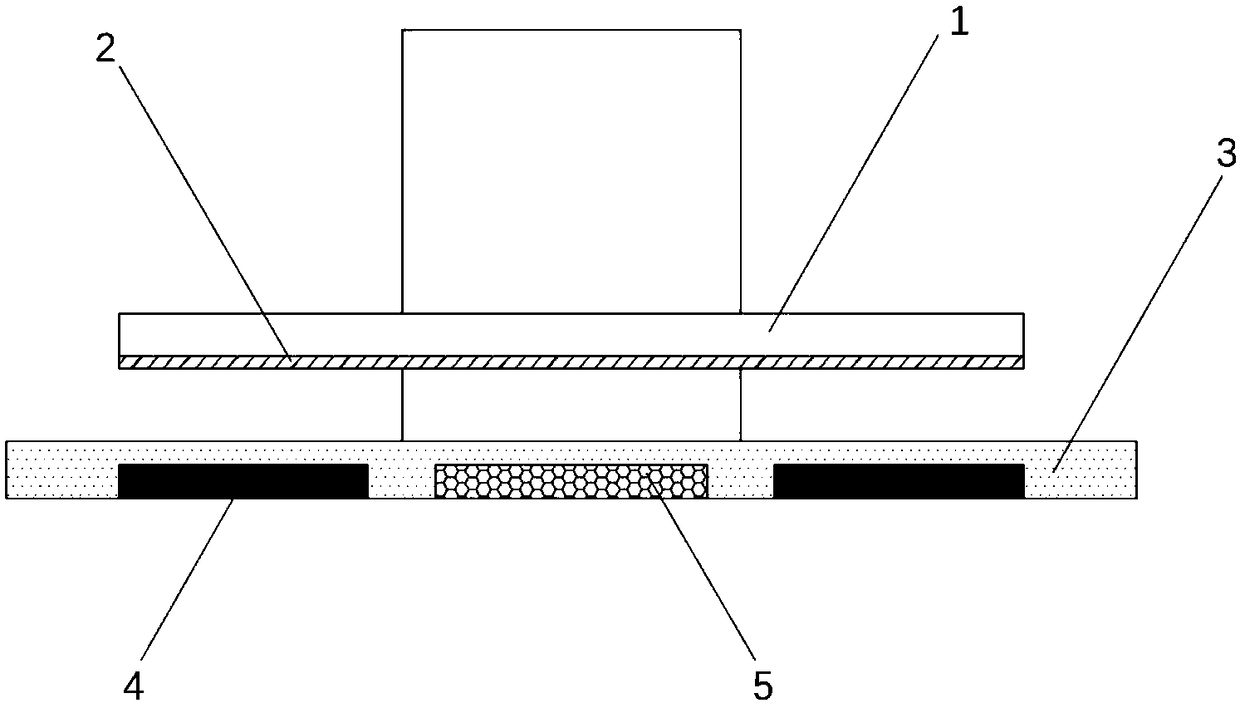

Omnidirectional slip sensor

A sensor and omni-directional technology, applied in the field of slip sensor, can solve the problem of not being able to measure the direction and speed of sliding, and achieve the effect of convenient production and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

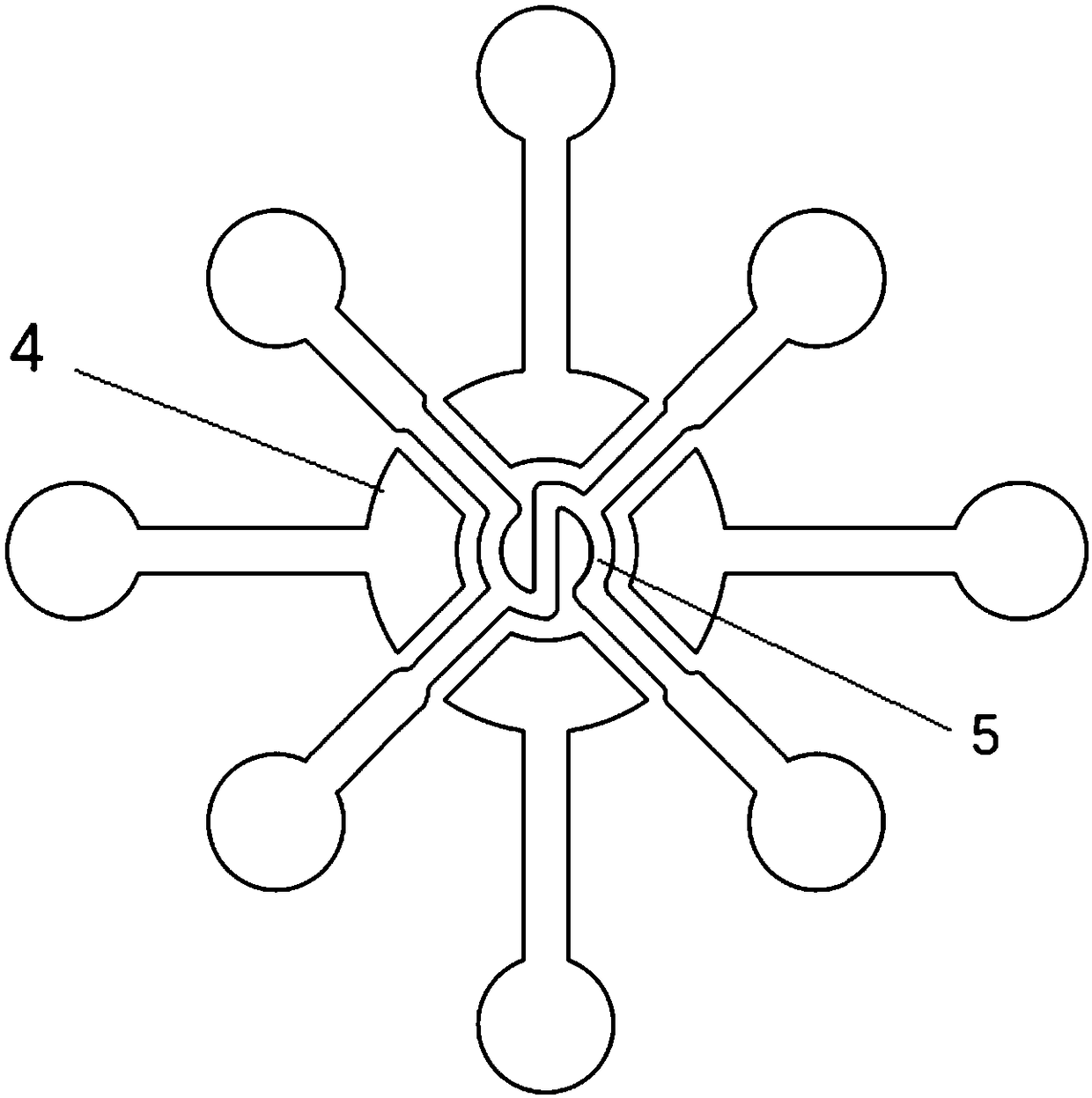

[0039] In this preparation example, a slip sensor based on a single-electrode nanogenerator is fabricated through some devices, which specifically includes the following steps:

[0040] 1) First, print two tough resin molds by a laser 3D printer, one of which is a model array with a large circular groove in the middle containing a small circular groove, wherein the large circular groove is 7 mm in diameter and 380 microns in depth; the diameter of the small circular groove 3 mm deep and 750 microns; the other mold is an array of circular grooves, 3 mm in diameter and 2.5 mm deep. Wash the two molds with deionized water, then blow dry with nitrogen;

[0041] 2) Mix the PDMS prepolymer and the curing agent in the ratio of 10:1 on the electronic scale, and pour the mixed PDMS into the mold after fully stirring, and use a vacuum pump to perform three vacuum treatments to remove the excess air in the PDMS, Put the mold in an oven at 50°C for 3 hours;

[0042] 3) Peel off the PDMS...

preparation example 2

[0046] Preparation example 2: The difference between this preparation example and preparation example 1 is that the parameters such as the sensor structure size and the materials used for the electrodes are different.

[0047] In this embodiment, a slip sensor based on a single-electrode nanogenerator is fabricated through some devices, which specifically includes the following steps:

[0048] 1) First, print a PLA mold by a thermosetting 3D printer. One of the molds is a model array with a large circular groove in the middle containing a small circular groove. The large circular groove has a diameter of 8 mm and a depth of 600 microns; the diameter of the small circular groove is 3 mm deep 2 mm; the other mold is an array of circular grooves, circular grooves 3 mm in diameter and 5 mm deep. Wash the mold with deionized water, then blow dry with nitrogen;

[0049] 2) Mix the PDMS prepolymer and the curing agent in the ratio of 10:1 on the electronic scale, and pour the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com