Intelligent ore drawing device of ore leakage trolley

An intelligent, trolley technology, applied in the direction of conveyor control device, loading/unloading, transportation and packaging, etc., can solve the problems of increased production costs, overflow mines, belt outage, etc., to avoid secondary failures and avoid damage to electrical components , Avoid the effect of large-scale accumulation of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

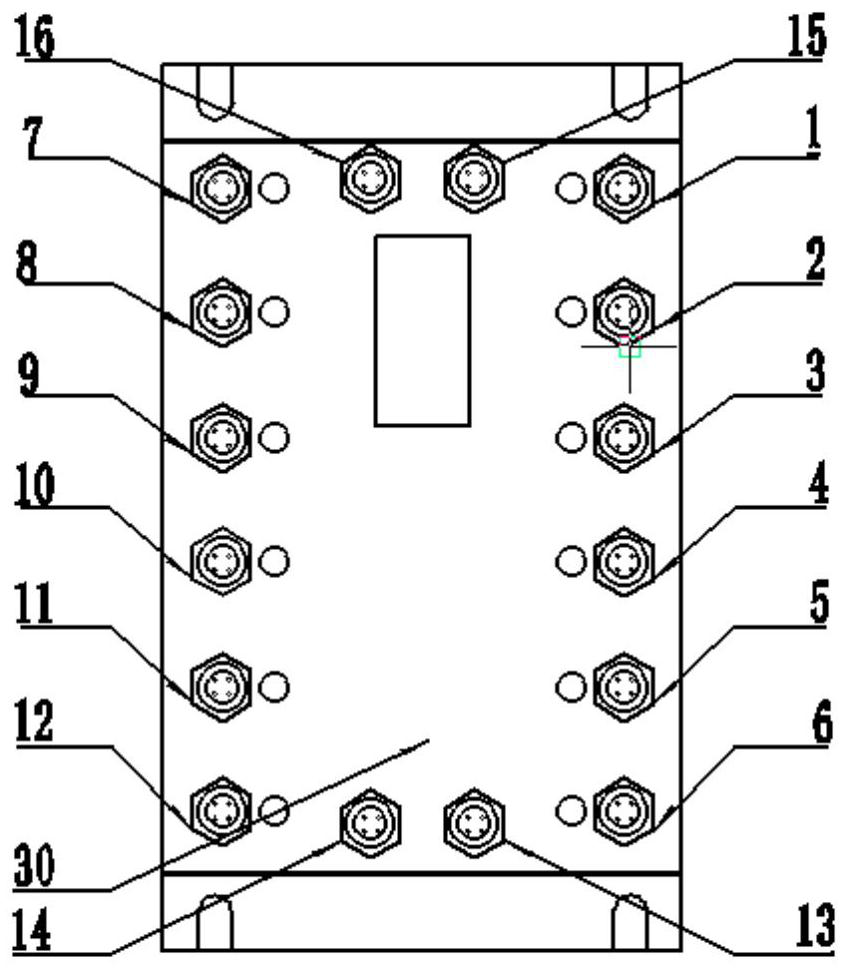

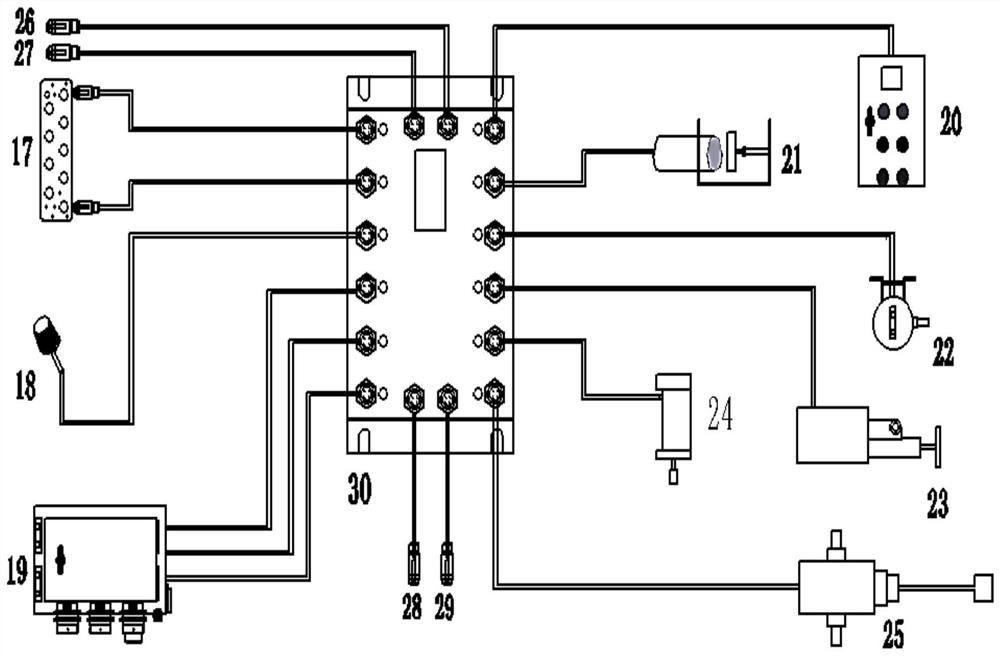

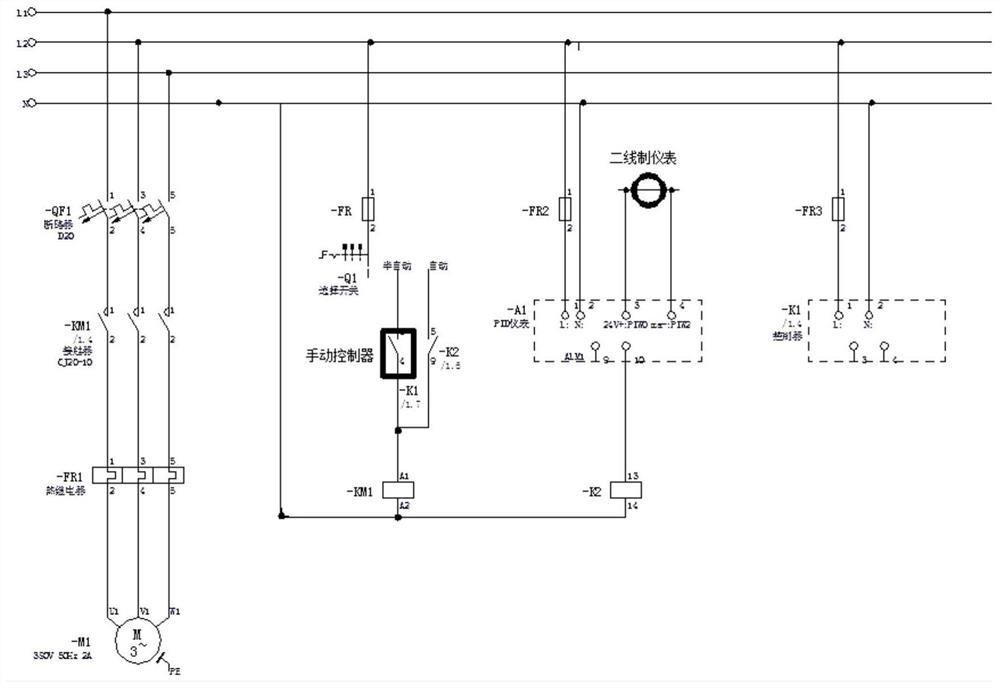

[0012] Example 1: see figure 1 , an intelligent ore drawing device for a ore leakage trolley, the wiring port, the right side of the device module 30 of the ore leakage trolley for preventing ore stacking is screwed in order from top to bottom, and a start control contactor interface 1 and a belt deviation sensor interface 2 are installed. Belt overflow sensor interface 3, belt slip sensor interface 4, silo liquid level sensor interface 5, belt hopper overflow sensor interface 6, ore leakage trolley anti-piling device module 30, the left side is screwed in order from top to bottom to install There are program input interface 7, program input interface 8, wireless transmitting antenna interface 9, start control contactor interface 10, start control contactor interface 11, start control contactor interface 12, device module 30 for ore leakage trolley, upper end The power line interface 16, the bus CAN port 15, the device module 30 for the mine leakage trolley are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com