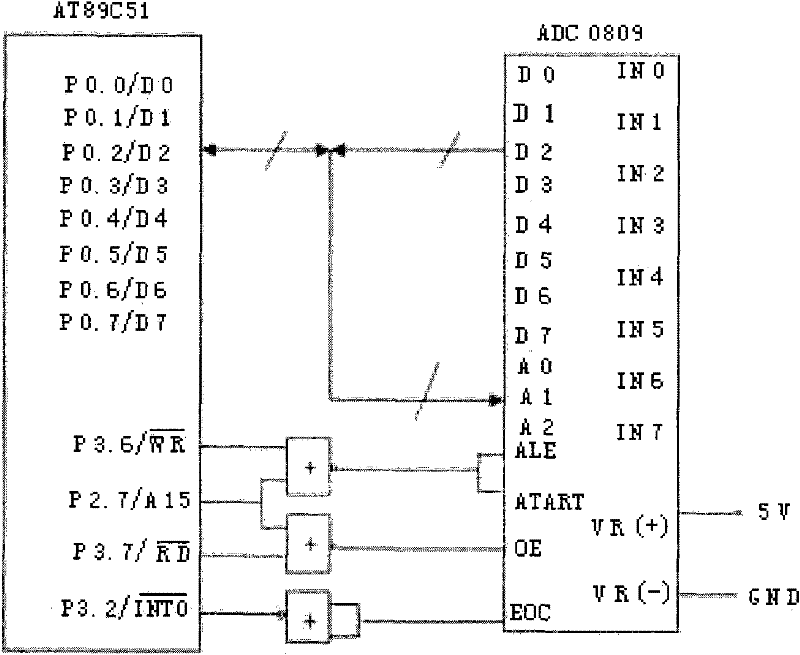

InactiveCN113664827AHigh gripping accuracyReduce slippageProgramme-controlled manipulatorSignal conditioning circuitsMicrocomputer system

The invention discloses an anti-skid control system for a grabbing manipulator. The anti-skid control system comprises a slip sensor mounted on the manipulator, a signal conditioning circuit connected with the slip sensor, an upper computer PC connected with the signal conditioning circuit, a single-chip microcomputer system connected with the upper computer PC, and a driving motor connected with the single-chip microcomputer system and mounted on a manipulator steering engine. By means of the anti-skid control system, the grabbing precision of the manipulator is effectively improved, and meanwhile the slippage condition of the manipulator in the grabbing operation process is relieved.

Owner:YANCHENG INST OF TECH

Piezoelectric flexible sliding sensor and preparation method thereof

ActiveCN112665764BIncrease distribution densitySuitable for surface loadingForce measurement using piezo-electric devicesMeasurement of force applied to control membersCapacitanceConductive coating

The invention belongs to the field of flexible sliding sensors, and in particular relates to a piezoelectric flexible sliding sensor and a preparation method thereof. The flexible sliding sensor consists of a flexible base layer, a piezoelectric force sensitive layer and a surface packaging layer from bottom to top in sequence; The piezoelectric force-sensitive layer is composed of piezoelectric capacitive sensing units and electrode leads, and n piezoelectric capacitive sensing units are arranged in concentric circles to form a piezoelectric capacitive sensing array, and the piezoelectric capacitive sensing units are composed of Composed of core-shell structure nanofibers and semi-wrapped conductive coating, each core-shell structure nanofiber is a conductive core and a piezoelectric shell from the inside to the outside, and the piezoelectric shell is embedded in the middle of the conductive core and the semi-wrapped conductive coating. A piezoelectric capacitive sensing unit is formed. Under the action of an external force, the piezoelectric shell is polarized, and charges are generated on the conductive core and the semi-wrapped conductive coating. The invention has the advantages of being flexible and suitable for loading on a curved surface, fast in response, high in the distribution density of sensing units, and capable of slip prediction.

Owner:WENZHOU UNIVERSITY

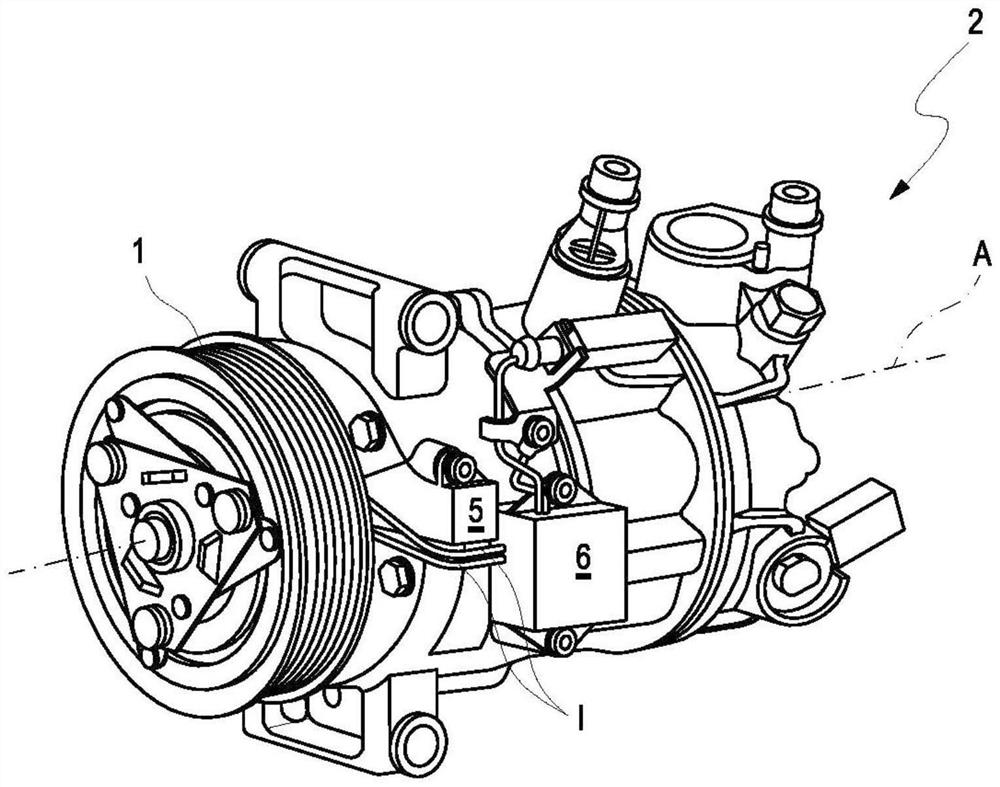

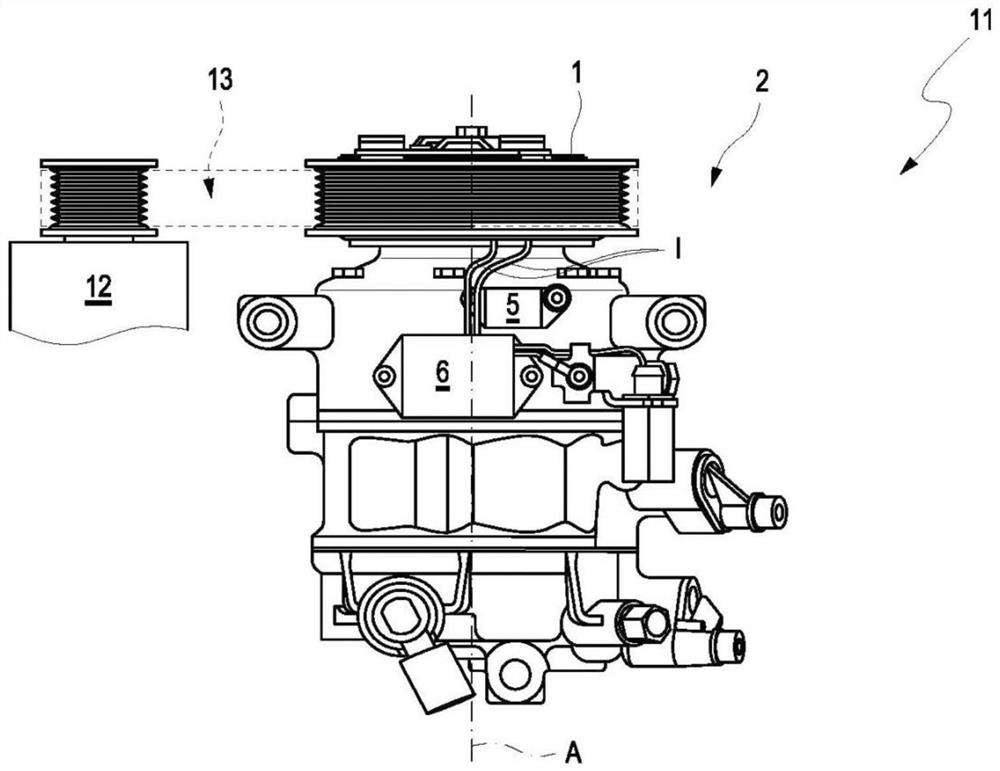

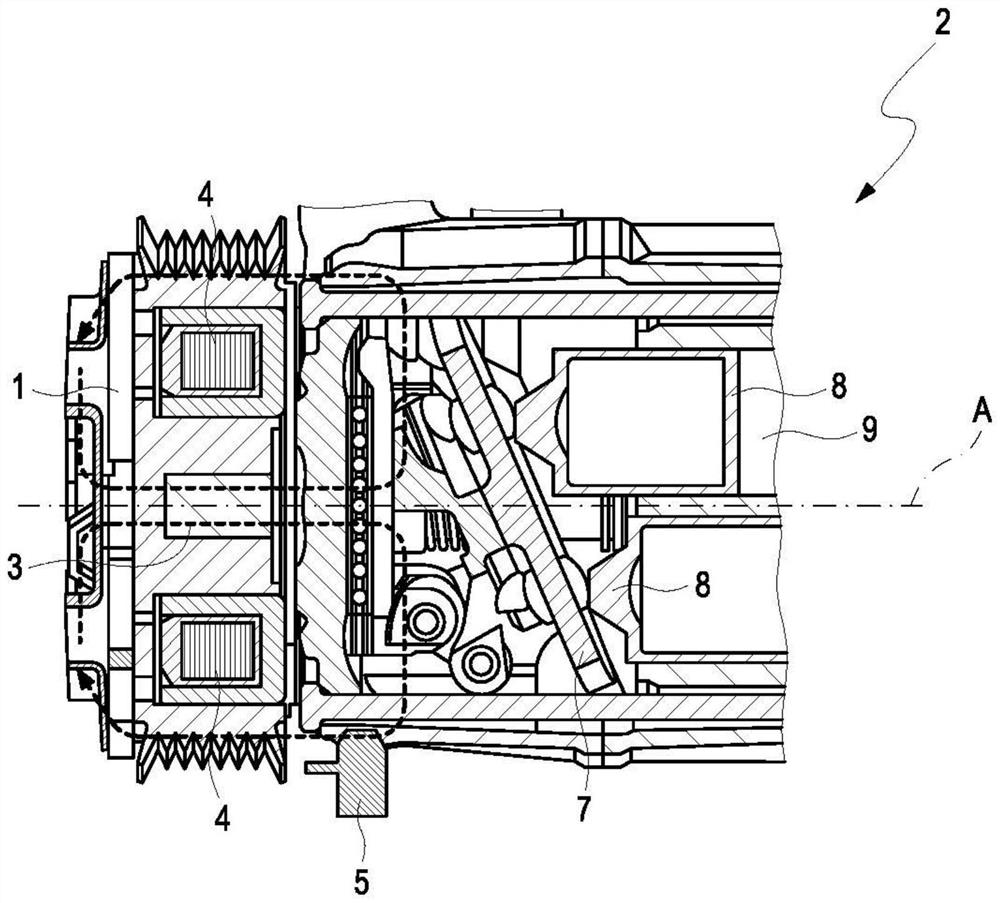

Method for controlling air-conditioning compressor, compressor and motor vehicle

PendingCN114763052APrecise Slip DetectionIncreased fail-safetyClutchesAir-treating devicesElectromagnetic clutchDrive shaft

An electromagnetic clutch (1), in particular for an air-conditioning compressor (2) of a motor vehicle (11), transmits torque to a drive shaft (3) of the compressor (2) as a function of a current (I) fed to a clutch coil (4) of the electromagnetic clutch (1) to generate an electromagnetic clutch force. According to the control method (10), the slip of the electromagnetic clutch (1) is determined from the difference between the rpm of the electromagnetic clutch (1) and the rpm of the drive shaft (3) and is monitored by a slip sensor (5). The current (I) and the generated clutch force are adjusted by a pulse width modulation controller (6) of the compressor (2) as a function of the slip. A pulse width modulation controller (6) is electrically connected to the clutch coil (4) and modulates the pulse width of the current (I) fed to the clutch coil (4).

Owner:MAHLE INT GMBH

Myoelectric bionic arm system based on nerve redistribution technology

The invention discloses a myoelectric bionic arm system based on nerve redistribution technology. The aim is to overcome the lack of functions of existing bionic arms and the inability to control the entire artificial arm with myoelectric signals. It includes a tactile sensor, a tactile signal amplifying circuit and a tactile signal filter circuit, which are connected by wires in turn; The motor is fed into the motor and connected by wires in turn; it also includes a level conversion chip and a PC, and the single-chip microcomputer and the level conversion chip are connected to the PC by wires in turn. The tactile sensory signal filter circuit is connected with the electric wire of the level conversion chip. The myoelectric electrodes are pasted on the skin of the chest muscles, the tactile sensor is installed on the artificial finger, the level conversion chip and the PC are removed after the system is debugged, and other components are installed on the artificial arm. The single-chip microcomputer controls the stepper motor 17 to rotate and stop according to the myoelectric signal and the tactile sensation signal, so as to realize the control of the artificial arm.

Owner:JILIN UNIV

Connecting devices for rail vehicles

ActiveCN105438152BRealize energy transferSolve problems such as resonanceBraking systemsDrive shaftResonance

The invention relates to a connecting device for a rail vehicle. The connecting device is connected between a transmission shaft of a mechanical anti-slipping sensor and an axle of the rail vehicle and comprises a connecting block and an elastic connecting body, and the connecting block is connected to the elastic connecting body in a slidable mode. The connecting block is fixed to the connecting end of the transmission shaft, the elastic connecting body is fixed to the connecting end of the axle, and the end face of the connecting end of the elastic connecting body is parallel to the end face of the connecting end of the axle. A channel for the elastic connecting body to penetrate through in a sliding mode is formed in the connecting block, and the sliding friction factor between the channel of the connecting block and the elastic connecting body is smaller than or equal to 0.11. Connection matching between the connecting block and the elastic connecting body is adopted in the connecting device, relative sliding and elastic deformation can be generated, angular speed sudden change caused by eccentric motion of the transmission shaft is relieved, and namely the angular acceleration alpha approaches zero, so that energy is transmitted between the axle and the transmission shaft, and then resonance of the mechanical anti-slipping sensor and other problems are solved.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com