Method and apparatus for in-situ adjustment of wafer slip detection during workpiece polishing

A slip, wafer technology, used in grinding/polishing equipment, metal processing equipment, control of workpiece feed movement, etc., can solve problems such as negative process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

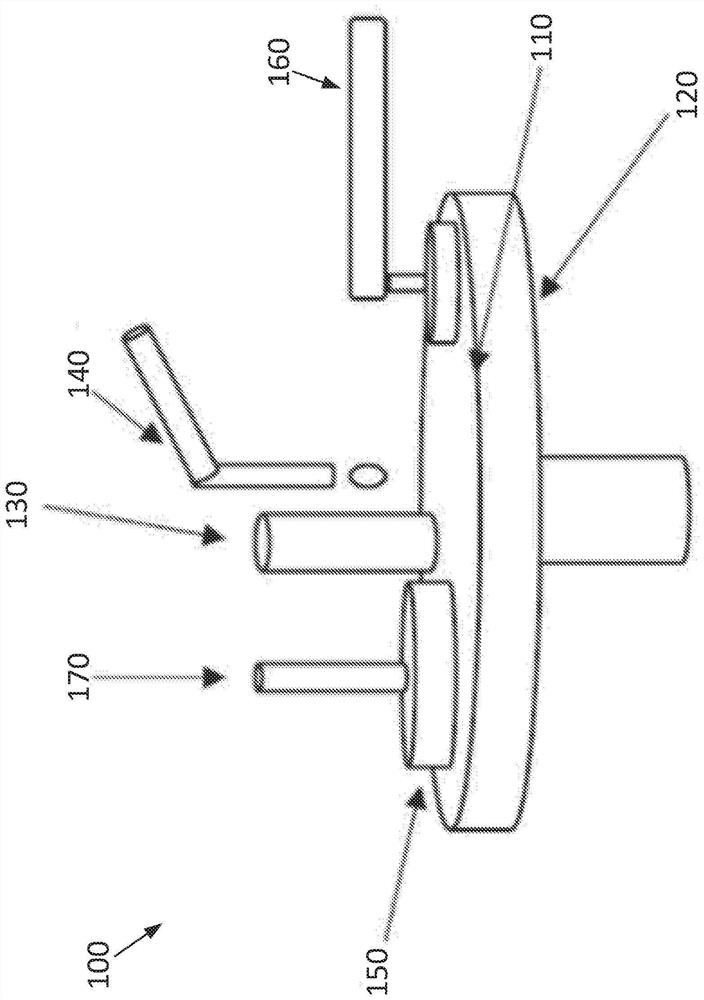

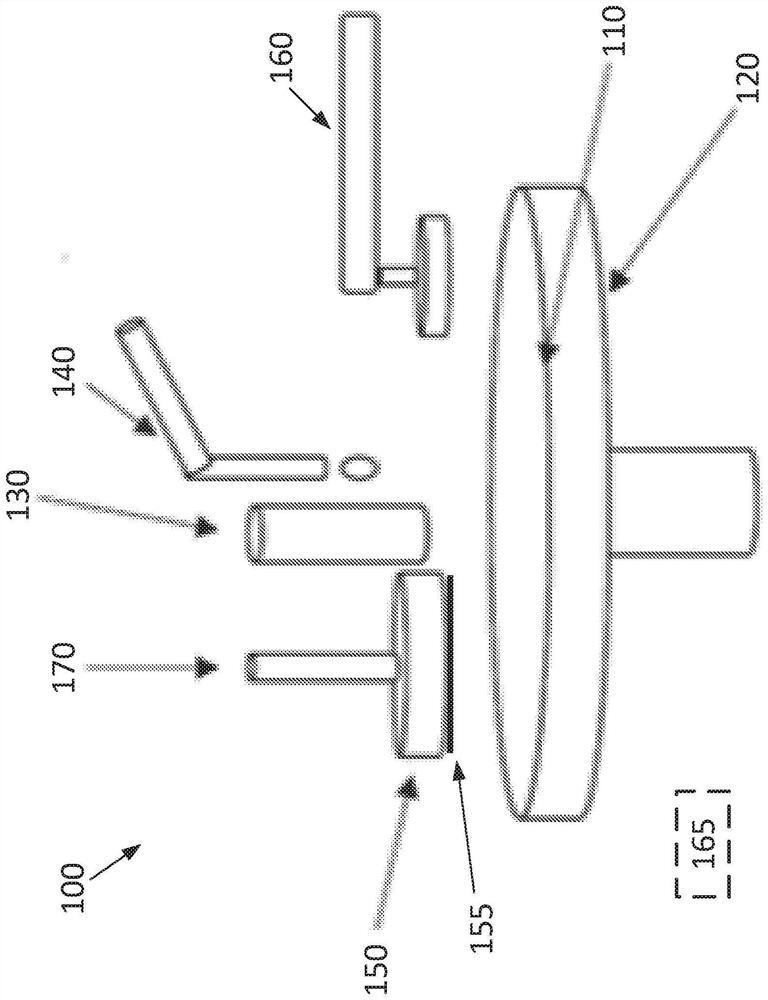

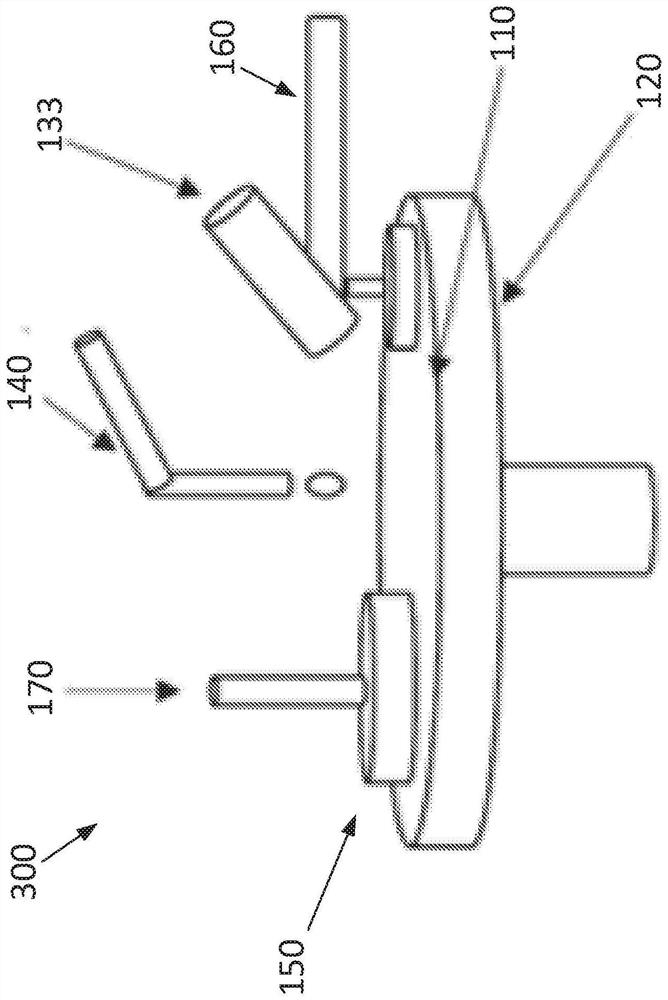

[0034] Detailed embodiments of the disclosed technology will now be described with reference to the accompanying drawings.

[0035] Introduction to Chemical Mechanical Polishing (CMP) Systems

[0036] The adoption and use of chemical mechanical polishing (CMP) to planarize thin films in the manufacture of semiconductor ICs, MEMS devices, and LEDs, as well as many other similar applications, is common among all companies manufacturing the "chips" used in these types of devices . This adoption includes making chips for mobile phones, tablets and other portable devices, as well as desktop and laptop computers. Advances in nanotechnology and micromachining hold great promise for the widespread use and adaptation of digital devices in the medical field, the automotive field, and the Internet of Things ("IoT"). Chemical mechanical polishing for thin film planarization was invented and developed in the early 1980s by scientists and engineers at IBM Corporation. Today, this proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com