An intelligent and automatic sand box production line

A production line and sand box technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as poor consistency, reduced tool life, large shape and weight, etc., to increase clamping accuracy, Improve the effect of centering precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

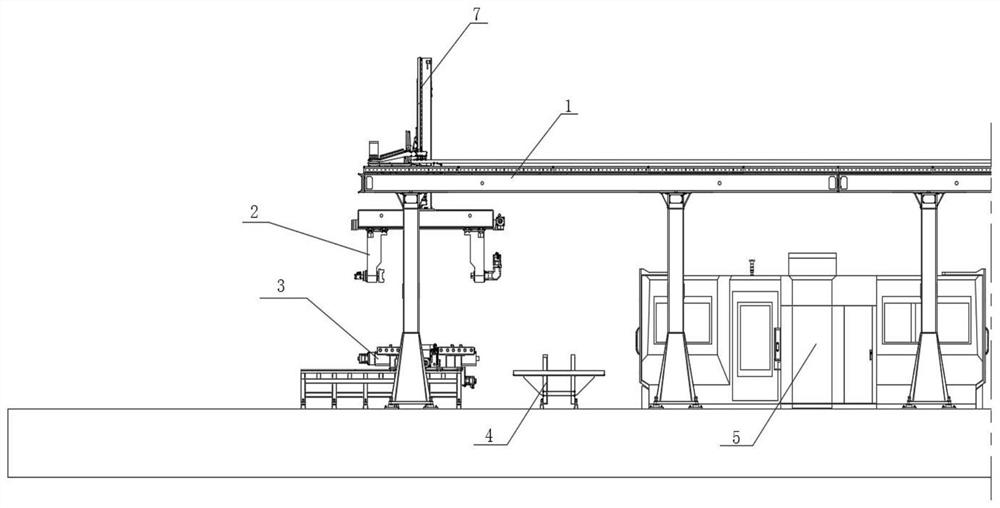

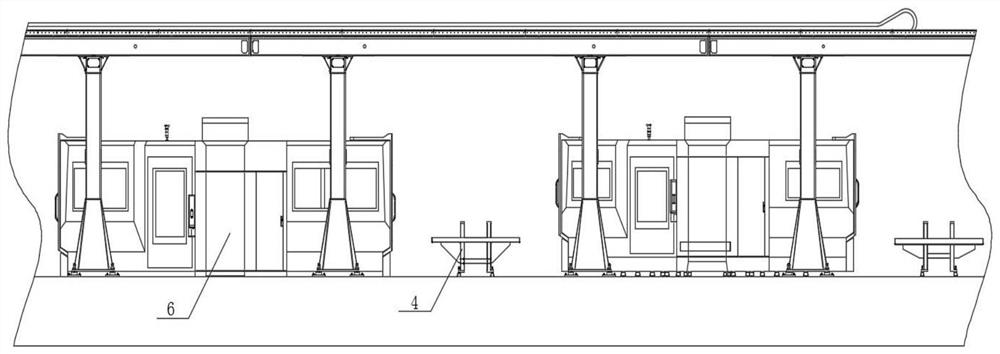

[0051] see Figure 1-18 , an intelligent and automatic sand box production line, including a truss 1, along the straight line of the truss 1, a reversible servo manipulator 2, a two-way self-centering mechanism 3 and 2 cutting machine tools are arranged in sequence.

[0052] A linear slide rail is installed on the truss 1, and a servo moving device 7 is installed on the linear slide rail. Adopt the way that the guide mechanism in the prior art is connected to the driving motor to move, and the expansion description will not be made here), the servo moving device 7 is connected to the servo manipulator 2 below, and the servo manipulator 2 hands can sequentially clamp the sand box to the two-way self-centering Mechanism 3 and the cutting machine tool. A material storage platform 4 is provided between the two-way self-centering mechanism 3 and the two cutting machine tools to store the processing materials of each unit there.

[0053] Servo manipulator 2 comprises arm beam 23, ...

Embodiment 2

[0062] On the basis of embodiment 1, this embodiment also includes the following technical features:

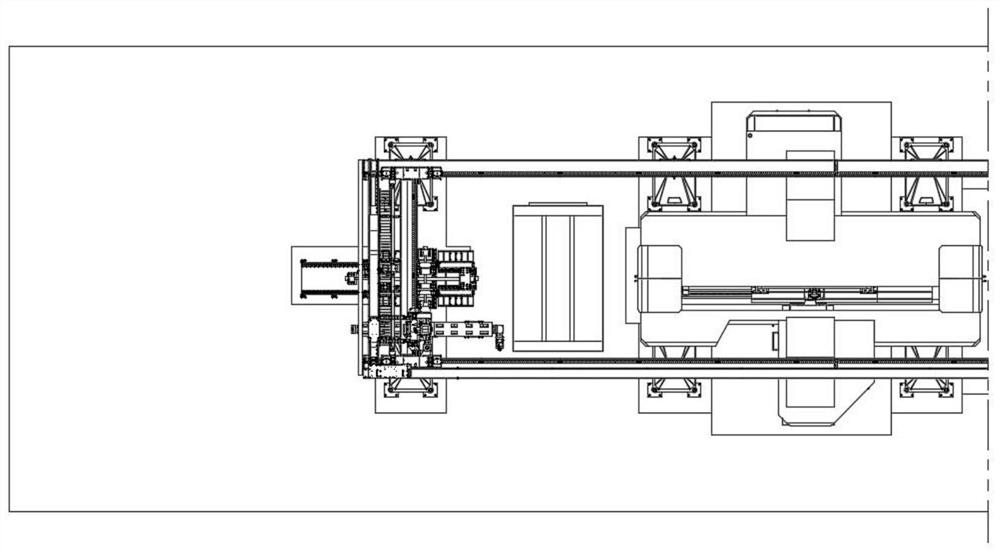

[0063] The cutting machine tool comprises a vertical double-sided processing machine tool 5, which comprises a cross-shaped base 57, the base 57X upwards and Y upwards are provided with linear slide rails, and the base 57X upwards passes through the drive mechanism and the slide block (due to the angle of view, in the figure Not marked out, the driving mechanism adopts the screw rod drive mode of the prior art in this scheme) and is equipped with two symmetrical tool workbenches 58, and column 59 is all installed on the tool workbench 58, and main shaft 51 is all installed on the column 59 And the tool magazine 52, the tool magazine 52 provides suitable milling cutters for the main shaft 51 in order to process the end faces on both sides of the sand box III 55 (the connection mode between the tool magazine 52 and the main shaft 51 adopts the prior art, and will not be desc...

Embodiment 3

[0067] On the basis of embodiment 2, this embodiment also includes the following technical features:

[0068] The cutting machine tool also includes a horizontal double-sided processing machine tool 6. This machine tool includes a cross-shaped base II 67, and the base II 67 is provided with linear slides upwards X and Y upwards (the linear slides are not marked in the figure due to the viewing angle). Ⅱ67X passes through the driving mechanism upwards (due to the viewing angle, it is not marked in the figure, the driving mechanism in this scheme adopts the screw rod driving method of the prior art) and is equipped with two symmetrical tool tables Ⅱ69, and the tool tables Ⅱ69 are equipped with The column II610 is installed, and the spindle II61 and the tool magazine II62 are installed on the column II610. The tool magazine II62 provides suitable milling cutters for the spindle II61 to process the end faces on both sides of the sand box IV63 (the connection method between the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com