Stacking table for plate processing

A sheet metal processing and palletizing technology, which is applied in the field of sheet metal processing pallets, can solve problems such as easy adhesion of sheets, affect processing, and accurate clamping, and achieve stable rotation, reduce impact, and improve clamping accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

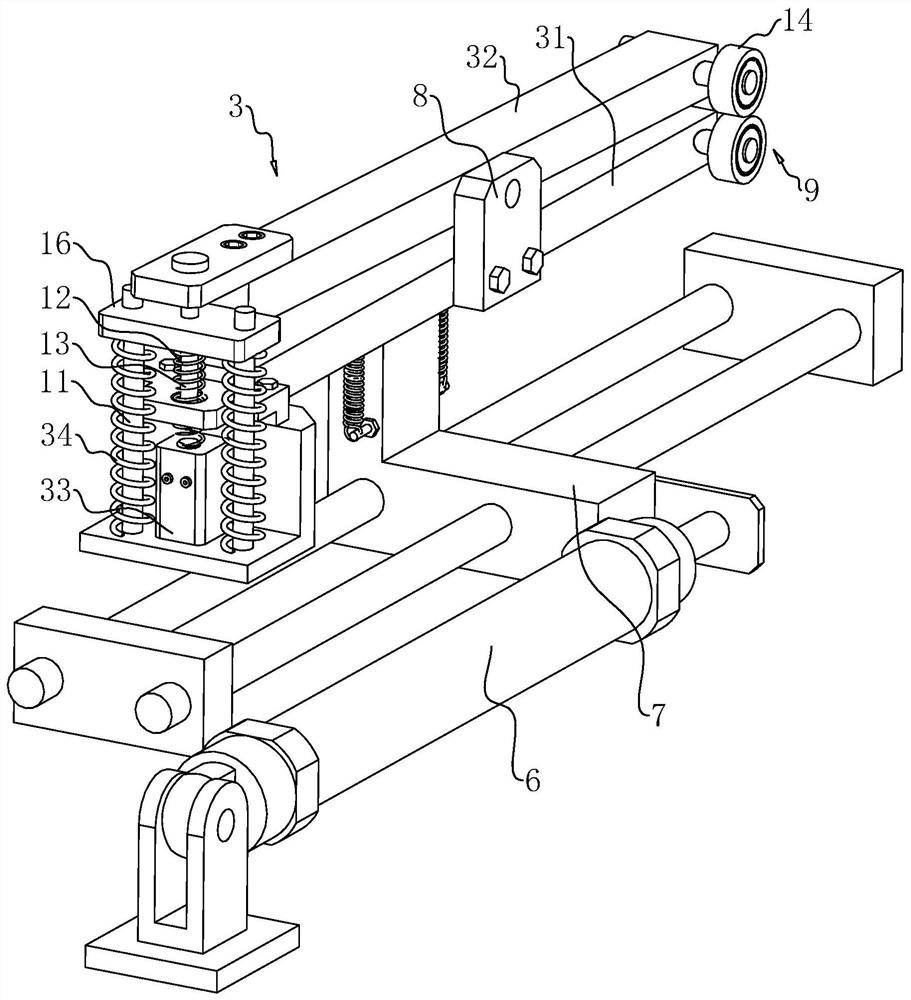

[0035] The following is attached Figure 1-4 The application is described in further detail.

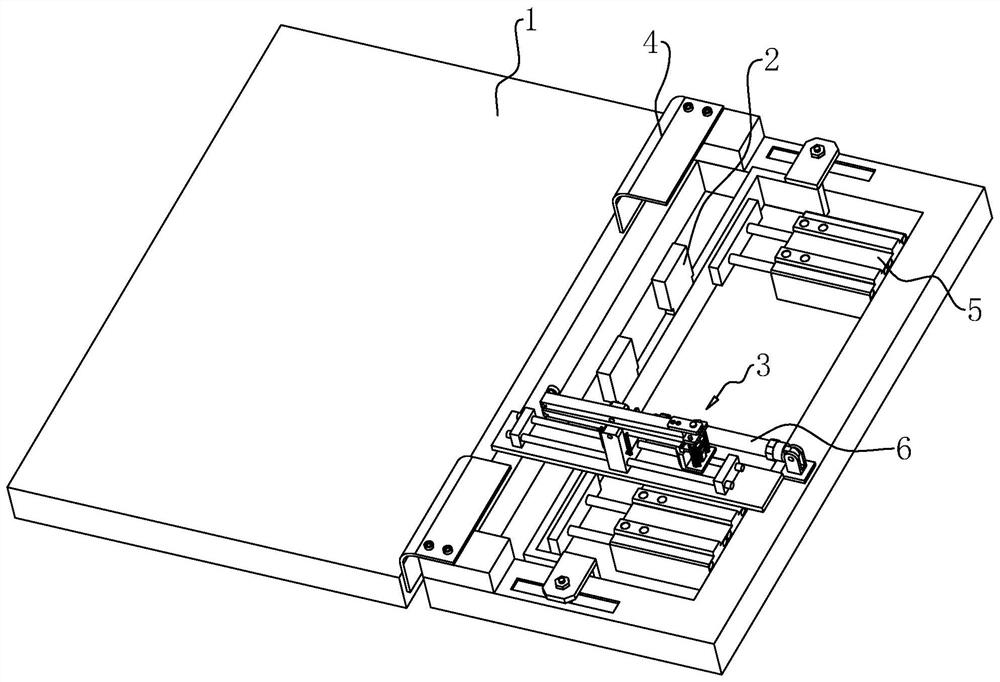

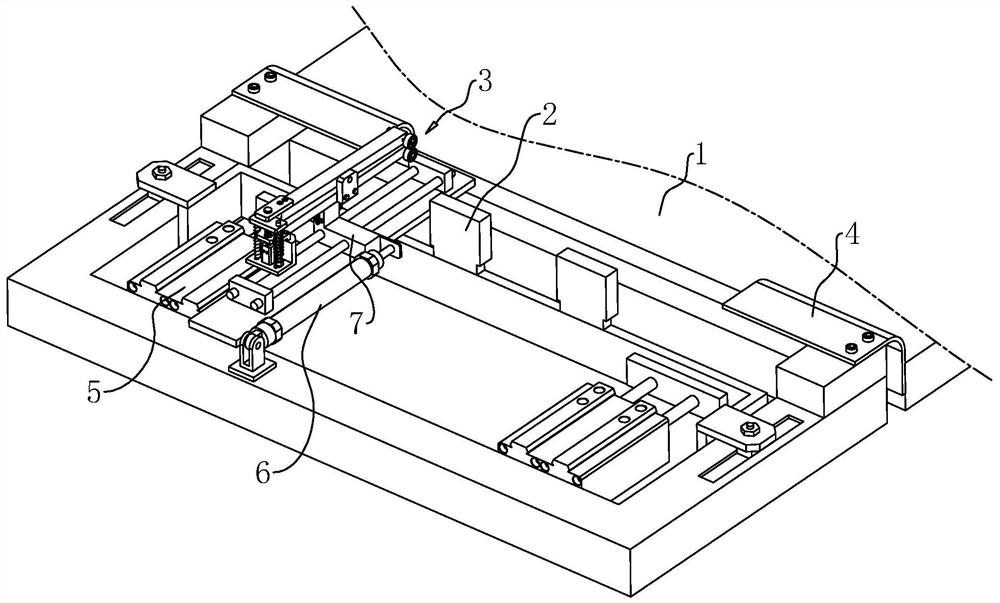

[0036] The embodiment of the present application discloses a stacking platform for plate processing, which can be used for stacking some plates, and is used in conjunction with some manipulators and adsorption parts. refer to figure 1 and figure 2 , the stacking platform includes a placement platform 1, a magnetic tensioner 2 and a detection mechanism 3, the placement platform 1 is set horizontally, and the plates are stacked on the placement platform 1; there are two magnetic tensioners 2, which are arranged at intervals between the placement platform 1 On one side, the magnetic splitter 2 separates the stack of plates on the placement platform 1 through magnetic force; on the side of the placement platform 1 close to the detection mechanism 3, a baffle 4 is attached at intervals; the detection mechanism 3 is set on the placement platform 1 Close to the same side of the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com