Automatic water gap classifying machine

A classifier and nozzle technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problem of inaccurate clamping and placement, and achieve the effect of improving clamping accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

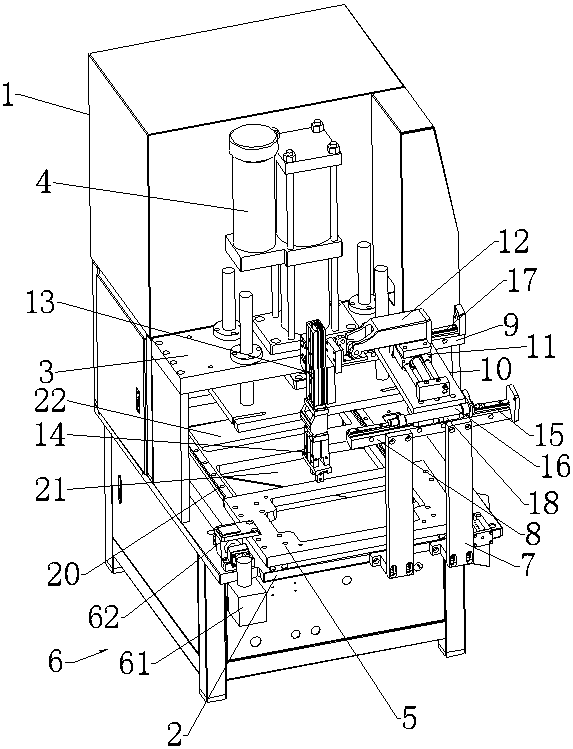

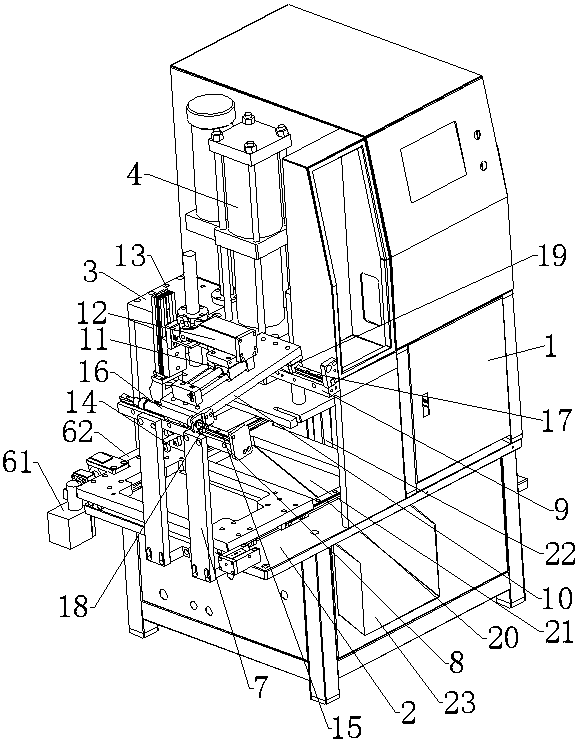

[0014] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0015] Such as figure 1 and figure 2 As shown, the automatic nozzle sorting machine includes a frame 1, a plate 2 and a workbench 3 are arranged on the frame 1, a stamping die 4 located above the platen 2 is arranged on the workbench 3, and the platen 2 is slidingly arranged There is a discharge rack 5 capable of sliding back and forth, a driving device 6 for driving the discharge rack 5 to move forward and backward on the front end side of the platen 2, a bracket 7 is provided at the front end of the platen 2, and a first fixed platform 8 is provided on the top of the support 7. The top of the workbench 3 is provided with a second fixed table 9, and a slide plate 10 capable of sliding left and right is provided between the first fixed table 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com