Robot arm used for handling LCD screens

A robot arm and LCD screen technology, applied in the field of robot arms, can solve the problems of screen CB unit damage, fragility, and LCD screen cannot have strong impact and vibration, and achieve the effect of avoiding damage and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

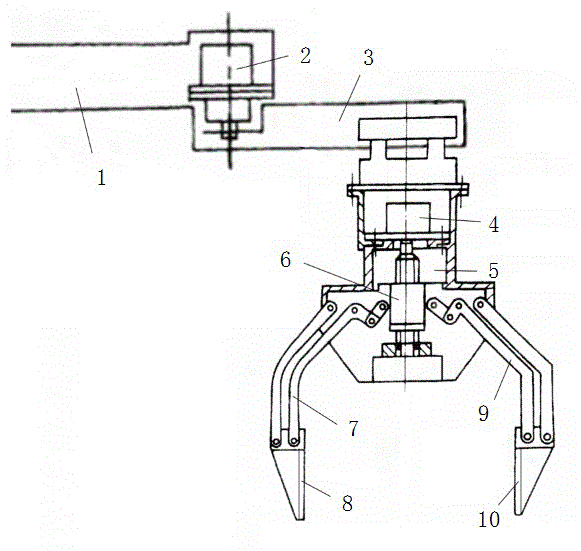

[0016] Such as figure 1 As shown, a robot arm for carrying LCD screens includes a boom 1 connected to a robot column. The end of the boom 1 is provided with a connected forearm 3 and a forearm motor 2. The forearm motor 2 can drive the forearm 3 Perform a rotary motion. The end of the forearm 3 is provided with a claw for carrying the liquid crystal screen, wherein the claw includes a claw motor 4 , a first finger 7 and a second finger 9 .

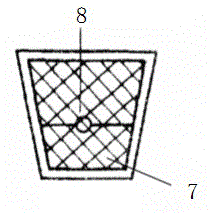

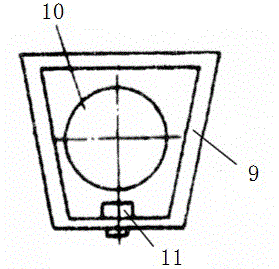

[0017] Such as figure 2 As shown, the bottom of the first finger 7 is provided with a first sensor group 8, and the first sensor group 8 includes a slip sensor (a sensor used to detect the degree of slippag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com